Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Cable Pits PDF

Cargado por

azanwtaDescripción original:

Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Cable Pits PDF

Cargado por

azanwtaCopyright:

Formatos disponibles

EP 20 00 04 05 SP

CABLE PITS

Version 3.0

Issued February 2012

Owner:

Chief Engineer Electrical

Approved

by:

Neal Hook

Chief Engineer

Electrical

Authorised

by:

Neal Hook

Chief Engineer

Electrical

Disclaimer

This document was prepared for use on the RailCorp Network only.

RailCorp makes no warranties, express or implied, that compliance with the contents of this document shall be

sufficient to ensure safe systems or work or operation. It is the document users sole responsibility to ensure that the

copy of the document it is viewing is the current version of the document as in use by RailCorp.

RailCorp accepts no liability whatsoever in relation to the use of this document by any party, and RailCorp excludes

any liability which arises in any manner by the use of this document.

Copyright

The information in this document is protected by Copyright and no part of this document may be reproduced, altered,

stored or transmitted by any person without the prior consent of RailCorp.

UNCONTROLLED WHEN PRINTED

Page 1 of 11

Engineering Standard

Engineering Standard

Electrical

RailCorp Engineering Standard Electrical

Cable Pits

EP 20 00 04 05 SP

Document control

Version

2.0

3.0

RailCorp

Issued February 2012

Date

June 2008

May 2010

February 2012

Summary of change

Last Technical Review

Application of TMA 400 format

Contents of previous section on Introduction

incorporated in Scope and application. Joint bays

excluded from scope.

References updated.

Section on Design requirements renamed as

General; list of requirements expanded; some

provisions relocated to other sections.

Section on Confined space added.

Section on Dimensions added; this section includes

provisions for previous sections (deleted in this version)

on Space for persons working and Future

maintainability.

Requirement for spare ducts expressed as a

percentage of total ducts per circuit instead of a table

(section 6).

Section on Access steps renamed as Access

ladders; reference to AS 1657.

Section on fall arrest system added

Section on Design documentation added.

Order of sections re-arranged.

Minor editorial changes.

UNCONTROLLED WHEN PRINTED

Page 2 of 11

Version 3.0

RailCorp Engineering Standard Electrical

Cable Pits

EP 20 00 04 05 SP

Contents

1

Scope and application ............................................................................................................4

2

2.1

2.2

2.3

2.4

References...............................................................................................................................4

Australian and international standards......................................................................................4

RailCorp documents..................................................................................................................4

RailCorp drawings.....................................................................................................................5

Other references .......................................................................................................................5

General .....................................................................................................................................5

Location ...................................................................................................................................5

Confined space .......................................................................................................................6

Cable entries and ducts..........................................................................................................6

Dimensions..............................................................................................................................6

Provision of support for cables and joints...........................................................................7

Pulling eyes .............................................................................................................................7

10

Access ladders........................................................................................................................7

11

Fall arrest system....................................................................................................................7

12

Pit covers and access covers................................................................................................7

13

Drainage ...................................................................................................................................8

14

Ventilation................................................................................................................................8

15

Identification of cables ...........................................................................................................9

16

Other services in high voltage cable pits .............................................................................9

17

Signage ....................................................................................................................................9

18

18.1

18.2

18.3

Design documentation .........................................................................................................10

For Construction drawings ......................................................................................................10

Other design documents .........................................................................................................10

As built drawings .....................................................................................................................10

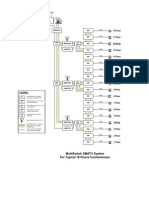

Appendix A

Cable Layout Configuration in Pits......................................................................11

Circular Pits ............................................................................................................................................11

Rectangular Pits .....................................................................................................................................11

RailCorp

Issued February 2012

UNCONTROLLED WHEN PRINTED

Page 3 of 11

Version 3.0

RailCorp Engineering Standard Electrical

Cable Pits

EP 20 00 04 05 SP

Scope and application

This document sets out the requirements for the design and construction of cable pits for

high voltage and 1500V dc cables.

The requirements of this document apply to all new cable pits, including those at

substations.

