Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Mill Optimization

Cargado por

DSG100%(5)100% encontró este documento útil (5 votos)

714 vistas45 páginasCOAL MILL OPTIMIZATION FOR SUB BITUMINOUS COALS

Título original

MILL OPTIMIZATION

Derechos de autor

© © All Rights Reserved

Formatos disponibles

PDF, TXT o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCOAL MILL OPTIMIZATION FOR SUB BITUMINOUS COALS

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

100%(5)100% encontró este documento útil (5 votos)

714 vistas45 páginasMill Optimization

Cargado por

DSGCOAL MILL OPTIMIZATION FOR SUB BITUMINOUS COALS

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

Está en la página 1de 45

www.AsianSBCUsers.

com I 2011 Conference

Presented By:

Richard Storm

Innovative Combustion Technologies, Inc.

Optimizing boiler and coal mill

performance

2367 Lakeside Drive, Suite A-1

Birmingham, Alabama 35244

(205) 453-0236

www.AsianSBCUsers.com I 2011 Conference

OXYGEN AND AIR:

Stratified oxygen at the furnace or boiler

exit

Air heater leakage greater than 10%

Combustion air distribution to the

burners exceeds 10%

Air in-leakage through the ash hoppers

Air in-leakage through the nose arch,

penthouse or convection pass areas

FOULING AND SLAGGING

Furnace exit S.H. inlet slagging

Fouling of the convention pass and/or the air

heater baskets

Burner eyebrows and waterwall slagging

HIGH GAS TEMPERATURES

Flue gas temperature at the furnace exit

is greater than 2,150F (1177C) peak

Stratified flue gas temperatures

Economizer gas outlet temperature

greater than 750F (399 C Respectively)

Overhead tube metals in the superheater

and the reheater

FANS AND DAMPERS:

I.D. fan capacity inadequate

I.D. and F.D. fan clearances are not

optimum

Damper, register, and fan control

louvers are not timed from 0-100% on

the operating drive or hand control

BOILER DRUM

LEVEL

Uneven furnace

heat release can

contribute to non-

uniform steam

generation in the

waterwall circuits,

resulting in varied

steam by weight in

the furnace circuitry,

and sometimes tube

failures or steam

purity problems

STEAM AND STEAM

TEMPERATURE CONTROLS

High de-superheating spray

flows

Higher or lower steam

temperatures than design

PULVERIZER AND BURNER LINES FUEL DISTRIBUTION:

Fuel Imbalances

Primary airflow for the Air/Fuel ratio is not correct

Poor fineness (Less than 75% passing 75 micron & >0.3% not passing 300 micron

Fuel temperatures less than 135F (57C)

Pulverizer rejects high

Mechanical tolerances are out of specification and the burners are not within 1/4

FLYASH

Flyash unburned carbon

(LOI) greater than 5% for

bituminous coals and

greater than 0.5% for

subbituminous coals

Electrostatic precipitator

performance reduced due

to ash conductivity or

high carbon content

Symptoms of a Boiler Needing Combustion Optimization

www.AsianSBCUsers.com I 2011 Conference

The Definition of Optimum Combustion is at least these factors:

Blue Highlighted parameters are environmentally driven factors

Highlighted in Green are heat rate factors of optimum combustion

Completed combustion within the furnace (no Secondary combustion at the Superheater)

Acceptable NO

X

Acceptable CO

Fly ash unburned carbon satisfactorily

Full load capability and meet all environmental and fuel quality requirements

De-superheating spray water flows minimal

Design Steam temperature attained

No reducing atmosphere in the lower furnace causing waterwall wastage

Primary airflow is optimized

No furnace slagging

No convection pass fouling

Minimal Pop corn ash

Burn lowest quality (least expensive) fuel with no adverse consequence

Flames stable and satisfy flame scanners

Satisfactorily low LOI so that ESP performs satisfactorily for minimum opacity

www.AsianSBCUsers.com I 2011 Conference

Common boiler tests to optimize combustion and boiler reliability

www.AsianSBCUsers.com I 2011 Conference

13 Prerequisites For Optimum Combustion

(Ensures Proper and Optimum inputs)

Furnace exit must be

oxidizing preferably, 3%.

Fuel lines balanced by

Dirty Air test to 5% or

better.

Fuel lines balanced in

fuel flow to 10% or

better

Fuel line fineness >75%

passing a 75 Micron

screen. 300 Micron

particles <0.3%.

Primary airflow shall be

accurately measured &

controlled to 3%

accuracy.

Over fire air shall be

accurately measured &

controlled to 3%

accuracy.

Primary air/fuel ratio shall

be accurately controlled

when above minimum.

Fuel line minimum

velocities shall be 3,300

fpm.

Mechanical tolerances

of burners and dampers

shall be 1/4 or better.

Secondary air distribution to

burners should be within 5%

to 10%.

Fuel feed to the pulverizer should

be smooth during load changes

and measured and controlled as

accurately as possible. Load cell

equipped gravimetric feeders are

preferred.

Fuel feed quality and size should

be consistent. Consistent raw

coal sizing of feed to pulverizer is

a good start.

www.AsianSBCUsers.com I 2011 Conference

High furnace exit gas temperatures

contribute to overheated metals,

slagging, excessive sootblower

operation, production of popcorn

ash, fouling of SCRs and APHs

Coal pulverizer spillage

from pulverizer throats

that are too large

Non optimum primary airflow

measurement and control ;

Excessive NO

X

levels

Flyash Carbon losses

High primary airflows contribute to

unnecessarily high dry gas losses

and also poor fuel distribution and

poor coal fineness.

