Documentos de Académico

Documentos de Profesional

Documentos de Cultura

377 Series Trip Valves

Cargado por

Mijin28Descripción original:

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

377 Series Trip Valves

Cargado por

Mijin28Copyright:

Formatos disponibles

www.Fisher.

com

D

2

0

0

3

1

8

X

0

1

2

377 Series Trip Valves

The 377 Series pressure-sensing trip valves (see

figures 1 and 2) are for control applications where a

specific valve/actuator action is required when

supply pressure falls below a specific point. When

supply pressure falls below the trip point (see figure

3), the trip valve causes the actuator to fail up, lock

in the last position, or fail down. When the supply

pressure rises above the trip point, the 377 Series

trip valve automatically resets, allowing the system

to return to normal operation. The trip valve can be

top-mounted on a manifold, yoke-mounted, or

bracket-mounted to match the application

requirements. The 377 Series trip valves can be

used with 480, 585C, 1061, 1066, 1069, and G

Series piston actuators.

Features

D Cost EffectiveSingle trip valve construction

reduces costs and spare part requirements of those

systems using three separate switching valves to

perform the failure functions. A single trip valve

greatly simplifies piping requirements.

D Ease of Mode ConversionConversion to any

of the fail modes requires only minor hookup

changes.

D Adjustable Trip ValveThe trip point is

adjustable for specific supply pressure requirements.

D Reliable OperationThe trip valve design

includes large diaphragm areas and few moving

parts for efficient performance, minimum

maintenance, and long service life.

W4292-1/IL

Figure 1. 377 Series Trip Valve

W8435-1

Figure 2. Type 377 Trip Valve Mounted on Size 130 Type

585C Actuator

Product Bulletin

62.3:377

October 2002 377 Series Trip Valves

377 Series Trip Valves

Product Bulletin

62.3:377

October 2002

2

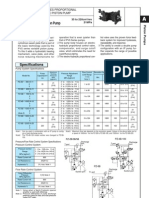

Specifications

Available Configurations

When supply pressure falls below the trip point,

Type 377D Trip Valve: Fails actuator piston

down. Includes check valve and volume tank

Type 377L Trip Valve: Locks actuator piston in

the last position

Type 377U Trip Valve: Fails actuator piston up.

Includes check valve and volume tank.

All 377 Series Trip Valves can be converted to

any of the above fail modes with minor hookup

changes

Allowable Supply Pressure for Trip Valve

Maximum: 10.3 bar (150 psig)

Minimum: 3.8 bar (55 psig)

Outlet Pressure

Normal Operation: Pressure from control device

Fail-Up or Fail-Down Mode: Maximum volume

tank pressure

Lock-In-Last-Position: Respective cylinder

pressure

Trip Point

(1)

Adjustable from a minimum of 2.8 bar (40 psig) to

a maximum of 72 percent of supply pressure; see

figure 3.

Reset: 12.5 to 33 percent above adjusted trip

point

Flow Coefficients (C

v

)

(2)

Depends on flow path (shown in figure 4) as

follows

Port A to Port B: 0.47

Port B to Port C: 0.56

Port D to Port E: 0.48

Port E to Port F: 0.64

Body Connections

1/4-inch NPT female

Temperature Capabilities

Nitrile Diaphragms and O-Rings: 40 to 82!C

(40 to 180!F)

Fluoroelastomer Diaphragms and O-Rings:

18 to 104!C (0 to 220!F)

Volume Tank Maximum Internal Working

Pressure

Standard: 14.5 bar (240 psig) for Type 377D or

377U

ASME Approved: 9.3 bar (135 psig) for Type

377D or 377U

Volume Tank Sizing

See sizing section

Mounting

Top-Mounted: Manifold-mounted between the

positioner and 480 Series actuator (manifolds

cannot be supplied with 585C, 1061, 1066, and

1069 Series piston actuators)

Side-Mounted: Yoke mounted or bracket

mounted

Approximate Weight

Trip Valve: 2.0 kg (4.5 pounds)

Mounting Manifold: 0.5 kg (1.2 pounds)

Volume Tank: Varies between 5.4 and 21 kg (12

and 47 pounds) depending on size

Construction Materials

Body, Spring Case, and ManifoldAluminum

Cover25% mineral-filled thermoplastic

polyester

O-Ringsnitrile or fluoroelastomer

Diaphragmsnitrile or fluoroelastomer

Interior partsbrass, aluminum, steel, and

stainless steel

1. If the trip point is not specified, the trip point is factory-set at 72 percent of supply pressure or 2.8 bar (40 psig), whichever is higher.

