Documentos de Académico

Documentos de Profesional

Documentos de Cultura

69kV and Above Oil Immersed Transformer Instruction Manual

Cargado por

Yaser Majeed0 calificaciones0% encontró este documento útil (0 votos)

293 vistas30 páginasnew

Derechos de autor

© © All Rights Reserved

Formatos disponibles

PDF, TXT o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentonew

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

0 calificaciones0% encontró este documento útil (0 votos)

293 vistas30 páginas69kV and Above Oil Immersed Transformer Instruction Manual

Cargado por

Yaser Majeednew

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

Está en la página 1de 30

Power Transformer Instruction Manual

Version 1.0 Page 1 of 30

Oil Filled Power Transformer

Instruction Manual

66 kV and above

JSHP Transformer Co., Ltd.

Power Transformer Instruction Manual

Version 1.0 Page 2 of 30

Table of Contents

1. General

2. Receiving

3. Moving and Handling

4. Storage

5. Assembly and Installation

6. Processing and Vacuuming

7. Field Testing

8. Energization

9. Maintenance

10. Attachments

Power Transformer Instruction Manual

Version 1.0 Page 3 of 30

1. General

This manual applies to J iangSu HuaPengs (J SHP) modern liquid filled power

transformers with high voltage rating of 69 kV and above. It is developed to assist

in transformer receiving, installation, test and maintenance procedures.

1.1 Safety

The installation, operation and maintenance of power transformers present

many potentially dangerous situations such as falling, asphyxiation, high

pressure and high voltage. Always observe safety precautions and follow all

applicable safety procedures such as OSHA requirements, local safety

requirements and safe working practices. Good judgment must be used when

installing, operating and maintaining power transformers.

1.2 Contact information

In the event of shipping damage, or any information that is not covered in this

manual, contact J SHPs Service Department.

J SHP Transformer Co., Ltd.

68 Kunlun Development Zone

Liyang City, J iangsu Province, P.R. China

Phone: +86-519-87319099

Fax: +86-519-87319215

Email: rui_yin@jshp.com

Power Transformer Instruction Manual

Version 1.0 Page 4 of 30

2. Receiving

It is important that shipping damage be detected before the transformer is off-

loaded. A though inspection of the unit and its accessories should be made as

soon as possible to identify any shipping damage. J SHPs transformers are

covered by warranty against defective materials and workmanship. This warranty

does not cover shipping damage and therefore does not relieve the user of the

responsibility of accepting damaged transformer and/or it accessories from the

carrier.

2.1 Inspection on receipt

Representatives from both J SHP and the carrier should be present during the

inspection. Any evidence of damage should be noted on the Bill of Landing.

Before removing the unit from rail car or truck, perform the following

inspections to identify any damage that may have occurred during shipment.

2.1.1 Impact recorder

Impact recorders are provided on all rails and some truck shipment. The

impact recorder used by J SHP is a three way device capable of

measuring shocks in the longitudinal, vertical and transverse directions.

On shipments where impact recorders are provided, remove the tape in

the presence of J SHP and carriers representative. If the tape recorder

stopped or jammed before the transformer reached its destination,

indicate this on the tape. Also write down the tape removal time and date

on the tape. Have a representative sign the tape.

To analyze the tape, it is best to do it indoor or in an area sheltered form

wind. Traces in longitudinal, vertical and transverse directions which are

less than 3G, 2G and 2G are considered acceptable. Impact higher than

those figures is considered rough handling and might cause shipping

damage. In this case, authorization is needed from J SHP to inspect the

unit further. If the traces indicate no probable shipping damage, the

receiving inspection may proceed.

Replace tape in the recorders, seal and ship back to J SHP at the

following address within one week:

J iangSu HuaPeng Transformer Co., Ltd.

No. 68 Kunlun Development Zone

LiYang City, J iangSu Province

PR China 213300

Attn: Shipping Dept.

Power Transformer Instruction Manual

Version 1.0 Page 5 of 30

2.1.2 External inspection

A damaged tank assembly may mean a faulty or damaged transformer. It

is important that the transformer be inspected before it is off-loaded. A

thorough inspection at this point saves time and cost of off-loading a

damaged transformer. In addition, proper claims can be filed if damage

is found or hidden damage is suspected.

i. Transformer tank

Visually inspect transformer tank, cover, drain valve, radiator valves

and other external accessories mounted on the tank. Note any

external damage.

All welds or bolted-on flanges and covers should be in place and

secure, all valves and cabinet doors should be tightly sealed.

Check attached radiators for bent or dented fins.

Look for signs of oil leakage along weld seams on the exterior of

small power transformers which are normally shipped oil filled.

Check gas pressure in the tank for dry air or N2 filled units. These

units should have a positive or negative gas pressure in the tank if

there is no leak. Zero gauge pressure is a good indication of a leak.

Refer to section 2.4 for test for moisture entry if a leak is suspected.

ii. Bracing, blocking and tie down

Inspect bracing, blocking, etc. Note all damage, shifting and

movement, etc. Take photos as well to substantiate possible claims.

Depressed steel platform cars usually have steels blocks welded to

the deck and placed tightly against the transformer base at each end.

Excessive impact could show up as dents in the base of the unit or

results in block movement. Side blocks are normally placed tight

against the base and tank movement will result in as scratched paint.

Flat car or truck loads normally use wood braces and blocking

timbers. Some movement is expected, however, broken blocks or

crashed timbers indicate rough handling.

Anchoring or spring loaded tie down rods should be straight and

tight. All nuts should be tight as well. Any bent or looseness

indicates movement of the unit.

Power Transformer Instruction Manual

Version 1.0 Page 6 of 30

iii. Accessories inspection

Check the packing list against the materials received. Look for

missing creates or containers.

Check radiators or coolers for dented or broken fins, loose or

missing fans, etc.

Check bushings and lightning arresters for cracked or broken

porcelains, oil leaks, porcelain shifts, etc.

Check conservator tanks for dents, cracks and leaks.

2.2 Internal inspection and tests

When required, follow the procedures listed below to conductor internal

inspection.

2.2.1 Safety precautions

Do not allow anyone to enter the tank unless the oxygen content of gas

at the tank bottom is measured and considered acceptable. The oxygen

content should be at between 19.5% and 30%. For units shipped with

nitrogen, purge air space with dry air first.

Always have a person stationed at the opening outside the tank

whenever anyone is in the tank.

Before removing any covers and fittings, Make sure that there is no

gauge pressure in the tank and the oil level is under that particular

opening.

Fire extinguishers should be provided and smoking should not be

allowed.

Ground transformer tank, all windings and all oil handling and

processing equipment.

Do not perform electrical tests while the unit is under vacuum.

Do not walk on the cover while the unit is under vacuum.

2.2.2 Internal inspection preparation

Power Transformer Instruction Manual

Version 1.0 Page 7 of 30

Extreme care must be taken to protect the transformer, especially its

insulation system from damage. Care should also be taken to prevent

foreign materials form entering the tank during inspection.

All personnel working on the top of the tank, while its open, should

empty all pockets and remove all watches and jewelry. Wear protective

clothing and shoe covers.

All tools, hardware and any other foreign objects that will be used

during the inspection should be accounted for. If anything is dropped

into to the tank and cannot be retrieved, notify J SHPs representive

immediately.

Have provisions for closing the tank in case of rain or sudden weather

change.

For transformers shipped dry, follow the steps below to perform internal

inspection.

Adjust the internal pressure to zero PSI before opening the tank.

Record the time tank is opened to determine total exposure time.

Do not open the tank if the transformer temperature is below 0C.

