Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Fluid Velocities - Recommendation

Cargado por

jnmanivannanTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Fluid Velocities - Recommendation

Cargado por

jnmanivannanCopyright:

Formatos disponibles

Recommended Mean Velocities in Pipe From Various Sources

Fluid

Dry Gas 100 fps

Wet Gas 80 fps

High Pressure Steam (150 psig+) 150 fps

Low Pressure Steam (< 50 psig) 100 fps

Air 100 fps

Vapor Lines, General Max velocity 0.3 mach or 0.5 psi/100 ft

Light Volatile Liquid near Bubble Point, Pump Suction 0.5 ft head total suction line

Pump Discharge, Tower Reflux 3 to 5 psi/100 ft

Hot Oil Headers 1.5 psi/100 ft

Vacuum Vapor Lines below 50 MM Abs Pressure Allow max of 5% absolute pressure for friction loss

Source: Branan, "Rules of Thumb for Chemicl Engineers", 2nd ed., Page 5

Typical Design Velocities for Process System Applications

Service

Average liquid process

Pump suction, supercooled fluid

Pump suction, boiling fluid

Boiler feed water

Gravity liquid drain lines

Liquid to reboiler (no pump)

Vapor-liquid mixture out of reboiler

Vapor to condenser

Gravity separator flows

Liquid Fluid

Ammonia, liquid Steel

Benzene Steel

Bromine, liquid Glass

Calcium chloride Steel

Carbon tetrachloride Steel

Chlorine, dry liquid Steel, Schedule 80

Chloroform, liquid Copper, steel

Ethylene dibromide Glass

Ethylene dichloride Steel

Ethylene glycol Steel

Hydrochloric acid, liquid Rubber-lined

Methyl chloride, liquid Steel

Oils, lubricating Steel

Perchlorethylene Steel

Propylene glycol Steel

Sodium chloride solution Steel

Sodium chloride sol'n w/solids Monel, Ni

Sodium hydroxide, 0-30% Steel, Ni

Sodium hydroxide, 30-50% Steel, Ni

6 min; 15 max

6

5

6

5

6

4

6

6

4

4

6

6

5

5

1.5 - 4

2 - 7

15 - 30

15 - 80

6

6

5

6

Velocity, ft/sec

Velocity, ft/sec

4 - 6.5

0.5 - 1.5

1 - 5

0.5 - 3

4 - 8

Pipe Material

Velocity

Sodium hydroxide, 50-73% Steel, Ni

Styrene Steel

Sulfuric acid, 88-93% 316 SS, lead

Sulfuric acid, 93-100% Cast iron; Steel, Sched 80

Trichlorethylene Steel

Vinyl chloride Steel

Vinylidene chloride Steel

Water, average service Steel

Water, pump suction Steel

Water, usual maximum economical Steel

Water, sea and brackish Rubber-lined, Saran

Water, sea and brackish Concrete-lined

Gaseous or Vapor Fluid

Acetylene Steel

Air, 0 to 30 psig Steel

Ammonia Steel

Bromine Glass

Chlorine, dry Steel, Schedule 80

Chloroform Copper, steel

Ethylene Steel

Hydrochloric acid Rubber-lined, Saran

Hydrogen Steel

Methyl chloride Steel

Natural gas Steel

Oxygen (ambient temp.) Steel

Oxygen (low temp.) 304 SS

Steam, 0-30 psi, sat. Steel

Steam, 15 psi up, superheated Steel

Steam, 30-150 psi, sat or superheated Steel

Sulfur dioxide Steel

3 to 8; 6 avg

3 to 8 ; 6 avg

5 to 12

7 to 10

5 to 8

4

6

6

6

4

4

Velocity, ft/sec

30 (max)

6

65

65

100

35

30 to 80

35

100

65

0.1 to 165

0.1 to 250

65

100

65

75 (Max)

65

0.1 to 100

Pipe Material

Max velocity 0.3 mach or 0.5 psi/100 ft

Allow max of 5% absolute pressure for friction loss

Velocity

También podría gustarte

- Recommended velocities and pressure drops for common process pipelinesDocumento5 páginasRecommended velocities and pressure drops for common process pipelinesger80100% (1)