2. Values represent nominal C

v

measures for each port pair using a trip valve/actuator combination.

377 Series Trip Valves

Product Bulletin

62.3:377

October 2002

3

10.3

4 5 6 7 8 9 10

110

100

90

80

70

60

50

40

7.6

7

6

5

4

3

150 140 130 120 110 100 90 80 70 60 55

NOTE:

TRIP POINT MAY BE SET TO ANY VALUE BETWEEN

2.8 BAR (40 PSIG) AND THE MAXIMUM TRIP POINT LINE.

RESET OCCURS AT 12.5 TO 33 PERCENT

ABOVE ADJUSTED TRIP POINT.

T

R

I

P

P

O

I

N

T

,

P

S

I

G

T

R

I

P

P

O

I

N

T

,

B

A

R

SUPPLY PRESSURE, BAR

SUPPLY PRESSURE, PSIG

A2779-2/IL

MAXIMUM TRIP POINT

SETTING TO ENSURE

RESET

1

1

2

2

Figure 3. Maximum Trip Point Settings

UPPER

DIAPHRAGM

EXHAUST

PORT

RESTRICTION

PORT A

PORT B

PORT D

PORT E

PLUG

ASSEMBLIES

PORT F PORT C

VALVE

PLUG SPRING

SUPPLY

CONNECTION

LOWER

DIAPHRAGM

W4303-1/IL

Figure 4. Simplified Sectional View of Trip Valve

Principle of Operation

Type 377D Trip Valve

In normal operation, supply pressure loads the upper

diaphragm (see figure 4) of the unit. The valve plug

spring keeps the exhaust port closed. Supply

pressure also loads the lower diaphragm through the

restriction, causing the plug assemblies to move

down and isolate ports C and F while connecting

port A to B and port D to E. Normal actuator control

pressure flows from the control device to the top of

the cylinder through ports A and B and to the bottom

of the cylinder through ports D and E. A volume tank

is charged to maximum supply pressure through a

check valve in order to retain maximum supply

pressure in the volume tank if supply pressure drops.

When supply pressure falls below the trip point

pressure in the fail-down mode (see figure 5), the

exhaust port opens, venting the supply pressure that

is loading the lower diaphragm. This causes the

upper ports of the plug assemblies to close and shut

off normal pressure flow from the control device to

the actuator.

Volume tank pressure then flows through ports C

and B to the top of the actuator cylinder, while

pressure in the bottom of the actuator cylinder is

vented through ports E and F. The pressure

imbalance created forces the actuator piston down.

When supply pressure is restored, it loads the upper

and lower diaphragms, causing the trip valve to

reset. The exhaust port closes. The upper ports of

the plug assemblies open, and the lower ports close.

Normal actuator control pressure flow from the

control device is restored through ports A and B and

ports D and E. The check valve opens and recharges

the volume tank to the maximum supply pressure.

Type 377L Trip Valve

When supply pressure falls below the trip point in the

lock-in-last-position mode (see figure 6), the exhaust

port opens, venting supply pressure from the lower

diaphragm. This causes the upper ports of the plug

assemblies to close and the lower ports to open.

Since ports C and F are plugged, no pressure

change occurs on either side of the actuator piston,

and the piston is pressure-locked in position upon

loss of supply pressure. No volume tank is

necessary in this mode. When supply pressure is

restored, the plug assemblies move back into the

normal operating position, and supply pressure flows

from the control device through ports A and B to the

actuator.

