Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Calculating The System Head

Cargado por

Sam Wing Hong0 calificaciones0% encontró este documento útil (0 votos)

166 vistas9 páginasCalculation water system head

Título original

Calculating the System Head

Derechos de autor

© © All Rights Reserved

Formatos disponibles

PDF, TXT o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCalculation water system head

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

0 calificaciones0% encontró este documento útil (0 votos)

166 vistas9 páginasCalculating The System Head

Cargado por

Sam Wing HongCalculation water system head

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

Está en la página 1de 9

1/2/13 Calculating the sy stem head

1/9 www.mcnally institute.com/07-html/7-01.html

SUBJECT : Calculating the total system head in USCS units 7-1:

USCS stands for "United States Customary System Units" as opposed to the SI (Le Syst`eme

International d`Units) or metric units that have been adopted by the International standards

Organization (ISO).

It turn out that "head" is a very convenient term in the pumping business. Capacity is

measured in gallons per minute, and each gallon of liquid has weight, so we can easily

calculate the pounds per minute being pumped. Head or height is measured in feet, so if we

multiply these two together we get foot- pounds per minute which converts directly to work at

the rate of 33,000 foot pounds per minute equals one horsepower.

Pressure is not as convenient a term because the amount of pressure that the pump will

deliver depends upon the weight (specific gravity) of the liquid being pumped and the specific

gravity changes with temperature, type of fluid, and fluid concentration.

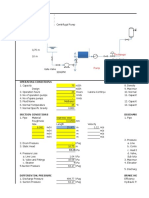

If you will refer to FIG 1, you should get a clear picture of what is meant by static head. Note

that we always measure from the center line of the pump to the highest liquid level

To calculate head accurately we must calculate the total head on both the suction and

discharge sides of the pump. In addition to the static head we will learn that there is a head

caused by resistance in the piping, fittings and valves called friction head, and a head caused

by any pressure that might be acting on the liquid in the tanks including atmospheric pressure,

called " surface pressure head".

Once we know these heads, we will then subtract the suction head from the discharge head

and the amount remaining will be the amount of head that the pump must be able to generate

at the rated flow. Here is how it looks in a formula:

System head = total discharge head - total suction head

1/2/13 Calculating the sy stem head

2/9 www.mcnally institute.com/07-html/7-01.html

H = hd - hs

The total discharge head is made from three separate heads:

hd = hsd + hpd + hfd

hd = total discharge head

hsd = discharge static head

hpd = discharge surface pressure head

hfd = discharge friction head

The total suction head also consists of three separate heads

hs = hss + hps - hfs

hs = total suction head

hss = suction static head

hps = suction surface pressure head

hfs = suction friction head

As we make these calculations, you must sure that all calculations are made in either "feet of

liquid gauge" or "feet of liquid absolute". In case you have forgotten "absolute means that you

have added atmospheric pressure (head) to the gauge reading.

Now we will make some actual calculations:

Figure #2 demonstrates that the discharge head is still measured to the liquid level, but you

will note that it is below the maximum height of the piping.

Although the pump must deliver enough head to get up to this maximum piping height, it will

not have to continue to deliver this head when the pump is running because of the "siphon

effect". There is of course a maximum siphon effect. It is derived from: 14.7 psi (atmospheric

pressure) x 2.31 feet / psi = 33.4 feet maximum siphon effect.

