Documentos de Académico

Documentos de Profesional

Documentos de Cultura

GDPMD Guide - Update 1st August 2014 Sheet1

Cargado por

naravichandran3662Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

GDPMD Guide - Update 1st August 2014 Sheet1

Cargado por

naravichandran3662Copyright:

Formatos disponibles

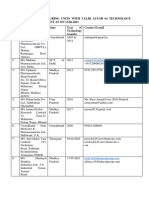

UPDATE:

August 1st 2014

GUIDE

FOR

THE

IMPLEMENTATION

OF

GOOD

DISTRIBUTION

PRACTICES

FOR

MEDICAL

DEVICE

(GDPMD)

Provision

no.

2

3

4

10

11

12

13

Provision

Requirements

Recommendations/Notes

Scope and application

GDPMD

is

applicable

to

Authorized

representatives

of

foreign

manufacturers,

importers

and

distributors,

IT

IS

Manufacturers

will

be

required

to

be

ISO

13485

certified.

NOT

APPLICAPLE

to

manufacturers

and

retailers

of

medical

devices.

Justification

has

to

be

provided

if

a

GDPMD

requirement

is

not

applicable

It

is

recommended

to

document

these

justification

in

the

Quality

Manual

or

Regulatory

Compliance

manual

GDPMD

certification

to

be

conducted

by

an

approved

Conformity

Assessment

Body

(CAB)

A

list

of

approved

CAB's

is

available

here:

http://www.mdb.gov.my/mdb/index.php?option=com_content&task=view&id

=185&Itemid=138

Definitions

"Authority"

means

the

Medical

Device

Authority

(MDA)

MDA

is

a

division

in

the

Ministry

of

Health

Malaysia

(MOH)

in

charge

of

regulating

medical

device

and

its

industry

players

in

the

country.

Organization

Define

the

organization

structure,

duties

and

responsibilities

Organizational

chart

with

names

and

positions

showing

interrelationship

of

all

key

personnel.

For

each

position,

develop

job

descriptions

with

title,

authorities

and

responsibilities.

Setup

AND

maintain

GDPMD

regulatory

compliance

system

It

is

stated

here

that

the

organization

shall

maintain

the

effectiveness

of

the

regulatory

compliance

system

by

implementing

appropriate

CAPA

system

GDPMD

Regulatory

Compliance

Establish,

document

and

implement

GDPMD

RCS

System

is

generally

described

in

the

Regulatory

Compliance

Manual

System

(RCS)

-General

Identify

proccesses

needed

for

the

GDPMD

Define

a

3

layers

process

map

showing

interaction:

management,

realization

and

support

Determine

criteria

and

methods

needed

for

the

control

of

these

processes

process

matrix

with

process

name,

pilot,

activities,

indicators,

review

frequency

and

effectiveness

criteria

(targets)

Ensure

resources

availability

for

each

process,

resources

needs

shall

be

reviewed

on

a

regular

basis

(during

management

reviews,

meetings,etc)

Monitor,

measure

and

analyze

these

processes

analyze

process

matrix

indicators

on

a

regular

basis

(it

is

a

good

practice

to

review

quarterly)

Implement

actions

to

achieve

planned

results

and

maintain

effectiveness

implement

CAPA

system

Identify

and

control

outsourced

processes

ie:

sterilization,

packaging...

a

close

monitoring

of

these

processes

is

also

required.

Documentation

Regulatory

Compliance

manual

equivalent

to

"Quality

Manual"

for

ISO13485.

Describe

clearly

which

medical

devices

the

establishment

is

dealing

with

and

their

status

of

compliance

(in

Malaysia

and

abroad)

make

a

reference

to

GDPMD

RCS

procedures,

other

documents/records

needed

for

compliance.

scope

of

GDPMD

RCS

including

details

of

and

justification

fo

any

exclusion

and/or

non-application

Specific

information

related

to

premises,

personnel

and

medical

device

conformity

assessment/registration

holder

Detailed

description

on

how

the

relevant

and

applicable

regulatory

requirements

are

adressed

for

each

Suggestion

here

is

to

prepare

a

checklist

with

requirements,

applicability

and

medical

device

specified

in

the

scipe

of

the

GDPMD

RCS

reference

documents

provided

as

a

compliance

objective

evidence

For

each

type

of

MD,

the

establishment

shall

maintain

a

file.

Similar

to

DMR

(Device

Master

Record)

for

a

manufacturer,

this

should

include

all

the

specifications

required

for

proper

handling

of

a

device

by

the

establishment

(it

is

device

specific)..

Document

control

Document

control

procedure

establish

a

procedure

on

how

to

control

documents

(incl.

numbering,

structure,

archiving,

disposition,

etc)

prepared,

approved,

signed

by

an

authorized

person

establish

a

signature

matrix

including

levels

of

authorization

for

each

type

of

document

prevent

unintended

use

of

superseded

version

include

change

control

in

document

control

procedure

establish

and

maintain

records

of

GDPMD

RCS

establish

an

instruction

for

Good

documentation

practices

define

controls

for

the

identification,

storage,

protection,

retrieval,

retention

time

and

disposition

establish

a

procedure

for

control

of

records

(incl.

list

of

GDPMD

records)

records

retention

determine

retention

time

for

each

type

of

record

Responsibilities

and

authorities responsibilities

and

authorities

to

be

documented

and

communicated

it

is

a

good

practice

to

have

responsibilities

and

authorities

documented

in

a

specific

section

for

each

procedure

interrelations

between

all

personnel

Organization

chart

(including

handling

personnel)

Designated

person

Appoint

designated

person

Equivalent

to

Management

representative.

This

is

generally

the

person

having

a

good

knowledge

of

GDPMD

requirements

(Quality

Manager,

Quality

Engineer,

QA

executive,

etc)

Suggestion:

a

letter

of

appoinment

should

be

issued

to

the

DP.