377 Series Trip Valves

Product Bulletin

62.3:377

October 2002

4

35A6996-C

A2283-4/IL

Figure 5. Type 377D Trip Valve Shown Tripped

35A6998-C

A2285-4/IL

Figure 6. Type 377L Trip Valve Shown Tripped

377 Series Trip Valves

Product Bulletin

62.3:377

October 2002

5

SPRING

VALVE PLUG

UPPER

DIAPHRAGM

EXHAUST

PORT

SUPPLY

PRESSURE

LOWER

DIAPHRAGM

PORT D

PORT E

LOWER

PORTS

PORT F

PORT C

PLUG ASSEMBLIES

UPPER PORTS

PORT B

PORT A

VENT

MAIN

SPRING

ACTUATOR

CONTROL

DEVICE

CHECK

VALVE

VOLUME

TANK

SUPPLY PRESSURE

CONTROL PRESSURE TO TOP OF

CYLINDER (BLOCKED)

CONTROL PRESSURE TO BOTTOM

OF CYLINDER (BLOCKED)

PRESSURE FROM TOP OF CYLINDER

(VENTING)

PRESSURE TO BOTTOM OF CYLINDER

(FROM VOLUME TANK)

LOWER DIAPHRAGM LOADING PRESSURE

(BEING VENTED)

35A6997C

A22845 / IL

Figure 7. Type 377U Trip Valve Shown Tripped

Type 377U Trip Valve

The fail-up mode of operation (figure 7) is similar to

the fail-down mode of operation except that

connections to port C and F are reversed. When

supply pressure falls below the trip point, the top of

the actuator cylinder vents, and volume tank

pressure loads the bottom of the actuator cylinder.

The pressure imbalance created forces the actuator

piston up.

377 Series Trip Valves

Product Bulletin

62.3:377

October 2002

6

A2281-1 / IL

Figure 8. Volume Tank Sizing Graph

Volume Tank Sizing

Note: State and local regulations may require the

use of ASME-approved volume tanks. Determine

requirements and applicable regulations for

proper volume tank selection.

Seven different tanks of varying capacities are

available. The volume tank must be selected so that

its pressure at any time is greater than the minimum

percentage of maximum supply pressure required to

stroke the actuator (see figure 8).

1. Size the volume tank as indicated below:

For Actuators on

Sliding Stem Valves,

Determine:

For Actuators on

Rotary-Shaft Valves,

Determine:

Y= F/AP x 100 Y= P

r

/P x 100

Where:

Y = Minimum failure positioning percentage

F = Actuator thrust required in normal operation to

position the valve at the desired limit of travel

A = Effective piston area (from the appropriate

actuator bulletin)

P = Maximum supply pressure available

P

r

=Highest pressure required by the actuator to

stroke the valve (from the appropriate actuator sizing

technique)

2. With the minimum failure positioning percentage

obtained in step 1, enter the value on the abscissa of

the graph in figure 8. Locate the corresponding point

on the curve, and read across to find the volume ratio,

R.

3. Determine:

V

T

= (XA)/R

Where:

X = Maximum actuator travel from the appropriate

actuator bulletin. For rotary actuators, substitute total

displacement (XA). Actuator displacement can be

found in the product bulletin, or contact your Fisher

sales office.

V

T

= Minimum volume tank size required

R = Volume ratio from step 2

377 Series Trip Valves

Product Bulletin

62.3:377

October 2002

7

Table 1. Standard Volume Tank Dimensions

Tank Volume J L

Liters Inch

3

mm Inches mm Inches

11.8

21.6

33.4

42.9

65.6

721

1315

2036

2615

4001

309

310

309

309

309

12.16

12.19

12.16

12.16

12.16

318

451

607

737

1095

12.5

17.75

23.88

29.00

43.12

131.1 8002

Requires two 65.6 liter (4001 inch

3

) volume

tanks

Table 2. ASME-Approved Volume Tank Dimensions

Tank Volume J L

Liters Inch

3

mm Inches mm Inches

8.5

24.9

30.0

42.8

68.8

71.6

518

1520

1831

2609

4199

4371

208

305

254

305

360

305

8.19

12.00

10.00

12.00

14.19

12.00

337

427

684

681

792

1087

13.25

16.81

26.94

26.81

31.19

42.81

143.2 8742

Requires two 71.6 liter (4371 inch

3

) volume

tanks

Canadian Registered

114

227

303

454

6930

13860

18480

27720

406

508

610

610

16

20

24

24

1034

1286

1295

1932

40.69

50.63

51.00

76.06

908 55440

Requires two 454 liter (27720 inch

3

) volume

tanks

AF4605-K

19A7995-A

A2778-4 / IL

57

(2.25)

CAP

REMOVAL

CLEARANCE

1/4-18 NPT

VENT CONNECTION

(mm)

INCH

76

(3.00)

90

(3.56)

54

(2.12)

141

(5.56)

46

(1.81)

100

(3.94)

154

(6.06)

PORT D

PORT E

PORT F

PORT C

STANDARD

TANK

ASMEAPPROVED

TANK

L

L

J

J

1/4-18 NPT

SUPPLY CONNECTION

1

1

NOTE

REFER TO TABLES 1 AND 2 FOR J AND L DIMENSIONS 1

Figure 9. Dimensions of Trip Valve with Manifold (Also See Tables 1 and 2)

Installation

The 377 Series trip valve may be mounted in any

position without affecting normal operation.

