Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Broaches - Basic Characteristic

Cargado por

Dhan CDerechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Broaches - Basic Characteristic

Cargado por

Dhan CCopyright:

Formatos disponibles

Broaches The basic characteristic

Broaches handle mass production with high accuracy and high efficiency.

It is very important to point out that complex shapes can be steadily produced without

requiring special skills.

Broaches are widely used for small batches production or wide variety of products as well.

The most important characteristic of broaching operation are:

Extremely short machining time with high accuracy

Easy machining of the same complex shapes in the axis direction

No special skill are required, since machining condition such as depth of cut per

tooth or the total amount of cutting are decided when designed and manufactured

Fine finish surface, and high accuracy of size

Workpiece is fixed by pressure when cutting

Parts names

There are many types of broaches, but basically the broaches for internals have the same

characteristic elements.

The figure N1 shows a typical broach with the following part names:

Fig. N1

1)- Pull end (shank)

2)- Retriever (rear shank)

3)- Chamfer of front pilot

4)- Front pilot

5)- Active part (with cutting teeth)

6)- Rear pilot

Design of an internal broach is determined by the specification of the broaching machine:

shape and size of grip part, pulling out capacity, length that can manage by stroke length,

the shape and size of the workpiece to be processed.

The shank and the rear shank length must be designed in according with the machine

characteristic.

The front pilot (entry guide) must be longer than the length of the workpiece in order to

always correctly guide the tooth that first cut into the material. This is to be added to the

cutting length when there is a recess in the middle or on the processing standard surface

of the workpiece to be machined.

Standard width allowance of pre-broaching hole diameter is 0,05 mm, but its better to link

this value both to outside diameter of the broach and to the accuracy of pre-broaching

bore (see table N1 and fig. N2), in order o reduce the deviation angle .

Sometimes its better to make a double chamfering before the guide diameter in order to

facilitate the entry of the workpiece in the guide; see figure N3.

Fig. N2

Fig.N3

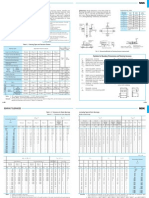

Tab.N1- Value of a (in mm) for different Diam. and accuracy of the pre-broaching bore

Diameter of the bore Bore finished by reamer Bore finished by 2 drill pass Bore finished by 1 drill pass

10 mm 0,02 0,07 0,20

20 mm 0,03 0,07 0,25

30 mm 0,03 0,08 0,30

40 mm 0,04 0,08 0,40

50 mm 0,04 0,09 0,45

60 mm 0,04 0,09 0,50

80 mm 0,05 0,10 0,50

90 mm 0,05 0,10 0,50

100 mm 0,06 0,11 0,50

The deviation angle can be calculated with: =

There are the best condition when L

1

= L V but if the length of the workpiece L is

more of 75 mm is enough to have

The shapes and the sizes of the pull end (shank) are object of the UNI and DIN

normalization. With reference of figure N4 there are the following norms numbers:

Fig.N4-A = UNI 4117 and DIN 1415

Fig.N4-B = UNI 4117 and DIN 1415

Fig.N4-C = UNI 4120 and DIN 1415

Fig:N4-D = UNI 8083 and DIN 1417

Fig.N4-D = Drummond standard shank

Fig.n4

The tooth shape

The typical tooth of a broach are shown in the fig: N5.

Fig.N5

P = Pitch

S = Land width

H = Tooth depth

R = Tooth back radius

r = Tooth face radius

q = Straight land on tip

= Rake angle

1

= Clearance angle

= Clearance angle of straight land

i = Amount of cut per tooth

In according with the pitch there are the number of teeth contemporaneously in contact

with the surface of the workpiece.

The minimum number of teeth in contact must be 2 3, but the maximum cannot be more

of 6 7. The value of the pitch can be calculate with the following formula:

=

Where K is a coefficient and L is the length of the bore.

The value of the K is:

For steel: K = 1,8

For bronze K = 1,7

For cast iron K = 1,6

For the finishing teeth the value of K must multiply for 0,87.

If the length of the workpiece divided by the pitch is an integer number maybe during the

cutting operation there are some vibrations.

Irregular pitch its applied to avoid resonating of cutting vibration. Especially in round

broaches, its effective for undulations and accuracy on the processing surface.

For irregular pitch add or take 0,5 to 1,0 mm to or from the standard pitch.