Where approved by the RailCorp nominated engineering authority, joints in underground

cables may be provided in joint bays rather than cable pits. These joint bays are

generally back filled with clean sand or other suitable material after the joints have been

made. Access covers are not provided for joint bays. This document is not applicable to

joint bays.

For more information about conducting safety risk management assessments when

assessing requirements to be considered when designing and constructing cable pits,

see RailCorp Safety Management System Element 6: Risk Management.

References

2.1

Australian and international standards

AS 1657:1992

AS/NZS 1891.4:2009

AS 2865:2009

AS 3996:2006

AS 4799:2000

2.2

Fixed platforms, walkways, stairways and ladders Design,

construction and installation

Industrial fall-arrest systems and devices Part 4: Selection, use

and maintenance

Confined spaces

Access covers and grates

Installation of underground utility services and pipelines within

railway boundaries

RailCorp documents

EP 20 00 00 03 SP

EP 20 00 03 01 SP

EP 20 00 04 02 SP

EP 20 10 00 02 SP

EPD 0013

EPE 0002

ESC 540

ESM 102

SMS-06-FM-0038

SMS-06-GD-0035

SMS-06-PR-0240

SMS-06-SW-0254

SPG 0705

TMD 0001

RailCorp

Issued February 2012

Above ground cable installation systems

HV and 1500V dc cables Joints and terminations

Underground installation configurations for high voltage and

1500 Vdc cables

High voltage cable

Technical reviews

Mains Installation (OHW, HV Aerial Lines, HV and 1500V

Cables) Design Competencies and Authorities

Service installations within the rail corridor

Communication Outdoor Cabling Standard

Confined Space Identification and Assessment Checklist

Confined Spaces

Working at Heights

Physical Restraint Systems (Anchorages)

Construction of Cable Routes and Signalling Civil Works

CAD and Drafting Manual

UNCONTROLLED WHEN PRINTED

Page 4 of 11

Version 3.0

RailCorp Engineering Standard Electrical

Cable Pits

2.3

RailCorp drawings

EL 0024639

2.4

EP 20 00 04 05 SP

Underground cables Under track crossing arrangement

Other references

NSW Occupational Health and Safety Regulation 2001

General

Cable pits are generally provided for:

Cable joints

Pulling of cables during installation

The requirements for cable pits are determined from the following considerations:

Gradient and depth of the duct line

Changes in route direction

Maximum allowable pulling tension of the cable

Minimum bending radii of cables

Maximum length of cable on a drum

Joints in cable

De-rating of cables

Protection of all cables in the same pit

Construction and maintenance of the cable installation

Cross bonding requirements, if any

Provision for future cable installations

Requirements of the Occupational Health and Safety Act and Regulation

Water table levels

Drainage arrangements

Presence of other services in the vicinity, eg Signalling and Communication cable

routes

Vehicular and pedestrian traffic at the cable pit location

Proximity to tracks

The internal surfaces of cable pits shall be smooth, chemically inert and as far as

practical impervious to water.

Location

The location of cable pits shall comply with the requirements of ESC 540 and AS 4799.

Cable pits shall not be located within three metres from the nearest rail of any track.

The design of cable pits shall be coordinated with that of the drainage system, as well as

other services such as Signalling and Communication cable routes. Cable pits shall be

designed and located such that access to other RailCorp infrastructure will not be

impeded, unless prior agreement by the relevant maintainer has been obtained.

The standard RailCorp cable construction as set out in EP 20 10 00 02 SP is such that

the cables are not suitable for immersion in water for extensive time periods. Cable pits

shall therefore be designed so that the cables are at a level that is well above the water

table. Information on relevant water table levels shall be provided by the Designer at or

before the Preliminary Design Review.

Cable pits shall be located to allow for safe access of persons and plant to the pits for

construction and maintenance of the cables in the pit.

RailCorp

Issued February 2012

UNCONTROLLED WHEN PRINTED

Page 5 of 11

Version 3.0

RailCorp Engineering Standard Electrical

Cable Pits

EP 20 00 04 05 SP

Confined space

As far as practical cable pits shall be designed so that they are not confined spaces.

Refer to the NSW Occupational Health and Safety Regulation, AS 2865, SMS-06-GD0035 and SMS-06-FM-0038 for the definition and identification of confined spaces.

