Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Method Statemant Hydro

Cargado por

jay_rajeshirkeDerechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Method Statemant Hydro

Cargado por

jay_rajeshirkeCopyright:

Formatos disponibles

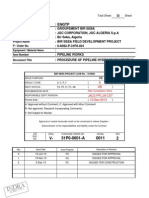

DOCUMENT No.

REVISION No.

PAGE

OF

CONSOLIDATED CONTRACTORS COMPANY

:

:

:

:

MS-846-038

4

1

8

QGX-CCS-004-A-0038

METHOD STATEMENT

FOR

HYDROTESTING OF

U/G & A/G PIPING SYSTEM

MS 846 - 038

QGll LNG ONSHORE FACILITIES PROJECT

RAS LAFFAN - QATAR

Approved for Construction

Revised to CTJV comments

27/12/05

MR

DM

FG

RD

Approved for Construction

Revised to CTJV comments

14/11/05

MR

DM

FG

RD

Approved for Construction

Revised to CTJV comments

20/10/05

MR

DM

FG

RD

Approved for Construction

Revised to CTJV comments

29/09/05

MR

DM

FG

RD

DATE

PREPARED

BY

SAFETY

REVIEW

QA REVIEW

APPR'D BY

CCIC

REV

COMMENTS

File No:

CTJV

QGX2 PROJECT

CTJV

CONSOLIDATED CONTRACTORS COMPANY

DOCUMENT No.

REVISION No.

PAGE

OF

:

:

:

:

MS-846-038

4

2

8

INDEX

1.

SCOPE

2.

PURPOSE

3.

REFERENCES

4.

DEFINITIONS

5.

RESPONSIBILITIES

6.

SAFETY

7.

GENERAL

8.

TOOLS AND EQUIPMENT

9.

DOCUMENTS

10.

PREPARATION

11.

TEST PERFORMANCE & WITNESS

12.

ATTACHMENT

12.1 TEST BLIND THICKNESS CHART

12.2 JSA

12.3 It should be noted that sample test pack complete with

flow chart was submitted and B Approved as part of

QA/QC Documentation. Pack therefore as agreed by

these departments shall be used.

1.

SCOPE

File No:

CTJV

QGX2 PROJECT

CONSOLIDATED CONTRACTORS COMPANY

1.1

2.

4.

:

:

:

:

MS-846-038

4

3

8

This Method Statement outlines the requirements and related activities for the

Hydrostatic testing of underground and above ground piping systems.

PURPOSE

2.1

3.

DOCUMENT No.

REVISION No.

PAGE

OF

To ensure that all information, material, tools, equipment, manpower and

supervision are available for execution of the work. Also to ensure that work steps

are analyzed and all safety measures are taken so that work can be executed in a

safe and timely manner.

REFERENCES

3.1

Safety Procedure QGX/20/00/SA/PC/NA/100 to 124

3.2

QA-QC Requirements QGX/20/00/CS/PC/NA/020

3.3

Piping Fabrication, Erection and Testing QCP-846-115

3.4

ASME B31.3 Process Piping

3.5

Piping Fabrication, Erection and Testing QGX/20/00/MP/TS/NA/001

DEFINITIONS

For the purpose of this method statement, the following definitions shall apply:

5.

4.1

Company

Qatar Liquefied Gas Company

4.2

Contractor

Chiyoda & Technip Joint Venture (CTJV)

4.3

Sub Contractor

4.3

Permit to Work

Document issued by Qatar Gas / CTJV

4.5

MS

Method Statement

4.6

QCP

Quality Control Procedure

4.7

ITP

Inspection and Test Plan

4.8

NDT

Non-Destructive Testing

4.9

JSA

Job Safety Analysis

Consolidated Contractors Int`l Co / Teyseer JV

RESPONSIBILITIES

5.1

The Sub Contractor is responsible for the hydrostatic testing of above and

underground piping systems according to applicable safety procedures, project

specifications and manufacturers recommended procedure.

