Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Industrial Tour Report-Descon Engineering Limited

Cargado por

msaqibraza93Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Industrial Tour Report-Descon Engineering Limited

Cargado por

msaqibraza93Copyright:

Formatos disponibles

DESCON ENGINEERING LIMITED

ASME Project

American Society of Mechanical Engineering, UET Lahore chapter this year, like every year, organised a

team for the Thermodynamic Section and assigned a project, Design Analysis and Fabricate of Water Tube

Boiler. The team comprises of 18 members working as a unit to put forth their immense effort in reaching

a new milestone. The Water Tube Boiler that is being worked on is to be forwarded in various project

exhibitions to demonstrate the calliper of ASME UET Lahore chapter.

Some Specifications and Details of the Boiler

What is a water tube boiler?

A water-tube boiler is a type of boiler in which water circulates in tubes which are heated externally by the

fire. Water-tube boilers are used for high-pressure boilers. Fuel (coal) is burned inside the furnace, creating

hot gas which heats up water in the steam-generating tubes. In smaller boilers, additional generating tubes

are separate in the furnace, while larger utility boilers rely on the water-filled tubes that make up the walls

of the furnace to generate steam.

A water tube boiler is more

geared towards the latter setting

than the former though, since

water tube boilers can create

large amounts of steam and

recycle water for use again and

again if kept in a closed system.

There are several, important

pieces that make up a water tube

boiler, though.

In water tube boilers, water is

circulated though the tubes and hot

flue gases flow outside the tubes,

e.g. Bob cock & Wilcox, Admiralty

three drum, Y-160 and Foster

wheeler D-type. The water tube

boiler is employed for high

pressure, high temperature, high

capacity steam applications, e.g.

providing

steam

for

main

propulsion turbines of cargo pump

turbines.

Parts of a water tube boiler

Furnace - Furnace is usually membrane walled and gas tight. Most of the heat transfer occurs in the furnace

in the form of direct radiation.

Super Heater - Inverted 'U' is most widely used. There are other types like vertical 'S' type drainable. Super

heater is usually embedded in the boiler bank. When superheat temperature is high, part of the super

heater section is directly place in the furnace to increase direct radiation and reduce size.

DESCON ENGINEERING LIMITED

Boiler Bank - Boiler bank connects both the drums. Natural circulation occurs without the aid of any

external down comers

Economisers - Economizer is used downstream of Boiler bank to preheat the feed water absorbing heat

from hot exhaust gases

Pipes- In a water tube boiler, water runs through pipes. The pipes are heated by surrounding fire or hot

gases, and the more the water is heated, the higher it goes until it becomes steam. The pipes then allow the

steam to escape into the upper drum.

Upper Drum- The upper drum is where the steam goes once it's travelled the length of the pipes. The

steam collects in the upper drum, away from the heated pipe, and begins to condense back into water. As

the steam once more becomes liquid it drips down from the upper drum and is collected in a lower drum,

or the mud drum.

Lower Drum- The lower drum is set at the bottom of the water tube boiler beneath the upper drum. The

condensed steam collects here and from the mud drum it goes back into the pipes. The more pressure from

built-up water, the more water that will be turned back into steam and passed through the pipes yet again.

Re-heater- The function of Re-heater is to reheat the steam coming out from high pressure turbine. The Reheater is composed of two sections.

Burners- As evident from the name, these are used for burning pulverized coal or oil.

Working Principle of a Water Tube Boiler

In the water-tube boiler, water flowed through tubes heated externally by combustion gases, and steam

was collected above in a drum. Water tube boilers are very huge and their water holding capacity is

enormous. The water-tube boiler became the standard for all large boilers as they allowed for higher

pressures than earlier boilers, higher than 30 b. Example, Babcock & Wilcox boiler manufactured at

Thermax Boilers Limited. It is a horizontal, externally fired, stationary, high pressure, and water tube boiler

with a super heater

The coal is fed from hopper on to the grate

where it is burnt. The flue gases are deflected by

the fire brick baffles so that they pass across the

left side of the tubes in a beneficial path

transferring heat to water in the tubes and to

the steam in the super heater and finally they

escape into the atmosphere through the

chimney. The drought is regulated by a damper

placed at the back chamber.