Where it is not practical to do so, the design and installation of the cable pit shall comply

with the relevant requirements applicable to confined spaces. Hazards involved in

working in a confined space should be minimised at the design stage and during the

initial installation of equipment.

Cable entries and ducts

Cable entries or ducts entering the pit shall be in the form of a bellmouth, smooth and

free of sharp edges to prevent damage to the cable during installation and subsequent

operation of the cable.

Cable entries into circular pits shall be positioned to be tangential to the pit as shown in

Appendix A.

Cable entries into rectangular pits shall be positioned to the side of the pit as shown in

Appendix A.

Where ducts or ground line troughing enters a cable pit, the ducts or ground line

troughing shall be encased in concrete for a distance of 300 mm from the pit to hold the

ducts or ground line troughing securely in position.

The height of cable entries and ducts shall be such that the cable is at least 300mm

above the floor of the pit at the entry.

Spare cable entries or ducts shall be provided for future use. The minimum number of

spare entries or ducts for HV and 1500V dc cables shall be 30% of the total for each

circuit. Where there are project specific requirements for additional spare cable entries or

ducts that are not associated with any specific circuit, and unless otherwise specified,

such cable entries or ducts shall be of the same size as the largest one provided for the

pit.

Spare cable entries and ducts shall be provided at or above the same level as those

housing cables.

Cable entries or ducts shall be sealed to prevent the ingress of soil, water and dangerous

gases into the pit.

Dimensions

The pit shall be of sufficient size to provide a safe work and rescue environment under

the Occupational Health and Safety Act for the activities to be performed in the pit.

The dimensions of a cable pit shall be suitable for the planned installation as well as

designed future construction and maintenance activities. These should include, but not

limited to

Minimum bending radii consideration, including those for possible future cable

installation utilising the spare ducts

Space requirements for installation and maintenance of cable joints

Allowance for future cable joints for repairs to the cable installation, if required by

the maintenance strategy for future cable faults.

RailCorp

Issued February 2012

UNCONTROLLED WHEN PRINTED

Page 6 of 11

Version 3.0

RailCorp Engineering Standard Electrical

Cable Pits

EP 20 00 04 05 SP

Provision of support for cables and joints

The principles set out in document EP 20 00 00 03 SP shall generally apply to the

support of cables within cable pits. Cables and joints within the pit shall be properly and

securely supported by suitable cable cleats / clamps and permanent racking. Timber

supports shall not be used.

Pulling eyes

Pulling eyes shall be provided as close as possible to the pulling alignment of the cable in

all pits constructed for the purpose of pulling in cables. Pulling eyes shall be located as

shown in Appendix A and shall:

be suitably located opposite the cable entries or ducts in the pit wall to assist with

the installation of cables

have a safe working load not less than three (3) times the maximum allowable

pulling tension of the cables to be installed

The safe working load of each pulling eye shall be clearly and permanently labelled on or

adjacent to the pulling eye.

10

Access ladders

Access ladders complying with AS 1657 shall be provided for entry to and egress from

the pit. Clearance requirements around the access ladder shall comply with the

requirements of AS 1657. Future cable installations utilising the spare cable entries and

ducts shall be considered in determining the clearance requirements.

11

Fall arrest system

Where a fall arrest system is required during entry and egress, anchorage points suitable

for attachment of two persons and complying with AS/NZS 1891.4 and SMS-06-SW-0254

shall be provided.

12

Pit covers and access covers

Removable covers shall be provided for all cable pits.

Cable pit covers and access covers shall be flush with the surrounding finished surface

on platforms, access roads or other areas subject to pedestrian or road traffic. At other

locations the top of the cable pit shall be 300 mm above the surrounding ground level to

prevent the ingress of water and silt. Refer to section 4 for the requirements for cable pit

locations,

Cable pit access covers may, in some instances, also be the cable pit covers. However

on large cable pits it will be necessary to install access covers within the cable pit cover

as the cable pit cover will be too large and heavy to be moved without cranes or other

lifting equipment.

