Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Shahi Unit 9-Libre

Cargado por

mohinig88Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Shahi Unit 9-Libre

Cargado por

mohinig88Copyright:

Formatos disponibles

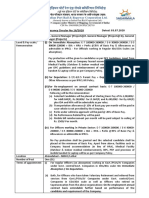

Shahi Exports Pvt. Ltd.

, Unit-9

CONTENTS

PAGES

Acknowledgement

02

1.0 Objective of the internship

03

2.0 Role of Garment Industry in Indian GDP

04

3.0 Introduction to the company

05

A. Departmental Study

4.0 Plant lay out

11

5.0 Merchandising

15

6.0 Sampling

18

7.0 Planning

21

8.0 Industrial Engineering Department

24

9.0 Fabric Store

29

10.0 Trim and Accessory Store

36

11.0 Cutting

40

12.0 Embroidery

48

13.0 Production (Sewing)

52

14.0 Washing

57

15.0 Quality Assurance

62

16.0 Finishing and Packaging

69

17.0 Human Resources

75

B. Style study

80

C. Appendixes

98

D. Project

116

18.0 Project I

Maintenance and machine movement database

117

19.0 Project II

Spare Register

132

20.0 Project III

On line implementation of finishing machine

153

21.0 Project IV

Efficiency Analysis

158

21.0 Learning Experience

167

Page 1

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

Acknowledgement

Our Internship at Shahi Exports Pvt. ltd., unit-09, Bengaluru was a fleeting journey of erudition

where we achieved an unparalleled blend of learning and experience. We would like to extend our

whole hearted thanks to the entire Shahi unit-9 Team for providing their immense support constantly.

Above all we would like to thank Mr. Sreedhar, General Manager

(Operations) and Mr. Mahadeve Gowda (AGM-HR), who made this internship possible for us. We

would also like to convey our heartfelt gratitude to Mr. Raghuveer (factory manager). Considering our

exposure to all the departments, we would also extend our thanks Mr. Bheema Reddy, (I.E and

industry mentor) who helped us in every way he could. We also thank Ms. Pavitra (HR) and Ms.

Krishnapriya (IE) for their help and support.

We would also like to convey thanks to our institute National

Institute of Fashion Technology, Kannur for arranging such an opportunity for us. We would also

extend our thanks to Mr. Chandramouli (assistant faculty and internship mentor, NIFT Kannur)

and Mr. Chakravarty (assistant faculty, NIFT Kannur) for helping and guiding us with our projects

and the documentation.

Without the help of these people, this Internship would not have been a success. So we thank them all from

the core of our heart.

Page 2

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

1.0 OBJECTIVE

Garment Industry is kind of a field where practical knowledge and personal experience matters the

most in tackling critical situations and taking major decisions. Thus on job experience is much needed

along with through subject knowledge.

The objective of this summer internship was:

To gain practical exposure on real life on job experience.

To apply the theoretical class room knowledge in practical situations.

It aims toward blending the theoretical knowledge with work experience.

To observe the process flow from order placement till shipment.

Learn the various manufacturing process.

To work on a mutually identified problem or assignment or project and work on it.

1.1 STATEMENT OF STUDY

To study the garment manufacturing process thoroughly, to observe and execute different department

functions and to execute small projects/assignments as per organizational need.

1.2 SIGNIFICANCE OF STUDY

The study will help gain hands on experience on various manufacturing processes like cutting, sewing,

finishing, checking, data generation and use of IT tools in various stages of garment manufacturing.

Page 3

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

2.0 ROLE OF GARMENT INDUSTRY IN INDIAN GDP

The garment industry comprises manufacturers of ready-made garments for both the domestic and

export markets. This sector is one of the largest employer after agriculture and its importance in Indias

economy is recognized for its contribution to industrial production and export earnings.

The Apparel Manufacturing Industry transforms fabrics produced by textile manufacturers into clothing

and accessories that fill the retail stores. By cutting and sewing fabrics or other materials, such as

leather, rubberized fabrics, plastics, and furs, workers in this industry help to keep consumers warm,

dry and in style.

The apparel industry traditionally has consisted mostly of production workers who performed the cutting

and sewing functions in an assembly line. This industry remains labor-intensive, despite advances in

technology and workplace practices. Although many workers still perform this work in the United States,

the industry increasingly contracts out its production work to foreign suppliers to take advantage of

lower labor costs in other countries. In its place, a growing number of apparel manufacturers are

performing only the entrepreneurial functions involved in apparel manufacturing such as buying raw

materials, designing clothes and accessories and preparing samples, arranging for the production and

distribution of the apparel, and marketing the finished product.

As the opportunity increases the competition also increases. India is getting tough completion from

China, Sri Lanka and Bangladesh because of cheap labour and government policies. The textile and

apparel manufacturing industries are rapidly modernizing, as new investments in automation and

information technology have been made necessary by growing international competition.

Occupations provided by the Industry

The textile industry offers employment opportunities in a variety of occupations, but production occupations

accounted for 64 percent of all jobs. Some of these production occupations are unique to the industry.

Additional opportunities also exist in material-moving, administrative support, maintenance, repair,

management, and professional occupations. The industry also employs a small number of workers in

service and sales occupations.

Page 4

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

3.0 INTRODUCTION TO SHAHI

Shahi Export House stand steeped in time. The company started its operation way back in 1974 at Delhi,

Bangalore operations began on 1st July 1988 with 250 associates and 104 machines. Expanded over 200

times in last 36 years. Today Shahi is a $120 million firm. Manufacturing with a work force of 18,000

employees out of which 70% are women. Established in Delhi, Shahi stands vertically integrated as one of the

largest manufacturers and exporters in India offering ready-to-wear garments for ladies, men and children.

Keeping in mind the demand and need to explore new markets with different product range, Shahi started its

knits Division in the year 2000 and home division in the year 2004. Shahi is a recognized Trading House and

have received many awards for outstanding export performance. Shahi is mainly recognized for its excellence

in quality, product range, service and reliability. Shahi is a privately owned but professionally managed

company with a competent core team, experienced managers to lead each manufacturing unit assisted by

production managers and merchandising heads.

3.1 MANUFACTURING CAPACITY

Shahi manufactures 6.7 million pcs of high quality wovens & knits per month and caters to all segments in the

apparel industry men, women and kids wear.

Over 4 million square feet is dedicated to the manufacturing units which are located in Delhi, Bangalore,

Tirupur and Salem.

3.2 CLIENTELE

Gap

Old Navy

Tommy Hilfiger

Guess

H&M

Pacsun

Decathlon

Debenhams

Express

Nautica

Sean Jean

Brooks Brothers

SSI

Chaps

Polo

J Crew

Target

JC Penny

PVH

Izod

Talbots

KDC

Sears

Aeo

A&F

Hollister

Liz Claiborne

Gymboree

Benetton

Kohl's

Federated

J Jill

Club Monaco

Eddie Bauer

French Cconnection

Armani Exchange

Page 5

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

3.3 PRODUCT RANGE

Menswear (MNB division)

PRODUCTS

Tops Casual Wear

Tops Semi Casual Wear

Bottoms Casual Wear

Bottoms Semi Casual Wear

Casual Non Lined Jackets

MATERIALS

100% cotton, poplins, twills, light canvas

Rib stop, Herringbone weave, Bedford cords, Sateen weave

Madras, special madras, seersuckers, dobbies and jacquards.

