Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Installation-Operation-Maintenance Manual For Foam Proportioning System - DPS

Cargado por

Roshin990 calificaciones0% encontró este documento útil (0 votos)

510 vistas10 páginasFoam Proportioning

Título original

Installation-Operation-Maintenance Manual for Foam Proportioning System -DPS

Derechos de autor

© © All Rights Reserved

Formatos disponibles

PDF, TXT o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoFoam Proportioning

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

0 calificaciones0% encontró este documento útil (0 votos)

510 vistas10 páginasInstallation-Operation-Maintenance Manual For Foam Proportioning System - DPS

Cargado por

Roshin99Foam Proportioning

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

Está en la página 1de 10

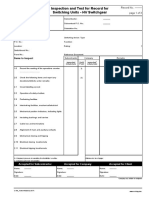

Pr oj ect : Upgr adi ng DPS & B- Bl ock Faci l i t i es

Cl i ent Ref . : AD122 / L- 017

Our Ref . : M- 304942

Equi pment Tag No: A- 1243

I NSTALLATI ON & OPERATI ON &

MAI NTENANCE MANUAL FOR FOAM

PROPORTI ONI NG SYSTEM (DPS)

A 21.11.2011 M.SASON E.SEN

REV

DATE

NOTES

PREPARED

BY

APPROVED

BY

CUSTOMER

APPROVAL

DATE

DOAN YANGIN

Sndrme San ve Tic. A..

DOAN YANGIN

Sndrme San ve Tic A

DALEEL PETROLEUM L.L.C.

UPGRADING DPS & B-BLOCK

FACILITIES PROJECT

INSTALLATION & OPERATION &

MAINTENANCE MANUAL FOR FOAM

PROPORTIONING SYSTEM (DPS)

Date 18.11.2011

Ref. AD122 / L017

Revision - A -

Page No 2 / 10

HEALTH AND SAFETY

All work to be carried out in accordance with site rules and national regulations.

The equipment is designed to withstand normal operating conditions and

pressures. When properly used and maintained by trained personnel it

represents minimal risk to health and safety.

It is the responsibility of the person installing or erecting any items of equipment

to ensure that it is installed in compliance with the instructions and to ensure that

the equipment is safe for use under normal operating conditions.

WARNING

Where appropriate, components and equipment under pressure and

electrical connections should be isolated from supply before undertaking

any servicing or maintenance.

DOAN YANGIN

Sndrme San ve Tic A

DALEEL PETROLEUM L.L.C.

UPGRADING DPS & B-BLOCK

FACILITIES PROJECT

INSTALLATION & OPERATION &

MAINTENANCE MANUAL FOR FOAM

PROPORTIONING SYSTEM (DPS)

Date 18.11.2011

Ref. AD122 / L017

Revision - A -

Page No 3 / 10

INSTALLATION

- Locate DPS Foam Proportioning Skid (Pack No:2) onto the concrete foundation

and remove 4 off heightening legs from the skid frame.

- Drain case of the Pelton wheel (P-1254A) should be aligned with the drain channel

which is opened previously on the foundation.

- Locate the 950 L. Foam Tank (Pack No:6) onto the concrete foundation according

to the Dogan Yangin drawing 304942-PGL-002.

- Take out Skid Interconnection Pipes from the Pack No:3.

- 2 off interconnecting pipes are needed to connect the skid to the foam tank. All

corresponding pipe ends are marked with a number for easy matching.

- Connect the skid to the tank by the help of interconnecting pipes.

- Mark the foundation bolt positions.

- Take out interconnecting pumps and lift the skid and foam tank to give access for

drilling.

- Refer to the chemical bolt manufacturers instructions for drilling, installation and

torque details.

- After allowing sufficient time for the bond to cure, tighten the anchor bolts to the

torque setting recommended in the manufacturers instructions.

- Adjust the height of the packing with shims in each bolt position until piping is

Horizontal and all flanges are Vertical.

- Locate the skid & foam tank on the foundation and connect by using interconnecting

pipes again.

- Locate DPS Skid Outlet Manifold (Pack No:7) and connect the manifold to the skid

according to the Dogan Yangn drawing 304942-PGL-002

- Connect 2 off solenoid coils (can be found attached on the skid frame) to the deluge

valves pre-installed in the manifold.

- Connect 1 conduit (which can be found attached on the skid frame) to the bottom

of the foam tank by the help of the pipe clamps found bottom of the tank.

- Connect the wires to the low level gauge.

- Locate 1 off 4 OS&Y Gate Valve and 1off 4 Y Type Strainer (Pack No:4) and

install to the inlet of the skid according to the Dogan Yangin drawing 304942-PGL-

002

- Locate Magnetic Level Gauge and valves (Pack No:3) and connect to

flanges on Foam Tank. For detailed instructions refer to the manufacturers manual.

