Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Unit Profile: Vikram Cement - Line-I

Cargado por

Anoop Tiwari0 calificaciones0% encontró este documento útil (0 votos)

323 vistas21 páginasVikram CEMENT Line-I is one of the modern Cement Plants of Grasim Industries Ltd., of Aditya Birla Group. It is equipped with the latest modern KHD Dry Process, Double Stream 5 Stage Preheater with separate precalciner for Kiln Pyro Processing, Vertical Raw Mill and Coal Mill of Loesche make and close circuit 2 chamber Cement Mill for grinding. Energy conservation has been the main thrust area and the following significantly proven, modern and innovative, major equipment

Descripción original:

Título original

Vikram Cement Neemuch

Derechos de autor

© © All Rights Reserved

Formatos disponibles

PDF, TXT o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoVikram CEMENT Line-I is one of the modern Cement Plants of Grasim Industries Ltd., of Aditya Birla Group. It is equipped with the latest modern KHD Dry Process, Double Stream 5 Stage Preheater with separate precalciner for Kiln Pyro Processing, Vertical Raw Mill and Coal Mill of Loesche make and close circuit 2 chamber Cement Mill for grinding. Energy conservation has been the main thrust area and the following significantly proven, modern and innovative, major equipment

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

0 calificaciones0% encontró este documento útil (0 votos)

323 vistas21 páginasUnit Profile: Vikram Cement - Line-I

Cargado por

Anoop TiwariVikram CEMENT Line-I is one of the modern Cement Plants of Grasim Industries Ltd., of Aditya Birla Group. It is equipped with the latest modern KHD Dry Process, Double Stream 5 Stage Preheater with separate precalciner for Kiln Pyro Processing, Vertical Raw Mill and Coal Mill of Loesche make and close circuit 2 chamber Cement Mill for grinding. Energy conservation has been the main thrust area and the following significantly proven, modern and innovative, major equipment

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

Está en la página 1de 21

VIKRAM CEMENT LINE-I

(Unit of Grasim Industries Ltd.)

Vikramnagar; P.O. Khor; Distt.Neemuch (MP)

UNIT PROFILE

Commissioned in 1985 Vikram Cement Line-I is one of the modern Cement Plants of

Grasim Industries Ltd., of Aditya Birla Group. The capacity was enhanced to 0.75

Million Tonnes Per Annum from 0.5 Million Tonnes Per Annum in 1989. Vikram

Cement Line-1 is equipped with the latest modern KHD Dry Process, Double Stream 5

stage preheater with separate precalciner for Kiln Pyro Processing, Vertical Raw Mill and

Coal Mill of Loesche make and close circuit 2 chamber Cement Mill for grinding.

Complete process control and instrumentation is computerized. 104% capacity utilisation

was achieved in year 2003-2004. Line-I again upgraded from 5 Stage to 6 Stage

Preheater by M/s KHD and production increased from 0.75 Million Ton to 0.90 Million

Ton in March 2002.

Energy conservation has been the main thrust area and the following significantly proven,

modern and innovative, major equipments have been installed.

01. Mechanical transport for Kiln Feed system (Bucket Elevator)

02. High efficiency Raw Mill fan with SPRS

03. Plant upgradation from 5 Stage to 6 Stage Preheater

04. Upgradation of Raw Mill Classifier.

In addition to the above energy conservation schemes and ideas that have been already

implemented many are in pipeline/in the implementation stage.

PLANT VIEW - VIKRAM CEMENT LINE-1 IS FIRST FROM LEFT

2

With many feathers like TPM Excellence Award, ISO:14001 & ISO:9001 certification

etc. in its cap, it is one of the most energy efficient plant of its type in the view of world

standards. A list of important accreditation won by the unit is given below:

ISO:9001 Certification RWTUV, Germany 1998

Rajiv Gandhi National Quality Award 1997

ISO:14001 EMS Certification DNV Rotterdam, Netherlands 1997

IMC Ramkrishna Bajaj National Quality Award (Certificate of Merit) 1997

IMC Ramkrishna Bajaj National Quality Award - 1998

AV Birla Award for Outstanding Achievement 1997

TPM Excellence Award -1995 and TPM Consistency Award - 2001 (J IPM, J apan)

British Safety Council Award - 1996, 1997, 1999 & 2000

National Safety Council Award (MP Chapter)-1997, 1998 & 1999

OHSAS 18001- Occupational Health & Safety Assessment Series - DNV,

Netherlands 2001

Greentech Environment Excellence Award 2001

SA 8000 DNV 2003

Energy Efficiency in Indian Cement Industry by NCCBM 2000

Excellence Award Bharat Shell 2000

Fuller Energy Award M.P. Chamber of CMA 2000 & 2003

ENERGY CONSUMPTION

Total energy input for manufacture of cement as percentage of manufacturing cost is

about 40% of total cost. The cost of coal, diesel & furnace oil and electricity (purchased

and self generated) are constantly rising.

Electrical energy has been brought down from 94.23 kWh/ton Cement in 2001-2002 to

88.21 kWh/ton Cement in 2003-2004.

Specific thermal energy consumption from 731 KCal/Kg clinker in 2001-2002 to 707

KCal/Kg clinker in 2003-2004.

Cement and clinker production vis a vis the cost of electrical energy and fuel for the last

3 years have been as given below:

2001-2002 2002-2003 2003-2004

Cement production (Lac Ton) 9.30 9.48 9.32

Elect. energy cost (Rs. in lac) 2287.22 3527.20 3558.29

Clinker production (Lac Ton) 5.04 9.03 8.10*

Thermal energy cost (Rs.in lac) 1339.11 2066.61 2143.18

The thermal and electrical energy costs have been brought down inspite of increasing

price of Coal, Furnace Oil/Diesel and Electrical.

*Less clinker production due to poor market

3

ENERGY CONSERVATION - ACHIEVEMENTS

Energy conservation has been one of the main agenda of Vikram Cement since the

commissioning of the plant.

The reducing trend of the specific thermal energy consumption shown below is indicator

of achievements.

Specific energy, specific power

consumption

2001-2002 2002-2003 2003-2004

Specific power in Kwh/Ton cement 94.23 85.98 88.21*

Specific energy in KCal/Kg clinker 731 708 707

*Higher power consumption in cement grinding due to high blaine blended cement and

low production

Petcoke is being used in increasing percentage as fuel by Vikram Cement. Due to poor

grindability and finer grinding requirements, specific electrical energy consumption has

increased, but the total cost has considerably come down.

