Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Esquire Builders Hoist Opt & Maint Manual

Cargado por

mailme_vijuDerechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Esquire Builders Hoist Opt & Maint Manual

Cargado por

mailme_vijuCopyright:

Formatos disponibles

TOWER HOIST

HEAVY DUTY

1000 33

INSTALLATION AND OPERATING

INSTRUCTION MANUAL

WORKS: - PLOT 316-317, ROAD H, G.I.D.C.

POR-RAMANGAMDI-391 243

DIST. VADODARA, GUJARAT, INDIA.

: (0265) 2830189, 2830965, Fax: 2830 594.

ESQUIRE TOWER HOIST

HEAVY DUTY

(1000 - 33)

BEFORE THE MACHINE IS COMMISSIONED, PLEASE READ THE

MANUAL THOROUGHLY.

GENERAL INSTRUCTIONS:

1: Clean the whole machine once a day

2: Cover the machine with plastic when not in use

3: Lubricate the machine DAILY

4: Periodically inspect the wearing parts and check that none of the nuts and

bolts are loose.

SPECIFICATIONS:

Models 1000.33 (HEAVY DUTY)

Capacity (Gross) 1000 Kg.

Height 15 mts. 100 mts.

Wire Rope Dia. 12 mm

Trolley Speed 30 mts./min

Primemover 12 hp Double cylinder, air

cooled Diesel Engine or 12.5 hp

Elec. Motor

Power Transmission:

Power is transmitted from engine/motor to wire rope drum via fiber roller shaft, mounted on

gunmetal bushed pedestal. Fiber roller shaft transmit power to wire rope drum as and when require

by friction drive when both bring together by operating handle. Fiber roller shaft is driven by

engine/motor through chain drive.

Lubrication:

Forced feed lubricators (Grease cups/ Nipples) are provided at all necessary points that are easily

accessible.

Optional Items:

Pipe scaffolding for erecting the tower hoist.

Tilting bucket trolley system for conveying of wet concrete during Beam / column/slab

casting.

Discharge chutes.

1

INSTRUCTIONS FOR INSTALLATION

Before installing the hoist, ensure that a foundation is ready as per drawing. If the soil is loose

type, ensure that the sides are shored, to prevent the pit from collapsing.

Examine various sections of hoist after arrival at site. Check lubrication of all parts; fill the

radiator with water if the engine is water cooled. Check oil level of engine. Fill fuel tank with

HIGH SPEED DIESEL oil. Before starting the engine, crank few turns to check the movements.

INSTRUCTIONS FOR ERECTION

Place the bottom piece of tower structure with pulley in the pit; on the side perpendicular to the

building, and opposite of the mixer, Rear parts of the structure should be touching the pit side.

Bolt or nail down the plate to the foundation of the pit either with 16 mm x 50 mm rods or by

foundation bolts. The wire rope pulley fitted on the tower structure should be towards the

WINCH MECHANISM and above the pit level, to avoid the touching of wire rope to the ground.

After the bottom piece is fixed, place the first section of the tower on top of it and bolt it. Care

should be taken to maintain the PLUMB of the tower. It should be ensured that proper alignment

is maintained and there should be no GAP between matching tower structures. Continue this

process till required height is obtained.

Place the top section with pulley on the tower structure at the desired height with the hook side

facing towards inside of the pit.

Remove the top roller and bottom locking flats on the channel platforms, and place it against the

tower structure such that the bottom rollers are in contact with the tower structure Replace the top

ROLLER and the bottom FLAT to the channel platform such that the leading edge of the tower is

between the top roller and the bottom roller.

Keep the winch as far away as possible from the pit and never less than 15 FEET.

Release the brake of the winch mechanism. Pull the wire rope out and pass it through the bottom

pulley of the tower, top pulley of the top piece, through the pulley of channel platform and bolt it

with the hook provided at the top of the tower structure.

Anchor the winch mechanism firmly to the ground by providing 4 Nos. crossbars in the lugs

provided. Place sand bags in front of the wheels as an extra precaution.

2

OPERATING INSTRUCTIONS

1.

After installation of the hoist please run the channel platform with empty bucket without load for

checking the alignment of the moving parts. Also set the clutch and brake if necessary.

2.

