Documentos de Académico

Documentos de Profesional

Documentos de Cultura

4340

Cargado por

fedaquiDerechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

4340

Cargado por

fedaquiCopyright:

Formatos disponibles

DATA SHEET

LESCALLOY 4340 VAC-ARC

HIGH STRENGTH ALLOY STEEL

Typical

Composition

C

0.40

Mn

0.75

Si

0.30

Cr

0.80

Ni

1.80

Mo

0.25

GENERAL CHARACTERISTICS

LESCALLOY 4340 VAC-ARC steel is a low alloy, nickel-chromium-molybdenum steel capable of being

heat treated to high strength levels. The alloy has a good combination of ductility, toughness and strength

along with high hardenability.

LESCALLOY 4340 VAC-ARC steel is produced by the consumable electrode vacuum arc remelting process

to provide optimum cleanliness and preferred ingot structure.

PHYSICAL PROPERTIES

TEMPERING CURVE

Density: 0.283 lb/in3 (7.84 g/cm3)

Thermal Conductivity:

21.67 BTUft/h/ft2/F (37.48 W/mK)

Coefficient of Thermal Expansion:

Specific Heat: 0.107 BTU/lb./F (0.107 cal/g/C)

HEAT TREATMENT

Normalize: 1600-1700F (871-927C), air cool.

Austenitize: 1475-1575F (802-857C), oil quench.

400-1200F (204-649C), depending on

Temper:

desired strength. Temper between 400500F (204-260C) to obtain tensile

strengths above 260 ksi (1793 MPa).

Tempered Twice - 2 + 2 Hours

Tempering Temperature C

204

316

427

538

649

60

Hardness Rockwell C

Temp Range

in / in / F mm / mm / C

F

C

( x 10-6 )

( x 10-6 )

0 - 200 -18 - 93

6.3

11.3

0 - 1200 -18 - 649

8.1

14.6

Austenitized 1550F (843C) - Oil Quenched

50

40

30

20

400

500

600

700

800

900

1000 1100 1200

Tempering Temperature F

WORKABILITY

Forging: Forge between 1950 and 2250F (1066-1232C). Because of the air hardening capability of the

material, preheating and furnace cooling or cooling in ash or lime after forging is recommended.

Machining: Normalize and then temper at approximately 1200F (629C) for optimum machinability.

Weldability: This steel can be welded by gas or arc fusion methods. Due to the air hardening characteristics

of the steel, the part should be annealed or normalized and tempered after welding.

COPYRIGHT 2007 by Latrobe Specialty Steel Co.

Registered Trademark of Latrobe Specialty Steel Co.

LESCALLOY 4340 VAC-ARC

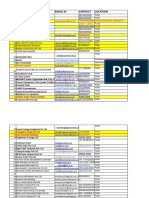

MECHANICAL PROPERTIES

TYPICAL TRANSVERSE TENSILE PROPERTIES

(Note Different Tempering Temperatures)

Bar Size

in

mm

3 rd.

89 rd.

7 sq.

191 sq.

10 sq. 267 sq.

Temper*

F

C

400

204

500

260

1100

593

ksi

276

265

165

U.T.S

MPa

1905

1830

1140

0.2% Y.S.

ksi

MPa

222

1530

222

1530

150

1035

Elong.

%

11.0

8.0

18.0

R.A.

%

35.0

25.0

60.0

* Prior Treatment: Normalized 1650/1700F (899/927C), Austenitized 1500/1525F (816/829C), Oil Quenched

TYPICAL HARDENABILITY DATA

Rockwell C Hardness

Maximum

60

60

60

60

59

58

57

57

56

56

93

Test Temperature C

316

204

427

538

649

1000

1200

50

Minimum

52

52

52

52

51

48

46

44

42

40

40

Hardness Rockwell C

Distance from

Quenched End

in

mm

1/16

1.6

3.2

6.4

12.7

19.1

1

25

2

51

1

32

1

38

1

45

ELEVATED TEMPERATURE HARDNESS DATA

B

C

30

20

10

CLEANLINESS STANDARDS

0RT

Lescalloy 4340 VAC-ARC steel conforms to AMS

2300 for magnetic particle cleanliness. The

microcleanliness of Lescalloy 4340 VAC-ARC

steel is typified by the following worst field

specifications, in accordance with ASTM E45.

