Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Low Cost Pressure Transducer for Critical Applications

Cargado por

wjawichDescripción original:

Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Low Cost Pressure Transducer for Critical Applications

Cargado por

wjawichCopyright:

Formatos disponibles

Model 201 Pressure Transducer

Very Low Differential Gauge Pressure

Corrosive Gases or Liquids

Applications

Vapor Recovery Systems

Exhaust Gas Control

Systems

Industrial Scrubbers

Low Pressure Industrial

Features

etras Model 201 is an accurate, low

cost, pressure transducer for measuring

very low differential or gauge pressures.

The 201s all-welded no o-ring construction

results in a leak-free design, ideal for the most

critical low range applications. The 201

process connection is designed to be used

with pressure media compatible with stainless steel and 600 Series Inconel.

Setras patented variable capacitance sensor

design combines the ultimate in simplicity,

with high accuracy and superior thermal

stability. It features an Inconel diaphragm

and an insulated electrode, which forms a

variable capacitor. As pressure increases or

decreases, the capacitance changes. This

change in capacitance is detected and

converted to a fully conditioned linear current

output signal .

0 to 5 WC

0 to 10 WC

0 to 50 WC

0 to 2.5 WC

0 to 5 WC

0 to 25 WC

Can be used for Gauge or

Differential Pressure

Measurements

Meets CE Conformance

Standards

Its rugged design, high overpessure capability

and wide operating temperature, make

the Model 201 ideal for the most

demanding applications.

When it comes to a product to

rely on - choose the Model 201.

When it comes to a company to

trust - choose Setra.

Gauge Pressure Ranges

0 to 2 PSI

0 to 20 PSI

0 to 1 PSI

0 to 2 PSI

Low Full Scale Range

All-Welded Construction

No O-Rings

Wide Compensated

Operating Temperature

High Overpressure of

10 PSI on Ranges up

to 2 PSI and 45 PSI on

20 PSI Ranges

0 to 10 mbar

0 to 20 mbar

0 to 100 mbar

0 to 5 mbar

0 to 10 mbar

0 to 50 mbar

0 to 1 kPa

0 to 2 kPa

0 to 10 kPa

0 to 0.5 kPa

0 to 1 kPa

0 to 5 kPa

ISO

9001:

2000

Certified

Visit Setra Online:

http://www.setra.com

NOTE: Setra quality standards are based on ANSI-Z540-1.

The calibration of this product is NIST traceable.

Patent Pending

Inconel is a registered trademark of Inco Alloys International, Inc.

Huntington, WV, USA.

159 Swanson Rd., Boxborough, MA 01719/Telephone: 978-263-1400/Fax: 978-264-0292

800-257-3872

Model 201 Specifications

Performance Data

Accuracy RSS (at constant temp)

Non-Linearity, BFSL

Hysteresis

Non-Repeatability

0.5% FS

0.45% FS

0.025% FS

0.025% FS

Thermal Effects**

Compensated Range F (C)

Zero Shift %FS/100F (50C)

Span Shift %FS/100F(50C)

-25 to +175 (-7 to +80)

2.0 (1.8)

1.5 (1.4)

Warm-up Shift

Response Time

Long Term Stability

Proof Pressure***

0.1% FS/15 Minutes

20 Milliseconds

0.5% FS/1 YR

10 PSI (Ranges up to 2 PSI)

45 PSI (20 PSI Range)

Burst Pressure

100 PSI

*RSS of Non-Linearity, Non-Repeatability and Hysteresis.

**Units calibrated at nominal 70F. Maximum thermal error computed from

this datum.

****Proof Pressure:The maximum pressure that may be applied without

changing performance beyond specifications (0.5% FS zero shift).

Environmental Data

Electrical Data (Current)

Temperature

Operating* F (C)

Storage F (C)

Acceleration

Shock**

Circuit

2-Wire

Output*

4 to 20 mA**

External Load

0 to 800 Ohms

Minimum supply voltage (VDC) = 12 + 0.02 x

(Resistance of receiver plus line).

Maximum supply voltage (VDC) = 30 + 0.004 x

(Resistance of receiver plus line).

-40 to +175 (-40 to +80)

-40 to +185(-40 to +85)

10g Maximum

50g Operating

*Operating temperature limits of the electronics only.

Pressure media temperatures may be considerably higher or lower.