Bottom ash

carbon content

High furnace exit gas

temperatures contribute to high

de-superheating spray water

flows that are significant steam

turbine cycle heat-rate

penalties.

Overall Plant Performance Opportunities

(>50% are Related to the Pulverizers)

www.AsianSBCUsers.com I 2011 Conference

Consequences of Non-Optimum Burner Belt

Performance:

The inputs must be Optimal

No control of air and fuel after it enters the boiler

High spray water flows to S.H. and R.H.

Tube metal over heating and reliability

problems

Slagging and Fouling

Higher NOx

Popcorn Ash

SCR Fouling

APH Fouling

Elevated economizer outlet gas

temperature

Burner Belt Performance is never Optimal

with less than perfect Pulverizer Performance

www.AsianSBCUsers.com I 2011 Conference

1. Evaluate Coal Factors that influence mill capacity (Raw Coal

Size, HGI, Moisture, HHV, Fineness, Hp/Ton)

2. Fuel Loading & Feed Rate Control

3. Clean Air Balance within + 2%

4. Dirty air flow Balance within + 5%

5. Measured Primary air Hot K Factor calibrations +2-3%

(measured vs. actual)

6. Mill temperature Control, Damper Control and Responsiveness

to Load Control

7. Air-Fuel Ratio /fuel ratios are required for Optimum Flame

Lengths and Carbon Burnout

8. Total air flow Measurement / Control Optimized ; Balance of

Mass Air & Fuel Flow

9. Fuel line fineness and distribution testing by air/fuel ratio

sampling & ensuring optimum fineness levels of >75% thru 200

mesh (75 micron) & 99.7% thru 50 Mesh (300 Micron)

10. Fuel line balancing through classifier changes or fuel line

distribution modifications to achieve +10%

11. Blueprinting of tolerances, mechanical settings and control

settings

Optimizing Mill and Burner Performance

8

www.AsianSBCUsers.com I 2011 Conference

Poor Pulverizer Performance Increases FEGT by Delaying Combustion

Increased Slagging and Lower Performance

Poor fuel fineness and

distribution aggravates high

center of combustion

Good /uniform mixing in the

burner zone. Burner

mechanical tolerances,

fineness, fuel/air balance

and PA flow proper and

precise

Molten slag on

the furnace wall

Reducing areas w/fuel

stratifications and excessive

CO levels

Sticky plastic slag deposits on

pendants. Slag temperature at or

above ash softening temperature

Excessive de-superheating

water sprays, for both S.H.

and R.H.

Air inlet & outlet flue

gases higher than

design

Tube spacing permits slag

bridging between the tube

assemblies, when the ash is

soft, sticky and/or molten

9

www.AsianSBCUsers.com I 2011 Conference

Importance of Fineness

Higher fineness levels always promote more even distribution of fuel between a mills

separate burner lines.

Better distribution promotes better combustion, inherently lower NOx emissions and lower fly

ash L.O.I. or carbon content.

Better than 10% fuel balance is not achieved until better than 70% passing 200 Mesh (75

micron) is achieved.

www.AsianSBCUsers.com I 2011 Conference

Major Factors Related to NO

X

Production

Fixed Factors:

Boiler Design

Fuel Factors

Burner Configuration/Design

Variable Factors:

Pulverizer Performance

Fuel Line Balancing

Combustion Air Balancing and Proportioning

Air In-Leakage

www.AsianSBCUsers.com I 2011 Conference

Thermal NO

X

Accounts for approximately 20 - 30% of NO

X

produced

Formed from the nitrogen in the combustion air (>2800F)

Fuel NO

X

Accounts for approximately 70%-80% of NO

X

produced

Formed from the nitrogen in the fuel

Sources of NO

X

Low NO

X

Pulverized Fuel Firing

www.AsianSBCUsers.com I 2011 Conference

Higher coal fineness will promote less slagging

When combustion is completed lower in the furnace cavity, the water walls

have increased time to absorb heat released from the fuel

Increased heat release in the lower furnace results in a higher proportion of

heat absorbed by the waterwalls

Higher heat absorption by the waterwalls relates to a reduction in furnace

exit gas temperature

Reduction in furnace exit gas temperature resulting from completion of

combustion in the lower furnace with higher fineness results in lower

slagging propensities and lower NOx.

Understanding the Effects of Coal Fineness

on NO

X

and/or Slagging

www.AsianSBCUsers.com I 2011 Conference

Burner Stoichiometry differs when fuel is not balanced and NO

X

is higher

1.17

0.87

0.76

0.72

1.10

0.90

0.7

0.8

0.9

1

1.1

1.2

1.3

Stoichiometry

Fuel

Lean

Fuel

Rich

Fuel

Lean

Fuel

Rich

Very High NO

X

Lack of Excess Air to

these burners will yield

secondary combustion

Very High NO

X

14

www.AsianSBCUsers.com I 2011 Conference

Effect of Mill Air Flow on NO

x

, 500 Mw Wall Fired Boiler

Decreasing Mill Air Flow (Primary Air Flow)

NO

X

reduced by:

Optimized mill air flow

Air flow was high due to

oversized vane wheels coal

spillage with proper air flow.