3/9 www.mcnally institute.com/07-html/7-01.html

We will begin with the total suction head calculation

1. The suction head is negative because the liquid level in the suction tank is below the

centerline of the pump:

hss = - 6 feet

2. The suction tank is open, so the suction surface pressure equals atmospheric pressure :

hps = 0 feet gauge

3. You will not have to calculate the suction friction head, I will tell you it is:

hfs = 4 feet at rated flow

4. The total suction head is a gauge value because atmosphere was given as 0,

hs = hss + hps - hfs = -6 + 0 - 4 = -10 feet of liquid gauge at rated flow

The total discharge head calculation

1. The static discharge head is:

hsd = 125 feet

2. The discharge tank is also open to atmospheric pressure, thus:

hpd = 0 feet, gauge

3. I will give you the discharge friction head as:

hfd = 25 feet at rated flow

4. The total discharge head is:

hd = hsd + hpd + hfd = 125 + 0 + 25 = 150 feet of liquid gauge at rated flow

The total system head calculation:

H = hd - hs = 150 - (-10)= 160 feet of liquid at rated flow

Note: did you notice that when we subtracted a minus number (-10) from a positive number

(150) we ended up with a positive 160 because whenever you subtract minus numbers it is

the same as adding them? If you have trouble with this concept you can learn more about it

from a mathematics book.

Our next example involves a few more calculations, but you should be able to handle them. In

this example we are going to learn how to handle a vacuum application. Pipe friction numbers

are taken from the Hydraulic Institute Engineering Data Book. You can get a copy of this

publication from your library if you want to see the actual charts. I have some of this

information in the chart section of this web site.

Specifications:

1. Transferring 1000 gpm. weak acid from the vacuum receiver to the storage tank

2. Specific Gravity - 0.98

3. Viscosity - equal to water

4. Piping - All 6" Schedule 40 steel pipe

1/2/13 Calculating the sy stem head

5/9 www.mcnally institute.com/07-html/7-01.html

5. Discharge piping rises 40 feet vertically above the pump centerline and then runs 400 feet

horizontally. There is one 90 flanged elbow in this line

6. Suction piping has a square edge inlet, four feet of pipe, one gate valve, and one 90

flanged elbow all of which are 6" in diameter.

7. The minimum level in the vacuum receiver is 5 feet above the pump centerline.

8. The pressure on top of the liquid in the vacuum receiver is 20 inches of mercury, vacuum.

To calculate suction surface pressure use one of the following formulas:

inches of mercury x 1.133/ specific gravity = feet of liquid

pounds per square inch x 2.31/specific gravity = feet of liquid

Millimeters of mercury / (22.4 x specific gravity) = feet of liquid

Now that you have all of the necessary information we will begin by dividing the system into

two different sections, using the pump as the dividing line.

Total suction head calculation

1. The suction side of the system shows a minimum static head of 5 feet above suction

centerline. Therefore, the static suction head is:

hss = 5 feet

2. Using the first conversion formula, the suction surface pressure is:

hps = -20 Hg x 1.133/ 0.98 = -23.12 feet gauge

3. The suction friction head, hfs, equals the sum of all the friction losses in the suction line.

Friction loss in 6" pipe at 1000 gpm from table 15 of the Hydraulic Institute Engineering Data

Book, is 6.17 feet per 100 feet of pipe.

in 4 feet of pipe friction loss = 4/100 x 6.17 = 0.3 feet

Friction loss coefficients (K factors) for the inlet, elbow and valve can be added together and

multiplied by the velocity head:

FITTING K FROM TABLE

6" Square edge inlet 0.50 32 (a)

6" 90 flanged elbow 0.29 32 (a)

6" Gate valve 0.11 32 (b)

Total coefficient, K = 0.90

Total friction loss on the suction side is:

hfs = 0.3 + 1.7 = 2.0 feet at 1000 gpm.

4. The total suction head then becomes:

hs = hss + hps - hfs = 5 + (-23.12) - 2.0 = -20.12 feet, gauge at 1000 gpm.

Total discharge head calculation

1. Static discharge head = hsd = 40 feet

2. Discharge surface pressure = hpd = 0 feet gauge

3. Discharge friction head = hfd = sum of the following losses :

Friction loss in 6" pipe at 1000 gpm. from table 15, is 6.17 feet per hundred feet of

pipe.

In 440 feet of pipe the friction loss = 440/100 x 6.17 = 27.2 feet

Friction loss in 6" elbow:

from table 32 (a), K = 0,29

from table 15, V

2

/2g = 1.92 at 1000 gpm.

