Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Multi-Commodity Warehouse Planning

Cargado por

AndresMartinez28Descripción original:

Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Multi-Commodity Warehouse Planning

Cargado por

AndresMartinez28Copyright:

Formatos disponibles

This article was downloaded by: [181.114.126.

147]

On: 01 June 2014, At: 15:03

Publisher: Taylor & Francis

Informa Ltd Registered in England and Wales Registered Number: 1072954 Registered office: Mortimer House,

37-41 Mortimer Street, London W1T 3JH, UK

International Journal of Production Research

Publication details, including instructions for authors and subscription information:

http://www.tandfonline.com/loi/tprs20

Multi-commodity warehouse location and distribution

planning with inventory consideration

Ronald G. Askin

a

, Ilaria Baffo

b

& Mingjun Xia

a

a

School of Computing, Informatics, and Decision System Engineering, Arizona State

University, Tempe, Arizona, United States of America.

b

Institute of Industrial Research and Automation, National Research Council of Italy, Rome,

Italy.

Published online: 10 Jun 2013.

To cite this article: Ronald G. Askin, Ilaria Baffo & Mingjun Xia (2014) Multi-commodity warehouse location and

distribution planning with inventory consideration, International Journal of Production Research, 52:7, 1897-1910, DOI:

10.1080/00207543.2013.787171

To link to this article: http://dx.doi.org/10.1080/00207543.2013.787171

PLEASE SCROLL DOWN FOR ARTICLE

Taylor & Francis makes every effort to ensure the accuracy of all the information (the Content) contained

in the publications on our platform. However, Taylor & Francis, our agents, and our licensors make no

representations or warranties whatsoever as to the accuracy, completeness, or suitability for any purpose of the

Content. Any opinions and views expressed in this publication are the opinions and views of the authors, and

are not the views of or endorsed by Taylor & Francis. The accuracy of the Content should not be relied upon and

should be independently verified with primary sources of information. Taylor and Francis shall not be liable for

any losses, actions, claims, proceedings, demands, costs, expenses, damages, and other liabilities whatsoever

or howsoever caused arising directly or indirectly in connection with, in relation to or arising out of the use of

the Content.

This article may be used for research, teaching, and private study purposes. Any substantial or systematic

reproduction, redistribution, reselling, loan, sub-licensing, systematic supply, or distribution in any

form to anyone is expressly forbidden. Terms & Conditions of access and use can be found at http://

www.tandfonline.com/page/terms-and-conditions

Multi-commodity warehouse location and distribution planning with inventory consideration

Ronald G. Askin

a

, Ilaria Baffo

b

and Mingjun Xia

a

*

a

School of Computing, Informatics, and Decision System Engineering, Arizona State University, Tempe, Arizona, United States of

America;

b

Institute of Industrial Research and Automation, National Research Council of Italy, Rome, Italy

(Received 21 February 2013; nal version received 13 March 2013)

We consider the problem of designing a distribution network for a logistics provider that acquires products from multiple

facilities and then delivers those products to many retail outlets. Potential locations for consolidation facilities that

combine shipments for cost reduction and service improvements are considered. The problem is formulated with direct

shipment and consolidation opportunities. A novel mathematical model is derived to solve a complex facility location

problem determining: (i) the location and capacity level of warehouses to open; (ii) the distribution route from each

production facility to each retailer outlet; and (iii) the quantity of products stocked at each warehouse and retailer. A

genetic algorithm and a specic problem heuristic are designed, tested and compared on several realistic scenarios.

Keywords: facility location; distribution; inventory; genetic algorithm; consolidation

1. Introduction

Logistics systems are designed to provide ore to door transport. The system transforms materials into products via a

production network and then delivers products to customers through a distribution network. Strategically located distri-

bution centres or warehouses are commonly used to store items and meet delivery goals during distribution. Modelling

their logistics network and solving a facility location problem (FLP) is a key element in strategic planning for a wide

range of private and public rms. The FLP has its roots in the pioneering work of Weber (1909) who considered the

Fermat-Weber problem of locating a single facility to minimise the total travel distance between the site and a set of

customers. High costs associated with property acquisition and facility construction make facility location or relocation

projects long-term investments, and many other contributing factors such as actual road network and congestion,

customer response time demands and dynamic customer bases complicate site selection and facility design.

Strategic decisions, such as location and capacity of warehouses, are generally planned separately from tactical

issues such as the mode of transport and service level, and operational issues such as order sizes and lead times. How-

ever, this separate treatment may generate a suboptimal solution. As shown in the literature review in the next section,

the available research on integrated models is limited. Relevant issues include: multiple-commodity ows, random

demand, capacity considerations, lead time and safety stock; and few authors have considered all these parts together.

However, this combined problem is quite general in practice, multiple distribution options exist, inventory cost is a

major factor, retailers often face random demands for many commodities, and safety stock is used in the presence of

uncertain demand to guarantee a service level. The need to integrate these issues drives the motivation for this paper.

We consider the selection of warehouse locations and capacity levels from a predetermined nite set of options. We

also consider the subsequent choice of distribution paths from multiple product suppliers to retailers in a three-echelon

(facility, warehouse and retailer) supply chain system. Our objective is to optimise the whole system and minimise the

total cost which includes xed location cost, inventory cost and transportation cost. We consider two shipment methods

for products to each retailer: direct shipment from facility to retailer and indirect shipment from facility to warehouse

and then from warehouse to retailer. We also group multiple products into sets based on environmental or other factors

and allow consolidation in transportation. With respect to inventory, we include both safety stock and regular inventory

and consider the trade-off between inventory and transportation costs when delivery time requirements must be met or

replaced by safety stock. Another major contribution of our work is in capturing nonlinear aspects of shipping cost and

directly addressing inventory requirement to meet a service objective as a function of the selected multi-commodity

distribution network architecture.

*Corresponding author. Email: Mingjun.Xia@asu.edu

International Journal of Production Research, 2014

Vol. 52, No. 7, 18971910, http://dx.doi.org/10.1080/00207543.2013.787171

2013 Taylor & Francis

D

o

w

n

l

o

a

d

e

d

b

y

[

1

8

1

.

1

1

4

.

1

2

6

.

1

4

7

]

a

t

1

5

:

0

3

0

1

J

u

n

e

2

0

1

4

The remainder of this paper is organised as follows. Section 2 reviews related research work. Section 3 presents the

proposed model for the facility location problem with multiple plants, multiple commodities, safety stock consideration

and direct shipment option. Section 4 presents two heuristics and examines their computation feasibility, solution quality,

and robustness. A conclusion is provided in Section 5.

2. Literature review

Our research builds upon the standard xed charge capacitated facility location problem (CFLP) with single sourcing.

Numerous research has appeared on this topic. Cornejols, Sridharan, and Thizy (1991), Sridharan (1995), Owen and

Daskin (1998), Revelle, Eiselt, and Daskin (2008) and Melo, Nickel, and Saldanha-da-Gama (2009) present summaries

of FLP/CFLP. More details about general characterises in FLP/CFLP can be found in these papers.

Traditional CFLP only considers xed location cost and transportation cost. Daskin, Coullard, and Shen (2002) and

Ozsen, Coullard, and Daskin (2008) are among the rst authors who consider inventory control in CFLP. When

considering inventory control, only cycle inventory is necessary for constant/known demand. However, in the case of

stochastic/unknown demand, safety stock plays an important role to overcome the unexpected demand. Sourirajan,

Ozsen, and Uzsoy (2007, 2009) included the inventory, lead time, and service level in their papers. Nozick and

Turnquist (2001) considered the trade-off among facility costs, inventory costs, transportation costs and customer

responsiveness.

Among the available research, the multiple-commodity case has received limited attention. There may be two rea-

sons for this: a multiple-commodity problem can be translated to a single-commodity problem based on an independent

assumption; the complexity of a multiple-commodity problem.

The complexity of CFLP has also limited much of the facility location literature to simplied static and deterministic

models. The rst paper, published by Ballou (1968), recognised the limited application of static and deterministic loca-

tion models. Dynamic programming was then used to determine the best schedule for opening a subset of these sites as

an optimal location and relocation strategy for the planning period. Qi and Shen (2007) introduced an integrated

supply chain design model that considers unreliable supply. Santoso et al. (2004) and Shen and Qi (2007) outlined a

model for the stochastic supply chain design problem.