Worst Fields

Thin

Heavy

A

2.0

1.0

B

1.5

1.0

C

1.5

1.0

D

2.0

1.5

200

400

600

800

Test Temperature F

Normalize

Austenitize

Temper

1650F (899C) / 1 hr / AC

1500F (816C) / hr / OQ

475F (246C) / 2 + 2 hours / AC

Normalize

Austenitize

Temper

1650F (899C) / 1 hr / AC

1500F (816C) / hr / OQ

900F (482C) / 2 + 2 hours / AC

Normalize

Austenitize

Temper

1650F (899C) / 1 hr / AC

1475F (802C) / hr / OQ

1100F (593C) / 2 hours / AC

SPECIFICATIONS

The following list of popular industry specifications is offered for general familiarization and cross-reference

purposes. This should not be considered a complete listing.

AMS 6414

AMS 6415 (Air Melt)

AMS-S-5000 (Air Melt)

299-947-055 (Bell Helicopter)

SS 9702 (Sikorsky)

Latrobe, Pennsylvania 15650-0031 U.S.A.

Phone: (724) 537-7711 Fax: (724) 532-6316

www.latrobesteel.com

COPYRIGHT 2007 by Latrobe Specialty Steel Co.

04/07

También podría gustarte

- Properties and Grades of FastenersDocumento3 páginasProperties and Grades of Fastenerschez ezAún no hay calificaciones

- Cross Reference Ro SteelsDocumento17 páginasCross Reference Ro SteelsJosé SilvérioAún no hay calificaciones

- 20160323110112-Sae 1215Documento1 página20160323110112-Sae 1215awesome_600Aún no hay calificaciones

- Alloy Steel ChartDocumento4 páginasAlloy Steel Chartmodi_mihirAún no hay calificaciones

- ASM Cross Reference For NonferrousDocumento17 páginasASM Cross Reference For Nonferrousfedaqui100% (2)

- ST 35.8 (Germany / DIN) : Material PropertiesDocumento3 páginasST 35.8 (Germany / DIN) : Material Propertiesmohammad zareiAún no hay calificaciones

- Introduction to Soil Investigation ReportDocumento76 páginasIntroduction to Soil Investigation ReportRuzengulalebih ZEta's-Listik50% (2)

- Flexivity of Thermostat Metals: Standard Test Methods ForDocumento7 páginasFlexivity of Thermostat Metals: Standard Test Methods ForAnurag YadavAún no hay calificaciones

- 15-5 PHDocumento2 páginas15-5 PHfedaquiAún no hay calificaciones

- 15-5 PHDocumento2 páginas15-5 PHfedaquiAún no hay calificaciones

- Ssab Emea Ab, Se-781 84 Borlänge, Sweden: Carbon Equivalent Etc C93-C99Documento1 páginaSsab Emea Ab, Se-781 84 Borlänge, Sweden: Carbon Equivalent Etc C93-C99angelokyoAún no hay calificaciones

- 13-8 MoDocumento2 páginas13-8 MofedaquiAún no hay calificaciones

- Kaiser Aluminum Soft Alloy Tube PDFDocumento31 páginasKaiser Aluminum Soft Alloy Tube PDFgerrzen64Aún no hay calificaciones

- Life Insurance Exam Questions and Answers PDFDocumento13 páginasLife Insurance Exam Questions and Answers PDFDairo GaniyatAún no hay calificaciones

- Astm A269 PDFDocumento1 páginaAstm A269 PDFRahulAún no hay calificaciones

- MTC Sample Dia 36 Inch Heat 639914 4130Documento2 páginasMTC Sample Dia 36 Inch Heat 639914 4130emadabdelsattarAún no hay calificaciones

- Grades of Steel ChartDocumento3 páginasGrades of Steel ChartKimAún no hay calificaciones

- 347623-Po 4503181944-Li 1Documento6 páginas347623-Po 4503181944-Li 1Rita WilliamsAún no hay calificaciones

- EN 10 204 - 3.1 Quality Inspection PO.011.2022 10396282-30 21547528 2023-07-21Documento1 páginaEN 10 204 - 3.1 Quality Inspection PO.011.2022 10396282-30 21547528 2023-07-21Ehab Attia SelimAún no hay calificaciones

