Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Area Reinforcement Calculator

Cargado por

Anonymous Iev5ggSRDerechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Area Reinforcement Calculator

Cargado por

Anonymous Iev5ggSRCopyright:

Formatos disponibles

S

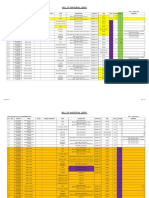

Project: KAT065

RasLaffan B

Isometric: 10EKG50BR001, Rev. 1

Document No.

Area Reinforcement Calculation

As per para 104.3 of ASME B31.1(2004) (for branches intersecting perpendicularly to run pipe, = 90)

Line KKS :

Design Pressure, P0 :

Operating Temperature, T0:

10EKG50BR001

39 (bar)

Weld Number

15

565.62 (psi)

80 ( C)

Material : A106 Gr.B

Allowable Stress

15000 (psi)

OD of Run Pipe, DO1 : 20"

OD of the Run Pipe, DOh :

103.41 (N/mm)

508 (mm)

20.00 (in)

0.50 (in)

Thk. of the Run Pipe :

OD of branch pipe, DO2 : 8"

OD of branch pipe, DOb :

219.08 (mm)

8.63 (in)

Thk. Of the branch pipe :

Pipe Manufacturing :

Corriosion Allowancer, c :

176 ( F)

Thk. of Main Header, tO1:

Sch 30

12.70 (mm)

Thk. at Vent Inlet, tO2: Sch STD

9.53 (mm)

0.38 (in)

Seamless

0.00 (in)

0 (mm)

Pressure Factor, y

0.4

1.0

Weld efficiency factor, E

Run Pipe Min. Wall thk, Th :

0.438 (in)

11.11 (mm)

Branch Pipe Min. Wall thk, Tb :

0.328 (in)

8.34 (mm)

Req. Min. Wall thickness of Run Pipe,Tmh

0.371 (in)

9.44 (mm)

Req. Min. Wall thickness of Branch Pipe,Tmb

0.160 (in)

4.07 (mm)

ID of Branch, d1 :

Half width of reinforcement zone, d2 :

7.969 (in)

7.969 (in)

202.40 (mm)

202.40 (mm)

Altiitude of reinforcement zone, L4 :

0.821 (in)

20.85 (mm)

Reinforcement area required, A7 :

2.960 (in2)

1909.76 (mm2)

Reinforced area by header, A1 :

0.526 (in2)

339.44 (mm2)

Reinforced area by branch, A2 :

0.276 (in2)

178.02 (mm2)

Reinforced area by welding, A3 :

0.037 (in2)

24.09 (mm2)

-2.121 (in2)

-1368.22 (mm2)

REINFORCEMENT REQUIRED, Less by

Proceed further only if reinforcement is required

Pad thickness, tr :

Width of Pad, W :

0.63 (in)

2.56 (in)

16 (mm)

65 (mm)

Clearance b/w ID of pad and branch OD :

Pad Diameter, dp :

0.16 (in)

14 (in)

4 (mm)

357.08 (mm)

Recalculate L4 :

Recalulate reinforced area by welding, A3 :

0.82 (in)

20.85 (mm)

Recalculate A1+A2+A3+A4 :

Utilisation Factor :

By:

Chck:

0.18 (in2)

4.51 (mm2)

4.07 (in2)

2623.05 (mm2)

72.81% (Keep below 80%)

Page 1 of 5

UNID N0:

System: EKG

Dated: 2005-09-28

260945423.xls

Isometric: 10EKG50BR001, Rev. 1

Document No.

Node No: -

By:

Chck:

Stress Report: N/A

Page 2 of 5

UNID N0:

Project: KAT065

RasLaffan B

Remarks: Note (1)

System: EKG

Dated: 2005-09-28

260945423.xls

Project: KAT065

RasLaffan B

Annexure :1

Document No.

Assumptions:

1)

The Branch and the header pipe intersect perpendicularly.

2)

Reinforcement pad material is considered same as the parent header material.

3)

Branch pipe and the header pipe are assumed to be of same material.

4)

Nominal pipe thickness of header and the branch is reduced by:

12.5 % for all seamless pipes

0.3 mm for all welded pipes,except API grades there 12.5% prevail.

5)

Weld Point is the weld no. of the branch pipe to header pipe as given in isometric.

6)

Branch pipes with NB 2" and less do not require stub in connection.

7)

No pads to be used for A335 P22 and P91 materials. Only Weldolets allowed.

