Documentos de Académico

Documentos de Profesional

Documentos de Cultura

(2013) US20130324758 Process For Manufacturing Acrolein-Acrylic Acid

Cargado por

remi19880 calificaciones0% encontró este documento útil (0 votos)

32 vistas13 páginasTítulo original

(2013) US20130324758 Process for Manufacturing Acrolein-Acrylic Acid

Derechos de autor

© © All Rights Reserved

Formatos disponibles

PDF, TXT o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

0 calificaciones0% encontró este documento útil (0 votos)

32 vistas13 páginas(2013) US20130324758 Process For Manufacturing Acrolein-Acrylic Acid

Cargado por

remi1988Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

Está en la página 1de 13

US 20130324758A1

( 19 ) United Sta tes

( 12) Pa tent Applica tion Publica tion ( 10) Pub. N 0. 2 US 2013/0324758 A1

Deva ux et a ] . ( 43) Pub. Da te: Dec. 5, 2013

( 54) PROCESS FOR MAN UFACTURIN G Publica tion Cla s s i? ca tion

ACROLEIN /ACRYLIC ACID ( 51) Int CL

C07C 51/16 ( 2006 . 01)

C07C 319 /02 ( 2006 . 01)

( 75) Inventor s : J ea n- Fr a ncois Deva ux; Soucieu En C07C 45/28 ( 2006 . 01)

J a r r es t ( FR) ; J ea n- Luc Dubois ; Miller y C07C 253/18 ( 2006 - 01)

( FR) ( 52) US. Cl.

CPC . . . . . . . . . . . . . . . C07C 51/16 ( 2013. 01) ; C07C 253/18

( 2013. 01) ; C07C319 /02 ( 2013. 01) ; C07C

45/28 ( 2013. 01)

( 73) As s ig nee: Ar kema Fr a nce, Colombia /s ( FR) USPC . . . . . . . . . . . 558/315; 56 2/532; 56 2/534; 56 2/535;

56 2/549 ; 56 8/6 3; 56 8/449

( 21) Appl. N O. Z 13/9 81, 9 27 ( 57) ABSTRACT

_ The pr es ent invention r ela tes to the s elective elimina tion of

( 22) PCT Flledi J a n- 26 : 2012 pr opa na l in a cr olein- r ich s tr ea ms to pr oduce a cr olein a nd/or

a cr y lic a cid a nd/or a cr y lonitr ile a nd/or methy lmer ca ptopr o

( 86 ) PCT N O; PCT/IB12/0039 6 piona ldehy de conta ining loW a mount of pr opa na l a nd/or pr o

pionic a cid a nd/or pr opionitr ile. One s ubj ect of the pr es ent

371 ( c) ( 1) ; invention is a pr oces s for ma nufa ctur ing a cr olein compr is ing

( 2) ( 4) Da te. Aug 20 2013 a s tep of s elective elimina tion of pr opa na l in a n a cr olein- r ich

s tr ea m in conta ct W ith a ca ta ly s t compr is ing a t lea s t moly b

_ _ _ _ _ denum. Another s ubj ect of the pr es ent invention is a pr oces s

( 30) For elg n Apphca tlon Pnonty Da ta for ma nufa ctur ing a cr y lic a cid fr om g ly cer ol including a s tep

of s elective elimina tion of pr opa na l in a n a cr olein- r ich s tr ea m

J a n. 28; 2011 ( IB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201 1/ 00046 8 in conta ct W ith a ca ta ly s t compr is ing a t lea s t moly bdenum.

US 2013/0324758 A1

PROCESS FOR MAN UFACTURIN G

ACROLEIN /ACRYLIC ACID

[ 0001] The W or k lea ding to this invention ha s r eceived

funding fr om the Eur opea n Community s Seventh Fr a me

wor k Pr og r a m FP7/2007- 2013 under g r a nt a g r eement no

22886 7.

TECHN ICAL FIELD

[ 0002] The pr es ent invention r ela tes to the s elective elimi

na tion of pr opa na l in a cr olein- r ich s tr ea ms to pr oduce

a cr olein a nd/or a cr y lic a cid a nd/or a cr y lonitr ile conta ining

loW a mount of pr opa na l a nd/or pr opionic a cid a nd/or pr opi

onitr ile.

[ 0003] One s ubj ect ofthe pr es ent invention is a pr oces s for

ma nufa ctur ing a cr olein compr is ing a s tep of s elective elimi

na tion of pr opa na l in a n a cr olein- r ich s tr ea m. Another s ubj ect

of the pr es ent invention is a pr oces s for ma nufa ctur ing a cr y lic

a cid fr om g ly cer ol including a s tep of s elective elimina tion of

pr opa na l in a n a cr olein- r ich s tr ea m.

BACKGROUN D ART

[ 0004] Acr olein is a key inter media te for the s y nthes is of

methy lmer ca ptopr opiona ldehy de a nd of methionine, a s y n

thetic a minoa cid us ed a s a n a nima l feed s upplement, W hich

ha s emer g ed a s a s ubs titute for ? s hmea l. Acr olein is a ls o a

non- is ola ted s y nthetic inter media te of a cr y lic a cid a nd a cr y

lonitr ile for W hich the impor ta nce of their a pplica tions a nd its

der iva tives is knoW n. Acr olein a ls o lea ds , via r ea ction W ith

methy l viny l ether then hy dr oly s is , to g luta r a ldehy de, W hich

ha s ma ny us es in lea ther ta nning , a s a biocide in oil W ell

dr illing a nd dur ing the tr ea tment of cutting oils , a nd a s a

chemica l s ter ila nt a nd dis infecta nt for hos pita l eq uipment.

Acr olein a ls o lea ds to py r idine or g luta r a ldehy de.

[ 0005] Acr y lic a cid is a compound tha t is us ed es s entia lly

a s poly mer iza tion monomer or comonomer for the ma nufa c

tur e of a ver y br oa d r a ng e of ? na l pr oducts . Thes e ? na l

pr oducts a r e ma nufa ctur ed by poly mer iZ a tion of the a cid or of

the der iva tives of this a cid, in the es ter ( poly a cr y la tes ) or

a mide ( poly a cr y la mides ) for m. A ver y impor ta nt outlet for

a cr y lic a cid is the ma nufa ctur e of s uper a bs or bents , in W hich

a pa r tia lly neutr a liZ ed ( mixtur e of a cr y lic a cid a nd s odium

a cr y la te or a cr y la tes of other ca tions ) a cr y lic a cid is poly mer

iZ ed, or els e a cr y lic a cid is poly mer ized a nd the poly a cr y lic

compound obta ined is pa r tia lly neutr a liZ ed. Thes e poly mer s

a r e us ed a s is or a s copoly mer s in ? elds a s va r ied a s hy g iene,

deter g ents , pa ints , va r nis hes , a dhes ives , pa per , textiles ,

lea ther , a nd the like.