Circulate dry air. When transformer is opened and exposed to the

environment, dry air (dew point of -40C) should be purged

through the tank to prevent moisture entrance. Clear plastic sheets

may be placed over the manhole openings to reduce the air volume

required.

For transformers shipped oil filled, follow the steps below to perform

internal inspection.

Adjust the internal pressure to zero PSI before opening the tank.

Lower the oil level to allow for a limited internal inspection.

Record the time tank is opened to determine total exposure time.

2.3 Perform internal inspections

For transformers shipped dry, the internal inspection should include, but not

limited to, the following:

Access the overall condition of the active parts and all components.

Check internal parts for tightness and damage.

Inspect coils and insulation. Look for misaligned spacers or loose blocks.

Look for loose insulation between the core and core clamps and any signs

of lamination shifting. Make sure core ground lead is not loose.

Power Transformer Instruction Manual

Version 1.0 Page 8 of 30

Conduct core megger at 500 volts. A minimum of 200 volts megohms is

acceptable.

Check lead/cable for insulation abrasions, frayed strands at bushing

connecting stud. Look for broken lead supports.

Check contact alignment and tap leads of the off load tap changer. Make

sure operating mechanism is free of damage.

Check the support of current transformers. Verify that all leads from the

CTs to the terminal blocks are secure and free of damage.

Look for debris at the bottom of the tank.

Look for signs of moisture such as rust or free water.

For transformers shipped oil filled, the internal inspection should include, but

not limited to, the following:

Access the overall condition of the active parts and all components.

Look for signs of moisture such as rust or free water.

Make sure core ground lead is not loose.

A visual inspection, through the oil, should be made to look for evidence

of damage or loose parts.

The oil should be drained completely to allow a thorough inspection if there

are any indications of damage or if the impact recorders indicate excessive

impact.

2.4 Test for moisture

If moisture entrance is suspected, pressurize the tank to 6 PSI gauge pressure

with dry air and look for leaks with soap and bubbles. Check welded and

gasketed joints. If the leaks are found, repair leaks and re-pressurize the tank

to 6 PSI. Let the unit sit for at least 24 hours and perform a dew point

measurement.

The dew point inside a transformer can be related to the partial pressure of

water vapour at the surface of the insulation material. This is called the vapour

pressure and it is measured in micrometers of mercury.

Once known, the vapour pressure and the temperature of the insulation

material determine the moisture content (percent by weight) at the surface of

the insulation material assuming that all the partial pressure of gases in the gas

space and in the insulation have come to equilibrium.

The attached chart, Figure 1, converts the measured dew point into the vapour

pressure. The chart for determining moisture content from vapour pressure is

called the moisture equilibrium chart, Figure 2. using the two charts, the

moisture content can be determined.

Power Transformer Instruction Manual

Version 1.0 Page 9 of 30

To make good judgment of moisture content, the actual temperature of the

insulation materials must be known as accurate as possible. The best way to

accomplish this is to make the dew point measurements in early morning

hours when the insulation temperature, the tank pressure and the ambient

temperature are all still relatively equal. In addition, the vapour pressure must

be adjusted for any overpressure in the transformer tank.

Results which occur in the unacceptable range should be referred to J SHPs

service department.

2.5 Damage claims

All shipping damage, both obvious and hidden, will be filed by J SHP. When

obvious damage is observed, contact J SHP customer service immediately. A

damage report must be completed by the carrier. Under no circumstance is a

damaged shipment to be removed from the rail car or truck without written

authorization from J SHP.

All hidden damage claims should be filed if:

The impact recorders indicate transit impact has exceed 3G, 2G and 2G in

the longitudinal, vertical and lateral direction.

Prolonged period of 2-3 hours or more of vertical ribbon effect is recorded.

The impact recorders did not run full time.

Excessively rough handling is evident.

Contact J SHP customer service immediately if hidden damage is suspected.

The bill of landing should be signed with a statement Unit received with

possible hidden damage.

Power Transformer Instruction Manual

Version 1.0 Page 10 of 30

3. Moving and Handling

When no shipping damage is detected, the customer should remove the

transformer from the rail car or truck and move it to the installation or storage site.

Extreme caution must be used in moving a transformer. Unsafe practices may

result in serious injury or even death. Unsafe practices may also result in major

damage to the transformer, substation equipment or moving equipment.

3.1 Before the move

The outline drawing of each transformer included with this manual has

information on the weight of the unit, clearances required, and the locations of

lifting eyes, jacking pads and mounting pads.

The new location should have been prepared and certified as ready, and the

pathway along which the transformer will be moved should have been cleared

of all obstacles.

Before positioning the transformer on a permanent or temporary pad, the

foundation and surroundings should be checked carefully. Because of the

weight of a power transformer is normally heavy and the weight is

concentrated in a relatively small area, there is considerable stress on both the

transformer and its foundation.

In addition to the strength required to support the unit, the mounting must

provide for maintenance and service access to the transformer.

3.2 Move preparation

3.2.1 Newly received transformer should be inspected in accordance with the

procedures described in the Receiving section of this manual.

3.2.2 For transformers that are to be moved from storage, pre-move inspection

and processing should be performed.

Follow the steps below to prepare the move.

List all accessories and equipment that must be disconnected before

moving.

Relieve pressure in the tank.

Match mark, disconnect and remove all accessories that must be

removed.

Clean and seal all tank openings created by the removal or

disconnection immediately.

Power Transformer Instruction Manual

Version 1.0 Page 11 of 30

Wrap, identify and store all removed items in a dry location pending

reinstallation.

Inspect the tank exterior for damage or deterioration.

Release and remove and bolts or nuts fastening the transformer to its

foundation.

Order, if necessary, damaged components during disassembly.

3.3 Actual move

The outline drawing of each transformer included with this manual has

information on the various weights of the transformer and the precise location

of the various lifting, pulling eyes, skid noses and jack bosses, etc.

When making a decision on the moving technique, take into consideration the

size and weight of the transformer, the job site condition and the type and

capacity of the lifting and moving equipment.

3.3.1 Lifting and moving transformer by crane

Whenever possible, the transformer should be lifted and positioned by

crane. Moving by swing crane should not be attempted if working space

is inadequate or overhead obstacles do not permit the crane boom to be

raised or moved effectively.

When a crane is used to lift the unit, lift hooks or hitches should be

attached only to the lifting eyes built into the tank and the cables must be

held apart by a spreader to prevent bending the lifting lugs or putting too

much strain on other parts of the tank. Safety ropes or guide lines should

be attached only to the towing eyes at the tank base and the load should

be carefully controlled during the lift operation. The load should never

be permitted to swing freely.

Before the transformer can be lifted, the internal pressure should be less

3 PSI.

3.3.2 Moving transformer by rolling or skidding

When lifting a transformer by crane becomes impractical, the

transformer can be moved along the ground by rolling or skidding.

Although the actual moving procedures will vary with the size and

weight of the transformer, the condition of the ground over which it

must be moved, and the travel distance. To ensure a successful move,

the following precautions should be observed.

