Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Spidere Pentru Fixarea Fatadelor Din Sticla Sadev Classic Eng Nou 52058

Cargado por

Iulia PetrescuDerechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Spidere Pentru Fixarea Fatadelor Din Sticla Sadev Classic Eng Nou 52058

Cargado por

Iulia PetrescuCopyright:

Formatos disponibles

chap_03-ATTACHES-cat-classic-gb:Mise en page 1

25/11/09

21:20

Page 1

SPIDERS

Casted stainless steel spider

Ref: S3000 > Page 3.05

Ref: S3001 > Page 3.07

Ref: S3006 > Page 3.09

SUMMARY

SPIDERS

::

SPIDERS

Casted aluminium spider

Ref: S3007 > Page 3.11

Laser cut spider

Ref: S3003 > Page 3.13

Casted stainless steel spider,

with plate

Ref: S3100 > Page 3.15

Ref: S3101 > Page 3.17

Accessories

Page 3.19

Suggested mounting instructions

Page 3.21

::

4 steps to order your spiders

Page 3.23

Pages 3.03 >> 3.25

Tel. +33 (0)4 50 08 39 00 - Fax +33 (0)4 50 08 39 49

Order form

Page 3.25

3.02

www.sadev.com - info@sadev.com

chap_03-ATTACHES-cat-classic-gb:Mise en page 1

25/11/09

21:20

Page 2

SPIDERS

Specification sheet spiders:

::

Original texts from cahier 3574 du CSTB

The technique:

The spider plays the role of intermediary between the carrying structure and the fittings fixed onto the glass panel.

The fineness of its lines allows the construction to retain all its transparency.

SPIDERS

3.1.4 Functional clearances

The anticipated functional clearances of the spiders as well as the point fittings have to allow the glass to move towards their fixing points

without creating any stress in the plane of the glass or embedding moments under:

- the effects of the wind or snow loads (shortening of the distance between glass holes and deformation of the structure)

- the differential thermal dilatations between the structure and the glasses

- the differential displacements of the spiders

FIXED POINT

17 mm

SLOTTED POINT

17 x 24 mm

The glass panels are either supported or suspended. Every glass

is generally held by two carrying points (supporting the weight)

allowing horizontal movements due to dilatation

Whichever technical dispositions are

adopted for the realization of the functional clearances, those ones have to

remain operational with the time (no seizing, buttressing, jamming or uncontrolled tightening). This can be obtained

for example by the use of spacers.

FREE POINT

24 mm

FREE POINT

24 mm

The other fixing points have to allow movements in all

directions in the plane of the glass.

The fixing of the spiders on the faade:

In order to obtain a correct adjustment of the

spider, it is recommended to use an intermediary part, the Omega.

This part allows a bidirectional adjustment.

Tel. +33 (0)4 50 08 39 00 - Fax +33 (0)4 50 08 39 49

The central slotted hole has

to be imperatively oriented

horizontally, so that the supported

weight does not cause the spider

to slide down.

3.03

www.sadev.com - info@sadev.com

chap_03-ATTACHES-cat-classic-gb:Mise en page 1

25/11/09

21:20

Page 3

SPIDERS

::

The anti-rotation of the spider:

daN

3.1.3 To

(lb)avoid the risk of displacement of the spiders under the weight of the glasses during installation or in case of accidental glass breakage,

the spiders have to be locked in rotation by any appropriate means (for example: use of high resistance bolts under controlled tightening, elastic

and cotter pins etc.).

ULS

0,1 mm

SPIDERS

SLS

1 mm

1 - In case of glass breakage, the spider is dragged in rotation by the remaining glass panel.

Its from this point that the pins maintain the

spider in position.

2 - All spiders positioned at the border of the

faade are dragged in rotation by the glass

panels. The pins maintain continuously the

spiders in position.

The layout of the spiders on the faade:

Each SADEV spider is delivered in accordance to its position on the faade.

In order to facilitate the orientation of the different positions, weve classified them in several mounting instructions that cover all scenarios.

For all requests, its sufficient for you to give us the inventory of your different positions. For example: 56 specimens of S3000 5.

01-THE STUDY

02-THE IDENTIFICATION

3

S3000

POSITION 3

1

14

14

14

16

17

16

17

16

10

17

16

17

16

17

11

12

11

13

13

For more information please find the page How to order your spiders? at the end of this chapter.

Tel. +33 (0)4 50 08 39 00 - Fax +33 (0)4 50 08 39 49

3.04

www.sadev.com - info@sadev.com

chap_03-ATTACHES-cat-classic-gb:Mise en page 1

25/11/09

21:21

Page 4

SPIDERS

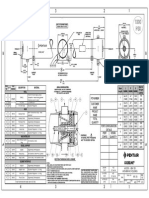

Reference: S3000 MONTI

Designation : casted stainless steel spider.

AS

TECH

NICAL

SE

SME

SPIDERS

GIS

RE

RE

TE D

Technical assessment

available online at

www.sadev.com

Glass side view

Material: AISI 316 Surface finish: dull polished GR400

Dimensions:

Glass side view

Tel. +33 (0)4 50 08 39 00 - Fax +33 (0)4 50 08 39 49

::

3.05

www.sadev.com - info@sadev.com

chap_03-ATTACHES-cat-classic-gb:Mise en page 1

25/11/09

21:21

Page 5

SPIDERS

::

Modle : S3000 MONTI

Mechanical performances:

Load parallel to glass

(per arm)

ULS

SLS* at 1 mm

434 daN

(975 lb)

SLS

0,1 mm

ULS*

398 daN

(894 lb)

Load perpendicular

to glass (per arm)

SLS* at 1 mm

238 daN

(535 lb)

ULS*

300 daN

(674 lb)

*SLS: Serviceability Limit State (load causing a deformation of 1 mm)

ULS: Ultimate Limit State: Elastic limit Rp0.1 (maximal load causing a permanent

deformation of the spider of 0,1 mm).