File No:

CTJV

QGX2 PROJECT

CONSOLIDATED CONTRACTORS COMPANY

6.

DOCUMENT No.

REVISION No.

PAGE

OF

:

:

:

:

MS-846-038

4

4

8

5.2

The authorized permit holder/signatory shall obtain work permits from the

Company/CTJV as appropriate.

5.3

Contractor & Sub-contractor Engineer/Supervisor/Foreman will ensure the safe and

efficient working environment to plant and equipment to carry out the hydrostatic

testing activity.

5.4

The Contractor and Sub-contractors Quality Control Inspectors will be responsible

for the inspection of pressurized piping system in accordance with the project

specification and procedure.

5.5

All the safety equipment, vehicles, barricades, road and hazard signs for Hydro

testing Works will be provided by the Sub-contractor.

SAFETY

6.1

Good housekeeping shall be maintained throughout the period.

6.2

The hydrostatic testing will be undertaken in accordance with the project safety

manual. QGX/20/00/SA/PC/NA/100.

6.3

Non essential personnel shall be cleared from the vicinity of the test pipe system.

6.4

Personnel involved in the pressure test shall have an identification mark on the

helmet so that test personnel can be easily identified in the test area.

6.5

A safety watch guard will be assigned throughout the test period.

6.6

The subcontractor will inform their safety department of the day to day testing

activities by means of written advisory at least one day before test is conducted.

6.7

Contractor / Subcontractor safety personnel will conduct a joint walk with testing

personnel to familiarize themselves with system to be tested and to identify any

potential hazards.

6.8

Proper and safe means of access and egress shall be provided and maintained for

all personnel in order to carry out inspection and testing of piping system.

6.9

Pressure system shall have a safe exclusion zone in all directions for any non

related activities. The parameters of this zone shall vary according to the volume of

test medium and the pressure it will be subjected to. As rule of thumb this would be

1,5 meter for every 10 bar and sufficient distance to avoid being engulfed if total

release of test medium is released.

6.10

Adequate warning sign boards will be placed around barricaded area where the test

is being carried out for the awareness of non related personnel.

6.11

When venting water from system particular care shall be taken to prevent water

from venting into adjacent work places or onto electrical equipment or wiring.

6.12

JSA and MS shall be attached to work permit.

6.13

All necessary approved PPE shall be provided and worn at all times.

File No:

CTJV

QGX2 PROJECT

CONSOLIDATED CONTRACTORS COMPANY

8.

:

:

:

:

MS-846-038

4

5

8

6.14

Sufficient illumination shall be provided in all areas whilst working at night.

6.15

Subcontractor to obtain PTW prior to start of test.

6.16

All activities shall be suspended in case of emergency and not restarted until the

PTW has been revalidated.

6.17

After successful completion of the pressure testing and gradual de-pressurization,

the draining operation will commence. Draining will be routed to disposal area as

allocated by contractor. During the draining operation, all necessary precautions will

be taken to control the water flow in order to avoid pollution, damage to the existing

facilities and without hazard to vehicles or equipment.

6.18

Sand bedding surround and backfilling of underground systems shall commence as

soon as instructed by the Contractor so to offer a natural anchoring to the pipeline,

protection of bedding/surround the coating from extensive exposure to high

temperatures, or any damaging action inflicted by bad weather conditions and prior

to pressure testing as per conditions in Procedure QGX/20/00/MP/TS/NA/001

Section 13.2. (Applicable for U/G Piping only)

7.

DOCUMENT No.

REVISION No.

PAGE

OF

GENERAL

7.1

Fabrication and Erection

a)

Will be in accordance with all applicable codes and

QGX/20/00/MP/TS/NA/001

b)

All NDT/PWHT requirements shall be completed prior to release for

pressure test.

c)

Reinforcing pads shall be pneumatically tested for any leaks at a

pressure of 60 to 100 psig. A soap solution shall be applied to

inspect all welds. Snoop or equivalent shall be used for stainless

steel.

d)

In case of jacketed pipe the inner shall be hydro tested prior to

fabricating the outer casing.