- Connect 4 inlet piping (by Others) to the 4 OS&Y Gate Valve.

- Connect 3 T-1201 Foam Solution Piping (by Others) to outlet flange of the 3

Deluge Valve (DV-478).

DOAN YANGIN

Sndrme San ve Tic A

DALEEL PETROLEUM L.L.C.

UPGRADING DPS & B-BLOCK

FACILITIES PROJECT

INSTALLATION & OPERATION &

MAINTENANCE MANUAL FOR FOAM

PROPORTIONING SYSTEM (DPS)

Date 18.11.2011

Ref. AD122 / L017

Revision - A -

Page No 4 / 10

- Connect 4 T-1241 Foam Solution Piping (by Others) to the outlet flange of the 4

Deluge Valve (DV-477).

- If remote start function will be used, remove temporary link from the terminals 1 & 2

in the control panel and connect wires from remote start button (by Others).

- If remote stop function will be used, connect wires to the Terminals 2 & 3 in the

control panel from remote stop button (by Others)

- If Pump Running signal will be supervised, connect wires to the terminals 4 & 5 in

the control panel (by Others).

- If Electric Pump Fault signal will be supervised, connect wires to the terminals 6 &

7 in the control panel (by Others).

- If Electric Pump Trip function will be used, connect wires to the terminals 10 & 11

in the control panel (by Others).

- For remote operation of the Deluge Valve (DV-477), connect wires (24 Vdc) from

DCS to the terminals 12 & 13 in the control panel (by Others).

- For remote operation of the Deluge Valve (DV-478), connect wires (24 Vdc) from

DCS to the terminals 14 & 15 in the control panel (by Others).

- For remote operation of the Deluge Valve (PV-475), connect wires (24 Vdc) from

DCS to the terminals 16 & 17 in the control panel (by Others).

- For remote operation of the valve (DV-476), connect wires (24 Vdc) from DCS to

the terminals 18 &19 in the control panel (by Others).

- Connect 415V supply to the terminal R, S, T, N terminal in the control panel and

make sure all three lamps are ON.

- Connect air pressure to the valves DV-476, DV-477 and DV-478.

- Fill the foam tank with FP-350 foam supplied.

- Bleed air from the system by opening High Point Vent Valves (From the flush

valves of the pressure gauges located at each Foam pumps discharge).

DOAN YANGIN

Sndrme San ve Tic A

DALEEL PETROLEUM L.L.C.

UPGRADING DPS & B-BLOCK

FACILITIES PROJECT

INSTALLATION & OPERATION &

MAINTENANCE MANUAL FOR FOAM

PROPORTIONING SYSTEM (DPS)

Date 18.11.2011

Ref. AD122 / L017

Revision - A -

Page No 5 / 10

OPERATION

Remote Operation from DCS;

- For valve numbers, please refer to the drawing attached to this manual.

- The following skid mounted valves should be in normally CLOSED position;

o 14 16 17

- The following skid mounted valves should be in normally OPEN position;

o 1 2 4 6 8 9 10 11 12 15 18

- The following skid mounted valves should be air pressurized;

o 5 7 - 13

- Ensure the ex-proof control panel has no alarm condition.

- The water pressure inlet of the proportioner should be minimum 9 bar.

- Remotely start electric motor driven foam pump (P-1254B).

- In the event of having problem with electric motor driven foam pump (P-1254B);

activate the spare pelton wheel driven foam pump (P-1254A) by energizing the

solenoid of the deluge valve #3.

- The foam discharge pressure of the foam pump should be minimum 11 bar.

- Supervise the foam concentrate capacity from magnetic level gauge and low

level switch.

WARNING: The pumps shall not be run without Foam Concentrate

- Note that during all these operations one person needs to be in the foam

pumping station to supervise systems while working.

- Energize the solenoid of the #13 pneumatic controlled ball valve (DV-476).

- Foam concentrate should now be fixing with fire water to produce correct

proportioning of foam solution.

- Energize the solenoid of the Deluge Valve controlling the foam discharge (#5 or

#7) of the related tank in fire.

- Examine the duplex gauge of the Balance Valve. Foam (Black) and water (red)

pressures should be equal.

- After extinguishing the fire, de-energize the solenoid of the deluge valve #5 or #7.

- De-energize the solenoid of the pneumatic controlled ball valve (#13).

- If electric motor driven foam pump (P-1254B) is running, remotely Stop the foam

pump.

- If pelton driven foam pump (P-1254A) is running, de-energize the solenoid of the

deluge valve #3.