To move the channel platform upward push the operating lever of the winch to the maximum

position engaging the wire rope drum with the fiber roller assembly for friction driver and release

it from braking.

3.

To stop the channel platform at the desired height, pull the operating lever to the maximum

position. This will disengage the wire rope drum from its contact with the fiber roller drive and

engage the same with the brake shoe.

4.

To lower the bucket to the ground, hold the operating lever halfway to enable the wire rope drum

to get disengaged from the brake shoe without getting engaged to the fiber roller drive. The

operator should be alert to control the descend of the bucket.

PROTECT THE WINCH MECHANISM AND WIRE ROPE FROM EXTERNAL

AGENCIES AND DO NOT ALLOW DUST TO SETTLE ON THE SURFACE.

3

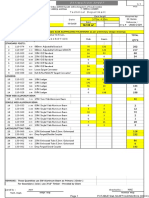

SPARE PART LIST

WIRE ROPE DRUM SHAFT ASSLY WITH BRAKE SHOE

Sr.

Part No. Description

Nos.

Remarks

No. Reqd.

01. HD-100-01 Pedestal for wire Rope Drum 02

02 HD-100-02 Shaft for Wire Rope Drum 01

03 HD-100-03 Eccentric Boss 02

04 HD-100-04 Key for Eccentric Boss 02

05 HD-100-05 G.M. Bush for Drum Flange 02

06 HD-100-06 Drum Flange 02

07 HD-100-07 Wire Rope Drum Pipe 01

08 HD-100-08 Packing for Wire Rope Drum 02

09 HD-100-09 Op. Lever Handle (C.I.) 01

10 HD-100-10 Key for Op. Lever Handle 01

11 HD-100-11 Op. Lever MS Part 01

12 HD-100-12 Counter Wt. Pc. 01

13 HD-100-13 Wire Rope 01

14 HD-100-14 Clamps for Wire Rope 02

15 HD-100-15 Brake Shoe (Feb.) 02

16 HD-100-16 Brake liner with brass screw 02

17 HD-100-17 Grease cups/ Nipples 04

5

SPARE PART LIST

FIBER ROLLER SHAFT ASSLY

Sr. Part No. Description Nos. Remarks

No. Reqd.

01. HD-200-01 Pedestal for Fiber Roller Shaft 02

02 HD-200-02 G.M. Bush for Fiber Roller Pedestal 02

03 HD-200-03 Shaft for Fiber Roller 01

04 HD-200-04 Fiber Washer Hub (MS) 02

05 HD-200-05 Cover for Hub (C.I.) 02

06 HD-200-06 Fiber Washer 14

07 HD-200-07 Key for Fiber Washer Hub 02

08 HD-200-08 Adj. Washer for Shaft (Fiber Roller) 02

09 HD-200-09 70 Teeth Sprocket 01

10 HD-200-10 Key for 70 Teeth Sprocket 01

11 HD-200-11 Thrust Bearing 02

12 HD-200-12 Grease cups/Nipples 02

7

SPARE PART LIST

TOWER WITH TOP PIECE & BOTTOM PIECE

Sr. Part No. Description Nos. Remarks

No. Reqd.

01. HD-400-01 Tower Std. Length 3Mt./ 2Mt./2.5Mt.

02 HD-400-02 Top Tower Pc. 0.5 Mt. /2.5Mt. 01

03 HD-400-03 Top Pulley Bracket comp. Assly. 01

04 HD-400-04 Bottom Tower Pc. 2.5 Mt. 01

05 HD-400-05 Bottom Pulley Bracket comp. Assly. 01

06 HD-400-06 U Clamp for Wire Rope Locking 01

07 HD-400-07 Locking Flat with Slot

SPARE PART LIST

CHANNEL PLATFORM & BUCKET ASSLY

Sr. Part No. Description Nos. Remarks

No. Reqd.