7.2

Pipe Cleaning Requirements

Pipe cleaning shall be in accordance with QGX/20/00/MP/TS/NA/001

CLAUSE 11.7

a) Pipes of 6 dia and larger shall be internally cleaned by manually flushing

with air blow in order to remove all trash or construction debris left inside

the pipe. All inline instruments shall be removed and protected. All control

valves shall be removed prior to cleaning and testing. Permanent plant

like pumps and vessels shall be isolated from this cleaning process.

b) An inspection sheet is to be signed by subcontractor, contractor and

company with a marked up isometric or line number clearly indicating the

limit of cleaning carried or part thereof inspected and passed clean. This

document will be attached to the test pack.

TOOLS AND EQUIPMENT

File No:

CTJV

QGX2 PROJECT

CONSOLIDATED CONTRACTORS COMPANY

8.1

3

8.2

9.

:

:

:

:

MS-846-038

4

6

8

The following tools and equipment shall be made available to perform the field

testing of piping systems.

DOCUMENT No.

REVISION No.

PAGE

OF

Pressure displacement pumps ( hose from pump to be crimped and fitted

with Chicago Pin and whip cord )

Fill tank and isolation valves

Filling pumps

Test manifolds with PSV set to applicable safety pressure.

Hand tools

Pneumatic sockets

Torque wrenches

Calibrated pressure gauges and recorders

Blinds and plugs QA approved.

Pressure gauges shall have a range of 1.5 to 4 times the required test pressure with

adequate dial accuracy to allow an exact reading of the test pressure. Gauges shall

be of 6 dial with build in vibration dampers. Gauges shall be calibrated within 30

days preceding the test. Two gauges minimum shall be installed at lowest and

highest point where practical.

DOCUMENTS

9.1

9.2

9.3

9.4

4

9.5

Prior to any pressure test all pertaining documents shall be compiled in Test

Package and submitted for approval by contractor and company. (Sample of Test

Pack Documents submitted under QCP 846-115)

Using a marked up set of P & ID in the system definition the extent of the test

system will be clearly indicated as well as blank and spade points.

Subcontractor shall not test through equipment without prior approval of contractor

and company.

A typical test pack shall include the following documents:

Marked up last revision of P & ID marked up showing test limits and

routing.

Isometric marked up with all weld numbers and limits as per the P &

ID

Weld history traceability.

Pressure Test Confirmation Record

Piping Pressure Test Release Report

Holiday test result for U/G Piping

Pre Hydro Punch List

Location Map

Blind Thickness Chart

Isometric control sheet from Talisman indicating NDT & PWHT

Cleaning Record

Last revision of the Line List with applicable lines highlighted

Concession Request if applicable

The marked up isometric drawing will indicate the location of pressurization point,

pressure gauge locations, vent location, control valves removed, FE, Flow gauge,

level gauges, strainer elements and critical soft seated ball valves which are not

part of the test.

File No:

CTJV

QGX2 PROJECT

CONSOLIDATED CONTRACTORS COMPANY

9.6

9.7

10.

DOCUMENT No.

REVISION No.

PAGE

OF

:

:

:

:

MS-846-038

4

7

8

Pre test punch list shall be prepared by Sub contractor as part of Test Pack and

Items Cat A cleared before test. Cat B items to be cleared as post test requirement.

Pipe cleaning Records shall be completed and signed by contractor for dia 6 and

larger and by Company for 24 and larger.

PREPARATIONS

10.1

Demin water shall be used for hydro testing austenitic stainless steel piping and

piping systems containing dissimilar materials where part of the system is stainless

steel. Water should not contain more than 50 ppm chloride ions. This condition

should be verified by lab testing sample from source prior to filling operation. Sea

water will be permissible for testing of sea water cooling lines only. All water should

be drained from test system immediately upon completion of test unless by

arrangement from contractor.

