Documentos de Académico

Documentos de Profesional

Documentos de Cultura

LG White Paper PLC PDF

Cargado por

chandanjha2010Descripción original:

Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

LG White Paper PLC PDF

Cargado por

chandanjha2010Copyright:

Formatos disponibles

Introducing the power of PLC

White paper

Introducing the power of PLC

Introduction 3

PLC is No.1 communication technology in Europe 4

Utility-owned network 5

Robustness of PLC installations 5

PLC integration into transformer stations 6

Network topology 6

Emissions 6

Dedicated frequency band and controlled output levels 6

OFDM PLC - A quantum leap forward in PLC technology 7

Interoperability 8

PLC offers the lowest total cost of ownership 9

PLC compared to other communication technologies for smart metering 10

Conclusion 11

2

Introducing the power of PLC

3

Introducing the power of PLC

Introduction

Power Line Communication (PLC) is a well-established

communications technology that was initially used

for telemetry purposes. The frst large-scale PLC

deployments took place in the 1990s. Today, PLC

technology has reached maturity with many vendors

offering fully operational communication solutions for a

wide range of industry applications.

In the late 1990s, energy utilities set out to use PLC

technology in the smart metering rollouts, which

has turned it into the dominant smart metering

communications technology in Europe. PLC proved to

deliver reliable performance at reasonable procurement,

installation and operation cost points.

In recent years, new open OFDM-based PLC

technologies have been developed and are currently

being feld-tested and deployed. This new generation

of PLC technology will provide higher communication

bandwidth for future advanced smart grid applications.

Landis+Gyr is a key PLC technology market player and

is actively involved in the development of this future

technology.

a single specifcation and standard for CENELEC

A-Band power line communications for smart grid

products and services.

Currently, large volumes of meters equipped with

PRIME technology are being installed in Spain. Their

number is expected to reach 1 million metering

points by March 2013.

According to ABI Research, PLC technology is the

number one smart metering technology in the world.

This is a remarkable success for PLC technology

considering the large number of national regulatory

and legislative bodies in and outside Europe promoting

the use of other communication technologies in smart

metering.

Source: ABI Research

4

Introducing the power of PLC

PLC communication is the number one

technology for smart metering in Europe

The table below shows the installed PLC endpoints in

Europe by country.

Country Endpoints

[millions]

% of installed AMM

base

Italy 36 99%

Sweden 3 58%

Finland 1.5 52%

Denmark 1.3 79%

France 0.3 Pilot

Spain 0.2 Beginning of rollout

Norway 0.15 76%

The European market data presented above has been

obtained from the BERG IN-SIGHT research report

PLC accounts for the majority of smart metering

installations in Scandinavia, whilst the Italian utility Enel

operates the largest PLC installation in Europe.

Large-scale PLC deployments:

France: In 2011, ERDF carried out a pilot of 300,000

metering points with PLAN+ PLC communications.

The pilot will be followed by a mass rollout of 35

million meters over the next fve years. Currently,

PLAN+ is the only technology available in the

market based on the international IEC 61334-5-1

standard, which is fully integrated with the smart

metering application standards of IEC 62056-61/62.

Several international chip manufacturers offer chips

supporting the PLAN+ technology.

Spain: Iberdrola has successfully completed

development of its next generation OFDM-

based PLC technology PRIME, which is now in

rollout phase. The PRIME PLC technology can

be integrated with the smart metering application

standards of IEC 62056-61/62. PRIME Alliance,

founded by a number of leading industry players

such as Iberdrola and Landis+Gyr, strives to develop

2. The utility provides the requested services directly

by investing in the necessary infrastructure. In this

case, PLC is the cost-effcient alternative based

on CAPEX and OPEX considerations. In addition,

PLC gives the utility complete control over the

communication network and, thereby, provides

the optimum basis to fulfll requirements set by the

regulator.