[ 0006 ] Acr olein a nd/or a cr y lic a cid a r e pr oduced indus tr i

a lly by oxida tion of pr opy lene us ing oxy g en or a n oxy g en

compr is ing mixtur e in the pr es ence of ca ta ly s t s y s tems ba s ed

on mixed oxides . This r ea ction is g ener a lly ca r r ied out in the

g a s pha s e a nd g ener a lly in tW o s ta g es to g ive a cr y lic a cid: the

? r s t s ta g e ca r r ies out the s ubs ta ntia lly q ua ntita tive oxida tion

of the pr opy lene to g ive a n a cr olein- r ich mixtur e, in W hich

a cr y lic a cid is a minor component, a nd then the s econd s ta g e

ca r r ies out the s elective oxida tion of the a cr olein to g ive

a cr y lic a cid.

[ 0007] The r ea ction conditions of thes e tW o s ta g es , ca r r ied

out in tW o multitubula r r ea ctor s in s er ies or in a s ing le r ea ctor

compr is ing the tW o r ea ction s ta g es in s er ies , a r e differ ent a nd

r eq uir e ca ta ly s ts s uited to the r ea ction; hoW ever , it is not

neces s a r y to is ola te the a cr olein fr om the ? r s t s ta g e dur ing

this tW o- s ta g e pr oces s .

Dec. 5, 2013

[ 0008] The s ta r ting ma ter ia ls us ed for a cr olein or a cr y lic

a cid pr oduction r es ult fr om oil or na tur a l g a s a nd cons e

q uently the a cr olein or a cr y lic a cid a r e for med fr om a non

r eneW a ble fos s il ca r bon s ta r ting ma ter ia l. In the context of the

commitments of the ma j or ity of indus tr ia liZ ed countr ies to

r educe emis s ions of g r eenhous e g a s es , it a ppea r s pa r ticula r ly

impor ta nt to ma nufa ctur e novel pr oducts ba s ed on a r eneW

a ble s ta r ting ma ter ia l, contr ibuting to r educing the envir on

menta l effects a nd g loba l W a r ming potentia l.

[ 0009 ] Gly cer ol is der ived fr om pla nt oils in the pr oduction

of biodies el fuels or oleochemica ls s uch a s fa tty a cids or fa tty

a lcohol or fa tty es ter s . Gly cer ol is one of the r a W ma ter ia ls

envis a g ed a s a s ubs titute for pr opy lene, g ly cer ol being a ble to

be s ubj ected to a ca ta ly tic dehy dr a tion r ea ction in or der to

pr oduce a cr olein. Such a pr oces s ma kes it pos s ible to thus

r es pond to the concept of g r een chemis tr y W ithin a mor e

g ener a l context of pr otecting the envir onment. Ther e a r e a ls o

ma ny pos s ible W a y s to a cces s to r eneW a ble g ly cer ol, for

exa mple by fer menta tion of s ug a r s or by hy dr og enoly s is r ea c

tions .

[ 0010] This pr oces s is hig hly a na log ous to the s y nthetic

pr oces s s ta r ting fr om pr opy lene ins ofa r a s the inter media te

pr oduct, a cr olein, r es ulting fr om the ? r s t s ta g e is the s a me a nd

ins ofa r a s the s econd s ta g e is ca r r ied out under the s a me

oper a ting conditions .

[ 0011] HoW ever , the r ea ction of the ? r s t s ta g e of the pr oces s

of the invention, the dehy dr a tion r ea ction, is differ ent fr om

the r ea ction for the oxida tion of pr opy lene of the us ua l pr o

ces s . The dehy dr a tion r ea ction, per for med in the g a s pha s e, is

ca r r ied out us ing differ ent s olid ca ta ly s ts fr om thos e us ed for

the oxida tion of pr opy lene. The a cr olein- r ich e? luent r es ult

ing fr om the ? r s t dehy dr a tion s ta g e, intended to feed the

s econd s ta g e of oxida tion of a cr olein to g ive a cr y lic a cid,

compr is es a g r ea ter a mount of W a ter a nd in a ddition exhibits

s ubs ta ntia l differ ences a s r eg a r ds by - pr oducts r es ulting fr om

the r ea ction mecha nis ms involved.

[ 0012] N umer ous ca ta ly s t s y s tems ha ve a lr ea dy been the

s ubj ect of s tudies for the dehy dr a tion r ea ction of g ly cer ol to

a cr olein.

[ 0013] Us . Pa t. N o. 5, 387, 720 des cr ibes a pr oces s for pr o

ducing a cr olein by dehy dr a tion of g ly cer ol, in liq uid pha s e or

in g a s pha s e, a t a temper a tur e r a ng ing up to 3400 C. , over

a cidic s olid ca ta ly s ts tha t a r e de? ned by their Ha mmett a cid

ity . The ca ta ly s ts mus t ha ve a Ha mmett a cidity beloW + 2 a nd

pr efer a bly beloW 3. Thes e ca ta ly s ts cor r es pond, for

exa mple, to na tur a l or s y nthetic s iliceous ma ter ia ls , s uch a s

mor denite, montmor illonite a nd a cidic Z eolites ; s uppor ts ,

s uch a s oxides or s iliceous ma ter ia ls , for exa mple a lumina

( A1203) , tita nium oxide ( TiOZ ) , cover ed by monoba s ic, diba

s ic or tr iba s ic inor g a nic a cids ; oxides or mixed oxides s uch a s

g a mma - a lumina , Z nO/Al2O3 mixed oxide, or els e het

er opoly a cids . The us e of thes e ca ta ly s ts W ould ma ke it pos

s ible to s olve the pr oblem of for ma tion of s econda r y pr oducts

g ener a ted W ith the ir on phos pha te ty pe ca ta ly s ts des cr ibed in

the document FR 6 9 5, 9 31.

[ 0014] Accor ding to Applica tion W O 06 /087084, the

s tr ong ly a cidic s olid ca ta ly s ts W hos e Ha mmett a cidity H0 is

betW een 9 a nd 18 ha ve a s tr ong ca ta ly tic a ctivity for the

dehy dr a tion r ea ction of g ly cer ol to a cr olein a nd a r e dea cti

va ted les s q uickly .

[ 0015] In the document W O 09 /044, 081 it ha s been pr o

pos ed to ca r r y out the r ea ction for dehy dr a tion of g ly cer ol in

the pr es ence of a ca ta ly s t s y s tem compr is ing oxy g en, ir on,

phos phor us , a nd one or mor e elements chos en fr om a lka li

US 2013/0324758 A1

meta ls , a lka line- ea r th meta ls , Al, Si, B, Co, Cr , N i, V , Z n, Z r ,

Sn, Sb, Ag , Cu, N b, Mo, Y, Mn, Pt, Rh a nd the r a r e ea r ths La ,

Ce, Sm.