01. HD-500-01 Step Top Roller 02

02 HD-500-02 G.M. Bush for Step Roller 02

03 HD-500-03 Pin (Th.) for Step Roller With Nut 02

04 HD-500-04 Plain Bottom Roller 02

05 HD-500-05 G.M. Bush for Plain Bottom Roller 02

06 HD-500-06 Bottom Roller Shaft 01

07 HD-500-07 Dist. Piece for Roller 02

08 HD-500-08 Locking Collar for Roller 02

09 HD-500-09 Locking Cam Shaft 01

10 HD-500-10 Locking Eccentric Boss 02

11 HD-500-11 Key for Eccentric Boss 02

12 HD-500-12 Locking Flat (Stopper) 02

13 HD-500-13 Comp. Spring (small) for Handle 01

14 HD-500-14 Comp. Spring for Pulley Bracket 01

15 HD-500-15 Sq. Shaft for center Bracket 01

16. HD-500-16 Wire Rope Pulley 01

17 HD-500-17 G.M. Bush for Wire Rope Pulley 01

18 HD-500-18 Pin for Wire Rope Pulley 01

19 HD-500-19 Guard for Rope Pulley 01

20 HD-500-20 Bucket 01

21 HD-500-21 Bucket Bend Angle with Taper Pins 02

22 HD-500-22 Guide Channel for Bucket 02

23 HD-500-23 Lever for Bucket lock 01

24 HD-500-24 Op. Handle Piece for Bucket 01

25 HD-500-25 Grease Cups/Nipples 05

9

350

125

3

2

2

M16

FOUNDATION DETAIL FOR TOWER HOIST ON GROUND LEVEL

SECTION - A A

1750

RCC 600 X 600

X 400 DEEP

BOTTOM TOWER CENTER LINE

TOWER

STRUCTURE

G.L.

1

7

5

0

A

SCAFFOLDING

FOUNDATION BOLT SIZE M16 X 300 LONG WITH DOUBLE HEX. NUT & PLAIN WASHER (BY CLIENT)

FOUNDATION POCKET SIZE 100 X 100 X 300 DEEP

100

1

5

0

3

0

0

600

4

0

0

6

0

0

600

SCAFFOLDING CENTER

200 / 225

1

0

0 A

G.L.

11

350

100

500

3

2

2

M16

FOUNDATION DETAIL FOR TOWER HOIST IN PIT

SECTION - A A

1750

RCC

BOTTOM TOWER CENTER LINE

1600

TOWER

STRUCTURE

A

G.L.

356

3

5

6

1

7

5

0

229 BK.WALL

A

1

0

0

0

(

M

I

N

.

I

F

I

N

P

I

T

)

SCAFFOLDING

FOUNDATION BOLT SIZE M16 X 300 LONG WITH DOUBLE HEX. NUT & PLAIN WASHER (BY CLIENT)

FOUNDATION POCKET SIZE 100 X 100 X 300 DEEP

100

60

C

L

E

A

R

G

A

P

(

T

O

S

U

I

T

S

I

T

E

)

200 / 225

4

5

0

M

M

1

5

0

G.L.

12

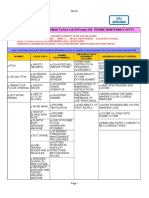

SPARES PART LIST

PRIME MOVER & DRIVE ASSLY

Sr. Part No. Description Nos. Remarks

No. Reqd.

01. HD-300-01 Roller Chain with Lock Complete 01

02 HD-300-02 Lock only for Roller Chain 01

03 HD-300-03 Half Link for Roller Chain 01

04 HD-300-04 Engine/Motor Chain Wheel 11 teeth 01

05 HD-300-05 Key for 11 Teeth Chain Wheel 01

06 HD-300-06 Cabin Complete 01

07 HD-300-07 Guard for Chain 01

08 HD-300-08 Stand only for Ele. Motor 01

09 HD-300-09 Stand only for Starter and Switch 01

PACKING LIST

ENGINE STARTING HANDLE 01

ENGINE / MOTOR WARRANTY CARD 01

SCREW DRIVER 01

FIX SPANNER 12 X 13 01

FIX SPANNER 14 X 17 01

FIX SPANNER 17 X 19 01

FIX SPANNER 24 X 27 01

RING SPANNER 17 X 19 01

RING SPANNER 24 X 27 01

TUBULAR BOX SPANNER 21 X 23 (For Pneumatic wheel) 01

MS ROD (For Pneumatic wheel) 01

WIRE ROPE CLAMPS 12 mm 02

GREASE GUN 01

13

MANUFACTURERS WARRANTY

In the events of any defect being discovered within the period of 6 months

from the date of delivery, then provided that the alleged defective part if

returned to Dealer/works (freight paid), we shall examine such part carefully

and of satisfied, the defect replaced with a new one free of cost.