Robustness of PLC installations

PLC offers the simplest type of installation out

of all Neighborhood Area Network (NAN) access

technologies. Installation is Plug-and-Play in any

environment and does not require any additional work

other than installing meter hardware.

Compared to wireless access technologies (GPRS,

UMTS, RF Mesh, WiMax), PLC offers the following

advantages:

Immediate establishment of communication during

the installation process and, thereby, avoidance of

any costly waiting times for the installer

No antenna tuning or adjustment of antenna

direction required

Communication is also possible in diffcult

environments (for example, metal-shielded cases,

deep underground installations, etc.), where no

other access technology can provide a solution

Antenna cannot be removed during operation

(tampering protection), antenna cannot fail

(reliability). The fact that the communication

interface is powered by 230V offers intrinsic

security against tampering

5

Introducing the power of PLC

Utility-owned network

With the introduction of PLC, the energy distributor

adds value to his most important asset the distribution

network. In addition to the distribution of energy,

the same network also provides the basis for smart

metering-related communications.

By re-using the electricity distribution network

for communications, the utility can also re-use

maintenance tools and resources, thereby avoiding

the maintenance costs of a dedicated communication

network. With every extension of the electricity

distribution network, the communication network grows

accordingly.

In most EU countries, the regulator assigns

responsibility for smart metering services to the

network operator. The network operator has two

options to deal with this task:

1. The utility subcontracts service provision to a

telecom operator with a corresponding service-

based contract. In order to get the necessary

service guarantees, the utility has to enter into

costly service level agreements with the telecom

operator.

Network topology

PLC is the only NAN access technology that is

inherently linked to the topology of the power

distribution network.

Knowledge regarding the network topology, such as

problems and vulnerabilities on specifc nodes, is

extremely valuable information for a utility operator.

Managing a smart grid requires detailed and timely

information on the status of each node, potential

breakdowns and malfunctions. Only PLC can offer

such information without the installation of additional

infrastructure and separate communication networks.

GIS systems can be easily integrated into the PLC

infrastructure for visualization purposes.

Emissions

Compared to wireless access technologies, PLC

offers the advantage that no wireless emissions are

produced. Landis+Gyrs PLC operates in the Cenelec A

band, where emissions are strictly limited according to

international norms.

Dedicated frequency band and controlled

output levels

The Cenelec PLC standard EN 50065-1 is accepted

all over Europe. This standard specifes the output

levels for PLC transmissions and assigns a dedicated

frequency band (Cenelec A band) specifcally for

utility use. PLC is the only medium offering the utility a

protected frequency band for exclusive use. Exclusive

use of the dedicated frequency band is a prerequisite

for communication reliability over the lifetime of the

smart meter installation, which secures the utilitys

long-term investments. The Cenelec standard is

recognized within Europe and throughout the world.

This means that PLC users beneft from the wide range

of high volume equipment offered by a large number of

international manufacturers.

PLC transmits signals within a dedicated frequency

band and a maximum power level that conforms

to regulatory requirements. With over 10 years of

6

Introducing the power of PLC

Compared to other wired access technologies

(Ethernet, Fibre and PSTN), only PLC offers the key

advantage: the communication channel is directly linked

to the device itself. This means:

No installation of additional communication wiring is

required.

Communication is seamlessly established by

powering up the device.

No communication cables or equipment can be

removed or tampered with during operation.

PLC integration into transformer

stations

PLC communication is almost always relayed via a

transformer station. This offers major advantages:

It is possible to combine classic data concentrator

functions and smart grid/transformer station

automation functions in a single device at marginal

additional cost

Smart grid (transformer and substation automation)

features can be easily integrated into smart metering

infrastructure by using a common communication

network and IT infrastructure

PLC offers inherent physical security aspects other

solutions cannot offer:

Access to transformer stations is highly

protected and supervised.

Power cables are typically laid underground to

prevent tampering.

Carrying signals on 230V lines inherently

provides a degree of natural protection. Physical

access is much more diffcult than to a wireless

or low voltage network and presents a physical

danger.