Another very important element is the value of H, the tooth depth.

From this value depends the capacity of the chip room to contain all material cut, and also

depends the resistance of the teeth and of the broach.

The value of the H is calculated with the parameters shown in the table N2.

Tab. N2

Aluminium

=

2

Soft cast iron, bronze, brass

=

2,25

Soft steel, hard cast iron

=

2,5

Hard steel

=

2,8

Rake and clearance angles

These angles depend basically of the workpiece material, especially the rake angle.

Clearance angle should be smaller than that of others tools in order to keep minimum the

decrease of diameter due to resharpening, and the irregularity of depth of cut by each

tooth due to different stock removed by grinding wheel from each tooth during

resharpening operation.

The figure N6 show the stock removed S and in according with this value and with the

clearance angle , we can calculate the difference of diameter of the tooth before and after

resharpening:

= 2

Fig.N6

The table N3 shows these two angles. Its possible to observe that for the finishing teeth

the clearance angle are very small.

Sometimes these finishing teeth have a straight land of 0,3 0,5 mm without clearance

angle (means this part is cylindrical) in order to keep constant the diameter of these teeth.

Stock removed by

resharpening

Table N3

Work material Rake angle

Clearance angle

Roughing teeth Finishing teeth

Cast iron and bronze 4 6 2 1

Steel with R800 N/mm

2

13 18 2 1

Steel with R=800-1000 N/mm

2

10 15 2 1

Steel with R=1000-1200 N/mm

2

8 10 2 1

Aluminium alloy 15 20 3 130

Copper alloy 5 8 1 30

Nicks

The nicks prevent chip interference and facilitates outflow of chip when round tooth or

cutting edge is large.

In the broaches for internal gears or for involute splines there are also a side face relief

angle in order to reduce the friction when contact area of material to be processed and

tooth flank broadens, adhesion on tooth flank and tear on finish surface occur.

But sometimes this side relief angle is not sufficient to avoid problems about chip outflow.

Its necessary, in these case, also to break the chip in smaller parts.

Nicks should be displaced tooth by tooth (arranged in zigzag) so as not to overlapped by

adjoining teeth.

Also the size of the nicks must be enough large to avoid some interference between

adjacent chips like shown in the figure N7.

Fig. N7

The figure N8 shows different types of nicks

Fig.N8

Nicks not enough large Nicks with right size

También podría gustarte

- Metco 16C 10-040Documento8 páginasMetco 16C 10-040JSH100Aún no hay calificaciones

- Product Catalogue-300M Series Modular Planetary Gearboxes IE2-IE3 - ENG - R02 - 0Documento598 páginasProduct Catalogue-300M Series Modular Planetary Gearboxes IE2-IE3 - ENG - R02 - 0Dispatch TranstechgearsAún no hay calificaciones

- Gear Cutters 01Documento4 páginasGear Cutters 01Raúl MuñizAún no hay calificaciones

- Transform and Sinusoidal Funct 11Documento16 páginasTransform and Sinusoidal Funct 11Dhan CAún no hay calificaciones

- 02 SAMSS 011 FlangesDocumento30 páginas02 SAMSS 011 FlangesALI100% (2)

- Helicoil Catalog - hc2000 Rev.5Documento36 páginasHelicoil Catalog - hc2000 Rev.5Hugo CastroAún no hay calificaciones

- Material WeldingDocumento1 páginaMaterial WeldingDebashish ChatterjeeAún no hay calificaciones

- Gears, Splines, and Serrations: Unit 24Documento8 páginasGears, Splines, and Serrations: Unit 24Satish Dhandole100% (1)

- Ch-6 Reaming, Boring, BroachingDocumento47 páginasCh-6 Reaming, Boring, BroachingAnkush AhirraoAún no hay calificaciones

- G1975 - Instruction ManualDocumento36 páginasG1975 - Instruction ManualLeon GalindoAún no hay calificaciones

- Screw ThreadsDocumento37 páginasScrew ThreadsOmkaar SinghAún no hay calificaciones

- Tools CatalogueDocumento402 páginasTools CatalogueMetroo SuplyyAún no hay calificaciones

- Fine Blanking Design GuideDocumento33 páginasFine Blanking Design GuideVikram Borkhediya100% (5)

- Titanium DRILLINGDocumento50 páginasTitanium DRILLINGDome StoiAún no hay calificaciones

