Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Wet Alarm Valves

Cargado por

Tezar2012Descripción original:

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Wet Alarm Valves

Cargado por

Tezar2012Copyright:

Formatos disponibles

Wet alarm valves

FM trim

www.rolland-sprinklers.com

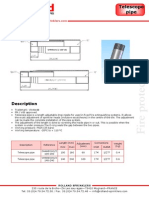

Description

Usually, a wet alarm valve station comprise:

- a Rolland wet alarm valve linked to the water motor gong.

- a set of valves and by pass used to test the system.

- a drain valve.

- a test valve

- gauges to measure the pressure of the supply line and of the system side pressure.

- a pressure switch

- a retard chamber can be added when the supply line pressure is variable. The retard chamber prevents

false alarms.

Valve operation

When a sprinkler head or a test valve is opened, pressure in the system side of the clapper is reduced below

the pressure of the system side. Then the clapper raises allowing the flow of water to reach the sprinkler

system for distribution on the fire. The water flows to the uncovered grooved into the retard chamber (if

installed) and the alarm device (usually the water motor gong).

A pressure surge or a water hammer in the supply line will induce an intermittent raise of the clapper and by

consequences false alarms. To prevent these troubles, Rolland alarm stations are equipped with two

particular features:

a by-pass with check valve allows a pressure surge from the supply to pass the alarm valve clapper.

-

the retard chamber consists of two specially designed inlet and drain orifices. The retard chamber is

equipped with a strainer in the intake line to prevent foreign matter from clogging the intake orifice. Even

if a strong water hammer raises the alarm valve clapper, the water will first flows to the retard chamber

before reaching the water motor gong.

Take care to the installation of the check valve on the alarm station trimming to be sure that the water flow

goes in the right direction. The arrow on the check valve by pass body must point toward the alarm valve.

The arrow on the drain system check valve must points towards the main drain valve.

Specifications

Diameter

3"

4"

6"

8"

Connexion

flange/flange

flange/grooved

or flange/flange

flange/grooved

or flange/flange

flange/flange

Flange type

PN 16

PN 16

PN 16

PN 16

Orange-red

(RAL 2002)

Orange-red

(RAL 2002)

Orange-red

(RAL 2002)

Orange-red

(RAL 2002)

Height (cm)

27,70

26,30

28,70

29.70

Weight (kg)

23,60

23,00 (B/R)

23.40 (B/B)

29.40 (B/R)

33.60 (B/B)

54.50

Approval

F.M

F.M.

F.M.

FM

Reference

POSTEEAU3"BB

POSTEEAU4BR (B/R)

POSTEEAU4 BB (B/B)

POSTEEAU6BR (B/R)

POSTEEAU6 BB (B/B)

POSTEEAU8"BB

Colour

Fire protection

Description of the wet alarm valve station is general. Before each installation of wet alarm valve station you

have to refer to the required standards (Factory Mutual or others).

Page 1/9

ROLLAND SPRINKLERS

235 route de la BiolleZA Les sauvages73410 MognardFRANCE

Tel. 33.(0)4.79.54.72.50 / Fax. 33.(0)4.79.54.72.48 info@rolland-sprinklers.com

Wet alarm valves

FM trim

www.rolland-sprinklers.com

Equivalent length

Item

Diameter

Equivalent length (m)

Rolland wet alarm valve

1.0

Rolland wet alarm valve

3.8

Rolland wet alarm valve

10.0

Rolland wet alarm valve

10.5

Based on Hazen-Williams formula, C factor = 120

Fire protection

Based on French stell pipe (Tarif T19 except 8")

Information based on BRE tests results.

Removing the system from service

WARNING: The system should only be removed from service for maintenance and repairs. All the area

concerned by the alarm valve station must be under control until the system is back in service. Advise all

authorities having jurisdiction of the fire system removal, first to secure the area and secondly to avoid

troubles due to false alarms during repair and maintenance.

1 - Close the main supply valve of the fire sprinkler system.

2 Open the drain valve (V5) of the wet alarm valve station.

3 Drain the complete system and open the test point and all auxiliary drain valves of the fire sprinkler

system.