Calculation:

1)

Reinforcement pad calculation has been carried out as per ASME B31.1 Para 104.3

2)

Reinforcement pad calculation applicable only to stub in connection.

3)

Reinforcement requirements should also be checked considering limiting stress at the

branch point both from stress and internal pressure view point. Relevant stress

calculation should be performed using appropriate stress analysis program and the

summary of the output for reinforced tee nodes should be furnished in Annexure 3.

Description of Notes:

Note(1) Reinforcement pad req'd both in stress analysis viewpoint and in internal pressure viewpoint

Note(2) Reinforcement pad req'd not in stress analysis viewpoint, but in internal pressure viewpoint

Note(3) Reinforcement pad req'd in stress analysis viewpoint, but not in internal pressure viewpoint

Note(4) Reinforcement pad req'd neither in stress analysis viewpoint nor in internal pressure viewpoint

By:

Chck:

Page 3 of 5

UNID N0:

System: EKG

Dated: 2005-09-28

260945423.xls

Project: KAT065

RasLaffan B

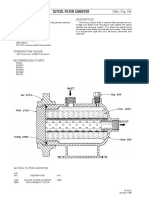

Reinforcement Area Sketch

Document No.

ANNEXURE - 2

FIG .1 : REINFORCEMENT AREA SKETCH

- ASME B 31.1 FIG. 104.31 (D)

Tm b

Tb

d1

L4

Tm h

A3

A4

=

A2

B

R

A

N

C

H

A4

A3

Tr

A4

A1

d2

Th

A7

d2

MAIN HEADER

FIG. 2 : FIGURE SHOWING WELD THROAT

- ASME B 31.1 FIG. 127.4.4 (A)

THEORETICAL THROAT

LEG

LENGTH

By:

Chck:

Page 4 of 5

UNID N0:

System: EKG

Dated: 2005-09-28

260945423.xls

Project: KAT065

RasLaffan B

Annexure :3

Document No.

Stress Analysis input /output summary for the Reinforced Tee Points

By:

Chck:

NODE

NO.

DESCRIPTION

SIF

MAX

STRESS

N/mm2

ALLOWABLE

STRESS

N/mm2

CODE

STRESS

%

CASE

STRESS ANALYSIS

DOC. NO.

11190

Reinforced TEE with 20

mm pad thickness

5.891

105.68

115.89

91.2

CASE 45

(OCC)

SHI_SA_001

Page 5 of 5

UNID N0:

REMARKS

System: EKG

Dated: 2005-09-28

260945423.xls

También podría gustarte

- Area Reinforcement CalculatorDocumento5 páginasArea Reinforcement CalculatorAnonymous Iev5ggSR100% (1)

- Reinf S1Documento2 páginasReinf S1tasingenieriaAún no hay calificaciones

- PIPE THICKNESS CALCULATIONDocumento11 páginasPIPE THICKNESS CALCULATIONvazzoleralex6884100% (1)

- 42in Branch Reinforment CalDocumento10 páginas42in Branch Reinforment CalDhakshina KAún no hay calificaciones

- Reinforcement CalculationDocumento2 páginasReinforcement CalculationVekaymech100% (9)

- Branch Reinforcement Pad Requirement CalculationDocumento2 páginasBranch Reinforcement Pad Requirement CalculationAntoshal100% (4)

- Pipe Reinforcement Calculation (ASME-B31.3)Documento3 páginasPipe Reinforcement Calculation (ASME-B31.3)jenshid100% (2)

- Reinforcement Pad CalculationDocumento4 páginasReinforcement Pad CalculationMohammad AbdullahAún no hay calificaciones

- ASME 31 - 8mDocumento1 páginaASME 31 - 8mMarcoAlbaAún no hay calificaciones

- Asme b31 3 03 PDFDocumento3 páginasAsme b31 3 03 PDFAtallah BoufatahAún no hay calificaciones

- Calculation of Pipe Reinforcement ASME B31 3Documento4 páginasCalculation of Pipe Reinforcement ASME B31 3ArmandoZacariasAcosta0% (1)

- Calculation of PipeReinforcement ASMEB31 1Documento4 páginasCalculation of PipeReinforcement ASMEB31 1threedlabsAún no hay calificaciones

- Sif B31 3Documento24 páginasSif B31 3vuqar0979100% (1)