The position of water tubes near the furnace is

heated to a higher temper than the rest. Owing

to higher temperature, the density of water

decreases and hence the water rises through the

DESCON ENGINEERING LIMITED

uptake header and short tube to the drum. The water at the back end, which is at a lesser temperature,

now travels down through the long tube and the downcomer header. Thus, a continuous circulation of

water called as natural circulations established between the water tubes and the drum. The steam

produced gets collected above the water in the drum. Here, saturated steam is drawn off the top of the

drum Since water droplets can severely damage turbine blades, dry steam from the steam-drum is again

heated to generate superheated steam at 730F (390C) or higher in order to ensure that there is no water

entrained in the steam. Cool water at the bottom of the steam drum returns to the feed-water drum via

large-bore 'down comer tubes', where it helps pre-heat the feed-water supply. To increase the economy of

the boiler, the exhaust gasses are also used to pre-heat the air blown into the furnace and warm the

feedwater supply. Such water-tube boilers in thermal power station are also called steam generating unit

Visit to Descon Engineering Private Limited

The ASME, Student body of UET Lahore chapter,

Thermodynamic Section organized an educational and field

trip to Descon Engineering Private Limited(Lahore

Manufacturing Works )for all ASME members to aid them in

the learning of the working of Boiler and its manufacturing

process. The feedback from all the Thermodynamic Section

members, the executive body members and the faculty of

Descon was appreciable. A delegation was sent from UET

Lahore to Descon prior to the visit to asking for permission to

visit them during their working hours so that students could

visually see and learn the various processes carried out in the

industry and workshops.

A bus was arranged to take the members from UET to Descon

and bring them back to UET. The visit timings were from 12-3

pm. After we reached there, all members were first given a

brief introduction of Descon by a presentation on multimedia

in a hall, by Descon employees followed by a tea break. A short

question- answering session was also conducted and all the

queries of members were appropriately answered by the

Descon faculty. Later on we were allowed to explore the

industry on foot and observe all the processes being carried

out that could be relevant and useful for our boiler

manufacturing. Some of the relevant processes included

welding, forging, casting and operations of a lathe machine.

After a knowledge filled visit to all the workshops the

members were offered lunch at their local restaurant.

The Descon representatives later on the day handed out their

brochures and a hardcopy of their productive data to the

executive body members of the Thermody-namic ASME

section which was intended to allow students to boost their

knowledge about Descon and later on assist them in job

interviews.

Thus a successful and informative field trip came to an end

with executive members briefing the section members of the

DESCON ENGINEERING LIMITED

manufacturing processes with appropriate sequence to be used for boiler construction. A technical

discussion session was carried out eventually to clarify any further queries regarding the manufacturing.

As a result of the field trip new dates, deadlines and revised tasks were then planned to propagate the

fabrication process.

DESCON ENGINEERIG

Descon Engineering Limited is an integrated engineering services and manufacturing company operating in

Pakistan, South East Asia and the Middle East since its inception in 1977. It has evolved into a leading

engineering company serving various sectors. With major operations in Pakistan, Qatar, Kuwait, Saudi

Arabia, and the United Arab Emirates, a workforce of over 38,000 extensive equipment resources, and a

history of executing large-scale construction and manufacturing projects. The integrated package of

services encompasses engineering, procurement, manufacturing, construction, commissioning

and maintenance.

With over 30 years of engineering, procurement, construction, manufacturing and project management

experience, alliances with the worlds leading process equipment technology developers and multiple

state-of-the-art fabrication facilities. Descon delivers high quality process equipment solutions at the most

competitive prices.

PROJECTS

Descon has executed major projects in the sectors of oil and gas, chemical, petrochemical, fertilizer,

power, cement and infrastructure. These projects have been delivered to clients who are investors,

operators or themselves EPC contractors. Major international exploration and production companies, oil

marketing companies and owners/operators have had their investments secured by entrusting Descon to

implement their projects according to their budgets and time schedules while adhering to international

quality standards and with zero tolerance towards unsafe practices and damage to the environment.

The combination of an experienced human resource pool and well established project management

systems have enabled us to succeed and grow in a competitive environment. From compact process plants

to large civil infrastructure projects we have delivered a wide variety of projects of national importance.

Descon has executed power projects with a total capacity of approximately 10,000 MW. Descon has to a

large extent helped shape the fertilizer sector in the region. The fertilizer complexes include Ammonia,

Urea, DAP and NP Plants as well as CO2 recovery units. In chemical and petrochemical industry a wide

range of plants, such as; PTA, Ethylene, Polyethylene, Polypropylene, PDH, Hydrogen, Nitrogen Peroxide

etc. Descon manufacturing facilities have delivered a wide range of cement plant equipment, including

kilns, silos, hoppers/bins and conveying equipment in middle-east. Descon has rapidly established itself as

a key player in infrastructure projects and successfully execute large-scale projects like dams, barrages,

canals, highways and hydro-electric units. Heavy lifts and rigging expertise is based on a demonstrated

track record and an extensive fleet of cranes, the largest of which is of 1200 tons capacity.