- Aluminium and Aluminium Alloys Extruded Rod Bar Tube and Profiles Mechanical Properties 1Documento8 páginasAluminium and Aluminium Alloys Extruded Rod Bar Tube and Profiles Mechanical Properties 1Hussain MahmudAún no hay calificaciones

- Hot Rolled Carbon Steel Sheet, Plate and Strip According To IS 1079:2017Documento8 páginasHot Rolled Carbon Steel Sheet, Plate and Strip According To IS 1079:2017raghavendragouda patilAún no hay calificaciones

- Comaparação A572 G50-A992Documento4 páginasComaparação A572 G50-A992Tiago CastelaniAún no hay calificaciones

- Certificate FF 16662Documento3 páginasCertificate FF 16662Ionela IonelaAún no hay calificaciones

- ASME IX Welder QualificationDocumento1 páginaASME IX Welder QualificationWaqas WaqasAún no hay calificaciones

- S690Documento2 páginasS690corsini999Aún no hay calificaciones

- 2062Documento17 páginas2062hswed91100% (1)

- 4340M or 300MDocumento2 páginas4340M or 300MfedaquiAún no hay calificaciones

- 4340M or 300MDocumento2 páginas4340M or 300MfedaquiAún no hay calificaciones

- Q.850 ISDN Cause CodesDocumento12 páginasQ.850 ISDN Cause CodesJack CastineAún no hay calificaciones

- Aisi 4140 En8 En19Documento1 páginaAisi 4140 En8 En19Jose KurianAún no hay calificaciones

- Company Name Email Id Contact Location: 3 Praj Industries Limited Yogesh960488815Pune-Nagar Road, SanaswadiDocumento65 páginasCompany Name Email Id Contact Location: 3 Praj Industries Limited Yogesh960488815Pune-Nagar Road, SanaswadiDhruv Parekh100% (1)

- Alloy SteelDocumento7 páginasAlloy SteelRavinJohnAún no hay calificaciones

- Rra Heat Treatment of Al 7075-T6Documento12 páginasRra Heat Treatment of Al 7075-T6Arissa Lidia Eva AdventiaAún no hay calificaciones

- Ssab Emea Ab, Se-613 80 Oxelösund, Sweden: Carbon Equivalent Etc C93-C99Documento1 páginaSsab Emea Ab, Se-613 80 Oxelösund, Sweden: Carbon Equivalent Etc C93-C99fernandojAún no hay calificaciones

- AISI 1040: General Purpose Mild Steel for Forging, Machining & Heat TreatingDocumento2 páginasAISI 1040: General Purpose Mild Steel for Forging, Machining & Heat Treatingho_chauhanAún no hay calificaciones

- Tata Steel - YMPRESS S500MC - Data SheetDocumento2 páginasTata Steel - YMPRESS S500MC - Data SheetpnagarajjAún no hay calificaciones

- Impact AR500 PlateDocumento2 páginasImpact AR500 PlateMario Diez100% (1)

- Welding Rod For c5 & f5 - Er 80s-b6Documento1 páginaWelding Rod For c5 & f5 - Er 80s-b6SatyamEngAún no hay calificaciones

- Hastelloy B2 Alloy B2 UNS N10665 DIN 2.4617Documento3 páginasHastelloy B2 Alloy B2 UNS N10665 DIN 2.4617SamkitAún no hay calificaciones

- Spec alloy steel wire grade SAE 52100Documento6 páginasSpec alloy steel wire grade SAE 52100Nour Saad EdweekAún no hay calificaciones

- HeadDocumento1 páginaHeadabdulloh_99Aún no hay calificaciones

- Astm A659-18Documento3 páginasAstm A659-18Ryan ZhangAún no hay calificaciones

- Is 513 Amendment-1Documento2 páginasIs 513 Amendment-1sanjeev00747488Aún no hay calificaciones

- Test CertificateDocumento1 páginaTest CertificateNithin AbrahamAún no hay calificaciones

- Certified Mill Test Report: S O L D T O S H I P T ODocumento1 páginaCertified Mill Test Report: S O L D T O S H I P T OMohamed RaafatAún no hay calificaciones

- Esab Buddy TIG400iDocumento2 páginasEsab Buddy TIG400iJeganeswaranAún no hay calificaciones

- Is 7283.1992 PDFDocumento10 páginasIs 7283.1992 PDFTuff qualityAún no hay calificaciones