Management

review

Management

review

A

review

of

the

GDPMD

RCS

shall

be

organized

on

a

regular

basis

(ie.quarterly)

where

the

management

team

will

review

the

whole

system

to

ensure

compliance.

Minutes

of

the

management

review

shall

be

recorded.

Review

Input

results

of

internal

and

external

audit

management

review

shall

include

all

of

the

review

input

Review Output

Personnel

14

Training

15

Infrastrucure

16

Work environment

17

Cleanliness and pest control

18

Authorization

19

Communication channel

customer

complaint/feedback

GDPMD

regulatory

compliance

system

and

medical

device

compliance

surveillance

and

vigilancee

activities

including

field

safety

corrective

actions,

advisory

notes,

recalls

and

adverse

event/incident

reporting

feedback

from

manufacturer

feedback

and

directives

from

the

authority

status

of

preventive

and

corrective

actions

follow-up

actions

from

previous

management

review

changes

that

could

affect

the

GDPMD

recommendatios

for

compliance

corrective

and

preventive

actions

required

effectiveness

of

GDPMD

and

its

compliance

with

Malaysian

medical

device

regulatory

requirements

resource

needs

Personnel

shall

be

competent

and

possesses

appropriate

professional

knowledge,education,

training,

skills

and

experience.

Personnel

providing

post

market

technical

support

for

active

devices

shall

conform

to

the

requirements

and/or

standards

recognized

by

the

authority

Adequate

number

of

competent

personnel

involved

in

the

supply

chain

to

ensure

quality,

safety

and

performance

Determine

the

necessary

competences

Provide

training

Evaluate

training

effectiveness

Maintain

training

records,

skills

and

experience

Ensure

premises

ad

equipment

used

are

suitable,

secure,

safe

and

adequate

Establish

documented

requirements

management

review

shall

include

any

decisions

and

actions

related

to

the

review

output

Employee

Individual

file

shall

include

CV,

certificates,etc...

Technicians performing after sales service shall be trained to execute

maintenance activities as per manufacturer specifications and local regulations.

Adequate means enough resources to run the operations safely and efficiently.

This will depend on the company business requirements.

eg: during annual performance reviews

Suggestion: develop training needs based on performance review outcome

Training evaluation form with effectiveness evaluation section

Training records shall be part of the GDPMD system

Proper space for storage and handling of the product

Suggestion: Establish work instruction for maintaning the premises and

equipment, including their frequencies

Maintain records of maintenance activities

Records shall be part of the GDPMD system

Determine and manage work environment needed

eg. Special work environment such as controlled room needed?

Establish documented requirements for health, cleanliness and clothing of personnel if contact between such Suggestion: Establish work instruction for health, cleanliness and dressing of

personnel and medical devices or work environment that could adversely affect quality of medical devices

personnel

Establish documented procedure or work instructions to monitoring and control conditions for work

Establish procedure/work instruction for work environment monitoring

environment that could adversely affect quality of medical devices

(Temperature, Humidity)

Ensure all personnel who are required to work temporarily under special environment that could adversely This requirement can be included in procedure/work instruction for work

affect quality of medical devices are appropriately trained or supervised by a trained person

environment monitoring

Establish special arrangements and document the control of contaminated or potentially contaminated

This requirement can be included in procedure/work instruction for work

medical devices, work environment or personnel

environment monitoring

Establish documented requirements

Suggestion: Establish procedure/work instruction for cleaning of premises, pest

control program, including frequency and methods

Maintain records of cleaning

Cleaning records shall be part of the GDPMD system

Establish a pest control program

Suggestion: Establish procedure/work instruction for pest control program.

Pest control program can be managed internally or by pest control service

provider (eg. Installation of insect light trap (for flying insect) and installation of

rodent trap)

Maintain records of pest control program

Pest control records shall be part of the GDPMD system

Obtain required authorization to become authorized representative,importer or distributor

Suggestion: obtain letter of authorization from relevant party to become

authorized representative, importer or distributor.

Establish and maintain written agreement with relevant party

Written agreement shall be part of the GDPMD system (distribution agreement,

regulatory agreement, etc.)

Establish and maintain communication channel and feedback mechanisms with relevant party

Suggestion: create status report providing medical device feedback information

to relevant party (Post-Market Surveillance)

Manage and communicate with users, public and authority on medical devices dealing with

Establish and maintain efficient communication channel with manufacturers

19

Communication channel

20

Receipt of stock

21

Storage and stock handling

22

Stock rotation

23

Delivery to customers

24

Control

of

nonconforming

medical

devices

including

returned

medical

devices

Establish

feedback

mechanism

for

collecting

comments

and

complaints

from

users

and

public,

to

be

Suggestion:

create

complaint

form

(eg:

8D

report)

forwarded

to

relevant

party

as

applicable

Establish

mechanism

to

provide

information

on

maintenance

services,

including

calibration,

provision

of

spare

suggestion:

include

in

Manuals,

IFU,

leaflets,etc.

parts

and

other

services,

to

the

users

Establish

and

implement

inspection/other

activities

to

ensure

medical

device

meets

specified

requirements Suggestion:

Perform

incoming

inspection,

create

incoming

inspection

log

Maintain

records

of

verification

Inspection

records

shall

be

part

of

the

GDPMD

system

Identify

storage

measures

for

specific

medical

devices

and

stored

in

accordance

with

manufacturer's

Suggestion:

Establish

procedure/work

instruction

for

storage

and

stock

handling

instructions

Provide

suitable

storage

Provide

suitable

storage

area

eg.

Warehouse

Maintain

updated

distribution

records

of

medical

devices

dealing

with

Maintain

distribution

records

of

medical

devices

it

deals

with,including

the

make,

model,

batch

number,

serial

number

and

quantity.