4 Check on the sprinkler system gauges (M1) of the alarm valve station that shows zero (no pressure).

5 In case of freezing risks, be sure that drainage of the system is complete.

6 Install a panel close to the alarm valve station to inform of the system removal from service.

Maintenance and solutions

The Rolland alarm valve is constructed in order to have nothing to adjust.

If you have troubles on the alarm sprinkler system (not operating, false alarms, ), first follow these

instructions:

Inspect and clean up the reduced orifice and the filter of the retard chamber.

Inspect and clean up the filter installed on the alarm sprinkler line.

If you note that the sprinkler system pressure gauge (M1) is identical to the supply pressure gauge (M1) and

no tests or drainage valves has operated, no sprinklers are activated, no leakage is seen, then you should

follow these instructions:

Inspect and clean up the small clapper (CP2) on the by pass of the trimming. If it is required, change it.

Page 2/9

ROLLAND SPRINKLERS

235 route de la BiolleZA Les sauvages73410 MognardFRANCE

Tel. 33.(0)4.79.54.72.50 / Fax. 33.(0)4.79.54.72.48 info@rolland-sprinklers.com

Wet alarm valves

FM trim

www.rolland-sprinklers.com

Inspect and clean up the gasket seat of the wet alarm valve. If it is required, proceed to the change of

the alarm valve gaskets. In this case, follow these instructions :

A Follow the instructions of the paragraph removal the system from service.

B Once the alarm valve fully drained, remove the cover plate allowing inspection of the alarm valve

clapper assembly, seat and interior.

C Raise the clapper from its seat and scoop out any scale or solid particle around the valve seat. Lip

the surface of the valve seat with a clean cloth.

D Renew the rubber gasket of the clapper facing. To do it, the clapper can be removed from the body

by dismantling the main pin.

E Renew the rubber gasket of the cover plate and replace correctly the cover plate on the alarm valve.

Proceed to the instructions of the quarterly inspections and tests.

Procedure after a fire

Warning: be sure that the fire is completely extinguished by visiting all the buildings covered by the

sprinkler system. Keep watch these buildings until the system is not back in service

1 - Close the main supply valve of the fire sprinkler system.

2 - Open the drain valve (V5) of the wet alarm valve station. Drain the complete system and open the test

point and all auxiliary drain valves of the fire sprinkler system.

3 - Change all the sprinklers that have operated during the fire. Renew these sprinklers by sprinklers which

have exactly the same characteristics (temperature, upright or pendent, ). Use the special sprinkler

wrench to replace the sprinklers. Never install a sprinkler that could have been shocked. Never try to

repair a sprinkler. Never try to paint a sprinkler.

Make sure that the spare sprinkler box containing replacement sprinkler is always complete.

4 - Close the alarm valve (V1).

5 Close the drain valve (V5). Close the test point and any auxiliary drain valves of the sprinkler system.

6 - Carefully open the main supply valve to fill slowly the sprinkler system. It will also avoid to any foreign

materials in the supply main from being washed into the alarm valve. During this time, the clapper will

be opened and it will close automatically when sufficient water has entered the system piping.

7 - When a steady flow of water is maintained form the test point and the auxiliary drain valve, close it.

Fire protection

8 - Open completely the main supply valve and seal it.

9 - Open the alarm valve (V1). If this valve stays closed, the gong will not operate in case of system

operating.

10 Perform the test.

Page 3/9

ROLLAND SPRINKLERS

235 route de la BiolleZA Les sauvages73410 MognardFRANCE

Tel. 33.(0)4.79.54.72.50 / Fax. 33.(0)4.79.54.72.48 info@rolland-sprinklers.com

Wet alarm valves

FM trim

www.rolland-sprinklers.com

Inspections and tests

You must follow the rules and advises of Authorities having jurisdiction and to apply their decisions.

WARNING: The system should only be removed from service for maintenance and repairs. All the area

concerned by the alarm valve station must be under control until the system is back in service. Advise all

authorities having jurisdiction of the fire system removal, first to secure the area and secondly to avoid

troubles due to false alarms during repair and maintenance.

Weekly tests and inspections:

The sprinkler alarm trim must be tested once a week. Follow these instructions:

A

Note the pressure on the sprinkler line gauge (M1) of the alarm valve.