- ASTM A694 F60 - Heat Treatment and Mechanical Properties - ICRF 2012Documento3 páginasASTM A694 F60 - Heat Treatment and Mechanical Properties - ICRF 2012Noushad Bin JamalAún no hay calificaciones

- JSW Steel LTDDocumento1 páginaJSW Steel LTDRanjan BhatiaAún no hay calificaciones

- JIS G4801 SUP10 Steel GuideDocumento2 páginasJIS G4801 SUP10 Steel GuideĐình Sỹ TTPAún no hay calificaciones

- C43Documento1 páginaC43rudramansingh123Aún no hay calificaciones

- Market Study Metals AssignmentDocumento21 páginasMarket Study Metals AssignmentAanchal MukherjeeAún no hay calificaciones

- Astm A827-14Documento3 páginasAstm A827-14Артем Титов100% (1)

- SIS-S 501 50 AG Hot Rolled Steel Rounds (Up To Dia 180mm)Documento5 páginasSIS-S 501 50 AG Hot Rolled Steel Rounds (Up To Dia 180mm)Rajoo PrajapatiAún no hay calificaciones

- ASTM-A572 Grade 50 Steel Chemical & Mechanical PropertiesDocumento1 páginaASTM-A572 Grade 50 Steel Chemical & Mechanical PropertiesMinhas ArshadAún no hay calificaciones

- Data Table For Grades Tool Die Steels SKD-11Documento3 páginasData Table For Grades Tool Die Steels SKD-11Adhi candra irawanAún no hay calificaciones

- Astm f1315 - 2006 DensityDocumento3 páginasAstm f1315 - 2006 DensityRyan Jonathan MartinAún no hay calificaciones

- GTAW Welding of CP Titanium and Ti6Al4VDocumento1 páginaGTAW Welding of CP Titanium and Ti6Al4VDeepak KumarAún no hay calificaciones

- Stainless Steel Alloys Comparsion ChartDocumento3 páginasStainless Steel Alloys Comparsion Chartsengcyan100% (1)

- TM-0028M-F (Property Requirements of Internally-Threaded Fasteners, Steel)Documento5 páginasTM-0028M-F (Property Requirements of Internally-Threaded Fasteners, Steel)方綵樺Aún no hay calificaciones

- Ss Grade 50 - Galvanized Steel Coils & SheetsDocumento1 páginaSs Grade 50 - Galvanized Steel Coils & SheetshealgoseAún no hay calificaciones

- Carbon Steel Specifications and ApplicationsDocumento2 páginasCarbon Steel Specifications and ApplicationsRajendraAún no hay calificaciones

- AISI 1018 Mild Low Carbon Steel PDFDocumento3 páginasAISI 1018 Mild Low Carbon Steel PDFFebrian JhaAún no hay calificaciones

- Properties of Ss410Documento5 páginasProperties of Ss410gregkilatonAún no hay calificaciones

- Section 2.0 Alloy SteelsDocumento10 páginasSection 2.0 Alloy SteelsAloísio NascimentoAún no hay calificaciones

- 4140 HTDocumento2 páginas4140 HTwillys8Aún no hay calificaciones

- 410 Data Sheet PDFDocumento2 páginas410 Data Sheet PDFraviteja036Aún no hay calificaciones

- 410S Data BulletinDocumento4 páginas410S Data BulletinkatchaniAún no hay calificaciones

- 17 4Documento2 páginas17 4fedaquiAún no hay calificaciones

- Low Alloy Steels Part2Documento1 páginaLow Alloy Steels Part2fedaquiAún no hay calificaciones

- Workbench Under Stair Storage PlansDocumento20 páginasWorkbench Under Stair Storage PlansKeleen WrightAún no hay calificaciones

- Photomicrographs of Iron and Steel, ReedDocumento288 páginasPhotomicrographs of Iron and Steel, Reedfedaqui100% (1)

- Alloy20 PennSDainlessProductsDocumento2 páginasAlloy20 PennSDainlessProductsfedaquiAún no hay calificaciones

- Nickel Maraging Steel PropertiesDocumento30 páginasNickel Maraging Steel PropertiesRobert NatasorpAún no hay calificaciones

- 17 4Documento2 páginas17 4fedaquiAún no hay calificaciones

- ASCII TableDocumento7 páginasASCII TableSheriff SammyAún no hay calificaciones

- Oyo Summer Internship ReportDocumento31 páginasOyo Summer Internship ReportJayasree S RAún no hay calificaciones