The defective part, which has to be replaced, will become property of the

company that is Esquire machines pvt. Ltd, Vadodara.

The benefit of this guarantee is to the first owner and cannot be transferred.

WE ARE NOT RESPONSIBLE FOR:

Electrical motor, starter or engine. The company will pass on to the

customer the benefit of any guarantee given by such manufacturers, and will

on behalf of customer take up with such manufacturers any complaints

which they may have regarding the workmanship or material.

Defects due to wear & tear, accident, improper adjustment, misuse or

neglect of maintenance, etc.

Spare parts manufactured by third parties or by the customer.

WARRANTY IS FOR FOLLOWING EQUIPMENT:

Machine No.: - ______________________

Guarantee Card No.: - ______________________.

Invoice No.: - ______________________ Date: - ___________

Hoist:- Heavy duty _________Mediumduty________ Light duty_________

Engine Make: - 12 HP / HTC / Kirloskar, Air cooled, Sr. No.________

Engine Type: - Normal / Hsd.-SR

Electric Motor: - 12.5 HP / 15 HP / Crompton / Kirloskar / NGEF

Electric Motor Sr.No. _________________

Wheels.:- Pneumatic / M.S.

Optional: - Duel Drive.

Name & Address of Purchaser:

________________________________

________________________________ For & On behalf of

_____________________________________

______________________________________ ESQUIRE

14

También podría gustarte

- Builder Hoist Erection JSA HSE ProfessionalsDocumento2 páginasBuilder Hoist Erection JSA HSE ProfessionalsMAM ENERGINDOAún no hay calificaciones

- POTABLE Slab SCAFFOLDING BOQ (CRCC)Documento1 páginaPOTABLE Slab SCAFFOLDING BOQ (CRCC)Mohamed AdelAún no hay calificaciones

- 1370323828p - TRX 2319Documento2 páginas1370323828p - TRX 2319Anonymous e3yfLHTBv100% (1)

- Potain Tower Cranes Spec 7aa631Documento8 páginasPotain Tower Cranes Spec 7aa631Ismail SaziliAún no hay calificaciones

- Safe Operating Manual of Vibro HammerDocumento1 páginaSafe Operating Manual of Vibro HammerDan AlbertAún no hay calificaciones

- Method Statement For External Painting Work With Using Suspended PlatformDocumento22 páginasMethod Statement For External Painting Work With Using Suspended PlatformĐặng Quang HuyAún no hay calificaciones

- (UG10) Builder Hoist PDFDocumento2 páginas(UG10) Builder Hoist PDFavinashAún no hay calificaciones

- 2.0 Method StatementDocumento2 páginas2.0 Method StatementArden NeriAún no hay calificaciones

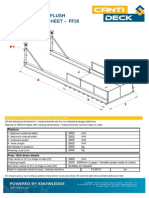

- FF35 CantiDeck Data SheetDocumento1 páginaFF35 CantiDeck Data SheetAndreas AntonopoulosAún no hay calificaciones

- Method Statement Lifting BP6 SiloDocumento34 páginasMethod Statement Lifting BP6 SiloCak Ijiey100% (1)

- Daily Pre-Start Checklist For Concrete Mixer Truck: Form: HDEC-HSE-CE-007 (E)Documento1 páginaDaily Pre-Start Checklist For Concrete Mixer Truck: Form: HDEC-HSE-CE-007 (E)hsepp lausememe100% (2)

- Concrete Batching PlantDocumento6 páginasConcrete Batching PlantBentara JururundingAún no hay calificaciones

- ECO DF Polymer PDFDocumento5 páginasECO DF Polymer PDFDeepak GareraAún no hay calificaciones

- Tower Crane InstallationDocumento6 páginasTower Crane Installationanon_177735386Aún no hay calificaciones

- PT-03 JSA Dismantling of Slip Form (22-05-09)Documento10 páginasPT-03 JSA Dismantling of Slip Form (22-05-09)M Waqas HabibAún no hay calificaciones

- Scaffolding HIRADocumento15 páginasScaffolding HIRAlina ekawatiAún no hay calificaciones

- Fabric Installation Details PDFDocumento5 páginasFabric Installation Details PDFDenise Koh Chin HuiAún no hay calificaciones