Friction loss = K V

2

/2g = 0.29 x 1.92 = 0.6 feet

The friction loss in the sudden enlargement at the end of the discharge line is called the exit

loss. In systems of this type where the area of the discharge tank is very large in comparison

to the area of the discharge pipe, the loss equals V

2

/2g, as shown in table 32 (b).

Friction loss at exit = V

2

/2g = 1.9 feet

The discharge friction head is the sum of the above losses, that is:

hfd = 27.2 + 0.6 + 1.9 = 29.7 feet at 1000 gpm.

4. The total discharge head then becomes:

hd = hsd + hpd + hfd = 40 + 0 + 29.7 = 69.7 feet, gauge at 1000 gpm.

c. Total system head calculation:

H = hd - hs = 69.7 - (-20.2) = 89.9 feet at 1000 gpm.

Our next example will be the same as the one we just finished except. that there is an

1/2/13 Calculating the sy stem head

7/9 www.mcnally institute.com/07-html/7-01.html

additional 10 feet of pipe and another 90 flanged elbow in the vertical leg. The total suction

head will be the same as in the previous example. Take a look at figure # 4

Nothing has changed on the suction side of the pump so the total suction head will remain the

same:

hs = -20.12 feet, gauge at 100 gpm.

Total discharge head calculation

1. The static discharge head "hsd" will change from 40 feet to 30 feet, since the highest liquid

surface in the discharge is now only 30 feet above the pump centerline.(This value is based

on the assumption that the vertical leg in the discharge tank is full of liquid and that as this

liquid falls it will tend to pull the liquid up and over the loop in the pipe line. This arrangement

is called a siphon leg).

2. The discharge surface pressure is unchanged:

hpd = 0 feet

3. The friction loss in the discharge pipe will be increased by the additional 10 feet of pipe and

the additional elbow.

In 10 feet of pipe the friction loss = 10/100 x 6.17 = 0.6 feet

The friction loss in the additional elbow = 0.6 feet

The friction head will then increase as follows:

hfd = 29.7 + 0.6 + 0.6 = 30.9 feet at 1000 gpm.

1/2/13 Calculating the sy stem head

8/9 www.mcnally institute.com/07-html/7-01.html

The total discharge head becomes:

hd = hsd + hpd + hfd

= 30 + 0 + 30.9

= 60.9 feet, gauge at 1000 gpm.

5. Total system head calculation

H = hd - hs = 60.9 - (-20.12) = 81 feet at 1000 gpm.

For our last example we will look at gauges. Take a look at FIG 5:

Specifications:

Capacity - 300 gpm.

Specific gravity - 1.3

Viscosity - Similar to water

Piping - 3 inch suction, 2 inch discharge

Atmospheric pressure - 14.7 psi.

Divide the heads into two sections again:

The discharge gauge head corrected to the centerline of the pump, in feet of liquid absolute is

found by adding the atmospheric pressure to the gauge reading to get absolute pressure, and

then converting to absolute head:

hgd = (130 + 14.7) x 2.31 / (1.3 Specific Gravity) + 4 = 261.1 feet, absolute

Note the 4 foot head correction to the pump centerline.

The discharge velocity head at 300 gpm. is found in table 9 of the Hydraulic Institute

Engineering Data Book

1/2/13 Calculating the sy stem head

9/9 www.mcnally institute.com/07-html/7-01.html

hvd = 12.8 feet at 300 gpm.

The suction gauge reading is in absolute terms so it needs only to be converted to feet of

liquid, absolute.

hgs = 40 x 2.3 / 1.3 +2 = 73.08 feet absolute

Note the 2 foot head correction to the pump centerline.

The suction velocity head at 300 gpm. is found in table 11 of the Pipe Friction Manual:

hvs = 2.63 feet at 300 gpm.