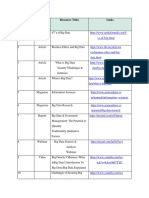

Table 1 summarises the major characteristics of our referenced papers in this research. The table classies papers by

the number of products, the type of demand, whether Inventory (I), Transportation (T), Safety Stock (SS), Stock Out

(SO) is considered, and also the main solution methods used in each paper.

3. Consolidation facility location and demand allocation model (CFLDAM)

We consider the selection of warehouse locations and sizes from a predetermined nite set of options and the subse-

quent choice of distribution paths from multiple product suppliers to retailers in a three-echelon supply chain (facility,

warehouse and retailer) system. Manufacturing facilities already exist and each provides one specic product. Ware-

houses can be located at potential locations with alternative sizes and need hold both cycle inventory and safety stock.

They may also effectively serve as cross-docking points. Retailers locations are also known in advance and the demand

rate for each product at each retailer is assumed to have a known distribution per time (assumed later to be normally

distributed for simplicity of presentation). Each retailer can order from a warehouse or directly from manufacturers but

chooses a single route for each product. In practice, this decision is based on cost and delivery lead time. In addition to

regular cycle inventory, retailers hold safety stock if the lead-time of replenishing one order is above a specic threshold

value (for example, one day).

Products are divided into sets based on environmental or other factors. Consolidation is allowed for shipping prod-

ucts in the same product set, but products from different product sets must be shipped separately. The holding cost rate

for products is the same for products in the same set. For instance, in a food chain, certain products may require refrig-

erated trucks. In other environments security or handling considerations may dictate compatibility of products.

Indices:

I Set of products.

S Set of product sets.

K Set of warehouses.

J Set of possible warehouse sizes small, medium and large.

R Set of retailers.

n Set of subscripts, n =1, , 5, where 1 means from a facility to a retailer, 2 means from a facility to a

warehouse, 3 means from a warehouse to a retailer, 4 means at a warehouse, 5 means at a retailer.

1898 R.G. Askin et al.

D

o

w

n

l

o

a

d

e

d

b

y

[

1

8

1

.

1

1

4

.

1

2

6

.

1

4

7

]

a

t

1

5

:

0

3

0

1

J

u

n

e

2

0

1

4

Table 1. Literature review summary.

Product Demand I T SS SO Main solution method

Bidhandi and Yusuff (2011) Multiple Stationary X X X Sample average approximation

Deterministic Benders decomposition

Dasci and Verter (2001) Single Stationary X An extension of handling headways

Stochastic

Daskin, Coullard, and Shen (2002) Single Stationary X X X X Lagrangian relaxation

Stochastic

Eskigun et al. (2005) Single Stationary X Heuristic algorithm based on LP-

relaxation Deterministic

Gebennini, Gamberini, and Manzini

(2009)

Single Dynamic X X X X Recursive heuristic

Stochastic

Hinojosa, Puerto, and Fernndez (2000) Multiple Dynamic X Lagrangian relaxation

Deterministic

Jawahar, Gunasekaran, and Balaji

(2012)

Single Stationary X X X Heuristic algorithm based on

LP-relaxation Deterministic

Lee and Park (2010) Single Stationary X Heuristic algorithm based on

LP-relaxation Deterministic

Lu and Bostelb (2007) Single Stationary X Heuristic algorithm based on

LP-relaxation Deterministic

Manzini and Gebennini (2008) Single Stationary X X X Mixed integer linear programming

solver Multiple Deterministic

Miranda and Garrido (2004) Single Stationary X X X Lagrangian relaxation

Stochastic

Miranda and Garrido (2009) Single Stationary X X X X Heuristic algorithm

Stochastic

Melo, Nickel, and Saldanha-da-Gama

(2005)

Multiple Dynamic X X Mixed integer linear programming

solver Deterministic

Novaes et al. (2009) Single Stationary X Voronoi diagrams

Stochastic

zceylan and Paksoy (2013) Single Stationary X Mixed integer linear programming

solver Deterministic

Ozsen, Coullard, and Daskin (2008) Single Stationary X X X Lagrangian relaxation

Stochastic

Pourakbar, Farahani, and Asgari (2007) Single Stationary X X Genetic algorithm

Deterministic

Qi and Shen (2007) Single Stationary X X Lagrangian relaxation

Stochastic

Rudi, Kapur, and Pyke (2001) Single Stationary X X Mathematical analysis

Stochastic

Santoso et al. (2004) Multiple Stationary X X Sample average approximation

Deterministic Benders decomposition

Shen and Qi (2007) Single Stationary X X X Lagrangian relaxation

Stochastic

Shu, Teo, and Shen (2005) Single Stationary X X X Column generation algorithm

Stochastic

Silva and de la Figuera (2007) Single Stationary X X X Heuristic algorithm

Stochastic

Snyder and Daskin (2005) Single Stationary X Lagrangian relaxation

Deterministic

Sourirajan, Ozsen, and Uzsoy (2007) Single Stationary X X Lagrangian relaxation

Stochastic

Sourirajan, Ozsen, and Uzsoy (2009) Single Stationary X X Genetic algorithm

Stochastic

Tagaras and Vlachos (2001) Single Dynamic X X Mathematical analysis

Deterministic Simulation

Yao et al. (2010) Multiple Stationary

Stochastic

X X X Heuristic algorithm

Yigit et al. (2006) Single Dynamic

Deterministic

X Simulated annealing

Notes: I, Inventory; T, Transportation; SS, Safety stock; SO, Stock out.

International Journal of Production Research 1899

D

o

w

n

l

o

a

d

e

d

b

y

[

1

8

1

.

1

1

4

.

1

2

6

.

1

4

7

]

a

t

1

5

:

0

3

0

1

J

u

n

e

2

0

1

4

Parameters:

f

kj

Fixed cost of opening one warehouse at location k with size j.

U

kj

Capacity of one warehouse at location k with size j.

lt

nij

Lead time from point i to j(n = 1, 2, 3).

C

nij

Capacity of one truck used for shipping from point i to j(n = 1, 2, 3).

A

nij

Setup cost of each order from point i to j(n = 1, 2, 3).

a

nij

Fixed transportation cost per trip for using one truck from point i to j(n = 1, 2, 3).

bl

nij

Variable transportation cost from point i to j(n = 1, 2, 3).

h

nij

Holding cost of product i at point j per time based on average inventory level (n = 4, 5).

h

s

r

Holding cost of product set S at retailer r.

t

nij

1 if the lead time from point i to j is greater than threshold value (one day), 0 otherwise (n = 1, 3).

D

ir

Demand mean of product i at retailer r per time.

r

2

ir

Demand variance of product i at retailer r.

z

a

Inverse of the Standard Normal for a probability of .

M A very big number.

Decision variables:

w

kj

1 if opening one warehouse at location k at size j, 0 otherwise.

x

ir

1 if retailer r orders product i from facility i directly, 0 otherwise.

x

ikr

1 if retailer r orders product i from warehouse k, 0 otherwise.

Q

nij

Quantity of one order of product i from the facility to j(n = 1, 2).

Q

3ikr

Quantity of one order of product i from warehouse k to retailer r.

Q

s

3kr

Quantity of one order of one product set s from warehouse k to retailer r.

The objective is to minimise the total cost including: xed warehouse location costs (depreciation), regular inventory

cost, safety stock cost, order cost and transportation cost. When calculating safety stock at a warehouse, risk-pooling is

applied for each product. At a warehouse, the total safety stock for one product is shown in Equation (1) and is deter-

mined as the desired condence multiplier times the standard deviation of cumulative product demand served by that

warehouse.

SS

i

z

a

r

r

2

ir

lt

2ik

x

ikr

_

(1)

When calculating the transportation cost, we assume a xed cost of using a truck per shipment along with a variable

cost related to number of units and shipping distance. Thus, cost for each order is equal to: xed cost number of

trucks + variable cost distance quantity of one order. Assuming full truck load order size, the cost is shown in

Equation (2).