- PRESSURE DESIGN AND REINFORCEMENT OF STRAIGHT PIPES AND BRANCH CONNECTIONSDocumento5 páginasPRESSURE DESIGN AND REINFORCEMENT OF STRAIGHT PIPES AND BRANCH CONNECTIONSUmar Aslam0% (1)

- SIF CalculatorDocumento4 páginasSIF CalculatorKannaphat WattanaphanAún no hay calificaciones

- Nozzle Reinforcement Calculation Excel SheetDocumento3 páginasNozzle Reinforcement Calculation Excel Sheetramesh punjabiAún no hay calificaciones

- Wall Thickness Calculation for Piping SystemsDocumento47 páginasWall Thickness Calculation for Piping Systemsthinhvipro100% (1)

- Copiar de ReinforcementAreaDocumento6 páginasCopiar de ReinforcementArealavascudoAún no hay calificaciones

- Branch RF CalcDocumento6 páginasBranch RF CalcHarish Harish0% (1)

- Pipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)Documento1 páginaPipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)farhadAún no hay calificaciones

- Preva: Pressure Vessels and Heat ExchangersDocumento6 páginasPreva: Pressure Vessels and Heat ExchangersTrishul Nath PallayAún no hay calificaciones

- TECHLOK Clamp Connector Technical WebversionDocumento32 páginasTECHLOK Clamp Connector Technical WebversionAndresAún no hay calificaciones

- Pipe Saddle Support CalculationsDocumento1 páginaPipe Saddle Support CalculationsAbir Baran HandaAún no hay calificaciones

- Saddle Support Design SpreadsheetDocumento17 páginasSaddle Support Design SpreadsheetChiragJansari50% (2)

- SIF ExcelDocumento3 páginasSIF ExcelaravindhcamAún no hay calificaciones

- Pipes. Maximum Span Between Pipe Supports For A Given Maximum Bending StressDocumento64 páginasPipes. Maximum Span Between Pipe Supports For A Given Maximum Bending StressselisenAún no hay calificaciones

- Wall Thickness and MITERDocumento1 páginaWall Thickness and MITERnirgaAún no hay calificaciones

- Stress Analysis of Reactor Nozzle To HeadDocumento5 páginasStress Analysis of Reactor Nozzle To HeadKagira Drawing SoltuionAún no hay calificaciones

- TrunnionDocumento20 páginasTrunnionGowtham JayaprakashAún no hay calificaciones

- Standard Shoe Verification Rev - ADocumento19 páginasStandard Shoe Verification Rev - AballisnothingAún no hay calificaciones

- Pipe Support Span CalculationDocumento1 páginaPipe Support Span CalculationAshitava SenAún no hay calificaciones

- Checklist For Stress Analysis-PipingDocumento1 páginaChecklist For Stress Analysis-PipingShailin ShahAún no hay calificaciones

- Calculating saddle dimensions for pipesDocumento2 páginasCalculating saddle dimensions for pipesrinabiswas50% (2)

- ASME B31.3 Process PipingDocumento1 páginaASME B31.3 Process PipingalvinchuanAún no hay calificaciones

- DummyDocumento1 páginaDummythopa_nath100% (2)

- Pressure Drop Calculation - 6 Inch Permeate and Reject PumpDocumento2 páginasPressure Drop Calculation - 6 Inch Permeate and Reject Pumpalmandhari33Aún no hay calificaciones

- Calculation For Reinforced PadDocumento4 páginasCalculation For Reinforced Padjsridhar_34750% (2)

- ASME Ver1 4 (Beta)Documento2 páginasASME Ver1 4 (Beta)arunradAún no hay calificaciones

- Design Sheet As Per ASME 31.8 2012 For 12inch TeeDocumento3 páginasDesign Sheet As Per ASME 31.8 2012 For 12inch TeechethanAún no hay calificaciones

- Pressure & Temperature ClassificationDocumento1 páginaPressure & Temperature Classificationkeo85100% (1)

- Small Vertical Pressure Vessel Leg Support Design - Boiler and Pressure Vessel Engineering - Eng-Tips PDFDocumento6 páginasSmall Vertical Pressure Vessel Leg Support Design - Boiler and Pressure Vessel Engineering - Eng-Tips PDFhussamammarAún no hay calificaciones

- ASME B31.3 Pipe Wall ThicknessDocumento2 páginasASME B31.3 Pipe Wall ThicknessAnonymous cyKuQKAún no hay calificaciones