The total system head developed by the pump =:

H = (hgd + hvd ) - ( hgs + hvs ) = (261.1 + 12.8) - (73.08 + 2.6)= 198.22 feet

absolute at 300 gpm.

For information about my CD with over 600 Seal & Pump

Subjects explained, click here

Link to the Mc Nally home page

También podría gustarte

- An Analytical Drilling Model of Drag Bits For Evaluation of Rock StrengthDocumento14 páginasAn Analytical Drilling Model of Drag Bits For Evaluation of Rock StrengthImeirdaOlivantiaAún no hay calificaciones

- Calculation of Flow Rate For Orifice Venturi or Flow Nozzle Meter Si UnitsDocumento18 páginasCalculation of Flow Rate For Orifice Venturi or Flow Nozzle Meter Si UnitsPrakash WarrierAún no hay calificaciones

- Resistance Equivalent Length FittingsDocumento3 páginasResistance Equivalent Length FittingsRicardo DaclanAún no hay calificaciones

- Different Types of Ejectors PDFDocumento25 páginasDifferent Types of Ejectors PDFumer shaikhAún no hay calificaciones

- Spe 31656 MS PDFDocumento99 páginasSpe 31656 MS PDFVíctor Eduardo Salas OlguínAún no hay calificaciones

- Minor Losses in Piping SystemsDocumento25 páginasMinor Losses in Piping SystemsdsdeshpandeAún no hay calificaciones

- Compute Time To Drain or Empty A Tank, Pond, or ReservoirDocumento5 páginasCompute Time To Drain or Empty A Tank, Pond, or ReservoirJayakrishnan RadhakrishnanAún no hay calificaciones

- Is 202 Pipe StiffnessDocumento4 páginasIs 202 Pipe StiffnessshrwncmAún no hay calificaciones

- Pressure Drop TheoryDocumento5 páginasPressure Drop Theorykaruna346100% (1)

- Fluid Properties Table for Common Gases and LiquidsDocumento22 páginasFluid Properties Table for Common Gases and LiquidsShaik FaridhAún no hay calificaciones

- Horizontal Well Planning-Build Curve Design: Frank Schuh, Drilling Technology, IncDocumento15 páginasHorizontal Well Planning-Build Curve Design: Frank Schuh, Drilling Technology, IncMontadher Al-saedi100% (1)

- Drilling Hydraulics FormulaeDocumento3 páginasDrilling Hydraulics FormulaeAngel NgoAún no hay calificaciones

- 16 - Blending and AgitationDocumento20 páginas16 - Blending and AgitationRafael ReyesAún no hay calificaciones

- Calculate Reynolds NumberDocumento1 páginaCalculate Reynolds NumberRafael Restituyo LopezAún no hay calificaciones

- Well Control Worksheet For A Surface Bop Stack: CANNON 1-21Documento2 páginasWell Control Worksheet For A Surface Bop Stack: CANNON 1-21scrbdgharaviAún no hay calificaciones

- Well cement plug calculationsDocumento1 páginaWell cement plug calculationsnamphong_vnvnAún no hay calificaciones

- Fluid Flow Basics OF Throttling ValvesDocumento43 páginasFluid Flow Basics OF Throttling ValvesSandro AraújoAún no hay calificaciones

- GS 130-5 Guidance For Specification 130-5 Flow Elements For Plant Control and Measurement ServiceDocumento28 páginasGS 130-5 Guidance For Specification 130-5 Flow Elements For Plant Control and Measurement ServiceYuasti Hasna FauziyahAún no hay calificaciones

- Two Phase Flow HorizontalDocumento4 páginasTwo Phase Flow Horizontalnamphong_vnvnAún no hay calificaciones

- Maximum Allowable Casing Pressure ChartDocumento6 páginasMaximum Allowable Casing Pressure ChartSudish BhatAún no hay calificaciones

- Mathcad - Gorilla VII Mud Pump CalcsDocumento2 páginasMathcad - Gorilla VII Mud Pump CalcsMohamed SaeedAún no hay calificaciones

