Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Automotive Brakes Repair

Cargado por

JoaoTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Automotive Brakes Repair

Cargado por

JoaoCopyright:

Formatos disponibles

BR Menu

Procedure Menu

Uniform

Procedures

For Collision

Repair

BR11Brakes

Copyright 1998 Inter-Industry Conference On Auto Collision Repair

1. Description

This procedure describes repair, replacement, and inspection

requirements for collision-damaged brake systems.

2. Purpose

The purpose of this procedure is to provide industry-accepted

requirements for performing high-quality repair of brake systems. This

procedure is intended for use by professionals who are qualified through

training and experience.

v.2.3

3.

Referenced Documents

The following documents are considered part of this procedure by

reference.

3.1 Procedures

BR51

HM01

PS01

Brakes, Anti-Lock And Traction Control

Hazardous Materials

Personnel Safety

3.2 Other Information

Equipment-specific information

Vehicle-specific repair information

Copyright 1999 Inter-Industry Conference On Auto Collision Repair

v.3.2

BR112

4.

Equipment And Material Requirements

4.1 Equipment

The use of this equipment is included in this procedure:

pressure bleeding equipment with adapters, if necessary

vacuum bleeding equipment

ISO or double-flare flaring tools

HEPA-filter vacuum system

drum and rotor resurfacing equipment

dial indicator or runout gauge

micrometer

flare-nut wrench set

caliper piston retractor

adjusting tool

brake spring pliers

5.

Damage Analysis

5.1 General Damage

Inspect a brake system for these conditions:

damage to the hoses, lines, connections, master cylinder,

and booster

leaks

contaminated brake fluid

discolored brake fluid

improper pedal feel and operation

improper operation of the parking brake system

5.2 Drums Or Rotors

Inspect brake drums and rotors for these conditions:

cracks or scoring

glazing, contamination, or corrosion

improper diameter of drums, or thickness of rotors

radial runout of drums, or lateral runout of rotors

parallel surfaces of drums or rotors

(contd)

Copyright 1999 Inter-Industry Conference On Auto Collision Repair

v.3.2

BR113

5.

Damage Analysis (contd)

5.3 Wheel Cylinders And Backing Plates, Or Calipers And

Splash Shields

Inspect wheel cylinders and backing plates, or calipers and

splash shields, for these conditions:

visible damage

damage to mounting fasteners or hardware

leaks

internal corrosion or scoring

damaged parking brake hardware

5.4 Shoes Or Pads

Inspect shoes or pads for these conditions:

visible damage

contamination

excessive or uneven lining wear

glazing

6.

Personnel Safety

6.1 General Safety

General safety information is in PS01.

6.2 Brake Fluid Safety

To prevent injury when working with brake fluid:

Wear rubber gloves.

Immediately clean up spilled brake fluid.

Do not expose brake fluid to open flame.

Wear eye protection.

Avoid skin contact with brake fluid.

(contd)

Copyright 1999 Inter-Industry Conference On Auto Collision Repair

v.3.2

BR114

6. Personnel Safety (contd)

6.3 Brake Dust Safety

To prevent exposure to brake dust, which may contain asbestos

fibers:

Wear a HEPA-type respirator.

Use a HEPA-filter vacuum system to clean dust from brake

parts. Do not clean brake parts by dry brushing, or with an

air nozzle.

Use water or brake cleaning solvent for cleaning dust.

6.4 High-Pressure Safety

If the vehicle is equipped with an anti-lock brake system (ABS),

follow the depressurizing methods described in BR51.

7. Environmental Safety

7.1 Brake Fluid And Asbestos

To protect the environment during brake system repairs:

Do not mix brake fluid with other waste materials.

Collect and properly dispose of used brake fluid.

Collect and properly dispose of asbestos waste. Follow local

regulations for asbestos disposal.

Hazardous material safety information is in HM01.

Copyright 1998 Inter-Industry Conference On Auto Collision Repair

v.2.3

BR115

8.

Vehicle Protection

8.1 Brake System

To protect the brake system from damage:

Immediately plug any open lines or hoses.

Do not press the brake pedal when a drum or caliper is removed.

Do not press the brake pedal when a hose or line is disconnected or

open.

Do not allow grease, oil, or brake fluid to contact the drums, rotors, or

linings.