**Mil-Std. 202F, Method 213B, Cond. C

*Calibrated at factory with a 24 VDC loop supply voltage and a 250 ohm load.

**Zero output factory set to within .08mA.

**Span (Full Scale) output factory set to within .08mA.

Physical Description

Case*

Pressure Fitting

Vent**

Stainless Steel

1/4 NPT External

Through Barbed Fitting at Bottom of

Case

Electrical Connection 2ft. Multiconductor Cable

3 Screw Terminal Block

Zero/Span Adjustment Top External Access

Weight

6 ounces

Pressure Media

Positive Pressure Media

Liquids or Gases Compatible with Stainless Steel and Inconel.

Reference Pressure Media

Clean Dry Air or Non-Corrosive G

Specifications subject to change without notice.

*NEMA 4 Rated when A1 electrical termination is ordered.

**When T1 Terminal strip electrical termination is ordered, venting is through

zero or span screw.

Outline Drawing

CONDUIT

FITTING

1/2 NPT

IN

MM

7/8 HEX

2.00 DIA

50 DIA

1.99

50

Zero Adjust

Screw

Span Adjust

Screw

REFERENCE PORT

BARBED FITTING FOR

1/4 ID TUBE CONNECTION 1.96

50

1/4 - 18 NPT

MALE

POSITIVE PRESSURE

PROCESS PORT

ORDERING INFORMATION

Code all blocks in table.

Example: Part No. 2011005WG2M1102H is a Model 201, 0 to 5 in. W.C., 1/4 NPT Fitting, 4 to 20 mA Output, 2ft. of Cable and 0.5% FS Accuracy.

27 01 10 11

Model

2011 = 201

005WD

010WD

050WD

2R5WB

005WB

025WB

002PD

020PD

001PB

002PB

=

=

=

=

=

=

=

=

=

=

Range

5 in.W.C.

001KD =

10 in. W.C.

002KD =

50 in.W.C.

010KD =

2.5 in. W.C. 0R5KB =

5 in. W.C.

001KB =

25 in.W.C.

005KB =

2 PSI

010MD =

20 PSI

020MD =

1 PSI

100MD =

2 PSI

005MB =

010MB =

050MB =

While we provide application assistance on all Setra products, both

personally and through our literature, it is the customers responsibility

to determine the suitability of the product in the application.

1 1

Type of Fitting

Output

Accuracy

Elec. Termination

Standard

1 kPa

11= 4 to 20 mA

Standard

A1 = 1/2 Male NPT

2M = 1/4 18 NPT Male

2 kPa

H = 0.5% FS

Conduit w/Cable F = 0.25% FS

2T = 1/4 Tube Stub

10 kPa

B1

=

4-Pin Bayonet

2F = 1/4 18 NPT Female

0.5 kPa

Connector

o

J7 = 7/16 SAE 37 Flare

1 kPa

H1

=

Hirschmann w/

5 kPa

Large Male Fitting

10 Millibar

T1

=

3-Screw

Terminal

20 Millibar

Strip

100 Millibar

02 = 2 ft. Cable

5 Millibar

10 Millibar

Please contact factory for versions not shown.

50 Millibar

159 Swanson Road, Boxborough, MA 01719/Tel: 978-263-1400;

Toll Free: 800-257-3872; Fax: 978-264-0292; email: sales@setra.com

SSP201 Rev. B 05/23/07

5.41

137

También podría gustarte

- Flow Switches BarksdaleDocumento20 páginasFlow Switches BarksdaleDian PramadiAún no hay calificaciones

- Ue 24013Documento8 páginasUe 24013Johnny CormanAún no hay calificaciones

- Model DPT 264: Very Low Differential Pressure TransducerDocumento2 páginasModel DPT 264: Very Low Differential Pressure Transducersuperpuma86Aún no hay calificaciones

- In-Line Electronic Flow Switches: Ameritrol Inc. Ameritrol IncDocumento6 páginasIn-Line Electronic Flow Switches: Ameritrol Inc. Ameritrol IncRuben AlvaradoAún no hay calificaciones

- B&M Series 1000 SwitchesDocumento12 páginasB&M Series 1000 SwitchesscribdkhatnAún no hay calificaciones

- Blind Pressure & Differential Pressure Switches GuideDocumento0 páginasBlind Pressure & Differential Pressure Switches GuideMilosglAún no hay calificaciones