Mill made checks and stripes

100% Linen, checks and stripes, solids

Blended fabrics with chief value cotton blends, in solids, checks and stripes

Corduroy, Velvet

Womenswear Ladies Fashion Division

PRODUCTS

Blouses

Dresses

Skirts

Tunics

Camp Shirts

MATERIALS

Cotton Twill, Canvas, Cambric, Poplin, Voile, Jacquard, Texture, Yarn Dyes

Cotton Spandex

Cotton Nylon Spandex

Cotton Poly Spandex

Ringed Denim

Synthetics: Moss Crape, Terry Voile, Georgette, Burnout, and Velvet

Page 6

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

Womenswear Ladies Specialty Division

PRODUCTS

Woven Casual Tops

Woven Casual Bottoms

Knitted Tops

Wrinkle Free Shirts & Blouses

Dress Shirts

Denim Wear

MATERIALS

Cotton Voils / Cambric / Poplin / Twill / Denims / Wrinkle Free

Yarn Dyed / Jacquard / Velvet / Viscous / Dobby's / Schiffly's

Corduroy / Stretch / Georgette / Chiffon

Womenswear Bottoms

PRODUCTS

Chino shorts and pants

Cargo shorts and pants

Lounge pants

Basic Skirts in heavy weight fabrics' up to 9 0z

Cargo skirts

MATERIALS

All cotton woven fabrics like twills, canvas, rib stop, herring bone weave, Bedford cords,

corduroys, sateen weave etc.

Page 7

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

3.4 INFRASTRUCTURE

Shahi has more than 30 state of the art manufacturing facilities. The total production capacity of the

company is around 6.7 million per month (both woven and knits). It has over 24000 machines.

Washing and embroidery facilities of Shahi are the best in apparel sector in India. More than 90

Multi-head computerized embroidery machines having capacity of 40 billion stitches per month. 100

Front loading washing machines having facility of over 50 tones of garment per day. State-Of-theArt fabric processing/dyeing/printing plant.

The entire Shahi organization works on a single ERP system, which unifies the working of all the

departments. The ERP, Movex, is cross-functional and enterprise wide. This allows to typically

handling the manufacturing, logistics, distribution, inventory, shipping, invoicing, and accounting in

the company. This also synchronizes all business activities like sales, delivery, billing, production,

inventory management, quality management, and human resources management.

Through Enterprise Resource Planning, Shahi has amalgamated the company's information

systems & have designed it to bind more closely all company functions including human resources,

inventories and financials while simultaneously linking the company to customers and vendors.

Modules like CRM, SRM, SCM and EPM not only give efficient services to customers but also help

to deal effectively with suppliers.

Awards

Best exporters Award from AEPC

Best Vendor of the year rated by Wal-Mart/JC Penney/ Target.

Best Manufacturing facilities rated by NIFT.

3.5 SHAHI IN BANGALORE

Bangalore operations of Shahi started on July 01, 1988 with 250 Associates and 104 machines.

Since its inception Bangalore, operations have expanded by 50 times in 20 years.

All activities in woven section are being monitored by zonal head office i.e. Unit 7 as it is a

centralized organization. Major decisions in departments like merchandising, executive planning,

sourcing etc are being taken and executed by this unit only and informed to the other units as and

when required.

Page 8

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

NAME OF FACTORY

Shahi Exports Pvt. Ltd.

FACTORY CODE

Unit-09

YEAR OF ESTABLISHMENT

2008

DATE OF COMMENCEMENT OF

2008

PRODUCTION

SECTOR

Private Ltd., Export House

ANNUAL TURNOVER

Rs. 150 crores

EMPLOYEE STRENGTH

4000 capacity, currently-3,100

HEAD OFFICE

Shahi Exports Pvt. Ltd, Unit-7 (Bengaluru operations),

Shahi Exports Pvt. Ltd, Faridabad (All operations)

FACTORY ADDRESS

th

Shahi Exports Pvt. Ltd, 171, 7 Main Road, Industrial Suburb, Peenya

2nd Stage, 3rd Phase, BBMP ward no. II, Bengaluru- 560058, INDIA

PRODUCT CATEGORY

Ladies Specialty Division (LSD & LFD)- Tops, dresses etc

FABRICS BEING HANDLED

100% cotton, Cotton spandex blends, Cotton satin blends, Silk, Chiffon

Cotton polyester nylon blends.

Centralized decision all major mill made and power loom

FABRIC SUPPLIERS

suppliers in India and abroad, Main suppliers include Arvind,

JCT Textiles, Indus Fila, Bombay Rayon, Alok Industries, Henly

Ltd, Vardhaman Ltd etc.

CLIENTELE

All major brands in USA and Europe. Refer page 5.

MONTHLY PRODUCTION

3,00,000/ month

CAPACITIES

Page 9

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

Departmental Studies

Page 10

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

4.0 PLANT LAYOUT OF UNIT 9:

Shahi unit 9 has a total area of 100000 square meters. It is a production unit having four floors and a

basement facility for washing and other departments also. The roof top is designed for the canteen

facility and training purpose.

Ground Floor (Not to scale)

Page 11

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

Floor 1 to 4 (Not to scale)

Page 12

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

Basement (Not to Scale)

Page 13

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

The plant lay out has designed in order to effectively utilize the entire area. As shown in previous

diagrams it can be figured out easily that each floor has entire set of processes that makes each floor

self sufficient to some extent.

The details of each floor are:Basement: Trim store, Maintenance Department, Washing unit, Dispatch zone

Ground Floor: Fabric store, Sampling, CAD, Cutting, Embroidery, IED, Planning and other

administrative staff.

1st Floor: Sewing (Production), Finishing, Packaging.

2nd Floor: Sewing (Production), Buttoning section, Finishing, Packaging.

3rd Floor: Sewing (Production), Buttoning section, Finishing, Packaging.

4th Floor: Sewing (Production), Buttoning section, Finishing, Packaging.

5th Floor: Roof top designed for canteen and training of operators.

1st Floor

2nd Floor

Basement

Ground floor

3rd Floor

4th Floor

Material Flow in between the floor

Page 14

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

5.0 MERCHANDISING

Merchandising is a process through which products are planned, developed, executed and

presented to the buyer. It includes directing and overseeing the development of product line from start

to finish. Marketing and merchandising department: A team of merchandisers and marketers work

together under a profit controls head. Merchandisers handle the foreign buyers. The teams are made

according to the buyers being handled.