Transport Cost=Shipment a

Q

C

_ _

bl Q (2)

An economic order quantity model is used to determine the initial optimal order quantity. And since the existence of

order cost, we can show that it is near optimal to use multiple full-truck loads at one time instead of sending one full-

truck load several times. Let Q

0

be the optimal economic order quantity assuming xed truck costs are linearised. Due

to the relative insensitivity of actual cost to quantity and the economics of full truckload shipments, the actual order

quantity used is selected from the oor or ceiling function of Q

0

as either Q dQ

0

=Ce C or Q

0

bQ

0

=Cc C. Bounds

on maximal loss from considering only full truck loads are derived in the Appendix. The model is easily extended to

allow for multiple capacity truck options in the case that the natural order size is signicantly different than the capacity

of the normal truck for such shipments. The modeller could include options for 20, 40 and 53 containers for instance

or even smaller delivery trucks for local deliveries from warehouses to retailers. Indeed, structurally, options such as

mail packages could even be considered.

1900 R.G. Askin et al.

D

o

w

n

l

o

a

d

e

d

b

y

[

1

8

1

.

1

1

4

.

1

2

6

.

1

4

7

]

a

t

1

5

:

0

3

0

1

J

u

n

e

2

0

1

4

The proposed model assuming shipment quantities are multiples of truck loads, and the formulation is then:

Minimise

j

f

kj

w

kj

i

Q

2ik

h

4ik

2

i

z

a

h

4ik

r

r

2

ir

lt

2ik

x

ikr

_

_ _

s

Q

s

3kr

h

s

r

i

Q

1ir

h

5ir

2

i

z

a

h

5ir

k

r

ir

t

3kr

x

ikr

lt

3kr

_

r

ir

t

1ir

x

ir

lt

1ir

_

_ _ _ _

i

A

1ir

a

1ir

Q

1ir

C

1ir

_ _

bl

1ir

Q

1ir

_ _

D

ir

x

ir

Q

1ir

i

A

2ik

a

2ik

Q

2ik

C

2ik

_ _

bl

2ik

Q

2ik

_ _

r

D

ir

x

ikr

Q

2ik

s

A

3kr

a

3kr

Q

s

3kr

C

3kr

_ _

bl

3kr

Q

s

3kr

_ _

i2S

D

ir

x

ikr

Q

s

3kr

_ _

(3)

Subject to:

Q

2ik

j

Mw

kj

8i; k (4)

Q

s

3kr

j

Mw

kj

8s; k; r (5)

Q

s

3kr

i2S

Q

3ikr

8s; k; r (6)

j

w

kj

1 8k (7)

k

x

ikr

x

ir

1 8i; r (8)

i

Q

2ik

2

r

r

2

ir

lt

2ik

x

ikr

_

0:8

j

U

kj

w

kj

8k (9)

Q

1ir

; Q

2ik

; Q

s

3kr

0 8i; s; k; r (10)

x

ir

; x

ikr

2 f0; 1g 8i; k; r (11)

The objective function (3) has six terms the xed warehouse location costs, the average inventory costs at ware-

houses, the average inventory costs at retailers, order cost, the transportation cost from facilities to retailers directly, the

transportation costs from facilities to warehouses and the transportation costs from warehouses to retailers when needed.

Safety stock at a site is based on desired percentiles of its replenishment lead time demand. When delivery lead time

(distance) is below an acceptable threshold, safety stock is not needed. The order quantities are computed by rst nd-

ing the optimal continuous economic order quantity and then costing out the options of that quantity against the rounded

up and down full truck load alternatives. Based on the choice of x

ir

, x

ikr

we nd the candidate continuous optimal order

quantity value using the typical EOQ model as shown in Equations (12) to (14). As described above, these values are

then rounded to nd the appropriate Q value for use in the model.

Q

0

1ir

2A

1ir

D

ir

x

ir

h

5ir

_

(12)

International Journal of Production Research 1901

D

o

w

n

l

o

a

d

e

d

b

y

[

1

8

1

.

1

1

4

.

1

2

6

.

1

4

7

]

a

t

1

5

:

0

3

0

1

J

u

n

e

2

0

1

4

Q

0

2ik

2A

2ik

(

r

D

ir

x

ikr

)

h

4ik

(13)

Q

s0

3kr

2A

3kr

(

i2S

D

ir

x

ikr

)

h

s

r

; Q

0

3ikr

Q

s0

3kr

D

ir

i2S

D

ir

_ _

(14)

The cost model is adaptable. For instance, suppose orders are for multiple truck loads. The model above assumes all

loads are shipped at once. However, if truck loads are spaced in time by the ratio of truck capacity to demand, then the

inventory terms in (3) would be replaced by expressions of the form Ch / 2 (a similar change is used in Equation (9)).

Constraint sets (4) and (5) require that shipping quantities for one plant to one warehouse or from one warehouse to

one retailer can be greater than 0 only when we open this warehouse. Constraint set (6) sets the total shipping quantity

of one product set equal to the summation of all the shipping quantities of products in this product set. Constraint set

(7) limits opening at most one warehouse at one potential warehouse location. Constraint set (8) requires only one

supplier for each retailer-product combination; the retailer can order directly from the plant or order from one ware-

house. Constraint set (9) assumes random access and guarantees the average inventory level at each warehouse should

be less than the effective capacity of this warehouse. Average inventory includes cycle stock plus safety stock. Effective

capacity is nominally set at 80% of total space (but is easily adjusted). Average inventory is equal to average cycle

inventory plus a safety stock based on replenishment lead time and total product volume. Constraints set (10) and (11)

are non-negative and binary constraints.

4. The model application

Deriving optimal or near-optimal solutions to location problems has fed the growth of the eld of location analysis over

the past three decades (Jamarillo, Bhadury, and Batta 2002). The large number of integer variables makes it computa-

tionally difcult to solve. For this reason a genetic algorithm approach is applied.

4.1 The genetic algorithm overview

The concept of a genetic algorithm (GA) was developed by Holland (1975) and then described by Goldberg (1989).

GAs are stochastic research techniques based on the mechanism of natural selection with the search for better organ-

isms (problem solutions) over time as the organisms evolve by random changes in their genes. Changes that enhance

survival are more likely to be passed down to future generations via reproduction (Konak, Coit, and Smith 2006).

GA starts by creating an initial Population of individuals wherein each individual is dened by a chromosome

consisting of a sequence of genes. An associated tness function (objective function) measures the survival probabil-

ity (solution quality) of a chromosome as a function of its gene sequence. A new generation in GA is built using

operators generally known as Crossover and Mutation operators. In Crossover, two chromosomes, called parents, are

combined together to form two new chromosomes, called offspring. Mutation operators randomly change the value

of genes. A set number of individuals are retained in each generation with the likelihood of survival being based on

the tness function. In the metaheuristic adaptation of evolution, the best individual found is retained as the

incumbent solution.

4.2 GA for warehouses location problem

In recent years genetic algorithms (GAs) have been used to solve several optimisation problems, but applications

of GAs to location models have been relatively few. Hosage and Goodchild (1986) and Chaudhry, He, and

Chaudhry (2003) present an application of GA for the p-median problem. Gen and Syarif (2005) propose a span-

ning tree-based GA to solve a location facility problem considering multi products and multi periods. Finally,

Jamarillo, Bhadury, and Batta (2002) and Zhou, Min, and Gen (2003) propose GA application to two simple

models for location-allocation problems. We present a GA application for a complex model of location consider-

ing several factories with single product production, several potential sites for opening warehouses, multiple cus-

tomers having different and continuous demand for each product and the choice of direct or indirect shipment

from factories and retailers. In the next section we present the GA heuristic in detail and then report the outcome

of empirical tests.

1902 R.G. Askin et al.

D

o

w

n

l

o

a

d

e

d

b

y

[

1

8

1

.

1

1

4

.

1

2

6

.