RailCorp

Issued February 2012

UNCONTROLLED WHEN PRINTED

Page 7 of 11

Version 3.0

RailCorp Engineering Standard Electrical

Cable Pits

EP 20 00 04 05 SP

Cable pit access covers shall:

comply with AS 3996

be removable without the need for lifting appliances such as cranes etc

be of sufficient mechanical strength for the environment in which they are installed

and loading conditions to which they may be subjected

be designed to resist the ingress of water

be vermin proof

require the use of specialised tools, keys or locking systems to gain access to the

cable pit

Cable pit covers and access covers located at trafficable areas within the rail corridor

shall be designed for road vehicle loads in accordance with ESC 540.

13

Drainage

Adequate drainage shall be provided to discharge water from the pit. The arrangement

shall be coordinated and integrated with the drainage system in the area. The drain shall

be vermin proof.

Where it is impractical to provide drainage, the pit shall be provided with a sump suitable

for the placement of a sump pump. The floor of the cable pit shall be suitably graded

towards the sump. The minimum depth of the sump pit shall be 300mm.

14

Ventilation

The pit shall be designed to:

avoid the build up of any contaminants or combustible atmospheres;

facilitate the use of portable ventilating equipment by providing adequate access

and ventilating openings in the pit cover

When the entire top area of the pit is not covered by cable pit access covers, two access

openings shall be provided at diagonally opposite ends of the pit as shown in Figure 1 for

safe access and ventilating purposes.

Figure 1 - Cable pit cover provided with access and ventilation openings.

RailCorp

Issued February 2012

UNCONTROLLED WHEN PRINTED

Page 8 of 11

Version 3.0

RailCorp Engineering Standard Electrical

Cable Pits

15

EP 20 00 04 05 SP

Identification of cables

All cables entering and exiting a pit shall be positively identified by corrosion resistant

tags with the cables owner, voltage and designated feeder number clearly shown by

engraving or embossing. The tags shall be securely attached to the relevant cable with a

corrosion resistant securing system.

All high voltage cables within shared pits shall be suitably identified as high voltage cable

in a permanent manner, i.e. by binding the cable with a suitable plastic warning tape in

accordance with the requirements of SPG 0705.

16

Other services in high voltage cable pits

Communication cables and high voltage and 1500V dc cables shall not be in the same

pit. Refer to ESM 102 for separation requirements between Communication cables and

high voltage and 1500V dc cable pits.

The installation of low voltage and signalling cables with high voltage cables should be

avoided. However, if it is necessary to locate all services in the same pit, the high voltage

cable(s) shall be grouped and identified as specified in Section 15. Signalling or low

voltage cables shall be physically separated by a continuous rigid barrier.

High voltage cable joints shall not be located in cable pits with signalling services, low

voltage cables or other utility services.

Other services shall not be installed in high voltage and 1500V dc cable pits unless prior

approval has been granted by the RailCorp Nominated Engineering Authority.

For the purpose of this section pilot wire and DTS fibre optic cables associated with a

high voltage feeder are considered as part of the high voltage cables.

17

Signage

Suitable signs shall be installed in a prominent position where applicable:

RailCorp

Issued February 2012

Confined space signage in accordance with AS 2865

Fall arrest system anchorage points signage in accordance with AS/NZS 1891.4

Safe working load of each pulling eye

Warning sign for the presence of gas cables in the pit

Danger High Voltage warning sign

UNCONTROLLED WHEN PRINTED

Page 9 of 11

Version 3.0

RailCorp Engineering Standard Electrical

Cable Pits

EP 20 00 04 05 SP

18

Design documentation

18.1

For Construction drawings

Design drawings for Electrical aspects of cable pits shall comply with TMD 0001

Sections 1, 2 and 4, and include details of the following:

Geographical location of the pit

Drainage arrangements

Plans and sections showing relevant dimensions

Arrangement of cable entries and ducts, including duct sizes and identifications of

cables in each duct

Arrangement for segregation of services

Arrangements for support of cables and joints

Cable runs through the pit with bending radius for each cable

Provision for access and egress

Pulling eyes

Anchorage for fall arrest systems, if applicable

Signage

Structural design of cable pits shall be documented separately in another set of drawings

complying with TMD 0001 Sections 1, 2 and 3.