1 mm

Configuration:

Glass side view

2 arms 90

Weight: 1,41 kg

3 arms

Weight: 2 kg

2 arms 180

Weight: 1,1 kg

1 arm 180

Weight: 0,71 kg

1 arm 90

Weight: 0,89 kg

4 arms

Weight: 2,6 kg

Represents a fixed point 17 mm, a slotted point 17x24 mm, or a free

point 24 mm depending on the position of the spider on the faade (see

suggested mounting instructions at the end of the chapter).

Suggested mounting instruction:

The drilling diameter for the pins is 6 mm. Do not drill the holes for the pins in your structure before mounting the spiders. To fix the spider on your structure the

Omega (see accessories) is highly recommended to adjust the spiders position. The fixing of the spider is done with a M16 or a M12 bolt (out of Sadev supply).

This bolt shall not be fitted into a vertical slotted holes due to the risk of slipping (under the weight), the pins are not designed to hold any permanent loads (cf. specification sheet). The spider has to be positioned on a flat support. The slotted holes 17x24 mm and free holes 24 mm in the spider are not to be used to adjust

the spider! They are needed to absorb the manufacturing tolerances and the thermal deformation of the glass and of the structure.The spiders are standardized for

M14 fittings (FXR, FXV); other diameters are available on request.

SADEV recommends using thread locking compound, except in case of specific mounting constraints.

Tel. +33 (0)4 50 08 39 00 - Fax +33 (0)4 50 08 39 49

3.06

www.sadev.com - info@sadev.com

SPIDERS

daN

(lb)

chap_03-ATTACHES-cat-classic-gb:Mise en page 1

25/11/09

21:21

Page 6

SPIDERS

Reference: S3001

Designation : casted stainless steel spider

SE

AS

SPIDERS

TECH

NICAL

Technical assessment

available online at

www.sadev.com

SME

Glass side view

Material: AISI 316 Surface finish: electro polished

Dimensions:

Glass side view

Tel. +33 (0)4 50 08 39 00 - Fax +33 (0)4 50 08 39 49

::

3.07

www.sadev.com - info@sadev.com

chap_03-ATTACHES-cat-classic-gb:Mise en page 1

25/11/09

21:21

Page 7

SPIDERS

::

Reference: S3001

Mechanical performances:

Load parallel to glass

(per arm)

ULS

SLS* at 1 mm

257 daN

(577 lb)

SLS

0,1 mm

ULS*

241 daN

(541 lb)

Load perpendicular

to glass (per arm)

SLS* at 1 mm

110 daN

(247 lb)

ULS*

155 daN

(348 lb)

*SLS: Serviceability Limit State (load causing a deformation of 1 mm)

ULS: Ultimate Limit State: Elastic limit Rp0.1 (maximal load causing a permanent

deformation of the spider of 0,1 mm).

1 mm

Configuration:

Glass side view

2 arms 90

Weight: 0,8 kg

3 arms

Weight: 1,06 kg

2 arms 180

Weight: 0,58 kg

1 arms 180

Weight: 0,41 kg

1 arm 90

Weight: 0,49 kg

4 arms

Weight: 1,52 kg

Represents a fixed point 17 mm, a slotted point 17x24 mm, or a free

point 24 mm depending on the position of the spider on the faade (see

suggested mounting instructions at the end of the chapter).

Suggested mounting instruction:

The drilling diameter for the pins is 6 mm. Do not drill the holes for the pins in your structure before mounting the spiders. To fix the spider on your structure the

Omega (see accessories) is highly recommended to adjust the spiders position. The fixing of the spider is done with a M16 or a M12 bolt (out of Sadev supply).

This bolt shall not be fitted into a vertical slotted holes due to the risk of slipping (under the weight), the pins are not designed to hold any permanent loads (cf. specification sheet). The spider has to be positioned on a flat support. The slotted holes 17x24 mm and free holes 24 mm in the spider are not to be used to adjust

the spider! They are needed to absorb the manufacturing tolerances and the thermal deformation of the glass and of the structure.The spiders are standardized for

M14 fittings (FXR, FXV); other diameters are available on request.

SADEV recommends using thread locking compound, except in case of specific mounting constraints.

Tel. +33 (0)4 50 08 39 00 - Fax +33 (0)4 50 08 39 49

3.08

www.sadev.com - info@sadev.com

SPIDERS

daN

(lb)

chap_03-ATTACHES-cat-classic-gb:Mise en page 1

25/11/09

21:21

Page 8

SPIDERS

Reference: S3006 VERTECH

Designation : casted stainless steel spider.

SPIDERS

GIS

RE

RE

TE D

Glass side view

Material: AISI 316 Surface finish: dull polished GR400

Dimensions:

Glass side view

Tel. +33 (0)4 50 08 39 00 - Fax +33 (0)4 50 08 39 49

::

3.09

www.sadev.com - info@sadev.com

chap_03-ATTACHES-cat-classic-gb:Mise en page 1

25/11/09

21:21

Page 9

SPIDERS

::

Reference: S3006 VERTECH

Mechanical performances:

Load parallel to glass

(per arm)

ULS

SLS* at 1 mm

No tests

available

SLS

0,1 mm

Load perpendicular

to glass (per arm)

ULS*

No tests

available

SLS* at 1 mm

No tests

available

ULS*

No tests

available

*SLS: Serviceability Limit State (load causing a deformation of 1 mm)

ULS: Ultimate Limit State: Elastic limit Rp0.1 (maximal load causing a permanent

deformation of the spider of 0,1 mm).

1 mm

Configuration:

Glass side view

2 arms 90

Weight: 1,20 kg

3 arms

Weight: 1,62 kg

2 arms 180

Weight: 0,94 kg

1 arm 180

Weight: 0,62 kg

1 arm 90

Weight: 0,78 kg

4 arms

Weight: 2,14 kg

Represents a fixed point 17 mm, a slotted point 17x24 mm, or a free

point 24 mm depending on the position of the spider on the faade (see

suggested mounting instructions at the end of the chapter).

Suggested mounting instruction:

The drilling diameter for the pins is 6 mm. Do not drill the holes for the pins in your structure before mounting the spiders. To fix the spider on your structure the

Omega (see accessories) is highly recommended to adjust the spiders position. The fixing of the spider is done with a M16 or a M12 bolt (out of Sadev supply).