- Hdpe Pipe Wall Thickness CalculationsDocumento1 páginaHdpe Pipe Wall Thickness CalculationsTsouki TsoukiAún no hay calificaciones

- Checking of Collar Bolts in Shear & Bearing: Client: India Eqpt.: Job No. DR No. Rev. Document NumberDocumento1 páginaChecking of Collar Bolts in Shear & Bearing: Client: India Eqpt.: Job No. DR No. Rev. Document NumbershazanAún no hay calificaciones

- Expansion Loop CalculationDocumento2 páginasExpansion Loop Calculationsk130986100% (1)

- Nozzle Pipe Length CalculatorDocumento5 páginasNozzle Pipe Length CalculatorRyan Goh Chuang HongAún no hay calificaciones

- Imperial Piping Weight Load Calculation WorkbookDocumento13 páginasImperial Piping Weight Load Calculation WorkbookKakoDa100% (1)

- Nozzle Calculation - Primary Reformer Stack-R0Documento22 páginasNozzle Calculation - Primary Reformer Stack-R0Aditya Jain100% (1)

- AISC DG02 Example 003 PDFDocumento7 páginasAISC DG02 Example 003 PDFMohamed Abo-ZaidAún no hay calificaciones

- Studding Outlet Calculation - PV Elite 2016Documento8 páginasStudding Outlet Calculation - PV Elite 2016Liu YangtzeAún no hay calificaciones

- Nozzle Calculation - Auxiliary Boiler Stack-R0Documento13 páginasNozzle Calculation - Auxiliary Boiler Stack-R0Aditya JainAún no hay calificaciones

- VD-SRU-V-004-100-Rev ADocumento51 páginasVD-SRU-V-004-100-Rev ASYedZYnAleAún no hay calificaciones

- Miter B1 ADocumento55 páginasMiter B1 AFarid TataAún no hay calificaciones

- EN6114Documento17 páginasEN6114Andrei Cozma67% (3)

- Trunnion N392-3 R0Documento30 páginasTrunnion N392-3 R0Sergio Smith100% (1)

- PV Elite 2013 SP3 Licensee: ISGEC TubeSheet CalcDocumento8 páginasPV Elite 2013 SP3 Licensee: ISGEC TubeSheet CalcMayank MittalAún no hay calificaciones

- SampleCalculationspipingB3132008 PDFDocumento13 páginasSampleCalculationspipingB3132008 PDFsosatlantiqueAún no hay calificaciones

- Statical Calculation of 50m TowerDocumento25 páginasStatical Calculation of 50m TowerYusuf Akkuş75% (4)

- 1.0 Rectangular Column-BIAXIALDocumento31 páginas1.0 Rectangular Column-BIAXIALFranklyn P. Genove100% (1)

- DGN Status 16.Documento2 páginasDGN Status 16.Anonymous Iev5ggSRAún no hay calificaciones

- Safety Valve Reaction Foce Calculation: Isometric: 10Lbg10Br192, Rev. A Project: Kat065 Raslaffan BDocumento4 páginasSafety Valve Reaction Foce Calculation: Isometric: 10Lbg10Br192, Rev. A Project: Kat065 Raslaffan BAnonymous Iev5ggSRAún no hay calificaciones

- Pipe List Working LATESTDocumento2 páginasPipe List Working LATESTAnonymous Iev5ggSRAún no hay calificaciones

- FGD Bill of Materials for 693MW Power ProjectDocumento4 páginasFGD Bill of Materials for 693MW Power ProjectAnonymous Iev5ggSRAún no hay calificaciones

- Support Span Calculation FRP.Documento2 páginasSupport Span Calculation FRP.Anonymous Iev5ggSRAún no hay calificaciones

- Gr91 - DS2a2009 - Released Version by ECCC April09Documento3 páginasGr91 - DS2a2009 - Released Version by ECCC April09Anonymous Iev5ggSRAún no hay calificaciones

- 06-086-098 Weld Ring GasketsDocumento13 páginas06-086-098 Weld Ring GasketsRitesh VishambhariAún no hay calificaciones

- Stock Flanges Include Socket Weld, Butt Weld, NPTF and SAE StraightDocumento4 páginasStock Flanges Include Socket Weld, Butt Weld, NPTF and SAE StraightAnonymous Iev5ggSRAún no hay calificaciones

- 04 044 052 Spiroflex Spiral Wound GasketsDocumento9 páginas04 044 052 Spiroflex Spiral Wound Gasketsgazwang478Aún no hay calificaciones