PLC sniffng/jamming equipment is much more

diffcult to obtain than wireless sniffng/jamming

equipment.

7

Introducing the power of PLC

experience and rollouts of 40 million metering points,

Landis+Gyr is convinced that PLC networks can be

operated without running the risk of interfering with any

other communication services.

Finally, EN 50065-1 is backed by a comprehensive test

infrastructure. Renowned national and international test

institutes offer EN 50065-1 testing on a competitive

basis.

A quantum leap forward in PLC technology

With the introduction of OFDM (Orthogonal Frequency

Division Multiplex) PLC, the communication speed of

smart metering applications will increase dramatically.

While todays PLC technologies offer a physical layer

throughput of 2 to 5kbps, the new OFDM PLC will have

its throughput increased by a factor of 10.

Today, there are two different OFDM-based PLC

technologies available in the market:

PRIME PLC is supported by the PRIME Alliance

with over 50 members chaired by Iberdrola. The

technology has already won a strong market

position with an installed base of 200,000 PRIME

meters rolled out in Spain alone by the end of 2011.

G3 PLC is supported by the G3 PLC Alliance. The

driving force behind G3 is EDF in France. In the next

two to three years, EDF will be feld-testing G3 PLC

technology. Mass rollout will start in 2015.

Both technologies are open and have been adopted

as starting points of the offcial ITU standard, G

9955 Narrow-band OFDM power line communication

transceivers - Physical layer specifcation.

By supporting both technologies, Landis+Gyr is

prepared to take its PLC portfolio offering to the next

level.

Several technology manufacturers are providing PLC

chips in accordance with the IEC 61334-5-1 standard

and several smart metering solution providers are

offering end-to-end solutions based on interoperable

PLC components. PLC is the widest spread smart

metering communication technology, and it offers

components from different manufacturers. By investing

in standardized PLC technology, a utility can avoid

the risk of stranded investments due to proprietary

technology.

The standards framework on this page allows enough

fexibility to incorporate new PLC technologies, thus

providing a smooth upgrade path from todays feld

proven S-FSK technology towards the emerging OFDM

technologies.

8

Introducing the power of PLC

Interoperability

PLC is the only access technology with proven IEC

standards (IEC 61334 series). PLC standards form the

core of a comprehensive smart metering architecture

based on international standards.

The smart metering architecture shown on this page is

also considered as a basis for the standardization work

issued by the European Commission under the mandate

M/441. M/441 architecture is built around a PLC

communication stack that is structured to ft perfectly

into the existing application standards framework. The

OSI layering ensures expandability taking the evolution

of PLC technology into account, while at the same

time maintaining backwards compatibility with proven

solutions.

The installation takes just a few minutes.

Plug and play installation of the PLC meter:

Once the meter has been installed, it is ready to

communicate. This reduces the installation cost

of PLC communication to almost zero and is a

signifcant cost advantage over RF solutions.

Meters serve as repeaters thus strengthening the

network.

Establishing the PLC communication network:

Landis+Gyr supports the entire installation process

with powerful installation tools and the central

system. The PLC communication network itself

does not require an installation process.

Cost of operating and maintaining the smart

metering system (OPEX)

The cost of operating the PLC network is

independent of third-party network operators and

therefore low compared to 2G/3G operation costs.

But most importantly, because of the unmatched

communication reliability, the cost of human

intervention is minimal.

The PLC network needs very little maintenance

from the system side. Moreover, the PLC network

monitoring capabilities of the system enable basic

network supervision.

The frmware of the data concentrator and the meter

can be remotely updated; hence no additional site

visits are required.

9

Introducing the power of PLC

The combination of standardized PLC with the global

concept of the expandable COSEM data model offers

the user consistency between todays solutions and

future technologies and applications. The universal

message- based security features offered by the

application layer are independent of the PLC technology

and can even be used in any other communication

medium.