This bolt shall not be fitted into a vertical slotted holes due to the risk of slipping (under the weight), the pins are not designed to hold any permanent loads (cf. specification sheet). The spider has to be positioned on a flat support. The slotted holes 17x24 mm and free holes 24 mm in the spider are not to be used to adjust

the spider! They are needed to absorb the manufacturing tolerances and the thermal deformation of the glass and of the structure.The spiders are standardized for

M14 fittings (FXR, FXV); other diameters are available on request.

SADEV recommends using thread locking compound, except in case of specific mounting constraints.

Tel. +33 (0)4 50 08 39 00 - Fax +33 (0)4 50 08 39 49

3.10

www.sadev.com - info@sadev.com

SPIDERS

daN

(lb)

chap_03-ATTACHES-cat-classic-gb:Mise en page 1

25/11/09

21:21

Page 10

SPIDERS

Designation : casted aluminium spider.

SE

TECH

NICAL

Technical assessment

available online at

www.sadev.com

AS

SPIDERS

Reference: S3007

SME

Glass side view

Material: AI Si 5 Mg Surface finish: Sanded

Dimensions:

Glass side view

Tel. +33 (0)4 50 08 39 00 - Fax +33 (0)4 50 08 39 49

::

3.11

www.sadev.com - info@sadev.com

chap_03-ATTACHES-cat-classic-gb:Mise en page 1

25/11/09

21:21

Page 11

SPIDERS

::

Reference: S3007

Mechanical performances:

Load parallel to glass

(per arm)

ULS

SLS* at 1 mm

235 daN

(528 lb)

SLS

0,1 mm

Load perpendicular

to glass (per arm)

ULS*

199 daN

(447 lb)

SLS* at 1 mm

182 daN

(409 lb)

ULS*

198 daN

(445 lb)

*SLS: Serviceability Limit State (load causing a deformation of 1 mm)

ULS: Ultimate Limit State: Elastic limit Rp0.1 (maximal load causing a permanent

deformation of the spider of 0,1 mm).

1 mm

Configuration:

Glass side view

2 arms 90

Weight: 0,68 kg

3 arms

Weight: 0,8 kg

2 arms 180

Weight: 0,58 kg

1 arm 180

Weight: 0,38 kg

1 arm 90

Weight: 0,48 kg

4 arms

Weight: 1,1 kg

Represents a fixed point 17 mm, a slotted point 17x24 mm, or a free

point 24 mm depending on the position of the spider on the faade (see

suggested mounting instructions at the end of the chapter).

Suggested mounting instruction:

The drilling diameter for the pins is 6 mm. Do not drill the holes for the pins in your structure before mounting the spiders. To fix the spider on your structure the

Omega (see accessories) is highly recommended to adjust the spiders position. The fixing of the spider is done with a M16 or a M12 bolt (out of Sadev supply).

This bolt shall not be fitted into a vertical slotted holes due to the risk of slipping (under the weight), the pins are not designed to hold any permanent loads (cf. specification sheet). The spider has to be positioned on a flat support. The slotted holes 17x24 mm and free holes 24 mm in the spider are not to be used to adjust

the spider! They are needed to absorb the manufacturing tolerances and the thermal deformation of the glass and of the structure.The spiders are standardized for

M14 fittings (FXR, FXV); other diameters are available on request.

SADEV recommends using thread locking compound, except in case of specific mounting constraints.

Tel. +33 (0)4 50 08 39 00 - Fax +33 (0)4 50 08 39 49

3.12

www.sadev.com - info@sadev.com

SPIDERS

daN

(lb)

chap_03-ATTACHES-cat-classic-gb:Mise en page 1

25/11/09

21:21

Page 12

SPIDERS

Reference: S3003

Designation : laser cut spider.

SPIDERS

AS

TECH

NICAL

SE

::

SME

Technical assessment

available online at

www.sadev.com

Glass side view

Material: AISI 316L Surface finish: dull polished GR220

Material: E36 / Epoxy painting, polished zinc undercoat

Thickness: E= 8 mm, 10 mm, 12 mm, 14 mm, 16 mm.

Dimensions:

Glass side view

Tel. +33 (0)4 50 08 39 00 - Fax +33 (0)4 50 08 39 49

3.13

www.sadev.com - info@sadev.com

chap_03-ATTACHES-cat-classic-gb:Mise en page 1

25/11/09

21:21

Page 13

SPIDERS

::

Reference: S3003

Mechanical performances:

Load parallel to glass

(per arm Ep. 10 mm)

ULS

SLS* at 1 mm

1077 daN

(2421 lb)

SLS

0,1 mm

ULS*

820 daN

(1843 lb)

Load perpendicular

to glass (per arm Ep. 10 mm)

SLS* at 1 mm

85 daN

(191 lb)

ULS*

136 daN

(305 lb)

*SLS: Serviceability Limit State (load causing a deformation of 1 mm)

ULS: Ultimate Limit State: Elastic limit Rp0.1 (maximal load causing a permanent

deformation of the spider of 0,1 mm).

1 mm

Configuration:

Glass side view

2 arms 90

Ep. 10 mm = Weight: 1,4 kg

3 arms

Ep. 10 mm =

Weight: 1,86 kg

2 arms 180

Ep. 10 mm = Weight: 1,04 kg

1 arm 180

Ep. 10 mm = Weight: 0,76 kg

1 arm 90

Ep. 10 mm = Weight: 0,90 kg

4 arms

Ep. 10 mm =

Weight: 2,32 kg

Represents a fixed point 17 mm, a slotted point 17x24 mm, or a free

point 24 mm depending on the position of the spider on the faade (see

suggested mounting instructions at the end of the chapter).

Suggested mounting instruction:

The drilling diameter for the pins is 6 mm. Do not drill the holes for the pins in your structure before mounting the spiders. To fix the spider on your structure the

Omega (see accessories) is highly recommended to adjust the spiders position. The fixing of the spider is done with a M16 or a M12 bolt (out of Sadev supply).