- Slide - Piping and Fluid Moving DevicesDocumento49 páginasSlide - Piping and Fluid Moving DevicesMrunaal NaseryAún no hay calificaciones

- Valves - PresentationDocumento119 páginasValves - Presentationkrahul100% (15)

- Tantaline Surface Alloy For Bursting Disc HoldersDocumento2 páginasTantaline Surface Alloy For Bursting Disc HoldersRoger BoursAún no hay calificaciones

- A 02 1064Documento4 páginasA 02 1064Marliton SalinasAún no hay calificaciones

- 00 AWWA StandardsDocumento3 páginas00 AWWA Standardsliviu_dovaAún no hay calificaciones

- Mechanical seal support systems ASME ANSI API specificationsDocumento18 páginasMechanical seal support systems ASME ANSI API specificationsYang Gul LeeAún no hay calificaciones

- Termowell MTRL Selection GuideDocumento9 páginasTermowell MTRL Selection GuideAnonymous OFP2ygPIdAún no hay calificaciones

- Standards SpreadsheetDocumento14 páginasStandards Spreadsheetyulianus_srAún no hay calificaciones

- Cooling Tower SpecificationDocumento14 páginasCooling Tower SpecificationAmzad DPAún no hay calificaciones

- Steam Purity Considerations For New TurbinesDocumento46 páginasSteam Purity Considerations For New Turbinesomertrik100% (1)

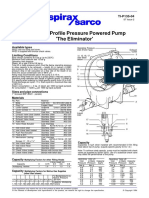

- PPEC Low Profile Pressure Powered Pump 'The Eliminator': Available TypesDocumento2 páginasPPEC Low Profile Pressure Powered Pump 'The Eliminator': Available TypesAndes PutraAún no hay calificaciones

- Pump Protection Valve DatasheetDocumento9 páginasPump Protection Valve DatasheetmishraenggAún no hay calificaciones

- Reguladores de Pressao para Gases Especiais RotarexDocumento100 páginasReguladores de Pressao para Gases Especiais RotarexElias Barros de FigueiredoAún no hay calificaciones

- Academic Word For EngineeringDocumento126 páginasAcademic Word For EngineeringBatari ASAún no hay calificaciones

- SJS 400 Pump Service ManualDocumento85 páginasSJS 400 Pump Service ManualDoni Kurniawan100% (1)

- Sizing Steam Pipes & Steam VelocitiesDocumento3 páginasSizing Steam Pipes & Steam VelocitiesMacarthur B. MonsantoAún no hay calificaciones

- Fluid Velocity in PipesDocumento1 páginaFluid Velocity in PipesDan SabadusAún no hay calificaciones

- Pressure GaugesDocumento36 páginasPressure GaugessenthilrsenthilAún no hay calificaciones

- PumpDocumento25 páginasPumpSenthil RajaguruAún no hay calificaciones

- Book 1Documento2 páginasBook 1louayAún no hay calificaciones

- Service vs. MaterialDocumento3 páginasService vs. MaterialRahul BagulAún no hay calificaciones

- SMC Pneumatics in Process AutomationDocumento12 páginasSMC Pneumatics in Process AutomationVimal Kumar100% (1)

- PFQDocumento9 páginasPFQVictorSanchezAún no hay calificaciones

- Boiler Water ChemistryDocumento63 páginasBoiler Water ChemistryDeepak JayAún no hay calificaciones

- Griffco Calibration Cylinders PDFDocumento2 páginasGriffco Calibration Cylinders PDFPuji RahmawatiAún no hay calificaciones

- Tuthill PumpDocumento3 páginasTuthill PumpRobert CumpaAún no hay calificaciones

- Medidor de Gas - Smith MeterTM Turbine Meters FMCDocumento5 páginasMedidor de Gas - Smith MeterTM Turbine Meters FMCjplutodAún no hay calificaciones