[ 0016 ] The document W O 09 /128, 555 des cr ibes a pr oces s

for pr epa r ing a cr olein by dehy dr a tion of g ly cer ol in the pr es

ence of a ca ta ly s t compr is ing ma inly a compound in W hich

pr otons in a heter opoly a cid a r e excha ng ed a t lea s t pa r tia lly

W ith a t lea s t one ca tion s elected fr om elements belong ing to

Gr oup 1 to Gr oup 16 of the Per iodic Ta ble of Elements .

[ 0017] In the document W O 10/046 , 227 the dehy dr a tion of

g ly cer ol is per for med in the pr es ence of a ca ta ly s t s y s tem

compr is ing oxy g en, phos phor us a nd a t lea s t one meta l chos en

fr om va na dium, bor on or a luminium.

[ 0018] However , the ca ta ly s ts r ecommended in the pr ior a r t

for pr oducing a cr olein fr om g ly cer ol g ener a lly lea d to the

for ma tion of by - pr oducts s uch a s hy dr oxy pr opa none, pr o

pa na ldehy de ( ca lled a ls o pr opa na l) , a ceta ldehy de, a cetone,

a ddition pr oducts of a cr olein to g ly cer ol, poly condens a tion

pr oducts of g ly cer ol, cy clic g ly cer ol ether s , a nd a ls o phenol

a nd poly a r oma tic compounds W hich a r e the s our ce of the

for ma tion of coke on the ca ta ly s t a nd ther efor e of its dea cti

va tion.

[ 0019 ] The pr es ence of the by - pr oducts in a cr olein, es pe

cia lly pr opa na l, pos es numer ous pr oblems for the s epa r a tion

of a cr olein a nd r eq uir es s epa r a tion a nd pur i? ca tion s teps

W hich lea d to hig h cos ts for the r ecover y of the pur i? ed

a cr olein. Fur ther mor e, W hen a cr olein is us ed for pr oducing

a cr y lic a cid, the pr opa na l pr es ent ma y be oxidized to pr opi

onic a cid, W hich is dif? cult to s epa r a te fr om a cr y lic a cid,

es pecia lly by dis tilla tion. Indeed, pr opa na l a nd pr opionic a cid

ha ve their boiling points of r es pectively 49 0 C. a nd 141 C.

W hich a r e ver y clos e to boiling points of 53 C. a nd 141 C.

r es pectively of the obj ective compounds of a cr olein a nd

a cr y lic a cid. The s a me pr oblem occur s W hen a cr olein is us ed

to ma ke methionine, or a ceta ls or a cr y lonitr ile, s ince the

boiling points of a cr y lonitr ile a nd pr opionitr ile a r e r es pec

tively 77 C. a nd 9 7 C. Thes e pr oblems exis t for the tW o

mea ns of pr oduction of a cr olein/a cr y lic a cid or a cr y loni

tr ileifr om pr opy lene or fr om g ly cer olis ince pr opa na l

r es ults a s a by - pr oduct in the g ly cer ol dehy dr a tion a nd in the

pr opy lene oxida tion, but pr opa na l is in a g r ea ter a mount in the

ca s e of g ly cer ol, pr oba bly oW ing to a loW er s electivity of the

r ea ction of dehy dr a tion of g ly cer ol.

[ 0020] Thes e impur ities tha t a r e pr es ent g r ea tly r educe the

? eld of a pplica tion of the a cr olein a nd a cr y lic a cid pr oduced

by dehy dr a tion of g ly cer ol. In pa r ticula r , impur ities s uch a s

non- poly mer iZ a ble s a tur a ted compounds ca n be pa r ticula r ly

tr oubles ome in the ? na l a pplica tion by modify ing the pr op

er ties of the ? nis hed pr oduct, by confer r ing toxic or cor r os ive

pr oper ties on the ? nis hed pr oduct or by incr ea s ing polluting

or g a nic dis cha r g es dur ing the s ta g es of ma nufa ctur e of the

a cr y lic poly mer a nd/ or of the ? nis hed pr oduct.

[ 0021] Cons eq uently , ther e is a need for a n a cr y lic a cid

W hich meets a ll the a bove- mentioned cons tr a ints , both

ups tr ea m, tha t is to s a y a n a cr y lic a cid es s entia lly ba s ed on a

non- fos s il na tur a l ca r bon s our ce, a nd doW ns tr ea m, tha t is to

s a y a n a cr y lic a cid W hich meets q ua lity s ta nda r ds a lloW ing it

to be us ed in the ma nufa ctur e of a br oa d r a ng e of technica l

poly mer s , W ithout, hoW ever , r eq uir ing a s ophis tica ted a nd

ther efor e expens ive pur i? ca tion.

[ 0022] To meet this need, it ha s a lr ea dy been pr opos ed, for

exa mple in W O 09 /044, 081, to pla ce tW o a ctive ca ta ly s t beds

in s er ies : the g a s eous r ea ction mixtur e conta ining g ly cer ol is

s ent to a ? r s t ca ta ly s t in conta ct W ith W hich the dehy dr a tion

Dec. 5, 2013

r ea ction of g ly cer ol is a t lea s t pa r tia lly ca r r ied out g ener a lly

r es ulting in s econda r y compounds s uch a s pr opa na l. The

r ea ction mixtur e thus obta ined is pa s s ed over a s econd ca ta

ly s t bed s uch a s a doped ca ta ly s t s y s tem ba s ed on ir on phos

pha te, on W hich the dehy dr a tion r ea ction of unr ea cted g ly c

er ol ma y continue a t the s a me time a s the conver s ion of

pr opa na l to a cr olein. The a cr olein obta ined a ccor ding to this

embodiment conta ins a minimiZ ed a mount of pr opa na l,

W hich W idens its ? eld of a pplica tion a nd fa cilita tes obta ining

hig h pur ity a cr y lic a cid. HoW ever , it W a s obs er ved tha t s uch

ca ta ly s ts lea d to a r a pid plug g ing of the fa cility due to the

for ma tion of pr oducts like ta r .

[ 0023] The con? g ur a tion of tW o a ctive ca ta ly s t beds in

s er ies to limit the pr es ence of pr opa na l in a cr olein ha s a ls o

been des cr ibed in the pr oces s of W O 10/046 , 227 us ing a

ca ta ly s t s y s tem ba s ed on a mixed oxide of phos phor us a nd

va na dium. HoW ever , thes e ca ta ly s ts a r e les s a ctive a t moder

a te temper a tur e.