Improvement in coal fineness.

15

www.AsianSBCUsers.com I 2011 Conference

1. Better Fuel Bound Nitrogen Release (Majority of NOx is fuel derived).

2. Better Fuel Distribution.

3. Permits lower Furnace Excess O

2

without complications.

Mill Fineness Improves NOx in at least (3) ways

Release of Fuel Bound Nitrogen in the

De-Volatilization Zone

Fuel

Nozzle

Good Fineness

Poor Fineness

N

N N

N

N

N

N

N N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

www.AsianSBCUsers.com I 2011 Conference

Secondary air flow

measured to ensure

uniform and proper total

air to fuel ratio between

burner elevations

Pulverizer air flow

measured within 3%;

Critical for best NO

X

,

slagging and exit gas

temperature

Proper and Optimum Boiler Air Flow Management is Essential to Achieving Lowest NO

X

without upper or lower furnace slagging, 725 Mw boiler firing subbituminous coal

www.AsianSBCUsers.com I 2011 Conference

Precise measurement & management of all airflow inputs

to the boiler is ideal

www.AsianSBCUsers.com I 2011 Conference

Proper O2 in the right places is needed because combustion must

be completed and carbon to CO2 in ~1 to 1.5 seconds at full load

www.AsianSBCUsers.com I 2011 Conference

The Importance of Fuel Preparation

& Furnace Residence Time

Ignition

Major De-volatilization

0.000 0.200 0.400 0.600 0.800 1.00

Heating & Minor De-volatilization

Carbon

Burnout

www.AsianSBCUsers.com I 2011 Conference

Common Mistake:

Low or No CO at Economizer = Optimized Air and Efficiency

Can be false if there are large furnace imbalances or boiler setting air ingress; CO

can continue to burn into the convection pass.

1.0% O

2

8,000 PPM CO

1.9% O

2

500-1200 PPM CO

3% O

2

150 PPM CO

0.5% O

2

> 30,000 PPM CO

www.AsianSBCUsers.com I 2011 Conference

Difference Between Complete and

Incomplete Combustion

C

O

O

O C

Products of Complete Combustion

Products of Incomplete Combustion

(CO

2

)

(CO)

+

+

14,540 Btu

4,350 Btu

www.AsianSBCUsers.com I 2011 Conference

Incomplete combustion at the furnace exit results in a hazy furnace, stack opacity,

and measurably high CO. It also contributes to boiler exit flue gas temperatures

being too high, and therefore, can contribute to super-heater tube overheating,

super-heater, and boiler generating bank tube plugging.

Due to Non Optimal Lower Furnace Heat Absorption

Resulting in Upper Furnace Short or Long Term Failures`

The Inter-Relationship of Combustion and Tube Reliability

www.AsianSBCUsers.com I 2011 Conference

Inspect tubes for corrosion

or wear, check for any

problems with alignment

bars and tube shields.

* Thoroughly inspect and repair all

ductwork and expansion joints

Optimize air heater seals,

basket cleanliness, check

and repair sector plates

and all moving parts

* Verify damper strokes (all

dampers to be verified from

inside ducts)

PA, FD, ID Fan

clearances and

damper/inlet vane

checks

Rebuild pulverizer

grinding elements

Refurbish burners to

design dimensions,

Dampers and/or tilts

synchronized

Air-in leakage

inspections and

repairs

Typical Outage Opportunities

www.AsianSBCUsers.com I 2011 Conference

Slagging will occur if furnace exit gas temperatures (F.E.G.T.) exceeds the fusion

temperature of ash from the coal being fired.

F.E.G.T. should be 100F to 150F below the ash softening temperature.

Higher fineness, proper primary (pulverizer) airflow and good fuel balance reduce

FEGT by allowing combustion to complete lower in the furnace. combustion in

completed lower in the furnace, the waterwalls absorb a higher amount of total

heat release by the fuel and FEGT is reduced.

Reducing ash fusion temperatures are always lower than those in an oxidizing

atmosphere. Ash melts into a slag due to lower melting points caused by a

reducing atmosphere allowing slag to be formed at lower temperatures.

Root Cause of Upper Furnace Slagging

FEGT Exceeds Ash Fusion Temperature

www.AsianSBCUsers.com I 2011 Conference

Typical FEGT

Measurement

Location

Controlling Furnace

Exit Conditions, one if

not the most important

factor to controlling

slagging, optimum

steam temperatures &

combustion efficiency.

www.AsianSBCUsers.com I 2011 Conference

FEGT is controlled by the amount

of heat absorbed by the water

walls, FEGT is lowered when:

1. Wall blowers are blown

2. Burner tilts down on tangentially

fired units

1. Combustion is completed faster

Better fineness

Good fuel & air Balance

2. Better mixing in the lower furnace,

more uniform:

O

2

Temperature

Slag deposition

www.AsianSBCUsers.com I 2011 Conference

Burner Tilts in upward orientation on tangentially fired units

reduces furnace residence time

www.AsianSBCUsers.com I 2011 Conference

Changing FEGT with Burner Tilts

2250F 2000F 1850F

Burner Tilts (+) UP Burner Tilts (0) Horizontal Burner Tilts (-) Down

Low W.W. Heat Absorption

Low Retention Time

Higest FEGT

Moderate Retention Time

Lower FEGT

Moderate W.W. Heat Absorption

Higest Retention Time

Highest W.W. Heat Absorption

Lowest FEGT

www.AsianSBCUsers.com I 2011 Conference

Delayed combustion = reduces waterwall

absorption = high FEGT (same effect as

smaller furnace)