18.2

Other design documents

The Designer shall provide the following documents to support the design as shown on

the For Construction drawings:

Relevant water table levels at the cable pits (see section 4)

Proposed maintenance strategy demonstrating the adequacy of the cable pit

locations and dimensions for repairing future cable faults (see section 7)

The Designer shall provide other documents and calculations to support the design

drawings as required by the RailCorp nominated engineering authority.

18.3

As built drawings

A full set of drawings, as listed in section 18.1 and showing the as-built configuration of

the cable pit(s), shall be provided for acceptance by the RailCorp Nominated Engineering

Authorities within 4 weeks of commissioning of any of the cables in the pit.

RailCorp

Issued February 2012

UNCONTROLLED WHEN PRINTED

Page 10 of 11

Version 3.0

RailCorp Engineering Standard Electrical

Cable Pits

Appendix A

EP 20 00 04 05 SP

Cable Layout Configuration in Pits

Circular Pits

Acceptable but not preferred. Rectangular pit is the preferred arrangement

Pulling eyes shall be installed opposite the cable entry and exit positions as indicated on

the diagram by the symbol o

Rectangular Pits

RailCorp

Issued February 2012

UNCONTROLLED WHEN PRINTED

Page 11 of 11

Version 3.0

También podría gustarte

- A1081A1081M-12 Standard Test Method For Evaluating Bond of Seven-Wire Steel Prestressing StrandDocumento5 páginasA1081A1081M-12 Standard Test Method For Evaluating Bond of Seven-Wire Steel Prestressing StrandDiego Egoávil MéndezAún no hay calificaciones

- FEWADocumento33 páginasFEWArasheed313Aún no hay calificaciones

- Stringing of Transmission Line TowerDocumento9 páginasStringing of Transmission Line Towershahid rasheedAún no hay calificaciones

- Cable Laying RequirementsDocumento29 páginasCable Laying RequirementsNur Amirah Abdul JamilAún no hay calificaciones

- 3 2 Rigging of Transmission Line Towers PDFDocumento5 páginas3 2 Rigging of Transmission Line Towers PDFsauravkafle1Aún no hay calificaciones

- Kawneer Curtain Wall SystemDocumento35 páginasKawneer Curtain Wall SystemCyrill GlennAún no hay calificaciones

- Genaral Details of A TransformerDocumento3 páginasGenaral Details of A TransformershaluAún no hay calificaciones

- 132KV TRX LineDocumento12 páginas132KV TRX LineNanban VkyAún no hay calificaciones

- E 3.4 High Voltage - Table of Contents: Last Updated September 2004Documento19 páginasE 3.4 High Voltage - Table of Contents: Last Updated September 200420353124Aún no hay calificaciones

- Catenary Voltage SupplyDocumento5 páginasCatenary Voltage SupplyAmir ZulfiAún no hay calificaciones

- Ohl Manual Vol.1 LV To 33kv Specifications v4 July 2006Documento437 páginasOhl Manual Vol.1 LV To 33kv Specifications v4 July 2006somchak2000Aún no hay calificaciones

- AC DC Railway Electrification and Protection: November 2014Documento43 páginasAC DC Railway Electrification and Protection: November 2014Akhilesh kumar Srivastava100% (1)

- Guided By: Prof. Ankit Shahpatel: Utilization of Electrical Enenrgy and TRACTION (2160907)Documento16 páginasGuided By: Prof. Ankit Shahpatel: Utilization of Electrical Enenrgy and TRACTION (2160907)sameerpatel15770100% (1)

- Checklist For Pre Commissioning of Water PumpDocumento3 páginasChecklist For Pre Commissioning of Water PumpGusti Prasetyo Rendy Anggara100% (1)

- Rail - Design and Rating PDFDocumento7 páginasRail - Design and Rating PDFCK TangAún no hay calificaciones

- RTU With Numerical RelaysDocumento7 páginasRTU With Numerical RelaysRamu GunaseelanAún no hay calificaciones

- LRT Rectifier: Power Supply and Overhead Catenary SystemDocumento3 páginasLRT Rectifier: Power Supply and Overhead Catenary SystemToffee BebeAún no hay calificaciones

- DC Cable LayingDocumento8 páginasDC Cable LayingAhamed UmarAún no hay calificaciones

- Line Trap 132kv 0Documento17 páginasLine Trap 132kv 0Neelakandan MasilamaniAún no hay calificaciones