B

Note the pressure on the supply line gauge (M1) of the alarm valve. Make sure that this one is

less than the one of the gauge (M1). If it is not the case, go to the paragraph maintenance and

solutions.

C - Open the alarm test valve (V2).

DCheck the right operation of the water motor gong and of the pressure switch.

E - Close the alarm test valve (V2). It should stop the water motor alarm gong. Then cancel the alarm

due to the pressure switch on the alarm panel.

F - Check again the pressure on the sprinkler line gauge (M1) of the alarm valve.

GSet the system back in service.

Quarterly tests and inspections:

A quarterly tests and inspections is usually required. Follow these instructions:

A

Close the main supply valve of the sprinkler system. Open it gain and check on alarm panel

that the valves contacts have sent the alarm signal to the alarm panel.

B

Inspect and clean up filter (optional) of the water motor alarm gong.

C - Proceed to the weekly tests and inspections. The alarm test of the sprinkler system can also be

obtained by operating the test point of the sprinkler system (refer to the Authorities having

jurisdiction). In this case that will involve the opening of the wet alarm valve clapper.

DSet the system back in service.

Fire protection

Inspections and tests must be done each time defined in the authorised rules. Most of the time theses

tests and inspections are made weekly, quarterly, annually,

Only inspections and tests made weekly and quarterly are given, on a general view, in this brochure. Any

inspection must also be completed by a visual control in order to see possible physical troubles on the

equipment (shocks, freezing problems, corrosion, ).

Page 4/9

ROLLAND SPRINKLERS

235 route de la BiolleZA Les sauvages73410 MognardFRANCE

Tel. 33.(0)4.79.54.72.50 / Fax. 33.(0)4.79.54.72.48 info@rolland-sprinklers.com

Wet alarm valves

FM trim

www.rolland-sprinklers.com

Spare parts 3, 4, 6"

3 ou 4"

6"

Description

Quantit par

clapet

4E.1

6E.1

Corps

Pour info

Pour info

Sige

4E.3

6E.3

Couvercle

4E.4

6E.4

Joint de couvercle

4E.5

6E.5

Boulon de couvercle

4E.7

6E.7

Clapet complet

6a

4E.8

6E.8

Clapet

6b

4E.9

6E.9

Joint de clapet

6c

4E.10

6E.10

Disque

6d

4E.11

6E.11

Boulon

6e

4E.12

6E.12

Joint torique

6f

4E.13

6E.13

Contre crou

6g

4E.14

6E.14

crou

4E.15

6E.15

Axe clapet

4E.16

6E.16

Bague

4E.17

6E.17

Bouchon

Spare parts 8"

Reference

8""

Description

Quantity

8E.1

Body

Pour info

Clapper seal

8E.3

Cover plate

8E.4

Cover gasket

8E.5

Cover bolts

8E.7

Clapper assembly

6a

8E.8

Clapper

6b

8E.9

Clapper gasket

6c

8E.10

Bolts

6d

8E.11

Retainer ring

8E.18

Bushing

8E.15

Clapper pin

8E.16

Clapper bushing

10

8E.17

Plug

Fire protection

Repre

Page 5/9

ROLLAND SPRINKLERS

235 route de la BiolleZA Les sauvages73410 MognardFRANCE

Tel. 33.(0)4.79.54.72.50 / Fax. 33.(0)4.79.54.72.48 info@rolland-sprinklers.com

Wet alarm valves

FM trim

www.rolland-sprinklers.com

3" WET ALARM VALVE / CLAPET D'ALARME SOUS EAU 3"

FM TRIM / EQUIPEMENT FM V2

PRESSURE SWITCH

PRESSOSTAT

NOT INCLUED IN THE TRIM

Fire protection

TO WATER MOTOR GONG

VERS CLOCHE D'ALARME

TO DRAIN

VERS VIDANGE

Ref.

Description

Qty

B2

Nipple

1/4"x60

B3

Nipple

1/2"x50

B4

Nipple

1/2"x60

B5

Nipple

1/2"x80

B7

Nipple

1/2"x120

Ref.