Two type of merchandising done in garment exports

Marketing merchandising.

Product merchandising.

5.1 Marketing merchandising

Main function of marketing merchandising is

Product Development

Costing

Ordering

Marketing merchandising is to bring orders, costing, product development and it has direct contact

with the buyer.

5.2 Product merchandising

Product merchandising is done in the unit. This includes all the responsibilities from sourcing to

finishing i.e. first sample onwards, the products merchandising work start and ends till shipment.

A Merchandisers key responsibility is as follows:

Product Development

Selling the concept

Confirming Deliveries

Market and product Analysis

Booking orders

Costing

Flow Monitoring

Raw Material

Production Follow Ups

Payments Follows

Designing and Sampling

Page 15

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

5.3 Department structure

MARKETING MERCHANDISER

HEAD MERCHANDISER

SENIOR MERCHANDISER

JUNIOR MERCHANDISER

In an export house, merchandising is a combination of business and technical aspects. Senior

merchandisers have responsibilities of products development and coordinating with the buyer, the

garment styles that meets buyers expectations in regards to delivery, quality, and price point. Junior

merchandisers have the responsibility of handling paper work and follow up, detailing with buyers,

overseas communication etc. Once the order is placed it is their duty to complete the necessary paper

work, provide breakdown information to all other department and get samples approved for fit, color

and quality. Communications with overseas and domestic suppliers, approval of production samples,

and development of fabric and yarns are also included in product development, which are cocoordinated with other departments. Merchandisers have to negotiate with the buyers on pricing, work

out delivery schedules, and investigate for future buyers. Overall we can say that merchandising is the

core department of the entire industry.

5.4 Costing

The most important activity for the merchant is to estimate correctly and negotiate for the cost of

production before the buyer sends on the PO. During the pre-development stage an initial costing

occurs to get an idea of the garment cost likely to be incurred per piece.

These costs includes general raw material cost, manufacturing cost, washing cost, markup cost etc.

Once the production sample is approved and the grading done a final costing is done accurately using

fabric averages from the CAD, cost of trims etc.

Page 16

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

Start

Obtain tech pack from buyer

Costing

Analyze fabric

consumption from

CAD

Sampling

Analyze cost of

trims and

fabric

Obtain general

sewing data from

IED

Develop sample as

per the tech pack

Prepare cost sheet

from sample

Develop proto

sample

Cost sheet & sample sent to buyer for approval

Confirmation

of order

Obtain PCD &

details from

production unit

Source trims &

fabric from

concerned dept.

Yes

No

Approval

Book washing &

embroidery capacity if

required

Cost sheet

reworked

Obtain GSD

from IED

Execution of order by entering details in ERP

Prepare sample as per buyer requirements

Forward the sample to buyer for approval

Hold pre production

meeting with the

production unit

Execute

bulk order

Yes

Follow up with

production

departments &

update the buyer

Approval

Submit required

documents to

documentation

dept

No

Comments received from buyer

should be incorporated and fit

sample reworked

Offer garments

for final

inspection.

Truck out

Follow up

on the

payments

for goods

End

Page 17

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

6.0 SAMPLING DEPARTMENT

In any export house, the sampling department is one of the most important departments and it plays a

vital in the uplifting of a unit.

Sampling department directly co-ordinates with the merchandising and production department.

Sampling is done to see how the product will look like when produced in bulk and to check whether

there are any discrepancies in the pattern are made according to the buyers specification.

Merchandiser procures order from the buyer. The buyer sends spec sheet, sketches, fabric details,

embellishment details, stitch type etc to the merchandiser. Merchandiser files this information along

with the details regarding costing, average, proto, fit, correction, size set and approval in to a style

package and hands it over to the Sampling department head.

Sampling is the product development stage. It is a process by which a small number of garments are

made so as to match the buyer requirement and to get approval from the buyer so as to start off the

production. The sample garments represent the accuracy of the patterns and quality of production skills

and techniques. The samples not only serve the purpose of communicating correctly with the buyer

regarding their styles and products, but it also helps to calculate the fabric consumption along with that

of thread and other accessories used.

It is different from bulk production as here each tailor is multi skilled. This department makes samples

on the basis of specifications and requirements sent by the buyer in the tech pack.

6.1 TYPES OF SAMPLES PRODUCED IN UNIT 9

Proto Sample.

Pilot Run Sample.

Shipment Sample.

Fit Sample.

Size Set.

Sales Sample.

Page 18

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

6.2 Machine details and workforce

The size of the sampling room is quiet less in unit 9 as it does sampling for some specific styles which runs in

the unit and others are done in head office. There were a total of 50 machines in the sampling department of

unit 9.

50 operators

2 pattern making tables

One CAD specialist

Two assistant Pattern makers

1 cutting tables

2 ironing tables

One Pattern Master

60 workers

6.3 The Details Attached to the Garment Sample

After the confirmation of order, each sample sent to the buyer has the following details attached to it,

with the help of a tag. It contains the details pertaining to both, what the buyer has demanded and what

supplement fabric/trim etc they have used (if applicable).

Ref no.

Fabric

Description

Style no/ Size

Color

Composition

Quantity

Store

Page 19

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

Page 20

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

7.0 PLANNING DEPARTMENT

Planning department has a vital role to play in the approval of the order and helps the merchants. The

major function is to determine, whether the company is capable of producing the particular style in the

given span of time and also helps them to know the capacity of the production floor.

Shahi has a centralized planning department which does the main planning and allocates the styles to

the particular units according to its capacity of that unit. In Shahi unit 9 there is only one planner who

co-ordinates all the planning processes with the central unit. Thus when unit -9 gets an order, it does

Start

On receiving the orders, allocate the same to units

based on line openings and buyers ratings

Provide details to the respective units on PCD,

order quantity & sample

Take inputs from IED on

productivity based on

garment analysis

Confirm the above details given

to concerned units in consultation

with GM & FM

Confirm in consultation

with embroidery,

washing departments

Confirm order plan with merchandising team

Provide MISreport to management every

fortnight

Planning follow up with factory till order

execution

End

the planning according to the current capacity of the unit.

Page 21

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

7.1 Detail Function:

On receiving the orders, from the merchants they start to

decide the date for having the PP (Pre-Production) meeting with the departments which are directly

involved with the planning, production and the finishing departments. Then the department will allocate

the style to the unit whichever has the capacity of completing the obtained project based on the line

openings and also buyers specifications and the skill of labor required for it.

The planning department then calculates and plans the PCD (Production commence date),

Order Quantity, Sample, order breakup, operation bulletin, etc. with respect to the particular unit in

which that particular order has been placed with.

The planning department takes the approval and conducts a meeting with the other

departments to come to end up giving a proper planning and scheduling dates for the particular style

which takes about 10 15 days.