Dimensions are shown in figure 9 and tables 1 and

2.

377 Series Trip Valves

Product Bulletin

62.3:377

October 2002

8

Ordering Information

Note: Fisher does not assume responsibility for

the selection, use, or maintenance of any

product. Responsibility for proper selection, use,

and maintenance of any Fisher product remains

solely with the purchaser and end user.

When ordering specify:

Application

1. Available supply pressure

2. Actuator type number and size

3. Input signal range

4. Operating ambient temperature

5. Trip point (If the trip point is not specified, the unit

is factory-set to trip at 72 percent of supply pressure

or 2.8 bar (40 psig), whichever is higher.)

6. Volume tank size

Trip Valve

Refer to the specifications. Review the information

under each specification and in the referenced

figures. Specify the desired choice wherever there is

a selection to be made. Be sure to specify the type

number as described in the Available Configurations

specification.

Refer to table 3 for guidelines on specifying the

correct trip valve.

Table 3. Guidelines for Specifying 377 Series Trip Valve

Actuator Type Fail Mode

Valve

Action

(1)

Trip Valve

Fail Open

PDTC 377U

Sliding-

Fail Open

PDTO 377D

Sliding

Stem

Fail Closed

PDTC 377D

Fail Closed

PDTO 377U

Rotary--

Fully

Clockwise

Clockwise to

377CW

Rotary

Type 1035,

Series G

Fully

Counter-clock

wise

Clockwise to

Close

377CCW

Rotary--

Fully

Clockwise

- - - 377CW

Rotary

Type 1069 Fully Counter-

clockwise

- - - 377CCW

1. PDTCPush Down to Close; PDTOPush Down to Open

Fisher

Marshalltown, Iowa 50158 USA

Cernay 68700 France

Sao Paulo 05424 Brazil

Singapore 128461

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy,

they are not to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use

or applicability. We reserve the right to modify or improve the designs or specifications of such products at any time without notice.

Fisher does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and

maintenance of any Fisher product remains solely with the purchaser and end-user.

EFisher Controls International, Inc. 1985, 2002; All Rights Reserved Printed in USA

Fisher is a mark owned by Fisher Controls International, Inc., a business of Emerson Process Management. The Emerson logo is a trade-

mark and service mark of Emerson Electric Co. All other marks are the property of their respective owners.

Emerson Process Management

www.Fisher.com

También podría gustarte

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGDe EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGAún no hay calificaciones

- Marvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SDe EverandMarvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SAún no hay calificaciones

- Pneumatic Actuator ElementsDocumento49 páginasPneumatic Actuator Elementsdk.vermaAún no hay calificaciones

- Nachi Vane PumpDocumento10 páginasNachi Vane PumpengineermarkAún no hay calificaciones

- 377 Series Trip Valves: Product BulletinDocumento3 páginas377 Series Trip Valves: Product BulletinIsmail AhmadAún no hay calificaciones

- 205 Drag Valves For Boiler Feedpump RecirculationDocumento6 páginas205 Drag Valves For Boiler Feedpump Recirculationesakkiraj1590Aún no hay calificaciones

- Models A & B Automatic Pressure Maintenance DevicesDocumento4 páginasModels A & B Automatic Pressure Maintenance DevicesHIDRUCOL SASAún no hay calificaciones

- All About HidrolicDocumento7 páginasAll About Hidrolicpiteng1945100% (3)

- cULus Listed FM Approved Pressure Maintenance DevicesDocumento4 páginascULus Listed FM Approved Pressure Maintenance DevicesSavy PhanethAún no hay calificaciones

- Variable Vane Pump VDCDocumento14 páginasVariable Vane Pump VDCDian PramadiAún no hay calificaciones