PLC offers the lowest Total Cost of

Ownership (TCO)

The TCO analysis of a smart metering system covers

the following aspects:

The cost of the smart metering equipment

The cost of installing the equipment and setting up

the system

The cost of operating and maintaining the system

In order to get a fair assessment of the TCO of a PLC-

based smart metering solution, the following points

must be considered:

Cost of smart metering equipment (CAPEX)

A PLC meter is the most cost-effective smart meter

due to the following:

PLC chip sets are mature and available from

many vendors. From the technical point of view,

integration into a meter is quite simple.

The large installed base has already driven the

cost down (economies of scale).

Cost of data concentrator:

In densely populated areas the ratio between metering

points and a data concentrator on average is 1:200 (and

can go up to 1:1000). This results in minimal costs for

each metering point.

Installation cost of feld equipment (OPEX)

Installation of the data concentrator:

Installation of the data concentrator is done at the

transformer station typically owned by the utility.

PLC compared to other communication

technologies for smart metering

In order for the utility to achieve a reliable

communication network and to fulfll the required

SLAs (Service Level Agreements) at the lowest Total

Cost of Ownership (TCO), it is essential to choose

the right communication technology. The selected

communication technology must ft in the geographical

environment and satisfy the utilitys business

requirements.

Today, there are basically four last mile*

communication technologies that can be used in smart

metering:

Power Line Communication (PLC)

RF Mesh

Point-to-point communication using a public mobile

network (2G/3G/4G)

Point-to-point communication using a private

broadband connection (e.g. FTTH)

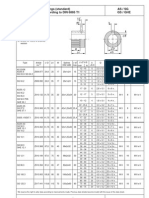

Key aspect

PLC RF Mesh

Public mobile

network

Broadband

connection

Meter point cost (incl. communication infrastructure such

as Data concentrator / RF collectors)

In medium to dense areas such as villages & cities

++ + - +

Meter point cost (incl. communication infrastructure such

as Data concentrator / RF collectors)

In rural areas

+ ++ - +

Meter point installation costs ++ 0 0 0

Performance for smart metering + + ++ ++

OPEX over lifetime ++ ++ -- ++

Risk of service discontinuation in 15 years ++ 0 - 0

Rating: ++ / + / 0 / - / --

As noted above, all four technologies have their

advantages and disadvantages, which need to be

carefully evaluated during the solution analysis phase.

Landis+Gyr is well positioned to assist its customers

with this task.

Introducing the power of PLC

10

In the comparison table on this page, these

technologies are rated based on key aspects applicable

to the smart metering solution.

Based on 25 years of experience in smart metering

in EMEA, Landis+Gyr considers PLC to be the last

mile technology that provides the most benefts to the

utilities.

*The last mile refers to the fnal leg of connectivity

from the utility to the consumer.

11

Introducing the power of PLC

Conclusion

With an installed base of over 40 million metering points

in Europe, PLC is by far the most commonly used

communication technology for smart metering.

Over the past 15 years, all advantages of the PLC

technology in large installations have been fully proven.

The electricity network was not designed to be used as

a communication channel; however, PLC technology is

mature enough to deal with even the most challenging

environments. Filtering techniques, repetition of

messages and sophisticated routing algorithms

guarantee exceptionally robust communication.

Connecting the meter to the PLC communication

network is just as simple as connecting the meter to the

mains. No additional work is required. The Landis+Gyr

PLC solution makes Plug-and-Play installation a reality.

By using PLC technology, the utility retains full control

over its distribution network. Smart metering based on

PLC is the frst step towards smart grid.

With the introduction of OFDM encoding, PLC is

brought to the next level, securing its prime position for

the next decade.

At Landis+Gyr, we believe that interoperability between

different manufactures is a must for successful smart

metering solutions. Based on the widely used PLC

technology and the IDIS (Interoperable Device Interface

Specifcation) initiative, we can offer maximum fexibility

and investment protection to our customers.

In summary, this report demonstrates that PLC, with its

low CAPEX and OPEX levels, is the most cost-effective

technology choice for smart metering rollout in densely

populated areas.