B8

Nipple

1/2"x150

CFF1 Elbow FF 90

1/2"

B9

Nipple

1/2"x200

CP2

Clapper FF

3/4"

B10

Nipple

3/4"x50

M1

Manometer

1/4"

B12

Nipple

3/4"x80

R2

Reducing nipple 3/4"M>1/4"F

B18

Nipple

1"1/2x80

R3

Reducing nipple 3/4"M>1/2"F

T1

Tee equal

1/2"

Ru1

Union

1/2" FF

T2

Tee equal

3/4"

Ru2

Union

3/4" FF

CMF1 Elbow MF 90

1/4"

V1

Valve

1/4"

CMF2 Elbow MF 90

1/2"

V2

Valve

1/2"

CMF3 Elbow MF 90

3/4"

V6

Valve

1"1/2

CMF5 Elbow MF 90

1"1/2

Pr1

Pressure switch

Description

Qty

3

2

1

Dimensions (mm)

Width

690

Depth

360

Height

590

Page 6/9

ROLLAND SPRINKLERS

235 route de la BiolleZA Les sauvages73410 MognardFRANCE

Tel. 33.(0)4.79.54.72.50 / Fax. 33.(0)4.79.54.72.48 info@rolland-sprinklers.com

Wet alarm valves

FM trim

www.rolland-sprinklers.com

3" WET ALARM VALVE / CLAPET D'ALARME SOUS EAU 3"

FM TRIM / EQUIPEMENT FM V1 (Circuit de vidange v1)

WITH RETARD CHAMBER / AVEC CHAMBRE DE RETARDEMENT

TO WATER MOTOR GONG

RACCORDEMENT CLOCHE D'ALARME

Ref.

Description

Qty

Fire protection

PRESSURE SWITCH

PRESSOSTAT

NOT INCLUED IN THE TRIM

TO DRAIN

VERS VIDANGE

B2

Nipple

1/4"x60

B3

Nipple

1/2"x50

B4

Nipple

1/2"x60

Ref.

B5

Nipple

1/2"x80

CFF1 Elbow FF 90

1/2"

B7

Nipple

1/2"x120

CP1

Clapper FF

1/2"

B8

Nipple

1/2"x150

CP2

Clapper FF

3/4"

B9

Nipple

1/2"x200

M1

Manometer

1/4"

B10

Nipple

3/4"x50

R2

Reducing nipple 3/4"M>1/4"F

B12

Nipple

3/4"x80

R3

Reducing nipple 3/4"M>1/2"F

B18

Nipple

1"1/2x80

Ru1

Union

1/2" FF

T1

Tee equal

1/2"

Ru2

Union

3/4" FF

T2

Tee equal

3/4"

V1

Valve

1/4"

Tr2

T rduit

1"1/2x1/2"

V2

Valve

1/2"

CMF1 Elbow MF 90

1/4"

V6

Valve

1"1/2

Width

690

CMF2 Elbow MF 90

1/2"

Ch

Chamber

Depth

420

CMF3 Elbow MF 90

3/4"

Pr1

Pressure switch

CMF5 Elbow MF 90

1"1/2

F1

Orifice rduit

Height

950

Description

Qty

2

2

Dimensions (mm)

Page 6/9

ROLLAND SPRINKLERS

235 route de la BiolleZA Les sauvages73410 MognardFRANCE

Tel. 33.(0)4.79.54.72.50 / Fax. 33.(0)4.79.54.72.48 info@rolland-sprinklers.com

Wet alarm valves

FM trim

www.rolland-sprinklers.com

4" WET ALARM VALVE / CLAPET D'ALARME SOUS EAU 4"

FM TRIM / EQUIPEMENT FM V3

PRESSURE SWITCH

PRESSOSTAT

NOT INCLUED IN THE TRIM

Fire protection

TO WATER MOTOR GONG

RACCORDEMENT CLOCHE D'ALARME

TO DRAIN

VERS VIDANGE

Ref.

Dimensions (mm)

Width

690

Depth

360

Height

690

Description

Qty

B2

Nipple

1/4"x60

B3

Nipple

1/2"x50

B4

Nipple

1/2"x60

B5

Nipple

1/2"x80

Ref.