- Broaching Machines-Broach Making Broaching OperationsDocumento48 páginasBroaching Machines-Broach Making Broaching OperationsS.DharanipathyAún no hay calificaciones

- Gear Manufacturing To TeachDocumento44 páginasGear Manufacturing To Teachvijchoudhary16Aún no hay calificaciones

- Is Key & KeywayDocumento12 páginasIs Key & KeywaySagar GandhiAún no hay calificaciones

- Production Technology (IV Sem)Documento24 páginasProduction Technology (IV Sem)Shubham AgrawalAún no hay calificaciones

- GB 20 & Astm 106Documento2 páginasGB 20 & Astm 106satheshAún no hay calificaciones

- PRO E LibraryDocumento11 páginasPRO E LibrarygokulahbAún no hay calificaciones

- Biax Electronic Scraper and AccessoriesDocumento16 páginasBiax Electronic Scraper and AccessoriesPaisaje Silencioso100% (1)

- Ebook Tapping Away Guide To Tapping and Threading Xometry SuppliesDocumento19 páginasEbook Tapping Away Guide To Tapping and Threading Xometry SuppliesAli KhubbakhtAún no hay calificaciones

- API 578 Mock QuestionDocumento4 páginasAPI 578 Mock QuestionsheikmoinAún no hay calificaciones

- Tool & Cutter GrinderDocumento64 páginasTool & Cutter GrinderAFIFAHZABIDI ZABIDIAún no hay calificaciones

- Honing Machine Actuated by ServomotorDocumento45 páginasHoning Machine Actuated by ServomotorNissan PatelAún no hay calificaciones

- Notes On Spur Gears: DefinitionsDocumento6 páginasNotes On Spur Gears: DefinitionsKrishna Murari MauryaAún no hay calificaciones

- STI 463 ModelDocumento1 páginaSTI 463 Modelਗਗਨ ਜੋਤAún no hay calificaciones

- Cutting With BroachDocumento5 páginasCutting With BroachJori Kristian RidayatAún no hay calificaciones

- Mil STD 2197aDocumento19 páginasMil STD 2197aLe Thanh HaiAún no hay calificaciones

- Shaktiman Tech. Tools (India) - Patiala Data SheetDocumento1 páginaShaktiman Tech. Tools (India) - Patiala Data Sheetਗਗਨ ਜੋਤAún no hay calificaciones

- Power Skiving PDFDocumento11 páginasPower Skiving PDFmadhavikAún no hay calificaciones

- SCDL Project PDFDocumento139 páginasSCDL Project PDFadnanshaikh09100% (1)

- The Shape of The Cone of The Twist Drills Unit-2Documento5 páginasThe Shape of The Cone of The Twist Drills Unit-2Akesh KakarlaAún no hay calificaciones

- Electrodes EquivalentDocumento15 páginasElectrodes Equivalentgrameshkreddy2013Aún no hay calificaciones

- Tapping ChucksDocumento14 páginasTapping ChucksDHAMODHARANAún no hay calificaciones

- English 4 Twisted DrillDocumento6 páginasEnglish 4 Twisted DrillBozkurt EkinAún no hay calificaciones

- Grinding Machine PDFDocumento23 páginasGrinding Machine PDFNagi NayakAún no hay calificaciones

- Handbook Prototyp Threading UsDocumento124 páginasHandbook Prototyp Threading UsRobotAún no hay calificaciones

- Lathebeddesign00hornrich PDFDocumento56 páginasLathebeddesign00hornrich PDFLatika KashyapAún no hay calificaciones

- Transport Mixers ZFDocumento6 páginasTransport Mixers ZFDhan C100% (2)

- 5.1 Chordal Tooth Thickness MeasurementDocumento20 páginas5.1 Chordal Tooth Thickness Measurementsharma RISHIAún no hay calificaciones

- Translated Copy of Translated Copy of DIN 58405-1Documento30 páginasTranslated Copy of Translated Copy of DIN 58405-1venkatAún no hay calificaciones

- 90-1 Rotary Table GuideDocumento5 páginas90-1 Rotary Table GuidehdquanAún no hay calificaciones

- Bonfiglioli Geared MotorDocumento584 páginasBonfiglioli Geared MotorProdip SarkarAún no hay calificaciones

- A Crowning Achievement For Automotive ApplicationsDocumento10 páginasA Crowning Achievement For Automotive ApplicationsCan CemreAún no hay calificaciones