- Ensure the foam solution and foam concentrate pressures drop to zero by

examining the pressure gauges.

DOAN YANGIN

Sndrme San ve Tic A

DALEEL PETROLEUM L.L.C.

UPGRADING DPS & B-BLOCK

FACILITIES PROJECT

INSTALLATION & OPERATION &

MAINTENANCE MANUAL FOR FOAM

PROPORTIONING SYSTEM (DPS)

Date 18.11.2011

Ref. AD122 / L017

Revision - A -

Page No 6 / 10

Emergency Operation (If Remote Operation Fails);

- For valve numbers, please refer to the drawing attached to this manual.

- The following skid mounted valves should be in normally CLOSED position;

o 14 16 17

- The following skid mounted valves should be in normally OPEN position;

o 1 2 4 6 8 9 10 11 12 15 18

- The following skid mounted valves should be air pressurized;

o 5 7 - 13

- Ensure the ex-proof control panel has no alarm condition.

- The water pressure inlet of the proportioner should be minimum 9 bar.

- Start electric motor driven foam pump (P-1254B) from the control panel located

on the skid.

- In the event of having problem with electric motor driven foam pump (P-1254B);

activate the spare pelton wheel driven foam pump (P-1254A) by opening the

emergency manual control valve of the deluge valve #3.

- The foam discharge pressure of the foam pump should be minimum 11 bar.

- Supervise the foam concentrate capacity from magnetic level gauge and low

level switch.

WARNING: The pumps shall not be run without Foam Concentrate

- Manually open the #13 pneumatic control valve from the top of the actuator by

the help of wrench.

- Foam concentrate should now be fixing with fire water to produce correct

proportioning of foam solution.

- Open the Deluge Valve controlling the foam discharge (#5 or #7) of the related

tank in fire manually by opening emergency manual control valve.

- Examine the duplex gauge of the Balance Valve. Foam (Black) and water (red)

pressures should be equal.

- After extinguishing the fire, close the emergency valve of the deluge valve #5

or #7.

- Close pneumatic controlled ball valve (#13) manually.

- If electric motor driven foam pump (P-1254B) is running, Stop the foam pump

from the local control panel.

- If pelton driven foam pump (P-1254A) is running, close the emergency

manual valve of the deluge valve #3.

- Ensure the foam solution and foam concentrate pressures drop to zero by

examining the pressure gauges.

DOAN YANGIN

Sndrme San ve Tic A

DALEEL PETROLEUM L.L.C.

UPGRADING DPS & B-BLOCK

FACILITIES PROJECT

INSTALLATION & OPERATION &

MAINTENANCE MANUAL FOR FOAM

PROPORTIONING SYSTEM (DPS)

Date 18.11.2011

Ref. AD122 / L017

Revision - A -

Page No 7 / 10

ROUTINE MAINTENANCE TESTING

Testing Electric Motor Driven Foam Pump Operation (Monthly);

- For valve numbers, please refer to the drawing attached to this manual.

- The following skid mounted valves should be in normally CLOSED position;

o 14 16 17

- The following skid mounted valves should be in normally OPEN position;

o 1 2 4 6 8 9 10 11 12 15 18

- The following skid mounted valves should be air pressurized;

o 5 7 - 13

- Ensure the ex-proof control panel has no alarm condition.

- The water pressure inlet of the proportioner should be minimum 9 bar.

- Start electric motor driven foam pump (P-1254B) from the control panel located

on the skid.

- The foam discharge pressure of the foam pump should be minimum 11 bar.

- Supervise the foam concentrate capacity from magnetic level gauge and low

level switch.

WARNING: The pumps shall not be run without Foam Concentrate

- Run the foam pump at least 15 minutes.

- Stop the electric motor driven foam pump (P-1254B) from the control panel

located on the skid.

- This test should be performed each month.

Testing Water Motor (Pelton) Driven Foam Pump Operation (Monthly);

- For valve numbers, please refer to the drawing attached to this manual.

- The following skid mounted valves should be in normally CLOSED position;

o 14 16 17

- The following skid mounted valves should be in normally OPEN position;

o 1 2 4 6 8 9 10 11 12 15 18

- The following skid mounted valves should be air pressurized;

o 5 7 - 13

- Ensure the ex-proof control panel has no alarm condition.

- The water pressure inlet of the proportioner should be minimum 9 bar.

- Start Pelton wheel driven foam pump (P-1254A) by opening the emergency

manual control valve of the deluge valve #3.

- The foam discharge pressure of the foam pump should be minimum 11 bar.

DOAN YANGIN

Sndrme San ve Tic A

DALEEL PETROLEUM L.L.C.