B7

Nipple

1/2"x120

CFF1

Elbow FF 90

1/2"

B9

Nipple

1/2"x200

CP2

Clapper FF

3/4"

B10

Nipple

3/4"x50

M1

Manometer

1/4"

B12

Nipple

3/4"x80

R2

Reducing nipple 3/4"M>1/4"F

B14

Nipple

2"x80

R3

Reducing nipple 3/4"M>1/2"F

T1

Tee equal

1/2"

Ru1

Union

1/2" FF

T2

Tee equal

Description

Qty

2

2

1

3/4"

Ru2

Union

3/4" FF

CMF1 Elbow MF 90

1/4"

V1

Valve

1/4"

CMF2 Elbow MF 90

1/2"

V2

Valve

1/2"

CMF3 Elbow MF 90

3/4"

V5

Valve

2"

CMF4 Elbow MF 90

2"

Pr1

Pressure switch

ROLLAND SPRINKLERS

235 route de la BiolleZA Les sauvages73410 MognardFRANCE

Tel. 33.(0)4.79.54.72.50 / Fax. 33.(0)4.79.54.72.48 info@rolland-sprinklers.com

Page 7/9

Wet alarm valves

FM trim

www.rolland-sprinklers.com

4" WET ALARM VALVE / CLAPET D'ALARME SOUS EAU 4"

FM TRIM / EQUIPEMENT FM V3 (Circuit de vidange ind C)

WITH RETARD CHAMBER / AVEC CHAMBRE DE RETARDEMENT

TO WATER MOTOR GONG

RACCORDEMENT CLOCHE D'ALARME

Fire protection

PRESSURE SWITCH

PRESSOSTAT

NOT INCLUED IN THE TRIM

Ref.

TO DRAIN

VERS VIDANGE

Dimensions (mm)

Width

690

Depth

360

Height

900

Description

Qty

B2

Nipple

1/4"x60

B3

Nipple

1/2"x50

Ref.

B4

Nipple

1/2"x60

CFF1

Elbow FF 90

1/2"

B5

Nipple

1/2"x80

CP1

Clapper FF

1/2"

B7

Nipple

1/2"x120

CP2

Clapper FF

3/4"

B9

Nipple

1/2"x200

M1

Manometer

1/4"

B10

Nipple

3/4"x50

R2

Reducing nipple 3/4"M>1/4"F

B12

Nipple

3/4"x80

R3

Reducing nipple 3/4"M>1/2"F

B14

Nipple

2"x80

Ru1

Union

1/2" FF

T1

Tee equal

1/2"

Ru2

Union

3/4" FF

T2

Tee equal

3/4"

V1

Valve

1/4"

Tr1

Tee reduced

2"x1/2"

V2

Valve

1/2"

CMF1 Elbow MF 90

1/4"

V5

Valve

2"

CMF2 Elbow MF 90

1/2"

Ch

Chamber

CMF3 Elbow MF 90

3/4"

Pr1

Pressure switch

CMF4 Elbow MF 90

2"

F1

Reduced orifice

Description

Qty

2

2

2

Page 7/9

ROLLAND SPRINKLERS

235 route de la BiolleZA Les sauvages73410 MognardFRANCE

Tel. 33.(0)4.79.54.72.50 / Fax. 33.(0)4.79.54.72.48 info@rolland-sprinklers.com

Wet alarm valves

FM trim

www.rolland-sprinklers.com

6" WET ALARM VALVE / CLAPET D'ALARME SOUS EAU 6"

FM TRIM / EQUIPEMENT FM V3

TO WATER MOTOR GONG

RACCORDEMENT CLOCHE D'ALARME

Fire protection

PRESSURE SWITCH

PRESSOSTAT

NOT INCLUED IN THE TRIM

TO DRAIN

VERS VIDANGE

Ref.

Description

Qty

B2

Nipple

1/4"x60

B3

Nipple

1/2"x50

B4

Nipple

1/2"x60

B5

Nipple

1/2"x80

B7

Nipple

1/2"x120

B9

Nipple

1/2"x200

Ref.

