Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Quality VFinal

Cargado por

ImmerDerechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Quality VFinal

Cargado por

ImmerCopyright:

Formatos disponibles

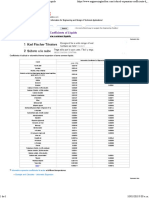

Quality control of chemical measurements

Camilo DAleman C., Eliana Chavarro M., Immer Caicedo G.

Mol Labs Ltda, Bogot, Colombia

The practice of customer service in chemical measurements develops a need for quality control associated with three properties of such measures:

1. Intermediate precision (IP) in measurements, therefore,

2. A common IP uncertainty. And

3. Dissimilar values in real matrix measurements.

An alternative use of algorithms z-score and En from proficiency testing, allow to draw all the data to be used as internal quality control.

There are two kinds of central points in this quality control charts: 1. Replicates (r ) and internal reference sample (rs ), measured in IP

conditions. 2. Reference materials (CMR ) and proficiency testing (PT ), measured in reproducibility conditions. But, their replicates can be

treated as replicates. Then it is possible to draw a control chart.

IP In Measurements

z-score 6,0

5,0

4,0

z-score = (x X) / s, will describe how much a point

deviates from a mean or specification point., by the

use of standard uncertainty uX = U/k.

As example in fig 1, Iodine number in vegetable

oils: mg I2/100g. Procedure AOAC 920.169.

Internal validation standard, safflower oil; replicates

Palm oil; CRM FAPAS oil, PT Sample from FAPAS

also. All data from IP replicates.

3,0

2,0

1,0

0,0

-1,0

-2,0

-3,0

-4,0

Fig. 1: Z-score Quality Control Chart.

As usual as it must be expected aleatory distribution of data points. Trends or non central distribution of data warns about

procedure troubles and reflects procedure, materials or analyst changes, and or equipment malfunctions.

Uncertainty control

En

En = (x X)/(U2x+ U2X): By the use of expanded

uncertainty U of the measurement in account. As

example, same data on fig 1. looks as fig 2. Also it

must be expected aleatory distribution of data points

on central distribution. At least 95% of uncertainty

lines must touch the central line, or uncertainty has

a poor estimation. IP uncertainty must be smaller

than the reproducibility one. Also if all data touch

the central line, uncertainty has a larger estimation.

Be careful of a chart with at least 30 data points.

3,0

2,0

1,0

+Uexp

0,0

-1,0

-Uexp

-2,0

-3,0

Fig. 2: En Quality Control Chart.

Uncertainty estimation could be controlled from this chart.

Conclusions

1 z-score and En quality control charts have advantage to integrate low medium or high of levels data measurement.

2. And few data points can be used to start adjusts in analytical procedures or uncertainty estimation.

3. But En has twice the information, one about central point and another on uncertainty.

Bibliography

[1] ISO 13528:2005. Statistical methods for use in proficiency testing by interlaboratory comparisons. First edition 2005-09-01.

[2] VIM 3ed. International vocabulary of metrology Basic and general concepts and associated terms. JCGM 200:2012

[3] ASTM. Manual on Presentation of Data and Control Chart Analysis. 7th Edition. February 2002.

También podría gustarte

- How Do We Know The Facts of Demography - Nathan KeyfitzDocumento37 páginasHow Do We Know The Facts of Demography - Nathan KeyfitzImmerAún no hay calificaciones

- Atomic WeightsDocumento1 páginaAtomic WeightsImmerAún no hay calificaciones

- Weighting Factors for Consensus ValuesDocumento9 páginasWeighting Factors for Consensus ValuesAgus KurniawanAún no hay calificaciones

- Biological Stains - Handbook On The Nature and Uses of The Dyes Employed in The Biological LaboratoryDocumento376 páginasBiological Stains - Handbook On The Nature and Uses of The Dyes Employed in The Biological LaboratoryImmerAún no hay calificaciones

- Volumetric or Cubical Expansion Coefficients of LiquidsDocumento1 páginaVolumetric or Cubical Expansion Coefficients of LiquidsImmerAún no hay calificaciones

- 3500-Al Rev Edit 2011Documento4 páginas3500-Al Rev Edit 2011ImmerAún no hay calificaciones