This bolt shall not be fitted into a vertical slotted holes due to the risk of slipping (under the weight), the pins are not designed to hold any permanent loads (cf. specification sheet). The spider has to be positioned on a flat support. The slotted holes 17x24 mm and free holes 24 mm in the spider are not to be used to adjust

the spider! They are needed to absorb the manufacturing tolerances and the thermal deformation of the glass and of the structure.The spiders are standardized for

M14 fittings (FXR, FXV); other diameters are available on request.

SADEV recommends using thread locking compound, except in case of specific mounting constraints.

Tel. +33 (0)4 50 08 39 00 - Fax +33 (0)4 50 08 39 49

3.14

www.sadev.com - info@sadev.com

SPIDERS

daN

(lb)

chap_03-ATTACHES-cat-classic-gb:Mise en page 1

25/11/09

21:22

Page 14

SPIDERS

Reference: S3100 MONTI

Designation : casted stainless steel spider, with plate.

AS

TECH

NICAL

SE

SME

RE

TE D

GIS

RE

Technical assessment

available online at

www.sadev.com

SPIDERS

Glass side view

Material: AISI 316 Surface finish: dull polished GR400

Dimensions:

Glass side view

Tel. +33 (0)4 50 08 39 00 - Fax +33 (0)4 50 08 39 49

::

3.15

www.sadev.com - info@sadev.com

chap_03-ATTACHES-cat-classic-gb:Mise en page 1

25/11/09

21:22

Page 15

SPIDERS

::

Reference: S3100 MONTI

Mechanical performances:

Load parallel to glass

(per arm)

ULS

SLS* at 1 mm

542 daN

(1218 lb)

SLS

0,1 mm

Load perpendicular

to glass (per arm)

ULS*

410 daN

(921 lb)

SLS* at 1 mm

195 daN

(438 lb)

ULS*

184 daN

(413 lb)

*SLS: Serviceability Limit State (load causing a deformation of 1 mm)

ULS: Ultimate Limit State: Elastic limit Rp0.1 (maximal load causing a permanent

deformation of the spider of 0,1 mm).

1 mm

Configuration:

Glass side view

1 arm 180

Weight: 1,06 kg

2 arms

Weight: 2,18 kg

1 arm 90

left

Weight: 1,59 kg

1 arm 90

right

Weight: 1,59 kg

Represents a fixed point 17 mm, a slotted point 17x24 mm, or a free

point 24 mm depending on the position of the spider on the faade (see

suggested mounting instructions at the end of the chapter).

Suggested mounting instruction:

The fixing of the spider is done with a M16 or a M12 bolt (out of Sadev supply). The slotted holes 17 x 24 mm and free holes 24 mm in the spider are not to be

used to adjust the spider! They are needed to absorb the manufacturing tolerances and the thermal deformation of the glass and of the structure.

The spiders are standardized for M14 fittings (FXR, FXV). Other diameters are available on request.

SADEV recommends using thread locking compound, except in case of specific mounting constraints.

Tel. +33 (0)4 50 08 39 00 - Fax +33 (0)4 50 08 39 49

3.16

www.sadev.com - info@sadev.com

SPIDERS

daN

(lb)

chap_03-ATTACHES-cat-classic-gb:Mise en page 1

25/11/09

21:22

Page 16

SPIDERS

Reference: S3101

Designation : casted stainless steel spider, with plate.

AS

TECH

NICAL

SE

SME

SPIDERS

Glass side view

Technical assessment

available online at

www.sadev.com

Material: AISI 316 Surface finish: electro polished

Dimensions:

Glass side view

Tel. +33 (0)4 50 08 39 00 - Fax +33 (0)4 50 08 39 49

::

3.17

www.sadev.com - info@sadev.com

chap_03-ATTACHES-cat-classic-gb:Mise en page 1

25/11/09

21:22

Page 17

SPIDERS

::

Reference: S3101

Mechanical performances:

Load parallel to glass

(per arm)

ULS

SLS* at 1 mm

457 daN

(1027 lb)

SLS

0,1 mm

ULS*

497 daN

(1117 lb)

Load perpendicular

to glass (per arm)

SLS* at 1 mm

128 daN

(287 lb)

ULS*

128 daN

(287 lb)

*SLS: Serviceability Limit State (load causing a deformation of 1 mm)

ULS: Ultimate Limit State: Elastic limit Rp0.1 (maximal load causing a permanent

deformation of the spider of 0,1 mm).

1 mm

Configuration:

Glass side view

1 arm 180

Weight: 0,79 kg

2 arms

Weight: 1,46 kg

1 arm 90

left

Weight: 1,1 kg

1 arm 90

right

Weight: 1,1 kg

Represents a fixed point 17 mm, a slotted point 17x24 mm, or a free

point 24 mm depending on the position of the spider on the faade (see

suggested mounting instructions at the end of the chapter).

Suggested mounting instruction:

The fixing of the spider is done with a M16 or a M12 bolt (out of Sadev supply). The slotted holes 17 x 24 mm and free holes 24 mm in the spider are not to be

used to adjust the spider! They are needed to absorb the manufacturing tolerances and the thermal deformation of the glass and of the structure.

The spiders are standardized for M14 fittings (FXR, FXV). Other diameters are available on request.

SADEV recommends using thread locking compound, except in case of specific mounting constraints.

Tel. +33 (0)4 50 08 39 00 - Fax +33 (0)4 50 08 39 49

3.18

www.sadev.com - info@sadev.com

SPIDERS

daN

(lb)

chap_03-ATTACHES-cat-classic-gb:Mise en page 1

25/11/09

21:22

Page 18

SPIDERS

Reference: BENDED OMEGA

::

Designation: bended omega for vertical mounting:

Vertical use COMPULSORY

Reference for spiders S3000, S3001, S3003, S3007:

OMGA-IN12V

OMGA-IN12V-R

AISI 316L Stainless steel model dull polished

Painted AISI 316L Stainless steel model with

your needed RAL-colour

Designation : fastenings kit for bended:

Kit for S3000 spiders.

Kit for S3001, S3003 and S3007 spiders.