- SERIES 08-80 Probe Style: Bimetal Temperature Limiting ThermostatsDocumento3 páginasSERIES 08-80 Probe Style: Bimetal Temperature Limiting ThermostatsAna Karen LandaAún no hay calificaciones

- Barton DP GaugeDocumento2 páginasBarton DP GaugeDeji AdesiyanAún no hay calificaciones

- DP SWITCHES HIGH STATIC PRESSURE ADJUSTABLE SET POINTDocumento6 páginasDP SWITCHES HIGH STATIC PRESSURE ADJUSTABLE SET POINTNavneet SinghAún no hay calificaciones

- Pressure TransmittersDocumento40 páginasPressure TransmittersMilosglAún no hay calificaciones

- Relay AP Suat DanfossDocumento16 páginasRelay AP Suat DanfossVo Ngoc DucAún no hay calificaciones

- Druck PT Data SheetDocumento7 páginasDruck PT Data Sheethits289Aún no hay calificaciones

- DATA SHEET Bourdon Tube Pressure Gauge With Switch ContactsDocumento12 páginasDATA SHEET Bourdon Tube Pressure Gauge With Switch ContactsMirwan MukminAún no hay calificaciones

- Model RSP Sanitary Electronic Pressure TransmitterDocumento2 páginasModel RSP Sanitary Electronic Pressure Transmittergrincheu70Aún no hay calificaciones

- Barksdale 7000pRESSUREDocumento4 páginasBarksdale 7000pRESSUREAdam SamyAún no hay calificaciones

- DS 117 GBDocumento8 páginasDS 117 GBAlexander Ruiz IbagueAún no hay calificaciones

- Ap B14 02L 01e - Akm - 38750 PDFDocumento4 páginasAp B14 02L 01e - Akm - 38750 PDFsamsungloverAún no hay calificaciones

- Prime 4 PD MeterDocumento4 páginasPrime 4 PD Metertiualbert8729100% (1)

- DRUCK PTX 600 SeriesDocumento4 páginasDRUCK PTX 600 SeriesFraFraFra87Aún no hay calificaciones

- Mechanical Pressure Switches: Version Also AvailableDocumento14 páginasMechanical Pressure Switches: Version Also AvailableMohamed Gawad ARayaAún no hay calificaciones

- Ap B14 03L 01e - 149 - 47209 PDFDocumento4 páginasAp B14 03L 01e - 149 - 47209 PDFsamsungloverAún no hay calificaciones

- Differential Pressure SwitchesDocumento8 páginasDifferential Pressure Switchessales1068Aún no hay calificaciones

- Turbine Meter NufloDocumento8 páginasTurbine Meter NufloJaime SeguraAún no hay calificaciones

- Cameron Temperature Switches Technical Data SheetDocumento28 páginasCameron Temperature Switches Technical Data Sheetvlcmstne04Aún no hay calificaciones

- 62 Series Servovalves Technical OverviewDocumento8 páginas62 Series Servovalves Technical OverviewDevendra BangarAún no hay calificaciones

- Forbes Flowswirl DocumentDocumento16 páginasForbes Flowswirl DocumentVikrant BhaleraoAún no hay calificaciones

- Sanitary Pressure Transmitter Type SA-11: Special FeaturesDocumento4 páginasSanitary Pressure Transmitter Type SA-11: Special FeaturesbehnamatgAún no hay calificaciones

- Ptx-600 Pressure TransducerDocumento4 páginasPtx-600 Pressure Transducerhvdb72Aún no hay calificaciones

- 100X DatasheetDocumento2 páginas100X Datasheetbiswasdipankar05Aún no hay calificaciones

- Mobrey 9000 Series Pressure TransmittersDocumento6 páginasMobrey 9000 Series Pressure TransmittersCardoso MalacaoAún no hay calificaciones

- MAgnetrol 75 Seires LEvelDocumento8 páginasMAgnetrol 75 Seires LEvelmarcoo8Aún no hay calificaciones

- AD01166M NUFLO Liquid Turbine Flow Meters Data SheetDocumento8 páginasAD01166M NUFLO Liquid Turbine Flow Meters Data SheetdediekosAún no hay calificaciones

- 2 and 3 Genesis Series PD Meter SpecificationsDocumento6 páginas2 and 3 Genesis Series PD Meter Specificationsjimbo2032Aún no hay calificaciones