Establish

adequate

precautions

and

control

to

prevent

deterioation

or

damage

of

medical

devices

Can

be

part

of

the

procedure/work

instruction

for

storage

and

stock

handling

Quarantine

status

and

quarantine

area

Provide

proper

identification

and

quarantine

area/storage

for

nonconform

products

Any

system

replacing

physical

quarantine

should

provide

equivalent

security

Storage

for

medical

device

presenting

special

risks

of

abuse,

fire

or

explosion

Provide

proper

storage

area

for

medical

device

presenting

special

risks

of

abuse,

fire

or

explosion

Identification

and

withdrawn

of

broken/damaged

medical

device

from

usable

stock

Provide

proper

identification

for

broken/damaged

medical

device

and

make

sure

the

medical

devices

are

withdrawn

from

usable

stock

(eg.

Store

in

quarantine

area)

Establish

stock

rotation

system

eg.

First-In-First-Out

(FIFO)

system

Identification

of

expired

medical

device

Provide

proper

identification

and

storage

area

for

medical

device

with

a

shelf-life

Dispose

expired

medical

device

Verify

that

certificate

of

registration,

license

and

other

applicable

documents

and

instructions

for

use

(IFU)

is

accompanied

with

registered

medical

device

Ensure

that

medical

device

bears

all

information

needed

Ensure

medical

device

should

only

be

sold/distributed

by

designated

persons

or

entities

only

Provide

proper

documentation

to

customers

Keep

record

of

delivery

transaction

Obtain

condition

of

storage,

transportation,

installation,

testing

and

commissioning

requirements,

users

and

service

manual,spare

part

list

and

certificate

from

manufacturer

and

provide

to

customer

Ensure

delivery

of

medical

device

adhere

specified

condition

Establish

specialized

method

of

delivery

from

the

point

of

collection

to

the

point

of

delivery

Ensure

delivery

of

medical

devices

presenting

special

risks

of

abuse,

fire

or

explosion

are

stored

in

safe,

and

transported

in

safe

conditions

Establish

documented

procedure

Refer to section Disposal of medical devices (clause 25)

Suggestion: create procedure/work instruction for delivery to customer

check whether all informations are available

suggestion: create list of approved distributor/customer

eg. : manuals, delivery notes with traceability information, etc

Records of delivery (eg. Delivery notes) shall be maintained

ensure all informations are obtained from manufacturer and provide to customer

eg.temperature control, special storage condition, etc.

suggestin: establish contract with forwarders

eg. Fire proof cabinet, etc.

Create control of nonconforming medical device procedure

Ensure

nonconforming

medical

device

is

identified

and

controlled

to

prevent

its

unintended

delivery

and

use To

be

included

in

the

procedure

Define

control

and

responsibilities

and

authorities

for

nonconforming

medical

device

handling

Deal

with

nonconforming

medical

device

with

one

or

more

of

following

ways:

-

by

taking

action

to

eliminate

detected

nonconformity

-

by

authorizing

delivery

and

use

under

concession

Ensure

nonconforming

medical

device

is

delivered

and

used

by

concession

only

if

regulatory

requirements

are

met

Maintain

records

of

justification

and

identify

person

authorizing

the

concession

25

26

27

28

29

Disposal of medical devices

Traceability

Maintain records

To be included in the procedure and form. The person authorizing concession

should be identified.

Records shall be part of GDPMD system

Take appropriate action when nonconforming medical device is detected after delivery

Implement Field Corrective Action if required. Refer to provision 40

Establish documented procedure

Create disposal of medical device procedure explaining how devices shall be

disposed (considering locl regulations).

Identify storage area (eg. Quarantine area)

Ensure,

if

the

medical

device

have

not

been

immediately

sent

for

disposal,

they

shall

be

kept

in

clearly

segregated,

safe

and

secured

area

and

identified

Maintain

records

Maintain

updated

records

providing

traceability

of

medical

devices

Records

retention

Ensure all parties involved in the supply chain shall be identifiable

Establish measures to ensure traceability of medical devices throughout distribution channels from

manufacturer/importer to the customer and to the patient

Records including expiry dates and batch records

Specific traceability

Establish tracking records for all implants

requirements for implantable If tracking is not possible for any individual medical devices, the tracking system is still required as follows:

medical devices

(i) to track the medical devices down to healthcare facility level

(ii) to keep track of the following:

- date of medical device was put into service/implanted into a patient

- date the device permanently retired from use or for an implanted medical device, the date it was implanted

Submit surveillance reports to authority at least once a year

Specific requirements for active Establish documented procedure and work instructions for performing installation, testing and

medical devices

commissioning and maintenance activities

Establish and maintain documented procedures, work environments and reference materials, tools and test

equipment and reference measurement procedures, for performing servicing activities including calibration,

repair, maintenance and verifying that they meet the regulatory requirements and applicable standards.

Outsourced activities

Establish

documented

requirements

which

contain

acceptance

criteria

for

installation,

testing

and

commissioning

of

medical

device.

Establish

installation

qualification

and

maintain

adequate

installation

and

inspection

instructions

for

medical

device

requiring

specified

installation

requirements,

and

where

appropriate,

test

procedure

Ensure

proper

installation,

testing

and

commissioning

Ensure

equipment

used

for

testing,

maintenance

and

conservation

of

medical

devices

are

calibrated

or

verified

at

specific

intervals

Ensure

calibration

and

maintenance

of

test

equipments

conforms

to

applicable

standards

maintain

testing

and

commissioning,

installation,

calibration

and

maintenance

service

records.