- Pole Mounted Substation Construction - Ausgrid NS122 - NSADocumento181 páginasPole Mounted Substation Construction - Ausgrid NS122 - NSAmanxman_1100% (1)

- Electrical Networks Standard Track Bonding For Signalling and Traction Return CurrentDocumento34 páginasElectrical Networks Standard Track Bonding For Signalling and Traction Return CurrentSivaji KotipalliAún no hay calificaciones

- Repair and RehabilitationDocumento26 páginasRepair and RehabilitationMolten Sapphire100% (1)

- PM Lecture V SlidesDocumento14 páginasPM Lecture V SlidesDaniyal ShahzaibAún no hay calificaciones

- Project - On Power Sub StationDocumento22 páginasProject - On Power Sub StationRavi KumarAún no hay calificaciones

- Earthing Functional RequirementsDocumento6 páginasEarthing Functional RequirementsEshanAún no hay calificaciones

- Lesson Plan For Training of P. Way Supervisor (Promotional Course) PDFDocumento368 páginasLesson Plan For Training of P. Way Supervisor (Promotional Course) PDFP C GargavaAún no hay calificaciones

- ZTE-LTE Troubleshooting GuideDocumento45 páginasZTE-LTE Troubleshooting Guideİsmail Akkaş67% (3)

- Esc 230 PDFDocumento31 páginasEsc 230 PDFEduardoAún no hay calificaciones

- Ep 08 00 00 10 SP PDFDocumento41 páginasEp 08 00 00 10 SP PDFtaarak143Aún no hay calificaciones

- TMA 413 Technical Reviews ManualDocumento68 páginasTMA 413 Technical Reviews Manualzhangj5100% (1)

- Railway Applications - Fixed Installations - Electrical Safety, Earthing and The Return CircuitDocumento34 páginasRailway Applications - Fixed Installations - Electrical Safety, Earthing and The Return CircuitCounter RoverAún no hay calificaciones

- ESC 361 Buffer Stops: Engineering Standard CivilDocumento15 páginasESC 361 Buffer Stops: Engineering Standard Civilbohemia61Aún no hay calificaciones

- Power Traction Transformers BrochureDocumento12 páginasPower Traction Transformers BrochureDave Chaudhury100% (1)

- 2020 Standard Specifications Construction PDFDocumento1146 páginas2020 Standard Specifications Construction PDFMonica VegaAún no hay calificaciones

- AC DC InterferenceDocumento10 páginasAC DC InterferenceIsmet HizyoluAún no hay calificaciones

- 11kV Voltage RegulatorDocumento12 páginas11kV Voltage Regulatoroadipphone7031Aún no hay calificaciones

- 14 - List of WorksDocumento170 páginas14 - List of Worksसुमित नेमाAún no hay calificaciones

- VRIOGS 001 2012 Rev B Structural Gauge EnvelopesDocumento32 páginasVRIOGS 001 2012 Rev B Structural Gauge Envelopesnur2318Aún no hay calificaciones

- EMC Analysis: For Railway Power Supply SystemDocumento10 páginasEMC Analysis: For Railway Power Supply SystemRakhmad sugih hartonoAún no hay calificaciones

- Electric Traction SystemDocumento23 páginasElectric Traction SystemAniket LikharAún no hay calificaciones

- CRN UnderbridgesDocumento49 páginasCRN Underbridgestidus00_3Aún no hay calificaciones

- Bridges SafetyDocumento60 páginasBridges SafetyMarcoFranchinottiAún no hay calificaciones

- L1-CHE-STD-061 v1 - Internal 22kV DistributionDocumento16 páginasL1-CHE-STD-061 v1 - Internal 22kV Distribution4493464Aún no hay calificaciones

- Support Structures: Substation Design InstructionDocumento9 páginasSupport Structures: Substation Design InstructionTony PedaAún no hay calificaciones

- L1 Che STD 009Documento19 páginasL1 Che STD 009rvim0002Aún no hay calificaciones

- L1-CHE-STD-013 MTM Stations StandardDocumento63 páginasL1-CHE-STD-013 MTM Stations Standardluke hainesAún no hay calificaciones