MANUFACTURING

Descon has seven manufacturing/fabrication facilities strategically located in Pakistan and the Gulf

Cooperation Countries. Each shop specializes in producing a specific type of product.

In general the product range spans industrial process equipment and fabricated items. Complete

packages such as boilers, process skids, tanks, heat transfer equipment are tailored to the client

requirements and delivered on a turnkey basis.

DESCON ENGINEERING LIMITED

Descon has provided over 134 boilers, with cumulative steam production of more than 5000 tons per

hour, over 1100 pressure vessels (columns, drums, separators etc), 500 heat exchangers, 450 storage

tanks and over 100,000 tons of steel structure.

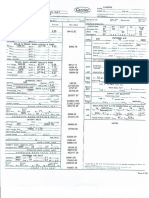

Descon is authorized to produce ASME certified equipment (A, PP, S, U and U2 stamps). Additional

certifications include R Stamp issued by National Board of Boiler and Pressure vessel inspectors and CE

marking (specifically for European Region). Manufacturing strength is complemented with global

technological alliances for specialized equipment. Integrated customized management systems ensure

cross functional monitoring of the processes and timely delivery of the goods. Use of quality management

system assures quality at each step of planning, design, fabrication & production.

PRODUCTS

Process Equipment

Pressure Vessels

Columns

Separators

Knock-out Drums

Slug Catchers

Heat Transfer Equipment

Heat Exchangers

Air Fin Coolers

Furnaces

Heaters

Boilers

Heat Recovery Steam Generators (HRSGs)

Once Through Steam Generators (OTSG)

Direct Fired

Process

Fossil or Non-Fossil Fuel Fired

Pre-Engineered Skids

Amine / TEG Units

Dew Point Control Units

Separator Packages

Glycol Dehydration

Chemical Injection

LPG Road Tankers

Rigid bobtail delivery truck

Articulated

Field Erected Storage Tanks

Flare Stacks

Steel Structure

Piping Spools

Wind Tower

Salt Heaters

Cement Plants

MILESTONES IN MANUFACTURING WORKS

It all started in a small one room office in Lahore. The pioneers of the company came from a fertilizer plant.

It was the entrepreneurial spirit of four people who had a vision of building a lasting institution prominent

for its professionalism and distinguished by the desire of creating a world-class engineering powerhouse.

1977 Company established

1980 Olayan Descon JV formed in Olayan Saudi Arabia

1982 Descon Manufacturing Works commissioned

1982 Office established in Abu Dhabi

2000 JV engineering company formed with JGC Corporation

2000 Presson Descon (PDIL) formed, a JV with Presson Canada

2001 Fabrication shop established in Ruwais, Abu Dhabi

2002 Yanbu workshop commissioned

2004 Descon Engineering Qatar, LLC established

2005 Hamriyah Manufacturing Works in Sharjah commissioned

DESCON ENGINEERING LIMITED

2006 Rousch Power Plant and Altern Energy acquired by Descon

2007 Karachi Manufacturing Works commissioned

2007 First major EPC contract acquired from Fertil, Abu Dhabi

2008 Descon Oxychem commissioned

2010 JGC-Descon becomes Descon Integrated Projects., Limited

2010 Fabrication shop commissioned in Qatar

DESIGN AND ENGINEERING

There are three distinct groups for engineering and the total number exceeds 600 design engineers:

Plant design

Product design

Infrastructure design

A strong in-house design and engineering capability exists to support proposal generation and project

exhibition. The design and engineering team has extensive experience of working to international industry

codes, standards, software and the best practices. The in-house capability to perform the following:

Basic Engineering

Detailed Engineering

Preparation of equipment specification and data sheets

Preparation of operation and maintenance manuals.