1

4

7

]

a

t

1

5

:

0

3

0

1

J

u

n

e

2

0

1

4

4.3 GA for the proposed model

4.3.1 Chromosome representation

The chromosome representing the problem solution is composed for each product by three sub-strings representing

respectively: (i) the direct shipment of products from a single factory to networks retailers (i to r), (ii) the link among a

single factory and the possible sites for opening warehouses (i to k), and (iii) the shipment of products from warehouses

to retailers (k to r). (The i to k link is unnecessary since it may be inferred by the other two, but we include it for ease

of description. During implementation, its presence did not impact performance). For each product-retailer there are

K + 1 possible tours for shipment. However, only one route must be chosen. A retailer can be supplied by one of the

warehouses or directly by the plant as showed by Figure 1.

Figure 2 shows a feasible solution where Product 1 (i1) is directly shipped from plant to retailer 1 and through ware-

house k1 for retailer 2. Retailers 1 and 2 are both supplied from warehouse k1 for Product 2. In this scenario warehouse

k2 is not opened and the corresponding chromosome is:

The genes are represented by binary values shown in Table 2. The gene in position 0 that assumes value equal to 1

means that retailer r1 is supplied directly by plant i1 for product 1. The 1 in position 5 indicates warehouse 1 is the

inter model shipment point for product 1 to retailer 2. The gene equal to 1 in position 10 means that there is a link

between plant i2 and warehouse k1. The gene in position 13 means that retailer r2 is supplied by warehouse k1 for

product 2. With respect to the model presented in Section 2, this string represents only the values of variables called

x. The values of variables called w are calculated with a simple method that cheques the value of the chromosomes

genes and decides to open a warehouse when a warehouse supplies at least 1 retailer. With respect to the chromosome

presented in Table 2, the corresponding string for the warehouses opened is shown is Table 3. The value 1 in position 0

means that warehouse k1 will be opened, the value 0 in position 1 means that warehouse k2 will be not opened.

i k r

x

ir

x

ikr

Figure 1. Shipment directions.

i1 k1 r1

i2 k2 r2

Figure 2. A feasible solution.

Table 2. Chromosome representation.

Product 1 (P1) Product 2 (P2)

From i to r From i to k From k to r From i to r From i to k From k to r

1 0 1 0 0 1 0 0 0 0 1 0 1 1 0 0

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

International Journal of Production Research 1903

D

o

w

n

l

o

a

d

e

d

b

y

[

1

8

1

.

1

1

4

.

1

2

6

.

1

4

7

]

a

t

1

5

:

0

3

0

1

J

u

n

e

2

0

1

4

4.3.2 Constraint feasibility and tness function evaluation

For each chromosome we need to control the feasibility with respect to the following constraints:

Single sourcing constraint: for each product a retailer has to be supplied and has to be supplied by the plant or

by just one warehouse.

Warehouses capacity limit.

The total ow entering a warehouse has to be equal to the ow exiting for each product.

If required, the limit about the service level (delivery time).

For the feasible individuals the next step is to calculate the tness function ( ff ) value corresponding to the objective

function of the model presented in Section 2. When the individual chromosome is not feasible with respect to ware-

houses capacity or service level, then the value of ff is assumed to be equal to a big integer called M. When the individ-

ual is not feasible with respect to other constraints then two methods called ToBuilt_1() and ToBuilt_2() are applied in

order to build a feasible solution from a infeasible solution. The rst method operates xing the rst sub-string of the

chromosome and building the rest of it. The second xes the last sub-string of the chromosome and builds the remain-

ing parts respecting the above-mentioned constraints.

4.3.3 Operators

In the general crossover, given a pair of parent strings, an arbitrary cut-off point is picked. The only difference of

our crossover operator with respect to the normal one is the choice of the cut-off point. In order to obtain feasi-

ble offspring, we chose the cut-off randomly from a predened set of possibilities. These points correspond to the

end of substring relative to a product. With respect to Table 1, the unique possible cut-off is between positions 7

and 8.

Mutation is an operation at the genes level. We adopt the typical manner to use this operator. With a pre-dened

probability a gene changes its value, from 1 to 0 or from 0 to 1. We only dene three kinds of mutations depending on

which substring of chromosome is changing. After this operation, the ToBuilt_1 and ToBuilt_2 () methods are applied

as necessary to re-establish the solutions feasibility.

4.3.4 Evolution mechanism

We adopt the mechanism known in the literature as Elitism. For every generation 10% of population represents the

Elit of the set and it is composed of the best solutions found during the evolution process. The remaining 90% of

population changes on basis of pre-determined percentages for applying Crossover and Mutation operators. The evolu-

tion stops when reaching the number of iterations declared or when we do not improve the best solution for a specied

large number of iterations.

4.4 Proposed greedy construction heuristic (GCH)

Merging concepts from opportunity cost and steepest approach, we develop a greedy heuristic for comparison to GA.

The GCH heuristic builds the solution step by step using a cascade method. Iteration makes a decision for a product

retailer pair and includes the decision taken in the previous iterations. The procedure is as follows:

Step 1: Set t = 0.

Step 2: To build a table with I R rows and K + 1 columns and evaluate the feasibility of the solution with respect

to warehouses capacity. If the constraint is satised then calculate the objective function for each product-

mode-retailer combination OF

ikr

(t) comparing the K + 1 possibilities of shipment (directly by plant or by K

warehouses). Otherwise put the OF

ikr

(t) equal to a big integer called M.

Table 3. Locations variables values.

k1 k2

Value 1 0

Position 0 1

1904 R.G. Askin et al.

D

o

w

n

l

o

a

d

e

d

b

y

[

1

8

1

.

1

1

4

.

1

2

6

.

1

4

7

]

a

t

1

5

:

0

3

0

1

J

u

n

e

2

0

1

4

Step 3: Comparing the value of OF

ikr

(t) for each row to select the minimum and the second smallest for each row

respectively called:

Min

ir

= min

k

{OF

ikr

(t)}, SecMin

ir

= min

k

{OF

ikr

(t)/Min

ir

}.

Step 4: Calculate

ir

as the difference between Min

ir

and SecMin

ir

(potential regret).

Step 5: Select the max

ir

{

ir

} and in correspondence to the column, x the solution for the relative product/retailer

couple. Set t = t + 1.

Step 6: Repeat the steps 25 for I R iterations.

Step 7: End.

As an alternative to Step 4, selection may be based solely on Min

ir

.

Table 4 shows an iteration of the heuristic described above. With 3 warehouses, two products, and four retailers, at

the rst iteration, a direct shipment for the couple plant i1 and retailer r1 is xed. The rest of the solution is built

though a cascade method. The selected product-mode-retailer combination is xed and removed from the table. All

affected values are then updated for the next iteration. Thus, the complexity is of O(I

2

R

2

K) consolidation policy and

objective function evaluations.

4.5 Empirical evaluation

4.5.1 Parameters and scenarios denition

Some products can be consolidated for shipment. In our model, we grouped those multiple products into two different

product sets. Consolidation is allowed for shipping products in the same product set, but products from different product

sets must be shipped separately. Holding costs for products are different for different product sets and different holding

places.

Manufacturing facilities and retailers are chosen as major cities in the United States. Potential warehouses can be

located at the locations of retailers. Each warehouse has three possible sizes small, medium and large. The distances

among cities are supplied by Daskin (1995). The xed cost of each warehouse is calculated on the basis of home value

in the respective cities, which is also supplied by Daskin (1995), and capacity of the warehouse which is set according

to potential service amount.

Demands of products at each retailer are normally distributed. The mean is proportional to the population around

that retailer. The variance of demand is calculated using coefcient of variation times mean demand. We set our service

level to be approximately 98% (Z value of 2).

Using trucks to distribute products, lead time between two cities depends on the distance and speed of a truck (500

miles/day). Each truck has specied capacity. Shipping cost of one order is computed as the xed cost of using trucks

plus variable costs which depends on distance and shipping quantity.

We compare eight scenarios dening the set of plants, possible sites for opening warehouses, customers locations

and kind of function used to dene the batch size. Table 5 illustrates the eight scenarios.

Using the chromosome representation described in the Section 4.3.1, the length of chromosome is dened as: Chro-

mosomes length = (number of plants number of customers) + (number of plants number of possible sites for ware-

houses) + (number of possible sites for warehouses number of customers). The length of chromosome joined with the

number of iterations required to reach a feasible solution determines the complexity of the algorithm and consequently

the computation time (CPU). Each element of the chromosome is called a gene so length is dened as number of genes.