B10

Nipple

3/4"x50

CFF1

Elbow FF 90

1/2"

B11

Nipple

3/4"x60

M1

Manometer

1/4"

B12

Nipple

3/4"x80

R2

Reducing nipple 3/4"M>1/4"F

B14

Nipple

2"x80

R3

Reducing nipple 3/4"M>1/2"F

T1

Tee equal

1/2"

Ru1

Union

1/2" FF

T2

Tee equal

3/4"

Ru2

Union

3/4" FF

CMF1 Elbow MF 90

1/4"

V1

Valve

1/4"

CMF2 Elbow MF 90

1/2"

V2

Valve

1/2"

CMF3 Elbow MF 90

3/4"

V5

Valve

2"

CMF4 Elbow MF 90

2"

Pr1

Pressure switch

Description

Qty

2

1

Dimensions (mm)

Width

730

Depth

360

Height

600

ROLLAND SPRINKLERS

235 route de la BiolleZA Les sauvages73410 MognardFRANCE

Tel. 33.(0)4.79.54.72.50 / Fax. 33.(0)4.79.54.72.48 info@rolland-sprinklers.com

Page 8/9

Wet alarm valves

FM trim

www.rolland-sprinklers.com

6" WET ALARM VALVE / CLAPET D'ALARME SOUS EAU 6"

FM TRIM / EQUIPEMENT FM V3 (Circuit de vidange ind C)

WITH RETARD CHAMBER / AVEC CHAMBRE DE RETARDEMENT

TO WATER MOTOR GONG

RACCORDEMENT CLOCHE D'ALARME

Ref.

TO DRAIN

VERS VIDANGE

Dimensions (mm)

Width

760

Depth

530

Height

920

Description

Fire protection

PRESSURE SWITCH

PRESSOSTAT

NOT INCLUED IN THE TRIM

Qty

B2

Nipple

1/4"x60

B3

Nipple

1/2"x50

B4

Nipple

1/2"x60

Ref.

B5

Nipple

1/2"x80

CFF1

Elbow FF 90

1/2"

B7

Nipple

1/2"x120

CP1

Clapper FF

1/2"

B9

Nipple

1/2"x200

CP2

Clapper FF

3/4"

B10

Nipple

3/4"x50

M1

Manometer

1/4"

B11

Nipple

3/4"x60

R2

Reducing nipple 3/4"M>1/4"F

B12

Nipple

3/4"x80

R3

Reducing nipple 3/4"M>1/2"F

B14

Nipple

2"x80

Ru1

Union

1/2" FF

T1

Tee equal

1/2"

Ru2

Union

3/4" FF

T2

Tee equal

3/4"

V1

Valve

1/4"

Tr1

Tee reduced

Description

Qty

2

2

3

2"x1/2"

V2

Valve

1/2"

CMF1 Elbow MF 90

1/4"

V5

Valve

2"

CMF2 Elbow MF 90

1/2"

Ch

Chamber

CMF3 Elbow MF 90

3/4"

Pr1

Pressure switch

CMF4 Elbow MF 90

2"

F1

Reduced orifice

ROLLAND SPRINKLERS

235 route de la BiolleZA Les sauvages73410 MognardFRANCE

Tel. 33.(0)4.79.54.72.50 / Fax. 33.(0)4.79.54.72.48 info@rolland-sprinklers.com

Page 8/9

Wet alarm valves

FM trim

www.rolland-sprinklers.com

8" WET ALARM VALVE / CLAPET D'ALARME SOUS EAU 8"

FM TRIM / EQUIPEMENT FM V1

TO WATER MOTOR GONG

RACCORDEMENT CLOCHE D'ALARME

Fire protection

PRESSURE SWITCH

PRESSOSTAT

NOT INCLUED IN THE TRIM

TO DRAIN

VERS VIDANGE

Ref.

Description

Qty

B3

Nipple

1/2"x50

B4

Nipple

1/2"x60

7

1

Ref.

B6

Nipple

1/2"x100

CFF1

Elbow FF 90

1/2"

B8

Nipple

1/2"x150

CFF2

Elbow FF 90

3/4"

B10

Nipple

3/4"x50

CP2

Clapper FF

3/4"

B11

Nipple

3/4"x60

M1

Manometer

1/4"

B12

Nipple

3/4"x80

R3

B15

Nipple

2"x150

Ru1

Union

1/2" FF

B21

Nipple

1/4"x150

Ru2

Union

3/4" FF

T1

Tee equal

1/2"

V1

Valve

1/4"

Width

640

T2

Tee equal

3/4"

V2

Valve

1/2"

Depth

520

CMF1

Elbow MF 90

1/4"