- As 2842-1986 Fluid Power - O-Rings and Housings - Inch Series Metric ConversionDocumento6 páginasAs 2842-1986 Fluid Power - O-Rings and Housings - Inch Series Metric ConversionSAI Global - APACAún no hay calificaciones

- DIN 69871 enDocumento69 páginasDIN 69871 enalphatoolsAún no hay calificaciones

- Maryland Metrics - Metric Thread CoarseDocumento2 páginasMaryland Metrics - Metric Thread CoarseBapu612345Aún no hay calificaciones

- Introduction To Universal Gear ShavingDocumento48 páginasIntroduction To Universal Gear ShavingNagesh KamannaAún no hay calificaciones

- Home Search Collections Journals About Contact Us My IopscienceDocumento8 páginasHome Search Collections Journals About Contact Us My IopscienceCan CemreAún no hay calificaciones

- Nomenclature of The Hob's PartsDocumento13 páginasNomenclature of The Hob's PartssilviolcAún no hay calificaciones

- As 3779-1990 Height Setting Micrometers and Riser BlocksDocumento7 páginasAs 3779-1990 Height Setting Micrometers and Riser BlocksSAI Global - APACAún no hay calificaciones

- Bearing CatalogueDocumento12 páginasBearing CatalogueSandeep MatetiAún no hay calificaciones

- Making Room For Productivity and Quality Requirements in Gear GrindingDocumento4 páginasMaking Room For Productivity and Quality Requirements in Gear GrindingJitu InduAún no hay calificaciones

- Cone Tolerance PDFDocumento21 páginasCone Tolerance PDFsosu_sorin3904Aún no hay calificaciones

- Characteristics of Trochoids and Their Application To Determining Gear Teeth Fillet ShapesDocumento14 páginasCharacteristics of Trochoids and Their Application To Determining Gear Teeth Fillet ShapesJohn FelemegkasAún no hay calificaciones

- Types of InvoluteDocumento4 páginasTypes of InvoluteBa Bu100% (1)

- How To Choose Cutting DataDocumento31 páginasHow To Choose Cutting DataJose JacksonAún no hay calificaciones

- Bosch20182019 Catalog - Taps and DiesDocumento8 páginasBosch20182019 Catalog - Taps and Diesrasim_m1146Aún no hay calificaciones

- Parallel Keys Is.2048.1983Documento9 páginasParallel Keys Is.2048.1983sbalajimAún no hay calificaciones

- Benchworking StudyDocumento100 páginasBenchworking StudyBrianRuaroAún no hay calificaciones

- Module Gear DataDocumento2 páginasModule Gear DataMuhammad HaiderAún no hay calificaciones

- Pioneer Avh-P3100dvd p3150dvd SMDocumento190 páginasPioneer Avh-P3100dvd p3150dvd SMRogerio E. SantoAún no hay calificaciones

- Proceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987De EverandProceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987W. R. TysonAún no hay calificaciones

- Broaching PrsDocumento41 páginasBroaching PrsParag PatelAún no hay calificaciones

- Tools Required: Boring BitsDocumento10 páginasTools Required: Boring BitsSai SudheerAún no hay calificaciones

- Mitec1 03 2005Documento21 páginasMitec1 03 2005Sunilkumar ReddyAún no hay calificaciones

- Cutting Gears With Form ToolsDocumento4 páginasCutting Gears With Form ToolssonytechoAún no hay calificaciones

- Reamers: Number of Cutting EdgeDocumento5 páginasReamers: Number of Cutting EdgeSunilkumar ReddyAún no hay calificaciones

- Shaving PDFDocumento8 páginasShaving PDFd_a0nAún no hay calificaciones

- Studies and Research, Pune: Symbiosis Institute of ComputerDocumento26 páginasStudies and Research, Pune: Symbiosis Institute of ComputerDhan CAún no hay calificaciones

- 2022 02 Zentek Corporate Presentation 2022 02-16-163810 LJFPDocumento23 páginas2022 02 Zentek Corporate Presentation 2022 02-16-163810 LJFPDhan CAún no hay calificaciones

- 6 BCA BBA Linux CommandsDocumento58 páginas6 BCA BBA Linux CommandsDhan CAún no hay calificaciones

- September LekhDocumento2 páginasSeptember LekhDhan CAún no hay calificaciones

- Asian Outsourcing O 0611 PDFDocumento34 páginasAsian Outsourcing O 0611 PDFDhan CAún no hay calificaciones