Table 4. Heuristic algorithm example.

OF

Direct

shipment

Warehouse 1

opened

Warehouse 2

opened

Warehouse 3

opened Min SecMin Delta

i

1

r

1

680.386 2.327.768 78.905.221 372.698.028 680.386 2.327.768 1.647.382

i

1

r

2

20.002.904 21.318.949 20.992.233 181.298.158 20.002.904 20.992.233 989.329

i

1

r

3

168.036.279 169.608.843 181.057.583 169.554.096 168.036.279 169.554.096 1.517.817

i

1

r

4

82.576.957 84.028.851 92.402.173 199.285.905 82.576.957 84.028.851 1.451.894

i

2

r

1

74.843.490 75.753.105 84.512.660 98.935.406 74.483.490 75.753.105 1.269.615

i

2

r

2

21.002.242 29.974.560 21.741.500 29.248.200 21.002.242 21.741.500 739.258

i

2

r

3

8.939.292 84.280.026 73.877.307 10.039.649 8.939.292 10.039.649 1.100.357

i

2

r

4

36.870.220 80.561.996 67.847.045 36.866.944 36.866.994 36.870.220 3.276

Max 1.647.382

International Journal of Production Research 1905

D

o

w

n

l

o

a

d

e

d

b

y

[

1

8

1

.

1

1

4

.

1

2

6

.

1

4

7

]

a

t

1

5

:

0

3

0

1

J

u

n

e

2

0

1

4

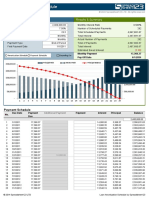

4.5.2 Results

For each scenario above, we test and compare the performance of the genetic and the two versions of the heuristic algo-

rithms. For the GA, we set the runs parameters as follows. The population size is equal to 100 individuals for the rst

six scenarios and equal to 10 for the last two scenarios. The number of iterations has been xed equal to 50,000. The

GA stops when it fails to improve the solution for 10,000 continuous iterations. Table 6 gives the results obtained for

the scenarios presented in the previous section. Heuristics introduced here are applied in Microsoft Visio Studio C++,

and all the computational time is obtained on a Intel(R) Core(TM)2 T5550 at 1.83 GHz using Windows 7.

The heuristic proved computationally efcient and provided the best solution in all but one case. The delta form of

the heuristic (making the selection based on difference between the best and second best options) outperformed the

min form in two cases and the min form performed best in one case. As expected, both forms of the heuristic per-

formed at least as well as direct shipments in all cases and better in ve of eight cases for the delta version and six of

eight for the min version. The genetic algorithm found the unique best feasible solution in the last case and tied for best

in two additional cases where no warehouses were opened. However the genetic algorithm required signicantly longer

computation time.

In addition to the two heuristics discussed earlier, the cost for all direct-shipping is also calculated. The

performances in terms of results are comparable, but the heuristic seems better in terms of CPU time. We also

tested larger scenarios for examples containing a set of 88 customers, two or ve plants, and 190 possible sites

were opening warehouses as suggested by Daskin. In these cases the GA gives solutions in a reasonable time

depending by the choice of population size. We do not report these results due to difculty evaluating the accuracy

of these solutions.

5. Conclusion and future research

This paper presents a new model to guide the design of a distribution network for shipping multiple products, each orig-

inating from its unique production plant, to retailers. Shipments may be direct or use intermediate warehouses for ship-

ment consolidation and/or inventory pooling prior to nal delivery to retail demand points. Facility costs, inventory

costs and shipping costs are considered. The model is exible and may consider factors such as multiple types of deliv-

ery trucks for each segment, full or less than full truck shipments and different service requirements. A bound is derived

on the maximum cost penalty that could be incurred from restricting all deliveries to full truck loads.

The output of the model indicates: (i) the location and capacity level of warehouses to open; (ii) the distribution

route from each production facility to each retailer; (iii) the quantity of products stocked at each warehouse and retailer;

and (iv) the average cost per time for the specied conguration and operating policy. Two versions of a greedy con-

struction heuristic and a genetic algorithm are developed to solve the model. The solution approaches are tested on a set

of problems ranging from two production plants and 10 customer regions to ve production facilities and 49 customer

regions. The construction heuristics are shown to provide computationally efcient approaches to obtain good solutions

as compared to a direct shipment strategy. Given a set of possible warehouse locations and standard cost data for ship-

ping alternatives and storage, the user can evaluate one or multiple scenarios and generate a system design by applying

the heuristic. The genetic algorithm also provides good, feasible solutions but requires greater computational effort to

produce comparable results.

In this work we assume a continuous demand distributed, experimentation further assumed a Gaussian distribution.

Future work could explore discrete demand. Another possible improvement can be the consideration of an additional

Table 5. Design of test problems.

Scenario

Number of

Plants

Number of Locations for

warehouses

Number of

Customers

Function to dene the

batch size

Length of Chromosome

(genes)

1 2 10 10 Floor 140

2 2 10 10 Ceiling 140

3 5 10 10 Floor 600

4 5 10 10 Ceiling 600

5 2 10 49 Floor 608

6 2 10 49 Ceiling 608

7 5 10 49 Floor 2745

8 5 10 49 Ceiling 2745

1906 R.G. Askin et al.

D

o

w

n

l

o

a

d

e

d

b

y

[

1

8

1

.

1

1

4

.

1

2

6

.

1

4

7

]

a

t

1

5

:

0

3

0

1

J

u

n

e

2

0

1

4

T

a

b

l

e

6

.

C

o

m

p

u

t

a

t

i

o

n

a

l

r

e

s

u

l

t

s

.

G

e

n

e

t

i

c

H

e

u

r

i

s

t

i

c

(

M

a

x

{

D

e

l

t

a

=

S

e

c

M

i

n

M

i

n

}

)

H

e

u

r

i

s

t

i

c

(

M

i

n

{

M

i

n

}

)

A

l

l

d

i

r

e

c

t

-

s

h

i

p

p

i

n

g

C

P

U

t

i

m

e

(

s

)

N

u

m

b

e

r

o

f

i

t

e

r

a

t

i

o

n

s

O

b

j

e

c

t

v

a

l

u

e

(

$

)

N

u

m

b

e

r

o

f

o

p

e

n

w

a

r

e

h

o

u

s

e

s

C

P

U

t

i

m

e

(

s

)

N

u

m

b

e

r

o

f

i

t

e

r

a

t

i

o

n

s

O

b

j

e

c

t

v

a

l

u

e

(

$

)

N

u

m

b

e

r

o

f

o

p

e

n

w

a

r

e

h

o

u

s

e

s

C

P

U

T

i

m

e

(

s

)

N

u

m

b

e

r

o

f

i

t

e

r

a

t

i

o

n

s

O

b

j

e

c

t

v

a

l

u

e

(

$

)

N

u

m

b

e

r

o

f

o

p

e

n

w

a

r

e

h

o

u

s

e

s

O

b

j

e

c

t

v

a

l

u

e

(

$

)

1

9

8

4

2

2

3

.

0

5

6

7

E

+

8

4

1

2

0

3

.

0

3

0

3

E

+

8

3

1

2

0

3

.

0

3

0

3

E

+

8

3

4

.

2

1

1

3

E

+

8

2

1

2

3

3

2

9

3

.

0

5

5

1

E

+

8

4

1

2

0

3

.

0

3

0

2

E

+

8

3

1

2

0

3

.

0

3

0

3

E

+

8

3

4

.

2

1

1

2

E

+

8

3

1

4

3

5

9

2

3

8

1

.

1

8

0

7

E

+

9

4

3

5

0

9

.

8

2

7

2

E

+

8

6

3

5

0

9

.

8

4

6

2

E

+

8

7

1

.

1

8

0

0

E

+

9

4

1

2

0

3

1

3

9

9

1

.

1

7

9

7

E

+

9

4

3

5

0

9

.

7

9

1

4

E

+

8

7

2

5

0

9

.

8

4

6

2

E

+

8

7

1

.

1

8

0

1

E

+

9

5

8

0

6

5

2

5

.