KIT-OM-VIS-S3000

KIT-OM-VIS-S300137

1

2

3

4

5

1

2

4

5

M12 bolt

Washer for M12

Insert (S3000 only)

Spring washer

M12 nut

M12 bolt

Washer for M12

Spring washer

M12 nut

Reference: CASTED STAINLESS

Designation: casted omega kit for S3006 spider for

vertical mounting:

STEEL OMEGA

RE

TE D

GIS

RE

SPIDERS

Adjustment (1)

of +/- 5 mm horizontally

and vertically

Registered

Vertical use COMPULSORY

Reference

S3000-OMEGA-R

AISI 316 Stainless steel model for S3006

Vertech spider. Finish dull polished GR400

Tel. +33 (0)4 50 08 39 00 - Fax +33 (0)4 50 08 39 49

3.19

1

2

3

4

5

6

Omega

M12 H bolt

Anti-rotation plate

Washer for M12

Spring washer

- M12 nut

www.sadev.com - info@sadev.com

chap_03-ATTACHES-cat-classic-gb:Mise en page 1

25/11/09

21:22

Page 19

SPIDERS

::

Stainless steel spacer:

The spacer is compulsory in order to allow the free displacement of the fitting towards the spider.

One spacer per spiders arm (or per fitting) are needed.

Diameter of the fitting

Reference

spacer for S3000, S3001, S3006,

S3100, S3101, S3003 thickness 12

M12

spacer for S3003 thickness 8

M12

ENT-12-16,5-8,5

spacer for S3003 thickness 10

M12

ENT-12-16,5-10,5

spacer for S3003 thickness 15

M12

ENT-12-16,5-15,5

ENT-12-16,5-12,5

spacer for S3007

M12

ENT-12-16,5-21,5

spacer for S3000, S3001, S3006,

S3100, S3101, S3003 thickness 12

M14

ENT-14-16,5-14,5

spacer for S3003 thickness 8

M14

ENT-14-16,5-8,5

spacer for S3003 thickness 10

M14

ENT-14-16,5-10,5

spacer for S3003 thickness 15

M14

ENT-14-16,5-15,5

spacer for S3007

M14

ENT-14-16,5-21,5

spacer for S3000, S3001, S3006,

S3100, S3101, S3003 thickness 12

M16

ENT-16-18,5-18,5

spacer for S3003 thickness 8

M16

ENT-16-18,5-8,5

spacer for S3003 thickness 10

M16

ENT-16-18,5-10,5

spacer for S3003 thickness 15

M16

ENT-16-18,5-15,5

spacer for S3007

M16

ENT-16-18,5-21,5

Stainless steel elastic pin:

The pin is compulsory in order to lock the spider in rotation towards the structure.

Two pins per spider are needed +5 %.

Designation:

Reference:

Pin for S3000, S3001, S3006, S3003

Pin for S3007

D1481A2-6-36

D1481A2-6-60

Special drill for stainless steel:

Special drill for stainless steel. Diameter 6 mm.

Rfrence :

09 90 01 60

Tel. +33 (0)4 50 08 39 00 - Fax +33 (0)4 50 08 39 49

3.20

www.sadev.com - info@sadev.com

SPIDERS

Designation

chap_03-ATTACHES-cat-classic-gb:Mise en page 1

25/11/09

21:22

Page 20

SPIDERS

Suggested mounting instruction:

SPIDERS

Montage - A

Montage - B

14

14

14

16

17

16

17

16

17

16

17

16

10

17

16

10

17

16

17

16

17

16

17

16

17

11

12

11

13

13

11

12

11

13

13

Montage - C

Montage - D

19

20

19

20

19

20

19

20

21

22

21

22

21

22

21

22

21

21

21

21

23

22

22

22

22

23

21

21

21

21

23

22

23

23

22

22

22

23

21

21

19

20

23

23

21

21

23

Tel. +33 (0)4 50 08 39 00 - Fax +33 (0)4 50 08 39 49

19

24

24

24

25

23

26

26

26

23

19

24

24

24

25

23

26

26

26

23

19

24

25

19

25

23

26

23

23

23

19

24

24

24

25

23

26

26

26

23

19

24

25

19

25

23

26

23

23

23

19

24

25

19

25

23

26

23

23

23

22

22

22

22

23

3.21

www.sadev.com - info@sadev.com

::

chap_03-ATTACHES-cat-classic-gb:Mise en page 1

25/11/09

21:22

Page 21

SPIDERS

::

Suggested mounting instructions for plate spiders:

daN

Montage

-E

1

ELS

Montage - F

1

3

1

3B

ELU

11

6

0,1 mm

13

11

11 1 mm

11

13

13

13

11

1sym

3sym

16

17

16

11

13

17

16

17

16

11

13

17

16

17

13

13

11

13

11

11

13

12

12

Montage - G

Montage - H

19

25

19

25

19

25

19

25

23

23

23

23

23

23

23

23

19

25

19

25

19

25

19

25

23

23

23

23

23

23

23

23

19

25

19

25

19

25

23

23

23

23

23

23

19

25

19

25

19

25

19

25

23

23

23

23

23

23

23

23

19

25

19

25

19

25

23

23

23

23

23

23

19

25

19

25

19

25

23

23

23

23

23

23

Tel. +33 (0)4 50 08 39 00 - Fax +33 (0)4 50 08 39 49

3.22

19

20

19

20

19

20

19

20

23

23

23

23

23

23

23

23

19

20

19

20

19

20

19

20

23

23

23

23

23

23

23

23

19

20

19

20

19

20

23

23

23

23

23

23

19

20

19

20

19

20

19

20

23

23

23

23

23

23

23

23

19

20

19

20

19

20

23

23

23

23

23

23

19

20

19

20

19

20

23

23

23

23

23

23

www.sadev.com - info@sadev.com

SPIDERS

chap_03-ATTACHES-cat-classic-gb:Mise en page 1

25/11/09

21:23

Page 22

SPIDERS

::

4 steps to order your spiders:

01-THE STUDY

02-THE IDENTIFICATION

03-THE ORDER

3

S3000

04-THE DELIVERY

x3

POSITION 3

S3000-3

SPIDERS

01-THE STUDY

Considering the mechanical performances and the esthetical design youve chosen for example - the S3000 spider. With the

help of the spiders drawings available on SADEVs web site www.sadev.com, you design your faade. At this stage you place

the different spiders (4 arms, 2 arms etc.) using the symbol O. You can already get inspired by the mounting instructions available at the end of this chapter.