The following major energy conservation schemes have been implemented during 2003-

2004.

01. Water spray in Preheater downcomer duct

02. Upgradation of Packer

03. Motorised slide gate at Preheater

04. Removal of ventury in Raw Mill duct

05. GRR in sepol fan of Cement Mill

In addition to the above measures, plant upgradation and optimization has been done and

many smaller energy conservation schemes have been implemented, under Kaizen, as a

part of TPM implementation.

Regular heat balance studies and false air leakage monitoring help in maintaining the

gain.

4

The thermal energy conservation schemes implemented since 2001-02 to 2003-2004 have

resulted in saving of 24 Kcal/kg clinker.

Electrical energy have been reduced from 2001-02 to 2003-04 about 6 units/ton of

cement.

Energy Conservation Plans and Target

Various energy conservation schemes under implementation/active consideration at

Vikram Cement are given below:

On-line cross belt analyser for raw material

On-line free lime analyser for reduction in cement grinding power

Enhance production of blended cement

Installation of Captive Thermal Power Plant for reduction of specific electrical energy

consumption by frequency & voltage optimisation and cost of energy generation.

Expert system for Raw Mill, Coal Mill, Kiln & Cement Mill

OMEGA plates for cooler

Coal Mill classifier upgradation

DC drive in cooler ID fan

The target for the unit for 2004 2005 for specific thermal energy is 705 KCal/Kg

Clinker and that for specific electrical energy consumption 86.0 Kwh/Tonne cement.

ENVIRONMENT & SAFETY

Environment and safety are the priority areas for Vikram Cement. This is reflected by

the list of credentials reproduced below:

We have set up our (EHS) Environment Health & Safety Policy. Vikram Cement

adopted Environment Management System and got certified to ISO 14001:1996 in

August 1997 and became 1

st

Cement Plant in India to get certified to EMS. Vikram

Cement also implemented and got certified to OHSAS 18001:1999 in August 2001 and

became one of 1

st

Cement Plant to certified OHSAS from DNV, Netherlands.

As further step in the drive to conserve environment and natural resources the unit has

taken following steps:

01. Use of high Calorific Value petcoke to reduce the use of high grade limestone and

increase the life of captive mines directly. Petcoke is waste product of Oil

Refineries and creates disposal problems.

02. Reduction in coal grinding power and stable running of plant by installing

separate grinding and handling system for petcoke

5

03. Mechanized Flyash Handling System and use of Flyash for high strength, high

durability cement. This will reduce disposal problem of Thermal Power Plant and

overall reduction in the use of energy for cement manufacture.

04. Large investment has been done for upgradation of plant capacity and reduction

of pollution.

05. Energy conservation as well as water conservation schemes are being

implemented.

GREEN BELT DEVELOPMENT

Variety of fruit and other environment friendly trees have been planted over 5 - 7.2

hectares area. The number of trees planted upto 2003-2004 period is 1,74,720. Their

survival rate of 85 to 90%. Tree plantation has been started since 1985 at the rate of

more than 17000 tree per year.

Vikram Cement has qualified engineers, scientists and well equipped laboratory for

environment monitoring on continuous basis and regular environment audits are carried

out by them.

Full fledged Safety Department under Senior Manager(Safety) and Fire Department

under Senior Manager(Security) at Vikram Cement. It has the following functions and

they are implemented religiously :

OHSAS 18001 - 1999 implementation

SHE Policy, Safety Manuals

Work Permit System. Regular Safety Audits, Safety Committee

On Site Emergency Plan

Regular Fire Drill.

Modern fire Fighting System

Fire Alarm System for all vital locations

Celebration of Departmentwise SAFETY WEEK

VIKRAM CEMENT LINE-II

(Unit of Grasim Industries Ltd.)

Vikramnagar; P.O. Khor; Distt.Neemuch (MP)

UNIT PROFILE

Commissioned in 1986 Vikram Cement Line-II is one of the modern Cement Plants of

Grasim Industries Ltd., of Aditya Birla Group. The capacity was enhanced to 0.75

Million Tonnes Per Annum from 0.5 Million Tonnes Per Annum in 1990. Vikram

Cement Line-2 is equipped with the latest modern KHD Dry Process, Double Stream 5

stage preheater with separate precalciner for Kiln Pyro Processing, Vertical Raw Mill and

Coal Mill of Loesche make and close circuit 2 chamber Cement Mill of KHD for

grinding. Complete process control and instrumentation is computerized. 91% capacity

utilisation in 2003-2004. Line-II again upgraded from 5 Stage to 6 Stage Preheater by

M/s KHD and production increased from 0.75 Million Ton to 0.9 Million Ton in August

2002.

Energy conservation has been the main thrust area and the following significantly proven,

modern and innovative, major equipments have been installed.

01. Mechanical transport for Kiln Feed system (Bucket Elevator)

02. High efficiency Raw Mill fan with SPRS

03. Plant upgradation from 5 Stage to 6 Stage Preheater

04. Upgradation of Raw Mill Classifier.

In addition to the above energy conservation schemes and ideas that have been already

implemented many are in pipeline/in the implementation stage.

PLANT VIEW - VIKRAM CEMENT-LINE-2 IS SECOND FROM LEFT

2

With many feathers like TPM Excellence Award, ISO:14001 & ISO:9001 certification

etc. in its cap, it is one of the most energy efficient plant of its type in the view of world

standards. A list of important accreditations won by the unit is given below:

ISO:9001 Certification RWTUV, Germany 1998

Rajiv Gandhi National Quality Award 1997

ISO:14001 EMS Certification DNV Rotterdam, Netherlands 1997

IMC Ramkrishna Bajaj National Quality Award (Certificate of Merit) 1997

IMC Ramkrishna Bajaj National Quality Award - 1998

AV Birla Award for Outstanding Achievement 1997

TPM Excellence Award -1995 and TPM Consistency Award - 2001 (J IPM, J apan)

British Safety Council Award - 1996, 1997, 1999 & 2000

National Safety Council Award (MP Chapter)-1997, 1998 & 1999

OHSAS 18001- Occupational Health & Safety Assessment Series - DNV,

Netherlands 1999

Greentech Environment Excellence Award 2001

SA 8000 DNV 2003

Energy Efficiency in Indian Cement Industry by NCCBM 2000

Excellence Award Bharat Shell 2000

Fuller Energy Award M.P. Chamber of CMA 2000 & 2003

ENERGY CONSUMPTION

Total energy input for manufacture of cement as percentage of manufacturing cost is

about 40% of total cost. The cost of coal, diesel & furnace oil and electricity (purchased

and self generated) are constantly rising.