Air Heater

To Precip/

Bag House

Air Inlet

Relationship between FEGT and

Furnace Heat Release Rate

www.AsianSBCUsers.com I 2011 Conference

Ash Fusion Temperatures

ID ST FT HT

www.AsianSBCUsers.com I 2011 Conference

The Furnace Exit should be Oxidizing because:

1. Reducing Ash Fusion Temperatures are always lower

2. Low or No O

2

increases Furnace Exit Gas Temperature

www.AsianSBCUsers.com I 2011 Conference

Low O

2

at the Furnace Exit also causes slagging

Ash chemistry changes and

ash fusion (melts) at lower

temperature

FEGT is higher because there is

insufficient excess oxygen to

complete combustion in the

lower furnace

www.AsianSBCUsers.com I 2011 Conference

Poor coarse coal fineness (>300 Micron particles) can impact on the lower

furnace slope causing heavy slagging in the lower furnace

www.AsianSBCUsers.com I 2011 Conference

SLAGGING

ZONE

F

O

U

L

I

N

G

Z

O

N

E

Tube spacing becomes

more restrictive as the

heat transfer process

changes from Radiant in

the furnace to

Convective heat transfer

in the back pass

Slagging / Fouling

www.AsianSBCUsers.com I 2011 Conference

20 Tips to help Prevent Slagging

Good control of the furnace exit conditions to minimize

or stop slagging. (Proper & uniform O

2

and

Temperature) Uniform furnace exit conditions across

the furnace (F/O

2

) = uniform slag deposition. (Uniform

slag is more easily managed. Active monitoring of the

FEGT is KEY. Operators need to be aware of FEGT to

optimize their cleaning strategies and make

adjustments. Trust but verify optical, acoustic and

calculated FEGT. High Velocity Thermocouple Testing

is the Gold standard of FEGT measurement HVT

measures bulk and discrete point temperatures.

Dont overuse OFA NOx can be too good

the benefits of over-staging will be short lived

Practice preventative not reactive soot

blowing by cleaning water walls, reducing FEGT

and Slagging conditions. Keeping the walls

clean and lowering furnace temperatures can

also reduce NOx, sometimes as much as 15%.

Optimize lower furnace fuel & air interactions to

maximize water wall heat absorption.

Know your coal before it enters the furnace

(Operator awareness) Control the coal quality

issues that you have control of, Plant coal

quality control starts in the coal yard. Raw coal

sizing, moisture (coal pile management), coal

drying (mill outlet temperature) and fineness.

Pulverizer performance is critical to preventing

lower furnace slag/clinkers. Avoid the splat

factor.

Use good walk downs and/or permanent cameras to

identify slag before it becomes a problem in the SH, the

plant can then shift from a normal to aggressive

sootblowing/cleaning mode of operation to manage or

remove the clinker online. Take Action rather than

waiting for a forced outage.

www.AsianSBCUsers.com I 2011 Conference

The Inter-Relationship of Combustion,

Slag and Tube Reliability

Non-Optimal furnace cleaning can significantly elevate the furnace exit gas temperature and

force heat to the convection pass

www.AsianSBCUsers.com I 2011 Conference

Superheater

Division Panels

(8 ctrs.)

Platen

Superheater

(19 ctrs.)

Front Pendant

Superheater Final

(4 ctrs.)

Front Pendant

Reheater

(9 ctrs.)

Rear Pendant

Reheater Final

(4 ctrs.)

Rear Pendant

Superheater

Economizer

Corner Firing

System

Furnace

Windbox

Preferred HVT

Traverse Plane

Preferred HVT

Traverse Plane

Platen

Superheater

(19 ctrs.)

Superheater

Division Panels

(8 ctrs.)

Front

Pendant

Reheater

(9 ctrs.)

Rear Pendant

Reheater Final

(4 ctrs.)

Front Pendant

Superheater

Final (4 ctrs.)

Rear Pendant

Superheater

Economizer

The strainer effect of the boiler tube spacing gets

smaller and more restrictive between the furnace and

boiler exit

www.AsianSBCUsers.com I 2011 Conference

SH/RH Heating surface areas optimized

Good steam temperatures with FEGT at or

less than ash softening temperature.

Practice prevention of slag rather than managing

slag incidents. Listen to your boiler when it tells

you it is sick; fevers high exit gas temperatures

or FEGT, hot tubes, vomiting high spray flows,

ash spills, dark bottom ash or fly ash, Shortness

of breath ID and FD fan limitations, high DPs

and low wind box pressures.

Soot blowing technologies have also

advanced a long way from a pipe with two

holes Ensure soot blower PMs are being

completed to maximize soot blowing

effectiveness.

Boiler setting air ingress minimized; furnace

O

2

is not low with normal economizer exit O

2.

Amount of heat absorbed by the water walls

regulates Furnace Exit Gas Temperature.

LOOK at the water walls; know what youre

looking for. (Slagging Conditions)

Remember the boiler is a heat engine, get

the inputs right. Fuel and air need to be in

the right places in the right amounts.

