Documentos de Académico

Documentos de Profesional

Documentos de Cultura

1647C Anchor ScrewInstall

Cargado por

Aob AprilDescripción original:

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

1647C Anchor ScrewInstall

Cargado por

Aob AprilCopyright:

Formatos disponibles

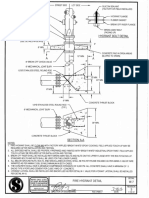

Anchor Bolt & Leveling Screw

Installation Detail

For All Epoxy Grout Systems

Technical Bulletin #

1647C

Bulletin Description

This bulletin illustrates the recommended method of protecting an anchor bolt and installing a

leveling screw prior to the pouring of Chockfast or Escoweld epoxy grout. The normal sequence

of preparation, mixing, and pouring is as follows:

Leveling

Screw

Base

Plate

Grout

3/8 inch RTV

minimum

Concrete

Expansion Joint

Compound

Foam Pipe

Insulation or

Tape Wrap

3 inch diameter

Leveling Pad with

rounded edges

glued in place with

Phillybond #6

Bolt Sleeve

Installation Instructions

1. Remove all laitence and foreign matter from the surface of the concrete by use of a

chipping hammer. All areas coming in contact with grout should be roughened.

2. Remove all debris such as concrete chips and all moisture from the bolt sleeve by the use

of an air hose.

3. The anchor bolt located within the concrete should be protected by a plastic bolt sleeve in

order to prevent the grout from coming in contact with the anchor bolt. This will ensure

proper stretch of the bolt.

4. If possible, fill the sleeve with a non-binding material such as Expansion Joint Compound

or spray foam insulation. If additional sealing is required, fill the top end of the pipe sleeve

with RTV Silicone.

5. Cover the top portion of the anchor bolt with Armaflex Pipe Insulation or wrap with foambacked tape to prevent it from touching the grout.

6. Sand blast the bottom of the base plate to obtain a 1 to 1 mil profile (SP-6) and coat with

ITW Polymer Technologies Rust Inhibitive Primer.

7. Attach a leveling pad to the surface of the concrete foundation using ITW Polymer

Technologies Phillybond #6. This pad must be round with rounded edges and must be

capable of supporting the load imposed by the leveling screw on the foundation.

8. Set and level the base plate. After leveling, apply paste wax to any areas on the base

plate that may get grout dripped on them to make it easier to clean later.

ITW POLYMER TECHNOLOGIES

130 Commerce Drive Montgomeryville, PA 18936 215-855-8450 Fax 215-855-4688

www.chockfastgrout.com www.escoweld.com

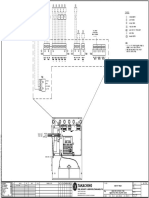

Anchor Bolt & Leveling Screw Detail

Bulletin No. 1647C, Page 2

9. Apply a heavy coat of non-melt grease to all leveling screws both before and after the

base plate is aligned.

10. Mix and pour the grout in accordance with Installation Specification for Pumps and

Drivers when Using Epoxy Grouts.

11. After the grout has hardened, remove the leveling screws and fill the holes with Silicone. If

this is not practical back off the leveling screws a minimum of three full turns

Reference

For further design considerations and application details please request the paper titled

Installation Specification for Pumps and Drivers when Using Epoxy Grouts or contact

ITW Polymer Technologies' Engineering Services Department.

Date

09/2005

General: Every reasonable effort is made to insure the

technical information and recommendations on these data

pages are true and accurate to the best of our knowledge

at the date of issuance. However, this information is subject

to change without notice. Prior versions of this publication

are invalid with the release of this version. Products and

information are intended for use by qualified applicators

that have the required background, technical knowledge,

and equipment to perform said tasks in a satisfactory

manner. Consult your local distributor for product

availability, additional product information, and technical

support.

Warranty: ITW Polymer Technologies, a division of Illinois Tool

Works Inc., warrants that its products meet their printed

specifications. This is the sole warranty. This warranty

expires one year after product shipment.

Warranty Claims: If any product fails to meet the above,

ITW Polymer Technologies will, at its option, either replace

the product or refund the purchase price. ITW Polymer

Technologies will have no other liability for breach of

warranty, negligence, or otherwise. All warranty claims

must be made in writing within one year of the date of

shipment. No other claims will be considered.

Disclaimer: ITW Polymer Technologies makes no other

warranty, expressed or implied, and specifically disclaims

any warranty of merchantability or fitness for a particular

purpose.

Suggestions concerning the use of products are not

warranties. The purchaser assumes the responsibility for

determining suitability of products and appropriate use.

ITW Polymer Technologies sole liability, for breach of

warranty, negligence or otherwise, shall be the

replacement of product or refund of the purchase

price, at ITW Polymer Technologies election. Under no

circumstances shall ITW Polymer Technologies be liable

for any indirect, incidental or consequential damages.