- 06-086-098 Weld Ring GasketsDocumento13 páginas06-086-098 Weld Ring GasketsRitesh VishambhariAún no hay calificaciones

- Grooved Kempchen PDFDocumento11 páginasGrooved Kempchen PDFAnonymous Iev5ggSRAún no hay calificaciones

- Ami Product Guide CatalogDocumento50 páginasAmi Product Guide CatalogAnonymous Iev5ggSRAún no hay calificaciones

- Senior Flexonics Expansion JointsDocumento93 páginasSenior Flexonics Expansion JointssunethbabuAún no hay calificaciones

- Structural Detailing in SteelDocumento253 páginasStructural Detailing in Steelandrugrasu100% (27)

- Everything You Need to Know About GRP PipesDocumento24 páginasEverything You Need to Know About GRP PipesmgjorAún no hay calificaciones

- Pipe Size CalculationDocumento28 páginasPipe Size CalculationAnonymous Iev5ggSR100% (1)

- Pipe Dimension and Support Span TableDocumento4 páginasPipe Dimension and Support Span TableAnonymous Iev5ggSRAún no hay calificaciones

- Snow Load As Weight Per MM Calculation 330Documento1 páginaSnow Load As Weight Per MM Calculation 330Anonymous Iev5ggSRAún no hay calificaciones

- Turbocompressor For Aeration STC-GO - SiemensDocumento6 páginasTurbocompressor For Aeration STC-GO - SiemensAnonymous Iev5ggSRAún no hay calificaciones

- Coade Piping Stress Analysis SeminarDocumento66 páginasCoade Piping Stress Analysis SeminarAnonymous Iev5ggSRAún no hay calificaciones

- Bourdon Effect in CAESAR II: Intergraph CASDocumento3 páginasBourdon Effect in CAESAR II: Intergraph CASAnonymous Iev5ggSR100% (1)

- Pipe Thickness Calculation AS Per ASME 31.3Documento11 páginasPipe Thickness Calculation AS Per ASME 31.3Anonymous Iev5ggSRAún no hay calificaciones

- Diagrams Indicating Terminal PointsDocumento6 páginasDiagrams Indicating Terminal PointsAnonymous Iev5ggSRAún no hay calificaciones

- En-13480 Allowable Stresses SH - Intergraph CADWorx & AnalysisDocumento7 páginasEn-13480 Allowable Stresses SH - Intergraph CADWorx & AnalysisAnonymous Iev5ggSRAún no hay calificaciones

- Tractebel Engineering Pvt. LTD.: GGNA-G-01136-123 Rev 00Documento4 páginasTractebel Engineering Pvt. LTD.: GGNA-G-01136-123 Rev 00Anonymous Iev5ggSRAún no hay calificaciones

- DM Water SystemDocumento1 páginaDM Water SystemAnonymous Iev5ggSRAún no hay calificaciones

- Safety Valve Reaction Foce Calculation: Isometric: 10Lbg10Br192, Rev. A Project: Kat065 Raslaffan BDocumento4 páginasSafety Valve Reaction Foce Calculation: Isometric: 10Lbg10Br192, Rev. A Project: Kat065 Raslaffan BAnonymous Iev5ggSRAún no hay calificaciones

- LISEGA Catalog 2010Documento7 páginasLISEGA Catalog 2010Olivier RioAún no hay calificaciones

- STEAM TURBINE 3 Design and MaterialsDocumento19 páginasSTEAM TURBINE 3 Design and MaterialsHandayani Kesumadewi100% (2)

- PipeHanger DesignEngineering Catalog PDFDocumento84 páginasPipeHanger DesignEngineering Catalog PDFRaheem_kaAún no hay calificaciones

- MV Introduction LetterDocumento1 páginaMV Introduction LetterSoriSori2008Aún no hay calificaciones

- KV Sizer GuideDocumento3 páginasKV Sizer GuideBasavaraj ManturAún no hay calificaciones

- Danfoss Sem Safe Section Valve Deluge Pipe SystemDocumento5 páginasDanfoss Sem Safe Section Valve Deluge Pipe SystemYusuf ÖğrenAún no hay calificaciones

- ME 503 Advanced Gas Dynamics SyllabusDocumento4 páginasME 503 Advanced Gas Dynamics SyllabuscansuyusAún no hay calificaciones