Authors:

Jrg Haas, Product Manager, Communication Devices

Daniel Lauk, Head Platform and Innovation

Thomas Schaub, Standards and Interoperability

Andreas Wirtz, Product Management, Post-rollout Offers

Landis+Gyr (Europe) AG

Theilerstrasse 1

6301 Zug

Switzerland

Tel: +41 (0)41 935 6000

Fax: +41 (0)41 935 6501

Email: info@landisgyr.com

Website: www.landisgyr.eu

Landis+Gyr is a registered trademark of

Landis+Gyr (Europe) AG, Switzerland

About Landis+Gyr

Landis+Gyr is the leading global provider of integrated

energy management products tailored to energy

company needs, and unique in its ability to deliver

true end-to-end advanced metering solutions. Today,

the company offers the broadest portfolio of products

and services in the electricity metering industry, and is

paving the way for the next generation of smart grid.

Landis+Gyr, a standalone growth platform of the

Toshiba Corporation and 40% owned by the Innovation

Network Corporation of Japan, operates in 30 countries

across fve continents, and employs 5,000 people with

the sole mission of helping the world manage energy

better.

More information is available at www.landisgyr.com.

D000044669 a en

También podría gustarte

- LG White Paper PLCDocumento11 páginasLG White Paper PLCiskandarn_el5735Aún no hay calificaciones

- Power Line CommunicationDocumento62 páginasPower Line CommunicationPantech ProLabs India Pvt LtdAún no hay calificaciones

- 4G Lte PDFDocumento29 páginas4G Lte PDFgjfjgjmgmjAún no hay calificaciones

- Synopsis: Submitted By: Mandeep Singh C09529 Eece 4 SEMDocumento10 páginasSynopsis: Submitted By: Mandeep Singh C09529 Eece 4 SEMOmji PandeyAún no hay calificaciones

- Alstom Digital Substation SolutionDocumento11 páginasAlstom Digital Substation SolutionHafeez AnsariAún no hay calificaciones

- WcdmaDocumento186 páginasWcdmaJc TuzonAún no hay calificaciones

- Implementation of A Distributed Rtu Monitoring System Using The Iec60870-5-104 Protocol Over Gprs Networks Arzuaga, A., Ojinaga, Z., Llano, A. Usyscom, Iberdrola SpainDocumento8 páginasImplementation of A Distributed Rtu Monitoring System Using The Iec60870-5-104 Protocol Over Gprs Networks Arzuaga, A., Ojinaga, Z., Llano, A. Usyscom, Iberdrola SpainSGQAún no hay calificaciones

- Andrew Britecell Plus User ManualDocumento241 páginasAndrew Britecell Plus User ManualFemi OketokiAún no hay calificaciones

- A Supplement To PLANT ENGINEERING and Control Engineering Magazines A Supplement To Control Engineering and PLANT ENGINEERING MagazinesDocumento16 páginasA Supplement To PLANT ENGINEERING and Control Engineering Magazines A Supplement To Control Engineering and PLANT ENGINEERING MagazinesIgnacio MarínAún no hay calificaciones

- Galli Paper 1Documento6 páginasGalli Paper 1Josh DineshAún no hay calificaciones

- Ijeee V4i3p101Documento4 páginasIjeee V4i3p101rutayisire steveAún no hay calificaciones

- #M2012104738 Public Safety LTE Global Edition enDocumento60 páginas#M2012104738 Public Safety LTE Global Edition ennm7713Aún no hay calificaciones

- Introduction To Power Line Communications (PLC)Documento6 páginasIntroduction To Power Line Communications (PLC)Brijendra KumarAún no hay calificaciones

- Acnw Assignmen T: Chaitanya Reddy 070911152 It-ADocumento6 páginasAcnw Assignmen T: Chaitanya Reddy 070911152 It-AChaitanya ReddyAún no hay calificaciones

- Paper Ieee PDFDocumento6 páginasPaper Ieee PDFchandanjha2010Aún no hay calificaciones