Air heater is clean & well maintained; a high

DP or Leakage doesnt lower furnace O

2

due to fan capacity.

Help pendant/platens clean themselves by

removing slag anchor points such as

certain types of wrapper tubes, alignment

lugs and rigid alignment/tie bars to allow

some swinging of the pendants.

20 Tips to help Prevent Slagging

www.AsianSBCUsers.com I 2011 Conference

Typical Slagging conditions on a Tangentially fired boiler

www.AsianSBCUsers.com I 2011 Conference

41

Tube spacing permits

slag bridging between the tube

assemblies, when the ash

Is soft, sticky and/or molten

Excessive desuperheating water

sprays, for both S.H. and R.H.

Sticky, plastic slag deposits on

pendants. Slag temperature at or

above ash softening temperature

Reducing areas w/ fuel

stratifications and

excessive CO levels

Molten slag on the

furnace water wall

Burner tilts upward or

horizontal reduce the

furnace mixing and

elevate the furnace

exit gas temperature

Poor fuel fineness and

distribution aggravates high

center of combustion

Air Heater inlet & outlet flue

gases higher than design

From

FD Fan

To

Stack

Poor Pulverizer Performance Increases FEGT due to Delayed

Combustion, Increasing Slagging and Lowering Performance

www.AsianSBCUsers.com I 2011 Conference

Optimized Tangentially fired boiler

No Air In-Leakage

Balanced Airflows,

Balanced Fuelflow,

Fuel Fineness >75%

Passing 200 Mesh and

<0.1% on 50 Mesh

Max. Temperature of 2,150F

and 3% Excess Oxygen At

Full Load Conditions

Air Heater Leakage (8% or Less)

From FD

Fan

To Stack

300F Max. Temperature

Leaving the Air Heater

Flyash Carbon in Ash

<3% for Eastern Fuel

<1% for Western Fuel

Gas Temperature Leaving

Economizer Max. of 775F

Preferred Temperature 750F

0.5% or Less Oxygen Rise

From Furnace to the

Economizer Outlet

Tight Penthouse

(No Air In-Leakage)

www.AsianSBCUsers.com I 2011 Conference

Typical Temperature of a Pulverizer

Between

500F &

700F

140F - 160F

130F 140F

Most pulverizer fires and/or puffs

are caused by coal spilling into

the high temperature area where

primary air enters the mill.

43

www.AsianSBCUsers.com I 2011 Conference

Typical temperature inside the mill with Coal

Moisture of 30%

www.AsianSBCUsers.com I 2011 Conference

100,000 LBS/HR Coal

X 3% Moisture

= 3,000 Moisture

Typical temperature inside the mill with Coal

Moisture of 3%

También podría gustarte

- Bowel Mill Inspection Guide LineDocumento10 páginasBowel Mill Inspection Guide Linesen_subhasis_58Aún no hay calificaciones

- Clinker FormationDocumento4 páginasClinker Formationanon_301652875Aún no hay calificaciones

- Ball Mill Training Program For Operations Engineers Ball Mills PDFDocumento70 páginasBall Mill Training Program For Operations Engineers Ball Mills PDFsrikanthAún no hay calificaciones

- BOE PaperDocumento3 páginasBOE PaperAnand Swami100% (2)

- Quality Bowl MillsDocumento3 páginasQuality Bowl MillsJimit ShahAún no hay calificaciones

- Coal MillDocumento40 páginasCoal MillRaja VigneshAún no hay calificaciones

- Ball and Race MillDocumento76 páginasBall and Race Millsandeep19861986100% (2)

- Coal MillDocumento60 páginasCoal MillNurun Nadjihah0% (1)

- Mill & Mill Rejects WriteupDocumento10 páginasMill & Mill Rejects WriteupEXECUTIVE ENGINEEER BOILER MAINTENANCEAún no hay calificaciones

- Mill RejectDocumento26 páginasMill Rejectnetygen1100% (2)

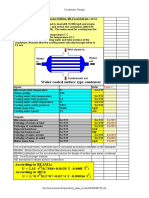

- Condenser DesignDocumento2 páginasCondenser DesignRahul ChandrawarAún no hay calificaciones

- Air Distribution SystemDocumento77 páginasAir Distribution SystemRohit JainAún no hay calificaciones

- Features & Working of Bowl MillsDocumento64 páginasFeatures & Working of Bowl Millssatendra_gangwarAún no hay calificaciones

- MilsDocumento97 páginasMilsKomma Ramesh100% (1)

- Paper4 Mill RejectDocumento39 páginasPaper4 Mill Rejectnetygen1Aún no hay calificaciones

- Coal Mill and Coal FeedersDocumento97 páginasCoal Mill and Coal Feederspartha halder67% (3)

- Presentation ON Pulveriser: Presented by Debasis MahapatraDocumento27 páginasPresentation ON Pulveriser: Presented by Debasis MahapatraRavi SatyapalAún no hay calificaciones

- SKF BRGDocumento22 páginasSKF BRGVijeth99Aún no hay calificaciones

- Cryogenic Air Separation Safe Design and Operation of An ASUDocumento18 páginasCryogenic Air Separation Safe Design and Operation of An ASUMohamed JalalaAún no hay calificaciones