S3000

02-THE IDENTIFICATION

Once the faade is designed, you have to identify the position of the spider so that SADEV can deliver the right spider with the correct configuration of the holes 17 mm, 17 x 24 mm and 24 mm. Therefore, get the mounting proposition(s) corresponding to

your faade and mark the position numbers on your drawing.

POSITION 3

1

14

14

14

16

17

16

17

16

10

17

16

17

16

17

11

12

11

13

13

Tel. +33 (0)4 50 08 39 00 - Fax +33 (0)4 50 08 39 49

3.23

www.sadev.com - info@sadev.com

chap_03-ATTACHES-cat-classic-gb:Mise en page 1

25/11/09

21:23

Page 23

SPIDERS

::

03-THE ORDER

Mounting suggestions:

S3000-3

A,

B,

Fittings diameter (FXR, FXV) :

C,

M12,

D,

M14,

E,

F,

M16,

G,

H.

autre :

REFERENCE

POSITION

5

17

16

14

1

3

-

S3000

S3000

S3000

S3000

S3000

S3000

Omga-in 12 v

D1481 a2-6-36

ENT-14-16,5-14,5

QTY

27

9

9

9

3

3

60

120

168

PRICE

SPIDERS

x3

All your spiders are now identified; sample the different spider quantities by position in the order form (end of the chapter).

04-THE DELIVERY

The spiders will be delivered packed in cardboard boxes and referenced by position. Do not forget to furnish

the montage team with the mounting drawings of your facade on which the mounting positions are indicated.

x3

x9

x27

x3

x9

S3000-1

S3000-17

x9

S3000-3

S3000-14

S3000-5

Tel. +33 (0)4 50 08 39 00 - Fax +33 (0)4 50 08 39 49

S3000-16

3.24

www.sadev.com - info@sadev.com

chap_03-ATTACHES-cat-classic-gb:Mise en page 1

25/11/09

21:23

Page 24

SPIDERS

::

Price request

Order

Order form for spider

Customer name:

Project name

Interlocutor:

Date:

Your phone number:

DISCOUNT

Your fax:

SPIDERS

Mounting suggestions: A, B, C, D, E, F,

Fittings diameter (FXR, FXV): M12, M14, M16,

REFERENCE

G, H.

Others :

POSITION

QTY

PRICE

TOTAL

Tel. +33 (0)4 50 08 39 00 - Fax +33 (0)4 50 08 39 49

3.25

www.sadev.com - info@sadev.com

También podría gustarte

- Sadev Classic en BdaDocumento146 páginasSadev Classic en BdaAnonymous kAxPF8vAún no hay calificaciones

- Sadev Classic FXR enDocumento38 páginasSadev Classic FXR enPeter DudasAún no hay calificaciones

- Sadev Classic FXV enDocumento15 páginasSadev Classic FXV enPeter DudasAún no hay calificaciones

- Herramientas de Corte SandvikDocumento11 páginasHerramientas de Corte SandvikCarlos Alfredo LauraAún no hay calificaciones

- Propeller Shaft Earthing Systems Handbook Installation GuideDocumento12 páginasPropeller Shaft Earthing Systems Handbook Installation GuideAndrewAún no hay calificaciones

- Pulleys TechDocumento8 páginasPulleys TechashkansoheylAún no hay calificaciones

- NL User Manual NLSC v04 en DigitalDocumento4 páginasNL User Manual NLSC v04 en DigitalEugenhoAún no hay calificaciones

- Mechanical seal detailsDocumento2 páginasMechanical seal detailsSalsa AmorirAún no hay calificaciones

- Sony Klv-32s400a Chassis Eg1l-GaDocumento81 páginasSony Klv-32s400a Chassis Eg1l-GaMohamed Salah80% (5)

- RFS 1.8mDocumento13 páginasRFS 1.8mMarius Tresor EdiboussieAún no hay calificaciones

- Structural Support Design Guidelines 8-25-16 PDFDocumento17 páginasStructural Support Design Guidelines 8-25-16 PDFsbalu12674Aún no hay calificaciones

- SAIC-D-2009 Rev 2Documento6 páginasSAIC-D-2009 Rev 2ரமேஷ் பாலக்காடுAún no hay calificaciones

- Guidelines For Hall IC SubassemblyDocumento9 páginasGuidelines For Hall IC SubassemblyvkmsAún no hay calificaciones

- Bouwfolder Sadef 2012 Eng-Spread LR PDFDocumento55 páginasBouwfolder Sadef 2012 Eng-Spread LR PDFMarcos AmorimAún no hay calificaciones

- Rigid Flexible Waveguide ComponentsDocumento10 páginasRigid Flexible Waveguide Componentsapi-30606527Aún no hay calificaciones

- Field Welding InstructionsDocumento6 páginasField Welding InstructionsErickAún no hay calificaciones

- Hydraulic Cylinder Parker 3lDocumento48 páginasHydraulic Cylinder Parker 3lDian Pramadi100% (2)

- Absco Space Saver Shed MODEL: 30152SECOK: 3.00mW X 1.52mD X 1.80mH, 2.08mHDocumento22 páginasAbsco Space Saver Shed MODEL: 30152SECOK: 3.00mW X 1.52mD X 1.80mH, 2.08mHDown LordAún no hay calificaciones

- Rotary Backshell Guide for MIL ConnectorsDocumento13 páginasRotary Backshell Guide for MIL Connectorsatul vermaAún no hay calificaciones

- Reduced Hex Flange Nuts Product GuideDocumento61 páginasReduced Hex Flange Nuts Product GuidePacoAún no hay calificaciones