- Electric Powerline Networking For A Smart Home.Documento7 páginasElectric Powerline Networking For A Smart Home.pp1708340Aún no hay calificaciones

- AHa Isplc-11 Presentation v2 PublicDocumento19 páginasAHa Isplc-11 Presentation v2 Publicinna_2oo6Aún no hay calificaciones

- 7585 Alcatel Lucent Deploying Ipmpls Communications Networks Smart Grids PDFDocumento20 páginas7585 Alcatel Lucent Deploying Ipmpls Communications Networks Smart Grids PDFPaulo CorreiaAún no hay calificaciones

- PLC in Energy MarketsDocumento15 páginasPLC in Energy MarketsKarim SenhajiAún no hay calificaciones

- Implementing PRIME For Robust and Reliable Power Line Communication (PLC)Documento9 páginasImplementing PRIME For Robust and Reliable Power Line Communication (PLC)Anaraida Garcia BaigorriAún no hay calificaciones

- Presentaion 1Documento6 páginasPresentaion 1Sadik NadafAún no hay calificaciones

- Performance Evaluation of Future AMI Applications in Smart Grid Neighborhood Area NetworksDocumento6 páginasPerformance Evaluation of Future AMI Applications in Smart Grid Neighborhood Area NetworkstaksasAún no hay calificaciones

- FPP Technical+Solution FINALDocumento66 páginasFPP Technical+Solution FINALMuruganAún no hay calificaciones

- Smart Metering Comm StandardsDocumento6 páginasSmart Metering Comm StandardsFernando CercanoAún no hay calificaciones

- ISGF White Paper On Next Generation Smart Metering - IP MeteringDocumento10 páginasISGF White Paper On Next Generation Smart Metering - IP MeteringDipankar GhoshAún no hay calificaciones

- TG5700 RTU - SiemensDocumento2 páginasTG5700 RTU - Siemenssina20795100% (1)

- Mission Critical Utilities Network Teleprotection AppNoteDocumento15 páginasMission Critical Utilities Network Teleprotection AppNoteBook LoverAún no hay calificaciones

- Overview Power Line CommunicationDocumento18 páginasOverview Power Line CommunicationIrfan Irawan Cbn100% (1)

- Communication of Smart GridDocumento19 páginasCommunication of Smart Gridanz77Aún no hay calificaciones

- Datatransmissionthroughpowerline 150307034245 Conversion Gate01 PDFDocumento10 páginasDatatransmissionthroughpowerline 150307034245 Conversion Gate01 PDFSanthosh V RaajendiranAún no hay calificaciones

- Medidores TRON - EM420i en 02-14Documento4 páginasMedidores TRON - EM420i en 02-14JuanRosas100% (1)

- Industrial Automation PDFDocumento9 páginasIndustrial Automation PDFRadu CostinAún no hay calificaciones

- Ziegler Protection1Documento10 páginasZiegler Protection1Jose Alberto RodriguezAún no hay calificaciones

- LightRadio WP1 Technical OverviewDocumento16 páginasLightRadio WP1 Technical Overviewmaster irtAún no hay calificaciones

- Power Line Carrier Communication (PLCC)Documento8 páginasPower Line Carrier Communication (PLCC)Mohit JunejaAún no hay calificaciones

- PLCCDocumento89 páginasPLCCBipandeep Gill100% (2)

- Alagappa Chettiar College of Engineering and Technology-Karaikudi 630 004Documento12 páginasAlagappa Chettiar College of Engineering and Technology-Karaikudi 630 004Ashwin JilAún no hay calificaciones

- Siemens Power LinkDocumento14 páginasSiemens Power Linkarya_85Aún no hay calificaciones

- IDIS (Interoperable Device Interface Specification)Documento7 páginasIDIS (Interoperable Device Interface Specification)Karim SenhajiAún no hay calificaciones