Firstly, they take inputs from IED (Industrial Engineering Department) on productivity based on

the garment details which includes, SAM value of the garment, number of components in the garment,

type of seams, length of stitches involved in the garment, types of machines required to finish the

garment, any specialized machine is required or not for the manufacturing of the garment, difficulties

involved during stitching of the garment if it is of a complicated style and structure, the skill level

required for the various operations of the garment and the ratio of the operators with respect to their

skill levels required for manufacturing the particular garment for all the operations all together. Then

they finally come to a conclusion about planning entire style.

Secondly, they confirm the details given to the concerned units i.e., they confirm the PCD, Order

quantity, sample and other similar information from them in consultation with the GM and FM.

Thirdly, they confirm this consultation if it is the final decision and then they also get a

confirmation from the embroidery, washing and finishing departments if the slots for the dates on which

they have planned for those particular styles is available and then after confirmation they fix the

particular dates on which the style has to reach the embroidery, washing and finishing departments.

After, a proper output has come from the PP meeting and there are proper confirmation

obtained from the departments the planning department will confirm the order plan with the merchants

and then provide MIS (Management Information System) report to the management every fortnight,

then they prepare a Batch Commitment Sheet and this sheet is prepared about 3 5 days before

the cutting date. This commitment sheet includes the details regarding the batch that has taken up the

job of producing the particular style, the quantity which they are committed to produce for a day and the

labor details (which involves the number of operators and to which operation they are assigned to and

Page 22

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

they skill level will also be mentioned). This sheet will have to be updated once in an hour to know the

hourly production of the batch.

Then there exists another kind of a sheet which is made that is a Batch Variance Sheet, this

sheet is completely based on the Batch Commitment Sheet and in this sheet the updating of the style in

the production floor is done and is given to the merchants on daily basis.

Then the planning department will follow up with the factory till the order is completely being

executed and the entire order quantity is being shipped.

The planning department is responsible for the timely input of the raw materials to the

production floor and they must make sure that none of the days the batch /sewing line must sit idle with

a reason of raw material non-availability.

The planning department keeps in constant touch will most of the departments like the IED,

Finishing, Washing, Production, Marketing, etc., the communication within the different departments is

done purely on the mail basis and sometimes through phone calls but any types of mails regarding

the changes in the line of the style or any such modifying sort of a situation then the department

maintains a hard copy of it for the future reference and confirmation.

7.2 Work Force:

Shahi unit 9 has only one planner who co-ordinates with the head office and the particular unit and

decides all the major planning activities in the unit.

Page 23

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

8.0 INDUSTRIAL ENGINEERING DEPARTMENT

The Industrial Engineering Department works on the basis of the following definition of Industrial

Engineering is, it is a systematic approach for

Design

Installation

Development

Implementation and Maintenance of the integrated system of Man, Material and Machine/

Equipment

The industrial engineering department works for their optimum utilization for the higher productivity of

the organization with ultimate goal of earning better profit.

The tech pack made by the IED for a particular order has been shown which consists of the following

details of a particular order,

Batch layout

Operation process chart

Operation bulletin

Critical point analysis

Cutting instructions

8.1 Department Structure:

General

manager

(operations)

Industrial

engineer

(senior)

Industrial engineer

(sampling executive)

Industrial engineer

(production)

assistants

Page 24

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

Start

Training, selection &

development

Systems

development

Work Measurement

Selection of operators,

helpers, supervisors,

checkers, QC, etc.

Time study

Method

study

OPD

Analysis

Skill matrix

Line

balancing

Batch layout

Style

bulletin

Batch

performanc

End

8.2 Function:

The IED department has to work with many other departments as this department gives the

entire idea of the garment construction and the thread and trims consumption criteria, operators skill

level categorization and other related aspects. Hence they play a vital role in determining the cost of

producing a single piece of the garment and cost of the factory for that particular style of garment.

The different departments with which the IED works are as follows:

Planning department - The IED department helps the planning department to know the time

required for the production of that particular style of the garment by calculating the SAM value for it

and they also help in finding the capacity of the factory based on which the planning department

takes a decision if they have to proceed with order or not.

Page 25

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

Merchandising department- The IED calculates the SAM value for the garment, calculates the

productivity of the given style for the initial costing and also calculates the accessories consumption

by the style and gives all these details to the merchandising department for the costing purpose

and it also gives the merchants suggestions regarding the reduction of the cost of manufacturing

the garment by modifying any of the steps and the method of doing it.

Research and development team-The IED people using the General Sewing Data (GSD) prepare

the style bulletin which includes the different types of seams and stitches that has to be done for the

garment and it also includes the length of the seams and the types of stitches that has to be carried

out at different places of the garment as per the buyers specifications and approval. Types of thread

(which is the TEX), area of placement of the trims and accessories and its location different kinds of

labels that are supposed to be placed, the criteria under which the finished garment has to be

checked, the times at which the inspection has to be carried out will also be mentioned in the style

bulletin, this bulletin will be similar to the Tech Pack but contains more technical data than that.

Human resource department -IED department will analyze and estimate the manpower and their

skill level which is required for the production of the garment. They also set a target to the batch for

an hour, for a shift and for a month which will help them to maintain their outputs and also helps in

timely completion of the order or sometimes earlier. They will also give the target to each operator

based on his/her capacity and skill in order to help them finish their piece of work on time and also

maintain the quality of their work.

After setting the targets for a batch and also for each operator then they will calculate the

efficiency. This efficiency is purely based on the daily output of the batch as well as the single operator

and then they come up with the monthly output by the particular batch.

This department maintains a file which is the DPR (Daily Production Report), in this report they

update the batch number, style/item number, actual output, committed output, SAM value of the

garment (both actual and that particular days SAM value), total production till date, average efficiency

of the batch till date, peak efficiency achieved, if the company was working that day or not, if there was

a delay of production then the reason behind it, information about the batch setting prior to the mass

production, etc., all this will be mentioned in this DPR.

Based on the operators performance which would have been observed for a specified period of

time, the department will allocate a grade to the operator which is as follows:

Page 26

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

Skill type

Grade

Highly skilled

Skilled

Semi skilled

The operators for each batch are taken in a ratio given below:

20% - Highly Skilled

25% - Skilled

50% - Semi skilled

Note: This is done irrespective to any style and buyer and the complication of the style.

A record is maintained in which the skills of operators are updated on timely bases. Because of

maintaining this record they keep in track of the operators skill and his efficiency, working method and

after a particular span of time they update the record.

Suppose a new operator joins and he is completely unaware of stitching then a training for

about 45 50 days is given to him/her and then based on their learning and grasping capacity a grade

is been allocated to them primarily. Suppose the operator/new employee knows or has a previous work

experience in a garment industry then he is just been asked about his job which he/she would have

done in the previous factory and then he/she is just given an hours test to know his skills and then

grade is been allocated.

Everyday the IED team there will be a meeting where in which they speak about the

maintenance of efficiency of the batch in the production floor. They also conduct a production review

meetings with the operation team in which they discuss about the line and the operation carried out in

the batch suppose the previously planned flow is not giving the estimated efficiency and output then

they will think of changing the line plan and review it and later follow the right one.