- Demolition Method Statement For Building Structures or Services - Method Statement HQDocumento5 páginasDemolition Method Statement For Building Structures or Services - Method Statement HQmody100% (2)

- Kerb and Channel Machine Placed Concrete PDFDocumento6 páginasKerb and Channel Machine Placed Concrete PDFbala subramanyamAún no hay calificaciones

- Lifting & Erection Work ChecklistDocumento1 páginaLifting & Erection Work ChecklistSreejith SureshAún no hay calificaciones

- Method Statement For General Concrete Work and Cutting Bending of Steel ReinforcementDocumento4 páginasMethod Statement For General Concrete Work and Cutting Bending of Steel ReinforcementSandip PaulAún no hay calificaciones

- SuperDeck User ManualDocumento21 páginasSuperDeck User Manualmikefara67% (3)

- Catalogo Chaglin YZ12HDDocumento4 páginasCatalogo Chaglin YZ12HDIwa RizaAún no hay calificaciones

- JSA - Main Turbine Lub Oil Pumps - OHDocumento2 páginasJSA - Main Turbine Lub Oil Pumps - OHShubham Gupta0% (1)

- IS803 - Code of Practice For Design Fabrication and Erection of Vertical Mild Steel Cylinderical Welded Oil StorageDocumento98 páginasIS803 - Code of Practice For Design Fabrication and Erection of Vertical Mild Steel Cylinderical Welded Oil StoragePankaj DhimanAún no hay calificaciones

- 286 Concrete Pump SafetyDocumento1 página286 Concrete Pump Safetyamolmanave6049Aún no hay calificaciones

- MAIT and XCMG Safety Checklists RefDocumento2 páginasMAIT and XCMG Safety Checklists RefSuresh Devarajan100% (1)

- Slip Form (Our Report)Documento16 páginasSlip Form (Our Report)Simran DeepAún no hay calificaciones

- Work Method Statement AtsDocumento2 páginasWork Method Statement AtsYasirSwatiAún no hay calificaciones

- Weekly Monthly Inspection-Pdf-En PDFDocumento1 páginaWeekly Monthly Inspection-Pdf-En PDFMohamed Moustafa ElashwahAún no hay calificaciones

- Method Statement For Assembly of 200 Ton Crawler CraneDocumento7 páginasMethod Statement For Assembly of 200 Ton Crawler CraneAnjo MolinaAún no hay calificaciones

- Piling Rig Plant Pre-Acceptance ChecklisDocumento3 páginasPiling Rig Plant Pre-Acceptance Checklisosama F. MohamedAún no hay calificaciones

- Calculation - GBPDocumento2 páginasCalculation - GBPFaiyazAún no hay calificaciones

- Gondola Load CalculationsDocumento6 páginasGondola Load Calculationssaskia0% (1)

- Concrete Pump TPIDocumento1 páginaConcrete Pump TPIWakil AhmadAún no hay calificaciones

- Vibro Hammer ChecklistDocumento2 páginasVibro Hammer ChecklistAbdus Samad100% (1)

- Ladder Inspection ChecklistDocumento1 páginaLadder Inspection ChecklistStansilous Tatenda NyagomoAún no hay calificaciones

- SWP 02 - Use of Mobile ScaffoldDocumento4 páginasSWP 02 - Use of Mobile ScaffoldGerald Wong NttAún no hay calificaciones

- Installation of The Mobile ScaffoldingDocumento7 páginasInstallation of The Mobile ScaffoldingBiswajit BiswasAún no hay calificaciones

- MS FOR INSTALLATION OF TOWER CRANE BETOX-200 Rev 1Documento5 páginasMS FOR INSTALLATION OF TOWER CRANE BETOX-200 Rev 1sattiAún no hay calificaciones

- Escorts F15 Pick and Carry Crane PDFDocumento2 páginasEscorts F15 Pick and Carry Crane PDFVenugopal SriAún no hay calificaciones

- Checklist For Equipment Inspection BOOM PLACERDocumento2 páginasChecklist For Equipment Inspection BOOM PLACERIdada Ezekiel100% (1)

- Job Safety Analysis: (Risk Assessment)Documento8 páginasJob Safety Analysis: (Risk Assessment)Ped KapedAún no hay calificaciones