- What Does PLC IoT MeanDocumento4 páginasWhat Does PLC IoT MeanjackAún no hay calificaciones

- 5g WorldDocumento4 páginas5g WorldSourav ChandraAún no hay calificaciones

- 5G MM WavesDocumento44 páginas5G MM WavesMahendra singhAún no hay calificaciones

- SISTEMA Onda PortadoraDocumento12 páginasSISTEMA Onda PortadoraLuis Vargas DiazAún no hay calificaciones

- CHAP 2bDocumento47 páginasCHAP 2bGANESAN AAún no hay calificaciones

- OSGP OverviewDocumento3 páginasOSGP OverviewRafik CherniAún no hay calificaciones

- ECv3i1 Energy Transformation TechnologiesDocumento4 páginasECv3i1 Energy Transformation TechnologiesSreenu ThejaAún no hay calificaciones

- MKT2014066262EN 9500 MPR BrochureDocumento12 páginasMKT2014066262EN 9500 MPR BrochureEgberi1Aún no hay calificaciones

- EEC-753 Industrial Training SeminarDocumento31 páginasEEC-753 Industrial Training SeminarRbh ThinksAún no hay calificaciones

- Planet Fieldbus: Devicenet and Ethernet/Ip: Positioning DrivesDocumento32 páginasPlanet Fieldbus: Devicenet and Ethernet/Ip: Positioning DrivesSergi Pons PallejaAún no hay calificaciones

- Key Technologies For IMT-Advanced Mobile Communication SystemsDocumento20 páginasKey Technologies For IMT-Advanced Mobile Communication SystemsAshish KumarAún no hay calificaciones

- Gas System and Solution Overview Smart Gas Metering/Advanced Metering InfrastructureDocumento17 páginasGas System and Solution Overview Smart Gas Metering/Advanced Metering InfrastructureLuis Ballesteros ChoqueAún no hay calificaciones

- M00103 BR en 3 Netcon 500 BrochureDocumento4 páginasM00103 BR en 3 Netcon 500 BrochureMochamad RidwanAún no hay calificaciones

- SP Water Utilities Experiences 06242016Documento6 páginasSP Water Utilities Experiences 06242016perdona9373Aún no hay calificaciones

- RA1611003011229Documento23 páginasRA1611003011229Shiv Pratap SinghAún no hay calificaciones

- KEYMILE Products ApplicationsDocumento20 páginasKEYMILE Products ApplicationsFarshad RouhaniAún no hay calificaciones

- The 5G Revolution: How the Next Generation of Wireless Will Change EverythingDe EverandThe 5G Revolution: How the Next Generation of Wireless Will Change EverythingAún no hay calificaciones

- Networked Control System: Fundamentals and ApplicationsDe EverandNetworked Control System: Fundamentals and ApplicationsAún no hay calificaciones

- SAE and the Evolved Packet Core: Driving the Mobile Broadband RevolutionDe EverandSAE and the Evolved Packet Core: Driving the Mobile Broadband RevolutionCalificación: 3 de 5 estrellas3/5 (2)

- Tutorial Eusipco Tonello PDFDocumento150 páginasTutorial Eusipco Tonello PDFchandanjha2010Aún no hay calificaciones

- ThesisMaster1 PDFDocumento195 páginasThesisMaster1 PDFchandanjha2010Aún no hay calificaciones

- Paper Ieee PDFDocumento6 páginasPaper Ieee PDFchandanjha2010Aún no hay calificaciones

- Paper Ieee PDFDocumento4 páginasPaper Ieee PDFchandanjha2010Aún no hay calificaciones

- Swot Analysis of PTCLDocumento5 páginasSwot Analysis of PTCLM Aqeel Akhtar JajjaAún no hay calificaciones

- Hatch Cover Maintenance PlanDocumento5 páginasHatch Cover Maintenance Planvinay3972Aún no hay calificaciones

- Opoc Engine ReportDocumento34 páginasOpoc Engine Reportapi-32792277367% (3)