- Pavc Complete Hy28 2662 CDDocumento46 páginasPavc Complete Hy28 2662 CDMoein Emani100% (1)

- Fluid Power Intensifiers Series PC, PD and PS: The Easier, Less Costly Way To Provide High Pressure Hydraulic PowerDocumento8 páginasFluid Power Intensifiers Series PC, PD and PS: The Easier, Less Costly Way To Provide High Pressure Hydraulic PowernvkjayanthAún no hay calificaciones

- Manual Comando Control Air Hd2Documento12 páginasManual Comando Control Air Hd2Brian Schmidt100% (2)

- Proportional Electro-Hydraulic ControlsDocumento31 páginasProportional Electro-Hydraulic ControlshassanHyro43100% (3)

- 5-EN 4050-A (Dig) - 2F1CDocumento9 páginas5-EN 4050-A (Dig) - 2F1Cabuzer1981Aún no hay calificaciones

- Manual 99 LDDocumento20 páginasManual 99 LDCristianAún no hay calificaciones

- Oil Pump Type E 1001 Gear Sizes 4-6-7Documento2 páginasOil Pump Type E 1001 Gear Sizes 4-6-7Titu NicuAún no hay calificaciones

- DV 06 ActuatorsizingDocumento2 páginasDV 06 ActuatorsizinginstsureshAún no hay calificaciones

- Bulletin 62.3:377 specifications and temperature capabilitiesDocumento1 páginaBulletin 62.3:377 specifications and temperature capabilitiesanon_179850881Aún no hay calificaciones

- AP GBDocumento2 páginasAP GBTitu NicuAún no hay calificaciones

- chp 3& 6 ihp msdteDocumento10 páginaschp 3& 6 ihp msdteRocky JAún no hay calificaciones

- 4.oil Hydraulic Circuit Trainer KitDocumento13 páginas4.oil Hydraulic Circuit Trainer KitAlmas 1710Aún no hay calificaciones

- Farval Dr45 & Dr460a Reversing ValvesDocumento8 páginasFarval Dr45 & Dr460a Reversing ValvesanwarmughalAún no hay calificaciones

- Farval Dr45 & Dr460a Reversing ValvesDocumento8 páginasFarval Dr45 & Dr460a Reversing ValvesRobinson MarinAún no hay calificaciones

- RENR8305RENR8305-04 - SIS 777f 1Documento4 páginasRENR8305RENR8305-04 - SIS 777f 1gadolineo100% (1)

- Eaton Hydraulic SystemDocumento16 páginasEaton Hydraulic SystemMuthu Kumar100% (4)

- Series PAVC Variable Displacement, Piston Pumps: Catalog 2600-101-2/USDocumento10 páginasSeries PAVC Variable Displacement, Piston Pumps: Catalog 2600-101-2/USmarvin17100% (1)

- Series RM Rate-Master Flowmeters: Specifications - Installation and Operating InstructionsDocumento2 páginasSeries RM Rate-Master Flowmeters: Specifications - Installation and Operating InstructionsDJoko Trend RedsAún no hay calificaciones

- Diagrama Hidraulico 777FDocumento4 páginasDiagrama Hidraulico 777Ffabioalbor100% (1)

- 7-EN 520-D - D5S 2-PortDocumento16 páginas7-EN 520-D - D5S 2-Portabuzer1981Aún no hay calificaciones

- SV Pumps ControlDocumento20 páginasSV Pumps ControlBala Krishnan NataAún no hay calificaciones

- Pump FundamentalsDocumento127 páginasPump FundamentalsSheik Mohd50% (2)

- Carter Hose End Control Valves GuideDocumento6 páginasCarter Hose End Control Valves GuidemecambAún no hay calificaciones

- Bul 36115 Servo Valve OperationDocumento12 páginasBul 36115 Servo Valve Operationrikkitech100% (1)

- PT-104 Pumping Trap Installation and MaintenanceDocumento12 páginasPT-104 Pumping Trap Installation and MaintenancevkumaranAún no hay calificaciones

- Sur-Flo Products Control Valve Liquid Turbine Meter RunDocumento40 páginasSur-Flo Products Control Valve Liquid Turbine Meter RunCheng HuangAún no hay calificaciones