[ 0024] The document W O 10/074, 177 r ela tes to a method

for pr epa r ing a cr y lic a cid fr om a compos ition conta ining

a cr olein a nd pr opa na l by g a s pha s e r ea ction us ing a s olid

ca ta ly s t compr is ing a t lea s t Mo a nd V a s es s entia l compo

nents . In this g a s pha s e r ea ction, a cr olein is conver ted to

a cr y lic a cid a nd pr opa na l is conver ted to a cr y lic a cid a nd to

pr opionic a cid. W ith this a cr olein oxida tion ca ta ly s t, pr opa na l

is conver ted a t a s imila r r a te a s a cr olein, a nd pr opa na l is

ma inly conver ted to pr opionic a cid. The conver s ion of pr o

pa na l into a cr y lic a cid is ver y loW ( 3% ) , a nd the a cr y lic a cid

thus obta ined conta ins a ver y pr opionic a cid content a nd

it ha s to be pur i? ed by cr y s ta lliza tion to r emove pr opionic

a cid.

[ 0025] Als o, it ha s been pr opos ed to r emove pr opionic a cid

fr om a n a cr y lic a cid s tr ea m, in pa r ticula r fr om a n a cr y lic a cid

mixed g a s obta ined by va por - pha s e oxida tion of pr opy lene

a nd/or pr opa ne, by r ea cting the a cr y lic a cid s tr ea m in the

pr es ence of a mixed meta l oxide conta ining a t lea s t Mo a nd/or

Bi ( J P 10- 218831) or in the pr es ence of a pr opionic a cid

r eduction meta l mixed oxide ca ta ly s t conta ining a t lea s t one

element s elected fr om the g r oup of Mo a ndW ( EP 2 039 6 74) .

Thes e methods either involve a hig h temper a tur e ( 300- 500

C. in J P 10- 218831) , or lea d to a s ig ni? ca nt los s of a cr y lic

a cid ( mor e tha n 6 % in EP 2 039 6 74) .

[ 0026 ] Other W is e, the ca ta ly tic oxida tive dehy dr og ena tion

of s a tur a ted a ldehy des in uns a tur a ted a ldehy des is W ell

knoW n in pr ior a r t.

[ 0027] For exa mple, Ha r g is et a l, in I&EC pr oduct r es ea r ch

a nd development, V ol 5, N o. 1, Ma r ch 19 6 6 , pp 72- 75 pr opos e

to us e a n oxide of a r s enic, a ntimony or bis muth to conver t

s ome s a tur a ted a ldehy des into the cor r es ponding uns a tur a ted

a ldehy des . Pr opiona ldehy de is conver ted into a cr olein by

us ing Sb2O4 a s oxida nt, but only W ith a s electivity of 6 2% for

a conver s ion of 5% .

[ 0028] The oxy dehy dr og ena tion of s a tur a ted a ldehy des to

uns a tur a ted a ldehy des ha s been a ls o des cr ibed, mor e s peci?

ca lly for the pr oduction of metha cr olein fr om is obuty r a lde

hy de in US. Pa t. N o. 4, 381, 411, us ing ir on phos phor ous

oxide conta ining a t lea s t one pr omotor . Conver s ion r a tes of

100% ha ve been obta ined for metha cr olein y ields r a ng ing

betW een 52% a nd 80% .

[ 0029 ] In Kinetics a nd Ca ta ly s is , V ol 44, N o. 2, ( 2003) pp

19 8- 201, is obuty r a ldehy de ha s been conver ted in metha c

r olein on a ir on phos pha te ca ta ly s t W ith a conver s ion of 80%

a nd a s electivity of 82% . Mor eover , it ha s been s hoW n tha t the

a ddition of a ver y s ma ll a mount of moly bdenum to FeiP

US 2013/0324758 A1

ca ta ly s t enha nces the oxida tion a ctivity W ithout modify ing

the hig h s electivity tha t or ig ina tes fr om ir on phos pha te. This

effect ha s not been s tudied in oxy - dehy dr og ena tion of pr opa

na l into a cr olein, but it ha s been obs er ved tha t W hen the

a mount of moly bdenum is la r g er tha t 4% in the ca ta ly s t, the

s electivity fa lls , tea ching a W a y to us e moly bdenum ba s ed

ca ta ly s t.

[ 0030] The document J P 54- 046 705 dis clos es a pr oces s for

pr epa r ing uns a tur a ted a ldehy des s uch a s a cr olein or metha c

r olein, a nd ca r boxy lic a cids s uch a s a cr y lic a cid or meth

a cr y lic a cid, by the va por pha s e oxida tion of C3 a nd C4

s a tur a ted a ldehy des s uch a s pr opa na l or is obuty r a ldehy de, in

the pr es ence of ca ta ly s ts conta ining Mo, P oxides a nd one or

tW o elements chos en a mong Z n, Cu or Ag , s uppor ted on a

ca lcined ca r r ier ha ving a s peci? c s ur fa ce a r ea of a t lea s t 10

m2/g . In ca s e of pr opa na l, a y ield of 53. 1% of a cr olein a nd

a cr y lic a cid is obta ined a t a conver s ion level of 72. 6 % , mea n

ing tha t hig h conver s ion of pr opa na l combined W ith a hig h

s electivity in a cr olein is dif? cult to obta in.

[ 0031] In J our na l ofCa ta ly s is 19 5, 36 0- 375 ( 2000) , J i Hu et

a l ha ve s tudied the oxida tive dehy dr og ena tion of is obuty r a l

dehy de to metha cr olein over PiMo ca ta ly s t. FIGS. 1 a nd 2

illus tr a te the effect of temper a tur e on the r ea ction. They s hoW

tha t the conver s ion of is obuty r a ldehy de r ea ches a ma ximum

of a bout 9 5% even a t hig h temper a tur e. It a ppea r s tha t it is

dif? cult to conver t mor e tha n a bout 9 5% of is obuty r a ldehy de

W ithout a ffecting the s electivity in metha cr olein.

[ 0032] In Rea ct. Kinet. Ca ta l. Lett. V ol 81, N o. 2, 383- 39 1

( 2004) , the s a me r ea ction ha ve been s tudied over Cs PMo

ca ta ly s t by Cicma nec et a l. FIGS. 3 a nd 4 illus tr a te the depen

dence of the conver s ion of is obuty r a ldehy de a nd the y ield of

metha cr olein on conta ct time. It a ppea r s tha t the conver s ion is

limited to 9 0% even W ith hig h conta ct time.

[ 0033] Pr ior a r t on the W hole tea ches a W a y to conver t s a tu

r a ted a ldehy des pr es ent a t loW level in the cor r es ponding

uns a tur a ted a ldehy des s ince the ma n of the a r t W ould expect

a deg r a da tion of the ca ta ly s t pr oper ties a nd a decr ea s e of

s electivity in uns a tur a ted a ldehy des .

[ 0034] In W O09 /127, 889 , a 16 . 3% a cr olein y ield W a s

obta ined fr om g ly cer ol a t 9 1. 3% conver s ion W ith a het

er opoly a cid conta ining moly bdenum. It s hoW s tha t het

er opoly a cids conta ining moly bdenum a r e ba d ca ta ly s ts for

the pr oduction of a cr olein fr om g ly cer ol. For tha t r ea s on, the

ma n of the a r t is not tempted to us e thos e ca ta ly s ts to elimina te

pr opa na l a s a n impur ity in a cr olein.