- Pre Installationfor Opgw 48 FDocumento5 páginasPre Installationfor Opgw 48 FMayank PorwalAún no hay calificaciones

- As 4292.1-2006 Railway Safety Management General RequirementsDocumento9 páginasAs 4292.1-2006 Railway Safety Management General RequirementsSAI Global - APACAún no hay calificaciones

- DC Traction Energy Recovery InvertersDocumento4 páginasDC Traction Energy Recovery Invertersrvim0002Aún no hay calificaciones

- As 4292.5-2006 Railway Safety Management Operational SystemsDocumento9 páginasAs 4292.5-2006 Railway Safety Management Operational SystemsSAI Global - APACAún no hay calificaciones

- Pre - Bid Meeting PPT - AEP 01Documento57 páginasPre - Bid Meeting PPT - AEP 01kesavmurthy_1972Aún no hay calificaciones

- RegthDocumento15 páginasRegthMohammedAún no hay calificaciones

- Temporary CSR Design Guidance Note PDFDocumento26 páginasTemporary CSR Design Guidance Note PDFKevin KamAún no hay calificaciones

- AC DC InterfaceDocumento28 páginasAC DC InterfaceLaurence MichaelAún no hay calificaciones

- As 1085.8-2002 Railway Track Material DogspikesDocumento7 páginasAs 1085.8-2002 Railway Track Material DogspikesSAI Global - APACAún no hay calificaciones

- T HR Ci 12040 ST PDFDocumento33 páginasT HR Ci 12040 ST PDFtaarak143Aún no hay calificaciones

- Overhead InstallationDocumento20 páginasOverhead Installationkariboo karibooxAún no hay calificaciones

- L1-SDD-STD-001 - Train Protection and Warning SystemDocumento14 páginasL1-SDD-STD-001 - Train Protection and Warning SystemCK TangAún no hay calificaciones

- Track Drainage - NSW - Very GoodDocumento83 páginasTrack Drainage - NSW - Very GoodFebrian QodriAún no hay calificaciones

- Power Swing Blocking: Brief DescriptionDocumento3 páginasPower Swing Blocking: Brief DescriptionmubarakkirkoAún no hay calificaciones

- Mar Ma RayDocumento60 páginasMar Ma RayIsmet Hizyolu100% (1)

- Prepared By: Chirag B. PatelDocumento11 páginasPrepared By: Chirag B. PatelPatel ChiragAún no hay calificaciones

- Guidelines For Location Codes and Decriptions For Compliant DrawingsDocumento2 páginasGuidelines For Location Codes and Decriptions For Compliant DrawingsCr WongAún no hay calificaciones

- EP 20 00 00 03 SP Above Ground Cable Installation Systems - Selection GuideDocumento11 páginasEP 20 00 00 03 SP Above Ground Cable Installation Systems - Selection Guidegoyalvikas86Aún no hay calificaciones

- Sheet Steel Industrial Light Fittings Series 3070: SCHUCH Quality - Your AdvantageDocumento6 páginasSheet Steel Industrial Light Fittings Series 3070: SCHUCH Quality - Your AdvantageazanwtaAún no hay calificaciones

- Customized Supervisory Control and Data Acquisition Scada Based Remote Terminal Unit Rtu For Low Voltage Distribution Automation System Soo Wai Lian T58.6.S66 2008Documento27 páginasCustomized Supervisory Control and Data Acquisition Scada Based Remote Terminal Unit Rtu For Low Voltage Distribution Automation System Soo Wai Lian T58.6.S66 2008azanwtaAún no hay calificaciones

- Grande Presentation FINAL PDFDocumento27 páginasGrande Presentation FINAL PDFazanwtaAún no hay calificaciones

- Toprank Corporation SDN BHD: China Strategic Partnership"Documento20 páginasToprank Corporation SDN BHD: China Strategic Partnership"azanwtaAún no hay calificaciones

- Typical MSW SchematicDocumento1 páginaTypical MSW SchematicazanwtaAún no hay calificaciones

- Detail TNB Feeder PillarDocumento1 páginaDetail TNB Feeder PillarazanwtaAún no hay calificaciones

- The Night Face Up - CortazarDocumento7 páginasThe Night Face Up - CortazarАдам АрагонAún no hay calificaciones