Page 27

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

8.3 Process followed of the IE department:

Once a style comes to the industry, the industrial engineering department gets into action. The IED

starts with the style study and analysis of the style which includes estimation of the work content for

each department (cutting, sewing and finishing), the machinery requirements for the smooth

functioning of these departments. The industrial engineering department then calculates the

process cost the style and compares it with the budgeted cost given by the head office. Finally, it

takes care of the special machines required for the particular style.

After the order is confirmed, the IED reanalyzes the style and find ways for method simplification

with factory managers and other concerned people. This result in a finalized operation bulletin and

the SAM and SMV are fixed.

Preproduction activities- This is the part where the sampling executive of the industrial

engineering department contemplates the special skills required for the style, required grade levels

of the operators and training them for specific jobs. This phase also takes care of the layout of the

batches for the style.

Now the implementation and execution of the style commences. In this process, the IE department

plans for the change-over of the new style from the previous running styles. It also calculates the

capacity and efficiency of each and every batch were the new style would run. They also effectively

synchronies each section of the batch so that idle time can be reduced both for the machinery and

operator.

Page 28

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

9.0 FABRIC STORES DEPARTMENT

The fabric stores department is centralized in unit-7 and all the fabric comes to this unit first from the

supplier and audited here and kept until it is distributed to other units.

9.1 Function:

Once the raw materials or the fabric is been sent by the supplier to the company and once they

reach in-house the concerned person keeps the track of all the documents and material, he/she checks

the quantity of the material in-house and the material ordered and cross checks i.e., he checks the

materials against invoice/ DC / Packing list.

After confirmation he enters the details in the ERP (MOVEX) in the GRN (Goods Received

Note). After preparing the GRN they have to do the bill entry and keep the record and maintain the

document of whatever the slips received or delivered.

Then the entries are forwarded to the head office for the checking and payment. Then after

preparing the GRN of everything that has been received a process selection is been made which

involves two steps that goes hand in hand. They are described as follows,

9.1. A Checking:

In this step the work order is being prepared and also the delivery of goods and the formalities

regarding the goods has to be carried out. All this happens in the process of receiving the goods to inhouse, there has to be another action which the fabric stores has to take care of is the situation of

delivering the fabrics to the other units and also to the cutting department of the same unit.

This department receives the required documents of production issues/ exports and similar

other related aspects from the merchants and then as soon as they receive this they enter the details of

the PO/ Export / Process follow ups into the MOVEX.

The department then checks the material availability with respect to the PO and other

documents as per the merchants given details. Then they look at the production issues / Export and as

per that two things are done. First, they pick the material as per the approval that would have been

given by the Fabric audit department and then they prepare the delivery challan and keeps it ready for

issue to the unit. Finally, at the end of both the cases the materials has to be issued after its inspection

by security line with DC that would have been given by the fabric audit department. This fabric audit

department will play a role in both issuing the materials. The fabric audit and the fabric sourcing

department in the unit 7 is the centralized unit and it holds the responsibility of collecting the raw

materials on behalf of all the other units and then distributes among them as per their order

placements.

Page 29

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

Job instructions for fabric stores department:

Receive fabric from central

warehouse and check against the

delivery chalan.

Check for center selvedge and end

to end variation for each roll.

Check for cuttable width of fabric for

each and every roll.

Prepare shade band and send to

merchant for approval

For shrinkage test of

100% rolls/ takes cut a

50cm X 50cm of fabric.

Approval

of shade

band

No

Inform merchant

reject rolls

C

Yes

Is

shrinkag

e <= 4%

Sanforization

Check 10% of received fabric lot for

using 4 point system

Scored

point<=

40

No

Check 100%

Yes

Compile two test reports send 1 to

pattern making and other to cutting

End

Page 30

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

The workflow after fabric is received from the supplier to the factory is as follows: In-house storage of the fabric

Inspection (making lots according to the shade, Four point inspection is done)

Shrinkage test is also done (In-house report preparation)

Report sent to the buyer for approval

Buyers comment received

If the test report and buyers comments are ok

Then fabric is issued for cutting

9.1. B Fabric inspection

Complete visual inspection is being done. There is no systematic recording.

defects.

Defects like weaving or colored patta are recorded without measuring the dimension of the

If fabric inspection is not done carefully, so there are chances that all defects may not to be

recorded.

Fabric inspection reports are at the discretion of the operator only.

Fabrics coming in lots are not taken for a second inspection.

Defects are recorded at the end of the inspection, as this may lead to mistakes.

The 4-point inspection system is followed for the fabric inspection.

Page 31

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

Fabric Audit Flow chart

Fabric and document receipt

Verification of details: colors, total

rolls, quantity.

Cutting the shrinkage, shade, csv

sample

100% width and shade segregation

Fabric and document receipt

Grouping

Pass

Fail

Numbering

100%

inspection

Shade approval

Writing shades on rolls.

Place on the rack for issue for cutting

In Movex making put away.

Page 32

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

Instructions for shade segregation at fabric store.

Cut 1 meter from each roll

Segregate cut piece into family of shades

Send one half for washing and retain another

half

After receiving the washed pieces organize the

pieces as per the family of shades after wash.

Prepare shade band and send to merchant for

approval

NO

Inform the

merchant and

reject the

rolls/ takkas

Are shade

band

approved?Yes

Give one unwashed color continuity

card to cutting and sewing and one

card to finishing and FSA

Cut the Pcs in A5 size and make 4 color

continuity card each for washed and

unwashed

End

Page 33

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

9.2 Four point fabric inspection system

The four point system has received the widest acceptance in both the textile and garment industry. It is

simple and easy to understand and execute.

The amount to inspect is at least 30% of the total fabric received. Rolls to be selected for inspection

should be at least 3 roll from each lot.

9.2. A Defect Classification:

The four point system classifies defects as shown: Length/Size of the defect

Penalty

3 or less

1 point

Over 3, but not over 6

2 point

Over 6, but not over 9

3 point

Over 9

4 Point

Major defects that are encountered are: 1. Weaving

2. Dyeing (patta, center selvage, streaks)

3. Prints (print repeat, pattern/ design, choke ups) etc.

A maximum of four points is charged to one linear yard. In this system the length of the defect is

measured to determine the penalty points. The four-point system provides for the evaluation of the

fabric on either a linear yard or square yard basis. As the fabric with more width, will have more area.

Or we can say that a 72 wide fabric will have twice the area when compared to a 36 wide fabric. As

the area of the fabric is more, this is obvious that the fabric will contain twice the number of defects.

Formula for calculating the number of defect points per hundred square yards: Total defect points found x 3600

Defect points per hundred square yards =

Fabric width (inch) * fabric length (yard)

Page 34

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

When rolls are checked according to this system and points are calculated. This again is a matter of

agreement with buyers clothing manual. Some buyers working on low price prints can accept fabric

with DHU as high as 40-44 points. On the other hand it is like: 1) 20-25 points Acceptable with most buyers

2) 25 & above 35 Discussed with buyer & decided.