[ 0035] It is ther efor e a n obj ective of the pr es ent invention to

pr ovide a pr oces s for s electively r emoving pr opa na l a s a n

impur ity fr om a n a cr olein- r ich s tr ea m W ithout a ffecting

a cr olein. As a r es ult, it ha s unexpectedly been found tha t the

mos t s elective ca ta ly s ts for pr opa na l elimina tion in a n

a cr olein- r ich s tr ea m compr is e a t lea s t the element moly bde

num.

[ 0036 ] It is a nother obj ective of the pr es ent invention to

pr ovide a pr oces s for ma nufa ctur ing a cr olein a nd/or a cr y lic

a cid conta ining loW a mount of pr opa na l a nd/or pr opionic

a cid.

[ 0037] It is a nother obj ective of the pr es ent invention to

pr ovide a pr oces s for ma nufa ctur ing a cr y lic a cid fr om g ly c

er ol including a s tep of s elective elimina tion of pr opa na l,

W hile pr oviding a cr y lic a cid es s entia lly ba s ed on a non- fos s il

na tur a l ca r bon s our ce a nd over coming the dr a wba cks of the

exis ting ca ta ly s ts for the dehy dr a tion of g ly cer ol.

Dec. 5, 2013

SUMMARY OF THE IN V EN TION

[ 0038] One s ubj ect of the pr es ent invention is ther efor e a

pr oces s for ma nufa ctur ing a cr olein cha r a cter ized in tha t it

compr is es s elective elimina tion of pr opa na l in a n a cr olein

r ich s tr ea m by pa s s ing the s a id s tr ea m in g a s pha s e in the

pr es ence of oxy g en thr oug h a ca ta ly s t compr is ing a t lea s t

moly bdenum a nd a t lea s t one element s elected fr om P, Si, W ,

Ti, Z r , V , N b, Ta , Cr , Mn, Fe, Co, N i, Cu, Z n, Ga , In, Tl, Sn,

Ag , As , Ge, B, Bi, La , Ba Sb Te, Ce, Pb.

[ 0039 ] In the pr es ent invention, s elective mea ns tha t pr o

pa na l is mor e conver ted tha n a cr olein on the bed of ca ta ly s t

a nd tha t pr opa na l is not conver ted into pr opionic a cid to a n

extent hig her tha n 50% . The conver s ion ( % ) of a ma ter ia l is

de? ned a s the r a tio betW een the mole number of ma ter ia l

r ea cted on the ca ta ly s t divided by the mole number of ma te

r ia l s upplied to the ca ta ly s t.

[ 0040] The a cr olein- r ich s tr ea m in the pr es ent invention

ma y be pr oduced by a ny conventiona l techniq ue knoW n by

thos e of or dina r y s kill in the a r t. Additiona lly , a ny conven

tiona l r a W ma ter ia l feed ma y be us ed to pr oduce a cr olein s o

long a s the a cr olein pr oduct s tr ea m conta ins s ome a mount of

pr opa na l.

[ 0041] Another s ubj ect of the invention is a pr oces s for

ma nufa ctur ing a cr y lic a cid compr is ing the oxida tion of

a cr olein obta ined a fter elimina tion of pr opa na l a ccor ding to

the a bove- mentioned pr oces s .

[ 0042] Another s ubj ect of the invention is a pr oces s for

ma nufa ctur ing a cr y lonitr ile compr is ing the a mmoxida tion of

a cr olein obta ined a fter elimina tion of pr opa na l a ccor ding to

the a bove- mentioned pr oces s .

[ 0043] Another s ubj ect of the invention is a pr oces s for

ma nufa ctur ing methy lmer ca ptopr opiona ldehy de us ed for

pr oducing methionine, compr is ing the a ddition of methy l

mer ca pta n to a cr olein obta ined a fter elimina tion of pr opa na l

a ccor ding to the a bove- mentioned pr oces s .

[ 0044] The pr es ent invention pr ovides fur ther a pr oces s for

ma nufa ctur ing bio- s our ced a cr y lic a cid conta ining a loW

a mount of pr opionic a cid fr om g ly cer ol, W hich is a r a W ma te

r ia l independent of petr oleum.

[ 0045] The invention W ill be mor e clea r ly under s tood on

r ea ding the folloW ing deta iled des cr iption, fr om the non

limiting exa mples of embodiments ther eof.

DETAILED DESCRIPTION

[ 0046 ] The ca ta ly s t for s elective elimina tion of pr opa na l

us ed in the pr oces s of the invention compr is es a t lea s t moly b

denum.

[ 0047] Adva nta g eous ly , the pr oces s for ma nufa ctur ing

a cr olein is cha r a cter ized in tha t it compr is es s elective elimi

na tion of pr opa na l in a n a cr olein- r ich s tr ea m by pa s s ing the

s a id s tr ea m in g a s pha s e in the pr es ence of oxy g en thr oug h a

ca ta ly s t compr is ing a t lea s t moly bdenum a nd a t lea s t one

element s elected fr om P, Si, W , Ti, Z r , V , N b, Ta , Cr , Mn, Fe,

Co, N i, Cu, Z n, Ga , In, Tl, Sn, Ag , As , Ge, B, Bi, La , Ba Sb Te,

Ce, Pb, chos en in the g r oup for med by the mixed meta l oxides

conta ining a t lea s t moly bdenum a nd heter opoly a cids con

ta ining a t lea s t moly bdenum.

[ 0048] In one embodiment of the invention, the ca ta ly s t

compr is es a t lea s t moly bdenum a nd a s ing le element s elected

fr om P, Si, W , Ti, Z r , V , N b, Ta , Cr , Mn, Fe, Co, N i, Cu, Z n, Ga ,

In, Tl, Sn, Ag , As , Ge, B, Bi, La , Ba Sb Te, Ce, Pb.

[ 0049 ] In one embodiment, the ca ta ly s t a ccor ding to the

invention ma y be a mixed meta l oxide ba s ed on moly bdenum

US 2013/0324758 A1

tha t is us ed W ith other feeds tocks tha n s a tur a ted a ldehy de, for

exa mple for metha nol oxida tion to for ma ldehy de ( Fei

M040 doped or not) a nd pr opy lene oxida tion to a cr olein

( ba s ed on bis muth moly bda te, for exa mple W ith a g ener a l

for mula des cr ibed in EP 19 87877: Mo l2Bia FebAcB dCeDfO, C

W her ein A is a t lea s t a n element s elected fr om coba lt a nd

nickel, B is a t lea s t a n element s elected fr om a lka li meta ls ,

a lka line ea r th meta ls a nd tha llium, C is a t lea s t a n element

s elected fr om tung s ten, s ilicon, a luminum, Z ir conium a nd

tita nium; D is a t lea s t a n element s elected fr om phos phor us ,

tellur ium, a ntimony , tin, cer ium, lea d, niobium, ma ng a nes e,

a r s enic a nd Z inc, pota s s ium) .