UPGRADING DPS & B-BLOCK

FACILITIES PROJECT

INSTALLATION & OPERATION &

MAINTENANCE MANUAL FOR FOAM

PROPORTIONING SYSTEM (DPS)

Date 18.11.2011

Ref. AD122 / L017

Revision - A -

Page No 8 / 10

- Supervise the foam concentrate capacity from magnetic level gauge and low

level switch.

WARNING: The pumps shall not be run without Foam Concentrate

- Run the foam pump at least 15 minutes.

- Stop Pelton wheel driven foam pump (P-1254A) by closing the emergency

manual control valve of the deluge valve #3.

- This test should be performed each month.

Testing Foam Proportioning System (Annually);

- For valve numbers, please refer to the drawing attached to this manual.

- The following skid mounted valves should be in normally CLOSED position;

o 14 16 17

- The following skid mounted valves should be in normally OPEN position;

o 1 2 4 6 8 9 10 11 12 15 18

- The following skid mounted valves should be air pressurized;

o 5 7 - 13

- Ensure the ex-proof control panel has no alarm condition.

- The water pressure inlet of the proportioner should be minimum 9 bar.

- Start electric motor driven foam pump (P-1254B) from the control panel located

on the skid.

- The foam discharge pressure of the foam pump should be minimum 11 bar.

- Supervise the foam concentrate capacity from magnetic level gauge and low

level switch.

WARNING: The pumps shall not be run without Foam Concentrate

- Manually open the #13 pneumatic control valve from the top of the actuator by

the help of wrench.

- Foam concentrate should now be fixing with fire water to produce correct

proportioning of foam solution.

- Close the OS&Y gate valve controlling the foam pourer of the relevant tank.

- Connect fire hose and a low expansion foam branchpipe to the 2 landing valve

of the foam solution hydrant located at the downstream of the deluge valve (#5 or

#7).

- Open the Deluge Valve controlling the foam discharge (#5 or #7) of the related

tank manually by opening emergency manual control valve.

DOAN YANGIN

Sndrme San ve Tic A

DALEEL PETROLEUM L.L.C.

UPGRADING DPS & B-BLOCK

FACILITIES PROJECT

INSTALLATION & OPERATION &

MAINTENANCE MANUAL FOR FOAM

PROPORTIONING SYSTEM (DPS)

Date 18.11.2011

Ref. AD122 / L017

Revision - A -

Page No 9 / 10

- Examine the duplex gauge of the Balance Valve. Foam (Black) and water (red)

pressures should be equal.

- Slowly open 2 landing valve of the foam solution hydrant and collect the foam

according to the NFPA-11A. Measure expansion, concentration and 25

drainage time according to the NFPA-11A.

- Close 2 landing valve of the foam solution hydrant.

- Close pneumatic controlled ball valve (#13) manually.

- Close the Deluge Valve controlling the foam discharge (#5 or #7) of the related

tank manually by closing emergency manual control valve.

- Stop the electric foam pump from the local control panel.

- Disconnect fire hose and low expansion branchpipe from the foam solution

hydrant.

- Open the OS&Y gate valve controlling the foam pourer of the relevant tank.

- Ensure the foam solution and foam concentrate pressures drop to zero by

examining the pressure gauges.

- Repeat same test for pelton wheel driven foam pump.

Flushing Foam Proportioning System (If Required);

- The following skid mounted valves should be in normally CLOSED position;

o 8 9 10 11 15 18

- The following skid mounted valves should be in normally OPEN position;

o 1 2 4 6 14

- Open 16 17 and drain valves on the foam concentrate pipelines to drain the

foam.

- Connect one end of the fire hose to the nearby fire hydrant and connect the other

end to the valve #16.

- Connect one end of the fire hose to the valve #17 and locate the other end to the

nearby drain.

- Close the drain valves, and open the hydrant valve slowly.

- Run the electric motor driven foam pump (P-1254B) and ensure the water

discharge from the hose outlet of the #17 valve.

- Stop the pump after 30 seconds and close 16 17.

- Repeat same for pelton wheel driven pump (P-1254A).

- Do not flush each pump more than 1 minute.

- Disconnect hoses from the fire hydrant and valves #16 17.

- Make sure the valves are in position below;

o CLOSE: 14 16 17

o OPEN: 1 2 4 6 8 9 10 11 12 15 18

o AIR PRESSURIZED: 5 7 - 13

DOAN YANGIN

Sndrme San ve Tic A

DALEEL PETROLEUM L.L.C.