Power Transformer Instruction Manual

Version 1.0 Page 12 of 30

i. The work surfaces including truck bed, railcar deck, skid way or

rollway and foundations must be as level as possible and absolutely

firm.

ii. Use jack bosses to raise the unit when necessary. Do not attempt to

raise the unit by placing jacks under the base, drain valves, pipe

connections or other attachments. Use the outline drawing for any

special instructions. Generally there are four jack bosses, one at each

corner. When lifting a transformer completely, use all the jacking

pads provided. To avoid springing the base, all jacks should be

loaded evenly. Interlocked hydraulic jacks are recommended for this

purpose.

iii. When the transformer is to be moved on rollers, all rollers used must

be of the same diameter and evenly and closely spaced. The use of

sound hardwood rollers greater than 6 in diameter or steel rollers

greater than 4 in diameter spaced on centers with less than 12

separation must be used. Rollers must extend at least 2 beyond the

tank base.

iv. Movement of the transformer should be controlled at all times. A

tow and drag winching system is recommended with one winch

pulling in the direction of movement and a second acting as a brake.

v. Towing cables must be attached only to the jack pads or

towing/pulling eyes provided. The tow cables should never be

looped around the tank or attached to the radiators/coolers, pipes, etc.

spreading yokes should be used if the hitch configuration will place

undue strain on the towing/pulling eyes on the tank.

vi. When turning a transformer, it is a good practice to place the

plywood or lubricated steel sheets under the base to minimize

turning resistance. Use pulling eyes only to attach the cable. As for

lateral movement, it should be accomplished by the use of the

towing/pulling eyes provided for the purpose.

vii. Keep the transformer level at all times. The transformer must never

be tilted more than 15 from the vertical in any direction.

Power Transformer Instruction Manual

Version 1.0 Page 13 of 30

4. Storage

Generally a transformer should be set up in a permanent location, assembled and

processed for operation as quickly as possible after receiving inspection is

complete. However, if the transformer needs to be stored before installation, the

following rules should be followed.

4.1 Storage location

The foundation should be firm and relatively level. If a transformer is to be

stored on a timber platform, support timbers should be closely and evenly

spaced. Transformers should never be stored on rollers, blocks or jacks. When

transformers are to be partially or fully activated during storage, the

conditions of access and ventilation appropriate to permanent location should

apply.

All transformers stored in temporary locations should be grounded as though

the installation was permanent. Ground connections to both the tank and

installed accessories should be checked carefully. Heaters should be

connected and energized to prevent condensation in closed compartments.

4.2 Storage duration

It is important to know the duration of the storage so proper procedures can be

followed. Generally speaking, the storage duration can be classified as less

than 3 months, between 3 and 18 months and over 18 months.

The storage period should be considered as beginning on the date of shipment

from the factory. All in-transit time and all time consumed in the receiving

process should be included in determining which storage classification is

applicable. An internal inspection is recommended if a transformer is shipped

without oil and will be stored for more than 3 months.

4.2.1 For units to be stored for less than 3 months, the storage procedures

are intended to preserve the as-delivered condition of the transformer.

Where practical, transformers not immediately energized should be

positioned in a permanent location and placed in a semi-active storage

condition. Where storage in a temporary location is necessary, inactive

storage is acceptable, however, the control cabinet and LTC control

cabinet heaters should be energized to prevent condensation.

i. When the transformer is stored in a semi-active mode on a

permanent pad, the transformer should be assembled, fitted with all

the accessories, processed for installation, filled with oil and have

all control cabinets and heaters energized.

Power Transformer Instruction Manual

Version 1.0 Page 14 of 30

ii. When the transformer is stored in an inactive mode on a temporary

pad, the transformer should be kept either in dry air (or nitrogen)

or oil filled.

When transformers are received filled with factory oil, they can be

stored for up to 3 months in the as received condition without

further attention.

To store the transformers in dry air, a positive pressure of 2-3 PSI

should be maintained at all times. A reserve air supply controlled

by a pressure regulator should be connected to the tank. The air

supply should be coupled to the tank via the pressure vacuum

regulator. Both the reserve air supply and tank pressure should be

monitored daily during the first 7 days of the storage period. Gauge

readings should be taken approximately the same time each day

and recorded carefully. If supply and tank pressure remain stable

during this period, the interval between readings may be extended.

To store the transformers in nitrogen, a positive pressure of 0.5-5

PSI should be maintained at all times. For normal pressurization, 2

PSI is recommended. If the tank is pressurized during warm

weather (above 25C), a 3 PSI reading is recommended.

Connections to the tank, installation of gauges or regulators and

monitoring procedures should be the same as described above for

dry air.

4.2.2 For units to be stored between 3 and 18 months, the transformers

should be filled with oil to the proper level. Transformers with

conservators should be filled to about 20 below the cover. The space

above the oil should be pressurized by dry air or nitrogen to 3 PSI.

Control cabinet and LTC control cabinet heaters must be energized to

prevent condensation.

4.2.3 For units to be stored more than 18 months, the transformer should be

completely assembled and fully functional. All accessories should be

installed and connected. All heaters, fans and pumps, etc. should be

connected and operational. Stored equipment should be tested and

maintained as though operational.

4.2.4 Accessories storage. Accessories not mounted on the transformer tank

at the factory or not installed immediately after receiving must be

protected from damage or deterioration during storage. Carefully

reseal shipping boxes opened for inspection and store inside to prevent

damage. All items stored outdoors should be covered and protected

from the weather.

Power Transformer Instruction Manual

Version 1.0 Page 15 of 30

Accessories stored outdoors and are not protected properly from the

weather are susceptible to rust and other moisture related damage.

4.2.5 Removal from storage. During long storage, moisture may accumulate

in transformer insulation if the transformer is not properly stored.

Excessive moisture in the insulation lowers its dielectric strength and

may cause failure

For transformer stored dry, a dew point measurement should be made

before relieving the storage pressure in the tank. When making a dew

point measurement, follow the instructions provided with the dew

point tester. The dew point of the gas sampled should be below the

acceptable limits shown on the moisture equilibrium chart, Figure 1.

1% moisture in the insulation system is considered acceptable.

For transformers stored oil filled, an oil sample should be measured for

moisture content. An acceptable limit is 15 ppm.

5. Assembly and Installation

Assembly and installation methods vary with the size and type of the transformer,

and facilities for handling transformers and their components. J SHPs Parts List

and Shipping Instructions should be used for items that are detached for shipment.

These items should be reassembled on the transformer as instructed below.

5.1 Ground the tank

Before assembling the transformer, the tank should be permanently grounded

by means of the grounding connection provided at the bottom of the tank. The

ground cable must be of correct size and must be 4/O or larger.

5.2 Contamination prevention

Carefully plan for control of all tools, hardware and other objects that are

going to be used in the assembly process.

5.3 Bushing installation

Remove bushings from their crates with care using rope or nylon slings. Make

sure not to damage or chip any of the porcelain skirts on the bushings. If the

porcelain is chipped or cracked, or if there is any other damage to the bushing,

contact J SHP for further instructions. Always make sure that the top end of

the bushing is higher than the lower end when handling bushings.

Power Transformer Instruction Manual

Version 1.0 Page 16 of 30

Place the bushing on a suitable surface for cleaning. The cover removed from

the crate can be used as a base with rugs to cushion the bottom threads. Never

rest the porcelain section on the bushing on anything. Use bushing flange for

support as necessary.

Clean the bushing well using a rag dampened with a fast drying solution such

as denatured alcohol. Check MADS prior to using any solvent. All bushing

surfaces which will be inside the tank should be wiped clean and tried to

prevent contamination of the oil in the tank.

Bushings with draw lead leave the factory with the conductor ends loosely

sealed. Dirt and moisture may accumulate in the conductor tube. To clean this,

draw a cloth saturated with cleaning solvent through the hollow conductor.

Make several passes until the cloth comes out clean. If the bushing comes

with a corona shield, make sure not to make any dent on the shield.

To install bushings, first relieve tank pressure to 0 PSI by loosening a manhole

cover, a shipping cover or a plug, whichever is most convenient to vent the

transformer.