10.2 Visual inspection shall be applied in lieu of pressure test for lines open to

atmosphere, open ended drains and valves without spools as part of vessel trim.

10.3 Precautions should be taken to avoid over pressurization due to the rise in pressure

caused by escalating temperatures.

10.4 Temporary supports shall be installed by sub contractor if required after engineering

review.

10.5 Components deemed to be excluded as listed in item 9.5 shall be removed.

10.6 Test manifold will be connected at lowest point in system.

10.7 Calibrated pressure gauges will be installed at lowest and highest point practical.

10.8 All safety measures as listed in Section 6 will be met.

10.9 High Point vent will be installed and remain open till line is completely full and

purged of all entrapped air.

10.10 All required blinding and spading will be carried out as detailed in test loop pack.

Blind thickness will be determined from blind chart and temporary gaskets will be

installed at all joints that will require slacking after test.

10.11 All parts of test loop will be tightened in accordance with the bolt sequence and

torque requirements.

10.12 Prior to start filling test system will be walked down and checked in its entirety to

ensure total compliance and safe to fill.

3

11.

TEST PERFORMANCE AND WITNESS

11.1 Hydrostatic Test:

Fill line with water and vent all air from loop to be tested.

Raise pressure to 1 bar and hold for 10 min checking for leaks at flange

joints.

Raise pressure at a maximum rate of 5 bar/ min.

Continue to raise pressure till desired test pressure is reached and system

has stabilized.

Visual checks of all test gauges shall be made at all hold points.

Hold pressure for 10 min at required test pressure and then inspect all pipe

joints, weld seams, screwed connections, valves, glands etc.

If any leaks are detected pressure needs to be bled off gradually till

atmospheric is reached and leak sealed accordingly. In some cases it might

be required to drain system completely in such event draining procedure

should be followed.

File No:

CTJV

QGX2 PROJECT

CONSOLIDATED CONTRACTORS COMPANY

12.

DOCUMENT No.

REVISION No.

PAGE

OF

:

:

:

:

The minimum testing period including holding time shall be 30 min or time it

takes to complete leak detection whichever is the greatest or as per the

Project Specification. In some cases manufacturers recommendations might

dictate longer or shorter holding periods.

The test will not be conducted when the outside of the system is wet or in

rain unless instructed by contractor.

After acceptance of test all vents and drains will be opened and system will

be depressurized slowly.

Draining should be conducted in safe manner and test medium should be

drained to designated area.

Holding time may be increased as required.

Pressure and temp readings to recorded on charts by means of calibrated

recorder.

ATTACHMENTS

Test Blind Thickness Chart

JSA

Demin Water Analysis Sheet

File No:

MS-846-038

4

8

8

CTJV

QGX2 PROJECT

También podría gustarte

- Industrial Piping and Equipment Estimating ManualDe EverandIndustrial Piping and Equipment Estimating ManualCalificación: 5 de 5 estrellas5/5 (7)

- Hydrotest Check List PDFDocumento1 páginaHydrotest Check List PDFSaut Maruli Tua Samosir100% (1)

- MS For Tank Installation - R1Documento6 páginasMS For Tank Installation - R1alvinchuan100% (1)

- Procedure For Test Header CertificationDocumento16 páginasProcedure For Test Header CertificationAdeoye OgunlamiAún no hay calificaciones

- Rreinforcement Pad Leak Test ProcedureDocumento5 páginasRreinforcement Pad Leak Test ProcedureAmin Thabet100% (2)

- QGL-CE-007-Guidelines For Preparation of Hydrostatic Test Packages For Submission To QP-DC Rev2Documento8 páginasQGL-CE-007-Guidelines For Preparation of Hydrostatic Test Packages For Submission To QP-DC Rev2vinh thieu100% (1)

- Air Leak TestingDocumento5 páginasAir Leak Testingkusdiyanta100% (2)

- IPASOLINK VR4 SpecificationsDocumento30 páginasIPASOLINK VR4 SpecificationsWisam Hassan75% (4)