- Building Information Modeling BIM Systems and TheiDocumento13 páginasBuilding Information Modeling BIM Systems and Theipurvakul10Aún no hay calificaciones

- Compacted Graphite Iron Was First Patented at About The Same Time As Ductile Iron in The Late 1940Documento4 páginasCompacted Graphite Iron Was First Patented at About The Same Time As Ductile Iron in The Late 1940Agustin GerardoAún no hay calificaciones

- Analysis of Business EnvironmentDocumento10 páginasAnalysis of Business Environmentrashmi123vaish50% (2)

- Kota StationDocumento5 páginasKota StationshashankjeeAún no hay calificaciones

- Arni AdvertisementDocumento2 páginasArni AdvertisementHemanthAún no hay calificaciones

- Revista Stiinte Politice Issue 42Documento264 páginasRevista Stiinte Politice Issue 42Costel111Aún no hay calificaciones

- User Manual For Online Super Market WebsiteDocumento3 páginasUser Manual For Online Super Market WebsiteTharunAún no hay calificaciones

- Digital Data, Digital SignalDocumento8 páginasDigital Data, Digital SignalBastomi Adi NugrohoAún no hay calificaciones

- ReadMe PDFDocumento31 páginasReadMe PDForaleculero117Aún no hay calificaciones

- CCNA - Access List QuestionsDocumento3 páginasCCNA - Access List QuestionsBaaska214Aún no hay calificaciones

- Bangkok-Singapore CDM JournalDocumento20 páginasBangkok-Singapore CDM JournalvasidhartaAún no hay calificaciones

- Invisible EyeDocumento16 páginasInvisible EyeSushmita Paul0% (1)

- Oracle9i Database Installation Guide Release 2 (9.2.0.1.0) For WindowsDocumento274 páginasOracle9i Database Installation Guide Release 2 (9.2.0.1.0) For WindowsrameshkadamAún no hay calificaciones

- IJV MARLEY AutomotiveDocumento6 páginasIJV MARLEY AutomotiveUmer HamidAún no hay calificaciones

- CE ThesisDocumento210 páginasCE ThesisKristin ArgosinoAún no hay calificaciones

- As / SG Gs / Ghe Dimensions For Couplings (Standard) Bore With Keyway According To DIN 6885 T1Documento1 páginaAs / SG Gs / Ghe Dimensions For Couplings (Standard) Bore With Keyway According To DIN 6885 T1hadeAún no hay calificaciones

- Chapter 3: Operating-System StructuresDocumento31 páginasChapter 3: Operating-System StructuresDiamond MindglanceAún no hay calificaciones

- Unit - 1: (B) Difference Between Thermodynamcis and Heat TransferDocumento66 páginasUnit - 1: (B) Difference Between Thermodynamcis and Heat TransferSayyadh Rahamath Baba100% (1)

- Parallel Processing:: Multiple Processor OrganizationDocumento24 páginasParallel Processing:: Multiple Processor OrganizationKrishnaAún no hay calificaciones

- Presentation 1Documento12 páginasPresentation 1Varun MaheshwariAún no hay calificaciones

- LRS Trading StrategyDocumento24 páginasLRS Trading Strategybharatbaba363Aún no hay calificaciones

- Ancient Civilizations AssignmentDocumento3 páginasAncient Civilizations Assignmentapi-240196832Aún no hay calificaciones

- CBB Exam Preparation CourseDocumento2 páginasCBB Exam Preparation CourseaadmaadmAún no hay calificaciones

- Flight Training Instruction: Naval Air Training CommandDocumento174 páginasFlight Training Instruction: Naval Air Training CommandITLHAPN100% (1)

- Homework 1Documento3 páginasHomework 1Bukhosi MsimangaAún no hay calificaciones

- Seminar ReportDocumento27 páginasSeminar ReportnitinAún no hay calificaciones

- Brake Actuator Instruction - ManualDocumento32 páginasBrake Actuator Instruction - ManualJoeAún no hay calificaciones