- NCM Firewall PortsDocumento8 páginasNCM Firewall PortsMohammed F. ShehataAún no hay calificaciones

- 1MRG022189 A en IED Connectivity Package Version 3.1 For Relion 670 SeriesDocumento3 páginas1MRG022189 A en IED Connectivity Package Version 3.1 For Relion 670 SeriesedwarcAún no hay calificaciones

- Vis Ib Pyp Visit Agenda RevisedDocumento5 páginasVis Ib Pyp Visit Agenda Revisedapi-267835665Aún no hay calificaciones

- 2510Documento2 páginas2510Angie BelmonteAún no hay calificaciones

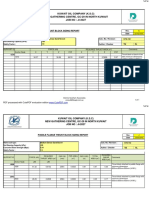

- Kuwait Oil Company (K.S.C) New Gathering Centre, Gc-29 in North Kuwait JOB NO: JI-2027Documento2 páginasKuwait Oil Company (K.S.C) New Gathering Centre, Gc-29 in North Kuwait JOB NO: JI-2027Velpandian ManiAún no hay calificaciones

- TSM For VE Sample Architecture - v1.0 PDFDocumento28 páginasTSM For VE Sample Architecture - v1.0 PDFArunmurAún no hay calificaciones

- Accenture QuestionsDocumento4 páginasAccenture QuestionsPriyanshu_Sing_2040Aún no hay calificaciones

- DWH Architecture & Lifecycle: Muchake Brian Tel: 0701178573Documento39 páginasDWH Architecture & Lifecycle: Muchake Brian Tel: 0701178573Nassim NassifAún no hay calificaciones

- Guangzhouoperahouse PDFDocumento2 páginasGuangzhouoperahouse PDFStevin OmpiAún no hay calificaciones

- Pryda - Connectors-Tie-Downs-Sept-2016Documento24 páginasPryda - Connectors-Tie-Downs-Sept-2016RuwiniAún no hay calificaciones

- WhitePaper Performance ConfigurationDocumento4 páginasWhitePaper Performance ConfigurationAnonymous 3fTYXaW7WAún no hay calificaciones

- 香港流畅节目Documento2 páginas香港流畅节目ymeyulfnAún no hay calificaciones

- SOAL PAS B. Inggris Kls X Ganjil 2020Documento9 páginasSOAL PAS B. Inggris Kls X Ganjil 2020taufan Adi SaputroAún no hay calificaciones

- 11 SE3 Software Design Principles PDFDocumento5 páginas11 SE3 Software Design Principles PDFbhuvi2312Aún no hay calificaciones

- DBreeze Documentation ActualDocumento133 páginasDBreeze Documentation ActualJackson HayesAún no hay calificaciones

- OpenVox B100/B200/B400/B800 Series BRI Card DatasheetDocumento1 páginaOpenVox B100/B200/B400/B800 Series BRI Card Datasheetmaple4VOIPAún no hay calificaciones

- Quick Unix ReferenceDocumento6 páginasQuick Unix ReferencetotaloncueAún no hay calificaciones

- Iit Madras Detailed SyllabusDocumento14 páginasIit Madras Detailed SyllabusSuperdudeGauravAún no hay calificaciones

- Hbase PDFDocumento8 páginasHbase PDFchandra reddyAún no hay calificaciones

- 13GR - 059 Bituthene HB Web PDFDocumento141 páginas13GR - 059 Bituthene HB Web PDFWendel MeloAún no hay calificaciones

- 400 Bad Request 400 Bad Request Nginx/1.2.9Documento16 páginas400 Bad Request 400 Bad Request Nginx/1.2.9thepraetorionAún no hay calificaciones

- Tivoli Workload SchedulderDocumento640 páginasTivoli Workload SchedulderlarretAún no hay calificaciones

- Inspection Request (Ir) : Project Name: 2.private Villa (G+1+P) MR. Jaralla AL Samikh Al RayyanDocumento4 páginasInspection Request (Ir) : Project Name: 2.private Villa (G+1+P) MR. Jaralla AL Samikh Al RayyanMohammed JavidAún no hay calificaciones

- Veyon User ManualDocumento24 páginasVeyon User Manualki_soewarsonoAún no hay calificaciones