[ 0050] Exa mples of FeiMoiO ir on moly bda te ca ta ly s ts

a r e des cr ibed in Ca ta ly s is Review, V ol 47 ( 2004) , pp 125- 174.

[ 0051] Ir on moly bdenum ba s ed ca ta ly s ts a r e commer cia lly

a va ila ble. For exa mple Siid Chemie s upplies s ever a l g r a des of

s uch ca ta ly s ts under the tr a de na me FAMAX: FAMAX J 5,

FAMAX MS, FAMAX HS, FAMAX TH.

[ 0052] Exa mples of pr opy lene oxida tion ca ta ly s ts to

a cr olein a r e des cr ibed in EP 9 00774, EP 11259 11, EP

19 87877, EP 10749 38, US. Pa t. N o. 6 , 26 8, 529 , US. Pa t. N o.

4, 837, 9 40.

[ 0053] Pr efer a bly , the ca ta ly s t compr is es moly bdenum a nd

a t lea s t one element s elected fr om P, Si, W , Cr , Mn, Fe, Co, N i,

Bi, Sb, Ce.

[ 0054] In one embodiment, the ca ta ly s t a ccor ding to the

invention compr is es a t lea s t one heter opoly a cid conta ining a t

lea s t moly bdenum.

[ 0055] Adva nta g eous ly , pr oton in the heter opoly a cid con

ta ining a t lea s t moly bdenum, ma y be pa r tia lly excha ng ed by

a t lea s t one ca tion s elected fr om elements belong ing to Gr oup

1 to 16 of the Per iodic Ta ble of elements .

[ 0056 ] The ca ta ly s t a ccor ding to the invention ma y be r ep

r es ented by the g ener a l for mula :

Aa XbYcZ dOe

in W hich

[ 0057] A is mor e tha n one ca tion s elected fr om elements

belong ing to Gr oup 1 to 16 of the Per iodic Ta ble of Elements

a nd la ntha nides , pr efer a bly one a lka li meta l ca tion s uch a s

ces ium, r ubidium or pota s s ium.

[ 0058] X is P or Si, pr efer a bly P

[ 0059 ] Y is Mo

[ 006 0] Z is mor e tha n one element s elected fr om the

g r oup compr is ing W , Ti, Z r , V , N b, Ta , Cr , Mn, Fe, Co,

N i, Cu, Z n, Ga , In, Tl, Sn, Ag , As , Ge, B, Bi, La , Ba , Sb,

Te, Ce a nd Pb, pr efer a bly Fe, Bi, Co, N i, W , V , Cr , Sb,

Mn, Ce

[ 006 1] a , b, c a nd d s a tis fy ing folloW ing r a ng es :

[ 006 2] 0s a s 9 , pr efer a bly 0< a s 9

[ 006 3] 0s bs 2 pr efer a bly 0. 1s bs 1. 5

[ 006 4] 0< cs 12 pr efer a bly 5< cs 12

[ 006 5] 0s d< 12 pr efer a bly 0s ds 4

[ 006 6 ] a nd e is a number deter mined by the oxida tion of the

elements .

[ 006 7] Exa mples of effective ca ta ly s ts a r e mixed oxides or

heter opoly a cid s a lts of FeMo, Cs PMo, Cs PW Mo or BiMoFe

ca ta ly s ts .

[ 006 8] The ca ta ly s t us ed in the pr es ent invention ca n be

pr epa r ed by a ny knoW n techniq ue, for exa mple a s des cr ibed

in W O/09 / 128, 555 ( heter opoly a cids ) or in Ca ta ly s is RevieW ,

V ol 47 ( 2004) , pp 125- 174 a nd the r efer ences des cr ibed

ther ein. Gener a lly , the r es ulting s olid component is ? na lly

Dec. 5, 2013

? r ed or ca lcined to obta in the ca ta ly s t for s elective elimina

tion of pr opa na l a ccor ding to the pr es ent invention.

[ 006 9 ] The ca lcina tion ca n be ca r r ied out in a ir or under

iner t g a s s uch a s nitr og en, helium a nd a r g on or under a n

a tmos pher e of mixed g a s of oxy g en a nd iner t g a s , us ua lly in

a fuma ce s uch a s muf? e fur na ce, r ota r y kiln, ? uidized bed

fur na ce. Ty pe of the fur na ce is not limited s pecia lly . The

ca lcina tion ca n be effected even in a r ea ction tube tha t is us ed

for the g ly cer in dehy dr a tion r ea ction. The ? r ing temper a tur e

is us ua lly 150 to 9 00 C. , pr efer a bly 200 to 800 C. a nd mor e

pr efer a bly 200 to 6 00 C. The ca lcina tion is continuedus ua lly

for 0. 5 to 10 hour s .

[ 0070] The ca ta ly s t in the pr oces s a ccor ding to the inven

tion ma y be a bulk a nd is us ed, in this ca s e, W ithout a ny

s uppor t.

[ 0071] The ca ta ly s t ma y a ls o be loa ded on a s uppor t ( or

ca r r ier ) , the a mount of s uppor t g ener a lly r epr es enting fr om 0

to 9 0% , pr efer a bly a t lea s t 5% of the tota l W eig ht of the

ca ta ly s t.

[ 0072] The ca r r ier ca nbe g r a nule a nd poW der a nd ma y ha ve

a ny s ha pe s uch a s s pher e, pellet, cy lindr ica l body , holloW

cy linder body , tr ilobe a nd q ua dr ilobe a nd ba r W ith optiona l

molding a id.

[ 0073] It is pos s ible to us e, a s a s uppor t, a ny ma ter ia l s uch

a s s ilica , a lumina , ma g nes ia , tita nium oxide, Z ir conia , s ilicon

ca r bide, s ilica / a lumina mixtur e, s ilica tes , dia toma ceous

ea r th, bor a tes or ca r bona tes on condition tha t thes e pr oducts

a r e s ta ble under the r ea ction conditions to W hich the ca ta ly s t

W ill be s ubj ected. Pr efer a bly , the ca ta ly s t is not a s uppor ted

ca ta ly s t.

[ 0074] The ca ta ly s t ma y ha ve a ny s ha pe a nd ca n be g r a nule

or poW der . It is pr efer a ble to mold the ca ta ly s t into a s ha pe of

s pher e, pellets , cy linder , holloW cy linder , ba r or the like,

optiona lly W ith a dding a molding a id. The ca ta ly s t ca n be

s ha ped into the a bove- con? g ur a tions tog ether W ith ca r r ier

a nd optiona l a uxilia r y a g ents . The molded ca ta ly s t ma y ha ve

a pa r ticle s iZ e of for exa mple 1 to 10 mm for a ? xed bed a nd

of les s tha n 1 mm for a ? uidized bed.