- CS547Documento11 páginasCS547Usman Suleman AhmadAún no hay calificaciones

- Real-Time Java and ATCDocumento44 páginasReal-Time Java and ATCdnk_victon6248Aún no hay calificaciones

- Less Than a Decade to Avoid Catastrophic Climate ChangeDocumento1 páginaLess Than a Decade to Avoid Catastrophic Climate ChangeXie YuJiaAún no hay calificaciones

- Public Relations Proposal Template: Executive SummaryDocumento3 páginasPublic Relations Proposal Template: Executive SummaryErmi SusilowatiAún no hay calificaciones

- 3.1.2 Cable FPLR 2X18 AwgDocumento3 páginas3.1.2 Cable FPLR 2X18 Awgluis rios granadosAún no hay calificaciones

- S-S-, AXXX XXX 008 (BIA Sept. 15, 2017)Documento7 páginasS-S-, AXXX XXX 008 (BIA Sept. 15, 2017)Immigrant & Refugee Appellate Center, LLCAún no hay calificaciones

- BVM Type B Casing Tong ManualDocumento3 páginasBVM Type B Casing Tong ManualJuan Gabriel GomezAún no hay calificaciones

- Instructions Manual Skatey 150/250/400/600Documento19 páginasInstructions Manual Skatey 150/250/400/600Denys GavrylovAún no hay calificaciones

- My Sweet Beer - 23 MaiDocumento14 páginasMy Sweet Beer - 23 Maihaytem chakiriAún no hay calificaciones

- Everything You Need to Know About Distribution TransformersDocumento2 páginasEverything You Need to Know About Distribution TransformersDONNYMUCKTEEAún no hay calificaciones

- MONETARY POLICY OBJECTIVES AND APPROACHESDocumento2 páginasMONETARY POLICY OBJECTIVES AND APPROACHESMarielle Catiis100% (1)

- Draft SemestralWorK Aircraft2Documento7 páginasDraft SemestralWorK Aircraft2Filip SkultetyAún no hay calificaciones

- Wireshark Lab: 802.11: Approach, 6 Ed., J.F. Kurose and K.W. RossDocumento5 páginasWireshark Lab: 802.11: Approach, 6 Ed., J.F. Kurose and K.W. RossN Azzati LabibahAún no hay calificaciones

- Tối Ưu Hóa Cho Khoa Học Dữ LiệuDocumento64 páginasTối Ưu Hóa Cho Khoa Học Dữ Liệuminhpc2911Aún no hay calificaciones

- Money and Financial InstitutionsDocumento26 páginasMoney and Financial InstitutionsSorgot Ilie-Liviu100% (1)

- Importance and Behavior of Capital Project Benefits Factors in Practice: Early EvidenceDocumento13 páginasImportance and Behavior of Capital Project Benefits Factors in Practice: Early EvidencevimalnandiAún no hay calificaciones

- A Study of Arcing Fault in The Low-Voltage Electrical InstallationDocumento11 páginasA Study of Arcing Fault in The Low-Voltage Electrical Installationaddin100% (1)

- Url Profile Results 200128191050Documento25 páginasUrl Profile Results 200128191050Wafiboi O. EtanoAún no hay calificaciones

- Black Bruin Hydraulic Motors On-Demand Wheel Drives EN CDocumento11 páginasBlack Bruin Hydraulic Motors On-Demand Wheel Drives EN CDiego AlbarracinAún no hay calificaciones

- Section - I: Cover Page Section - II:: IndexDocumento21 páginasSection - I: Cover Page Section - II:: Indexamit rajputAún no hay calificaciones

- Akriti Shrivastava CMBA2Y3-1906Documento6 páginasAkriti Shrivastava CMBA2Y3-1906Siddharth ChoudheryAún no hay calificaciones

- Impact of COVIDDocumento29 páginasImpact of COVIDMalkOo AnjumAún no hay calificaciones

- CLS1Documento3 páginasCLS1Shaina Kaye De GuzmanAún no hay calificaciones

- SESSON 1,2 AND 3 use casesDocumento23 páginasSESSON 1,2 AND 3 use casessunilsionAún no hay calificaciones

- Project 863 EvidenceDocumento5 páginasProject 863 EvidenceMilan TolhuisenAún no hay calificaciones