Electrical energy has been brought down from 91.89 kWh/Ton of Cement in 2001-02 to

89.67 kWh/Ton of Cement in 2003-2004 and specific thermal energy consumption from

728 KCal/Kg clinker in 2001-02 to 706 KCal/Kg clinker in 2003-2004.

Cement and clinker production vis a vis the cost of electrical energy and fuel for the last

3 years have been as given below:

2001-2002 2002-2003 2003-2004

Cement production (Lac Ton) 6.0* 7.16* 8.23*

Elect. energy cost (Rs. in lac) 2266.99 2940.71 3345.96

Clinker production (Lac Ton) 7.37 7.82 9.07

Thermal energy cost (Rs.in lac) 1944.38 1802.72 2241.96

The thermal and electrical energy costs have been brought down inspite of increasing

price of Coal, Furnace Oil/Diesel and Power

*Less cement production due to transfer of clinker to our Bhatinda Grinding Unit.

3

ENERGY CONSERVATION - ACHIEVEMENTS

Energy conservation has been one of the main agenda of Vikram Cement Line-2 since the

commissioning of the plant.

The reducing trend of the specific thermal energy consumption shown below is indicator

of achievements.

Specific energy, specific power

consumption

2001-2002 2002-2003 2003-2004

Specific power in Kwh/Ton cement 91.89 89.98 89.67

Specific energy in KCal/Kg clinker 728 713 707

91.89

89.98 89.67

70

80

90

100

2001-02 2002-03 2003-04

Year

K

C

a

l

/

K

g

C

l

i

n

k

e

r

Better

728

707

713

650

700

750

2001-02 2002-03 2003-04

Year

K

C

a

l

/

K

g

C

l

i

n

k

e

r

Better

REDUCTION OF REDUCTION OF

THERMAL ENERGY INPUT ELECTRICAL ENERGY INPUT

Petcoke is being used in increasing percentage as fuel by Vikram Cement Line-2. Due to

poor grindability and finer grinding requirements, specific electrical energy consumption

has increased, but the total cost has considerably come down.

The following major energy conservation schemes have been implemented during 2003-

2004.

01. Water spray in Preheater downcomer duct

02. Upgradation of Packer

03. Motorised slide gate at Preheater

04. Removal of ventury in Raw Mill duct

05. GRR in sepol fan of Cement Mill

06. Coal Mill classifier upgradation

In addition to the above measures, plant optimization and upgradation has been done and

many smaller energy conservation schemes have been implemented, under Kaizen, as a

part of TPM implementation.

4

Regular heat balance studies and false air leakage monitoring help in maintaining the

gain.

The thermal energy conservation schemes implemented since 2001-02 to 2003-2004 have

resulted in saving of 21Kcal/Kg Clinker.

Electrical energy has been reduced from 2001-2002 to 2003-2004 about 2 unit/ton of

cement.

Energy Conservation Plans and Target

Various energy conservation schemes under implementation/active consideration at

Vikram Cement Line-2 are given below:

On-line cross belt analyser for raw material

On-line free lime analyser for reduction in cement grinding power

Enhance production of blended cement

Water spray in Preheater Downcomer Duct

Installation of Captive Thermal Power Plant for reduction of specific electrical energy

consumption by frequency & voltage optimisation and cost of energy generation

Expert system for Raw Mill, Coal Mill, Kiln & Cement Mill

OMEGA plates for cooler

DC drives in cooler ID fan

The target for the unit for 2004 2005 for specific thermal energy is 705 KCal/Kg

Clinker and that for specific electrical energy consumption 87 Kwh/Ton cement.

ENVIRONMENT & SAFETY

Environment and safety are the priority areas for Vikram Cement. This is reflected by

the list of credentials reproduced below:

We have set up our (EHS) Environment Health & Safety Policy. Vikram Cement

adopted Environment Management System and got certified to ISO 14001:1996 in

August 1997 and became 1

st

Cement Plant in India to get certified to EMS. Vikram

Cement also implemented and got certified to OHSAS 18001:1999 in August 2001 and

became one of 1

st

Cement Plant to certified OHSAS from DNV, Netherlands.

As further step in the drive to conserve environment and natural resources the unit has

taken following steps:

01. Use of high Calorific Value petcoke to reduce the use of high grade limestone and

increase the life of captive mines directly. Petcoke is waste product of Oil

Refineries and creates disposal problems.

5

02. Reduction in coal grinding power and stable running of plant by installing

separate grinding and handling system for petcoke

03. Mechanized Flyash Handling System and use of Flyash for high strength, high

durability cement. This will reduce disposal problem of Thermal Power Plant and

overall reduction in the use of energy for cement manufacture.

04. Large investment has been planned for upgradation of plant capacity and

reduction of pollution.

GREEN BELT DEVELOPMENT IN MINES & PLANT

Variety of fruit and other environment friendly trees have been planted over 5 - 7.2

hectares area. The number of trees planted upto 2003-2004 period is 1,74,722. Their

survival rate of 85 to 90%. Tree plantation has been started since 1985 at the rate of

more than 16000 tree per year.

Vikram Cement has qualified engineers, scientists and well equipped laboratory for

environment monitoring on continuous basis and regular environment audits are carried

out by them.

Full fledged Safety Department under Senior Manager(Safety) and Fire Department

under Senior Manager(Security) at Vikram Cement. It has the following functions and

they are implemented religiously :

OHSAS 18001 - 1999 implementation

SHE Policy, Safety Manuals

Work Permit System. Regular Safety Audits, Safety Committee

On Site Emergency Plan

Regular Fire Drill.

Modern fire Fighting System

Fire Alarm System for all vital locations

Celebration of Departmentwise SAFETY WEEK

VIKRAM CEMENT LINE- III

(Unit of Grasim Industries Ltd.)