- Piping Related FormulasDocumento16 páginasPiping Related Formulasnike_y2kAún no hay calificaciones

- Head Vs Flow: Centrifugal Pump CurvesDocumento2 páginasHead Vs Flow: Centrifugal Pump CurvesAnonymous 70lCzDJvAún no hay calificaciones

- Pressure Drop in Laminar and Turbulent Flows in Circular PipeDocumento17 páginasPressure Drop in Laminar and Turbulent Flows in Circular Pipegestapo85Aún no hay calificaciones

- Fluid Mechanics Chapter 9 SummaryDocumento54 páginasFluid Mechanics Chapter 9 SummaryVithursan ThangarasaAún no hay calificaciones

- IWCF Surface BOP Kill Sheet DataDocumento11 páginasIWCF Surface BOP Kill Sheet DataAnuranjanAún no hay calificaciones

- Drainage from Tank in 35 minutesDocumento6 páginasDrainage from Tank in 35 minutesmlarakahanAún no hay calificaciones

- Lab ManuelDocumento79 páginasLab ManuelMarty SmurdaAún no hay calificaciones

- Hoisting Systems ExplainedDocumento21 páginasHoisting Systems Explainedsparda94Aún no hay calificaciones

- 19 Well ControlDocumento133 páginas19 Well ControlAvazdordi SadriAún no hay calificaciones

- Pressure Drop Calculation: SR. No. Parameter Value UnitDocumento1 páginaPressure Drop Calculation: SR. No. Parameter Value UnitSushil WadiyeAún no hay calificaciones

- Experiment On Friction in PipesDocumento15 páginasExperiment On Friction in PipesVijay ShetAún no hay calificaciones

- Pressure Loss - SwitchyardDocumento1 páginaPressure Loss - Switchyardkarthikraja21Aún no hay calificaciones

- Normalizing NPSH: Calculating Suction Specific SpeedDocumento5 páginasNormalizing NPSH: Calculating Suction Specific Speedorchids28Aún no hay calificaciones

- Orifice Plate Showing VenaDocumento6 páginasOrifice Plate Showing VenahugepotatoAún no hay calificaciones

- CEMENT PLUG METRE CALCULATORDocumento1 páginaCEMENT PLUG METRE CALCULATORDian SikumbangAún no hay calificaciones

- Asme II D Subsection 3 - Table TMDocumento62 páginasAsme II D Subsection 3 - Table TMyar_nlAún no hay calificaciones

- Design Data: 2" Threadolet CalculationDocumento2 páginasDesign Data: 2" Threadolet Calculationgrabetty50% (2)

- Orifice Calculation Sheet Service Fluid Oxygen: G Mass Flow RateDocumento2 páginasOrifice Calculation Sheet Service Fluid Oxygen: G Mass Flow RateGovind RaoAún no hay calificaciones

- Tech Drilling FractureGradDocumento43 páginasTech Drilling FractureGradHakan ÖzkaraAún no hay calificaciones

- Hazen-Williams Pressure Loss PPR (Rev01)Documento4 páginasHazen-Williams Pressure Loss PPR (Rev01)santhosh BabyAún no hay calificaciones

- Calculations: 1.1 Hydrostatic PressureDocumento10 páginasCalculations: 1.1 Hydrostatic PressureraoofAún no hay calificaciones

- Amount, Ib/gal Purpose Type of PressureDocumento4 páginasAmount, Ib/gal Purpose Type of PressureGabriela Flores100% (1)

- Orifice Flow Calculator For Gases, Steam, and VaporsDocumento2 páginasOrifice Flow Calculator For Gases, Steam, and Vaporsbakhtyar21Aún no hay calificaciones

- Api Casing Design: Design Parameters Loads at A DepthDocumento2 páginasApi Casing Design: Design Parameters Loads at A DepthrenatoAún no hay calificaciones

- StrippingDocumento17 páginasStrippingGhavban David0% (1)