3) 35 & above Normally considered as reject.

Accepted rolls of fabric are then sent to the cutting room.

9.3 Record Maintenance

There is a record register that maintains all the information related to the fabric rolls that come in the

store and that are issued out of the store to the production department.

9.4 Machinery and workforce and other details in fabric store, unit-9

Fabric inspecting machine: 1 in number, Ramsons,

Shade segregation/dark room: 1 light tester for dark room.

and other technical testing, 1 quality controller, 1 operator for erp and record maintenance.

Receiving procedure: DC Slip from central unit or supplier

Work Force: 1 Store Manager, 5 Fabric checker, 6 helper, 1 IED assistant for shade segregation

Capacity of store: 2, 50,000 meters

Issuing Procedure: Issue slip as per lay record.

Daily Inspection output: 6, 000 meters.

Fabric storing criterion: Buyer wise, Shade wise both in rolls and takkas.

Details on the label attached fabric roll: Fabric code, Color, Item number, Buyer, Roll number,

Marker, Width, Shade.

Page 35

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

10.0 TRIM AND ACCESSORY STORES DEPARTMENT

The basic function of the trims and accessories section is to stock buttons, laces, trims and other

related accessories. The stock is let out depending upon the order and the requirement of PPC

department or the merchandising/sampling department. The workflow is quite lucid here. First the

department that needs a particular material fills up a requisition slip for the same. It is then forwarded to

the stores manager, who then approves the demand depending on his discretion.

The accessory stores here are the central stores in the unit-7. The accessory stores generally

receives the materials from three different locations and they can be classified into,

Faridabad

Domestics

Imports

The acceptance of the raw materials or the accessories is generally done in terms of documents i.e.,

whatever it may be whether acceptance and receiving whenever they are done they are done

according to the documents that have been received from the merchants and also department makes

the document for anything they carry out within the store.

The department first receives a PO copy from the merchants, which the merchants would have

sent it to any one among the three above mentioned supplier types. As soon as the accessory

department comes to know about the date on which they will receive that particular material they will

make a note of it in their MOVEX that they will be receiving that material and this is termed as PRE

GRN.

Once the material reaches the stores on the prescribed day and date the concerned person verifies the

materials against invoice/ Delivery Challan and packing list which they would have received from the

merchant as already stated.

10.1 Standard operating procedure in trim store, unit 9

Receive invoice and LR (Lab report) copy from head office.

Enter the details in securing register.

Check LR details with physical quantity.

Check the carton quantity.

Page 36

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

Check the weight of consignment.

Cross check PO copy with reference to item number.

Prepare a trim card for approval.

Send material for storage.

Pass invoice account for billing.

Check the trims with respect to invoice details.

Cross check PO description with reference to material description with quantity.

Send entire goods to quality department (1.5 AQL or as per the buyer demand).

Data entry into system.

Issue as and when required.

10.2 Manpower, machines and other details of trim store unit 9:

Work force: 1 store in-charge, 1 assistant, 1 quality controller, 6 issuer, 3 helper.

Trims stored in unit-9: Button, Zip, Thread, Labels, Lace, Poly bag, Price tag, Hangers, Seizers,

Cartons, Other stationary items like files, issue slips and records.

Segregations Category: Buyers wise, Purchase order wise.

Major buyer shelves: Wal-Mart, JC Penny, Espirt, H & M, Target, Mango, AEO

Major AQL followed: 1.5-2.5

Page 37

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

Start

Accept & receive materials against documents

Prepare PREGRN

Verify materials against invoice/ Delivery challan & packing list

Carry out quality & quantity inspection as per AQL 1.5

Allocation of trims based on the nature of the item

Prepare GRN & do the bill entry. The same is

forwarded to accounts for payment

PROCESS

SELECTION

PRODUCTION

ISSUES

Prepare work order

Identify trims which have been

approved by merchants

Prepare delivery challan

Prepare delivery challan & keep trims

ready to issue to the factories

Forward trims along with

documents for processing

Materials to be issued after

inspection by security against DC

End

Page 38

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

After it is confirmed that the received materials is according to the documents then they carry out a

quality inspection and this inspection is carried out irrespective to the type of the buyer. The company

carries this inspection as per AQL standard 1.5 for all the types of goods received.

The AQL is defined as follows:

Example:

If an order is 10,500 units. When using General Inspection Level II, the factory learns from the second

chart that this quantity order equates to "M". The factory then goes to the first chart and sees that for

"M" they should inspect 315 garments. If they want a 2.5 AQL they can have 14 defective units or less

from the 315 that they inspect. If they have 15 defective units or more they are rejected. If they want a

4.0 AQL they can have 21 defect units or less to pass and they have 22 defects they will be rejection.

The defects are based on defective units (defective garment). It is not based on each actual defect on

the garment. For example, a shirt may have 3 different defects on the shirt, but this is only registered

as "one" defective garment.

After inspecting the materials for the quality as per AQL then the allocation of trims based on the nature

of the item.

Then the department prepares the GRN according to the materials received and against the

documents received obtained from the merchants and they also do the bill entry. The bills whatever

they enter is been forwarded to the accounts department for the payments and to fulfill other formalities

and a copy of it is also given to the sourcing department in order to inform them about the materials inhoused.

After this the department has to carry out two processes hand-in-hand they are,

Process selection :

In this method they prepare the work order and also the delivery challan and then they keep all the

documents and also forward the trims along with the document for processing.

Production issues:

Another thing that they have to do is identify trims which has been approved by merchants and then

prepare the delivery challan and keep the trims ready to issue to the factories. Materials to be issued

after inspected by security against DC as already mentioned.

Page 39

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

11.0 CUTTING DEPARTMENT

The cutting department does two major operations given below :

1. Firstly when there is a pilot run production for a smaller quantity say about 150 500 pieces.

2. Secondly during the mass/bulk production.

Job instructions for cutting department

Receive fabric from fabric

audit

Inspect whether the marker length is same as fabric

width before cutting

A

Proceed with spreading and

cutting for pilot run .150 Pcs

max.

Yes

Receive pilot run

comments

NO

If width is

correct

No

Report to cutting

head for revised

marker

Proceed with spread for

bulk

Randomly check the fabric while

spreading for:

Is correction required?

YES

Make alternate patterns

Qc form for

cutting

Marker edge parallel to selvedge.

Alignment of fabric

Tension

Count

Shade

Page 40

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

Record in QCform provided

Proceed with cutting operations.

Randomly check for:

Mis-cut

Notches

Match top, middle & bottom

plies with pattern.

Proceed with numbering for

shade wise sticker.