Ensure

control

outsourced

process

within

GDPMD

scope

Establish

requirements

to

ensure

outsourced

activities

conform

specified

requirements

Ensure

type

and

extent

of

control

applied

to

supplier

are

dependent

on

impact

on

meeting

the

requirements

of

GDPMD

ensure

outsourced

supplier

is

audited

as

part

of

establishment

unless

the

supplier

is

already

certified

to

GDPMD

covering

the

scope

of

outsourced

activities

develop

written

agreements

with

outsourced

party

Physically

segregated

from

other

medical

devices

to

avoid

any

confusion

Records of disposal shall be part of GDPMD system

Maintain a list for customer/serial number of lot number

specify records retention period

- as specified in regulatory requirements, at least equivalent to lifetime of

medical device as defined by manufacturer of medical device,or no less than two

years from the date that medical device is shipped from establishment,

whichever is the longest.

identify the distributor, importer, manufacturer, authorized representative, etc.

create traceability record

Maintain a record for batch number/expiry date

create implant tracking record/log to include all informations needed

submit yearly report to MDA

create installation, testing and commissioning and maintenance procedure and

work instructions (eg: MRI, XRay,etc..)

perfom installation qualification following the manufacturer protocol.

specify calibration or verification interval in work instruction

records should be part of GDPMD system

outsourced activities: eg. warehouse, sterilization, logistic, etc.

All outsouced activities should be closely monitored (auditing for example)

ensure outsourced supplier is audited

create agreement format and maintain records of agreement

identify segregation area

30

Counterfeit

adulterate,

unwholesome

and

tampered

medical

devices

31

Secondary

assembly

including

Availability

of

information

that

describes

characteristics

of

medical

devices

Ensure

all

informations

(instruction

for

use,

maintenance

activities,

etc.)

are

repackaging

available

Availability

of

documented

procedures,

documented

requirements,

work

instructions

and

reference

materials

Ensure

all

documents

are

available

during

secondary

assembly

activities

and

reference

measurement

procedures

as

necessary

The

use

of

suitable

equipment

packaging

machine,

label

printer,

etc.

Availability

and

use

of

monitoring

and

measuring

devices

ensure

suitable

monitoring

and

measuring

device

are

used

Implementation

of

monitoring

and

measurement

activities

first

piece

inspection,

statistical

process

control

(SPC),

etc.

Implementation

of

release

of

medical

device,

their

delivery

and

post-delivery

activities

final

release

inspection,etc.

Implementation

of

defined

operations

and

packaging

of

medical

devices

ensure

packaging

activities

are

according

to

packaging

work

instruction

Establish

and

maintain

a

record

for

each

batch

of

medical

devices

that

provides

traceabilty

and

identifies

the

eg.

Work

order,

tracking

records

amount

assembled

and

the

amount

approved

for

distribution

Ensure

batch

record

shall

be

verified

and

approved

by

qualified

personnel

suggestion:

include

responsibility

of

verification

of

batch

record

in

final

release

procedure

Assembly

documents

Kept

batch

assembly

records

maintain

assembly

records

eg.work

order,

operator

tracking

record,

etc.

Ensure

assembly

are

made

or

completed

at

each

time

action

is

taken

to

trace

significant

activities

of

assembly eg.

Verification

by

supervisor

is

needed

after

each

assembly

activities

completed

32

inform the Authority and manufacturer immediately.

Record retention

33

Materials control

inform authority through http://www.mdb.gov.my

as specified in regulatory requirements, at least equivalent to lifetime of medical

device as defined by product owner of medical device,or no less than two years

from the date that medical device is shipped from establishment, whichever is

the longest.

For each delivery, incoming medical device are checked for integrity of package and seal, for correspondence perform incoming inspection, label verification, etc.

between delivery note and the supplier's label, and for compliance with quality specification

medical device with breached primary package are not used for secondary assembly

locate in proper segregation area

medical device in storage area are appropriately labeled

Identify properly (labelling, storage area, etc.)

33

Materials control

34

Labelling

35

Good assembly practices

36

38

39

40

41

42

43

44

45

Appropriate

procedures

or

measures

are

taken

to

assure

identity

of

the

contents

of

each

packing

of

medical

device

Clearly

identify

bulk

containers

from

which

quantities

of

medical

device

that

have

been

drawn

Placed

medical

device

requiring

special

storage

conditions

in

areas

which

are

designed

an

equipped

to

provide

desired

conditions

Continuously

monitor

and

record

storage

and

conditions

Express

actual

storage

temperature

quantitatively

the

purchase,

handling,

and

control

of

all

packaging

materials

are

accorded

attention

similar

to

that

given

to

starting

materials

packaging

materials

are

issued

for

use

only

by

authorized

personnel

in

accordance

with

documented

procedure

when

setting

up

a

program

for

packaging

operations,

particular

attention

is

given

to

minimize

risk

if

cross-

contamination,

mix-ups

or

substitutions

different

medical

devices

shall

not

be

packaged

in

close

proximity

unless

there

is

physical

segregation

Ensure

repackaged

medical

devices

bear

all

original

labelling

(including

IFU

and

any

other

information

sheet

or

leaflet,

etc.)

and

all

labelling

information,

except

for

quantity

and

distributor

identity.

Check

medical

devices

and

materials

used

for

assembly

before

use

by

a

designated

person

for

quantity,

identity

and

conformity

with

the

packaging

instructions.

Performed

line

clearance

prior

commencement

of

assembly

operation

Check

and

record

the

correct

performance

of

any

printing

operation

which

is

carrried

out

separately

or

in

the

course

of

packaging

Re-check

printing

by

hand

at

regular

intervals

Assembly

equipment/apparatus

are

cleaned

according

to

detailed

and

written

procedures

and

stored

only

in

a

clean

and

dry

condition

Assembly

equipment/apparatus

do

not

present

any

hazard

to

the

medical

devices

Parts

of

assembly

equipment/apparatus

that

come

into

contact

with

medical

devices

do

not

effect

quality

of

medical

devices

and

present

any

hazard

Calibrate

and

check

control

environment

at

defined

intervals

and

adequate

records

of

calibration

shall

be

maintained.

Create procedure/work instruction

Conduct internal audits at planned intervals

Maintain records of audit and results

Take action to eliminate detected nonconformities and causes without undue delay

Establish documented procedure

Establish documented procedure

Internal audit plan should be created

Records of audit shall be part of GDPMD system

Action should be taken immediately

Create corrective action procedure and form.