- 01 - General FormulaeDocumento10 páginas01 - General FormulaescrbdgharaviAún no hay calificaciones

- Spreadsheet Use For Pipe FrictionDocumento31 páginasSpreadsheet Use For Pipe FrictionRohan AroraAún no hay calificaciones

- Minimum Stable FlowDocumento3 páginasMinimum Stable Flowdk4monjureAún no hay calificaciones

- DP FatigDocumento1 páginaDP FatigscrbdgharaviAún no hay calificaciones

- Tugas MekfluDocumento21 páginasTugas MekfluriloaddAún no hay calificaciones

- Pressure Drop in BendDocumento5 páginasPressure Drop in BendfitratulqadriAún no hay calificaciones

- Calculating total system head in USCS unitsDocumento9 páginasCalculating total system head in USCS unitsIrfanshah2013Aún no hay calificaciones

- Calculating total system head in USCS unitsDocumento10 páginasCalculating total system head in USCS unitsHussien Al-gaafary100% (4)

- Pump Equations and Formulas CalculatorDocumento11 páginasPump Equations and Formulas CalculatorOmar Elhady100% (2)

- System Head in Metric UnitsDocumento7 páginasSystem Head in Metric UnitsrammysiAún no hay calificaciones

- ESP Design - Step 4 Total Dynamic HeadDocumento6 páginasESP Design - Step 4 Total Dynamic HeadazareiforoushAún no hay calificaciones

- Is 5120Documento52 páginasIs 5120Otavio123Aún no hay calificaciones

- Pumps DefinitionsDocumento31 páginasPumps DefinitionsFortuna JohnAún no hay calificaciones

- Board of Engineers Malaysia Code of ConductDocumento12 páginasBoard of Engineers Malaysia Code of ConductJude FrancisAún no hay calificaciones

- REA2015 REG2015 (Final) PDFDocumento92 páginasREA2015 REG2015 (Final) PDFAuYongTheanSengAún no hay calificaciones

- PRV High Pressure Regulating Landing Valve Wet Riser SystemsDocumento1 páginaPRV High Pressure Regulating Landing Valve Wet Riser Systemskan_chan_01Aún no hay calificaciones

- HR T&CDocumento29 páginasHR T&CSam Wing HongAún no hay calificaciones

- Daikin Download Link (070915)Documento6 páginasDaikin Download Link (070915)Sam Wing HongAún no hay calificaciones

- Quality NBR Insulation Thickness Guide for Condensation ControlDocumento8 páginasQuality NBR Insulation Thickness Guide for Condensation ControlSam Wing HongAún no hay calificaciones

- Designing Your Compressed Air System - KAESER Compressor PDFDocumento8 páginasDesigning Your Compressed Air System - KAESER Compressor PDFhugoAún no hay calificaciones

- Examples of Fire Safety Engineering Calculations.Documento18 páginasExamples of Fire Safety Engineering Calculations.Sam Wing HongAún no hay calificaciones

- Cag I Air Compressor HPDocumento24 páginasCag I Air Compressor HPcamenitaAún no hay calificaciones

- Room Aircon Heat Load Estimate FormDocumento3 páginasRoom Aircon Heat Load Estimate FormMena G. El NimrAún no hay calificaciones

- Duct Pressure Loss CalculationDocumento24 páginasDuct Pressure Loss CalculationbernardsilvanoAún no hay calificaciones

- Bomba UBBL 1984 (Amendment 2012) HighlightDocumento11 páginasBomba UBBL 1984 (Amendment 2012) HighlightSam Wing HongAún no hay calificaciones

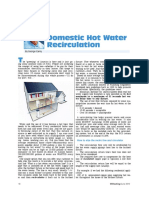

- Domestic Hot Water RecirculationDocumento2 páginasDomestic Hot Water RecirculationSam Wing HongAún no hay calificaciones

- TOLCO Pipe HangersDocumento26 páginasTOLCO Pipe HangersPaulo VeríssimoAún no hay calificaciones