Use only products designed for cleaning brake parts. Do not use

petroleum-based cleaners.

Do not dry parts with lubricated shop air.

Use only new brake fluid.

Use only brake fluid recommended by the vehicle maker, listed on the

master cylinder cover or in the service or owners manual.

Do not leave the caliper suspended by the fluid hose.

8.2 Adjacent Areas

Protect adjacent plastic and painted surfaces from exposure to brake fluid,

brake dust, and cleaning solvents. Immediately rinse off any spilled fluid

with water and clean the surface.

9.

Repair Procedure

Damaged parts must be replaced. Replacement of worn parts may also be

necessary to restore proper brake system performance. If the lining

thickness is less than the minimum allowable, the drum diameter exceeds

the maximum allowable, or the rotor thickness is less than the allowable

minimum, they must be replaced. Resurfacing or replacement is

necessary if the drums or rotors are warped, scored, glazed,

contaminated, or corroded. Always repair or replace parts on both sides of

the vehicle (in axle sets) to restore proper brake performance.

9.1 Brake Line Replacement

To replace a steel brake line:

1. Bend and route new brake lines to follow the original

factory routing. Replacement brake lines must be the

same size, type, and material used by the vehicle

maker.

Copyright 1999 Inter-Industry Conference On Auto Collision Repair

(contd)

v.3.2

BR116

9. Repair Procedure (contd)

2. Flare the brake lines using only a double flare or ISO flare,

duplicating the original flare used by the vehicle maker.

3. Thread the brake line nuts into the connection by hand, to prevent

cross-threading or stripping.

4. Properly torque the connections using a line wrench.

5. Install all retaining clips and fasteners to duplicate original

mounting methods.

6. Torque all fasteners to the vehicle makers recommendations.

7. Bleed the system, following the vehicle makers recommendations.

9.2 Brake Hose Replacement

To replace a brake hose:

1. Disconnect the steel brake line from the brake hose.

2. Remove the mounting bracket clips or nuts on the end

of the brake hose.

3. Disconnect any springs or brackets holding the hose.

4. Disconnect the brake hose from the wheel cylinder or

caliper. Remove the copper gasket.

5. Trial-fit the replacement hose. Replacement brake hoses must be

exact replacements for the original in size, type, and material.

6. Install a new copper gasket on the wheel cylinder side of the hose.

Thread the brake hose into the wheel cylinder or caliper by hand,

to prevent cross-threading or stripping.

7. Use a line or flare-nut wrench to properly torque the connections.

8. Install the mounting brackets. Torque all fasteners to the vehicle

makers recommendations.

9. Install the brake hose to the mounting brackets and support

springs. Make sure the hose does not rub against any other parts.

Do not twist the hose. The colored reference line on the hose must

be kept straight.

10. Thread the brake line to the hose by hand, to prevent crossthreading or stripping.

11. Use a line or flare-nut wrench to properly torque the connections.

12. Bleed the system, following the vehicle makers recommendations.

(contd)

Copyright 1998 Inter-Industry Conference On Auto Collision Repair

v.2.3

BR117

9. Repair Procedure (contd)

9.3 Drum And Shoes Removal

To remove the drum and shoes:

1. Restrain the vehicle and release the parking brake

(rear wheels only).

2. Raise the wheel, axle, or vehicle and remove the wheel

and tire assembly.

3. Remove the drum. Loosen the shoe adjustment if

necessary. If the drum is part of a hub assembly, protect the

bearings and grease from contamination.

4. Use a HEPA-filter vacuum system to remove and collect all brake

dust.

5. Note the locations of the springs, adjuster parts, and retaining

hardware.

6. Remove the retracting springs and adjuster assembly.

7. Remove the shoe hold-down springs and other retaining hardware.

8. Remove the shoes.

9. Inspect the backing plate and axle for damage. If the axle was

damaged remove and replace the axle and the bearings.

9.4 Rotor, Caliper, And Pads Removal

To remove the rotor, caliper, and pads:

1. Restrain the vehicle and release the parking brake

(rear wheels only).

2. Raise the wheel, axle, or vehicle and remove the wheel

and tire assembly.

3. Open the master cylinder and remove about half of the

fluid.

4. Compress the caliper pistons.

5. Use a HEPA-filter vacuum system to remove and collect all brake

dust.