- Nitoproof 230Documento2 páginasNitoproof 230Balasubramanian Ananth50% (2)

- Form Inspection Premob - Quarterly (1) - 2Documento26 páginasForm Inspection Premob - Quarterly (1) - 2Ryan RhamdhaniAún no hay calificaciones

- Statement of Construction Method - PACKAGE J - Expansion of Wastewater Treatment Plant (Repaired2)Documento23 páginasStatement of Construction Method - PACKAGE J - Expansion of Wastewater Treatment Plant (Repaired2)Lemy ChithuanAún no hay calificaciones

- 10 Risk Assessment - Pot BearingDocumento1 página10 Risk Assessment - Pot BearingEticala RohithAún no hay calificaciones

- APPENDIX 1 Issues For Method Statements in Industrial Roof WorkDocumento3 páginasAPPENDIX 1 Issues For Method Statements in Industrial Roof WorkJulianna BakerAún no hay calificaciones

- Polyseal 1PU: One Part Polyurethane Joint SealantDocumento2 páginasPolyseal 1PU: One Part Polyurethane Joint SealantVaittianathan MahavapillaiAún no hay calificaciones

- Operating Instructions: Hydraulic Climbing EquipmentDocumento20 páginasOperating Instructions: Hydraulic Climbing Equipmentemadnaguib100% (2)

- Fall Protection Work Plan - Roof CladdingDocumento2 páginasFall Protection Work Plan - Roof CladdingGibbs PerAún no hay calificaciones

- Maintenance: 1.3 General Maintenance Chart For Hitachi S6R EngineDocumento34 páginasMaintenance: 1.3 General Maintenance Chart For Hitachi S6R EngineKolo BenduAún no hay calificaciones

- Cmci Cmci: Cemtec 200Documento2 páginasCmci Cmci: Cemtec 200pravi3434Aún no hay calificaciones

- Davies 5 700 Liquid Tile Primer PDFDocumento1 páginaDavies 5 700 Liquid Tile Primer PDFKissa DolautaAún no hay calificaciones

- Safe Operating ProcessDocumento22 páginasSafe Operating ProcessMahesh MunratiwargoudAún no hay calificaciones

- Manual PDFDocumento70 páginasManual PDFUsama PopatiaAún no hay calificaciones

- Truck TipplerDocumento54 páginasTruck TipplerRAJAT DEO AGRAWAL100% (2)

- Freightliner Fld120Documento19 páginasFreightliner Fld120LO Consigo Antofagasta75% (4)

- Cement Mixer Model Mx-80 Owner'S/Operator'S - Parts ManualDocumento12 páginasCement Mixer Model Mx-80 Owner'S/Operator'S - Parts Manualrelh62Aún no hay calificaciones

- 180TCD Metric ManualDocumento6 páginas180TCD Metric ManualJose GonzalezAún no hay calificaciones

- Ifa (Border Roads) Manual: Controller General of Defence Accounts West Block-V, R.K. Puram, New Delhi-110066Documento293 páginasIfa (Border Roads) Manual: Controller General of Defence Accounts West Block-V, R.K. Puram, New Delhi-110066mailme_vijuAún no hay calificaciones

- Load Chart of MC Crane 115Documento2 páginasLoad Chart of MC Crane 115shivamkmr41Aún no hay calificaciones

- Bosch Spare Price 20131Documento371 páginasBosch Spare Price 20131mailme_viju100% (1)

- Dewalt CatalogDocumento8 páginasDewalt Catalogmailme_vijuAún no hay calificaciones

- Mobile Plants PDFDocumento12 páginasMobile Plants PDFmailme_vijuAún no hay calificaciones

- Deutz Engine 1012 1013 SerDocumento104 páginasDeutz Engine 1012 1013 Sermailme_viju100% (1)

- Tower Crane Inspection ChecklistDocumento4 páginasTower Crane Inspection Checklistmailme_viju100% (1)

- SP CBP 88Documento6 páginasSP CBP 88mailme_vijuAún no hay calificaciones

- Potain MR605BH32-LZO4Documento4 páginasPotain MR605BH32-LZO4mailme_vijuAún no hay calificaciones

- Potain MR90B-LZK3 Tower CraneDocumento4 páginasPotain MR90B-LZK3 Tower Cranemailme_vijuAún no hay calificaciones