DESIGN CODES AND STANDARDS

ASME

EN

ASTM

ANS

AISC

API

TEMA

AWS

ADR

TRD

SOFTWARE

Civil

STAAD Pro

STAAD Foundation

SAP-2000

Piping

CADPipe

CASESAR II

Mechanical

TANK

ASPEN B-JAC

DISASU

Electrical

ETAP

LUXICON

Smart Plant

Electrical

Process

Chempro

PRO II

FLARENET

HYSIS

PIPESIM

HTRI

ASPEN Plus / ASPEN ZYQAD

Tray 2000

Best Pipe

Paula

ASPEN (HTFS)

ESTPRO

DESCON ENGINEERING LIMITED

FABRICATION

Fabrication resources include:

Overhead Mobile Cranes

Fork Lifters

Shearing Machines

Radial Drilling

Magnetic Base Drill Machine

Column and Boom Welding Machi

QUALITY CONTROL AND ASSURANCE

A strong commitment to quality assurance and quality control (QA/QC) is inherent throughout the

manufacturing business process and is governed by a comprehensive ISO: 9001:2000 Quality Management

Systems.

Salient functions of QA/QC include the following:

Design verification

Inspection of incoming materials

Stage inspections

Non-destructive inspections

Visual and dimensional examination

Pressure testing

Liaising with third party inspection agencies

Preparation of inspection data manuals

DESCON ENGINEERING LIMITED

DESCON ENGINEERING LIMITED

DESCON ENGINEERING LIMITED

DESCON ENGINEERING LIMITED

QUESTION SESSION BY STUDENTS

The students of ASME, UET Lahore Chapter, were given a reception in conference room and Production

and Marketing engineer of Descon Mr. Umar khan delivered a presentation about the Descon. At the end

and during presentation, the students asked him questions.

Rizwan Ail asked about the industrial softwares. Mr. Umar khan Answered that Industry has its own

softwares that are purchased by that Company. The Engineers are specially trained to work on these

softwares. The duration of training is specific. These softwares are very productive and advance.

Another question asked by student was what type of Engineers do you hire? Mr. Umar Khan replied him

that here we hire l the engineers of all the departments but mostly are those of Mechanical and

Metallurgical.

The students asked what sorts of projects you do? Mr. Umar Khan replied we have different sectors, oil

and Gas, electricity Generation, Boilers, cement, Chemical power plant and in these sectors we are doing

various sorts of projects like designing and fabrication of boiler, Generation of Electricity of 100MW and we

are selling this electricity to Wapda. He also told us that recently a group of students of UET had a project

with us.

Another student also asked him about the working hours. He replied that we work in different shifts.

Generally, we have three shifts in a complete day and employees are being changed after each shift.

After this we visited the whole working area. The students asked the questions about milling, rolling,

forging and honing. Then we also visited Boiler section. There the fabrication of Boiler was in Operation.

We asked about maintenance, designing, operation, different technical terms to the Engineers. He briefed

us well. The students also visited welding section and also asked about different questions about types of

welding SMAW, GMAW, TIG, MIG and others as well.

STUDENTS AND COMPANYS RESPONSE

All the students enjoyed this marvellous Study tour. All the ASME student members appreciated Manager,

Assistance Manager and the whole management who arranged this tour. We found it very useful for our

studies. We had an opportunity to see the things practically and visualize the things. We also got an

opportunity to see the Engineers who are working in industry. Most of them were UETIANZ. We were also

encouraged to see them at main posts of the industry. The students were very satisfied and encouraged

the management to arrange such tours more and more. The companys response was credible. They

treated us in a very nice way. They answered our questions, honoured us, serve us with tea .They had

already done these arrangements before our arrival. During our visit all the employees of Descon helped

and encouraged us. After the visit, they also served us lunch. After this they said us good-Bye with well

wishes.

DESCON ENGINEERING LIMITED

CONCLUSION

It was a very credible Industrial tour. All the students enjoyed this and from learning point of view it was

too much productive for all juniors and seniors members. The students of different departments also got

an opportunity to see each other. All appreciated the management and expected more such tours to

different multinational industries all over the Pakistan.

Rizwan Ali

Bsc. Mechanical Engineering Student

Assistant Manager

Thermodynamics Section

ASME UET Lahore, Pakistan

rizwanali976@gmail.com

+92-300-4094863

También podría gustarte

- JJDocumento1 páginaJJmsaqibraza93Aún no hay calificaciones

- Under, Over and Critical DampingDocumento6 páginasUnder, Over and Critical Dampingxeron7126Aún no hay calificaciones

- New Text DocumentDocumento2 páginasNew Text Documentmsaqibraza93Aún no hay calificaciones

- Acceptance Form MSDocumento1 páginaAcceptance Form MSmsaqibraza93Aún no hay calificaciones