Modification of Warranty: No distributor or sales

representative has the authority to change the above

provisions. No change in the above provisions will be

valid unless in writing and signed by an officer or the

Technical Director of ITW Polymer Technologies. No

term of any purchase order shall serve to modify any

provision of this document.

Mediation and Arbitration: If any dispute arises relating

to products or product warranties, either the purchaser

or ITW Polymer Technologies may a) initiate mediation

under the then current Center for Public Resources

(CPR) Model Procedure for Mediation of Business

Disputes, or b) initiate a non-binding arbitration under

the rules of the American Arbitration Association for the

resolution of commercial disputes.

También podría gustarte

- Two Clamped Pipe Support Connections For Oil and Gas Brownfield PDocumento52 páginasTwo Clamped Pipe Support Connections For Oil and Gas Brownfield PAob AprilAún no hay calificaciones

- PipeHanger DesignEngineering Catalog PDFDocumento84 páginasPipeHanger DesignEngineering Catalog PDFRaheem_kaAún no hay calificaciones

- Pipe Support StandardDocumento319 páginasPipe Support StandardAntoshal92% (75)

- ASTM A307 Standard Specification For Carbon Steel Bolts, Studs, and Threaded Rod 60 000 PSI Tensile StrengthDocumento6 páginasASTM A307 Standard Specification For Carbon Steel Bolts, Studs, and Threaded Rod 60 000 PSI Tensile StrengthRichard RodriguezAún no hay calificaciones

- Redacted EmailsDocumento5 páginasRedacted EmailsAob AprilAún no hay calificaciones

- Once in a blue moonDocumento258 páginasOnce in a blue moonAob AprilAún no hay calificaciones

- Et02sn PDFDocumento6 páginasEt02sn PDFNakamura MinakoAún no hay calificaciones

- Specification For Pipe SupportDocumento330 páginasSpecification For Pipe Supportaibek92% (13)

- Chapter 07Documento39 páginasChapter 07kevinmathew27Aún no hay calificaciones

- Hydrant Bolt DetailDocumento1 páginaHydrant Bolt DetailAob AprilAún no hay calificaciones

- Et02sn PDFDocumento6 páginasEt02sn PDFNakamura MinakoAún no hay calificaciones

- ASME B16.34 - 1996-Valves PDFDocumento126 páginasASME B16.34 - 1996-Valves PDFVinay Kumar100% (2)

- Simple Trusses: Part 4: Zero-Force MembersDocumento2 páginasSimple Trusses: Part 4: Zero-Force MembersAob AprilAún no hay calificaciones

- SMMT FP As-Built Layout PlanDocumento9 páginasSMMT FP As-Built Layout PlanAob AprilAún no hay calificaciones

- Redacted EmailsDocumento5 páginasRedacted EmailsAob AprilAún no hay calificaciones

- Sco Latex Install Auto Fire SprinklerDocumento20 páginasSco Latex Install Auto Fire SprinklerAob AprilAún no hay calificaciones

- FS Ing 006Documento1 páginaFS Ing 006Aob AprilAún no hay calificaciones

- NFPA 13 Automatic Sprinkler Systems Handbook 2019 EditionDocumento2 páginasNFPA 13 Automatic Sprinkler Systems Handbook 2019 EditionAob April0% (3)

- FS Ing 007Documento1 páginaFS Ing 007Aob AprilAún no hay calificaciones

- FS Ing 002Documento1 páginaFS Ing 002Aob AprilAún no hay calificaciones

- FS Ing 003Documento1 páginaFS Ing 003Aob AprilAún no hay calificaciones

- FS Ing 005Documento1 páginaFS Ing 005Aob AprilAún no hay calificaciones

- FS Ing 000Documento1 páginaFS Ing 000Aob AprilAún no hay calificaciones

- FS Ing 004Documento1 páginaFS Ing 004Aob AprilAún no hay calificaciones

- Pipe Flow Expert Quick Start GuideDocumento19 páginasPipe Flow Expert Quick Start GuideHani KirmaniAún no hay calificaciones

- Pipe Flow Expert Results VerificationDocumento63 páginasPipe Flow Expert Results VerificationchrysanthiiiiiiAún no hay calificaciones

- Fire Fighting Drawing: Blow Film Building ComplianceDocumento4 páginasFire Fighting Drawing: Blow Film Building ComplianceAob AprilAún no hay calificaciones

- ResumeDocumento7 páginasResumeAob AprilAún no hay calificaciones

- Fire Fighting Drawing: Blow Film Building ComplianceDocumento4 páginasFire Fighting Drawing: Blow Film Building ComplianceAob AprilAún no hay calificaciones

- Pipe Flow Expert BrochureDocumento2 páginasPipe Flow Expert BrochureklganandAún no hay calificaciones

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5783)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (119)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2099)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- Tort Lecture 1Documento133 páginasTort Lecture 1Rvi MahayAún no hay calificaciones