0

6

0

2

E

+

7

0

1

0

9

8

5

.

0

6

0

2

E

+

7

0

1

0

9

8

5

.

0

6

0

2

E

+

7

0

5

.

0

6

0

2

E

+

7

6

3

9

5

8

9

5

.

0

6

1

8

E

+

7

0

1

0

9

8

5

.

0

6

1

8

E

+

7

0

9

9

8

5

.

0

6

1

8

E

+

7

0

5

.

0

6

1

8

E

+

7

7

1

7

,

7

7

1

2

3

,

7

6

0

1

.

7

4

3

0

E

+

8

1

4

9

2

4

5

1

.

5

4

5

4

E

+

8

0

2

5

2

4

5

1

.

5

4

5

2

E

+

8

1

1

.

5

4

5

4

E

+

8

8

2

0

,

4

8

6

2

5

,

9

0

0

1

.

5

1

5

2

E

+

8

1

4

9

2

4

5

1

.

5

4

5

2

E

+

8

1

2

4

2

4

5

1

.

5

4

5

2

E

+

8

1

1

.

5

4

5

4

E

+

8

International Journal of Production Research 1907

D

o

w

n

l

o

a

d

e

d

b

y

[

1

8

1

.

1

1

4

.

1

2

6

.

1

4

7

]

a

t

1

5

:

0

3

0

1

J

u

n

e

2

0

1

4

level of consolidation that would allow for early consolidation from multiple plants for long shipments to demand

regions which are then divided into delivery orders at local warehouses within demand regions. This can be modelled

by allowing transhipments between storage facilities. With regards to model solution, other chromosome denitions may

be considered for the genetic algorithm. The use of integers instead of binary values could improve the running time as

a result of chromosomes length reduction. Sensitivity to shipping policies could able be investigated.

References

Ballou, R. H. 1968. Dynamic Warehouse Location Analysis. Journal of Marketing Research 5 (3): 271276.

Bidhandi, H. M., and R. M. Yusuff. 2011. Integrated Supply Chain Planning under Uncertainty Using an Improved Stochastic

Approach. Applied Mathematical Modelling 35 (6): 26182630.

Chaudhry, S. S., S. S. He, and P. E. Chaudhry. 2003. Solving a Class of Facility Location Problems Using Genetic Algorithms.

Expert System 20 (2): 8691.

Cornuejols, G., R. Sridharan, and J. M. Thizy. 1991. A Comparison of Heuristics and Relaxations for the Capacitated Plant Location

Problem. European Journal of Operational Research 50 (3): 280297.

Dasci, A., and V. Verter. 2001. A Continuous Model for Productiondistribution System Design. European Journal of Operational

Research 129 (2): 287298.

Daskin, M. S. 1995. Network and Discrete Location. New York: John Wiley.

Daskin, M. S., C. R. Coullard, and Z.-J. M. Shen. 2002. An Inventory-Location Model: Formulation, Solution Algorithm and Com-

putational Results. Annals of Operations Research 110 (1): 83106.

Eskigun, E., R. Uzsoy, P. V. Preckel, G. Beaujon, S. Krishnan, and J. D. Tew. 2005. Outbound Supply Chain Network Design with

Mode Selection, Lead times and Capacitated Vehicle Distribution Centers. European Journal of Operational Research 165

(1): 182206.

Gebennini, E., R. Gamberini, and R. Manzini. 2009. An Integrated Production Distribution Model for the Dynamic Location and

Allocation Problem with Safety Stock Optimization. International Journal of Production Economics 122 (1): 286304.

Gen, M., and A. Syarif. 2005. Hybrid Genetic Algorithm for Multi-Period Production/Distribution Planning. Computers & Indus-

trial Engineering 48 (4): 799809.

Goldberg, D. E. 1989. Genetic Algorithms in Search, Optimization and Machine Learning. Boston: Addison-wesley Longman.

Hinojosa, Y., J. Puerto, and F. R. Fernndez. 2000. A Multiperiod Two-echelon Multicommodity Capacitated Plant Location Prob-

lem. European Journal of Operational Research 123 (2): 271291.

Holland, J. H. 1975. Adaptation in Natural and Articial Systems. Cambridge: The MIT.

Hosage, C. M., and M. F. Goodchild. 1986. Discrete Space Location-allocation Solutions from Genetic Algorithms. Annals of Oper-

ations Research 6 (2): 3546.

Jamarillo, J. H., J. Bhadury, and R. Batta. 2002. On the Use of Genetic Algorithm to Solve Location Problems. Computers & Oper-

ations Research 29 (6): 761779.

Jawahar, N., A. Gunasekaran, and N. Balaji. 2012. A Simulated Annealing Algorithm to the Multiperiod Fixed Charge Distribution

Problem Associated with Backorder and Inventory. International Journal of Production Research 50 (9): 25332554.

Konak, A., D. Coit, and A. E. Smith. 2006. Multi-objective Optimization Using Genetic Algorithms: A Tutorial. Reliability Engi-

neering and System Safety 91 (9): 9921007.

Lee, J. I. Moon, and J. Park. 2010. Multi-level Supply Chain Network Design with Routing. International Journal of Production

Research 48 (13): 39573976.

Lu, Z., and N. Bostelb. 2007. A Facility Location Model for Logistics Systems including Reverse Flows: The Case of Remanufac-

turing Activities. Computers & Operations Research 34 (2): 299323.

Manzini, R., and E. Gebennini. 2008. Optimization Models for the Dynamic Facility Location and Allocation Problem. Interna-

tional Journal of Production Research 46 (8): 20612086.

Melo, M. T., S. Nickel, and F. Saldanha-da-Gama. 2005. Dynamic Multi-commodity Capacitated Facility Location: A Mathematical

Modeling Framework for Strategic Supply Chain Planning. Computers & Operations Research 33 (1): 181208.

Melo, M. T., S. Nickel, and F. Saldanha-da-Gama. 2009. Facility Location and Supply Chain Management A Review. European

Journal of Operational Research 196 (2): 401412.

Miranda, P. A., and R. A. Garrido. 2004. Incorporating Inventory Control Decisions into a Strategic Distribution Network Design

Model with Stochastic Demand. Transportation Research Part E 40 (3): 183207.

Miranda, P. A., and R. A. Garrido. 2009. Inventory Service-Level Optimization within Distribution Network Design Problem. Inter-

national Journal of Production Economics 122 (1): 276285.

Novaes, A. G. N., J. E. S. Cursi, A. C. L. Silva, and J. C. Souza. 2009. Solving Continuous Locationdistricting Problems with

Voronoi Diagrams. Computers & Operations Research 36 (1): 4059.

Nozick, L. K., and M. A. Turnquist. 2001. Inventory, Transportation, Service Quality and the Location of Distribution Centers.

European Journal of Operational Research 129 (2): 362371.

1908 R.G. Askin et al.

D

o

w

n

l

o

a

d

e

d

b

y

[

1

8

1

.

1

1

4

.

1

2

6

.

1

4

7

]

a

t

1

5

:

0

3

0

1

J

u

n

e

2

0

1

4

Owen, S. H., and M. S. Daskin. 1998. Strategic Facility Location: A Review. European Journal of Operational Research 111 (3):

423447.

zceylan, E., and T. Paksoy. 2013. A Mixed Integer Programming Model for a Closed-loop Supply-chain Network. International

Journal of Production Research 51 (3): 718734.

Ozsen, L., C. R. Coullard, and M. S. Daskin. 2008. Capacitated Warehouse Location Model with Risk Pooling. Naval Research

Logistics 55 (4): 295312.

Pourakbar, M., R. Z. Farahani, and N. Asgari. 2007. A Joint Economic Lot-size Model for an Integrated Supply Network Using

Genetic Algorithm. Applied Mathematics and Computation 189 (1): 583596.

Qi, L., and Z.-J. M. Shen. 2007. A Supply Chain Design Model with Unreliable Supply. Naval Research Logistics 54 (8):

829844.

Revelle, C. S., H. A. Eiselt, and M. S. Daskin. 2008. A Bibliography for Some Fundamental Problem Categories in Discrete Loca-

tion Science. European Journal of Operational Research 184 (3): 817848.