- Biological Stains - Handbook On The Nature and Uses of The Dyes Employed in The Biological LaboratoryDocumento376 páginasBiological Stains - Handbook On The Nature and Uses of The Dyes Employed in The Biological LaboratoryImmerAún no hay calificaciones

- A Whirlwind Tour of PythonDocumento98 páginasA Whirlwind Tour of Pythonoloma_junda100% (2)

- Shapiro and Wilk 1965 - An Analysis of Variance Test For Normality PDFDocumento22 páginasShapiro and Wilk 1965 - An Analysis of Variance Test For Normality PDFImmerAún no hay calificaciones

- (Pure and Applied Chemistry) Nomenclature in Evaluation of Analytical Methods Including Detection and Quantification Capabilities (IUPAC Recommendations 1995)Documento25 páginas(Pure and Applied Chemistry) Nomenclature in Evaluation of Analytical Methods Including Detection and Quantification Capabilities (IUPAC Recommendations 1995)ImmerAún no hay calificaciones

- Limitations of the Horwitz equation for estimating measurement uncertaintiesDocumento12 páginasLimitations of the Horwitz equation for estimating measurement uncertaintiesImmerAún no hay calificaciones

- Primary Methods of Measurement in Chemical Analysis PDFDocumento6 páginasPrimary Methods of Measurement in Chemical Analysis PDFImmer100% (1)

- Representing Data Distributions PDFDocumento2 páginasRepresenting Data Distributions PDFImmerAún no hay calificaciones

- Temperature Calibration Depths of ImmersionDocumento7 páginasTemperature Calibration Depths of ImmersionNicole FloydAún no hay calificaciones

- An Enhanced Bootstrap Method To Detect Possible Fraudulent Behavior in Testing FacilitiesDocumento7 páginasAn Enhanced Bootstrap Method To Detect Possible Fraudulent Behavior in Testing FacilitiesImmerAún no hay calificaciones

- The Fitness For Purpose of AM EURACHEM PDFDocumento70 páginasThe Fitness For Purpose of AM EURACHEM PDFLeila EspinosaAún no hay calificaciones

- EC Trace 2003Documento43 páginasEC Trace 2003Andreas BraunAún no hay calificaciones

- RM Catalogue 161006 0Documento108 páginasRM Catalogue 161006 0ImmerAún no hay calificaciones

- PROLab Plus ManualDocumento162 páginasPROLab Plus ManualImmer100% (1)

- ILAC Policy For Participation in Proficiency Testing ActivitiesDocumento8 páginasILAC Policy For Participation in Proficiency Testing ActivitiesImmerAún no hay calificaciones

- Ich Q1F PDFDocumento1 páginaIch Q1F PDFSailaja ChirravuriAún no hay calificaciones

- Nist Technical Note 1297 SDocumento25 páginasNist Technical Note 1297 SRonny Andalas100% (1)

- What Causes Most Errors in Chemical AnalysisDocumento2 páginasWhat Causes Most Errors in Chemical AnalysisImmerAún no hay calificaciones

- E104 32317Documento5 páginasE104 32317ImmerAún no hay calificaciones

- Book of Abstracts PTDocumento116 páginasBook of Abstracts PTImmerAún no hay calificaciones

- Camilo Daleman C., Eliana Chavarro M., Immer Caicedo G. Mol Labs Ltda, Bogotá, ColombiaDocumento1 páginaCamilo Daleman C., Eliana Chavarro M., Immer Caicedo G. Mol Labs Ltda, Bogotá, ColombiaImmerAún no hay calificaciones

- Validating analyzer systems with nonparametric dataDocumento9 páginasValidating analyzer systems with nonparametric dataImmerAún no hay calificaciones

- Co010011n201412060165 PDFDocumento1 páginaCo010011n201412060165 PDFImmerAún no hay calificaciones

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (344)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (587)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (73)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (119)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2099)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- Sheet 1Documento1 páginaSheet 1Antonio SanchezAún no hay calificaciones

- BooksDocumento1 páginaBookspre_singh213650% (2)

- An Introduction To Environmental ScienceDocumento46 páginasAn Introduction To Environmental ScienceAmit AgrawalAún no hay calificaciones

- Introduction To Rural Community DevelopmentDocumento30 páginasIntroduction To Rural Community DevelopmentS.Rengasamy100% (20)