If the transformer is shipped without oil, start flowing dry air through the

transformer. Record the time to determine how long to hold vacuum on the

unit before filling.

For draw lead bushing installation, follow the steps listed below.

i. Remove the bushing shipping plate. Inspect the gasket and make sure

there is no damage. Clean the bushing mounting boss and install the

gasket.

ii. Pass a pull wire down through the center tube of the bushing and

attach it to the small hole in the top of the cable terminal stud. Lower

the bushing into the transformer opening. Do not allow slack in the

pull wire as it may allow the lead to become kinked below the end of

the bushing.

iii. Install the locking pin at the top of the bushing and remove the pull

wire. Thread the terminal cap in to position. Make sure the gasket is in

place. Tighten the terminal cap to seal against the gasket. Torque the

stud nut and cap as directed by the bushing manufacturers installation

instructions.

iv. Install and tighten the bushing flange hardware to apply even pressure

to the flange. Hardware should be tightened alternating across the

flange.

Power Transformer Instruction Manual

Version 1.0 Page 17 of 30

v. Check all leads to maximize clearance to ground or to other electrical

parts.

For bottom connected bushings, follow the steps listed below.

i. Lower the oil level when the transformer is shipped oil filled. Do not

drain oil below the top clamping ring.

ii. If the transformer is shipped dry, start flowing dry air through the

transformer and record the time.

iii. Remove the bushing cover plate. Inspect the gasket to make sure there

is no damage. Clean the bushing mounting boss with a solvent.

iv. Place the bushing into the right position on top of the transformer.

Install the internal transformer connectors to the bottom of the bushing

studs and tighten the bolts alternately and evenly with a wrench.

Secure the bushing on the transformer cover by tightening all the bolts

evenly in several steps. Do not attempt to pull the bolts down to the

final setting on the first tightening. Allow time between each

tightening to allow the gasket to seat properly.

v. Connect the internal bushing cables to the internal bushing spades.

vi. Check all leads to maximize clearances to ground or to other electrical

parts.

5.4 Radiator installation

Do not remove the shipping cover until ready to install radiators. Verify that

all radiator valves on the tank are closed before removing the shipping covers

on the radiator flanges. Use care to prevent gasket and paint damage. It is

recommended that the radiators be lifted from the crate with manila rope with

sling spreaders and be placed across suitable supports while preparing for

mounting to the tank.

Inspect for moisture or contamination inside the radiators headers. Contact

J SHP is contamination is found. Make sure the flange face is free of paint or

other material. Clean gasket groove and flange face and install gaskets.

Lift the radiator by lifting eye in the top header and swing it into position over

the valves. Bolt the radiator header to the valves with the bolts provided and

pull down evenly all the way around. Attach radiators with mounted fans first

and then attach the remaining radiators. Leave the radiator valves closed.

Touch up the paint when necessary.

Power Transformer Instruction Manual

Version 1.0 Page 18 of 30

For transformer shipped or stored with oil, do not allow oil level to fall below

the top of the top coil clamping ring. If there is insufficient oil in the tank, stop

the radiator filling process and add oil before completing radiator filling. If the

unit was shipped or stored over-filled with oil, the radiator valves should be

opened at this time to lower the oil level. Loosen the top radiator header plug

and slowly open the bottom radiator valves one at a time. This will allow the

radiators to be filled from the bottom, avoiding trapping of gases or air

pockets in the radiator. As the oil becomes visible around the header plug or

when all of the gas is purged from the radiators, tighten the header plug and

open the top valve. After all radiators have been filled with oil and the oil

adjusted to the 25C level, remove the top header plug, then reinstall using

Teflon pipe thread tape on the plug to prevent future leaks.

For transformer shipped or stored dry, leave the radiator valves closed until

the unit is ready for oil filling.

5.5 Cooler installation

Coolers should be placed plat on suitable support with fans on the top side.

Remove the shipping covers and make sure there is no internal contamination.

The gasket groove and flange faces should be clean.

5.6 Conservator installation

Install the conservator per outline drawing. Make sure flow pipe is correctly

aligned before tightening the tank down.

Following the mounting of all accessories, a final internal inspection should be

performed if any work has taken place inside the tank. Electrical connections

should be checked for tightness. Bushing gasket sealing and the draw lead

connections should be checked as well. Also check all leads for maximum

clearances. In addition, check the liquid float and operation of the indicator for

free movement.

Finally, verify all tools and foreign materials that have been used inside the tank

have been removed.

Reinstall all manhole and hand hole covers and other covers where a device has

not been installed.

Ground bushings to protect personnel and the transformer.

Record the time that the transformer is closed to determine total exposure time.

Power Transformer Instruction Manual

Version 1.0 Page 19 of 30

6. Processing and Vacuuming

Tests to be performed after final processing (24 hours):

Leak test. Apply 6 PSI of dry air on the unit. Log readings until pressure

levels off indicating no leak.

Core ground test. Hold a steady voltage for 3 minutes with a megger. The

minimum reading should be 200 volts megohms.

Ratio test. Complete readings on all taps and compare with test report

from factory.

Check all current transformers including hot spot heating coil circuit for

open circuit using an ohmmeter.

Oil quality check

Oil samples from the transformer should be taken from the oil sampling valve

at the bottom of the tank. Oil samples from tankers or drums should be taken

from the bottom as well.

Before the oil can be pumped into the transformer, it should have the

following characteristics:

Moisture content <15 ppm

Gas content <0.5%

Dielectric strength: >35 kV (ASTM 877), >60 kV (ASTM 1816, 0.08

gap)

Oil power factor. The maximum allowed is 0.5% at 90C

Processing for transformers shipped or stored oil filled

If any oil must be removed or added for any reason, the oil may be replaced

by one of the following methods.

i. If oil must be removed below the top of the core or below the top of a

350 kV BIL or above terminal board, the oil must be complete removed

and vacuum processed per section 6.4 below.

iii. If limited amount of oil, such as make up oil, is removed, it may be

allowed to add the oil through the manhole by laying the hose on top of

the core and directing the oil along the top of the core. Adding additional

amount of oil entails a greater risk of aeration of the oil and the

possibility of entrapping air bubbles in the windings. This method is

therefore not preferred and should only b used when there is no other

alternative.

Power Transformer Instruction Manual

Version 1.0 Page 20 of 30

If this method is used, a minimum of 24 hour sit time must be observed.

Vacuum filling procedure

Equipment needed for vacuum filling:

Vacuum pump, approximately 150 CFM capable of 200 microns in the

blank-off condition.

Filter press, approximately 30 gallons per minute.

Extra set of filters.

Vacuum gauge.

Vacuum pipes or flexible hoses (2 diameter minimum).

Oil supply lines and connections.

Vacuum valve.

Dry air supply.

The principal function of vacuum treatment is to remove trapped air and

moisture from the insulation. Small gas bubbles have much lower dielectric

strength than the solid and liquid insulation and may cause dielectric failure if

located in high stressed areas.

The transformer should be oil filled on relatively clear days when the

humidity is less the 70%. The oil temperature must be 0C or higher.

Before setting up the vacuum filling procedure the conservator and the air bag

should be checked carefully for any defects and contamination.

Follow the procedures below for vacuum filling:

i. Pressurize the air bag with 0.5 PSIG so that the air bag will be flat and

straight prior to oil filling. This work can be done on the ground before

the conservator is installed on the mounting bracket.

ii. Connect the vacuum line and vacuum gauges in preparation for pulling

a vacuum. An oil sight gauge (or tube) should be installed as well.

iii. Check all radiators or coolers to make sure that all the valves are open

and bolted to the open position.

iv. All transformers should be filled through bottom filling valve.

v. Make sure equalization is achieved between main tank and LTC and

between conservator tank and its bladder.

vi. Pull a vacuum to 1 torr.