UPGRADING DPS & B-BLOCK

FACILITIES PROJECT

INSTALLATION & OPERATION &

MAINTENANCE MANUAL FOR FOAM

PROPORTIONING SYSTEM (DPS)

Date 18.11.2011

Ref. AD122 / L017

Revision - A -

Page No 10 / 10

También podría gustarte

- Fire Protection Piping Installation and Testing-Feb. 12, 2014Documento104 páginasFire Protection Piping Installation and Testing-Feb. 12, 2014Abdul Wahed100% (7)

- O&M Fire FightingDocumento38 páginasO&M Fire FightingRajkumar Prasad100% (2)

- Tank Test CertificatesDocumento1 páginaTank Test CertificatesRoshin99Aún no hay calificaciones

- Hydrostatic Tests For Fire Sprinkler SystemsDocumento6 páginasHydrostatic Tests For Fire Sprinkler SystemsMohamed IbrahimAún no hay calificaciones

- ANNEXURE For HVW SPRAY SYSTEM - StandardDocumento1 páginaANNEXURE For HVW SPRAY SYSTEM - StandardVaibhav SawantAún no hay calificaciones

- AHU Commissioning Report DF016eDocumento8 páginasAHU Commissioning Report DF016evishwas salunkheAún no hay calificaciones

- Maintenance ManualDocumento17 páginasMaintenance ManualSean ChanAún no hay calificaciones

- Method of Statment of Fire HydrantDocumento13 páginasMethod of Statment of Fire Hydrantzia100% (1)

- TAD1140-1142VE: Low Cost of OwnershipDocumento2 páginasTAD1140-1142VE: Low Cost of OwnershipRachid Smaili100% (1)

- Boiler Exam PDFDocumento7 páginasBoiler Exam PDFJerick HernandezAún no hay calificaciones

- Cement Cooler ProcessDocumento57 páginasCement Cooler Processniteshvtank100% (2)

- Nfpa 20 ReviewedDocumento6 páginasNfpa 20 Reviewedakill3rAún no hay calificaciones

- Foam System Specification PDFDocumento22 páginasFoam System Specification PDFpequenita34Aún no hay calificaciones

- Sprinkler and SystmesDocumento4 páginasSprinkler and SystmesridwanAún no hay calificaciones

- 6.4 - Sprinklers For Concealed Spaces and Raised Floors PDFDocumento1 página6.4 - Sprinklers For Concealed Spaces and Raised Floors PDFHaitham MohammadAún no hay calificaciones

- 3844-Internal Fire Hydrants and HoseDocumento22 páginas3844-Internal Fire Hydrants and HoseSOMU_61100% (1)

- Deluge System Design GuideDocumento14 páginasDeluge System Design GuidePassmore DubeAún no hay calificaciones

- 01-01-1865-D ELDS Technical Manual Iss13Documento221 páginas01-01-1865-D ELDS Technical Manual Iss13Alberyt099Aún no hay calificaciones

- TAC Hydrant Manual PDFDocumento113 páginasTAC Hydrant Manual PDFVaibhav SawantAún no hay calificaciones

- Documentation AnsulDocumento40 páginasDocumentation AnsulkdsessionsAún no hay calificaciones

- FM 200 TestingDocumento12 páginasFM 200 Testingkazimali786Aún no hay calificaciones

- Fire FightingDocumento50 páginasFire FightingJagadeesh KandasamyAún no hay calificaciones

- FOAM TANK (1/2) : Fire Fighting Equipment Data SheetDocumento24 páginasFOAM TANK (1/2) : Fire Fighting Equipment Data SheetandinumailAún no hay calificaciones

- Installation of Sprinkler Piping SystemDocumento6 páginasInstallation of Sprinkler Piping SystemJosef MadronaAún no hay calificaciones

- PMG-ENG-O-DSH-U00-001-W Rev 3 Fire Fighting & Safety Equipment Datasheet - Part6 PDFDocumento1 páginaPMG-ENG-O-DSH-U00-001-W Rev 3 Fire Fighting & Safety Equipment Datasheet - Part6 PDFAditya PranotoAún no hay calificaciones

- Fire Pump Check ListDocumento1 páginaFire Pump Check ListArafat RobinAún no hay calificaciones

- Hydrant Stand Post (Double) : Technical Data SheetDocumento2 páginasHydrant Stand Post (Double) : Technical Data SheetshabahatAún no hay calificaciones

- Checklist For Pressure Testing Safely 2Documento2 páginasChecklist For Pressure Testing Safely 2Jonathan CambaAún no hay calificaciones

- FP ManualDocumento81 páginasFP Manualshekharvkate100% (4)

- Fire Fighting System Calculation PDFDocumento15 páginasFire Fighting System Calculation PDFعامر شیخAún no hay calificaciones

- Multiple Foam Deluge SystemDocumento10 páginasMultiple Foam Deluge SystemTrần VânAún no hay calificaciones