- ADP-1 Pneumatically Operated Liquid Drainer: List of MaterialsDocumento1 páginaADP-1 Pneumatically Operated Liquid Drainer: List of MaterialsJozsef MagyariAún no hay calificaciones

- Design CriteriaDocumento2 páginasDesign CriteriaPrasanna kumar subudhiAún no hay calificaciones

- Industrial Steam Tray ST5 PDFDocumento4 páginasIndustrial Steam Tray ST5 PDFKim Swee LimAún no hay calificaciones

- SulfaTreat Rev - DO - V2aDocumento25 páginasSulfaTreat Rev - DO - V2ayounghwanAún no hay calificaciones

- Astm PDFDocumento5 páginasAstm PDFJacildo Soares Cavalcante CavalcanteAún no hay calificaciones

- FAQ - Pump Tech DetailsDocumento4 páginasFAQ - Pump Tech DetailsRaghavendra SarafAún no hay calificaciones

- Additional Material Take-Off For Olein & SterinDocumento4 páginasAdditional Material Take-Off For Olein & SterinRizki HusniAún no hay calificaciones

- Section 5 Equipment Selection, Sizing & DesignDocumento43 páginasSection 5 Equipment Selection, Sizing & Designgad480Aún no hay calificaciones

- Common EtchantsDocumento2 páginasCommon EtchantsAndiniPermanaAún no hay calificaciones

- 2014 MVB & XTherm Service SchoolDocumento118 páginas2014 MVB & XTherm Service Schoolmalcivar67Aún no hay calificaciones

- Pipe Sizing ChartsDocumento8 páginasPipe Sizing ChartsSuat YilmazAún no hay calificaciones

- 8290 ProportionalR1Documento2 páginas8290 ProportionalR1Jesus N RodriguezAún no hay calificaciones

- 01 Cylinder Pressure RegulatorDocumento10 páginas01 Cylinder Pressure RegulatorZachary NgAún no hay calificaciones

- Flow Meters PresentationDocumento57 páginasFlow Meters Presentationwpt_meAún no hay calificaciones

- Pressure Drop Calculation Equations For PIPING and PIPELINEDocumento3 páginasPressure Drop Calculation Equations For PIPING and PIPELINETiano BaLajadia100% (4)

- Common EtchantsDocumento3 páginasCommon EtchantsValeria Reyes VilchezAún no hay calificaciones

- Centrifugal Slurry PumpDocumento3 páginasCentrifugal Slurry PumpJimmyhuAún no hay calificaciones

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersDe EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersAún no hay calificaciones

- Understanding Process Equipment for Operators and EngineersDe EverandUnderstanding Process Equipment for Operators and EngineersCalificación: 4.5 de 5 estrellas4.5/5 (3)

- Heating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsDe EverandHeating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsAún no hay calificaciones

- English-French and French-English dictionary of the motor car, cycle, and boatDe EverandEnglish-French and French-English dictionary of the motor car, cycle, and boatAún no hay calificaciones

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDe EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsCalificación: 4.5 de 5 estrellas4.5/5 (10)

- The Handbook of Heating, Ventilation and Air Conditioning (HVAC) for Design and ImplementationDe EverandThe Handbook of Heating, Ventilation and Air Conditioning (HVAC) for Design and ImplementationCalificación: 1 de 5 estrellas1/5 (1)

- All-in-One Manual of Industrial Piping Practice and MaintenanceDe EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceCalificación: 5 de 5 estrellas5/5 (1)

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1De EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Calificación: 3.5 de 5 estrellas3.5/5 (3)

- Dictionary of Textile Finishing: Deutsch/Englisch, English/GermanDe EverandDictionary of Textile Finishing: Deutsch/Englisch, English/GermanCalificación: 1.5 de 5 estrellas1.5/5 (3)

- Larsen and Toubro Cement Plant Equipment ListDocumento14 páginasLarsen and Toubro Cement Plant Equipment ListjnmanivannanAún no hay calificaciones

- Dola Char AnalysisDocumento3 páginasDola Char AnalysisS V NAGESHAún no hay calificaciones