Power Transformer Instruction Manual

Version 1.0 Page 21 of 30

vii. Hold a vacuum of at least 1 mm for a minimum of 4 hours, plus an

additional hour for each hour the transformer was open for inspection

and assembly. The vacuum must be held for a minimum of 8 hours at

1 torr. or lower for transformers rated up to 350 kV BIL, 12 hours for

450-550 kV BIL, 24 hours for 650-750 kV BIL and 48 hours ??for

825-1050 kV BIL. During this period, the vacuum level should be

recorded at least once every hour.

viii. At the end of vacuum hold cycle, the oil filling process can then be

started. An oil temperature of 50-75C is recommended as higher

temperature oil will speed up the impregnation of solid insulation.

ix. During oil filling, the vacuum level should be maintained at 5 torr. or

less. The operator should observe the oil sight gauge. When oil level

reaches approximately 10-12 inches form the top of the cover, the oil

filling process should be stopped by closing the top filling valve.

x. Break the vacuum with dry air or nitrogen. The main transformer

should then be pressurized to approximately 0.5 to 1 PSIG. The

vacuum fittings should also be removed at this time and the vent

sealed.

xi. Open the top filling valve. Fill the conservator tank until the oil level

gauge on the conservator register 25C or higher depending on oil

temperature. As the oil is being pumped into the conservator the

pressure in the bag should be observed and air bled off as the oil level

rises. The pressure in the bag should not exceed 2 PSIG during filling.

The vent valves on the conservator tank should be open to relieve the

air pressure in the conservator that will build as the oil is pumped into

the conservator.

xii. Inject 1 PSIG into the bladder. Oil should discharge from the

conservator tank filling valve. Install the male plug on the valve right

after. Adjust oil level so the gauge corresponds to the oil temperature.

Level correction with temperature should be considered.

xiii. Close top filling valve and remove fill line.

xiv. Air that is entrapped in various locations should be bled off as follows:

Normally the air entrapped in the top of the main transformer can

be bled off through the gas monitor.

Some transformers are designed with bushing wells or turrets.

There will be vent valves through which the air must be bled off.

Power Transformer Instruction Manual

Version 1.0 Page 22 of 30

There are some designs in which the top cover will be crowned.

These will have piping with vent valves through which this air

must be bled off.

In other cases there are vent valves on the conservator from which

the air must be bled off.

xv. Check thoroughly that all vent valves are closed so that oil will not be

forced out of them.

xvi. Check the gas monitor to make sure that all air has been purged from

the piping leading to the gas monitor. If this is not done, the gas

monitor will trip and show gas in the transformer.

xvii. It is recommended that the gas monitor be checked one week after the

transformer has been oil filled to confirm that it is reading in the

normal range. If it is not, more than likely there is air entrapped wither

in the gas monitor or the line that must be bled off.

Oil Filling When Core and Coil Assembly Are Below 0C

i. Pull a vacuum of 5 torr. for 4 hours.

ii. Following this, spray hot oil through the cover of the transformer. The

oil should be sprayed so that the stream is broken up into droplets for

more efficient heating of the core and coils. Maintain a vacuum of

10mm or better on the transformer during the oil spraying operation in

order to prevent oxidation of the oil and to aid in the removal of gas

from the insulation.

It will probably be necessary to maintain some oil in the bottom of the

unit to feed the output pump. Usually 12 to 24 inches of oil level in the

bottom will be sufficient. Do not allow the oil level in the bottom to

exceed 36 inches. A clear plastic hose can be used as an oil level

indicator. Pump the oil from the bottom of the transformer through

filters, through degasification and dehumidification equipment,

through the heat exchanger, and finally back to the cover of the

transformer.

The oil temperature entering the tip of the transformer should be as

high as possible but should not exceed 90C. Continue spraying the

hot oil under vacuum until the temperature of the core and coils is well

above 0C. The temperature of the core and the coils will be at

equilibrium conditions when the output oil temperature becomes

constant, and will be within 5C of the temperature of the input oil.

Power Transformer Instruction Manual

Version 1.0 Page 23 of 30

The heating rate can be increased by closing the bottom valves to the

coolers or radiators and by blanketing the outside of the tank to restrict

heat loss.

iii. After the temperature of the core and coils has been elevated above

0C, drain all oil from the tank and coolers or radiators. It will be

necessary to break the vacuum in order to drain the oil. The vacuum

must be broken with dry air (-60C dew point) to prevent condensation

in the tank.

iv. As soon as the oil is drained from the tank, immediately start the

vacuum treatment.

Open all valves to all radiators, pumps, coolers, or other cooling equipment.

Pull vacuum to 1 torr. and hold for 8 hours prior to filling. Then admit oil

(60C) into the top filter press valve while holding the vacuum level at 5 torr.

until oil reaches the normal level as shown by the liquid-level gauge. Then

proceed as explained on Section 6.4.

Safety precautions

Never leave a transformer that is under vacuum unattended.

Never walk or stand on a transformer cover when the unit is under vacuum.

Never apply any voltage to a transformer that is under vacuum.

7. Field Testing

The following tests must be performed before the transformer can be energized.

Oil dielectric strength. The minimum value should be over 40 kV (ASTM

D-877) or 35 kV (ASTM D-1816, 0.04 gap)

Oil power factor. The maximum allowed is 0.05% at 25C or 0.3% at

100C

Oil water content. The maximum 15 ppm

Ratio test. The maximum allowed is within 0.5% of calculated value. The

tested value should also be very close to the factory test results.

Insulation power factor and capacitance including bushings. The

maximum allowed power factor is 0.5% corrected to 20C. Capacitance

should not vary for more than 5% compared with factory test results.

Power Transformer Instruction Manual

Version 1.0 Page 24 of 30

Core ground test. The core ground should have been tested during the

internal inspection. If the internal inspection is not done, the core ground

should be tested at this time.

Winding resistance. The resistance of transformer windings can be

measured using either the resistance bridge method or the Drop in

Potential method. The values reported on the factory test report are

corrected to either 75 or 85C. Correct the measured value to the same

temperature base for comparison.

Current transformers. All current transformers must either have their

secondary windings short circuited or connected to a load before a voltage

is applied. Never open the secondary circuit of a current transformer while

the primary is carrying current. A high voltage might develop which can

be harmful to personnel or equipment.

Accessories test. For transformers furnished with thermometers for

measuring oil and winding temperatures, the settings for the signaling

should be made per customer standard. In addition, all indicators such as

fault pressure relays, pressure relief devices, etc. should be tested. Follow

instructions provided and check that all signals, trappings, etc., are going

through.

Fan motors. The direction of fan motors rotation should be checked to

ensure correct fan cooling.

8. Energization

8.1 Check the following before energization.

Transformer tank and neutral bushing(s) are properly grounded.

The connections to lines, bus bars and ground are secure.

No bushings and arresters are strained.

All bolts and gaskets are sufficiently tightened.

All relays are adjusted to specifications.

No tools or equipment are left on the transformer.

The off load tap changer is in the desired position and is locked in place

with a padlock.

All insulating oil is at its proper position.

Valves from the conservator to the main tank should be in open position.

All radiator/cooler valves should be open and bolted.

All paint damage is repaired.

Silica gel in conservator tank breather should be blue.

Terminal connections in control cabinet are tight.