Vikramnagar; P.O. Khor; Distt.Neemuch (MP)

UNIT PROFILE

Commissioned in 1991 Vikram Cement Line-3 is one of the most modern Cement Plants

of Grasim Industries Ltd., of Aditya Birla Group. Vikram Cement Line-3 is equipped

with the latest modern Dry Process, Double Stream 6 stage preheater with inline

precalciner for Kiln Pyro Processing. Close circuit ball mill with latest roll press and V-

Separator technology. Vertical Coal Mill supplied by M/s KP, Germany and close circuit

2 chamber Cement Mill with latest technology roll press for grinding. Complete process

control and instrumentation is computerized through FL Smith FUZZY LOGIC

Controller.

Energy conservation has been the main thrust area and the following significantly proven,

modern and innovative major equipments have been installed.

01. Mechanical transport for Kiln Feed in place of pneumatic transport system.

02. Variable speed drive for all clinker cooler fans.

03. Retrofitting of clinker cooler compartment-1 by IKN KIDS.

04. Upgradation of Raw Mill by installation of V-Separator.

05. Mechanical transport for raw meal

In addition to the large number of energy conservation schemes and ideas that have been

already implemented many are in pipeline/under implementation.

PLANT VIEW - VIKRAM CEMENT LINE- III

With many feathers like TPM Excellence Award, ISO:14001 & ISO:9001 certifications

etc. in its cap, it is one of the most energy efficient plants of its kind in the view of

world standards. A list of important accreditation won by the unit is given below:

2

ISO:9001 Certification RWTUV, Germany 1998

Rajiv Gandhi National Quality Award 1997

ISO:14001 EMS Certification DNV Rotterdam, Netherlands 1997

IMC Ramkrishna Bajaj National Quality Award (Certificate of Merit) 1997

IMC Ramkrishna Bajaj National Quality Award - 1998

AV Birla Award for Outstanding Achievement 1997

TPM Excellence Award -1995 and TPM Consistency Award - 2001 (J IPM, J apan)

British Safety Council Award - 1996, 1997, 1999 & 2000

National Safety Council Award (MP Chapter)-1997, 1998 & 1999

OHSAS 18001- Occupational Health & Safety Assessment Series - DNV,

Netherlands 1999

Greentech Environment Excellence Award 2001

SA 8000 DNV 2003

Energy Efficiency in Indian Cement Industry by NCCBM 2000

Excellence Award Bharat Shell 2000

Fuller Energy Award M.P. Chamber of CMA 2000 & 2003

ENERGY CONSUMPTION

Total energy input for manufacture of cement as percentage of manufacturing cost is

about 40% and is having an increasing trend as the costs of coal, diesel & furnace oil and

electricity (purchased and self generated) are constantly rising. Specific electrical and

thermal energy consumption per ton of cement and clinker at the unit for 2003-2004 has

been brought down considerably in last 3 years as given below:

Electrical energy has been brought down from 95.91 kWh/Ton Cement in 2001-2002 to

88.79 kWh/Ton Cement in 2003-2004.

Specific thermal energy consumption from 701 KCal/Kg clinker in 2001-02 to 699

KCal/Kg clinker in 2003-2004.

Cement and clinker production vis a vis the cost of electrical energy and fuel for the last

3 years have been as given below:

2001-2002 2002-2003 2003-2004

Cement production (Lac Ton) 10.61 9.47 9.83

Elect. energy cost (Rs. in lac) 3333.05 4153.22 4619.08

Clinker production (Lac Ton) 11.80 11.57 11.84

Thermal energy cost (Rs.in lac) 2912.46 2607.61 2913.58

The rising trend in the prices of purchased energy inputs might have further crossed the

above cost figures, but these have been kept under control by energy efficiency

improvement projects, energy conservation measures and energy substitution as indicated

by reduced specific energy consumption and cost above.

3

ENERGY CONSERVATION - ACHIEVEMENTS

Energy conservation has been one of the main agenda of Vikram Cement Line-III since

the commissioning of the plant. The reducing trend of the specific thermal and

electrical energy consumption shown below is indicator of achievements.

Fuller Energy Award from MP Chamber of Cement for Second Best Maximum

Reduction in 1998-99 in Electrical Energy Consumption per tonne of cement produced,

over 1997-98 has been awarded to the unit in recognition of its achievements.

Specific energy, specific power

consumption

2001-2002 2002-2003 2003-2004

Specific power in Kwh/Ton cement 95.91 90.59 88.79

Specific energy in KCal/Kg clinker 701 699 699

701

699 699

650

700

750

2001-02 2002-03 2004-04

Year

K

C

a

l

/

K

g

C

l

i

n

k

e

r

Better

95.91

90.59

88.79

80

90

100

2001-02 2002-03 2003-04

Year

K

w

h

/

T

o

f

C

e

m

.

Better

REDUCTION OF REDUCTION OF

THERMAL ENERGY INPUT ELECTRICAL ENERGY INPUT

The following major energy conservation schemes have been implemented during 03-04

01. Removal of unnecessary dampers and restrictions in fan ductings.

02. Bag house fan motor replacement with lower KW & rpm

03. Belt bucket elevator for raw meal feeding

04. Motorized slide gate at Preheater fan inlet.

05. Water spray system in Preheater top cyclone.

In addition to the above measures, plant optimization has been done and many smaller

energy conservation schemes have been implemented, under Kaizen, as a part of TPM

implementation.

Regular heat balance studies and false air leakage monitoring help in maintaining the

gain.

4

The thermal energy conservation schemes implemented since 2001-2002 to 2003 2004

have resulted in saving of 2.0 Kcal/Kg Clinker.

Electrical energy have been reduced from 2001-2002 to 2003-2004 about 7 unit/ton of

cement.

Energy Conservation Plans and Target

Various energy conservation schemes under implementation/active consideration at

Vikram Cement Line-III are given below:

V-separator in Cement Mill grinding circuit.

Water spray in Preheater top cyclone

On-line free lime analyser for reduction in cement grinding power.

Mechanical transport in place of pneumatic transport from Cement Mill to Cement

Silo.

Plant capacity enhancement

Water spray at Raw Mill inlet

Expert system for Raw Mill, Coal Mill, Kiln Cooler & Cement Mill

The target for the unit for 2004 2005 for specific thermal energy is 698 KCal/Kg

Clinker and that for specific electrical energy consumption 89.80 Kwh/Tonne cement.