- CH 5 Control ValvesDocumento42 páginasCH 5 Control ValvesFelix LaraAún no hay calificaciones

- Hydraulic Directional Control and Check ValvesDocumento28 páginasHydraulic Directional Control and Check ValvestunradotAún no hay calificaciones

- Series 2371 Self-Operated Pressure Regulators Pressure Reducing Valves For Food and Pharmaceutical Industries Type 2371-10 Pneumatic Set Point Adjustment Type 2371-11 Manual Set Point AdjustmentDocumento10 páginasSeries 2371 Self-Operated Pressure Regulators Pressure Reducing Valves For Food and Pharmaceutical Industries Type 2371-10 Pneumatic Set Point Adjustment Type 2371-11 Manual Set Point AdjustmenthecdomAún no hay calificaciones

- Pressure Reducing Valve GP-2000Documento8 páginasPressure Reducing Valve GP-2000Anonymous jEXSJ0ebAún no hay calificaciones

- Control Valves in Process PlantDocumento8 páginasControl Valves in Process Plantmukramah.yusufAún no hay calificaciones

- SECTION 07 Hydraulics2 9020-9030Documento16 páginasSECTION 07 Hydraulics2 9020-9030Vjz10997100% (2)

- Manual Training Hydraulic System Caterpillar Backhoe LoadersDocumento23 páginasManual Training Hydraulic System Caterpillar Backhoe Loaderseulogio89% (19)

- GPSA Control - Valve - SizingDocumento10 páginasGPSA Control - Valve - Sizingortegarober100% (1)

- Control Valve HelpDocumento6 páginasControl Valve HelpHimanshu SinghAún no hay calificaciones

- Bombas Serie PV - ParkerDocumento46 páginasBombas Serie PV - Parkergaston_ar44100% (1)

- Rtaa SB 4 - 10011991Documento6 páginasRtaa SB 4 - 10011991alcomech100% (3)

- lt3 00032 2 A p24 p30sDocumento67 páginaslt3 00032 2 A p24 p30sBruno SamaeianAún no hay calificaciones

- D10T Track-Type Tractor Hydraulic System: Dozer Control Valve 5Documento2 páginasD10T Track-Type Tractor Hydraulic System: Dozer Control Valve 5Roberto Antonio Chihuaihuan Araya100% (2)

- Control Balancing ValvesDocumento16 páginasControl Balancing ValvesblindjaxxAún no hay calificaciones

- SS 09Documento3 páginasSS 09Ajaykumar TiwariAún no hay calificaciones

- Hydraulics QuestionsDocumento2 páginasHydraulics QuestionspvrkusbbAún no hay calificaciones

- UVN Series Variable Volume Vane Uni-pumpDocumento3 páginasUVN Series Variable Volume Vane Uni-pumpgreatharunAún no hay calificaciones

- Eaton: Pressure or Pressure-Flow Compensator Control Adjustment ProceduresDocumento4 páginasEaton: Pressure or Pressure-Flow Compensator Control Adjustment ProceduresFernando SabinoAún no hay calificaciones

- AFA Alco Series ValveDocumento3 páginasAFA Alco Series ValveRay RavelAún no hay calificaciones

- Williams V Series Pump IomDocumento32 páginasWilliams V Series Pump IomHectorMaldonado100% (1)

- Engineering Technical Bulletins: Selecting Valves and Piping CoilsDocumento4 páginasEngineering Technical Bulletins: Selecting Valves and Piping Coilsforevertay2000Aún no hay calificaciones

- Automatic Pallet Changer Operator's AddendumDocumento18 páginasAutomatic Pallet Changer Operator's AddendumNam Ngô PhươngAún no hay calificaciones

- Dhi-Nvr4216-16P-4Ks2/L: 16 Channel 1U 2Hdds 16poe Network Video RecorderDocumento3 páginasDhi-Nvr4216-16P-4Ks2/L: 16 Channel 1U 2Hdds 16poe Network Video RecorderMijin28Aún no hay calificaciones

- Calculo de Presion HidrostaticaDocumento3 páginasCalculo de Presion HidrostaticaMijin28Aún no hay calificaciones

- ScripDocumento1 páginaScripMijin28Aún no hay calificaciones

- Types of Valve!!!!!Documento134 páginasTypes of Valve!!!!!BalvinderAún no hay calificaciones