- Moog ServovalvesDocumento8 páginasMoog Servovalvesdylan_dearing@hotmail.com100% (1)

- NAB Deltapi 2011Documento6 páginasNAB Deltapi 2011manashbdAún no hay calificaciones

- Sem 215 Smart Universal Temperature TransmitterDocumento4 páginasSem 215 Smart Universal Temperature TransmitterKalpesh PatilAún no hay calificaciones

- Reflux 819: Pressure RegulatorDocumento20 páginasReflux 819: Pressure RegulatorRafael Jose Tasco ZabaletaAún no hay calificaciones

- SM TM 1.5-4 Guardsman (G) Series02002Documento4 páginasSM TM 1.5-4 Guardsman (G) Series02002Paola Arevalo RinconAún no hay calificaciones

- Tradutor Diferencial PD-9 DRUCKDocumento2 páginasTradutor Diferencial PD-9 DRUCKjcbizarretaAún no hay calificaciones

- EP-311 - 313 Series Catalog PageDocumento2 páginasEP-311 - 313 Series Catalog PageMark Izsm AmersonAún no hay calificaciones

- L-Dens 427F Ex Density Sensor SpecificationsDocumento6 páginasL-Dens 427F Ex Density Sensor Specificationsd1arsenovskiAún no hay calificaciones

- Regulador de Modulo Dival 600Documento8 páginasRegulador de Modulo Dival 600Cory HansonAún no hay calificaciones

- F8834 VR75 GB 06 007 LowDocumento6 páginasF8834 VR75 GB 06 007 LowŁukasz OlszewskiAún no hay calificaciones

- Techrite Fenwal Fenwal 17000 & 18000 Series Thermoswitch Temperature Controllers 2013050684Documento8 páginasTechrite Fenwal Fenwal 17000 & 18000 Series Thermoswitch Temperature Controllers 2013050684jesusAún no hay calificaciones

- ElectrovalvulasDocumento8 páginasElectrovalvulasRaul Guevara TorresAún no hay calificaciones

- Switches CatalogDocumento48 páginasSwitches CatalogVicctor PiñaAún no hay calificaciones

- 19 102be PDFDocumento6 páginas19 102be PDFSani PoulouAún no hay calificaciones

- Yokogawa DPIT ModelDocumento11 páginasYokogawa DPIT ModelRoopa NaikAún no hay calificaciones

- DS-MT 3750a PDFDocumento4 páginasDS-MT 3750a PDFariksyaiful82Aún no hay calificaciones

- Transmision de Presion DiferencialDocumento12 páginasTransmision de Presion DiferencialRuben Arteaga'Aún no hay calificaciones

- Sor Adjustable Dead Band Pressure SwitchDocumento16 páginasSor Adjustable Dead Band Pressure SwitchAdam SamyAún no hay calificaciones

- Model 210 Digital Electro-Hydraulic Set Stop - PDF-, AttachmentDocumento4 páginasModel 210 Digital Electro-Hydraulic Set Stop - PDF-, AttachmentMohd HassanudinAún no hay calificaciones

- Magnetrol Model Tk1Documento4 páginasMagnetrol Model Tk1Billy Isea DenaroAún no hay calificaciones

- 2500-249 Series Level-Trol Pneumatic Liquid Level Controllers and TransmittersDocumento6 páginas2500-249 Series Level-Trol Pneumatic Liquid Level Controllers and TransmittersmoisesAún no hay calificaciones

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDe EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsAún no hay calificaciones

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsDe EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsCalificación: 3.5 de 5 estrellas3.5/5 (6)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1De EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Calificación: 2.5 de 5 estrellas2.5/5 (3)

- Acidizing Corrosion Inhibitors A ReviewDocumento12 páginasAcidizing Corrosion Inhibitors A ReviewwjawichAún no hay calificaciones

- Inhibition of Mild Steel Corrosion in Acid Media by N-benzyl-N - Phenyl ThioureaDocumento5 páginasInhibition of Mild Steel Corrosion in Acid Media by N-benzyl-N - Phenyl ThioureawjawichAún no hay calificaciones

- MigrationDocumento2 páginasMigrationwjawichAún no hay calificaciones

- Demulsification of Crude OilDocumento2 páginasDemulsification of Crude OilwjawichAún no hay calificaciones