ENVIRONMENT & SAFETY

Environment and safety are the priority areas for Vikram Cement. This is reflected by

the list of credentials reproduced below:

We have set up our (EHS) Environment Health & Safety Policy. Vikram Cement

adopted Environment Management System and got certified to ISO 14001:1996 in

August 1997 and became 1

st

Cement Plant in India to get certified to EMS. Vikram

Cement also implemented and got certified to OHSAS 18001:1999 in August 2001 and

became one of 1

st

Cement Plant to certified OHSAS from DNV, Netherlands.

As further step in the drive to conserve environment and natural resources the unit has

taken following steps:

01. Use of high Calorific Value petcoke to reduce the use of high grade limestone and

increase the life of captive mines directly. Petcoke is waste product of Oil

Refineries and creates disposal problems.

02. Reduction in coal grinding power and stable running of plant by installing

separate grinding and handling system for petcoke

5

03. Mechanized Flyash Handling System and use of Flyash for high strength, high

durability cement. This will reduce disposal problem of Thermal Power Plant and

overall reduction in the use of energy for cement manufacture.

04. Large investment has been planned for upgradation of plant capacity and

reduction of pollution.

GREEN BELT DEVELOPMENT IN PLANT

Variety of fruit and other environment friendly trees have been planted over 5 - 7.2

hectares area. The number of trees planted upto 2003-2004 period is 1,74,000. Their

survival rate of 85 to 90%. Tree plantation has been started since 1985 at the rate of

more than 16000 tree per year.

Vikram Cement has qualified engineers, scientists and well equipped laboratory for

environment monitoring on continuous basis and regular environment audits are carried

out by them.

Full fledged Safety Department under Senior Manager(Safety) and Fire Department

under Senior Manager(Security) at Vikram Cement. It has the following functions and

they are implemented religiously :

OHSAS 18001 - 1999 implementation

SHE Policy, Safety Manuals

Work Permit System. Regular Safety Audits, Safety Committee

On Site Emergency Plan

Regular Fire Drill.

Modern fire Fighting System

Fire Alarm System for all vital locations

Celebration of Departmentwise SAFETY WEEK

PROCESS FLOW SHEET

Limestone

quarry

Crusher

LS Stock Pile

Raw Mill

Raw meal

Silo

Rly. Wagon/

Truck

Wagon Tippler

Coal Crusher Coal Stock Pile

Coal Mill

Coal Silo

P.H.

Kiln Cooler

Clinker

Stock Pile

Cement Mill

Cement

Storage

Silo

Packing

Plant

Despatch

Truck

Wagon

Bulk Loading

VIKRAM CEMENT LINE-I

SHEET NO.2

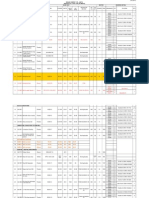

PERCENTAGE SPECIFIC POWER CONSUMPTION OF KILN AREA

28.39%

14.44%

8.72%

20%

14.33%

6%

4

.

9

0

%

PYRO STRING FAN

KILN STRING FAN

KILN AUXILARIES

COOLER GROUP

BAG HOUSE FAN

WATER PUMP

CD FAN

KILN MAIN DRIVE

2. PROBLEM FACED

1. REASON FOR SELECTION OF THEME

HENCE IT WAS DECIDED TO REDUCE SPECIFIC POWER

ON PYRO STRING FAN.

HIGHER SPECIFIC POWER CONSUMPTION IN PYRO STRING FAN

HIGH SPECIFIC POWER AT PYRO STRING FAN BECAUSE OF

HIGH GAS VOLUME AT HIGH EXIT GAS TEMPERATURE.

LOW PREHEATER EXIT GAS TEMPERATURE IS REQUIRED

FOR PET COCK GRINDING.

REDUCTION OF POWER CONSUMPTION IN PYRO

STRING PREHEATER FAN OF LINE-1 & II KILN

THEME NAME

SHEET NO.3

4. TARGET SETTING

6.96

5.87

0

4

8

B.M. TARGET

3. OUTLINE OF EQUIPMENT & PROCESSES

k

W

h

/

T

o

n

o

f

C

e

m

e

n

t

PYRO STRING FAN SP. POWER CONSUMPTION

GOOD

APR- 2004 AUG. -2004

AS PER FAN LAW :

V1/ T1 = V2 / T2 (AT CONSTANT PRESSURE)

HENCE REDUCTION IN TEMPERATURE

RESULTS IN REDUCTION IN FLOW (Q) THUS THE

RPM OF THE FAN IS REDUCED.

RPM

initial

(R

1

) = 860 , RPM

final

(R

2

) =810

FAN POWER final =POWER

initial

(R

1

/ R

2

)

3

= 130.42 kWh

(1.08 kWh / Ton of cement.)

FAN POWER CAN BE REDUCED BY COOLING

THE PYROSTRING EXIT GAS TEMPERATURE AT

CONSTANT PRODUCTION.

HENCE WE SELECT COOLING OPTION

5. ANALYSIS

ALTERNATIVES FOR REDUCTION POWER AT

PREHEATER FAN

17.69

3.09

1.13

0

10

20

30

LOW PRESSSURE

CYCLONE

NEW FAN PREHEATER EXIT

GAS COOLING

ALTERNATIVES

R

s

i

n

M

i

l

l

i

o

n

SHEET NO.4

SHEET NO. 6

EXIT GAS TEMPERATURE MEASURED : -

BEFORE KAIZEN 290

0

C

AFTER KAIZEN 180

0

C

COMPRESSOR &

PUMP HOUSE

COMPRESSOR

WATER

PUMP

7. KAIZEN CONTENT

5

PRE HEATER TOWER

TEMP-290

0

C

DOWN COMER DUCT

EXIT GAS

TEMP-180

0

C

PROBLEM

HIGH SPECIFIC POWER AT PYRO STRING FAN DUE TO

HANDLING OF HIGH EXIT GAS TEMPERATURE.

ACTIVITY :

EXIT GAS TEMPERATURE REDUCED BY WATER SPRAY

IN DOWN COMER DUCT

:

5

Spray nozzles

SAVING:-

A. SAVING (1.09 kWh / Ton OF CEMENT)

=1.09 X2874 X 345 DAYSX4.08 Rs./ kWh.