Rudi, N., S. Kapur, and D. F. Pyke. 2001. A Two-location Inventory Model with Transshipment and Local Decision Making. Man-

agement Science 47 (12): 16681680.

Santoso, T., S. Ahmed, M. Goetschalckx, and A. Shapiro. 2004. A Stochastic Programming Approach for Supply Chain Network

Design under Uncertainty. European Journal of Operational Research 167 (1): 96115.

Shen, Z.-J. M., and L. Qi. 2007. Incorporating Inventory and Routing Costs in Strategic Location Models. European Journal of

Operational Research 179 (2): 372389.

Shu, J., C. P. Teo, and Z.-J. M. Shen. 2005. Stochastic Transportation-inventory Network Design Problem. Operational Research

53 (1): 4860.

Silva, F. J. F., and D. S. de la Figuera. 2007. A Capacitated Facility Location Problem with Constrained Backlogging Probabilities.

International Journal of Production Research 45 (21): 51175134.

Snyder, L. V., and M. S. Daskin. 2005. Reliability Models for Facility Location: The Expected Failure Cost Case. Transportation

Science 39 (3): 400416.

Sourirajan, L., L. Ozsen, and R. Uzsoy. 2007. A Single Product Network Design Model with Lead Time and Safety Stock Consider-

ations. IIE Transactions 39 (5): 411424.

Sourirajan, L., L. Ozsen, and R. Uzsoy. 2009. A Genetic Algorithm for a Single Product Network Design Model with Lead Time

and Safety Stock Considerations. European Journal of Operational Research 197 (2): 599608.

Sridharan, R. 1995. The Capacitated Plant Location Problem. European Journal of Operational Research 87 (2): 203213.

Tagaras, G., and D. Vlachos. 2001. A Periodic Review Inventory System with Emergency Replenishments. Management Science

47 (3): 415429.

Weber, A. 1909. Theory of the Location of Industries. Chicago: The University of Chicago Press.

Yao, Z., L. H. Lee, W. Jaruphongsa, V. Tan, and C. F. Hui. 2010. Multi-source Facility Location-allocation and Inventory Problem.

European Journal of Operational Research 207 (2): 750762.

Yigit, W., M. Emin Aydin, and O. Turkbey. 2006. Solving Large-Scale Uncapacitated Facility Location Problems with Evolutionary

Simulated Annealing. International Journal of Production Research 44 (22): 47734791.

Zhou, G., H. Min, and M. Gen. 2003. A Genetic Algorithm Approach to the Bi-Criteria Allocation of Customers to Warehouses.

International Journal of Production Economics 86 (1): 3545.

Appendix

The proposed model assumes use of full-truck loads in transportation. However, the number of full-trucks in each order may be

greater than 1. In practice, these loads may be staggered but we assume all are shipped jointly in our current inventory calculations.

The model could be readily adjusted for other shipping scenarios as discussed earlier in the paper. Here we develop an upper bound

on the loss from use of full truck load shipments.

For each suppliercustomer pair, we want to minimise the total cost for this pair given a policy. Using the same parameters as in

the paper:

Minimise:

TC A a

Q

C

_ _

bl Q

_ _

D

Q

h

Q

2

(A:1)

Let the optimal quantity Q mC, where m may not be an integer. Total Cost function (A.1) becomes

TC(m) (A a dme bl m C)

D

m C

h

m C

2

(A:2)

International Journal of Production Research 1909

D

o

w

n

l

o

a

d

e

d

b

y

[

1

8

1

.

1

1

4

.

1

2

6

.

1

4

7

]

a

t

1

5

:

0

3

0

1

J

u

n

e

2

0

1

4

We want to know the maximum loss between this Q and the better of the oor and ceiling function multiples of C. Dene:

m

1

bmc; m

2

dme;

d

minfTC(m

1

) TC(m) ; TC(m

2

) TC(m)g; if m[1

TC(m

2

) TC(m); if 0\m\1

0; if m 1

_

_

_

TC(m

1

) TC(m)

AD

C

1

m

1

1

m

_ _

aD

C

dm

1

e

m

1

dme

m

_ _

hC

2

(m

1

m)

Note that m 1 m

1

m

TC(m

1

) TC(m)

AD

C

1

m 1

1

m

_ _

aD

C

1

dme

m

_ _

hC

2

(m m)

TC(m

1

) TC(m)

AD

Cm(m 1)

TC(m

2

) TC(m)

AD

C

1

m

2

1

m

_ _

aD

C

dm

2

e

m

2

dme

m

_ _

hC

2

(m

2

m)

Note that m m

2

m 1

TC(m

2

) TC(m)

AD

C

1

m 1

1

m

_ _

aD

C

1

dme

m

_ _

hC

2

(m 1 m)

TC(m

2

) TC(m)

hC

2

d

min

AD

Cm(m 1)

;

hC

2

_ _

; if m > 1

hC

2

; if 0\m\1

0; if m 1

_

_

.

In conclusion, d

hC

2

.

1910 R.G. Askin et al.

D

o

w

n

l

o

a

d

e

d

b

y

[

1

8

1

.

1

1

4

.

1

2

6

.

1

4

7

]

a

t

1

5

:

0

3

0

1

J

u

n

e

2

0

1

4

También podría gustarte

- Optimization Tools for LogisticsDe EverandOptimization Tools for LogisticsCalificación: 3 de 5 estrellas3/5 (2)

- Introduction To Supply ChainDocumento6 páginasIntroduction To Supply ChainAlexisAún no hay calificaciones

- Supply Chain ReviewerDocumento7 páginasSupply Chain ReviewerAlexisAún no hay calificaciones

- Escrito - Inventoy Routing - ProblemaDocumento7 páginasEscrito - Inventoy Routing - Problemapablo reyesAún no hay calificaciones

- INTT 356 Spring 2021 Ch11 HandoutsDocumento26 páginasINTT 356 Spring 2021 Ch11 HandoutsbbilgicberkAún no hay calificaciones

- Integrated Inventory Valuation in Multi-Echelon Production/distribution SystemsDocumento16 páginasIntegrated Inventory Valuation in Multi-Echelon Production/distribution SystemsIsabel Zanella ZancaAún no hay calificaciones

- Logistics ManagementDocumento8 páginasLogistics Managementmadhvendra99Aún no hay calificaciones

- Layout Design of Multiple Blocks Class-Based Storage Strategy WarehousesDocumento10 páginasLayout Design of Multiple Blocks Class-Based Storage Strategy WarehousesAnna LusianaAún no hay calificaciones

- SCMDocumento20 páginasSCMifaAún no hay calificaciones

- Partcipacion 3..Documento11 páginasPartcipacion 3..Ivonne CMAún no hay calificaciones

- Case Paper Inventory ManagementDocumento28 páginasCase Paper Inventory ManagementkintanAún no hay calificaciones

- A Bi-Objective Supply Chain Design Problem With Uncertainty by Cardona-Valdes (2011)Documento12 páginasA Bi-Objective Supply Chain Design Problem With Uncertainty by Cardona-Valdes (2011)jerc1324Aún no hay calificaciones

- Revised Strategy AssignmentDocumento21 páginasRevised Strategy Assignmentebrahim.mohammadiAún no hay calificaciones

- lựa chọn vị trí kho đa tiêu chí bằng tích phân ChoquetDocumento10 páginaslựa chọn vị trí kho đa tiêu chí bằng tích phân ChoquetVo Thi Hong Suong B2003525Aún no hay calificaciones

- (2015) The Production Routing Problem A Review of Formulations and Solution Algorithms PDFDocumento12 páginas(2015) The Production Routing Problem A Review of Formulations and Solution Algorithms PDFJota Mike MikeAún no hay calificaciones

- Swarm IntelliginceDocumento17 páginasSwarm IntelliginceTu LienAún no hay calificaciones

- Transportation Cost in Multi-Item Economic Order Quantity: Full Length Research PaperDocumento9 páginasTransportation Cost in Multi-Item Economic Order Quantity: Full Length Research PaperAkshay ThoratAún no hay calificaciones