- BF1-BF3 Atmos GIGA-I 200 - 295-55 - 4 - 6-L - 460 REV IE4Documento3 páginasBF1-BF3 Atmos GIGA-I 200 - 295-55 - 4 - 6-L - 460 REV IE4Virgilio B. CañizaresAún no hay calificaciones

- Power Team PA6 Pumps - CatalogDocumento2 páginasPower Team PA6 Pumps - CatalogTitanplyAún no hay calificaciones

- Spare Parts DC Pro XT V.en Rev.14Documento31 páginasSpare Parts DC Pro XT V.en Rev.14serkan çakmakAún no hay calificaciones

- Pressure Recovery and Loss Coefficient Variations in The Two Different Centrifugal Blower Volute DesignsDocumento9 páginasPressure Recovery and Loss Coefficient Variations in The Two Different Centrifugal Blower Volute DesignsJoseph Alexander BorgAún no hay calificaciones

- Wet Chemical Dataran KG BaruDocumento3 páginasWet Chemical Dataran KG BaruJeghiAún no hay calificaciones

- Components of The Glycol Circulating SystemDocumento3 páginasComponents of The Glycol Circulating SystemdndudcAún no hay calificaciones

- Computational Fluid Dynamics of The Pipe (Circular, Rectangular, Bend) and Velocity Profile StudyDocumento9 páginasComputational Fluid Dynamics of The Pipe (Circular, Rectangular, Bend) and Velocity Profile Studysaroj basnyatAún no hay calificaciones

- Mud Pump Spare Parts 6-8-22Documento1 páginaMud Pump Spare Parts 6-8-22Eden DavidsonAún no hay calificaciones

- Filter Glycol Particles Before PumpsDocumento2 páginasFilter Glycol Particles Before PumpsRicardo GómezAún no hay calificaciones

- Homework of Bernoulli EqDocumento8 páginasHomework of Bernoulli EqSinggih OktavianAún no hay calificaciones

- Metal Expansion Joints BellowsDocumento12 páginasMetal Expansion Joints BellowsHimangshu MandalAún no hay calificaciones

- 24Z075Documento52 páginas24Z075Boyan RadomirovAún no hay calificaciones

- Instruction Operation Mainteance For Turbocharger Abb VTR 354-11 Glory StarDocumento39 páginasInstruction Operation Mainteance For Turbocharger Abb VTR 354-11 Glory StarHuy Lễ NguyễnAún no hay calificaciones

- Mod 64 ValveDocumento32 páginasMod 64 ValveEduardo TapiaAún no hay calificaciones

- NuFlo Liquid Turbine FlowmetersDocumento6 páginasNuFlo Liquid Turbine FlowmetersphostyAún no hay calificaciones

- Introduction to Iranian Petroleum Standards (IPSDocumento4 páginasIntroduction to Iranian Petroleum Standards (IPSFatima NusserAún no hay calificaciones

- Piping Training RevDDocumento61 páginasPiping Training RevDRajeshSekar100% (1)

- Hydraulic SystemDocumento6 páginasHydraulic SystemHamzah AbuAloushAún no hay calificaciones

- Series 90 130 CC Axial Piston Pump: Parts ManualDocumento132 páginasSeries 90 130 CC Axial Piston Pump: Parts ManualGaren HovsepianAún no hay calificaciones

- Notes: PT Unilever Oleochemical Indonesia Sunshine Project Piping, Insulation & Mecahnical Tender - Osbl & IsblDocumento11 páginasNotes: PT Unilever Oleochemical Indonesia Sunshine Project Piping, Insulation & Mecahnical Tender - Osbl & Isblrizky youlandaAún no hay calificaciones

- Bellows Sealed DN20Documento3 páginasBellows Sealed DN20Turbo Snail RAún no hay calificaciones

- VENTILASI TAMBANG MENGENDALIKAN KUANTITAS UDARADocumento18 páginasVENTILASI TAMBANG MENGENDALIKAN KUANTITAS UDARAEndro kunAún no hay calificaciones

- Design of Pressure Vessel Cone under Internal & External PressureDocumento488 páginasDesign of Pressure Vessel Cone under Internal & External PressureMartin ZaballaAún no hay calificaciones

- Well Completion Equipment OverviewDocumento91 páginasWell Completion Equipment OverviewRanim Hisham100% (1)

- Air Release Valve Selection & SizingDocumento1 páginaAir Release Valve Selection & SizingMahmoud Eldusoky100% (1)

- PC1260Documento4 páginasPC1260hamadaAún no hay calificaciones