=Rs. 4.41 Million / Year.

ADDITIONAL BENEFITS: -

B. REDUCTION OF BREAK DOWN DUE TO FAN VIBRATION. (LAST 3 YEAR

AVERAGE BREAK DOWN 6.25 HOURS WITH 2 FREQUENCY PER YEAR )

SAVING =6.25Hrs.X 119.75TPH X Rs. 625/ Ton

= Rs.0.46 Million / Year.

INSTALLATION COST = Rs.18.00 Lacs

TOTAL SAVING = Rs. 48.7 Lacs / Year.

SPECIFIC POWER OF PH FAN

5.86 5.87 6.96

0

5

10

15

B.M.-APR04 Actual-AUG.04 Target

MONTH

GOOD

8. RESULTS

k

W

h

/

T

o

n

O

F

C

E

M

E

N

T

SHEET NO.7

También podría gustarte

- J.K. Lakshmi Cement LimitedDocumento18 páginasJ.K. Lakshmi Cement Limitedraobabar21Aún no hay calificaciones

- Cement Industry - Maihar Cement (Birla Gold)Documento13 páginasCement Industry - Maihar Cement (Birla Gold)Gaurav Kumar100% (2)

- D.G. Khan CementDocumento11 páginasD.G. Khan Cementkanwal_bawaAún no hay calificaciones

- ISO 50001 (Energy Management) in Food Industries: January 2014Documento6 páginasISO 50001 (Energy Management) in Food Industries: January 2014Eric LedesmaAún no hay calificaciones

- Cement ManualDocumento52 páginasCement Manualemad sabriAún no hay calificaciones

- SCM 310 Logistic and Transportation Section:2 Prepared For: Meshbaul Hasan ChowdhuryDocumento24 páginasSCM 310 Logistic and Transportation Section:2 Prepared For: Meshbaul Hasan ChowdhuryShamima AkterAún no hay calificaciones

- Lafarge Zambia 2015 Annual ReportDocumento60 páginasLafarge Zambia 2015 Annual Reportimbo9100% (1)

- Ambuja CementDocumento29 páginasAmbuja CementAnu SikkaAún no hay calificaciones

- Productivity of Cement Industry of PakistanDocumento37 páginasProductivity of Cement Industry of Pakistansyed usman wazir100% (9)

- Maple Leaf Cement FactoryDocumento290 páginasMaple Leaf Cement FactorySarfraz AliAún no hay calificaciones

- National Fire Service Week or Day Celebration Global EHS 059Documento16 páginasNational Fire Service Week or Day Celebration Global EHS 059Global EHSAún no hay calificaciones

- Energy Savings of Cement Industry Sir Usman SBDocumento6 páginasEnergy Savings of Cement Industry Sir Usman SBMuhammad ImranAún no hay calificaciones

- Iso 50001 enDocumento10 páginasIso 50001 enDragomir VasicAún no hay calificaciones

- Project On DG Khan CementDocumento26 páginasProject On DG Khan CementQaim MaharAún no hay calificaciones

- EIA Report MBS Isd Peshawar Morr NIIA - CompressedDocumento288 páginasEIA Report MBS Isd Peshawar Morr NIIA - CompressedMuhammad Waqas AhmedAún no hay calificaciones

- Ambuja CementDocumento25 páginasAmbuja CementHarshkinder SainiAún no hay calificaciones

- Package Cement Fugitive EmissionDocumento192 páginasPackage Cement Fugitive EmissionJay KumarAún no hay calificaciones

- Hse & SD PolicyDocumento5 páginasHse & SD PolicyRini ButarbutarAún no hay calificaciones

- A Look Into The Indian Cement Industry PresentationDocumento27 páginasA Look Into The Indian Cement Industry PresentationsumitkumareceAún no hay calificaciones

- Cement Processing Hol CimDocumento1 páginaCement Processing Hol CimShailesh RaneAún no hay calificaciones

- Environmental Audit of Sugar Factory: A Case Study of Kumbhi Kasari Sugar Factory, Kuditre, KolhapurDocumento7 páginasEnvironmental Audit of Sugar Factory: A Case Study of Kumbhi Kasari Sugar Factory, Kuditre, KolhapurUniversal Journal of Environmental Research and Technology0% (1)

- BLDG3012 - Week 2 PDFDocumento37 páginasBLDG3012 - Week 2 PDFQingyang PanAún no hay calificaciones

- Examining RCM Vs TPMDocumento16 páginasExamining RCM Vs TPMcarrot123456Aún no hay calificaciones

- IdemitsuDocumento28 páginasIdemitsuYulia M. SAún no hay calificaciones

- PSO Ar 2020 PDFDocumento365 páginasPSO Ar 2020 PDFJahangir KhanAún no hay calificaciones

- Energy DayDocumento8 páginasEnergy DayAkshay GuptaAún no hay calificaciones

- Strategic Management of AMBUJA CEMENT LTDDocumento210 páginasStrategic Management of AMBUJA CEMENT LTDpankaj_tari918268100% (2)

- Quarry Dust-Are You in Control?Documento29 páginasQuarry Dust-Are You in Control?Fritz LumasagAún no hay calificaciones

- Cement Industries in PakistanDocumento20 páginasCement Industries in PakistanAli Imran Jalali100% (1)

- On Shree Cement Jun 2010Documento39 páginasOn Shree Cement Jun 2010Ana JainAún no hay calificaciones

- Mock Drill Oil Bottling Plant Ban Gal OresDocumento34 páginasMock Drill Oil Bottling Plant Ban Gal OresYogendra KatiyarAún no hay calificaciones

- PRESENTATION On ShreeCementDocumento20 páginasPRESENTATION On ShreeCementDinesh SutharAún no hay calificaciones

- Dalimia Cements PDFDocumento133 páginasDalimia Cements PDFjsrao1100% (1)

- Environmental Quality (Clean Air) Regulations 1978Documento66 páginasEnvironmental Quality (Clean Air) Regulations 1978Muhammad Faiz bin Ahmad ShafiAún no hay calificaciones

- Key Performance Indicators For Sustainable ManufacDocumento6 páginasKey Performance Indicators For Sustainable ManufacShimondiAún no hay calificaciones