- MAZDA Tribute - Instrukcja Obslugi (2003) ENGDocumento245 páginasMAZDA Tribute - Instrukcja Obslugi (2003) ENGjszbpAún no hay calificaciones

- SITXHRM006Documento10 páginasSITXHRM006ajay80% (5)

- A-Qac-Pro-730-38930 Rev ADocumento10 páginasA-Qac-Pro-730-38930 Rev ARamzi ZoghlamiAún no hay calificaciones

- V-31P0-0001-A-0011 - 2 - 001 - Hydrostatic Test Procedure For Pipeline PDFDocumento32 páginasV-31P0-0001-A-0011 - 2 - 001 - Hydrostatic Test Procedure For Pipeline PDFpertmaster100% (1)

- Pressure TestingDocumento9 páginasPressure TestingSanjay SinghAún no hay calificaciones

- Iqwq-ce1092-Mpere-00-0001 - 1 Static Equipement Installation Plan (Tank)Documento17 páginasIqwq-ce1092-Mpere-00-0001 - 1 Static Equipement Installation Plan (Tank)Ali MajeedAún no hay calificaciones

- Vessel Final BoxDocumento14 páginasVessel Final Boxmanoj thakkarAún no hay calificaciones

- SA04C2-T-MET-AAG-00037 Hydrotest Method StatementDocumento25 páginasSA04C2-T-MET-AAG-00037 Hydrotest Method StatementABAID ULLAH100% (2)

- ITP - 003 - Rotating Equipment - IFRDocumento3 páginasITP - 003 - Rotating Equipment - IFRMari Belajar100% (1)

- Inspection and Test Plan For Water Tube BoilerDocumento13 páginasInspection and Test Plan For Water Tube BoilerVinh Do Thanh100% (1)

- Re-Welding, Expansion & HT ProcedureDocumento6 páginasRe-Welding, Expansion & HT Proceduresuria qaqcAún no hay calificaciones

- Hydrotest Procedure For HVAC PKG#2 (Incl. Fire Fighting) WorkDocumento8 páginasHydrotest Procedure For HVAC PKG#2 (Incl. Fire Fighting) WorkCipta Adikarya100% (1)

- Cover MDR, MDR Index Dan Pembatas (Rev)Documento19 páginasCover MDR, MDR Index Dan Pembatas (Rev)Richard Adolf100% (1)

- 1.sanitary Wastewater MOSDocumento13 páginas1.sanitary Wastewater MOSarshad iqbal0% (1)

- Hydrotest Procedure For PipingDocumento4 páginasHydrotest Procedure For Pipingsuria qaqcAún no hay calificaciones

- TP-01Hydrostatic Test Cover SheetDocumento4 páginasTP-01Hydrostatic Test Cover SheetAnonymous GaMb5H52100% (1)

- Ekulama1 Hydrostatic Testing Procedure - Rev 2Documento15 páginasEkulama1 Hydrostatic Testing Procedure - Rev 2eke23Aún no hay calificaciones

- Hydrotest ProcedureDocumento3 páginasHydrotest Procedureaman131100% (2)

- Tie in Procedure Rev. BDocumento8 páginasTie in Procedure Rev. BgenjiAún no hay calificaciones

- NT2 L3 M 000 21 00015 - Pigging - CleaningDocumento26 páginasNT2 L3 M 000 21 00015 - Pigging - CleaningHuynh Thanh Tam100% (1)

- Attachment - 7 - P158-150-PL-SPC-0003-00 - B01 Specifications For Pipeline Crossing Roads, Rail Roads and Minor Water WaysDocumento16 páginasAttachment - 7 - P158-150-PL-SPC-0003-00 - B01 Specifications For Pipeline Crossing Roads, Rail Roads and Minor Water Wayshasan shahriar0% (1)

- Erection Sequence of LNG TankDocumento29 páginasErection Sequence of LNG TankIshack MohammedAún no hay calificaciones