- LR J Wamo XMG Moy Aü''ZDocumento2 páginasLR J Wamo XMG Moy Aü''ZDhan CAún no hay calificaciones

- LR J Wamo XMG Moy Aü''ZDocumento2 páginasLR J Wamo XMG Moy Aü''ZDhan CAún no hay calificaciones

- CMM Software BrochureDocumento16 páginasCMM Software BrochureDhan CAún no hay calificaciones

- Amq Participant List 2015 PDFDocumento31 páginasAmq Participant List 2015 PDFDhan CAún no hay calificaciones

- Technical Formulas: Machine Screw & Fractional SizesDocumento1 páginaTechnical Formulas: Machine Screw & Fractional SizesDhan CAún no hay calificaciones

- DengueDocumento28 páginasDengueDhan CAún no hay calificaciones

- Asian Outsourcing O 0611Documento34 páginasAsian Outsourcing O 0611Dhan CAún no hay calificaciones

- Budgeting Angkor VatDocumento1 páginaBudgeting Angkor VatDhan CAún no hay calificaciones

- Helicopter FCU Screw Failure - EdittedDocumento21 páginasHelicopter FCU Screw Failure - EdittedUllas UAún no hay calificaciones

- Internship Report ISGEC PDFDocumento31 páginasInternship Report ISGEC PDFManu BhaRdWaJAún no hay calificaciones

- S355J2 N, S355J2+N, En10025-2 s355j2n Steel PlateDocumento2 páginasS355J2 N, S355J2+N, En10025-2 s355j2n Steel PlateEswaranAún no hay calificaciones

- Book 2Documento39 páginasBook 2VigneshAún no hay calificaciones

- Die Casting ProcessDocumento23 páginasDie Casting ProcessshayarigurunitinAún no hay calificaciones

- Bondhus CatalogDocumento52 páginasBondhus CatalogCarbide Processors IncAún no hay calificaciones

- Quenching ProcessDocumento14 páginasQuenching ProcessSandeep KumarAún no hay calificaciones

- Lincoln Strip Cladding Presentation April 2011Documento26 páginasLincoln Strip Cladding Presentation April 2011Renny DevassyAún no hay calificaciones

- Reinforcing Steel Bars Price List: Structural (Astm Grade 33)Documento1 páginaReinforcing Steel Bars Price List: Structural (Astm Grade 33)Emileandro Perito QuindiaganAún no hay calificaciones

- Zippo Armor Master List - MaoxianDocumento85 páginasZippo Armor Master List - MaoxianSigit Fitri MulyonoAún no hay calificaciones

- Creep Test (Theory)Documento4 páginasCreep Test (Theory)LoveloveAún no hay calificaciones

- Iso - Iso Standards - Ics 25.220Documento8 páginasIso - Iso Standards - Ics 25.220Harish Kumar Kannepalli0% (1)

- Hard Gold Plating For Edge ConnectorsDocumento12 páginasHard Gold Plating For Edge ConnectorsjackAún no hay calificaciones

- G2 Lab 1 Material Final Report V4Documento33 páginasG2 Lab 1 Material Final Report V4Harizx SaufixAún no hay calificaciones

- Cive 4364 Chapter 1 (MD Sp13)Documento30 páginasCive 4364 Chapter 1 (MD Sp13)satyaAún no hay calificaciones

- Introduction To Manufacturing Technology: Instructor: HAILEDocumento19 páginasIntroduction To Manufacturing Technology: Instructor: HAILEhaile mehariAún no hay calificaciones

- Main Hall Building Block Of: PannipitiyaDocumento1 páginaMain Hall Building Block Of: PannipitiyaPremasiri KarunarathnaAún no hay calificaciones

- Welding Wire Diameter CHART PDFDocumento1 páginaWelding Wire Diameter CHART PDFFerhat KahveciAún no hay calificaciones

- Corrosion Control of Reinforcement BarsDocumento6 páginasCorrosion Control of Reinforcement BarsBhaskar ReddyAún no hay calificaciones

- Askaynak CompanyDocumento28 páginasAskaynak Companymkpasha55mpAún no hay calificaciones

- 321 Stainless Steel Sheet SuppliersDocumento3 páginas321 Stainless Steel Sheet SuppliersSteel EmporiumAún no hay calificaciones