V5

Valve

2"

CMF4

Elbow MF 90

2"

Pr1

Pressure switch

Height

780

Description

Qty

Reducing nipple 3/4"M>1/2"F

Dimensions (mm)

Page 9/9

ROLLAND SPRINKLERS

235 route de la BiolleZA Les sauvages73410 MognardFRANCE

Tel. 33.(0)4.79.54.72.50 / Fax. 33.(0)4.79.54.72.48 info@rolland-sprinklers.com

Wet alarm valves

FM trim

www.rolland-sprinklers.com

8" W ET ALAR M VALVE / C LAPET D'ALARM E SOUS EAU 8"

FM Trim / Equipem ent FM V1 (C ircuit de vidange ind A)

W ith retard cham ber / Avec cham bre de retardem ent

TO W ATE R M OT OR GONG

RACC ORDEM ENT CLOCHE D'ALARM E

Fire protection

PRES SURE SWITCH

PRESS OS TAT

N OT IN CLUED IN THE T RIM

TO DRAIN

VERS VIDANGE

Ref.

Description

Qty

B3

Nipple

1/2"x50

B4

Nipple

1/2"x60

B5

Nipple

1/2"x80

Ref.

B6

Nipple

1/2"x100

CFF1

Elbow FF 90

1/2"

B8

Nipple

1/2"x150

CFF2

Elbow FF 90

3/4"

B10

Nipple

3/4"x50

CP1

Clapper FF

1/2"

B11

Nipple

3/4"x60

CP2

Clapper FF

3/4"

B12

Nipple

3/4"x80

M1

Manometer

1/4"

B15

Nipple

2"x150

R3

B20

Nipple

2"x100

Ru1

Union

1/2" FF

B21

Nipple

1/4"x150

Ru2

Union

3/4" FF

T1

Tee equal

1/2"

V1

Valve

1/4"

T2

Tee equal

3/4"

V2

Valve

1/2"

2"

Description

Qty

Reducing nipple 3/4"M>1/2"F

Dimensions (mm)

Tr1

Tee reduced

2"x1/2"

V5

Valve

Width

640

CMF1

Elbow MF 90

1/4"

Ch

Chamber

Depth

520

CMF2

Elbow MF 90

1/2"

Pr1

Pressure switch

CMF4

Elbow MF 90

2"

F1

Reduced orifice

Height

780

Page 9/9

ROLLAND SPRINKLERS

235 route de la BiolleZA Les sauvages73410 MognardFRANCE

Tel. 33.(0)4.79.54.72.50 / Fax. 33.(0)4.79.54.72.48 info@rolland-sprinklers.com

También podría gustarte

- Sprinklers CabinetsDocumento1 páginaSprinklers CabinetsTezar2012Aún no hay calificaciones

- Sprinkler GuardsDocumento1 páginaSprinkler GuardsTezar2012Aún no hay calificaciones

- Sprinklers K115Documento1 páginaSprinklers K115Tezar2012Aún no hay calificaciones

- Telescope PipesDocumento2 páginasTelescope PipesTezar2012Aún no hay calificaciones

- Two Pieces Escutcheons Screwed TypeDocumento1 páginaTwo Pieces Escutcheons Screwed TypeTezar2012Aún no hay calificaciones

- Two Pieces EscutcheonsDocumento1 páginaTwo Pieces EscutcheonsTezar2012Aún no hay calificaciones

- Quantitative Risk Analysis (QRA) : Germanischer Lloyd - Service/Product DescriptionDocumento12 páginasQuantitative Risk Analysis (QRA) : Germanischer Lloyd - Service/Product DescriptionMani KalyanaramanAún no hay calificaciones

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (73)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2219)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (119)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2099)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- Assignment 3 Fanno FlowDocumento3 páginasAssignment 3 Fanno FlowABHI THAKKAR0% (1)

- 0299 249 2 Sys Hy en 144Documento64 páginas0299 249 2 Sys Hy en 144api-19483250100% (1)

- Turbine Walkdown Checks PMIDocumento15 páginasTurbine Walkdown Checks PMIRajat SharmaAún no hay calificaciones

- CKD Air Unit FRL >>> นิวเมติกDocumento3 páginasCKD Air Unit FRL >>> นิวเมติกmon012Aún no hay calificaciones