[ 0075] The a cr olein- r ich s tr ea m in the pr oces s a ccor ding to

the invention ca n be s peci? ca lly the pr oduct s tr ea m of a

pr opy lene ( or other non- petr oleum ba s ed s our ces of hy dr o

ca r bons ) ca ta ly tic oxida tion pr oces s , or the pr oduct s tr ea m of

g ly cer ol dehy dr a tion in liq uid pha s e or in g a s pha s e, pr efer

a bly in g a s pha s e or in a s tr ea m of hy dr oxy pr opa na l dehy dr a

tion. Gener a lly , the a cr olein- r ich s tr ea m r es ults a s a g a s mix

tur e tha t is s ubmitted dir ectly for the pr oces s a ccor ding to the

invention

[ 0076 ] Exa mples of oper a ting conditions for dehy dr a ting

g ly cer ol into a cr olein a r e des cr ibed in the inter na tiona l pa tent

a pplica tions W O 06 /087083, W O 06 /087084, W O 09 /128,

555 or W O 10/046 , 227 of the Applica nt. Speci? ca lly , the

ca ta ly s t us ed for the r ea ction of dehy dr a tion is a ca ta ly s t

ha ving Ha mmett a cidity loW er tha n + 2. Speci? ca lly , the ca ta

ly s t us ed for the r ea ction of dehy dr a tion is a ca ta ly s t conta in

ing no moly bdenum.

[ 0077] Exa mples of oper a ting conditions for oxida tion of

pr opy lene into a cr olein a r e des cr ibed in Pr oces s Economic

Pr og r a m n 6 D fr om SR1 cons ulting a nd the r efer ence cited

ther ein.

[ 0078] The a mount of pr opa na l in the a cr olein- r ich s tr ea m

is g ener a lly les s tha n 0. 2, expr es s ed by the moles of pr opa na l

r ela tive to the moles of a cr olein pr es ent in the s tr ea m. It ma y

US 2013/0324758 A1

r a ng e fr om 1/4000 to 1/ 5 expr es s ed by the moles of pr opa na l

r ela tive to the moles of a cr olein pr es ent in the s tr ea m, pr ef

er a bly fr om 1/1000 to 1/ 10.

The a cr olein- r ich s tr ea m in the pr oces s a ccor ding to the

invention conta ins W a ter , oxy g en, a nd eventua lly by - pr oducts

s uch a s hy dr oxy pr opa none, a ceta ldehy de, a cetone, a ddition

pr oducts of a cr olein to g ly cer ol, poly condens a tion pr oducts

of g ly cer ol, cy clic g ly cer ol ether s , hy dr oxy pr opa na l, phenol

a nd poly a r oma tic compounds , pr opy lene, a cr y lic a cid, a nd

iner t g a s es s uch a s ca r bon oxide, ca r bon dioxide, nitr og en,

helium, a r g on, pr opa ne. The na tur e of the by - pr oducts a nd the

compos ition of the a cr olein- r ich s tr ea m depend of cour s e on

the r a W ma ter ia l us ed to pr oduce a cr olein.

[ 0079 ] Thus , in the ca s e W her e pr opy lene is the ma in r a W

ma ter ia l in a n oxida tion r ea ction to pr oduce a cr olein, the

a cr olein- r ich s tr ea m ma y conta in pr opa ne a s ther ma l ba lla s t.

[ 0080] In the ca s e W her e g ly cer ol is the ma in r a W ma ter ia l

in a dehy dr a tion pr oces s to pr oduce a cr olein, the mixtur e of

a cr olein a nd pr opa na l ma y conta in a la r g e a mount of W a ter

depending of the concentr a tion of g ly cer ol in the feed.

[ 0081] In the pr oces s a ccor ding to the invention, the con

centr a tion of a cr olein in the g a s mixtur e tha t is pa s s ed thr oug h

the ca ta ly s t r a ng es fr om 1 to 12 mole % , pr efer a bly fr om 4 to

10 mole % .

[ 0082] The pr oces s a ccor ding to the invention is ca r r ied out

in the pr es ence of oxy g en, or a n oxy g en- conta ining g a s s uch

a s a ir . Gener a lly , oxy g en is a lr ea dy pr es ent in the g a s mixtur e,

but fur ther oxy g en ma y be inj ected if the oxy g en concentr a

tion is too loW . Oxy g en content is compr is ed betW een 1 a nd

10% ( mol) a nd pr efer a bly betW een 3 a nd 7% ( mol) .

[ 0083] The concentr a tion of W a ter of the a cr olein- r ich

s tr ea m ma y va r y la r g ely . W a ter content is compr is ed betW een

3 a nd 9 0% ( mol) a nd pr efer a bly betW een 8 a nd 80% ( mol) .

[ 0084] The s elective elimina tion of pr opa na l oper a tes a t a

temper a tur e betW een 250 C. a nd 400 C. , pr efer a bly

betW een 280 a nd 350 C. , a nd a t a pr es s ur e betW een 1 a nd 5

ba r a bs olute a nd pr efer a bly betW een 1 a nd 2 ba r .

[ 0085] A feed r a te of the g a s r ea cta nt is a dva nta g eous ly

1000 to 40, 000 h' 1 in ter m of GHSV ( g a s hour ly s pa ce veloc

ity in nor ma l m3/h/volume of ca ta ly s t in m3) , pr efer a bly 3000

to 30000 h_ 1, mor e pr efer a bly 5000 to 20000 h_ l. If the

GHSV becomes loW er tha n 1000 h_ l, the s electivity W ill be

loW er ed. On the contr a r y , if the GHSV exceeds 40, 000 h_ 1,

the conver s ion W ill be loW er ed.

[ 0086 ] For ea ch ca ta ly s t ther e is a n optimum of temper a tur e

a nd GHSV for W hich a hig h conver s ion of pr opa na l is

obta ined a t a loW conver s ion of a cr olein.

[ 0087] The s elective elimina tion of pr opa na l in a n a cr olein

r ich s tr ea m a ccor ding the invention ca n be ca r r ied out in a

va r iety of r ea ctor s s uch a s ? xed bed, ? uid bed, cir cula ting

? uid bed a nd moving bed. Among them, the ? xed bed a nd the

? uid bed a r e pr efer a ble.