Fusing (As per test report

maintain temp., pressure&

time

YES

Quality

check

NO

Quality

check

Inform QAM

and cutting

manager

NO [Inform QA and cutting manager]

Bundling

Final audit

Feed to sewing floor as

required

Page 41

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

WORK PROCESS FLOW OF CUTTING DEPTT

FABRIC RECEIVED FROM FABRIC DEPTT CUTTING

RE-SORTING OF FABRIC AS PER LOT /SHRINKAGE/WIDTH

CUTTING APPROVEL BY Q.A

RECEIVING OF MARKER

CUT ORDER ISSUE

LAYING OF FABRIC

CUTTING (CAM / MANUL)

NUMBEREING

EMBROIDERY (IF REQ.)

FUSING (IF REQ.)

RECUTTING (IF REQ.)

Page 42

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

BUNDLING

QUALITY

AUDIT PASS

DESPATCH TO SEWING FROM SUPER MARKET

Cutting is a process of separating parts from the fabric as the pattern pieces in the marker for assembly

operations. This is carried out in the cutting room-an area, which normally indicates the activities of

marker planning, spreading and preparation for sewing as well as being used to refer to actual cutting

of garment parts from the lay. Marker planning is done in the CAD room. Garments are cut in bulk

simultaneously for which a lay is created; with a number of plies spread one above another. The marker

from CAD is fixed over the lay and it is cut with help of powerful electric cutters, or CAM m/c following

the lines of the patterns. The main objective of the cutting department is to cut the parts accurately and

economically and in sufficient volume to keep the production units supplied with work.

11.1 Basic work flow

Fabric requisition sheet

CAD mini marker

Marker planning Length of lay etc., size ratio and colors in which the patterns are to be cut

Along with this and approved sample and patterns of all sizes or the marker are also sent. The

cutting department checks the fabric status in the store and acquires it whenever the production

manager sends the cut order. Firstly 2-3 samples are cut from the pattern (medium size) sent by the

CAD room to check for any amendments in pattern. These activities are co-coordinated by the R&D

department. When the patterns are amended the production manager gets a size set cut and these

pieces are stitched and the QC on the floor locates any discrepancies related to pattern in the

stitched garments. Report with comments for alteration in the patterns is sent if needed the pattern

master allocated to that style corrects the patterns accordingly. The marker planning is also done

afresh to incorporate the changes. Only when the production manager is sure of the base pattern,

will he issue the job order for bulk cutting.

Page 43

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

All the fabric is not cut at one go. Rather it is cut as and when required by the production department

against the job order. The cutting department calculates the fabric quantity required the number of

pieces mentioned in the job card using the average given by the CAD department. About 5% is cut

more than required to make up for defective pieces or wastage in production. The cutting room

provides 1.5 days to 2 days of WIP to the production floor.

11.2 Bulk cutting process

11.2. A Solid cutting

Spreading

Spreading is a process of superimposing plies of fabric on a horizontal table in a manner, which permits

these plies to be cut simultaneously into product components acceptable for assembly. For this, first of

all a thin brown paper sheet is pasted on the cutting table using an adhesive tape to prevent the bottom

plies from shifting during cutting. Then the actual spreading process begins with the laying of first fabric

layer on this brown sheet and subsequently the other plies are laid.

The spreading of this lay is done either manually or automatically by the spreading machine. While

manual spreading is time consuming, the use of travelling machine gives faster and more accurate

results. The length of the lay depends upon the quality (also shade and shrinkage) of the fabric & length

of the marker as specified by the CAD. Whereas the lay height depends upon the thickness of the

fabric and the capacity of the machine.

The lengths of the plies being spread are kept as perfectly as possible while superimposing their sides

on one another. The difference between the lengths and breadths is kept as low as possible and

generally not more than inch +/-. The height of the lay is kept between 2 1/2 inches to 3 inches. An

increased height may affect quality cutting due to unstable layers. The tension at which the fabric is laid

is also monitored.

Positioning the marker

Positioning the marker is the process of placing the marker plan on the top of the lay and securing it

with adhesive to prevent its movement during cutting. When the marker is placed it is kept exactly

matching the length and width of the top ply of the lay. Details like style no., name of the part, size

number and number of components is printed on the marker as a guide. Then it is clamped for better

grip.

Page 44

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

Cutting

The lay is cut with help of electrically powered straight knife cutting machines or CAM m/c. the machine

is moved through the lay following the pattern lines of the marker and the reciprocating blade cut the

pieces of fabric progressively. Notches are also added, for smaller components like collars, ribs etc.

that need high accuracy, band knife-cutting machine is used. It is a non-portable cutting device, which

cuts the fabric as it is passed across the blade. The garments are kept aside as and when they are cut.

Spread

Place marker

Cut pattern pieces

11.2. B Block cutting

Jacquard, stripes and checks are not being spread with spreading machine due to requirements of

matching so they are spread manually. Often structures like jacquard and checks are spread and cut in

single number for accuracy. The plies are spread one at a time matching the strips with those in the

previous plies. Then blocks are cut out from this spread for specific number of pieces. The size of the

block is dictated by the CAD room itself, which sends a mini marker for the cutting of the blocks from

the lay and the placement of the patterns on the blocks. Accordingly the cut blocks are manually

marked on top with marking chalk and using hard paper patterns. The plies in the block are aligned to

match the stripes and rough cutting of the fabric following the markings of the patterns is done. The cut

shapes are again checked for alignment and the stripes superimposed. A final precise cutting occurs to

finish the pattern.

Cutting of stripped fabric is a much more time consuming process. The wastage involved is also more

due to cutting in two stages.

Spread

Mark blocks

Match

Match

Final precise shaping of patterns

Match

Cut patterns

Mark patterns

Page 45

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

11.3 Sorting and ticketing

The pieces cut out from the lay are now sorted out size wise. All the components of one garment size

are brought together it is very important to take care of the pieces cut from two different bolts( bundles)

of fabric are not mixed up. This is because within a lot there are bolt to bolt shade variations the sorted

pcs are now ticketed ticketing is the process of marking the cut components for shade matching

precision, and sequence identification. The workers secures one end of the stack and puts on the ticket

using ticket gun as he flips over the cut parts. The ticket contains the size, bundle no. and piece no. and

serves as important mans to track the parts of the garment in the assembly line from start to the end

11.4 Cut panel checking

The ticketed panels are now sent to the checking area for inspection of every individual piece for any

objectionable faults. Panels may have faults like wrong grain line, inappropriate size, incorrect shape

and any fabric defects like holes cuts shade variations etc., that do not lie within the acceptable quality

parameters, are removed from the cut lay a cutting component check report is filled for the total quantity

cut, check and approved. The rejected pieces are sent back and equal no of fresh panels are

separately cut, replaced in the set and ticketed with the same no. as the rejected ones. Other mendable

faults are marked with an alteration stickers and passed on these will be spotted out during garment

finishing or washing.

11.5 Bundling

The checked components of one style and in one size are now clubbed and bundled using ties. The

size of the bundle depends upon the requirement of the production plant. Each bundle will contain

pieces of same style and same size only. The cutting department issues the amount required by the

production department when asked for.