6. Remove the caliper and support it with a piece of wire tied to the

vehicle.

7. Remove the pads from the caliper.

8. Remove the rotor. If the rotor is part of a hub assembly, protect the

bearings and grease from contamination.

(contd)

Copyright 1998 Inter-Industry Conference On Auto Collision Repair

v.2.3

BR118

9. Repair Procedure (contd)

9.5 Parts Cleaning

1. Vacuum any dust from the disassembled parts and inspect for

damage or wear.

2. Remove any corrosion, ridges, or rough edges from the shoe

contact points on the backing plate.

3. Clean and inspect the springs, clips and other hardware.

4. Clean and lubricate the adjuster parts.

5. Inspect the wheel cylinder or caliper for leaks.

6. Inspect the caliper for seized pistons.

7. Inspect all bearings and seals for damage.

9.6 Drum And Shoe Installation

To install shoes and drums:

1. Replace the backing plate, if necessary, following the vehicle

makers recommendations.

2. Rebuild or replace the wheel cylinder, if necessary.

3. Lubricate the shoe contact points on the backing plate.

4. Position the shoes on the backing plate with the cylinder pushrods

and anchor pins engaged.

5. Install the hold-down springs and other retaining hardware.

6. Install the adjuster assembly and retracting springs.

7. Install the parking brake hardware (rear wheels only).

8. Install the drum. Loosen the adjuster, if necessary.

9. Adjust the brake shoes to the vehicle makers specifications.

10. Clean, inspect, repack, and adjust the wheel bearings, as

necessary.

11. Fill the master cylinder reservoirs with brake fluid.

12. Bleed the system, and adjust the parking brake, following the

vehicle makers recommendations.

13. Adjust the brakes as necessary.

14. Check the brake fluid level.

(contd)

Copyright 1998 Inter-Industry Conference On Auto Collision Repair

v.2.3

BR119

9. Repair Procedure (contd)

9.7 Rotor, Caliper, And Pads Installation

To install a rotor, caliper, and pads:

1. Install the rotor.

2. Clean, inspect, repack, and adjust the wheel bearings, as

necessary.

3. Lubricate the caliper sliding surfaces.

4. Compress the caliper pistons.

5. Install the pads in the caliper.

6. Install the caliper.

7. Torque the caliper fasteners to the vehicle makers

recommendations.

8. Replace any worn or damaged parking brake parts (rear only).

9. Fill the master cylinder reservoirs with brake fluid.

10. Bleed the system, and adjust the parking brake, following the

vehicle makers recommendations.

11. Check the brake fluid level.

10. Use Of Recycled (Salvage) Parts

10.1 Salvage Drums Or Rotors

Inspect a salvage drum or rotor for the following:

cracks, scoring, or other visible damage

maximum diameter or minimum thickness to allow

resurfacing

radial or lateral runout

corrosion that has caused pitting

Do not use salvage drums or rotors that are cracked or warped.

Salvage drums or rotors should be inspected to determine if they must be

resurfaced before installation. If after resurfacing, the drum diameter is

greater than the maximum allowable, or the rotor thickness is less than the

minimum allowable, the parts should be discarded.

10.2 Salvage Wheel Cylinders And Backing Plates, Or Calipers

Do not use salvage wheel cylinders, backing plates, or rotors having any

visible damage.

Copyright 1998 Inter-Industry Conference On Auto Collision Repair

v.2.3

BR1110

11. Inspection And Testing

11.1 Brake System Inspection

When repairs are completed, inspect a brake system for these conditions:

proper routing of all lines and hoses

proper brake fluid levels

proper installation of all fasteners, brackets, and retaining clips

no leaks

proper operation of the brake warning lamp

proper pedal operation and feel

proper shoe or pad retraction

proper operation of the parking brake system

proper operation of the brakes during a road-test

proper operation of the stop lamps

Correct any defects.