- Identify Parts of The Microscope and Their Functions Focus Specimens Using The Compound MicroscopeDocumento5 páginasIdentify Parts of The Microscope and Their Functions Focus Specimens Using The Compound MicroscopeMet XiiAún no hay calificaciones

- Chi-Square Test & Contingency AnalysisDocumento16 páginasChi-Square Test & Contingency AnalysisSin Jie LimAún no hay calificaciones

- Chapter 3 Reasearch MethodologyDocumento12 páginasChapter 3 Reasearch MethodologyRalph Belleza100% (2)

- 1920-2-PR1-Lesson 4Documento30 páginas1920-2-PR1-Lesson 4Ivy MuñozAún no hay calificaciones

- Problem Solving and Decision Making Illustrated Course Guides 2nd Edition Butterfield Test BankDocumento36 páginasProblem Solving and Decision Making Illustrated Course Guides 2nd Edition Butterfield Test Bankcentiareleveler1mar100% (29)

- Mit Wpu Ece PPT 24012022pptxDocumento59 páginasMit Wpu Ece PPT 24012022pptxMiles Joshua EspadillaAún no hay calificaciones

- Study at LUT BrochureDocumento28 páginasStudy at LUT BrochureWylk BeserraAún no hay calificaciones

- BAEnglish Language Linguistics PDFDocumento93 páginasBAEnglish Language Linguistics PDFAnonymous p5BEJzvqrkAún no hay calificaciones

- Asme PTC 60Documento5 páginasAsme PTC 60Cuong TranHungAún no hay calificaciones

- Major Schools of Thought in PsychologyDocumento1 páginaMajor Schools of Thought in PsychologyXedo Pingol100% (3)

- Unit 2 Experimental Design (Control Group Design and Two Factor Design)Documento15 páginasUnit 2 Experimental Design (Control Group Design and Two Factor Design)Manisha BhavsarAún no hay calificaciones

- Principles of ManagementDocumento320 páginasPrinciples of ManagementBineeta Sinha67% (9)

- Academic Calendar 2012-13 - I SemDocumento6 páginasAcademic Calendar 2012-13 - I Semrahulsharmaph15182Aún no hay calificaciones

- SubjectivityinArtHistoryandArt CriticismDocumento12 páginasSubjectivityinArtHistoryandArt CriticismMohammad SalauddinAún no hay calificaciones

- Framing Nature Conference AbstractsDocumento251 páginasFraming Nature Conference AbstractsAaron WuAún no hay calificaciones

- Ugay, Nicole G. BS Psychology 3-ADocumento4 páginasUgay, Nicole G. BS Psychology 3-ANicoleAún no hay calificaciones

- Fundamentals of GISDocumento11 páginasFundamentals of GISLaxman Koirala0% (1)

- Draft K-4 CurriculumDocumento280 páginasDraft K-4 Curriculumedmontonjournal100% (6)

- ASSIGNMENT - Postmodermism and Geaography 2019Documento7 páginasASSIGNMENT - Postmodermism and Geaography 2019Kwasi AdarkwaAún no hay calificaciones

- Research Ethics (Aanand) FinalDocumento11 páginasResearch Ethics (Aanand) FinalNaman DadhichAún no hay calificaciones

- New Horizon Gurukul: Home Work For Class: IxDocumento3 páginasNew Horizon Gurukul: Home Work For Class: IxSundari MuruganAún no hay calificaciones

- Rekod Transit Sains 2021Documento59 páginasRekod Transit Sains 2021cik tati100% (1)

- Basic Theology Biblio LogyDocumento16 páginasBasic Theology Biblio LogyFrans N PandjaitanAún no hay calificaciones

- Science of Human Movements - Meaning, Name, Directions of DevelopmentDocumento20 páginasScience of Human Movements - Meaning, Name, Directions of DevelopmentJoana Rose FantonialAún no hay calificaciones

- Mga Halimbawa NG Research Paper Sa Filipino PDFDocumento5 páginasMga Halimbawa NG Research Paper Sa Filipino PDFAliah Salman0% (3)

- Pearson - Understanding PsychologyDocumento66 páginasPearson - Understanding PsychologyLiam CasanovaAún no hay calificaciones