- KKKDocumento3 páginasKKKmsaqibraza93Aún no hay calificaciones

- NNDocumento1 páginaNNmsaqibraza93Aún no hay calificaciones

- LDocumento2 páginasLmsaqibraza93Aún no hay calificaciones

- New Microsoft Word DocumentDocumento1 páginaNew Microsoft Word Documentmsaqibraza93Aún no hay calificaciones

- Graph B/W Load and DeflectionDocumento1 páginaGraph B/W Load and Deflectionmsaqibraza93Aún no hay calificaciones

- NNDocumento1 páginaNNmsaqibraza93Aún no hay calificaciones

- New Microsoft Word DocumentDocumento1 páginaNew Microsoft Word Documentmsaqibraza93Aún no hay calificaciones

- JJDocumento1 páginaJJmsaqibraza93Aún no hay calificaciones

- JJDocumento1 páginaJJmsaqibraza93Aún no hay calificaciones

- New Microsoft Word DocumentDocumento1 páginaNew Microsoft Word Documentmsaqibraza93Aún no hay calificaciones

- New Microsoft Word DocumentDocumento1 páginaNew Microsoft Word Documentmsaqibraza93Aún no hay calificaciones

- New Microsoft Word DocumentDocumento1 páginaNew Microsoft Word Documentmsaqibraza93Aún no hay calificaciones

- New Microsoft Word DocumentDocumento1 páginaNew Microsoft Word Documentmsaqibraza93Aún no hay calificaciones

- Cam Using MatlabDocumento4 páginasCam Using Matlabmsaqibraza93Aún no hay calificaciones

- NDocumento3 páginasNmsaqibraza93Aún no hay calificaciones

- Hydrotesting of ShellDocumento4 páginasHydrotesting of Shellmsaqibraza93Aún no hay calificaciones

- English at Home BookDocumento22 páginasEnglish at Home BookShafique RehmanAún no hay calificaciones

- New Microsoft Word DocumentDocumento1 páginaNew Microsoft Word Documentmsaqibraza93Aún no hay calificaciones

- Mechanics of Material Lab: Submitted byDocumento2 páginasMechanics of Material Lab: Submitted bymsaqibraza93Aún no hay calificaciones

- Graph B/W T & Distance For Counter Flow For Multiple Temp Settings (QC 1 Litr/min)Documento1 páginaGraph B/W T & Distance For Counter Flow For Multiple Temp Settings (QC 1 Litr/min)msaqibraza93Aún no hay calificaciones

- Graph B/W T & Distance For Counter Flow For Multiple Temp Settings (QC 1 Litr/min)Documento1 páginaGraph B/W T & Distance For Counter Flow For Multiple Temp Settings (QC 1 Litr/min)msaqibraza93Aún no hay calificaciones

- Graph B/W T & Distance For Parallel FlowDocumento1 páginaGraph B/W T & Distance For Parallel Flowmsaqibraza93Aún no hay calificaciones

- Basic Principle of Each TestDocumento18 páginasBasic Principle of Each Testmsaqibraza93Aún no hay calificaciones

- Graph B/W T & Distance For Counter Flow For Multiple Temp SettingsDocumento1 páginaGraph B/W T & Distance For Counter Flow For Multiple Temp Settingsmsaqibraza93Aún no hay calificaciones

- Graph B/W T & Distance For Counter FlowDocumento1 páginaGraph B/W T & Distance For Counter Flowmsaqibraza93Aún no hay calificaciones

- Graph B/W T & Distance For Counter Flow For Multiple Temp Settings (QC 1 Litr/min)Documento1 páginaGraph B/W T & Distance For Counter Flow For Multiple Temp Settings (QC 1 Litr/min)msaqibraza93Aún no hay calificaciones

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (344)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (121)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2104)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- CMR - Plus - HYSYS (Aspentech)Documento8 páginasCMR - Plus - HYSYS (Aspentech)Ian MannAún no hay calificaciones

- Machines Guideline For Students (MEHB321)Documento18 páginasMachines Guideline For Students (MEHB321)Fikri AzimAún no hay calificaciones

- Refinery Presentation On 07th July 07Documento83 páginasRefinery Presentation On 07th July 07meenuAún no hay calificaciones

- Experiment 3 - Study and Performance Test On Reciprocating Compressor Test RigDocumento6 páginasExperiment 3 - Study and Performance Test On Reciprocating Compressor Test Rigf20221047Aún no hay calificaciones