- Hach DO 146900 Kit Dissolved OxygenDocumento29 páginasHach DO 146900 Kit Dissolved OxygenwjawichAún no hay calificaciones

- Sample PreparationDocumento2 páginasSample PreparationwjawichAún no hay calificaciones

- Stability Special CasesDocumento2 páginasStability Special CaseswjawichAún no hay calificaciones

- Application Paper On CentrifugationDocumento5 páginasApplication Paper On CentrifugationwjawichAún no hay calificaciones

- Turbiscan Data InterpretationDocumento32 páginasTurbiscan Data InterpretationwjawichAún no hay calificaciones

- Data InterpretationDocumento4 páginasData InterpretationwjawichAún no hay calificaciones

- Report 085Documento147 páginasReport 085Adekunle L. Omoniyi100% (1)

- 6th Central Pay Commission Salary CalculatorDocumento15 páginas6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Controlling Wax Deposition Presence Hydrates-01!25!10Documento85 páginasControlling Wax Deposition Presence Hydrates-01!25!10wjawichAún no hay calificaciones

- Using The Embedded Multimedia Card (eMMC) Storage Device On Intel®.Documento4 páginasUsing The Embedded Multimedia Card (eMMC) Storage Device On Intel®.wjawichAún no hay calificaciones

- NACE - Jubail GEWPT1Documento37 páginasNACE - Jubail GEWPT1riccardocozzaAún no hay calificaciones

- Belclene 200 Antiscalant: Product InformationDocumento8 páginasBelclene 200 Antiscalant: Product InformationwjawichAún no hay calificaciones

- Flame Retardants ThpsDocumento154 páginasFlame Retardants ThpswjawichAún no hay calificaciones

- Biocide in Paper Making ChemistryDocumento68 páginasBiocide in Paper Making ChemistrywjawichAún no hay calificaciones

- G55 &G5A Series Gas (CO) /air Driven PumpDocumento2 páginasG55 &G5A Series Gas (CO) /air Driven PumpwjawichAún no hay calificaciones

- Techbox Systems DSLDocumento4 páginasTechbox Systems DSLwjawichAún no hay calificaciones

- 466Documento10 páginas466wjawichAún no hay calificaciones

- Getting Started Guide Scratch2 PDFDocumento16 páginasGetting Started Guide Scratch2 PDFGilynCarpesoAmoscoAún no hay calificaciones

- High Temperature Aging Cell ® Instruction Manual: Part No. 760140001EA Rev. DDocumento36 páginasHigh Temperature Aging Cell ® Instruction Manual: Part No. 760140001EA Rev. DwjawichAún no hay calificaciones

- Ii. Pred Radar Graphs: N Xample F Adar RaphsDocumento7 páginasIi. Pred Radar Graphs: N Xample F Adar RaphswjawichAún no hay calificaciones

- Chemistry of Fatty AcidsDocumento44 páginasChemistry of Fatty Acidshenry_madumere1365100% (3)

- Atmp Gps MsdsDocumento8 páginasAtmp Gps MsdswjawichAún no hay calificaciones

- Im Speed Control PDFDocumento64 páginasIm Speed Control PDFseshubabu_999Aún no hay calificaciones

- Atmp Gps MsdsDocumento8 páginasAtmp Gps MsdswjawichAún no hay calificaciones

- Belclene 200 Antiscalant: Product InformationDocumento8 páginasBelclene 200 Antiscalant: Product InformationwjawichAún no hay calificaciones

- Corn MillingDocumento4 páginasCorn Millingonetwoone s50% (1)

- Translation EquivalenceDocumento6 páginasTranslation EquivalenceJamal Anwar TahaAún no hay calificaciones

- Cold Forging Process TutorialDocumento28 páginasCold Forging Process TutorialpanyamnrAún no hay calificaciones

- Variable Speed Pump Efficiency Calculation For Fluid Flow Systems With and Without Static HeadDocumento10 páginasVariable Speed Pump Efficiency Calculation For Fluid Flow Systems With and Without Static HeadVũ Tuệ MinhAún no hay calificaciones

- Board 2Documento1 páginaBoard 2kristine_nilsen_2Aún no hay calificaciones

- Paradigm Shift Essay 2Documento17 páginasParadigm Shift Essay 2api-607732716Aún no hay calificaciones