- Unit - 3 Fluid Power SymbolsDocumento23 páginasUnit - 3 Fluid Power Symbolsyuvaraja sAún no hay calificaciones

- 0302 Brass Fittings CatalogueDocumento59 páginas0302 Brass Fittings CatalogueCHALERMKIAT JIRARUNGSATEAN0% (1)

- Y-Pattern Check Valves FK 30.64 (7) GB: Primary CharacteristicsDocumento2 páginasY-Pattern Check Valves FK 30.64 (7) GB: Primary CharacteristicsNguyen KhaAún no hay calificaciones

- Darcy Friction Factor FormulaeDocumento10 páginasDarcy Friction Factor Formulaesiva242245Aún no hay calificaciones

- Experiment 3Documento9 páginasExperiment 3Abigail RadubanAún no hay calificaciones

- CPK LeafletDocumento2 páginasCPK LeaflettechdocuAún no hay calificaciones

- Fire Protection SysytemDocumento5 páginasFire Protection SysytemphilipyapAún no hay calificaciones

- S-RSBD Technical InfoDocumento60 páginasS-RSBD Technical Infokfathi55Aún no hay calificaciones

- Butt WeldDocumento14 páginasButt WeldHiru592Aún no hay calificaciones

- CPL25-Stainless Steel Self-Sealing CouplingsDocumento2 páginasCPL25-Stainless Steel Self-Sealing CouplingsSyed ImranAún no hay calificaciones

- r07220302 Mechanics of FluidsDocumento8 páginasr07220302 Mechanics of FluidsandhracollegesAún no hay calificaciones

- Valve CoatingDocumento5 páginasValve CoatingSasi Head OfficeAún no hay calificaciones

- Pressure Limitations and Safety FactorsDocumento6 páginasPressure Limitations and Safety Factorskuna098Aún no hay calificaciones

- Qsi Series CompressorDocumento142 páginasQsi Series CompressorJayAún no hay calificaciones

- Pneumatic Circuits Using Non-Return and Flow Control ValvesDocumento13 páginasPneumatic Circuits Using Non-Return and Flow Control ValvesABDULLA MOHAMED AHMED JASIM ASHOORAún no hay calificaciones

- Sum of Pressure Loss WorksheetDocumento4 páginasSum of Pressure Loss WorksheetAnonymous jvaG8m7Aún no hay calificaciones

- Three-Dimensional Cavity Flow Fields at Subsonic and Transonic SpeedsDocumento83 páginasThree-Dimensional Cavity Flow Fields at Subsonic and Transonic SpeedsMonitering EyeAún no hay calificaciones

- Varix High Performance Wafer Butterfly Valve: - Pn10, Pn16 and Pn25Documento2 páginasVarix High Performance Wafer Butterfly Valve: - Pn10, Pn16 and Pn25Saurabh Kumar SinghAún no hay calificaciones

- 36 PneumaticDocumento50 páginas36 PneumaticduythienddtAún no hay calificaciones

- Vertical Turbine Firefighting Pump InstallationDocumento4 páginasVertical Turbine Firefighting Pump InstallationWahid HusainAún no hay calificaciones

- Compressible Flow - (Solved Problems) PDFDocumento17 páginasCompressible Flow - (Solved Problems) PDFRimple MaheyAún no hay calificaciones

- SP1206 39 D4C Cartridge High Pressure PumpDocumento2 páginasSP1206 39 D4C Cartridge High Pressure PumpMarcin WersockiAún no hay calificaciones

- Carbon Steel Equivalents Across Europe and InternationallyDocumento5 páginasCarbon Steel Equivalents Across Europe and InternationallyInaamAún no hay calificaciones

- Documents - MX DPV Vertical Multistage Pumps 60 HZ Technical Data DP PumpsDocumento80 páginasDocuments - MX DPV Vertical Multistage Pumps 60 HZ Technical Data DP PumpsAnonymous ItzBhUGoi100% (1)

- Materials Wet Stand PipeDocumento1 páginaMaterials Wet Stand PipeApril Grace BautistaAún no hay calificaciones

- Taco Air SeparatorDocumento12 páginasTaco Air Separatoremongclooney11Aún no hay calificaciones