- Draft SCA Guidance On Smoke Control in Apartment BuildingsDocumento67 páginasDraft SCA Guidance On Smoke Control in Apartment BuildingsSam Wing HongAún no hay calificaciones

- Pyrochem Operation ManualDocumento82 páginasPyrochem Operation ManualSam Wing Hong100% (2)

- Papaya Pipe HangerDocumento2 páginasPapaya Pipe HangerSam Wing HongAún no hay calificaciones

- Engineering Sump Design Guide PDFDocumento8 páginasEngineering Sump Design Guide PDFHaimwant DhanieAún no hay calificaciones

- HVAC Handbook HVAC Design Brief (Singapore)Documento26 páginasHVAC Handbook HVAC Design Brief (Singapore)Sam Wing Hong50% (2)

- Quality NBR Insulation Thickness Guide for Condensation ControlDocumento8 páginasQuality NBR Insulation Thickness Guide for Condensation ControlSam Wing HongAún no hay calificaciones

- Choosing Soft Starter or Variable Frequency DriveDocumento4 páginasChoosing Soft Starter or Variable Frequency Drivesiva_nagesh_2Aún no hay calificaciones

- Lift Traffic Design Spreadsheet - All PeaksDocumento8 páginasLift Traffic Design Spreadsheet - All PeaksSam Wing HongAún no hay calificaciones

- Typical SMATV For Condo-ApartmentDocumento3 páginasTypical SMATV For Condo-ApartmentSam Wing HongAún no hay calificaciones

- Paper-on-Swimming Pool Circulation-Systems PDFDocumento5 páginasPaper-on-Swimming Pool Circulation-Systems PDFIlyas AhmedAún no hay calificaciones

- Typical MSW SchematicDocumento9 páginasTypical MSW SchematicSam Wing HongAún no hay calificaciones

- Hot Water Supply (Apprentice) M2 U10Documento39 páginasHot Water Supply (Apprentice) M2 U10Sam Wing HongAún no hay calificaciones

- Soil Pipe (Timplas)Documento9 páginasSoil Pipe (Timplas)Sam Wing HongAún no hay calificaciones

- Preliminary Calculation On Sizing of Surge VesselDocumento3 páginasPreliminary Calculation On Sizing of Surge VesselSam Wing Hong100% (3)

- Quality NBR Insulation Thickness Guide for Condensation ControlDocumento8 páginasQuality NBR Insulation Thickness Guide for Condensation ControlSam Wing HongAún no hay calificaciones

- Surge ControlDocumento14 páginasSurge Control31jamesAún no hay calificaciones

- PDF Manual de Reparaciones Estructurales Del Airbus A 320 CompressDocumento15 páginasPDF Manual de Reparaciones Estructurales Del Airbus A 320 CompressJosé LuisAún no hay calificaciones

- WP 13 General Annexes - Horizon 2023 2024 - enDocumento43 páginasWP 13 General Annexes - Horizon 2023 2024 - enLuchianAún no hay calificaciones

- Asphalt Laboratory Manual RevDocumento13 páginasAsphalt Laboratory Manual RevKurian C ChackoAún no hay calificaciones

- Big Data Analytics and Artificial Intelligence inDocumento10 páginasBig Data Analytics and Artificial Intelligence inMbaye Babacar MBODJAún no hay calificaciones

- Mastercam 8.1 Beta 4: New Verification Engine in Beta 4! Sub-Programs Post ChangesDocumento48 páginasMastercam 8.1 Beta 4: New Verification Engine in Beta 4! Sub-Programs Post ChangesSaul Saldana LoyaAún no hay calificaciones

- USTHB Master's Program Technical English Lesson on Reflexive Pronouns and Antenna FundamentalsDocumento4 páginasUSTHB Master's Program Technical English Lesson on Reflexive Pronouns and Antenna Fundamentalsmartin23Aún no hay calificaciones