- Sheet Pile Capping Manual-DawsonDocumento54 páginasSheet Pile Capping Manual-DawsonSankar CdmAún no hay calificaciones

- Gets InglesDocumento1088 páginasGets InglesKjatunMayu Gutierrez100% (6)

- Selden Yacht Catalogue MarineriggingDocumento101 páginasSelden Yacht Catalogue MarinerigginglmarinegroupAún no hay calificaciones

- Assembly TECHLOK 3 Fold English v3 2013Documento2 páginasAssembly TECHLOK 3 Fold English v3 2013Chup AlaAún no hay calificaciones

- PEM Self Clinching Self Locking FastenersDocumento4 páginasPEM Self Clinching Self Locking FastenersAce Industrial SuppliesAún no hay calificaciones

- NOV Elmar ICT WL Tools Poster A4Documento95 páginasNOV Elmar ICT WL Tools Poster A4AjayAún no hay calificaciones

- Instruction Manual Cardan ShaftsDocumento4 páginasInstruction Manual Cardan ShaftsMarinkons SrbicicAún no hay calificaciones

- ValvesDocumento10 páginasValvesInigoAún no hay calificaciones

- Sheet pile capping systems guideDocumento54 páginasSheet pile capping systems guideGabriel AmorimAún no hay calificaciones

- F Sockets SurfaceDocumento19 páginasF Sockets SurfacebansalrAún no hay calificaciones

- AV Industrial Products LTD Catalogue Anti Vibration MountsDocumento52 páginasAV Industrial Products LTD Catalogue Anti Vibration MountsAV Industrial Products LtdAún no hay calificaciones

- Nord Lock Steel Construction Washers User ManualDocumento4 páginasNord Lock Steel Construction Washers User ManualThoncatAún no hay calificaciones

- KVC 01Documento35 páginasKVC 01hamidreza_m85Aún no hay calificaciones

- PSK GET 9th v2Documento827 páginasPSK GET 9th v2Luis PozoAún no hay calificaciones

- Catálogo Accesorios para Cables NosermanDocumento5 páginasCatálogo Accesorios para Cables NosermanSebastian AndreoliAún no hay calificaciones

- Weldlok GratingDocumento16 páginasWeldlok Gratingnovadistributors100% (3)

- Multiplex Minimag Model RC Airplane Manual M13209Documento18 páginasMultiplex Minimag Model RC Airplane Manual M13209Anett ÁrvaiAún no hay calificaciones

- Emv PDFDocumento1 páginaEmv PDFexteh-uaAún no hay calificaciones

- Gas Pressure Regulator RMG 512: Operation and Maintenance, Spare PartsDocumento20 páginasGas Pressure Regulator RMG 512: Operation and Maintenance, Spare PartsPop IonutAún no hay calificaciones

- BIW - Points Discussed With The CustomerDocumento9 páginasBIW - Points Discussed With The CustomerJyoti Kale100% (1)

- InertiaDynamics CBCouplings310 SpecsheetDocumento2 páginasInertiaDynamics CBCouplings310 SpecsheetElectromateAún no hay calificaciones

- Needle Cages and Roller Cages: ConstructionDocumento12 páginasNeedle Cages and Roller Cages: ConstructionMohan Kumar MathrubaiAún no hay calificaciones

- Techdoc - Print - Page 3Documento4 páginasTechdoc - Print - Page 3franAún no hay calificaciones

- Installation Manual For Level Control Diaphragm: AddressDocumento11 páginasInstallation Manual For Level Control Diaphragm: AddresspredilettoAún no hay calificaciones

- Fluiteco CatalogoDocumento84 páginasFluiteco CatalogoPablo FaldutiAún no hay calificaciones

- TD-esc-02-De-En-16-014 Rev001 Unloading Segments (DOS) Delivery On SiteDocumento6 páginasTD-esc-02-De-En-16-014 Rev001 Unloading Segments (DOS) Delivery On SiteFelipe SilvaAún no hay calificaciones

- InertiaDynamics FlangeMtBk310p SpecsheetDocumento2 páginasInertiaDynamics FlangeMtBk310p SpecsheetElectromateAún no hay calificaciones

- (2012) Complete IELTS Bands 5-6.5 Student's BookDocumento3 páginas(2012) Complete IELTS Bands 5-6.5 Student's BookAhmed Hamdy0% (1)

- Presentation On Reinforcing Detailing of RCC MembersDocumento20 páginasPresentation On Reinforcing Detailing of RCC MembersprakashAún no hay calificaciones

- QueryDocumento2 páginasQueryTu PhamAún no hay calificaciones

- Manual Yamaha YST-SW012 (Service)Documento16 páginasManual Yamaha YST-SW012 (Service)Alex NikitinAún no hay calificaciones

- Jackscrew Backshell Installation Instructions: 190-00313-11 October, 2017 Revision EDocumento24 páginasJackscrew Backshell Installation Instructions: 190-00313-11 October, 2017 Revision EAlex AnishchykAún no hay calificaciones

- Weld Like a Pro: Beginning to Advanced TechniquesDe EverandWeld Like a Pro: Beginning to Advanced TechniquesCalificación: 4.5 de 5 estrellas4.5/5 (6)

- The Marmo Method Modelbuilding Guide #6: Building The Williams Bros. 1/72 scale Curtiss C-46A CommandoDe EverandThe Marmo Method Modelbuilding Guide #6: Building The Williams Bros. 1/72 scale Curtiss C-46A CommandoAún no hay calificaciones

- Screwcutting in the Lathe for Home Machinists: Reference Handbook for Both Imperial and Metric ProjectsDe EverandScrewcutting in the Lathe for Home Machinists: Reference Handbook for Both Imperial and Metric ProjectsAún no hay calificaciones

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesDe EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesCalificación: 5 de 5 estrellas5/5 (1)

- (Arh) - Architectural Design - Residences For The ElderlyDocumento235 páginas(Arh) - Architectural Design - Residences For The ElderlySebastian StanAún no hay calificaciones

- (Architectural Record Magazine) Architectural RecoDocumento165 páginas(Architectural Record Magazine) Architectural RecoIulia Ghibu100% (1)