- Speed and Hazard ManagementDocumento46 páginasSpeed and Hazard ManagementAshutosh ArunAún no hay calificaciones

- Orica Kurri ANE Appendix-10 GreenhouseDocumento45 páginasOrica Kurri ANE Appendix-10 GreenhouselladopiAún no hay calificaciones

- Sustainability in Cement Industry: Rakesh Bhargava Chief Climate & Sustainability Officer Shree Cement LTDDocumento35 páginasSustainability in Cement Industry: Rakesh Bhargava Chief Climate & Sustainability Officer Shree Cement LTDRamdeo YadavAún no hay calificaciones

- Wolayita Sodo Hospital Waste Water EvaluationDocumento9 páginasWolayita Sodo Hospital Waste Water EvaluationFasil GeberemeskelAún no hay calificaciones

- Technical Audit IN Murugappa GroupDocumento51 páginasTechnical Audit IN Murugappa Groupryan hardiantoAún no hay calificaciones

- CHECK LIST RISK ASSESSMENT - English - Docx (For Cement Mill and Packing Plant)Documento3 páginasCHECK LIST RISK ASSESSMENT - English - Docx (For Cement Mill and Packing Plant)Engr.Zabi Ullah100% (1)

- Critical Review On Risk Assessment Among Construction WorkersDocumento7 páginasCritical Review On Risk Assessment Among Construction WorkershfzhnAún no hay calificaciones

- EHS ManagerDocumento3 páginasEHS Managerapi-78943192Aún no hay calificaciones

- Operation Management PresentationDocumento47 páginasOperation Management PresentationApom LenggangAún no hay calificaciones

- DG Cement Khairpur Internship Report (More Info Added and More Explained)Documento32 páginasDG Cement Khairpur Internship Report (More Info Added and More Explained)Tutmash ShafiAún no hay calificaciones

- 2118 Cement Safety+maintenance 2020 NE PDFDocumento3 páginas2118 Cement Safety+maintenance 2020 NE PDFMohsin AliAún no hay calificaciones

- Mini Project 1 Eia CumeneDocumento14 páginasMini Project 1 Eia CumenefazliAún no hay calificaciones

- Complete ProjectDocumento79 páginasComplete ProjectMithun RajAún no hay calificaciones

- Ford Motor Company: Total Quality Management: Presented By:Sahil ReyazDocumento14 páginasFord Motor Company: Total Quality Management: Presented By:Sahil ReyazYASIR IMBA21Aún no hay calificaciones

- Characterization of Hazardous WasteDocumento15 páginasCharacterization of Hazardous WastekailasasundaramAún no hay calificaciones

- Performance Appraisal Maha Cement 222Documento100 páginasPerformance Appraisal Maha Cement 222kartik100% (1)

- 150 18 255 2013 Anlagenoptimierung HomogenisierungDocumento26 páginas150 18 255 2013 Anlagenoptimierung HomogenisierungAnonymous iI88Lt100% (1)

- BLDG3012 - Week 3 PDFDocumento52 páginasBLDG3012 - Week 3 PDFQingyang PanAún no hay calificaciones

- BLDG3012 - Week 5 PDFDocumento34 páginasBLDG3012 - Week 5 PDFQingyang PanAún no hay calificaciones

- Jowar FlakesDocumento8 páginasJowar FlakesAmit JainAún no hay calificaciones

- Madras CementDocumento42 páginasMadras CementAnonymous sfY8T3q0100% (1)

- IIPEC - Shree Cement Ltd-3Documento5 páginasIIPEC - Shree Cement Ltd-3Debajit BurhagohainAún no hay calificaciones

- Iipec NCCBM-2Documento10 páginasIipec NCCBM-2Debajit BurhagohainAún no hay calificaciones

- Unit Profile: Binani Cement LimitedDocumento7 páginasUnit Profile: Binani Cement LimitedPriyank MaheshwariAún no hay calificaciones

- Fans & Blowers-Calculation of PowerDocumento20 páginasFans & Blowers-Calculation of PowerPramod B.Wankhade92% (24)

- Formula Sheet GeometryDocumento2 páginasFormula Sheet GeometryAkchat JainAún no hay calificaciones

- Vade Mecum PDFDocumento286 páginasVade Mecum PDFAnoop Tiwari100% (1)

- Integration Formulas: 1. Common IntegralsDocumento5 páginasIntegration Formulas: 1. Common IntegralssiegherrAún no hay calificaciones

- 9 - RAWGRINDING CementDocumento28 páginas9 - RAWGRINDING CementAnoop Tiwari100% (2)

- Fan Flow CalDocumento7 páginasFan Flow CalAnoop TiwariAún no hay calificaciones

- 3 MillventDocumento24 páginas3 MillventAnoop Tiwari100% (1)

- User Guide PDFDocumento27 páginasUser Guide PDFbulentbulut100% (1)

- U-II Gear Box DetailsDocumento14 páginasU-II Gear Box DetailsAnoop Tiwari100% (1)

- Calculation of Grindability From Bond'S Work Index PlantDocumento2 páginasCalculation of Grindability From Bond'S Work Index PlantAnoop Tiwari100% (1)

- Surface Area of GMDocumento6 páginasSurface Area of GMAnoop TiwariAún no hay calificaciones

- Grindability CalculationDocumento3 páginasGrindability CalculationAnoop Tiwari100% (1)

- 04B BM PowerDocumento1 página04B BM PowerAnoop TiwariAún no hay calificaciones

- ESP ManualDocumento25 páginasESP ManualAnoop Tiwari100% (4)

- Calculation of Flame MomentumDocumento1 páginaCalculation of Flame MomentumAnoop TiwariAún no hay calificaciones

- 13 Roller Mills PDFDocumento21 páginas13 Roller Mills PDFAnoop TiwariAún no hay calificaciones

- 6 Grinding Work Index According To Bond PDFDocumento11 páginas6 Grinding Work Index According To Bond PDFAnoop Tiwari100% (2)

- Maintenance of GBDocumento46 páginasMaintenance of GBAnoop Tiwari100% (4)

- Is 1727 Method of Test For Pozzolanic Material E21 R1.180180834Documento51 páginasIs 1727 Method of Test For Pozzolanic Material E21 R1.180180834Hazem DiabAún no hay calificaciones