Create preventive action procedure and form.

Suggestion: corrective action and preventive action procedure can be combined

in one procedure

create proper labeling/identification/storage area

eg. Medical device that needs temperature control

create storage and condition monitoring record

record storage temperature in storage and condition monitoring record

ensure material control activities are according to procedure/work instruction

include responsibility of issuing packaging material in procedure/work instruction

proper identification, segregation area

create proper segregation area

perform labelling inspection/verification

perform inspection. Medical device and material used should be inspected by

designated personnel only.

suggestion: include line clearance activity in work instruction

perform label verification

perform cleaning according to cleaning procedure

calibration interval and checking of control environment should be specified in

procedure or etc.

records should be maintained

Quality control

Finished medical device assessment shall embrace all relevant factors,including assembly conditions, a review create final release procedure, inspection criteria, etc.

of packaging documentation, compliance with finished medical device specification and visual examination of Perform inspection/verification according to specified requirement

final finished pack

Process of secondary assembly shall not compromise conformity of medical device to essential principles of

safety and performance

Medical device complaints

Establish documented procedure

Create complaint handling procedure

Review all complaints and other information concerning potentially defective and counterfeit medical

To be included in complaint procedure and form (review section)

devices, including description of action to be taken and reporting to relevant parties, where appropriate

Record any complaint and investigate to identify origin or the reason for complaint

Create complaint form and complaint log

Maintain records of complaints, investigation and action taken

Create complaint form

Follow-up action should be taken after investigation and evaluation of complaint, where necessary

To be included in complaint form

Distribution records

Document all activities relating to distribution

Maintain distribution records including receipts, storage, delivery and disposal

FCA and FSN

Establish documented procedure

Create procedure for handling of FCA and FSN

Define responsibilities for planning, conducting and reporting of corrective actions in procedure

Include responsibilities in procedure

Establish writing a recall/withdrawal procedure in consultation with manufacturer

Establish recall procedure

Inform authority prior execution of FCA and FSN

Any adverse event shall be reported through mdb website:

http://www.mdb.gov.my/mdb/index.php?option=com_content&task=view&id=

19&Itemid=115

Inform customers to whom medical device was distributed with appropriate degree of urgency

customer should be informed immediately

Inform overseas counterparts on FCA and FSN if medical devices are exported

Communicate with overseas counterpart if medical devices are exported

Maintain records of action taken and approval by manufacturer and authority

Records shall be maintained

Recall

Establish documented procedure

Recommendation: Recall can be included in FCA procedure

Ensure the system comply with regulatory requirements

Manufacturer and/or authorized representative shall be informed in the event of recall

Inform Manufacturer and/or authorized representative

where recall is instituted by an entity other than manufacturer and/or authorized representative,

consult Manufacturer and/or authorized representative if recall is instituted by

consultation with manufacturer and/or authorized representative should, where possible, take place before other entity

recall is instituted

recall information shall be reported to the Authority

inform authority through http://www.mdb.gov.my

Progress of recall process should be recorded and a final report issued, which includes a reconcilliation

issue final report of recall process

between delivered and recovered quantities of products.

Mandatory problem reporting Establish documented procedure

Establish mandatory problem reporting procedure

Each incident report shall lead to a final report where corrective actions are applicable

create mandatory problem report form

Internal audits

Establish documented procedure

Define responsibilities,requirements for planning and conducting audits and

reporting of result and maintenance of audit records.

Plan an audit program

Establish audit plan

Define audit criteria, scope, frequency and methods

audit criteria, scope, frequency and methods should be included in the procedure

Corrective

action

Preventive

action

También podría gustarte

- Sample Management Review Agenda and MinutesDocumento6 páginasSample Management Review Agenda and MinutesTravis100% (3)

- ISO 13485 Internal Audit ChecklistDocumento23 páginasISO 13485 Internal Audit Checklistenrique59197291% (23)

- Quality ManualDocumento19 páginasQuality ManualKung Karona100% (2)

- MDPWG Ahmad Shariff Hambali Good Distribution For Medical Device GDPMDDocumento40 páginasMDPWG Ahmad Shariff Hambali Good Distribution For Medical Device GDPMDnaravichandran3662Aún no hay calificaciones

- SOP of Release or Rejection of Finished ProductDocumento1 páginaSOP of Release or Rejection of Finished ProductPrince MoniAún no hay calificaciones

- SOP On Monitoring of Temperature and Relative Humidity.Documento2 páginasSOP On Monitoring of Temperature and Relative Humidity.RainMan75100% (2)

- SOPSP05 VendorSelection BSDocumento3 páginasSOPSP05 VendorSelection BStroubledsoul100% (1)

- Audit Checklist For ISO 13485Documento6 páginasAudit Checklist For ISO 13485EdAún no hay calificaciones

- Capa FormDocumento3 páginasCapa FormZahid Nazir100% (1)

- Achieving and Maintaining Qualified Facilities with a Validation Master Plan (VMPDocumento3 páginasAchieving and Maintaining Qualified Facilities with a Validation Master Plan (VMPPrince MoniAún no hay calificaciones

- 7 steps CAPA medical devicesDocumento7 páginas7 steps CAPA medical devicesShantha Kumar ParameswaranAún no hay calificaciones

- Product Recall and Withdrawal ProcedureDocumento5 páginasProduct Recall and Withdrawal ProcedureNaizil Kareem100% (5)

- Quality System Manual: ISO 13485 U.S. QSR (21 CFR 820)Documento27 páginasQuality System Manual: ISO 13485 U.S. QSR (21 CFR 820)Khalid Mehboob100% (1)

- FDA Medical Device Complaint FormDocumento2 páginasFDA Medical Device Complaint Formclayton51175% (4)