Copyright 1998 Inter-Industry Conference On Auto Collision Repair

v.2.3

BR1111

También podría gustarte

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- Information Systems of Ford Motor CompanyDocumento2 páginasInformation Systems of Ford Motor CompanyJackholland100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (895)

- Flight Manual H175 - 161 - 1-GENERAL-INFORMATIONDocumento3 páginasFlight Manual H175 - 161 - 1-GENERAL-INFORMATIONArnaud Vincent100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- Lab Sheet - Wheel BalancingDocumento2 páginasLab Sheet - Wheel BalancingAkmal DanialAún no hay calificaciones

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (399)

- Errata For APA V1Documento4 páginasErrata For APA V1SukhoiLoverAún no hay calificaciones

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (266)

- 2014proch CatalogueDocumento271 páginas2014proch CatalogueAndreea BoacaraAún no hay calificaciones

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- Bridgestone Brands v. Balkrishna Indus. - ComplaintDocumento55 páginasBridgestone Brands v. Balkrishna Indus. - ComplaintSarah BursteinAún no hay calificaciones

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- MitsubishiDocumento7 páginasMitsubishiJhon Sanchez LopezAún no hay calificaciones

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- A380 BrochureDocumento2 páginasA380 BrochureAndres MeguencoAún no hay calificaciones

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (588)

- Four Stroke Petrol EngineDocumento11 páginasFour Stroke Petrol EngineBEDABYASA PINGAún no hay calificaciones

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

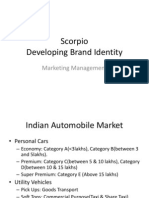

- Scorpio Developing Brand Identity: Marketing ManagementDocumento26 páginasScorpio Developing Brand Identity: Marketing ManagementDipesh JainAún no hay calificaciones

- Fuel Warning SystemDocumento12 páginasFuel Warning Systemjimmy_huamancayo100% (1)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- W CM AssignmentDocumento3 páginasW CM AssignmentSandeep DeodharAún no hay calificaciones

- TNVS Reqs and Eligible CarsDocumento2 páginasTNVS Reqs and Eligible CarsAvarel DPAún no hay calificaciones

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2259)

- Side Loader Container TruckDocumento22 páginasSide Loader Container TruckNIKE IKA NUZULAAún no hay calificaciones

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (73)

- NOR10 777-1 P68 SB-SI-SL Index 3Documento27 páginasNOR10 777-1 P68 SB-SI-SL Index 3riversgardenAún no hay calificaciones

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (344)

- Isuzu Impulse 1990Documento21 páginasIsuzu Impulse 1990Mac PirxAún no hay calificaciones

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- Suspension Control Arm Design Report 1Documento12 páginasSuspension Control Arm Design Report 1api-576590803Aún no hay calificaciones

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- Nexptg 1Documento4 páginasNexptg 1ericsson6cc5883Aún no hay calificaciones

- TR50A ManualDocumento372 páginasTR50A Manualrudyekajaya100% (1)

- Nozzles and Spares For: Electronic Injectors Eui/Eup/Heui/UisDocumento3 páginasNozzles and Spares For: Electronic Injectors Eui/Eup/Heui/Uisصلاح طه السيدAún no hay calificaciones

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- 9800i Spec SheetDocumento2 páginas9800i Spec SheetAl Fba0% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- Goes 800rsDocumento43 páginasGoes 800rsrhadamanteAún no hay calificaciones

- Your Personal SpecificationDocumento19 páginasYour Personal SpecificationVASNEVIAún no hay calificaciones

- Mahle Air Filter (Primary) For Tata - HitachiDocumento9 páginasMahle Air Filter (Primary) For Tata - HitachiSurajPandeyAún no hay calificaciones

- Cummins - ISX15 CM2350 (2013-17)Documento17 páginasCummins - ISX15 CM2350 (2013-17)ramsi17100% (6)

- Case Study/ Survey:-Department: - Guided By: - Made By:-: Scotch Yoke MechanisumDocumento10 páginasCase Study/ Survey:-Department: - Guided By: - Made By:-: Scotch Yoke Mechanisum28048 Pranav KarodpatiAún no hay calificaciones

- Air Bag Sytem 97Documento24 páginasAir Bag Sytem 97xstyle123Aún no hay calificaciones

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (121)

- D1105 BG2 1500RPMDocumento2 páginasD1105 BG2 1500RPMAnbarasanAún no hay calificaciones

- Protege Transmission RebuildDocumento29 páginasProtege Transmission RebuildBrody RivestAún no hay calificaciones

- Molas Tigre 2021Documento20 páginasMolas Tigre 2021Lucas Dlachievy Domingos MacedoAún no hay calificaciones

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2102)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)