- Physical Science Lesson 2Documento6 páginasPhysical Science Lesson 2api-384482519Aún no hay calificaciones

- The Storage of High Volatile CoalDocumento2 páginasThe Storage of High Volatile CoalcoalspotAún no hay calificaciones

- Bowl Mill Study 1Documento10 páginasBowl Mill Study 1DSG100% (1)

- Flue Gas Heat Recovery in Power Plants, Part IDocumento12 páginasFlue Gas Heat Recovery in Power Plants, Part IknsaravanaAún no hay calificaciones

- Pressurization Unit Pressure Vessel CalculationDocumento1 páginaPressurization Unit Pressure Vessel Calculationsheetalnath100% (1)

- PKR MillsDocumento37 páginasPKR Millsnetygen1Aún no hay calificaciones

- 07 - Combustion - Optimisation PDFDocumento90 páginas07 - Combustion - Optimisation PDFLakshmi NarayanAún no hay calificaciones

- KKP Boiler Training Material - Vol 1Documento92 páginasKKP Boiler Training Material - Vol 1parthi20065768Aún no hay calificaciones

- Operation Aspects & Boiler EmergenciesDocumento54 páginasOperation Aspects & Boiler EmergenciesPravivVivpraAún no hay calificaciones

- Coal Combustion Optimisation Gyanendra Sharma NPTI DelhiDocumento48 páginasCoal Combustion Optimisation Gyanendra Sharma NPTI DelhiNPTIAún no hay calificaciones

- Ash Handling System For EET-r3Documento49 páginasAsh Handling System For EET-r3netygen1Aún no hay calificaciones

- Mill - PerformanceDocumento51 páginasMill - PerformanceRavi Satyapal100% (1)

- 02.case Study On Boiler Tube Failure at JPLDocumento8 páginas02.case Study On Boiler Tube Failure at JPLAnonymous XBq5J84Aún no hay calificaciones

- Inerting Steam For Coal Mill Fire PDFDocumento12 páginasInerting Steam For Coal Mill Fire PDFparveen100% (1)

- Ray Bowl MillDocumento10 páginasRay Bowl Milldnageshm4n244Aún no hay calificaciones

- Power Station FansDocumento70 páginasPower Station FansShubham Verma100% (1)

- Coal Mill Performance OptimisationDocumento11 páginasCoal Mill Performance OptimisationSaurabh KumarAún no hay calificaciones

- Clinker Formation in BoilersDocumento2 páginasClinker Formation in BoilersArivu100% (3)

- Mill 1003Documento86 páginasMill 1003Arvind Kumar Kushwaha100% (3)

- Coal Mill Ball Tube Detailed InfoDocumento37 páginasCoal Mill Ball Tube Detailed Infobanukiran sambojuAún no hay calificaciones

- Blow Down Calculation For BoilerDocumento3 páginasBlow Down Calculation For BoilerCarla RodriguesAún no hay calificaciones

- CombustionDocumento38 páginasCombustionRajeevAgrawal100% (1)

- Pulverizers: By: G. RamachandranDocumento140 páginasPulverizers: By: G. Ramachandranshivshankar prajapatiAún no hay calificaciones

- Coal MillDocumento84 páginasCoal MillPartha MisraAún no hay calificaciones

- Mill Performance: Ravi Satyapal Mohammad Javed Pratik SinghDocumento39 páginasMill Performance: Ravi Satyapal Mohammad Javed Pratik SinghRavi Satyapal100% (1)

- Physical Metallurgy-18 Heat Treatment of SteelDocumento7 páginasPhysical Metallurgy-18 Heat Treatment of SteelDSGAún no hay calificaciones

- Paper 4 Dynamic Operating Regimes of Ball and Tube MillDocumento28 páginasPaper 4 Dynamic Operating Regimes of Ball and Tube MillAmitava Pal100% (1)

- Mill PerformanceDocumento21 páginasMill PerformanceSam100% (2)

- Ball & Tube Mill Manual 1Documento5 páginasBall & Tube Mill Manual 1Rakesh KiranAún no hay calificaciones

- Shree Cement - WHR PPT 15.6.16 - SCLDocumento22 páginasShree Cement - WHR PPT 15.6.16 - SCLSivakumaran RajuAún no hay calificaciones

- Battery Charger Manual - HBL PDFDocumento12 páginasBattery Charger Manual - HBL PDFDSG0% (1)

- Coal Mill SafetyDocumento17 páginasCoal Mill SafetyJoko Dewoto100% (4)

- Coal Pulverising in Boilers 1Documento96 páginasCoal Pulverising in Boilers 1Babu AravindAún no hay calificaciones

- Mill Dirty Air Flow - Ch-8.6Documento11 páginasMill Dirty Air Flow - Ch-8.6Gopal Chandra Sahu100% (1)

- 21-Application of Phoscst 90 RefractoryDocumento6 páginas21-Application of Phoscst 90 RefractorysonuAún no hay calificaciones

- Coal Mill Safety K ChandaDocumento12 páginasCoal Mill Safety K Chandanarasimhamurthy414Aún no hay calificaciones

- Introduction To Bowl MillsDocumento8 páginasIntroduction To Bowl MillsUtkarsh SinghAún no hay calificaciones

- Combustion Optimization-Technology Developments ExperiencesDocumento60 páginasCombustion Optimization-Technology Developments ExperiencesAnonymous gr5Pr9AV100% (1)