- A Multi-Objective Evolutionary Optimization Approach For An Integrated Location-Inventory Distribution Network Problem Under Vendor-Managed Inventory SystemsDocumento18 páginasA Multi-Objective Evolutionary Optimization Approach For An Integrated Location-Inventory Distribution Network Problem Under Vendor-Managed Inventory SystemsLuis Carlos Gonzales RengifoAún no hay calificaciones

- Author: Baker, P An Exploratory Framework of The Role of Inventory and Warehousing in International Supply ChainsDocumento14 páginasAuthor: Baker, P An Exploratory Framework of The Role of Inventory and Warehousing in International Supply ChainsKapil MittalAún no hay calificaciones

- POS Goetschalckx2002Documento18 páginasPOS Goetschalckx2002LudovikAún no hay calificaciones

- Lateral Transshipment PDFDocumento13 páginasLateral Transshipment PDFAbhishek Pratap SinghAún no hay calificaciones

- The 7 Balkan Conference On Operational Research Constanta, May 2005, RomaniaDocumento11 páginasThe 7 Balkan Conference On Operational Research Constanta, May 2005, RomaniabhargavAún no hay calificaciones

- Info SharingDocumento22 páginasInfo Sharingamostan27Aún no hay calificaciones

- Group Assignment Due Date 11.01.2023 Student Name(s)Documento5 páginasGroup Assignment Due Date 11.01.2023 Student Name(s)Duygu AghazadehAún no hay calificaciones

- Literature Review On WarehouseDocumento4 páginasLiterature Review On Warehousec5pjg3xh100% (1)

- Understanding Supply Chain RobustnessDocumento6 páginasUnderstanding Supply Chain RobustnessGuilherme VieiraAún no hay calificaciones

- Frito-Lay - Logistics ModelDocumento16 páginasFrito-Lay - Logistics ModelGopal ArunachalamAún no hay calificaciones

- Cross Docking Literature ReviewDocumento4 páginasCross Docking Literature Reviewea3j015d100% (1)

- Distribution, Warehousing and Material Handling Learning ObjectivesDocumento8 páginasDistribution, Warehousing and Material Handling Learning Objectivesstudentcare mtnAún no hay calificaciones

- A Comprehensive Survey of Guaranteed-Service Models For Multi-Echelon Inventory OptimizationDocumento57 páginasA Comprehensive Survey of Guaranteed-Service Models For Multi-Echelon Inventory Optimization刘向阳Aún no hay calificaciones

- European Journal of Operational Research: Thomas Kirschstein, Frank MeiselDocumento14 páginasEuropean Journal of Operational Research: Thomas Kirschstein, Frank MeiselSơn Trần BảoAún no hay calificaciones

- European Journal of Operational Research: Thomas Kirschstein, Frank MeiselDocumento14 páginasEuropean Journal of Operational Research: Thomas Kirschstein, Frank MeiselQuỳnh NguyễnAún no hay calificaciones

- Supply Chain DriversDocumento37 páginasSupply Chain DriversHarsh ThakurAún no hay calificaciones

- 11 - Chapter 2 PDFDocumento37 páginas11 - Chapter 2 PDFFavor OchiengAún no hay calificaciones

- 011-0161 An Integrated Inventory Control and Facility Location System With Capacity Constraints: A Multi-Objective Evolutionary ApproachDocumento25 páginas011-0161 An Integrated Inventory Control and Facility Location System With Capacity Constraints: A Multi-Objective Evolutionary ApproachomkarbhaskarAún no hay calificaciones

- Merge in TransitDocumento29 páginasMerge in TransitMauricio FurtadoAún no hay calificaciones

- References: Informs Management ScienceDocumento18 páginasReferences: Informs Management ScienceFabian EstebanAún no hay calificaciones

- Ondemand Warehousing2Documento52 páginasOndemand Warehousing2Gaurav SinghAún no hay calificaciones

- The Study of Li & Fung LimitedDocumento19 páginasThe Study of Li & Fung LimitedJames James ChowAún no hay calificaciones

- CostsrelationDocumento26 páginasCostsrelationManprita BasumataryAún no hay calificaciones

- An Emergency LSCMDocumento10 páginasAn Emergency LSCMSoujanya KanagalaAún no hay calificaciones

- An Introduction To Supply Chain ManagementDocumento5 páginasAn Introduction To Supply Chain Managementsukhbir24Aún no hay calificaciones

- Impact of Just-In-Time Inventory Systems On OEM Suppliers: Imds 106,2Documento18 páginasImpact of Just-In-Time Inventory Systems On OEM Suppliers: Imds 106,2newview111Aún no hay calificaciones

- Mahjoob (2021) Multi Product Multi Period (Genetic Algorithm)Documento15 páginasMahjoob (2021) Multi Product Multi Period (Genetic Algorithm)Mouna MonmonAún no hay calificaciones

- SCMDocumento5 páginasSCMSenai21dragoAún no hay calificaciones

- Term Paper OF Operation Management (O.M) : TopicDocumento15 páginasTerm Paper OF Operation Management (O.M) : TopicreyazmbaAún no hay calificaciones

- Introduction To LogisticsDocumento38 páginasIntroduction To LogisticsVivekanand SinghAún no hay calificaciones

- Mixed Integer PROGRAMMINGDocumento11 páginasMixed Integer PROGRAMMINGSumit DhallAún no hay calificaciones

- Third Party Logistics A Literature Review and Research AgendaDocumento9 páginasThird Party Logistics A Literature Review and Research AgendaafdtbbhtzAún no hay calificaciones

- Improved Genetic Algorithm For SCMDocumento14 páginasImproved Genetic Algorithm For SCMThulasi JajendrenAún no hay calificaciones

- Mobile InventoryDocumento15 páginasMobile InventoryclementiAún no hay calificaciones

- Picking Sorting Labeling Packing Loading Units Bill of LadingDocumento3 páginasPicking Sorting Labeling Packing Loading Units Bill of LadingRamanRoutAún no hay calificaciones

- Mathematical Model For WarehouseDocumento13 páginasMathematical Model For WarehouseGhassan SiregarAún no hay calificaciones

- European Journal of Operational ResearchDocumento21 páginasEuropean Journal of Operational ResearchPankaj GoyalAún no hay calificaciones

- A Solution For Cross-Docking Operations Planning For Cross-Docking Operations PlanningDocumento7 páginasA Solution For Cross-Docking Operations Planning For Cross-Docking Operations PlanningCem YuceltenAún no hay calificaciones

- Articol 2 Warehouse DesignDocumento12 páginasArticol 2 Warehouse DesignGabriela Uretu100% (1)

- A Comprehensive Survey of Guaranteed-Service Models For Multi-Echelon Inventory OptimizationDocumento59 páginasA Comprehensive Survey of Guaranteed-Service Models For Multi-Echelon Inventory OptimizationUmang SoniAún no hay calificaciones

- Optimization in Inventory-Routing Problem With Planned TransshipmentDocumento9 páginasOptimization in Inventory-Routing Problem With Planned TransshipmentSteve DemirelAún no hay calificaciones

- Retailer or E-Tailer JORSDocumento10 páginasRetailer or E-Tailer JORSdaxstarAún no hay calificaciones

- Top 25 Articles of MathematicsDocumento11 páginasTop 25 Articles of MathematicsShahzad AbbasAún no hay calificaciones

- IL Digital June2018Documento116 páginasIL Digital June2018AndresMartinez28Aún no hay calificaciones

- 2016-Q4-Market Analysis Services UpdateDocumento12 páginas2016-Q4-Market Analysis Services UpdateAndresMartinez28Aún no hay calificaciones

- Kata SlidesDocumento85 páginasKata SlidesAndresMartinez28Aún no hay calificaciones

- Introduction To Game Theory (Harvard) PDFDocumento167 páginasIntroduction To Game Theory (Harvard) PDFAndresMartinez28Aún no hay calificaciones

- Tuck EverlastingDocumento82 páginasTuck EverlastingAndresMartinez28100% (2)

- Best Practice Manufacturing NZDocumento1 páginaBest Practice Manufacturing NZAndresMartinez28Aún no hay calificaciones

- Phocos Datasheet Pico EngDocumento2 páginasPhocos Datasheet Pico EngAndresMartinez28Aún no hay calificaciones