- Nordic Faith: C, K, N H SDocumento2 páginasNordic Faith: C, K, N H SVuTienAnAún no hay calificaciones

- Ancoraj Zidarie Aparenta Jordahl 40843 Jordahl Jva WebDocumento48 páginasAncoraj Zidarie Aparenta Jordahl 40843 Jordahl Jva WebIulia PetrescuAún no hay calificaciones

- 10.1 - FMax Ext - Instructiuni Si Detalii de Montaj - EngDocumento84 páginas10.1 - FMax Ext - Instructiuni Si Detalii de Montaj - EngTirziu SergiuAún no hay calificaciones

- 2000 - The European Landscape ConventionDocumento8 páginas2000 - The European Landscape ConventionIulia PetrescuAún no hay calificaciones

- LEIPZIG CHARTER on Sustainable European CitiesDocumento7 páginasLEIPZIG CHARTER on Sustainable European CitiesTeodor ManeaAún no hay calificaciones

- Cembrit Cembonit InstalInstructions EXP 01 2013-3Documento39 páginasCembrit Cembonit InstalInstructions EXP 01 2013-3Iulia PetrescuAún no hay calificaciones

- 7585.PLAXISCEV21.00 Norsand User-ManualDocumento30 páginas7585.PLAXISCEV21.00 Norsand User-ManualBOOBOOAún no hay calificaciones

- Metall-Ceramic Framework Design Manual PDFDocumento52 páginasMetall-Ceramic Framework Design Manual PDFcasian meteaAún no hay calificaciones

- Applied Elasticity and plasticity syllabus covering stress analysis, strain analysis, equilibrium equations, energy methods, failure theories, and plastic behaviorDocumento2 páginasApplied Elasticity and plasticity syllabus covering stress analysis, strain analysis, equilibrium equations, energy methods, failure theories, and plastic behaviorManu Sharma Viswanadha50% (2)

- Seismic ExplorationDocumento20 páginasSeismic Explorationmunther alawsiAún no hay calificaciones

- Study of "P-Delta" Analysis For R.C. StructureDocumento4 páginasStudy of "P-Delta" Analysis For R.C. StructureGRD JournalsAún no hay calificaciones

- Effect of Halide Addition On Thermal and Elastic Properties of Binary Li2O-P2O5 GlassesDocumento4 páginasEffect of Halide Addition On Thermal and Elastic Properties of Binary Li2O-P2O5 Glassesb meryemAún no hay calificaciones

- Bayer Snap Fit Joints For PlasticsDocumento26 páginasBayer Snap Fit Joints For PlasticsEllen NicDiarmadaAún no hay calificaciones

- Tension Flange Effective Width in Reinforced Concrete Shear Walls PDFDocumento8 páginasTension Flange Effective Width in Reinforced Concrete Shear Walls PDFgrahambrasicAún no hay calificaciones

- ABS Rules for Buckling and Ultimate Strength AssessmentDocumento30 páginasABS Rules for Buckling and Ultimate Strength Assessmentding liuAún no hay calificaciones

- Chapter 1Documento12 páginasChapter 1Tavares PrestonAún no hay calificaciones

- Rock MechanicsDocumento55 páginasRock MechanicsSirajuddin KhanAún no hay calificaciones

- Creep ExperimentalDocumento8 páginasCreep ExperimentalPanji Haryono AzisAún no hay calificaciones

- Alkali-activated Concrete PropertiesDocumento8 páginasAlkali-activated Concrete PropertiesJônatas SouzaAún no hay calificaciones

- Beams On Elastic Foundation - HetenyiDocumento134 páginasBeams On Elastic Foundation - HetenyiBalaji GanesanAún no hay calificaciones

- New Developments in Dynamic Soft Reduction in Continuous Casting of Blooms For Rail and Stainless SteelsDocumento12 páginasNew Developments in Dynamic Soft Reduction in Continuous Casting of Blooms For Rail and Stainless SteelsLuca CestariAún no hay calificaciones

- Syllabus Diploma ElectricalDocumento136 páginasSyllabus Diploma Electricalrjpatil19Aún no hay calificaciones

- Bab 1-Force On MaterialDocumento25 páginasBab 1-Force On MaterialMARIA NATASYAAún no hay calificaciones

- Allowable Pump Piping LoadsDocumento4 páginasAllowable Pump Piping LoadsSeungmin Paek100% (2)

- Melt Ow Index: More Than Just A Quality Control Rheological Parameter. Part IIDocumento22 páginasMelt Ow Index: More Than Just A Quality Control Rheological Parameter. Part IIjulioAún no hay calificaciones

- Gravity DamDocumento19 páginasGravity DamrahulAún no hay calificaciones

- Plastic Analysis of Beams and FramesDocumento2 páginasPlastic Analysis of Beams and FramesFerialAssmaniAún no hay calificaciones

- ME206 Course PolicyDocumento2 páginasME206 Course Policyemremince_gsAún no hay calificaciones

- Chap 8Documento22 páginasChap 8Devansh GoelAún no hay calificaciones

- Water Glass Compound Starch Used As Suface Sizing AgentDocumento11 páginasWater Glass Compound Starch Used As Suface Sizing AgentRoxana FloresAún no hay calificaciones

- PEBD-EVA Blends PDFDocumento9 páginasPEBD-EVA Blends PDFDiana Carolina CalvoAún no hay calificaciones

- Stability Analysis of Pipe Rack in Petrochemical Facilities-IJAERDV04I0264348Documento11 páginasStability Analysis of Pipe Rack in Petrochemical Facilities-IJAERDV04I0264348Editor IJAERDAún no hay calificaciones

- Civil Mini Project DivyaKamathDocumento63 páginasCivil Mini Project DivyaKamathJanaki Vamaraju100% (1)

- Curriculam..Ce NitjDocumento76 páginasCurriculam..Ce NitjRAMAVATH BABUAún no hay calificaciones

- Technical Data Sheet: BackgroundDocumento6 páginasTechnical Data Sheet: BackgroundGabryelly MachadoAún no hay calificaciones