- Siemens PLCDocumento2 páginasSiemens PLCmailme_vijuAún no hay calificaciones

- mc205B PDFDocumento4 páginasmc205B PDFmailme_viju100% (1)

- Restricted Earth Fault RelayDocumento5 páginasRestricted Earth Fault Relaysuleman24750% (2)

- Legal NoticeDocumento3 páginasLegal NoticeT Jayant JaisooryaAún no hay calificaciones

- Stonecoal v3 Guidelines 2023-03-22Documento71 páginasStonecoal v3 Guidelines 2023-03-22Esha RamaswamiAún no hay calificaciones

- Sri Anjaneya Cotton Mills LimitedDocumento63 páginasSri Anjaneya Cotton Mills LimitedPrashanth PB50% (2)

- E. What Was The Chinese POW Death Rate in WW2 and The Second Sino-Japanese WarDocumento3 páginasE. What Was The Chinese POW Death Rate in WW2 and The Second Sino-Japanese WarPamela SantosAún no hay calificaciones

- ShowimgDocumento76 páginasShowimgROSHAN ROBERTAún no hay calificaciones

- Concept of InsuranceDocumento4 páginasConcept of InsuranceNazrul HoqueAún no hay calificaciones

- Data Mining With Apriori AlgorithmDocumento12 páginasData Mining With Apriori AlgorithmMAYANK JAINAún no hay calificaciones

- RK3066 Mid PDFDocumento17 páginasRK3066 Mid PDFSharon MurphyAún no hay calificaciones

- Freedom SW 2000 Owners Guide (975-0528!01!01 - Rev-D)Documento48 páginasFreedom SW 2000 Owners Guide (975-0528!01!01 - Rev-D)MatthewAún no hay calificaciones

- IDR PresentationDocumento11 páginasIDR Presentationparthesh laheriAún no hay calificaciones

- Pressuremeter TestDocumento33 páginasPressuremeter TestHo100% (1)

- Slides 5 - Disposal and AppraisalDocumento77 páginasSlides 5 - Disposal and AppraisalRave OcampoAún no hay calificaciones

- XIInfo Pract H Y 416Documento4 páginasXIInfo Pract H Y 416Neelima VijayanAún no hay calificaciones

- Lagundi/Dangla (Vitex Negundo)Documento2 páginasLagundi/Dangla (Vitex Negundo)Derrick Yson (Mangga Han)Aún no hay calificaciones

- Krunker SettingsDocumento2 páginasKrunker SettingsArsyad DanishAún no hay calificaciones

- Akebono NVH White PaperDocumento4 páginasAkebono NVH White Paperapi-3702571100% (1)

- Macroeconomics Measurement: Part 2: Measurement of National IncomeDocumento13 páginasMacroeconomics Measurement: Part 2: Measurement of National IncomeManish NepaliAún no hay calificaciones

- GMN RodamientosDocumento51 páginasGMN RodamientosJayAún no hay calificaciones

- Introduction To Plant Physiology!!!!Documento112 páginasIntroduction To Plant Physiology!!!!Bio SciencesAún no hay calificaciones

- Demand Management in Global Supply Chain - Disertasi S3Documento166 páginasDemand Management in Global Supply Chain - Disertasi S3Ahmad BuchoriAún no hay calificaciones

- Contemporary Philippine MusicDocumento11 páginasContemporary Philippine MusicmattyuuAún no hay calificaciones

- Mock MeetingDocumento2 páginasMock MeetingZain ZulfiqarAún no hay calificaciones

- Welcome Speech For Seminar in College 2Documento4 páginasWelcome Speech For Seminar in College 2Niño Jay C. GastonesAún no hay calificaciones

- Ventilation WorksheetDocumento1 páginaVentilation WorksheetIskandar 'muda' AdeAún no hay calificaciones

- IHRM Midterm ASHUVANI 201903040007Documento9 páginasIHRM Midterm ASHUVANI 201903040007ashu vaniAún no hay calificaciones

- Packet Tracer - VLSM Design and Implementation Practice TopologyDocumento3 páginasPacket Tracer - VLSM Design and Implementation Practice TopologyBenj MendozaAún no hay calificaciones

- Body Wash Base Guide Recipe PDFDocumento2 páginasBody Wash Base Guide Recipe PDFTanmay PatelAún no hay calificaciones