- 93-42-EC ER Checklist ExampleDocumento16 páginas93-42-EC ER Checklist Exampledulichsinhthai100% (2)

- 410 09e Checkliste For Assessment 13485 MDDDocumento51 páginas410 09e Checkliste For Assessment 13485 MDDeko Setyawan100% (1)

- ISO 13485 and ISO 9001 Correspondence GuideDocumento4 páginasISO 13485 and ISO 9001 Correspondence GuideGadus Spp100% (4)

- Quality Manual ExampleDocumento32 páginasQuality Manual ExamplesaiaviAún no hay calificaciones

- 820 - ISO 13485-2003 Comparison MatrixDocumento37 páginas820 - ISO 13485-2003 Comparison MatrixAli Imamudeen100% (2)

- GMP Audit Checklist for Pharmaceutical ManufacturingDocumento31 páginasGMP Audit Checklist for Pharmaceutical ManufacturingSandra100% (1)

- MRF Management ReviewDocumento4 páginasMRF Management ReviewhastinkakaAún no hay calificaciones

- ISO 13485 QMS manual indexDocumento5 páginasISO 13485 QMS manual indexQuality and Safety Consultants Co.Aún no hay calificaciones

- SOP For Internal AuditDocumento3 páginasSOP For Internal AuditMuhammad Nisar75% (4)

- Calibration Policy SOPDocumento3 páginasCalibration Policy SOPYousifAún no hay calificaciones

- 21 CFR 820 Audit ChecklistDocumento7 páginas21 CFR 820 Audit ChecklistFrankMartinez100% (1)

- ISO 13485 Gantt Chart - May 2020Documento4 páginasISO 13485 Gantt Chart - May 2020Rohini Gadhawe100% (4)

- 2016 StandardDocumento39 páginas2016 StandardAnkur Dhir100% (4)

- Calibration and Maintenance of Measuring and Monitoring Devices SOPDocumento3 páginasCalibration and Maintenance of Measuring and Monitoring Devices SOPBPG Service100% (1)

- Internal Quality Audit Checklist ISO 13485:2003 & ISO 9001:2000Documento29 páginasInternal Quality Audit Checklist ISO 13485:2003 & ISO 9001:2000JocelyneAún no hay calificaciones

- Technical FilesDocumento15 páginasTechnical Fileshitham shehataAún no hay calificaciones

- Managemnet Review SOP & RecordsDocumento3 páginasManagemnet Review SOP & RecordsPritam MitraAún no hay calificaciones

- OOS FormatDocumento4 páginasOOS Formatbpharmba100% (1)

- Pecb Iso 13485 Lead Auditor Exam Preparation GuideDocumento15 páginasPecb Iso 13485 Lead Auditor Exam Preparation GuiderberrospiAún no hay calificaciones

- 2016 Ia Sample ChecklistDocumento5 páginas2016 Ia Sample ChecklistMiss BreedloveAún no hay calificaciones

- MDR Readiness Checklist: Prepared by Cite Medical SolutionsDocumento37 páginasMDR Readiness Checklist: Prepared by Cite Medical SolutionsBeal100% (1)

- Good Distribution Practice For Medical Device108201532845PM1Documento60 páginasGood Distribution Practice For Medical Device108201532845PM1Sean100% (1)

- QSP-001633 - Rev 04 - Luminus Testing Laboratory Quality Manual207Documento34 páginasQSP-001633 - Rev 04 - Luminus Testing Laboratory Quality Manual207SureshAún no hay calificaciones

- ISO 13485 Process MatrixDocumento2 páginasISO 13485 Process MatrixManjunath BAún no hay calificaciones

- ISO 13485 PurchasingDocumento5 páginasISO 13485 PurchasingSubhashAún no hay calificaciones

- ISO 13485 Audit Report for Haiyan Kangyuan MedicalDocumento30 páginasISO 13485 Audit Report for Haiyan Kangyuan MedicalAymen ZebbarAún no hay calificaciones

- Iso 13485 Manual DocumentsDocumento14 páginasIso 13485 Manual DocumentsRRR1100% (1)

- ISO 13485 ComparisonDocumento6 páginasISO 13485 ComparisonMikeAún no hay calificaciones

- Audit TcoDocumento21 páginasAudit Tcoali reza malaekehAún no hay calificaciones

- Audit Checklist - IsO 13485 and MDDDocumento6 páginasAudit Checklist - IsO 13485 and MDDMarcos Poffo100% (2)

- MammographyDocumento27 páginasMammographyRohmatullah Anas100% (1)

- Standard Awareness Training 13485Documento21 páginasStandard Awareness Training 13485Jeelani BashaAún no hay calificaciones

- Cracking the Case of ISO 9001:2015 for Service: A Simple Guide to Implementing Quality Management in Service OrganizationsDe EverandCracking the Case of ISO 9001:2015 for Service: A Simple Guide to Implementing Quality Management in Service OrganizationsAún no hay calificaciones

- Preparing For Certification AuditDocumento58 páginasPreparing For Certification AuditAntonio P. SantosAún no hay calificaciones

- A Sample of The Completed Essential Principles Conformity Checklist MD CCLDocumento12 páginasA Sample of The Completed Essential Principles Conformity Checklist MD CCLAyman Ali100% (1)

- The ASQ Certified Quality Auditor HandbookDe EverandThe ASQ Certified Quality Auditor HandbookCalificación: 1 de 5 estrellas1/5 (2)

- ISO 13485 Lead Auditor Two Page BrochureDocumento2 páginasISO 13485 Lead Auditor Two Page BrochurePECBCERTIFICATIONAún no hay calificaciones

- Silabus Lead Auditor 9001Documento4 páginasSilabus Lead Auditor 9001Bobby Febri KrisdiyantoAún no hay calificaciones

- CLAUSE 8.5 Production and Service ProvisionDocumento10 páginasCLAUSE 8.5 Production and Service ProvisionNavnath TamhaneAún no hay calificaciones