- Belgian Overseas Chartering and Shipping N.V. vs. Philippine First Insurance Co., Inc.Documento16 páginasBelgian Overseas Chartering and Shipping N.V. vs. Philippine First Insurance Co., Inc.Lance Christian ZoletaAún no hay calificaciones

- Spouses Perena vs. Spouses ZarateDocumento8 páginasSpouses Perena vs. Spouses ZarateAlvin ClaridadesAún no hay calificaciones

- Proximate Cause and Scope of Liability Chapters 11 & 12 - Geistfeld - Product LiabilityDocumento93 páginasProximate Cause and Scope of Liability Chapters 11 & 12 - Geistfeld - Product LiabilityGeorge ConkAún no hay calificaciones

- Finals: Professional AdjustmentDocumento8 páginasFinals: Professional AdjustmentJustine JimenezAún no hay calificaciones

- Philippine School of Business Administration vs. Court of AppealDocumento5 páginasPhilippine School of Business Administration vs. Court of AppealMariane Capellan OgayaAún no hay calificaciones

- Bachelor Express vs. CADocumento5 páginasBachelor Express vs. CAFairyssa Bianca SagotAún no hay calificaciones

- Knutson Motion To DismissDocumento13 páginasKnutson Motion To DismissFOX 11 NewsAún no hay calificaciones

- ObliCon 1st Set of CasesDocumento210 páginasObliCon 1st Set of CasesTasneem C BalindongAún no hay calificaciones

- G.R. No. L-3756 June 30, 1952Documento1 páginaG.R. No. L-3756 June 30, 1952Sherwin Delfin Cinco100% (1)

- 4 Level 6 - Unit 13 Law of Tort Suggested Answers - June 2013Documento18 páginas4 Level 6 - Unit 13 Law of Tort Suggested Answers - June 2013Rossz FiúAún no hay calificaciones

- Kendrick Johnson: Issues in Complaint RevisedDocumento3 páginasKendrick Johnson: Issues in Complaint RevisedReNews It100% (1)

- Eastern Shipping Lines V IACDocumento6 páginasEastern Shipping Lines V IACVincent Rey BernardoAún no hay calificaciones

- Sps. Latonio v. McgeorgeDocumento12 páginasSps. Latonio v. McgeorgeKaye ArendainAún no hay calificaciones

- Cases Decided by Justice Del CastilloDocumento31 páginasCases Decided by Justice Del CastilloMa. Angelica de Guzman100% (2)

- SC upholds 6-month suspension of lawyer for gross negligenceDocumento9 páginasSC upholds 6-month suspension of lawyer for gross negligenceCherry BepitelAún no hay calificaciones

- BF Metal Vs LOMOTANDocumento2 páginasBF Metal Vs LOMOTANJoel MilanAún no hay calificaciones

- 2020-12-29 Madison Collins - STAMP FILED ComplaintDocumento7 páginas2020-12-29 Madison Collins - STAMP FILED ComplaintBrian CummingsAún no hay calificaciones

- Transportation Law Assignment No.1Documento50 páginasTransportation Law Assignment No.1ptdwnhroAún no hay calificaciones

- Philippine Civil Code provisions on necessary deposit and passenger safetyDocumento2 páginasPhilippine Civil Code provisions on necessary deposit and passenger safetyRic SaysonAún no hay calificaciones

- Gutierrez v. Gutierrez, 56 Phil 177Documento4 páginasGutierrez v. Gutierrez, 56 Phil 177BernsAún no hay calificaciones

- Terri D. Franklin v. Glen Kimbrel, 11th Cir. (2015)Documento18 páginasTerri D. Franklin v. Glen Kimbrel, 11th Cir. (2015)Scribd Government DocsAún no hay calificaciones

- Marques Vs Far East BankDocumento9 páginasMarques Vs Far East BankJewel Ivy Balabag DumapiasAún no hay calificaciones

- Law On Obligations & Contracts (BSA)Documento70 páginasLaw On Obligations & Contracts (BSA)Gabriel SincoAún no hay calificaciones

- National Bookstore v. CADocumento1 páginaNational Bookstore v. CARuss TuazonAún no hay calificaciones

- Consent in Health Care Law - An Overview Jizamol.P.RDocumento20 páginasConsent in Health Care Law - An Overview Jizamol.P.RJiza GireeshAún no hay calificaciones

- Steinaker Lawsuit DenialsDocumento7 páginasSteinaker Lawsuit DenialsErin LaviolaAún no hay calificaciones

- Gallagher DocumentDocumento13 páginasGallagher DocumentHelen BennettAún no hay calificaciones

- Adler V Dickson The HimalayaDocumento18 páginasAdler V Dickson The HimalayaDeepak ShoriAún no hay calificaciones

- Pelayo vs. Lauron DigestDocumento2 páginasPelayo vs. Lauron DigestFairyssa Bianca SagotAún no hay calificaciones