Power Transformer Instruction Manual

Version 1.0 Page 25 of 30

Place shorting straps across the full CT winding for all CT are not

connected to load. All CT secondary circuit must be grounded, whether

the CT is in use or not, either in the transformer control cabinet or at the

load.

Shorting straps on winding temperature indicator CT terminal block and

line drop compensator CT terminal block should be removed. Similarly,

shorting straps on all other CTs that connected to loads should be

removed.

Make sure heaters in control cabinet are in working condition.

Bleed gas detect relay.

Remove all temporary shipping plugs.

Reset all drag hands on alarm gauges and the LTC position indicator.

8.2 Sitting time

To guarantee complete oil penetration and dissolving of any gas bubbles in the

insulation, the transformer should not be energized until sufficient time has

passed to allow oil to dissolve any gas bubbles which were formed in the

vacuum filling process. The following table sows the recommended sit time

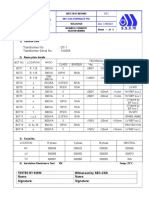

based on units BIL rating.

BIL (kV) Sit time (hours)

350 or less 12

450 to 550 16

650 to 750 24

825 to 1050 48

8.3 Energizing the transformer

Applying full voltage and allow the transformer to operate for at least 2 hours

without load. Listen for abnormal noises. Check for excessive vibrations.

After applying full voltage, the transformer can be loaded. The transformer

should be closely observed during the first few hours of operation under load.

Check gauges to see if specified limits are exceeded.

After several days of operation, check the oil moisture content and dissolved

gas level.

Power Transformer Instruction Manual

Version 1.0 Page 26 of 30

9. Maintenance

Proper maintenance is essential in ensuring trouble free transformer operation.

Power transformers in service are often subjected to various electrical, mechanical

and thermal stresses. In order to avoid faults, it is important to carefully inspect

and maintain the transformers.

Certain items on a transformer must be inspected regularly to ensure proper

operation and long service life. The frequency of these inspections is determined

by the size and type of the transformer, the operating environment and the

importance of the unit.

Internal inspections should be only conducted when there is a suspicion of trouble,

when oil is removed from the tank. In the event a transformer is opened for

inspection, follow the same procedures and precautions as for an initial

installation.

Spare transformer should be inspected and maintained in the same manner as

transformers in operation.

9.1 External maintenance

i. Regular annual inspection is required on transformer tank, tank cover,

gaskets and valves.

ii. Cleaning is another part of external maintenance. Use solvent to

thoroughly remove any oil that is on the tank or the gasket.

The bushing porcelain must be kept clean and inspected yearly. Abnormal

conditions such as sand and dust, salt deposits, chemical fumes, etc.

require more frequent cleaning to avoid accumulations on the surface.

Acceptable methods are hot line washing and washing with solvent.

Keep the heat radiating surface of the transformer clean. External surfaces

of coolers should be periodically cleaned. Transformers near the sea coast

or in highly corrosive environment should be painted regularly to prevent

corroding or rusting of metal parts.

All breathers and small openings in pressure relief valves and pressure-

vacuum bleeders must be kept clean and in good operating condition.

All ground buses and wiring leads to ground must be kept in good

condition.

9.2 Cooling systems

Power Transformer Instruction Manual

Version 1.0 Page 27 of 30

Cooling fan motors use pre-lubricated sealed ball bearings that do not require

lubrication maintenance. During extended periods of reduced capacity not

requiring fan operation, it is suggested that fans be run periodically to ensure

proper operation.

External cooling surfaces should be cleaned annually to remove any

accumulation of dirt or debris that may block external air passages of radiators

or coolers so that free air flow can be maintained.

9.3 Temperature

Transformer temperature, oil and/or winding, is one of the major factors that

determine the life of a transformer. Therefore it is important to monitor the

transformer temperature on a regular basis.

If the temperature of a transformer rises without load increase, it is possible

that some of the cooling is impaired. This situation should be carefully

investigated.

9.4 Oil

Transformer oil is hygroscopic thus easily absorbs moisture from the air. The

absorption of moisture is minimized by the conservator system with a silica

gel breather. The gel should be properly renewed or regenerated as soon as its

ability to absorb moisture begins to diminish. A change of gel colour from

blue to pink indicates saturation with moisture.

If the transformer oil has been exposed to air while work has been carried

out on the transformer, the oil should be checked for moisture content and

dielectric strength. A similar check of the oil should be made on all

transformers at regular intervals. IEC standards provide guidance for the

acceptance, maintenance, continued use and reclamation of insulating oil.

In addition to oil quality checks, oil levels in the tank and LTC mechanism

compartment should be checked weekly during the first month of operation

and annually afterwards.

In addition, dissolved gas analysis should be performed to provide early

warning of evolving problems within the transformer and to allow preventive

actions to be taken before serious damage occurs.

9.5 External circuit and control equipment

The following should be inspected 30 days after installation and once per year

afterwards.

Power Transformer Instruction Manual

Version 1.0 Page 28 of 30

Control circuit voltage.

Excessive heating of parts as evidenced by discoloration of metal parts,

charred insulation or odor.

Freedom of moving parts.

Excessive noise in relay coils.

Excessive arcing in opening circuit.

Evidence of water or oil in the control cabinet.

Proper functioning of timing devices, sequencing of devices, relief device

alarm contacts and thermometer contacts.

9.6 Accessories

All accessories should be tested once a year. Inspect all apparatus, electrical

cables and conductors, signaling and operating devices to the control room or

control board.

9.7 Paint

The paint of the transformer should be free of damage when the unit is put

into service or storage. In order to ensure maximum corrosion protection, all

damage, such as chipped paint or scratches through to the bare metal, should

be fixed and the paint thickness should be restored to its minimum value as

soon as possible.

If bare metal is exposed, the area must be sanded down to blend the damaged

area into the undamaged paint surface. Wipe the sanded area clean with

denatured alcohol or a solvent to remove dust or oil. The area must then be

brush or spray painted with primer, intermediate coat and finish coat. If the

primer is not damaged, lightly sand the damaged paint surface to smooth

rough edges. Brush or spray on the intermediate coat and then the finish coat

to restore or exceed the original finish thickness.

Power Transformer Instruction Manual

Version 1.0 Page 29 of 30

10. Attachments

Figure 1. Dew Point to vapour Pressure Conversion Chart

Power Transformer Instruction Manual

Version 1.0 Page 30 of 30

Figure 2. Moisture Equilibrium Chart

También podría gustarte

- Erection Procedure For Power TransformerDocumento3 páginasErection Procedure For Power Transformerparuchurivenkat5272Aún no hay calificaciones

- Distribution Transformer CIPLDocumento25 páginasDistribution Transformer CIPLanon_515911428Aún no hay calificaciones

- Transformer Installation ManualDocumento38 páginasTransformer Installation ManualbhsujanAún no hay calificaciones

- Transformer Maintenance Operation Installation Instruction Manual enDocumento24 páginasTransformer Maintenance Operation Installation Instruction Manual enelsayedAún no hay calificaciones

- On Transformer ManufacturingDocumento25 páginasOn Transformer ManufacturingThakur Dhananjay Singh Gaur100% (1)

- MG Transformers and Packaged Substations TX5299.V2Documento20 páginasMG Transformers and Packaged Substations TX5299.V2engnajeeb75Aún no hay calificaciones

- Knowledge is "Real Power": Introduction to Power QualityDe EverandKnowledge is "Real Power": Introduction to Power QualityAún no hay calificaciones