- Flue Gas System-2Documento56 páginasFlue Gas System-2SamAún no hay calificaciones

- Chapter 8 Fuel Firing SystemDocumento6 páginasChapter 8 Fuel Firing SystemBineet Kumar VarmaAún no hay calificaciones

- Milling Systems Milling Systems: PRB Users GroupDocumento42 páginasMilling Systems Milling Systems: PRB Users Groupvesridhar@yahoo.comAún no hay calificaciones

- Combustion Optimization Study in U#2 (By Ex BHEL Boiler Expert M. Somasundaram)Documento44 páginasCombustion Optimization Study in U#2 (By Ex BHEL Boiler Expert M. Somasundaram)karikalcholan m100% (1)

- Factors That Affect CFBC Panel Erosion by K.K.Parthiban PDFDocumento34 páginasFactors That Affect CFBC Panel Erosion by K.K.Parthiban PDFparthi20065768100% (1)

- Coal Mill OptimizationDocumento10 páginasCoal Mill OptimizationAdnan NawazAún no hay calificaciones

- NTPC PMI OFF AshHandlingSystemDocumento24 páginasNTPC PMI OFF AshHandlingSystemAshish UppuAún no hay calificaciones

- A Solution For Preventing Fouling in CFBC Boiler by K.K.parthibanDocumento30 páginasA Solution For Preventing Fouling in CFBC Boiler by K.K.parthibanparthi20065768100% (2)

- Clean Air Flow TestDocumento4 páginasClean Air Flow TestLakshminarayanAún no hay calificaciones

- Coal AnalysisDocumento55 páginasCoal Analysisvinod kumar100% (1)

- TATA Power Scaffold Safety StandardDocumento7 páginasTATA Power Scaffold Safety StandardDSG100% (1)

- Best Practices in Thermal Power Plant - EEC Technical Workshop - CompressedDocumento63 páginasBest Practices in Thermal Power Plant - EEC Technical Workshop - CompressedThe SWANAún no hay calificaciones

- DVC Combustion Modification Package August 2019Documento31 páginasDVC Combustion Modification Package August 2019Amitava PalAún no hay calificaciones

- Flue Gas SystemDocumento56 páginasFlue Gas SystemAmit PrajapatiAún no hay calificaciones

- Liquid Petroleum Gas (LPG) Systems: Installation NotesDocumento3 páginasLiquid Petroleum Gas (LPG) Systems: Installation NotesSamaila Anthony MalimaAún no hay calificaciones

- Data Sheet For Synchronous Generators: Company Job. Country RevisionDocumento5 páginasData Sheet For Synchronous Generators: Company Job. Country Revisionbrome2014Aún no hay calificaciones

- UntitledDocumento1 páginaUntitledAnubhav SinghAún no hay calificaciones

- How To Use This Severity Chart: Example Fan 625 Um (25 Mils)Documento2 páginasHow To Use This Severity Chart: Example Fan 625 Um (25 Mils)Aminul Haque SaikiaAún no hay calificaciones

- Chapter Outline:: Heat Treatment (And Temperature)Documento24 páginasChapter Outline:: Heat Treatment (And Temperature)DSGAún no hay calificaciones

- EPRI Materials Degradation - Aging 2008 - P041.01Documento44 páginasEPRI Materials Degradation - Aging 2008 - P041.01DSGAún no hay calificaciones

- DSR Aor For Wet Riser and Sprinkler System 2019Documento110 páginasDSR Aor For Wet Riser and Sprinkler System 2019Sambit Pattanaik50% (2)

- Science From 2-Chapter5Documento21 páginasScience From 2-Chapter5Kalvin Ng Chong YuAún no hay calificaciones

- Hunting Problems On Ind Drive TurbinesDocumento3 páginasHunting Problems On Ind Drive TurbinesDSGAún no hay calificaciones

- L18 Lecture 18 Wear 1 PDFDocumento6 páginasL18 Lecture 18 Wear 1 PDFDSGAún no hay calificaciones

- @ M/S.N.R.Agarwal Industries LTD Unit 3&4, Gidc, Phase-3, Vapi, GujratDocumento28 páginas@ M/S.N.R.Agarwal Industries LTD Unit 3&4, Gidc, Phase-3, Vapi, GujratDSGAún no hay calificaciones

- Cladding Technology Processes and ImagesDocumento7 páginasCladding Technology Processes and ImagesDSGAún no hay calificaciones

- Novajet: Multipurpose Self-Adhesive LabelsDocumento1 páginaNovajet: Multipurpose Self-Adhesive LabelsKartik Maheshwari HolaniAún no hay calificaciones

- 3 APH PERFORMANCE in NTPC STATIONS AjaySharmaDocumento15 páginas3 APH PERFORMANCE in NTPC STATIONS AjaySharmaDSGAún no hay calificaciones

- Fighting Fire With CO: by Dominique Dieken, P.E., Starr Technical Risks Agency IncDocumento6 páginasFighting Fire With CO: by Dominique Dieken, P.E., Starr Technical Risks Agency IncDSGAún no hay calificaciones

- Assignment 1 Mech 321 Properties and Failure of Materials Jan 2009Documento2 páginasAssignment 1 Mech 321 Properties and Failure of Materials Jan 2009DSGAún no hay calificaciones