- Application of ISO/IEC 17020:2012 For The Accreditation of Inspection BodiesDocumento14 páginasApplication of ISO/IEC 17020:2012 For The Accreditation of Inspection BodiesWilson VargasAún no hay calificaciones

- Ecole Polytechnique Federale de LausanneDocumento44 páginasEcole Polytechnique Federale de LausanneSyed Yahya HussainAún no hay calificaciones

- Course Tutorial ASP - Net TrainingDocumento67 páginasCourse Tutorial ASP - Net Traininglanka.rkAún no hay calificaciones

- Give Five Examples Each of Nature Having Reflection Symmetry and Radial Symmetry Reflection Symmetry Radial Symmetry Butterfly StarfishDocumento12 páginasGive Five Examples Each of Nature Having Reflection Symmetry and Radial Symmetry Reflection Symmetry Radial Symmetry Butterfly StarfishANNA MARY GINTOROAún no hay calificaciones

- Major Bank Performance IndicatorsDocumento35 páginasMajor Bank Performance IndicatorsAshish MehraAún no hay calificaciones

- All Associates Warning Against ChangesDocumento67 páginasAll Associates Warning Against Changesramesh0% (1)

- JD - Software Developer - Thesqua - Re GroupDocumento2 páginasJD - Software Developer - Thesqua - Re GroupPrateek GahlanAún no hay calificaciones

- Trading Course DetailsDocumento9 páginasTrading Course DetailsAnonymous O6q0dCOW6Aún no hay calificaciones

- Practice Like-Love - Hate and PronounsDocumento3 páginasPractice Like-Love - Hate and PronounsangelinarojascnAún no hay calificaciones

- Deep Groove Ball Bearings PDFDocumento11 páginasDeep Groove Ball Bearings PDFArpit VermaAún no hay calificaciones

- Ana White - PLANS - A Murphy Bed YOU Can Build, and Afford To Build - 2011-03-03Documento20 páginasAna White - PLANS - A Murphy Bed YOU Can Build, and Afford To Build - 2011-03-03Ahmad KamilAún no hay calificaciones

- Cisco CMTS Feature GuideDocumento756 páginasCisco CMTS Feature GuideEzequiel Mariano DaoudAún no hay calificaciones

- Time Table For Winter 2023 Theory ExaminationDocumento1 páginaTime Table For Winter 2023 Theory ExaminationSushant kakadeAún no hay calificaciones

- SWOT Analysis of Solar Energy in India: Abdul Khader.J Mohamed Idris.PDocumento4 páginasSWOT Analysis of Solar Energy in India: Abdul Khader.J Mohamed Idris.PSuhas VaishnavAún no hay calificaciones

- The Botanical AtlasDocumento74 páginasThe Botanical Atlasjamey_mork1100% (3)

- Um 0ah0a 006 EngDocumento1 páginaUm 0ah0a 006 EngGaudencio LingamenAún no hay calificaciones

- Tender Notice and Invitation To TenderDocumento1 páginaTender Notice and Invitation To TenderWina George MuyundaAún no hay calificaciones

- Robocon 2010 ReportDocumento46 páginasRobocon 2010 ReportDebal Saha100% (1)

- Programming Language Foundations PDFDocumento338 páginasProgramming Language Foundations PDFTOURE100% (2)

- Kahveci: OzkanDocumento2 páginasKahveci: OzkanVictor SmithAún no hay calificaciones

- For Coin & Blood (2nd Edition) - SicknessDocumento16 páginasFor Coin & Blood (2nd Edition) - SicknessMyriam Poveda50% (2)

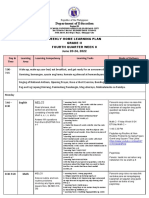

- Department of Education: Weekly Home Learning Plan Grade Ii Fourth Quarter Week 8Documento8 páginasDepartment of Education: Weekly Home Learning Plan Grade Ii Fourth Quarter Week 8Evelyn DEL ROSARIOAún no hay calificaciones

- The Learners Demonstrate An Understanding Of: The Learners Should Be Able To: The Learners Should Be Able ToDocumento21 páginasThe Learners Demonstrate An Understanding Of: The Learners Should Be Able To: The Learners Should Be Able ToBik Bok50% (2)

- Testbanks ch24Documento12 páginasTestbanks ch24Hassan ArafatAún no hay calificaciones