- User Guide PDFDocumento27 páginasUser Guide PDFbulentbulut100% (1)

- "Parampara": Name of Mentee: Himanshu ShrimaliDocumento6 páginas"Parampara": Name of Mentee: Himanshu ShrimaliAnoop TiwariAún no hay calificaciones

- Is.1288.1982 Gypsum PDFDocumento25 páginasIs.1288.1982 Gypsum PDFAnoop TiwariAún no hay calificaciones

- User Guide PDFDocumento27 páginasUser Guide PDFbulentbulut100% (1)

- 4 Drying of Raw Materials PDFDocumento33 páginas4 Drying of Raw Materials PDFAnoop TiwariAún no hay calificaciones

- 23 Kiln Lining PDFDocumento12 páginas23 Kiln Lining PDFAnoop TiwariAún no hay calificaciones

- Fulltext01 PDFDocumento79 páginasFulltext01 PDFAnoop TiwariAún no hay calificaciones

- FullerKinyonKompactPumps PDFDocumento4 páginasFullerKinyonKompactPumps PDFAnoop Tiwari0% (1)

- An4828 PDFDocumento25 páginasAn4828 PDFAnoop TiwariAún no hay calificaciones

- 18 Fuels in Cement Industry PDFDocumento41 páginas18 Fuels in Cement Industry PDFAnoop TiwariAún no hay calificaciones

- 14 Grinding Methods in The State of Development PDFDocumento13 páginas14 Grinding Methods in The State of Development PDFAnoop TiwariAún no hay calificaciones

- Megapower: Electrosurgical GeneratorDocumento45 páginasMegapower: Electrosurgical GeneratorAnibal Alfaro VillatoroAún no hay calificaciones

- Fan Tool Kit - Ad Hoc Group - V4ddDocumento121 páginasFan Tool Kit - Ad Hoc Group - V4ddhmaza shakeelAún no hay calificaciones

- Fitting in and Fighting Back: Stigma Management Strategies Among Homeless KidsDocumento24 páginasFitting in and Fighting Back: Stigma Management Strategies Among Homeless KidsIrisha AnandAún no hay calificaciones

- Automobile Air Conditioning SystemDocumento8 páginasAutomobile Air Conditioning SystemAyyan Gaonkhadkar100% (1)

- 2016 Specimen Paper 1 PDFDocumento16 páginas2016 Specimen Paper 1 PDFBioScMentor-1Aún no hay calificaciones

- Multicultural Aspects of Communication Disorders - CH 12Documento21 páginasMulticultural Aspects of Communication Disorders - CH 12Maitry PatelAún no hay calificaciones

- Jurnal Kasus Etikolegal Dalam Praktik KebidananDocumento13 páginasJurnal Kasus Etikolegal Dalam Praktik KebidananErni AnggieAún no hay calificaciones

- Full Download Book Microbiome Immunity Digestive Health and Nutrition Epidemiology Pathophysiology Prevention and Treatment PDFDocumento41 páginasFull Download Book Microbiome Immunity Digestive Health and Nutrition Epidemiology Pathophysiology Prevention and Treatment PDFmildred.walker324100% (15)

- Daily 500 Maximum 2500 Minimum 1000 Lead Time 15 Days EOQ 1200 Emergency Lead Time 3 DaysDocumento5 páginasDaily 500 Maximum 2500 Minimum 1000 Lead Time 15 Days EOQ 1200 Emergency Lead Time 3 DaysM Noaman AkbarAún no hay calificaciones

- TD-XT-D004-003 V2.00 20131204 XG1.UCD-135M185M300M Operation Manual PDFDocumento47 páginasTD-XT-D004-003 V2.00 20131204 XG1.UCD-135M185M300M Operation Manual PDFStan TC100% (1)

- 2nd Comprehensive ExamDocumento15 páginas2nd Comprehensive ExamLoala SMDAún no hay calificaciones

- EcodesDocumento2 páginasEcodesValentin IonutAún no hay calificaciones

- Mechanism of Enzyme ActionDocumento19 páginasMechanism of Enzyme ActionRubi AnnAún no hay calificaciones

- Different Types of FermentationDocumento26 páginasDifferent Types of FermentationCats and DogAún no hay calificaciones

- AcuityPDR BrochureDocumento3 páginasAcuityPDR BrochureJulian HutabaratAún no hay calificaciones

- Water Distiller - ManualDocumento2 páginasWater Distiller - ManualSanjeevi JagadishAún no hay calificaciones

- Production of AcetaldehydeDocumento124 páginasProduction of AcetaldehydeAdilaAnbreen80% (5)

- Stanford - Trauma - Guidelines June 2016 Draft Adult and Peds FINALDocumento166 páginasStanford - Trauma - Guidelines June 2016 Draft Adult and Peds FINALHaidir Muhammad100% (1)

- AssaultDocumento12 páginasAssaultEd Mundo100% (3)

- Method Setting Out of Drainage 2Documento9 páginasMethod Setting Out of Drainage 2amin100% (1)

- Psicologia BuenisimoDocumento6 páginasPsicologia BuenisimoSophieAún no hay calificaciones

- Endovascular Skills CourseDocumento20 páginasEndovascular Skills CourseAbdullah JibawiAún no hay calificaciones

- Stern TubesDocumento8 páginasStern Tubesweesweekwee8652Aún no hay calificaciones

- Weigh Bridge Miscellaneous Items DetailsDocumento1 páginaWeigh Bridge Miscellaneous Items DetailsChandan RayAún no hay calificaciones

- Hookah Bar Business PlanDocumento34 páginasHookah Bar Business PlanAbdelkebir LabyadAún no hay calificaciones

- PW6101 ProgrammationDocumento44 páginasPW6101 ProgrammationCédric DekeyserAún no hay calificaciones

- LPG PropertiesDocumento2 páginasLPG Propertiesvvk557Aún no hay calificaciones

- Introduction To Stainless SteelDocumento19 páginasIntroduction To Stainless Steelkrishna chiruAún no hay calificaciones

- 900 ADA - Rev13Documento306 páginas900 ADA - Rev13Miguel Ignacio Roman BarreraAún no hay calificaciones

- World Wide Emission Free E-Motercycle ProjectDocumento20 páginasWorld Wide Emission Free E-Motercycle ProjectAkshay SharmaAún no hay calificaciones