- Guidance On The Rules of Classification For General Medical DevicesDocumento29 páginasGuidance On The Rules of Classification For General Medical Devicesnaravichandran3662Aún no hay calificaciones

- GMPDocumento5 páginasGMPharwinderpanditAún no hay calificaciones

- HIMSS EMRAM Stage 7 DMTDocumento20 páginasHIMSS EMRAM Stage 7 DMTclrhoadesAún no hay calificaciones

- MDSAP QMS F0008.2.003 Internal Assessment Checklist 2017-03-01Documento15 páginasMDSAP QMS F0008.2.003 Internal Assessment Checklist 2017-03-01nsk79in@gmail.comAún no hay calificaciones

- Emergency Preparedness Concepts Test BankDocumento13 páginasEmergency Preparedness Concepts Test BankTyson Easo JonesAún no hay calificaciones

- Comprehensive Physical AssessmentDocumento2 páginasComprehensive Physical AssessmentJan Christian Dayto79% (33)

- Facilities and Environmental Conditions (Linked To Vol. III, Sec. 2) PDFDocumento8 páginasFacilities and Environmental Conditions (Linked To Vol. III, Sec. 2) PDFimran shaukatAún no hay calificaciones

- As ISO 14534-2003 Opthalmic Optics - Contact Lenses and Contact Lens Care Products - Fundamental RequirementsDocumento8 páginasAs ISO 14534-2003 Opthalmic Optics - Contact Lenses and Contact Lens Care Products - Fundamental RequirementsSAI Global - APACAún no hay calificaciones

- Control of Nonconforming ProductsDocumento2 páginasControl of Nonconforming ProductsPrince Moni100% (1)

- LS QA ManualDocumento55 páginasLS QA ManualjtwaniAún no hay calificaciones

- Iso 22001 Efresh IndiaDocumento13 páginasIso 22001 Efresh IndiaMahmoud KhalifaAún no hay calificaciones

- F001 GDPMDDocumento5 páginasF001 GDPMDnaravichandran3662Aún no hay calificaciones

- GD0009 Classification of General Medical DeviceDocumento39 páginasGD0009 Classification of General Medical DeviceAdel AdielaAún no hay calificaciones

- DOLE OHSC Audit Report FA1 2018Documento13 páginasDOLE OHSC Audit Report FA1 2018naravichandran3662Aún no hay calificaciones

- Ivd Medical Device Classification SystemDocumento19 páginasIvd Medical Device Classification SystemoytAún no hay calificaciones

- Module 3 - Approaches To Clean Vehicle ProcurementDocumento27 páginasModule 3 - Approaches To Clean Vehicle Procurementnaravichandran3662Aún no hay calificaciones

- How To Apply For In-Vitro Diagnostic (IVD) Medical Device Registration Under Medical Device Act 2012 (Act 737)Documento13 páginasHow To Apply For In-Vitro Diagnostic (IVD) Medical Device Registration Under Medical Device Act 2012 (Act 737)naravichandran3662Aún no hay calificaciones

- Additional Transition Period For Medical Device LabelingDocumento3 páginasAdditional Transition Period For Medical Device Labelingnaravichandran3662Aún no hay calificaciones

- Exemption From Registration Requirement For Export Only Medical Device (Revision 1) BMDocumento3 páginasExemption From Registration Requirement For Export Only Medical Device (Revision 1) BMnaravichandran3662Aún no hay calificaciones

- How To Apply For Establishment License Under Medical Device Act 2012 (Act 737) V2 MalaysiaDocumento7 páginasHow To Apply For Establishment License Under Medical Device Act 2012 (Act 737) V2 Malaysianaravichandran3662Aún no hay calificaciones

- E-MDES Manual 2020Documento152 páginasE-MDES Manual 2020naravichandran3662Aún no hay calificaciones

- MDA Establishment Licence RenewalDocumento14 páginasMDA Establishment Licence Renewalnaravichandran3662Aún no hay calificaciones

- Post-Market Responsibilities For Manufacturer and Authorized Representative (Revision 1)Documento3 páginasPost-Market Responsibilities For Manufacturer and Authorized Representative (Revision 1)naravichandran3662Aún no hay calificaciones

- 771 1Documento25 páginas771 1yogiforyouAún no hay calificaciones

- Medical Device (Declaration) Order 2017Documento5 páginasMedical Device (Declaration) Order 2017naravichandran3662Aún no hay calificaciones

- MDARR No 1 First Revision November 15Documento26 páginasMDARR No 1 First Revision November 15popopioAún no hay calificaciones

- Selangor - Senarai Klinik Perubatan Swasta Berdaftar 2018 (Update 260319)Documento115 páginasSelangor - Senarai Klinik Perubatan Swasta Berdaftar 2018 (Update 260319)naravichandran3662Aún no hay calificaciones

- Barriers To CommunicationDocumento34 páginasBarriers To Communicationnaravichandran3662Aún no hay calificaciones

- Compilation of Guidelines For Redress of Public Grievances - Naresh KadyanDocumento290 páginasCompilation of Guidelines For Redress of Public Grievances - Naresh KadyanNaresh KadyanAún no hay calificaciones

- Medical Device ACT 2012 (Act 737)Documento0 páginasMedical Device ACT 2012 (Act 737)Chee Chiow NeoAún no hay calificaciones

- Medical Device Authority Act 2012 (Eng) PDFDocumento24 páginasMedical Device Authority Act 2012 (Eng) PDFnaravichandran3662Aún no hay calificaciones

- SENARAI HOSPITAL SWASTA BERLESEN DI JOHOR DAN NEGERI-NEGERI LAINDocumento23 páginasSENARAI HOSPITAL SWASTA BERLESEN DI JOHOR DAN NEGERI-NEGERI LAINnaravichandran3662Aún no hay calificaciones