- STT250 Operator Manual en EN1I-6190 Honeywell PDFDocumento59 páginasSTT250 Operator Manual en EN1I-6190 Honeywell PDFSiva KrizzAún no hay calificaciones

- Worcester Controls 10, 15, 20 ACCESS I and 10-40 ACCESS M 39 Actuators Intrinsically SafeDocumento16 páginasWorcester Controls 10, 15, 20 ACCESS I and 10-40 ACCESS M 39 Actuators Intrinsically SafeMijin28Aún no hay calificaciones

- Serial CX ONEDocumento1 páginaSerial CX ONEMijin28Aún no hay calificaciones

- Iphone5 PCB Layout PDFDocumento1 páginaIphone5 PCB Layout PDFLuis RodriguezAún no hay calificaciones

- Types of Valve!!!!!Documento134 páginasTypes of Valve!!!!!BalvinderAún no hay calificaciones

- 4150K and 4160K Series Wizard II Pressure Transmitters ControllersDocumento40 páginas4150K and 4160K Series Wizard II Pressure Transmitters ControllersAkli DjebbariAún no hay calificaciones

- Experion PKSDocumento1 páginaExperion PKSMijin28Aún no hay calificaciones

- Link SDocumento1 páginaLink SMijin28Aún no hay calificaciones

- Worcester Controls 10, 15, 20 ACCESS I and 10-40 ACCESS M 39 Actuators Intrinsically SafeDocumento16 páginasWorcester Controls 10, 15, 20 ACCESS I and 10-40 ACCESS M 39 Actuators Intrinsically SafeMijin28Aún no hay calificaciones

- Wcabr1003 02Documento12 páginasWcabr1003 02Mijin28Aún no hay calificaciones

- 1250Documento1 página1250Mijin28Aún no hay calificaciones

- 206557Documento51 páginas206557Mijin28Aún no hay calificaciones

- Toshiba T300mviDocumento69 páginasToshiba T300mviMijin28Aún no hay calificaciones

- Technical Bulletin, Communicating With Allen-Bradley Programmable Logic ControllersDocumento6 páginasTechnical Bulletin, Communicating With Allen-Bradley Programmable Logic ControllersMijin28Aún no hay calificaciones

- Types of Valve!!!!!Documento134 páginasTypes of Valve!!!!!BalvinderAún no hay calificaciones

- Wcabr1003 02Documento12 páginasWcabr1003 02Mijin28Aún no hay calificaciones

- Pub014 001 00 - 0413Documento12 páginasPub014 001 00 - 0413Mijin28Aún no hay calificaciones

- CMF Manual Chapter 8 - Atlas Copco Air CompressorsDocumento30 páginasCMF Manual Chapter 8 - Atlas Copco Air CompressorsshambhoiAún no hay calificaciones

- Valves and Solenoid Valves Series EDocumento12 páginasValves and Solenoid Valves Series EMijin28Aún no hay calificaciones

- Cromc 6205 enDocumento5 páginasCromc 6205 enMijin28Aún no hay calificaciones

- Est3 Installation&Service ManualDocumento388 páginasEst3 Installation&Service Manualsumankashyap100% (1)

- CflalracDocumento67 páginasCflalracMijin28Aún no hay calificaciones

- Crosby-Pentair Omni 800, 900 DatasheetDocumento24 páginasCrosby-Pentair Omni 800, 900 DatasheetMijin28Aún no hay calificaciones

- 3800series PRV Catalog 0810C R2 PDFDocumento36 páginas3800series PRV Catalog 0810C R2 PDFMrr Afrasiabi0% (1)

- D 103207Documento8 páginasD 103207Mijin28Aún no hay calificaciones

- Actuador EmersonDocumento40 páginasActuador EmersonMijin28Aún no hay calificaciones

- Concept of Microgrid AND Evolution of Smart Grid: Dileep GDocumento45 páginasConcept of Microgrid AND Evolution of Smart Grid: Dileep GDileep GAún no hay calificaciones

- EPL 0006898 ArticleDocumento28 páginasEPL 0006898 ArticleGuillermo IdarragaAún no hay calificaciones

- SS 578 2012 Portable Fire Extinguishers (Formerly CP55)Documento45 páginasSS 578 2012 Portable Fire Extinguishers (Formerly CP55)Andreas Indrakusuma100% (1)