- ONS-09-0-PR-5254 - R3 ITP For Atmospheric Tank Work - AFCDocumento34 páginasONS-09-0-PR-5254 - R3 ITP For Atmospheric Tank Work - AFCshankarmech04@gmail.comAún no hay calificaciones

- Installation Procedure For Pressure VesselDocumento8 páginasInstallation Procedure For Pressure VesselSamuel Babu100% (1)

- 62-P-90Rev A Method Statement For Oxygen Line FabricationDocumento13 páginas62-P-90Rev A Method Statement For Oxygen Line FabricationAsadAliAliAún no hay calificaciones

- Kantas International Nigeria Limited: Generic Hydrotesting ProcedureDocumento7 páginasKantas International Nigeria Limited: Generic Hydrotesting ProcedureGbenga MoboladeAún no hay calificaciones

- Installation of Pipeline by HDD For NGN Pipeline ProjectDocumento48 páginasInstallation of Pipeline by HDD For NGN Pipeline ProjectDie HArd100% (1)

- Method Statement For CPFII Pipe Cleaning&Flushing With Air Works Rev1Documento9 páginasMethod Statement For CPFII Pipe Cleaning&Flushing With Air Works Rev1Delil OzanAún no hay calificaciones

- Method Statement - Non-Metallic Pipeline Instalation & Pull Through To HDDDocumento8 páginasMethod Statement - Non-Metallic Pipeline Instalation & Pull Through To HDDMuhammad IrsyadiAún no hay calificaciones

- Tasnee HDPE - LDPE Plant Project: Method Statement For Earthworks: Excavation and BackfillingDocumento10 páginasTasnee HDPE - LDPE Plant Project: Method Statement For Earthworks: Excavation and BackfillingFarhanAún no hay calificaciones

- Procedure Welding Part 2Documento14 páginasProcedure Welding Part 2mohammadAún no hay calificaciones

- Standard PracticeDocumento14 páginasStandard PracticeRomi Abdul RahmanAún no hay calificaciones

- Hydro Test ProcedureDocumento8 páginasHydro Test Procedurevinoth100% (3)

- 23792turret Buoy BookDocumento32 páginas23792turret Buoy BookTeck Tiong Huan100% (1)

- TIMAS-PR-PI-001 - Hot Tapping ProcedureDocumento11 páginasTIMAS-PR-PI-001 - Hot Tapping ProcedureMechanical Static WRKAún no hay calificaciones

- Method Statement Pipe Handling and AssemblyDocumento6 páginasMethod Statement Pipe Handling and AssemblyDanny NguAún no hay calificaciones

- Shop Fabrication Procedure (Supply of Tank Option#3) PDFDocumento7 páginasShop Fabrication Procedure (Supply of Tank Option#3) PDFGATOTAún no hay calificaciones

- CPP-NA2-PM-PLN-0015 Procedure For Hydrostatic TestingDocumento18 páginasCPP-NA2-PM-PLN-0015 Procedure For Hydrostatic TestingAdil Ijaz100% (1)

- 18-Weld Joint NumberingDocumento5 páginas18-Weld Joint NumberingAkhilesh Kumar100% (2)

- Construction Mos For Underground Piping: Vietnam Japan Gas Joint Stock CompanyDocumento18 páginasConstruction Mos For Underground Piping: Vietnam Japan Gas Joint Stock CompanyLai HuynhAún no hay calificaciones

- Hydrostatic Shell TestDocumento5 páginasHydrostatic Shell TestsojeckAún no hay calificaciones

- GRE Hydrotest Procedure PDFDocumento9 páginasGRE Hydrotest Procedure PDFMohammad Saif AliAún no hay calificaciones

- Tank InspectionDocumento6 páginasTank Inspectionangel onofre castelanAún no hay calificaciones

- W-c-ss-014 Steel Coating Works SpecificationsDocumento23 páginasW-c-ss-014 Steel Coating Works SpecificationswanroselanAún no hay calificaciones