- Commissioning of Fire SuppressionDocumento4 páginasCommissioning of Fire SuppressionNguyễn Tuấn SươngAún no hay calificaciones

- Fire Fighting SystemDocumento59 páginasFire Fighting Systembalaeee123Aún no hay calificaciones

- Fire Fighting - QatarDocumento21 páginasFire Fighting - QatarrajeshjamesAún no hay calificaciones

- Project Standards and Specifications Fire Water Systems Rev01Documento10 páginasProject Standards and Specifications Fire Water Systems Rev01Almer Ibnu FarhanAún no hay calificaciones

- Carbon Dioxide Fire Suppression SystemDocumento9 páginasCarbon Dioxide Fire Suppression SystemBen Lim100% (1)

- PN 38 2014 Fire Hydrants System Design, Installation, Commissioning and TestingDocumento5 páginasPN 38 2014 Fire Hydrants System Design, Installation, Commissioning and TestingKadiri OlanrewajuAún no hay calificaciones

- Maintenance of Fire Suppression SystemsDocumento2 páginasMaintenance of Fire Suppression SystemsRaja Prathap SinghAún no hay calificaciones

- Fire Fighting Equipment LayoutDocumento1 páginaFire Fighting Equipment LayoutAditya PranotoAún no hay calificaciones

- Clean Agent Suppression System Inspection Checklist PDFDocumento4 páginasClean Agent Suppression System Inspection Checklist PDFShah ArafatAún no hay calificaciones

- Fire Blanket Datasheet Mar13Documento1 páginaFire Blanket Datasheet Mar13Kannan KarunakaranAún no hay calificaciones

- Work Procedure Bitumen Mastic FlooringDocumento6 páginasWork Procedure Bitumen Mastic FlooringSWARUP MONDALAún no hay calificaciones

- Indian Standard - Code of Practice For Installation and Maintenance of Internal Fire Hydrants and Hose Reels On PremisesDocumento33 páginasIndian Standard - Code of Practice For Installation and Maintenance of Internal Fire Hydrants and Hose Reels On PremisesDilip VemulaAún no hay calificaciones

- Fire Protection - Rev.06Documento79 páginasFire Protection - Rev.06Anil MarturiAún no hay calificaciones

- Royal Oman Police (English)Documento191 páginasRoyal Oman Police (English)Khizer ArifAún no hay calificaciones

- Tie in MosDocumento2 páginasTie in MosAAISATAún no hay calificaciones

- Technical SpecificationDocumento12 páginasTechnical SpecificationYousuf KamalAún no hay calificaciones

- Deluge Valve ADocumento14 páginasDeluge Valve ASiddharth GupteAún no hay calificaciones

- Sprinklers PDFDocumento43 páginasSprinklers PDFpil7194Aún no hay calificaciones

- WMS or Procedure For FireproofingDocumento13 páginasWMS or Procedure For FireproofingRodelio RemoAún no hay calificaciones

- Fire Pump Capacity Standard CalcDocumento8 páginasFire Pump Capacity Standard Calck0nquerorAún no hay calificaciones

- Fire Water CommissioningDocumento2 páginasFire Water CommissioningismailchoughuleAún no hay calificaciones

- DIOM Tyco Hygood IG541Documento103 páginasDIOM Tyco Hygood IG541appril26Aún no hay calificaciones

- NFPA Fire PumpDocumento12 páginasNFPA Fire PumpSyed Faizan AliAún no hay calificaciones

- SECTION 15340 Water Spray Fixed Systems Rev 0Documento28 páginasSECTION 15340 Water Spray Fixed Systems Rev 0Basil OguakaAún no hay calificaciones

- Method of Statement Novec Cylinder RefillingDocumento2 páginasMethod of Statement Novec Cylinder RefillingKo Zay100% (1)

- PMG-EnG-O-DSH-U00-001-W Rev 3 Fire Fighting & Safety Equipment Datasheet - Part11Documento1 páginaPMG-EnG-O-DSH-U00-001-W Rev 3 Fire Fighting & Safety Equipment Datasheet - Part11Aditya PranotoAún no hay calificaciones

- Foam Mix Fire Sup TM HP0296 v2Documento126 páginasFoam Mix Fire Sup TM HP0296 v2Rachel Flores100% (1)

- Pre-Action Deluge System Test QCDD FormDocumento1 páginaPre-Action Deluge System Test QCDD FormMahmoud HassanAún no hay calificaciones

- Sr. No. Description of Item Qty. UNIT Rate Amount A Pumps: IITM at Madras Bill of Quantities For Pumps DATE: 04.07.16Documento2 páginasSr. No. Description of Item Qty. UNIT Rate Amount A Pumps: IITM at Madras Bill of Quantities For Pumps DATE: 04.07.16sanjay khatriAún no hay calificaciones