- SS - PR - PWR - PRB Guidelines P-Rod PicsDocumento47 páginasSS - PR - PWR - PRB Guidelines P-Rod PicsDSGAún no hay calificaciones

- Running Hrs of Tungsten Carbide Grinding RollerDocumento1 páginaRunning Hrs of Tungsten Carbide Grinding RollerDSGAún no hay calificaciones

- Running Hrs of Tungsten Carbide Grinding RollerDocumento1 páginaRunning Hrs of Tungsten Carbide Grinding RollerDSGAún no hay calificaciones

- Installation and Maintenance of SwitchgearDocumento12 páginasInstallation and Maintenance of SwitchgearcharzreeAún no hay calificaciones

- Boiler Plant Mechanical EquipmentDocumento52 páginasBoiler Plant Mechanical EquipmentAriyandiAún no hay calificaciones

- Technical Report On Electrostatic Precipitator: Geeco Enercon PVT LTD Tiruchirapalli - 620015 IndiaDocumento21 páginasTechnical Report On Electrostatic Precipitator: Geeco Enercon PVT LTD Tiruchirapalli - 620015 IndiaDSGAún no hay calificaciones

- Performance Improvement by Expert ConsultancyDocumento19 páginasPerformance Improvement by Expert ConsultancyDSGAún no hay calificaciones

- Technofit Technofit: Geeco Seminar Geeco SeminarDocumento12 páginasTechnofit Technofit: Geeco Seminar Geeco SeminarDSGAún no hay calificaciones

- Application of KKSDocumento18 páginasApplication of KKSrawatbs2020Aún no hay calificaciones

- FAG Bearing SuffixesDocumento4 páginasFAG Bearing SuffixesDSGAún no hay calificaciones

- Transmissionof HeatDocumento61 páginasTransmissionof HeatSudheer RevanthAún no hay calificaciones

- 15 Oil Fired Crucible FurnaceDocumento2 páginas15 Oil Fired Crucible Furnaceudaya kumarAún no hay calificaciones

- Topic 4.1 Psychometry and Air ConditioningDocumento76 páginasTopic 4.1 Psychometry and Air ConditioningCARL IJADE PINOAún no hay calificaciones

- GLASSDocumento1 páginaGLASSGizelle B NuñezAún no hay calificaciones

- ME ThermodynamicsDocumento58 páginasME ThermodynamicsprasobhaAún no hay calificaciones

- PQT LG Lk-0525ccDocumento229 páginasPQT LG Lk-0525ccGerardo Zamorano100% (2)

- Diagnosis and Management of Heatstroke: I Gede Yasa AsmaraDocumento8 páginasDiagnosis and Management of Heatstroke: I Gede Yasa AsmaraputryaAún no hay calificaciones

- Group Profile Eng PDFDocumento24 páginasGroup Profile Eng PDFrajamasaAún no hay calificaciones

- 0304 3894 (84) 85005 0Documento9 páginas0304 3894 (84) 85005 0bugmenot20200311Aún no hay calificaciones

- Curriculum Vitae: K.YeshwanthDocumento5 páginasCurriculum Vitae: K.YeshwanthShankker KumarAún no hay calificaciones

- HMT 7th Sem NIT Raipur QPaperDocumento28 páginasHMT 7th Sem NIT Raipur QPaperShashi Bhushan PatelAún no hay calificaciones

- Construction Issue: Qty. (Nos) AI DI AO DO Hvac System I Water Chilling Units 3Documento11 páginasConstruction Issue: Qty. (Nos) AI DI AO DO Hvac System I Water Chilling Units 3Al Amin Hossain Srabon100% (1)

- Car Hvac Systems: Mark Norman F. Chan Mark Paul C. PeñarroyoDocumento34 páginasCar Hvac Systems: Mark Norman F. Chan Mark Paul C. PeñarroyoJohndelon P. MendozaAún no hay calificaciones

- Appendix A: Conversion FactorsDocumento44 páginasAppendix A: Conversion FactorsZainalAbidinAún no hay calificaciones

- Heat Transfer Characteristics of Fan Coil Unit FCUDocumento6 páginasHeat Transfer Characteristics of Fan Coil Unit FCUShehan WijesingheAún no hay calificaciones

- Denver Id: Registered European Design Patented DesignDocumento11 páginasDenver Id: Registered European Design Patented DesignMekaNo1DAún no hay calificaciones

- Noise Control of Large Wet Cooling TowersDocumento8 páginasNoise Control of Large Wet Cooling TowersMario LopezAún no hay calificaciones

- Cooling Solutions About UsDocumento18 páginasCooling Solutions About UsBlender RemixAún no hay calificaciones

- EP3 Thermostat InstallDocumento18 páginasEP3 Thermostat InstallmiguelAún no hay calificaciones

- Lec 10Documento6 páginasLec 10Anonymous 2BJgxbxJAún no hay calificaciones

- Course Syllabi AE2Documento125 páginasCourse Syllabi AE2Anmar Hamid AliAún no hay calificaciones

- GATE Chemical Engineering 2011Documento20 páginasGATE Chemical Engineering 2011Gaurav SharmaAún no hay calificaciones

- Spiral Duct Manufacturers AssociationDocumento8 páginasSpiral Duct Manufacturers AssociationEduardo GarcíaAún no hay calificaciones