- Signup 1234yf ASHRAE Part 2Documento20 páginasSignup 1234yf ASHRAE Part 2Abhijit SarkarAún no hay calificaciones

- Ejectors Applications in Refrigeration TechnologyDocumento27 páginasEjectors Applications in Refrigeration TechnologyRizwan Ali100% (1)

- Ishan Equipments Pvt. Ltd. (Unit-Ii) : Form Iv ADocumento3 páginasIshan Equipments Pvt. Ltd. (Unit-Ii) : Form Iv AJaysinh KumpavatAún no hay calificaciones

- Main TGDocumento34 páginasMain TGAniket GargAún no hay calificaciones

- Blank Heat Load FormDocumento1 páginaBlank Heat Load FormJiuan AndradaAún no hay calificaciones

- Rrs-Group-Company-Profile PT - Raja Rafa SamudraDocumento36 páginasRrs-Group-Company-Profile PT - Raja Rafa SamudraYathi SyahriAún no hay calificaciones

- Catalogue of Water Cooled Chiller 20171206Documento14 páginasCatalogue of Water Cooled Chiller 20171206ferdie107Aún no hay calificaciones

- Efficiency Assessment of Condensing Steam TurbineDocumento6 páginasEfficiency Assessment of Condensing Steam TurbineJoko PurnomoAún no hay calificaciones

- ICE Assignment 15032017 035808AMDocumento5 páginasICE Assignment 15032017 035808AMGerlan Madrid MingoAún no hay calificaciones

- NRC Report August 2010 - MHI SG IssuesDocumento18 páginasNRC Report August 2010 - MHI SG IssuesEnformableAún no hay calificaciones

- Tom Durkin, Senior Partner Sims-Durkin Associates Indianapolis, IN Tom Durkin, Senior Partner Sims-Durkin Associates Indianapolis, INDocumento13 páginasTom Durkin, Senior Partner Sims-Durkin Associates Indianapolis, IN Tom Durkin, Senior Partner Sims-Durkin Associates Indianapolis, INCarlos SamaniegoAún no hay calificaciones

- General Pumping System and The Net Head Developed by A PumpDocumento14 páginasGeneral Pumping System and The Net Head Developed by A PumpMohit SharmaAún no hay calificaciones

- Renewable Energy EP703: Presented: Naser El NailyDocumento37 páginasRenewable Energy EP703: Presented: Naser El NailykemoAún no hay calificaciones

- Engineering Data RS160i A 60HZ 47659924 ADocumento1 páginaEngineering Data RS160i A 60HZ 47659924 AJoel100% (1)

- Shimpalee CV 092021Documento19 páginasShimpalee CV 092021Para DiseAún no hay calificaciones

- Allan Jacobson - ENERGY-Fuel Cell-2Documento23 páginasAllan Jacobson - ENERGY-Fuel Cell-2Swarup SahuAún no hay calificaciones

- Ba880 VLR60-251 enDocumento34 páginasBa880 VLR60-251 enluislisinAún no hay calificaciones

- Copper, Table 'X'. Flow of Water in Pipes Table: - Pipe Sizing - PageDocumento4 páginasCopper, Table 'X'. Flow of Water in Pipes Table: - Pipe Sizing - PagestarykltAún no hay calificaciones

- Introduction To Ic EnginesDocumento14 páginasIntroduction To Ic EnginesSai Sudheer100% (1)

- 12 Seaboard Armando RodriguezDocumento54 páginas12 Seaboard Armando RodriguezJean Luis Reyes BerroaAún no hay calificaciones

- Chimney Sizing Calculation-R1Documento3 páginasChimney Sizing Calculation-R1Arun Kumar67% (3)

- End-Suction EN733 Centrifugal Pump SKS: Water and Wastewater SolutionsDocumento6 páginasEnd-Suction EN733 Centrifugal Pump SKS: Water and Wastewater SolutionsARYAN_FATHONI_AMRIAún no hay calificaciones

- 0000868254Documento2139 páginas0000868254Raden MasAún no hay calificaciones

- 1 Tianjin Sinogas General Introduction-2021Documento52 páginas1 Tianjin Sinogas General Introduction-2021Cesar G.Aún no hay calificaciones

- Howden 20american 20fan 20product 20catalogDocumento8 páginasHowden 20american 20fan 20product 20catalogFarid ZubaidyAún no hay calificaciones

- Shathish Solar PVDocumento7 páginasShathish Solar PVshathishAún no hay calificaciones