- TEC-212200 - MET-DoR-005 (Method Statement For Installation and Inspection of Clean Agent system-FM 200 - 1Documento8 páginasTEC-212200 - MET-DoR-005 (Method Statement For Installation and Inspection of Clean Agent system-FM 200 - 1swamyAún no hay calificaciones

- Seko TEKNA DPG Pump Instruction ManualDocumento23 páginasSeko TEKNA DPG Pump Instruction ManualManuel Marín MartínezAún no hay calificaciones

- Series 919 Installation InstructionsDocumento8 páginasSeries 919 Installation InstructionsWattsAún no hay calificaciones

- Manual Zetkama Fig.215 - 216Documento8 páginasManual Zetkama Fig.215 - 216George_Wabag_2014Aún no hay calificaciones

- FootingDocumento5 páginasFootingMohammad Tawfiq Wara100% (4)

- Diff-Limit State & Working StressDocumento2 páginasDiff-Limit State & Working StressRoshin99100% (1)

- WeldingDocumento1 páginaWeldingVinothAún no hay calificaciones

- Test Record For Overcurrent - Earth Fault - Prot Relay-Induction TypeDocumento1 páginaTest Record For Overcurrent - Earth Fault - Prot Relay-Induction TypeRoshin99Aún no hay calificaciones

- Footings Soil PressureDocumento8 páginasFootings Soil Pressuredeepakram04Aún no hay calificaciones

- Inspection Report For Field WeldDocumento1 páginaInspection Report For Field WeldRoshin99Aún no hay calificaciones

- Inspection Record For Switch HousesDocumento1 páginaInspection Record For Switch HousesRoshin99Aún no hay calificaciones

- Inspection Record For Cabinets - ConsolesDocumento2 páginasInspection Record For Cabinets - ConsolesRoshin99Aún no hay calificaciones

- Insp Record For Install Accept Safeguarding SystemDocumento1 páginaInsp Record For Install Accept Safeguarding SystemRoshin99Aún no hay calificaciones

- IR For Cable Tray & LaddersDocumento1 páginaIR For Cable Tray & LaddersSchwihdi ZakAún no hay calificaciones

- Inspection Record For Air Ducting System: Items To InspectDocumento1 páginaInspection Record For Air Ducting System: Items To InspectSchwihdi ZakAún no hay calificaciones

- Concrete Placement RecordDocumento1 páginaConcrete Placement RecordRoshin99100% (1)

- Insp Record For Block WorkDocumento1 páginaInsp Record For Block WorkRoshin99Aún no hay calificaciones

- Inspection Record For GatesDocumento1 páginaInspection Record For GatesRoshin99Aún no hay calificaciones

- Insp Record For Block WorkDocumento1 páginaInsp Record For Block WorkRoshin99Aún no hay calificaciones

- Instion Test Record-PaintingDocumento1 páginaInstion Test Record-PaintingkeronsAún no hay calificaciones

- Inspection & Test Record Control Valve Pre-InstallationDocumento1 páginaInspection & Test Record Control Valve Pre-InstallationRoshin99Aún no hay calificaciones

- Site Engineering Query (SEQ)Documento1 páginaSite Engineering Query (SEQ)Roshin99Aún no hay calificaciones

- Record of Vessel TestsDocumento1 páginaRecord of Vessel TestsRoshin99Aún no hay calificaciones

- Incoming Equipment Inspection RecordDocumento1 páginaIncoming Equipment Inspection RecordRoshin99Aún no hay calificaciones

- Certificate For Mech Completion - Ready For Start UpDocumento1 páginaCertificate For Mech Completion - Ready For Start UpRoshin99Aún no hay calificaciones

- Continuity Test Record For Earthing Conductor For EquipmentDocumento1 páginaContinuity Test Record For Earthing Conductor For EquipmentRoshin99Aún no hay calificaciones

- Report For Quality Audit PDFDocumento1 páginaReport For Quality Audit PDFRoshin99Aún no hay calificaciones

- Insp & Test Records of Switching Units-HV - SwitchgearDocumento3 páginasInsp & Test Records of Switching Units-HV - SwitchgearRoshin99100% (2)

- Inspection Record For Air Handling Units: Record No.: - Page 1 of 2Documento2 páginasInspection Record For Air Handling Units: Record No.: - Page 1 of 2Schwihdi ZakAún no hay calificaciones

- Insp & Test Recds For Outgoing Units-LV SwitchgearDocumento2 páginasInsp & Test Recds For Outgoing Units-LV SwitchgearRoshin99Aún no hay calificaciones