- GRSM 00 Cons PL 015 Rev.2 Pipeline Tie in ProcedureDocumento7 páginasGRSM 00 Cons PL 015 Rev.2 Pipeline Tie in ProcedureAgus SupriadiAún no hay calificaciones

- 2005-6031-2L-0009 Rev.C Specification For Pipeline TestingDocumento13 páginas2005-6031-2L-0009 Rev.C Specification For Pipeline Testinghavuta100% (1)

- Technical SpecificationsDocumento62 páginasTechnical SpecificationsRamu Nallathambi100% (1)

- SHell 141185244 Blasting and Painting ProcedureDocumento51 páginasSHell 141185244 Blasting and Painting Proceduremuhamadrafie1975100% (3)

- MS For Hydro Test ModDocumento7 páginasMS For Hydro Test ModIbrahim KhanAún no hay calificaciones

- GRP Installation Procedure PDFDocumento13 páginasGRP Installation Procedure PDFpparreraAún no hay calificaciones

- Pig Launcher Fabrication Activity PlanDocumento1 páginaPig Launcher Fabrication Activity PlanbeqsAún no hay calificaciones

- Reinforcement Pad Leak Test Procedure - Method StatementDocumento6 páginasReinforcement Pad Leak Test Procedure - Method StatementJaveed A. KhanAún no hay calificaciones

- Tank Erection Procedure: Note: This Is The Sample Document For The Related Job OnlyDocumento5 páginasTank Erection Procedure: Note: This Is The Sample Document For The Related Job Onlygeorge israelAún no hay calificaciones

- MS For Pressure Test-ReDocumento9 páginasMS For Pressure Test-Reanishdev6Aún no hay calificaciones

- Procedure For Pneumatic Test Dated 29-09-06Documento6 páginasProcedure For Pneumatic Test Dated 29-09-06ravi00098Aún no hay calificaciones

- Audit ChecklistDocumento28 páginasAudit Checklistjay_rajeshirkeAún no hay calificaciones

- 4 - Choke Manifold DrawingDocumento1 página4 - Choke Manifold Drawingjay_rajeshirke0% (1)

- Choke ManifoldDocumento2 páginasChoke Manifoldjay_rajeshirke100% (1)

- Product Group Category ExternalDocumento80 páginasProduct Group Category Externaljay_rajeshirke100% (1)

- Audit ChecklistDocumento29 páginasAudit Checklistferdigodren1Aún no hay calificaciones

- Orientation Aspect and Impact TrainingDocumento75 páginasOrientation Aspect and Impact Trainingjay_rajeshirkeAún no hay calificaciones

- Well Test Procedures ManualDocumento108 páginasWell Test Procedures Manualapi-2693096593% (29)

- Ral Colour ChartDocumento2 páginasRal Colour Chartjay_rajeshirkeAún no hay calificaciones

- Sect 02 How To Conduct TalkDocumento1 páginaSect 02 How To Conduct Talkjay_rajeshirkeAún no hay calificaciones

- EFCO Valve Repair ProductsDocumento20 páginasEFCO Valve Repair Productsjay_rajeshirkeAún no hay calificaciones

- Monalisa LakewoodsDocumento33 páginasMonalisa Lakewoodsjay_rajeshirkeAún no hay calificaciones

- Actuators: Characteristics, Advantages, Disadvantages, and Applications of Each TypeDocumento41 páginasActuators: Characteristics, Advantages, Disadvantages, and Applications of Each Typejay_rajeshirkeAún no hay calificaciones

- Wed May 17 17:16:21 2000Documento22 páginasWed May 17 17:16:21 2000jay_rajeshirke100% (1)

- Valve CalculationDocumento2 páginasValve Calculationjay_rajeshirkeAún no hay calificaciones

- TeroMatec Brochure enDocumento12 páginasTeroMatec Brochure enjay_rajeshirkeAún no hay calificaciones