- Right Choice of Dry Type or Liquid-Filled TransformerDocumento7 páginasRight Choice of Dry Type or Liquid-Filled TransformerEngr. AbdullahAún no hay calificaciones

- Testing Manual Final PDFDocumento96 páginasTesting Manual Final PDFdgangopadhyay3064Aún no hay calificaciones

- ABB Variable Shunt Reactors For Network Stability Control PDFDocumento4 páginasABB Variable Shunt Reactors For Network Stability Control PDFdes1982100% (1)

- Transformer Test: Prepared By: Nishant AcharyaDocumento30 páginasTransformer Test: Prepared By: Nishant AcharyaVishal PatelAún no hay calificaciones

- Medium Voltage Capacitor Bank SpecificationsDocumento4 páginasMedium Voltage Capacitor Bank SpecificationsAlexander WijesooriyaAún no hay calificaciones

- SS-4 HV TestingDocumento1 páginaSS-4 HV TestingSoumya BhowmickAún no hay calificaciones

- Atvus PRVDocumento6 páginasAtvus PRVvipulpanchotiyaAún no hay calificaciones

- GE Wavecast Dry Type TransformerDocumento16 páginasGE Wavecast Dry Type Transformeranindya19879479Aún no hay calificaciones

- What SF6 Gas TestingDocumento4 páginasWhat SF6 Gas TestingAnonymous V1oLCBAún no hay calificaciones

- Transformer Testing by Afees Ahamed Egger IndiaDocumento27 páginasTransformer Testing by Afees Ahamed Egger IndialrpatraAún no hay calificaciones

- Doble Lemke Power Transformer Advanced PD Monitoring UHF 2009Documento21 páginasDoble Lemke Power Transformer Advanced PD Monitoring UHF 2009taufiqishak09Aún no hay calificaciones

- Testing and Commissioning Report of Olakha SubstationDocumento130 páginasTesting and Commissioning Report of Olakha SubstationCheten Tshering100% (1)

- TransformerDocumento6 páginasTransformerrasheed313Aún no hay calificaciones

- Tan Delta Test - Loss Angle Test - Dissipation Factor Test - Electrical4U PDFDocumento10 páginasTan Delta Test - Loss Angle Test - Dissipation Factor Test - Electrical4U PDFDan AndreiAún no hay calificaciones

- Pre-Commissioning Tests and Checks For Power TransformersDocumento71 páginasPre-Commissioning Tests and Checks For Power TransformersKeshav Chanjal100% (1)

- Schärer-Elektronik AG CH - 5614 Sarmenstorf: Trip Circuit Supervision Relay TSG 910Documento2 páginasSchärer-Elektronik AG CH - 5614 Sarmenstorf: Trip Circuit Supervision Relay TSG 910electrical tecAún no hay calificaciones

- Luckyindia CGL Power Transformer CatalogueDocumento14 páginasLuckyindia CGL Power Transformer CatalogueSharafat AliAún no hay calificaciones

- Transformer OilDocumento4 páginasTransformer OilJohnParkerAún no hay calificaciones

- NGTS 201 Issue2 PDFDocumento27 páginasNGTS 201 Issue2 PDFjuanluismartosAún no hay calificaciones

- Management and Safe Handling Procedures For (Sf6) GasDocumento21 páginasManagement and Safe Handling Procedures For (Sf6) GasKhaled KhaledAún no hay calificaciones

- Power Transformers: Your Partner in Energy SolutionsDocumento24 páginasPower Transformers: Your Partner in Energy SolutionsHamayoun MurtazaAún no hay calificaciones

- Restricted Earth Fault Protection Scheme For Protection of Unit TransformerDocumento54 páginasRestricted Earth Fault Protection Scheme For Protection of Unit TransformerFaizal SamaAún no hay calificaciones

- Power Transformer ENUDocumento32 páginasPower Transformer ENUDaniel RizzoAún no hay calificaciones

- Tan-Delta TestDocumento2 páginasTan-Delta TestRakesh BabuAún no hay calificaciones

- Transformer Protection FinalDocumento72 páginasTransformer Protection FinalAvnish Bhasin100% (2)

- Inrush Phenomena in TransformerDocumento49 páginasInrush Phenomena in TransformerLingaraj PatraAún no hay calificaciones

- On-Site Transformer Testing and DiagnosticsDocumento8 páginasOn-Site Transformer Testing and DiagnosticsJhay Phee LlorenteAún no hay calificaciones

- Method Statement For Partial Discharge Measurement: Application NoteDocumento13 páginasMethod Statement For Partial Discharge Measurement: Application Notejmrs7322Aún no hay calificaciones

- IS 2026-2 (2010) - Power Transformers, Part 2 - Temperature-RiseDocumento17 páginasIS 2026-2 (2010) - Power Transformers, Part 2 - Temperature-Riserajiv71Aún no hay calificaciones

- Bizu Teste Trafo Power Transformer Testing Brochure ENUDocumento32 páginasBizu Teste Trafo Power Transformer Testing Brochure ENUdiogoufrn-1Aún no hay calificaciones

- Main Components of Electrical Substation: Incoming LineDocumento10 páginasMain Components of Electrical Substation: Incoming LineShiv Kumar Verma100% (1)

- On Line Processing of Xmer OilDocumento16 páginasOn Line Processing of Xmer OilrajfabAún no hay calificaciones

- Checklist For VT Rev00Documento3 páginasChecklist For VT Rev00Santhosh Kumar Vinayagam100% (1)

- DFR Measurement On CT PDFDocumento26 páginasDFR Measurement On CT PDFdkymq100% (1)

- Gis Testing RequirementsDocumento7 páginasGis Testing Requirementswaqas_a_shaikh4348Aún no hay calificaciones

- 420kV Reactor - Rev - 08Documento83 páginas420kV Reactor - Rev - 08Anil Marturi100% (1)

- Transformer Tech TestingDocumento60 páginasTransformer Tech TestingCiel Aire100% (1)

- CVT - EMVTS ComparisionDocumento1 páginaCVT - EMVTS ComparisiondseshireddyAún no hay calificaciones

- CRGODocumento15 páginasCRGOipraoAún no hay calificaciones

- AutoTransformers P-169:09 WAPDADocumento58 páginasAutoTransformers P-169:09 WAPDArzor100% (3)

- 380 GIS - Site TestDocumento21 páginas380 GIS - Site TestSameer SyedAún no hay calificaciones

- GT - 1 Bushing Current Transformer Ir Test ReportDocumento5 páginasGT - 1 Bushing Current Transformer Ir Test ReportPrathap KumarAún no hay calificaciones

- GIS Test ProceduresDocumento5 páginasGIS Test ProceduresAnonymous oLacDgIAún no hay calificaciones

- A2.24 Thermal PerformancesID55VER20Documento15 páginasA2.24 Thermal PerformancesID55VER20Fajar Adi PrabowoAún no hay calificaciones

- The Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsDe EverandThe Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsAún no hay calificaciones

- ATDocumento16 páginasATjganguy2004Aún no hay calificaciones

- Distribution Transformer Instruction ManualDocumento10 páginasDistribution Transformer Instruction ManualmartinpellsAún no hay calificaciones

- Liquid Filled Instruction ManualDocumento17 páginasLiquid Filled Instruction ManualedwinAún no hay calificaciones

- Erection Ing Maintenance of Power TfsDocumento82 páginasErection Ing Maintenance of Power TfskameshAún no hay calificaciones

- Transformer Installation & Commissioning With MaintenanceDocumento106 páginasTransformer Installation & Commissioning With MaintenancerpshvjuAún no hay calificaciones