- Site Engg Query & Status ReportDocumento1 páginaSite Engg Query & Status ReportRoshin99Aún no hay calificaciones

- Insp & Test Record Underground Piping PDFDocumento1 páginaInsp & Test Record Underground Piping PDFRoshin99Aún no hay calificaciones

- Ch.2 QADocumento9 páginasCh.2 QArogers4759100% (1)

- T 135 SeDocumento349 páginasT 135 SeAhmad FahmiAún no hay calificaciones

- Carburetor Tech Info PDFDocumento6 páginasCarburetor Tech Info PDFbatman2054Aún no hay calificaciones

- June 2004 QP - Paper 1 CIE Chemistry IGCSEDocumento16 páginasJune 2004 QP - Paper 1 CIE Chemistry IGCSEMedo O. EzzatAún no hay calificaciones

- Storage Tank Management Manual (USCG)Documento47 páginasStorage Tank Management Manual (USCG)MHavocAún no hay calificaciones

- Multec Gasoline Multi Port Fuel Injectors PDFDocumento3 páginasMultec Gasoline Multi Port Fuel Injectors PDFAlejandro SabaAún no hay calificaciones

- Mitsubishi - Commercial Spec Sheets - Industrial Engine - Variable Speed - S4Q2-Z365SPDocumento1 páginaMitsubishi - Commercial Spec Sheets - Industrial Engine - Variable Speed - S4Q2-Z365SPjoanna joannaAún no hay calificaciones

- 3-MasstoMassStoichiometryProblem1 2Documento3 páginas3-MasstoMassStoichiometryProblem1 2kjjkimkmkAún no hay calificaciones

- FDP Hwu Dubai (MSC)Documento123 páginasFDP Hwu Dubai (MSC)vijaymoorthy14Aún no hay calificaciones

- Mitsubishi Project Report PDFDocumento44 páginasMitsubishi Project Report PDFsameer kumar100% (1)

- 4-1 Sistema ElectricoDocumento3 páginas4-1 Sistema ElectricoMario HernandezAún no hay calificaciones

- Large Scale Recycling Process For Scrap Tires and Rubber ProductsDocumento11 páginasLarge Scale Recycling Process For Scrap Tires and Rubber ProductsMuhammad Abdul RaufAún no hay calificaciones

- Alto Shaam 7-14ESGDocumento4 páginasAlto Shaam 7-14ESGwsfc-ebayAún no hay calificaciones

- TM - 9 2350 292 34Documento20 páginasTM - 9 2350 292 34Opas Vichaikammart0% (1)

- EMD645FINALDocumento8 páginasEMD645FINALzona amrullohAún no hay calificaciones

- Service 31200353 04-14-11 ANSI EnglishDocumento230 páginasService 31200353 04-14-11 ANSI EnglishRoberto JuniorAún no hay calificaciones

- Exercise: AlkaneDocumento17 páginasExercise: AlkaneHenerita RayAún no hay calificaciones

- Group 6 - Industry Analysis - Oil and Natural GasDocumento24 páginasGroup 6 - Industry Analysis - Oil and Natural GasRehan TyagiAún no hay calificaciones

- Fuel Facilities DODDocumento40 páginasFuel Facilities DODJun KhoAún no hay calificaciones

- ZX125 135 225us Elec eDocumento1 páginaZX125 135 225us Elec ejacklyn ade putra100% (3)

- 0599Documento2 páginas0599Edinson Ariel Chavarro Quintero100% (1)

- Pure Aromatics Recovery From Coke Oven Light Oil (COLO) : Division Edeleanu Refining TechnologiesDocumento30 páginasPure Aromatics Recovery From Coke Oven Light Oil (COLO) : Division Edeleanu Refining TechnologiesIppo MakunouchiAún no hay calificaciones

- Pocket Guide ReactorsDocumento2 páginasPocket Guide ReactorsRanti WarfiAún no hay calificaciones

- Determination of Sulfur Dioxide Concentration in Ambient Air by Using Sulfur Dioxide AnalyzerDocumento1 páginaDetermination of Sulfur Dioxide Concentration in Ambient Air by Using Sulfur Dioxide AnalyzerWan NabilAún no hay calificaciones

- CVE312 Fluid Mechanics II New NOTEDocumento28 páginasCVE312 Fluid Mechanics II New NOTEOyedotun TundeAún no hay calificaciones

- Quy75 Catalogue - 20120726Documento26 páginasQuy75 Catalogue - 20120726Devii Nafri YantiAún no hay calificaciones

- Centaour 50 Solar TurbineDocumento2 páginasCentaour 50 Solar TurbineTifano KhristiyantoAún no hay calificaciones