11.6 Fusing

Fusing is also carried out in the cutting room itself. The parts of to be fused are separated from the

bundle the fusing material (like interlining) is cut according to the size of the components to be fused.

The components along with the cut fusing material are kept between two paper sheets and the pack is

passed through the fusing machine. By means of temperature and pressure fussing takes place at a

particular speed and for a particular time. The pack comes out at the other end on conveyers and the

pieces are removed and re-bundled.

Page 46

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

11.7 Manpower, Machinery and other details:

Machine

Quantity

Make

Spreading machine

F k Arna

Straight knives

10

Eastman

Band knives

Eastman

Fusing m/c

Shima

Spreading Table

Mica surface

Manpower: 1 cutting manager, 1 incharge, 4 supervisors, 1 cutting executive, 1 minusing incharge (i.e.

- cut order plan), 100 workforces.

Daily Production: 14,000 to 18,000 pcs. per day.

Spreading tables: 6 lines

Bundling and ticketing tables: 2 lines

WIP to Sewing floor: 1.5 days to 2 days

Page 47

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

12.0 EMBROIDERY DEPARTMENT

Shahi has a centralized embroidery department in unit -7 which is the second largest embroidery unit in

Asia. Unit 9 has a small embroidery section consisting of 3 multi headed machines.

12.1 SOP for embroidery department

Receive design from merchant against order.

Strike off design.

Scan and punch design.

Pilot run of style.

Receipt of panels from cutting

Start bulk production.

Marking

Framing

embroidery

Trimming and checking.

Pack goods.

Dispatch goods.

12.2 Detail functioning of the department:

The department receives Artwork from the merchandising department which contains the following

details

Total length and width of the design

Style name

Quality details- no. of stitches/inch

Quality check points

Placement of design

Pattern position

Color etc.

They refer the buyer wise design details from the production book in which the details of each order

are maintained.

These details are entered into the software which is linked to the machines.

The machines operate according to the details entered into the software.

Page 48

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

The details about the threads (strength, plies) to be used come from the Production Planning and

Control Department

The department remains in constant touch with the Pattern Making and Cutting departments for the

correct positioning of the designs and enabling continuous work flow respectively.

Start

Receive designs from the merchant

Scan and punch design

Strike- off of design

Samples to be done against orders

Conduct pilot run of the styles

Start bulk production

Trimming & checking

Packing

Delivery

Style reconciliation

End

Page 49

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

12.3 Manpower, Machinery and other details:

12.3.a Manpower:

No. of operators: 3 per shift

No of Checkers: 2 per shift

No. of supervisor: 1 per shift

No of Manager/ Incharge: 1

12.3.b Embroidery machines

Machine details

Company: Barudan

Model: 912K

Electronic, computerized, automatic

Multi-head: 20 heads/machine

Capacity : 1.8 million stitches /day

No. of machine : 3

12.3.c Types of stitches

Zigzag

Satin

Running

Titanium

12.3.d Embroidery Threads

Zari

Tribal polyester- strong

Rayon- not strong

Other threads as per requisition

Page 50

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

12.3.d Time taken for initial set up (12 pcs)

Small logo- hour

Big design- 2 to 3 hours

Framing- 5 min for 12 frames

12.3.e Quality

100% inspection is done

Major defects

Bobbin thread on the right side of garment

Puckering

Loose stitch

Remedies for defects

Manual embroidery

Re-embroidery

Re-cutting (if the above two dont solve the problem

12.3.f Costing

Cost depends on the no. of colors in the design as well as the size of the design

Size

0-3000 stitches: Rs.4 per pc

3000-10,000 stitches: Rs.1 per 1000 stitch

> 10,000 stitches: Rs.0.85 per 1000 stitch

If colors in the design are more than 2 then per colour 5 paisa increase per piece.

Garment embroidery is costlier than parts embroidery

Tolerance: 2mm-3mm

Page 51

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

13.1 SEWING DEPARTMENT

13.1 Introduction:

Production at Shahi, Unit - 9 comes under LSD/ LFD Division and involved in the production of

womens Casual and semi formal shirts, tops, dresses etc.

Main brands to which this unit caters are :

TARGET

WALMART

ESPIRT etc.

13.2 Production System followed:

Progressive Bundling System. Batch production at some floors. Depends on order.

Each floor has 8 batches.

This unit has four production floors totally having 32 lines of production.

Capacity: The production unit has a capacity of 12,000-15,000 pieces per day

Each batch has approx 45-65 workstations and machines apart from button sewing, button

sewing, and folding machines.

13.3 Functioning of the department:

The production floor does production in two types:

Once during pilot production where they have to produce about 250 500 garments for the new

style which is sent to the buyer to check the workmanship and production skills of the factory.

Bulk production

The production floor receives the details as below:

the style or the garment,

the batch for which the style has to be installed,

target for each day

number of operators required,

any extra kinds of machines that are to be used for the particular style,

Breakup of the production quantity.

Page 52

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

After receiving all these details they send a request for the cut parts from the cutting and sorting

section and the request is sent to the accessory stores for all the accessories that are required for the

particular style then they start the production for the new style.

Before starting the proper production the production floor does a process of batch-setting for the floor

which is training the operators for the new style that has to be produced in bulk.

In progressive bundling system, this batch setting and teaching session will go on for about 23 days,

but in the newly introduced lean manufacturing system, batch-setting can be done 6 hours and the

production does not stop meanwhile but remains in the running process simultaneously.

After this batch setting process the production for the next day starts with a smaller commitment i.e.,

may be for 50 pieces for the entire day and then the production gradually increases from 50 100

150 and so on, this will make the operators learn slowly and precisely about the processes that has to

be carried out for the particular style.

The sections for the sewing process in progressive bundling system :

Front section

Sleeve section

Cuff section

Back section

Collar section

Assembly

Kaja and buttons section

The sections for the sewing process in Group/ Modular production System :-

Front section (one batch for entire front)

Collar and Sleeve section(One batch for collar and sleeves)

Back section(One batch for entire back)

Assembly (To assembly)

Kaja and buttons section

Page 53

Department of fashion technology, National Institute of fashion Technology, Kannur

Shahi Exports Pvt. Ltd., Unit-9

During the process of garment making there exists two types of checking, they are

In-process checking.

End line checking. Here there exists both AQL audit and normal checking.

The supervisor plays a vital role in the production floor. He/she manages the entire batch which is been

allocated to them and they have the following functions to perform:-

1. They have to convey the proper stitching method to the operators.

2. Guide the operators when they face difficulty in making an operation and teach them the most

suitable and an easy method of performing the task.

3. Check if the entire operator in the batch/line is busy with the work being allocated to them.

4. If the operator does not have any material to work on then the supervisor has to get him/her their

material and ask them to work.

5. Complain the production managers if the operators are not performing their best.

6. Have to maintain a proper communication between the operators and the management.

7. Should be in a position to tell the manager about each operators skill level whenever asked for.