- Welding Inspection - Codes and StandardDocumento30 páginasWelding Inspection - Codes and StandardAdhie Sulaksono100% (2)

- In Process Inspection in Machine Shop: Unit Testing / User Manual Quality ManagementDocumento11 páginasIn Process Inspection in Machine Shop: Unit Testing / User Manual Quality Managementjay_rajeshirkeAún no hay calificaciones

- Sap ScriptDocumento15 páginasSap ScriptamarpoonamAún no hay calificaciones

- Theory of EstimationDocumento2 páginasTheory of EstimationSushil Rana MagarAún no hay calificaciones

- Electrical Multimedia 5Documento44 páginasElectrical Multimedia 5ding0398100% (1)

- Application For Banking Facilities When Studying in SwedenDocumento2 páginasApplication For Banking Facilities When Studying in SwedenFikan Mubarok RohimsyahAún no hay calificaciones

- Pres 2Documento15 páginasPres 2Karim MagdyAún no hay calificaciones

- Design of IPv6 Tactical Network Based On Commercia PDFDocumento7 páginasDesign of IPv6 Tactical Network Based On Commercia PDFVladimir OleynikovAún no hay calificaciones

- Inter VXLAN RoutingDocumento2 páginasInter VXLAN Routingsaqr8000Aún no hay calificaciones

- Mobistat Stazioni MobiliDocumento26 páginasMobistat Stazioni MobiliAnonymous 1aHRPIIFfIAún no hay calificaciones

- Acer Al1916w SM 1Documento57 páginasAcer Al1916w SM 1Anonymous C6Vaod9Aún no hay calificaciones

- COQ FormDocumento2 páginasCOQ FormDanial AliAún no hay calificaciones

- Vodic Za IMUNESDocumento54 páginasVodic Za IMUNESEntontoniAún no hay calificaciones

- URB CatalogueDocumento424 páginasURB Cataloguedruta.calin4754Aún no hay calificaciones

- DA-10287 Manual English 20121211 PDFDocumento7 páginasDA-10287 Manual English 20121211 PDFbuns301Aún no hay calificaciones

- Changhong Chassis LS18 PDFDocumento34 páginasChanghong Chassis LS18 PDFJuan CoronelAún no hay calificaciones

- Linux Processes: Process AttributesDocumento12 páginasLinux Processes: Process AttributesTarun KumarAún no hay calificaciones

- 1 Introduction To OFSDocumento22 páginas1 Introduction To OFSMalligaAún no hay calificaciones

- Automation ControllerDocumento14 páginasAutomation Controllersheraaz87Aún no hay calificaciones

- 1 62F North Wing Electrical Load ScheduleDocumento1 página1 62F North Wing Electrical Load ScheduleJoyce RoaAún no hay calificaciones

- How To Write A Movie Review (With Sample Reviews)Documento211 páginasHow To Write A Movie Review (With Sample Reviews)JosepgAún no hay calificaciones

- Construction Management Sample Drawing File PDFDocumento93 páginasConstruction Management Sample Drawing File PDFfrmarzoAún no hay calificaciones

- Web Technology Lab Manual PDFDocumento40 páginasWeb Technology Lab Manual PDFlosaferAún no hay calificaciones

- Converter ALL Purpose Worksheet (Conversions)Documento28 páginasConverter ALL Purpose Worksheet (Conversions)CharyAún no hay calificaciones

- Robinson Fan Manual 1Documento26 páginasRobinson Fan Manual 1Aykut Avcı100% (2)

- Method Statement (SHR1 MES NAP ELV 00004 - 00)Documento23 páginasMethod Statement (SHR1 MES NAP ELV 00004 - 00)waseem2016Aún no hay calificaciones

- Intro To CCNA SecurityDocumento52 páginasIntro To CCNA SecurityRatnesh KumarAún no hay calificaciones

- Primo Rogerjr ITE292 2BSIT C1 1SDocumento4 páginasPrimo Rogerjr ITE292 2BSIT C1 1SRoger PrimoAún no hay calificaciones