- Long Span PrattDocumento36 páginasLong Span PrattCarmel Buniel SabadoAún no hay calificaciones

- COAL COMBUSTION CALCULATIONS AND FLUE GAS ANALYSISDocumento5 páginasCOAL COMBUSTION CALCULATIONS AND FLUE GAS ANALYSISDenny ThomasAún no hay calificaciones

- 22268Documento290 páginas22268jnmanivannanAún no hay calificaciones

- EI2009Documento717 páginasEI2009jnmanivannanAún no hay calificaciones

- Average values and data qualifiers from literature on wastewater constituentsDocumento46 páginasAverage values and data qualifiers from literature on wastewater constituentsjnmanivannanAún no hay calificaciones

- Steam Trap EstimatorDocumento9 páginasSteam Trap EstimatorjnmanivannanAún no hay calificaciones

- Structural Sections SpreadsheetDocumento74 páginasStructural Sections Spreadsheetpiper1985Aún no hay calificaciones

- Brown Field Pipe Rack Design ForcesDocumento7 páginasBrown Field Pipe Rack Design ForcesjnmanivannanAún no hay calificaciones

- Soil Resistivity1Documento12 páginasSoil Resistivity1jnmanivannanAún no hay calificaciones

- AHU Supply Front PackageDocumento10 páginasAHU Supply Front PackagejnmanivannanAún no hay calificaciones

- Emiss Calc HotmixDocumento37 páginasEmiss Calc HotmixjnmanivannanAún no hay calificaciones

- Chimney Qty ReinforcementDocumento25 páginasChimney Qty ReinforcementjnmanivannanAún no hay calificaciones

- EH GPR Checklist v1-2Documento8 páginasEH GPR Checklist v1-2jnmanivannanAún no hay calificaciones

- DFMEA analysis of Sand Bed Turnover Monitor projectDocumento2 páginasDFMEA analysis of Sand Bed Turnover Monitor projectjnmanivannanAún no hay calificaciones

- EI2009Documento717 páginasEI2009jnmanivannanAún no hay calificaciones

- Plant SpecificationsDocumento4 páginasPlant SpecificationsjnmanivannanAún no hay calificaciones

- GEMI Equations ToolDocumento10 páginasGEMI Equations TooljnmanivannanAún no hay calificaciones

- GEMI Equations ToolDocumento10 páginasGEMI Equations TooljnmanivannanAún no hay calificaciones

- H 2 EauDocumento4 páginasH 2 EaujnmanivannanAún no hay calificaciones

- GiwlistDocumento1 páginaGiwlistjnmanivannanAún no hay calificaciones

- Journal of Engineering Physics and Thermophysics Volume 47 Issue 1 1984 (Doi 10.1007 - bf00832588) E. N. Pis'Mennyi - Study of Flow On The Surface of Fins On Cross-Finned TubesDocumento5 páginasJournal of Engineering Physics and Thermophysics Volume 47 Issue 1 1984 (Doi 10.1007 - bf00832588) E. N. Pis'Mennyi - Study of Flow On The Surface of Fins On Cross-Finned TubesjnmanivannanAún no hay calificaciones

- Normality Acid, N Sample Vol: ML PHDocumento10 páginasNormality Acid, N Sample Vol: ML PHjnmanivannanAún no hay calificaciones

- FEMA Equip ScheduleDocumento14 páginasFEMA Equip SchedulejnmanivannanAún no hay calificaciones

- Calculation Form CombustionDocumento2 páginasCalculation Form CombustionjnmanivannanAún no hay calificaciones

- H 2 EauDocumento4 páginasH 2 EaujnmanivannanAún no hay calificaciones

- 보온재두께계산Documento2 páginas보온재두께계산Sharon LambertAún no hay calificaciones

- Fluid HeatDocumento83 páginasFluid HeatjnmanivannanAún no hay calificaciones

- Busbar Size Calculation (22.8.12)Documento16 páginasBusbar Size Calculation (22.8.12)Jeya KannanAún no hay calificaciones