- WPKL Senarai Klinik Perubatan Swasta Berdaftar 2018 (Update 260319)Documento65 páginasWPKL Senarai Klinik Perubatan Swasta Berdaftar 2018 (Update 260319)naravichandran3662Aún no hay calificaciones

- Barriers To CommunicationDocumento34 páginasBarriers To Communicationnaravichandran3662Aún no hay calificaciones

- Quality and Costs of Primary Care - Malaysia Phase 1 ReportDocumento170 páginasQuality and Costs of Primary Care - Malaysia Phase 1 Reportnaravichandran3662Aún no hay calificaciones

- MDA - GD0026 - Requirement On Labelling of MD 3rd EdDocumento13 páginasMDA - GD0026 - Requirement On Labelling of MD 3rd Ednaravichandran3662Aún no hay calificaciones

- E-Book Ophthalmology Referral Guide For GPsDocumento11 páginasE-Book Ophthalmology Referral Guide For GPsnaravichandran3662Aún no hay calificaciones

- Are Malaysian Police Really StressedDocumento10 páginasAre Malaysian Police Really Stressednaravichandran3662Aún no hay calificaciones

- Peaceful Assembly Act 736Documento21 páginasPeaceful Assembly Act 736William AnthonyAún no hay calificaciones

- Peaceful Assembly Act 736Documento21 páginasPeaceful Assembly Act 736William AnthonyAún no hay calificaciones

- DR Wong Teck WeeipadDocumento2 páginasDR Wong Teck Weeipadtwwong68Aún no hay calificaciones

- Philips Respironics Bipap ST Niv Noninvasive VentilatorDocumento2 páginasPhilips Respironics Bipap ST Niv Noninvasive Ventilatorsonia87Aún no hay calificaciones

- Fa14 Concept Map 10-26-14 2Documento2 páginasFa14 Concept Map 10-26-14 2api-270415831Aún no hay calificaciones

- Nextier - Pharma 101 - 29-Jun-2016Documento28 páginasNextier - Pharma 101 - 29-Jun-2016Ammar ImtiazAún no hay calificaciones

- Apotex Pharmachem Product ListDocumento2 páginasApotex Pharmachem Product Listমোঃ এমদাদুল হকAún no hay calificaciones

- List of Manufacturing Units With Valid Ayush 64 Technology Transfer Agreement As On 15.06.2021Documento5 páginasList of Manufacturing Units With Valid Ayush 64 Technology Transfer Agreement As On 15.06.2021Sunira EnterprisesAún no hay calificaciones

- Hesi v2Documento125 páginasHesi v2kandiezein88Aún no hay calificaciones

- Evaluation of scales in immune-mediated polyneuropathiesDocumento222 páginasEvaluation of scales in immune-mediated polyneuropathiesAngelo MalerbaAún no hay calificaciones

- Hand Hygiene: Protocol For UWS ClinicsDocumento8 páginasHand Hygiene: Protocol For UWS ClinicsOliaAún no hay calificaciones

- Sound Transduction EarDocumento7 páginasSound Transduction Earhsc5013100% (1)

- Unit-V Chapter 20. Breathing and Exchange of Gases: Important PointsDocumento13 páginasUnit-V Chapter 20. Breathing and Exchange of Gases: Important PointsminaAún no hay calificaciones

- Reflex ActionDocumento26 páginasReflex ActionMudassar RoomiAún no hay calificaciones

- Jurnal InvaginasiDocumento3 páginasJurnal InvaginasiAbdurrohman IzzuddinAún no hay calificaciones

- A Review On Acacia Arabica - An Indian Medicinal Plant: IJPSR (2012), Vol. 3, Issue 07 (Review Article)Documento11 páginasA Review On Acacia Arabica - An Indian Medicinal Plant: IJPSR (2012), Vol. 3, Issue 07 (Review Article)amit chavanAún no hay calificaciones

- Depression in Today - BioDocumento5 páginasDepression in Today - Bioapi-272648963Aún no hay calificaciones

- Sage Char-Lee ResumeDocumento2 páginasSage Char-Lee Resumeapi-510197139Aún no hay calificaciones

- (Schedule P: Drugs and Cosmetics Rules 1945Documento7 páginas(Schedule P: Drugs and Cosmetics Rules 1945rpadmakrishnanAún no hay calificaciones

- Clinical Experience With The Constellation Vision SystemDocumento16 páginasClinical Experience With The Constellation Vision SystemMohammad Abdullah BawtagAún no hay calificaciones

- FISIOGRAFT ENG Set 17 PDFDocumento28 páginasFISIOGRAFT ENG Set 17 PDFmaxAún no hay calificaciones

- Hypertension: Hozan Jaza MSC Clinical Pharmacy College of Pharmacy 10/12/2020Documento81 páginasHypertension: Hozan Jaza MSC Clinical Pharmacy College of Pharmacy 10/12/2020Alan K MhamadAún no hay calificaciones

- Bonifacio V. Romero High School Tle Beauty Care 9 1st Quarter Examination S.Y. 2018-2019Documento6 páginasBonifacio V. Romero High School Tle Beauty Care 9 1st Quarter Examination S.Y. 2018-2019Virginia Saavedra100% (1)

- Masterlist SummaryDocumento6 páginasMasterlist Summarykentclark03Aún no hay calificaciones

- Staph and Strep Lab Report BMS 501Documento2 páginasStaph and Strep Lab Report BMS 501aruiz93Aún no hay calificaciones

- NephrologyDocumento5 páginasNephrologyPooja NalluriAún no hay calificaciones

- DR Koenig Redacted Expert Report Publicly FiledDocumento14 páginasDR Koenig Redacted Expert Report Publicly FiledBrit StackAún no hay calificaciones

- Biology Contents - RPSC FSO by Food TecKnowDocumento35 páginasBiology Contents - RPSC FSO by Food TecKnowRahul JainAún no hay calificaciones