- Troubleshooting KobelcoDocumento10 páginasTroubleshooting KobelcoPaijo100% (24)

- TM 5-5060 1942 Le Roi Motorized Compressor On GMC DeuceDocumento221 páginasTM 5-5060 1942 Le Roi Motorized Compressor On GMC DeuceAdvocateAún no hay calificaciones

- Instr 12205 Elements Transmitters Transducers DisplacersDocumento103 páginasInstr 12205 Elements Transmitters Transducers DisplacersKumar SomasundaramAún no hay calificaciones

- Presentation FatigueDocumento22 páginasPresentation FatigueRavi Kiran MeesalaAún no hay calificaciones

- IEDs; A Contemporary Viewpoint on Threats and PrecautionsDocumento67 páginasIEDs; A Contemporary Viewpoint on Threats and PrecautionsDeepak Mishra100% (2)

- GEA PHE NT enDocumento2 páginasGEA PHE NT enVLASTAR100% (2)

- 21st Refinery Technology Meet - The CompendiumDocumento474 páginas21st Refinery Technology Meet - The CompendiumAnurag Ingle100% (5)

- CHE 511a - EditedDocumento45 páginasCHE 511a - EditedNicoole Tiu0% (1)

- Automotive Application Guide 2014 - BR PDFDocumento60 páginasAutomotive Application Guide 2014 - BR PDFbnc1100% (1)

- Act 139 Factories and Machinery Act 1967Documento45 páginasAct 139 Factories and Machinery Act 1967Adam Haida & Co100% (2)

- Project Report of POL Terminals2 PDFDocumento31 páginasProject Report of POL Terminals2 PDFRashmi RanjanAún no hay calificaciones

- Strategic Analysis of ExxonMobil's GrowthDocumento31 páginasStrategic Analysis of ExxonMobil's Growthashish_1288% (8)

- Centrifugal compressor wet seal gas recoveryDocumento13 páginasCentrifugal compressor wet seal gas recoveryAhmad Riaz KhanAún no hay calificaciones

- User Manual Mariner 50Documento24 páginasUser Manual Mariner 50Cyrille PVAún no hay calificaciones

- Engine Construction and OperationDocumento31 páginasEngine Construction and OperationRohit NewarAún no hay calificaciones

- SKF TIH 030M - 230V SpecificationDocumento3 páginasSKF TIH 030M - 230V SpecificationÇAĞATAY ÇALIŞKANAún no hay calificaciones

- Basic Principles and Operation of A TransformerDocumento28 páginasBasic Principles and Operation of A Transformershaggy_harteAún no hay calificaciones

- Упражнения на отработку Second ConditionalDocumento6 páginasУпражнения на отработку Second ConditionalНаргиля ГаджиеваAún no hay calificaciones

- Day 4 Fossil Fuels Lesson PlanDocumento3 páginasDay 4 Fossil Fuels Lesson Planapi-308499386Aún no hay calificaciones

- Can Your Roof Handle The Weight of Solar Panels?Documento2 páginasCan Your Roof Handle The Weight of Solar Panels?Princess Joan UlitAún no hay calificaciones

- Pneumatic Maneuvering SystemDocumento65 páginasPneumatic Maneuvering Systemminhankyaw100% (3)

- Glycerol Production, Consumption, Prices, Characterization and New Trends in CombustionDocumento19 páginasGlycerol Production, Consumption, Prices, Characterization and New Trends in CombustionmkamalzamanAún no hay calificaciones

- Fermentor TypesDocumento33 páginasFermentor TypesFahad MukhtarAún no hay calificaciones

- MBQ60T65PES Target Datasheet: 650V Field Stop IGBTDocumento1 páginaMBQ60T65PES Target Datasheet: 650V Field Stop IGBTamrAún no hay calificaciones

- Minerals Engineering: Paul W. Cleary, Matt D. SinnottDocumento22 páginasMinerals Engineering: Paul W. Cleary, Matt D. SinnottAlbertoAún no hay calificaciones

- En 16252-2012Documento42 páginasEn 16252-2012Fabio Manente100% (1)

- Chapter 2 Internal Combustion Engine Performance ParametersDocumento10 páginasChapter 2 Internal Combustion Engine Performance ParametersFlancAún no hay calificaciones