- SAP PPM 5.0 Certification Exam TopicsDocumento7 páginasSAP PPM 5.0 Certification Exam TopicsongkecanthoAún no hay calificaciones

- Adss-Eke 150 (Mm12c) eDocumento7 páginasAdss-Eke 150 (Mm12c) eYuseidy Rguez PaezAún no hay calificaciones

- Us00-000 831 01 02 02Documento18 páginasUs00-000 831 01 02 02Cristian Camilo0% (1)

- Trip WireDocumento19 páginasTrip Wirepinky065558100% (2)

- BATAM Selco Amprah Agustus (@) 2021Documento31 páginasBATAM Selco Amprah Agustus (@) 2021rentalkiosAún no hay calificaciones

- Mockups Showeet (Standard)Documento46 páginasMockups Showeet (Standard)Palo Alto Turismo y EntretenimientoAún no hay calificaciones

- General Format Feasibility StudyDocumento7 páginasGeneral Format Feasibility StudyRynjeff Lui-Pio100% (1)

- Report CategoryWiseSECCVerification 315700301009 08 2019Documento2 páginasReport CategoryWiseSECCVerification 315700301009 08 2019Sandeep ChauhanAún no hay calificaciones

- BF 00571142Documento1 páginaBF 00571142Tymoteusz DziedzicAún no hay calificaciones

- Follow The Directions - GR 1 - 3 PDFDocumento80 páginasFollow The Directions - GR 1 - 3 PDFUmmiIndia100% (2)

- KV Sainik Vihar Class 6 Science Holidays HomeworkDocumento7 páginasKV Sainik Vihar Class 6 Science Holidays HomeworkABYAN ShaikAún no hay calificaciones

- PandoraFMS Alerts WhatsappDocumento6 páginasPandoraFMS Alerts Whatsapppacolo89Aún no hay calificaciones

- 08 - Chapter 1 - Waveguide-Transmission Line - Microstrip LinesDocumento76 páginas08 - Chapter 1 - Waveguide-Transmission Line - Microstrip Linesgilberto araujoAún no hay calificaciones

- Stainless Steel Welding Alloys ChartDocumento1 páginaStainless Steel Welding Alloys Chartlaz_kAún no hay calificaciones

- Volume 5 Issue 1Documento625 páginasVolume 5 Issue 1IJAET Journal0% (1)

- Muhammad Ajmal: Electrical EngineerDocumento1 páginaMuhammad Ajmal: Electrical EngineerMuhammad AbrarAún no hay calificaciones

- Hydraulic System Trainer AS-10Documento13 páginasHydraulic System Trainer AS-10Tanlets Gery100% (1)

- BSBCRT511 Project Portfolio - Revised - Answers IncludedDocumento26 páginasBSBCRT511 Project Portfolio - Revised - Answers IncludedShivanee JhaumalAún no hay calificaciones

- CH 07Documento40 páginasCH 07Ambreen31Aún no hay calificaciones

- Handout 4: Course Notes Were Prepared by Dr. R.M.A.P. Rajatheva and Revised by Dr. Poompat SaengudomlertDocumento7 páginasHandout 4: Course Notes Were Prepared by Dr. R.M.A.P. Rajatheva and Revised by Dr. Poompat SaengudomlertBryan YaranonAún no hay calificaciones

- ACP160DDocumento14 páginasACP160Dinbox934Aún no hay calificaciones

- Automatic Helmet DetectDocumento4 páginasAutomatic Helmet Detectvasanth100% (1)

- Career Paralysis (PT 1) - Five Reasons Why Our Brains Get Stuck Making Career DecisionsDocumento99 páginasCareer Paralysis (PT 1) - Five Reasons Why Our Brains Get Stuck Making Career DecisionsToni ErdfeldAún no hay calificaciones

- Magazine 55 EnglishPartDocumento50 páginasMagazine 55 EnglishPartAli AwamiAún no hay calificaciones