- Areva Transformer ManualDocumento97 páginasAreva Transformer Manualnidnitrkl051296100% (2)

- Operation and Maintenance Manual For SubstationDocumento16 páginasOperation and Maintenance Manual For Substationprathaban723Aún no hay calificaciones

- Pending Works List 25-1-2017Documento3 páginasPending Works List 25-1-2017Yaser MajeedAún no hay calificaciones

- NEIE - Cargo Movement Report - 7961Documento1 páginaNEIE - Cargo Movement Report - 7961Yaser MajeedAún no hay calificaciones

- Income Distribution - Month Ended Jan 31, 2022: 24/7 Call Centre 111-331-331 & 332Documento6 páginasIncome Distribution - Month Ended Jan 31, 2022: 24/7 Call Centre 111-331-331 & 332Yaser MajeedAún no hay calificaciones

- Chemaflex 276Documento5 páginasChemaflex 276Yaser MajeedAún no hay calificaciones

- 220Kv New Chistian Grid Station: Detail of ThimblesDocumento2 páginas220Kv New Chistian Grid Station: Detail of ThimblesYaser Majeed100% (1)

- 220/132 KV New Chishtian Substation: Companies Techical Staff and Mirza Khan Labour's Robbery DetailsDocumento1 página220/132 KV New Chishtian Substation: Companies Techical Staff and Mirza Khan Labour's Robbery DetailsYaser MajeedAún no hay calificaciones

- 220KV High Level (13.5+5.5+4) M 3Documento2 páginas220KV High Level (13.5+5.5+4) M 3Yaser MajeedAún no hay calificaciones

- Submission of Disconnectors DrawingsDocumento1 páginaSubmission of Disconnectors DrawingsYaser MajeedAún no hay calificaciones

- Chief Engineer (Design-I) Barqaab Consulting Services LahoreDocumento1 páginaChief Engineer (Design-I) Barqaab Consulting Services LahoreYaser MajeedAún no hay calificaciones

- 220Kv Sub Station Chishtian: Description 1st Layer 2nd Layer 3rd Layer 4th Layer 5th LayerDocumento1 página220Kv Sub Station Chishtian: Description 1st Layer 2nd Layer 3rd Layer 4th Layer 5th LayerYaser MajeedAún no hay calificaciones

- 220Kv Sub Station Chishtian: Description 1st Layer 2nd Layer 3rd Layer 4th Layer 5th LayerDocumento1 página220Kv Sub Station Chishtian: Description 1st Layer 2nd Layer 3rd Layer 4th Layer 5th LayerYaser MajeedAún no hay calificaciones

- Dismanletling and Reconstruciton of Boundary Wall ModifiedDocumento2 páginasDismanletling and Reconstruciton of Boundary Wall ModifiedYaser MajeedAún no hay calificaciones

- Request For Reimbursement of Soil Investigation BillDocumento1 páginaRequest For Reimbursement of Soil Investigation BillYaser MajeedAún no hay calificaciones

- Saes P 121Documento19 páginasSaes P 121aglegarte50% (2)

- Maintenance Procedure For Switchyard Equipment Volume-II (EHDocumento39 páginasMaintenance Procedure For Switchyard Equipment Volume-II (EHbisas_rishiAún no hay calificaciones

- Determining Settings For Capacitor Bank Protection2columnDocumento9 páginasDetermining Settings For Capacitor Bank Protection2columnvksharma13Aún no hay calificaciones

- JTS 02-04-01 Technical SpecificationDocumento66 páginasJTS 02-04-01 Technical Specificationfabiano_projetoAún no hay calificaciones

- Sabre VRN2a Technical Sales BrochureDocumento6 páginasSabre VRN2a Technical Sales BrochureDerWeisse TigerAún no hay calificaciones

- EE2201 Measurement and Instrumentation Lecture NotesDocumento73 páginasEE2201 Measurement and Instrumentation Lecture NotesDeepa Dhilip100% (1)

- RISHMaster 3430 Versatile Digtial Multifunctional Instrument With 37 Electrical ParametersDocumento5 páginasRISHMaster 3430 Versatile Digtial Multifunctional Instrument With 37 Electrical ParametersAarif PatelAún no hay calificaciones

- 500KV Grid Station Project Report (Final) Power EngineeringDocumento39 páginas500KV Grid Station Project Report (Final) Power EngineeringEngr Kami Sayal50% (4)

- TTR310 ManualDocumento134 páginasTTR310 ManualJonathan FuentesAún no hay calificaciones

- NTPC CW - 3006600303 - Sec - C - Rev - BDocumento93 páginasNTPC CW - 3006600303 - Sec - C - Rev - BGautamupadhyay100% (1)

- Acti 9 Iem3000 - Metsect5cc025Documento2 páginasActi 9 Iem3000 - Metsect5cc025Paun AlAún no hay calificaciones

- Presentation On All Products With Detailed CCV and CTDocumento121 páginasPresentation On All Products With Detailed CCV and CTS ManoharAún no hay calificaciones

- RCMA420 Datasheet NAE1042051Documento6 páginasRCMA420 Datasheet NAE1042051jmmendesAún no hay calificaciones

- Transformer SpecificationDocumento110 páginasTransformer SpecificationS Rao CheepuriAún no hay calificaciones

- Areva DigsilentDocumento28 páginasAreva DigsilentAniela0% (1)

- Specification of 400kva Standard 11000/415V Distribution SubstationDocumento6 páginasSpecification of 400kva Standard 11000/415V Distribution SubstationHarun Mohamod100% (1)

- Stator Differential Protection During Transformer Inrush Conditions in The 489Documento4 páginasStator Differential Protection During Transformer Inrush Conditions in The 489meraatAún no hay calificaciones

- Users Manual: Earth Ground ClampDocumento30 páginasUsers Manual: Earth Ground Clamptesya konelaAún no hay calificaciones

- P63x UK M A543Documento638 páginasP63x UK M A543Hung VuAún no hay calificaciones

- Magneto Optic Current Transformer Technology (MOCT) : Attish JainDocumento5 páginasMagneto Optic Current Transformer Technology (MOCT) : Attish JaindiljithAún no hay calificaciones

- Internship ThesisDocumento23 páginasInternship ThesisWaqas Shah0% (2)

- Current Transformer GuideDocumento47 páginasCurrent Transformer GuideSrinivas KosuruAún no hay calificaciones

- Gae CT-110Documento2 páginasGae CT-110aditarmandoAún no hay calificaciones

- Capacitor Bank DesignDocumento31 páginasCapacitor Bank DesignRamani Ranjan Chiku100% (1)

- PowerPoint - Introduction To Protection Relay - RevBDocumento44 páginasPowerPoint - Introduction To Protection Relay - RevBGopinath SubramaniAún no hay calificaciones

- Relay SettingDocumento144 páginasRelay SettingJaleesAún no hay calificaciones

- 03 TLP Using Directional Overcurrent Elements Part I r5Documento46 páginas03 TLP Using Directional Overcurrent Elements Part I r5afmAún no hay calificaciones

- CSEB (Chhattisgarh State Electricity Board) Korba East Vocational Training Presentation I IDocumento44 páginasCSEB (Chhattisgarh State Electricity Board) Korba East Vocational Training Presentation I Ihaxxo24Aún no hay calificaciones

- Selec Product Catlog PDFDocumento58 páginasSelec Product Catlog PDFiyappan5016Aún no hay calificaciones

- EE4T2 Electrical Measurements & InstrumentationDocumento2 páginasEE4T2 Electrical Measurements & InstrumentationOluwamodupe EstherAún no hay calificaciones