- InvoiceDocumento1 páginaInvoiceKidambi SureshAún no hay calificaciones

- Research InstrumentsDocumento28 páginasResearch InstrumentsAnjeneatte Amarille AlforqueAún no hay calificaciones

- Well Control for Completions and InterventionsDe EverandWell Control for Completions and InterventionsCalificación: 4 de 5 estrellas4/5 (10)

- Enhanced Oil Recovery Handout: A Focus on WaterfloodingDe EverandEnhanced Oil Recovery Handout: A Focus on WaterfloodingAún no hay calificaciones

- Well Integrity for Workovers and RecompletionsDe EverandWell Integrity for Workovers and RecompletionsCalificación: 5 de 5 estrellas5/5 (3)

- A Practical Handbook for Drilling Fluids ProcessingDe EverandA Practical Handbook for Drilling Fluids ProcessingAún no hay calificaciones

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesDe EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesCalificación: 4 de 5 estrellas4/5 (2)

- Advanced Production Decline Analysis and ApplicationDe EverandAdvanced Production Decline Analysis and ApplicationCalificación: 3.5 de 5 estrellas3.5/5 (4)

- Casing and Liners for Drilling and Completion: Design and ApplicationDe EverandCasing and Liners for Drilling and Completion: Design and ApplicationCalificación: 5 de 5 estrellas5/5 (3)

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsDe EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsAún no hay calificaciones

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideDe EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideCalificación: 2 de 5 estrellas2/5 (1)

- Asset Integrity Management for Offshore and Onshore StructuresDe EverandAsset Integrity Management for Offshore and Onshore StructuresAún no hay calificaciones

- Flow Analysis for Hydrocarbon Pipeline EngineeringDe EverandFlow Analysis for Hydrocarbon Pipeline EngineeringAún no hay calificaciones

- Industrial Piping and Equipment Estimating ManualDe EverandIndustrial Piping and Equipment Estimating ManualCalificación: 5 de 5 estrellas5/5 (7)

- Hydrocarbon Fluid Inclusions in Petroliferous BasinsDe EverandHydrocarbon Fluid Inclusions in Petroliferous BasinsAún no hay calificaciones

- Hybrid Enhanced Oil Recovery Using Smart WaterfloodingDe EverandHybrid Enhanced Oil Recovery Using Smart WaterfloodingAún no hay calificaciones

- An Operations Guide to Safety and Environmental Management Systems (SEMS): Making Sense of BSEE SEMS RegulationsDe EverandAn Operations Guide to Safety and Environmental Management Systems (SEMS): Making Sense of BSEE SEMS RegulationsAún no hay calificaciones

- A Practical Guide to Piping and Valves for the Oil and Gas IndustryDe EverandA Practical Guide to Piping and Valves for the Oil and Gas IndustryCalificación: 5 de 5 estrellas5/5 (3)

- The Petroleum Engineering Handbook: Sustainable OperationsDe EverandThe Petroleum Engineering Handbook: Sustainable OperationsCalificación: 3.5 de 5 estrellas3.5/5 (5)

- Reservoir Engineering: The Fundamentals, Simulation, and Management of Conventional and Unconventional RecoveriesDe EverandReservoir Engineering: The Fundamentals, Simulation, and Management of Conventional and Unconventional RecoveriesCalificación: 5 de 5 estrellas5/5 (7)

- Guide to the Practical Use of Chemicals in Refineries and PipelinesDe EverandGuide to the Practical Use of Chemicals in Refineries and PipelinesCalificación: 5 de 5 estrellas5/5 (1)

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesDe EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesCalificación: 3.5 de 5 estrellas3.5/5 (3)

- Essentials of Oil and Gas Utilities: Process Design, Equipment, and OperationsDe EverandEssentials of Oil and Gas Utilities: Process Design, Equipment, and OperationsCalificación: 4.5 de 5 estrellas4.5/5 (4)

- 100 AI Use Cases in the Upstream Industry: A Comprehensive Guide for Professionals and Researchers to Overcome Industry Challenges Using AI and PythonDe Everand100 AI Use Cases in the Upstream Industry: A Comprehensive Guide for Professionals and Researchers to Overcome Industry Challenges Using AI and PythonAún no hay calificaciones