[ 0088] W hen a ? uid bed or cir cula ting ? uid bed r ea ctor is

us ed a s a ? r s t r ea ctor for the pr oduction of the a cr olein- r ich

s tr ea m, the pr opa na l elimina tion ca ta ly s t ca n be us ed a s a

? xedbed doW ns tr ea m of the s a id ? r s t r ea ctor , or it ca nbe us ed

a s a compa r tmenta lized ? uid bed r ea ctor . This ty pe of r ea ctor

ca n be ma de by us ing a g r id or a mes h W ithin the ? uid bed tha t

keep the ? r s t ca ta ly s t in the loW er pa r t of the ? uid bed a nd the

pr opa na l elimina tion ca ta ly s t in the upper pa r t of the ? uid

bed.

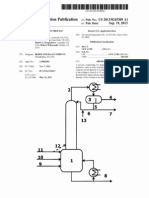

[ 0089 ] In a ? r s t embodiment of the invention, the pr oduc

tion of the a cr olein- r ich s tr ea m a nd the s elective elimina tion

of pr opa na l a r e ca r r ied out in a ta ndem- ty pe r ea ctor compr is

Dec. 5, 2013

ing tW o r ea ctor s linked to ea ch other , W her e the tW o r ea ctor s

a r e ? lled W ith a ca ta ly s t for the pr oduction of a cr olein a nd a

ca ta ly s t for the s elective elimina tion of pr opa na l r es pectively ,

a nd W her e the pr oduction of a cr olein a nd the elimina tion of

pr opa na l a r e s epa r a tely conducted in their r es pective r ea ctor s .

[ 009 0] In a s econd embodiment of the invention, the pr o

duction of the a cr olein- r ich s tr ea m a nd the s elective elimina

tion of pr opa na l a r e ca r r ied out in a s ing le- r ea ctor - ty pe, W her e

the r ea ctor ? lled W ith a ca ta ly s t for the s elective elimina tion

of pr opa na l on the r ea ction g a s outlet s ide a nd W ith a ca ta ly s t

for the pr oduction of a cr olein on the r ea ction g a s inlet s ide,

thus conducting in the s ing le r ea ctor the pr oduction of

a cr olein folloW ed by the s elective elimina tion of pr opa na l. It

is pr efer a ble tha t the r ea ctor ha s differ ent Z one of temper a tur e

contr ol s o tha t elimina tion of pr opa na l ca n be oper a ted a t a

differ ent temper a tur e fr om the pr oduction of a cr olein. In ca s e

of a ? xed bed r ea ctor , a pr efer r ed con? g ur a tion is W hen the

g a s is moving upW a r d thr oug h the bed a nd the pr opa na l

elimina tion ca ta ly s t is pla ced on top of the ca ta ly s t for the

pr oduction of a cr olein.

[ 009 1] In the ca s e of ? xed beds , W hen a multitubula r r ea ctor

is us ed for the a cr olein pr oduction a pr efer r ed con? g ur a tion

for the s elective elimina tion of pr opa na l is a la y er of ca ta ly s t

on top of the tubula r pla te, a bove the r ea ctor tubes conta ining

the a cr olein pr oducing ca ta ly s t. This con? g ur a tion is pr e

fer r ed to r epla ce mor e ea s ily the pr opa na l elimina tion ca ta ly s t

by va cuum unloa ding .

[ 009 2] Acr olein thus obta ined by the pr oces s a ccor ding to

the invention conta ins les s tha n 5000 ppm, even les s tha n

1000 ppm of pr opa na l.

[ 009 3] Another s ubj ect of the invention is the us e of a

ca ta ly s t compr is ing a t lea s t moly bdenum a nd a t lea s t one

element s elected fr om P, Si, W , Ti, Z r , V , N b, Ta , Cr , Mn, Fe,

Co, N i, Cu, Z n, Ga , In, Tl, Sn, Ag , As , Ge, B, Bi, La , Ba Sb Te,

Ce, Pb, chos en in the g r oup for med by the mixed meta l oxides

conta ining a t lea s t moly bdenum a nd heter opoly a cids con

ta ining a t lea s t moly bdenum, to r educe the content of pr opa

na l loW er tha n 5000 ppm, pr efer a bly loW er tha n 1000 ppm, in

a n a cr olein- r ich s tr ea m.

[ 009 4] Acr olein obta ined by the pr oces s a ccor ding to the

invention ca n be a dva nta g eous ly fur ther s ubj ected to knoW n

oxida tion methods to pr oduce a cr y lic a cid W ith a loW content

of pr opionic a cid, ty pica lly conta ining les s tha n 5000 ppm,

even les s tha n 1000 ppm of pr opionic a cid, W hich is a ty pica l

s peci? ca tion level for a br oa d r a ng e of a pplica tions .

[ 009 5] Thus , a nother s ubj ect of the invention is the us e of a

ca ta ly s t compr is ing a t lea s t moly bdenum a nd a t lea s t one

element s elected fr om P, Si, W , Ti, Z r , V , N b, Ta , Cr , Mn, Fe,

Co, N i, Cu, Z n, Ga , In, Tl, Sn, Ag , As , Ge, B, Bi, La , Ba Sb Te,

Ce, Pb, chos en in the g r oup for med by the mixed meta l oxides

conta ining a t lea s t moly bdenum a nd heter opoly a cids con

ta ining a t lea s t moly bdenum to pr oduce a cr y lic a cid W ith a

loW content of pr opionic a cid, ty pica lly conta ining les s tha n

5000 ppm, even les s tha n 1000 ppm of pr opionic a cid.

[ 009 6 ] Gener a lly , the oxida tion r ea ction is ca r r ied out in the

pr es ence of molecula r oxy g en or of a mixtur e compr is ing

molecula r oxy g en, a t a temper a tur e r a ng ing fr om 200 C. to

350 C. , pr efer a bly fr om 250 C. to 320 C. , a nd under a

pr es s ur e r a ng ing fr om 1 to 5 ba r , in the pr es ence of a n oxida

tion ca ta ly s t compr is ing a t lea s t one element chos en fr om the

lis t Mo, V , W , Re, Cr , Mn, Fe, Co, N i, Cu, Z n, Sn, Te, Sb, Bi,

Pt, Pd, Ru a nd Rh, pr es ent in the meta llic for m or in the oxide,

s ulfa te or phos pha te for m. Us e is ma de in pa r ticula r of the

for mula tions compr is ing Mo a nd/or V a nd/or W a nd/or Cu

US 2013/0324758 A1

a nd/ or Sb a nd/or Fe a s ma in cons tituents . The oxida tion ca ta

ly s t ma y be s uppor ted on a ca r r ier s uch a s Z ir conia , s ilica ,

a lumina , s tea tite a nd combina tion ther eof a nd s ilicon ca r bide.

Acr olein g a s s tr ea m conta ins the s a me kind of components a s

the s elective elimina tion s tep of pr opa na l, s uch a s W a ter , or

iner t g a s es s uch a s ca r bon oxide, ca r bon dioxide, nitr og en,

helium, a r g on, pr opa ne or or g a nic impur ities .

[ 009 7] Acr olein obta ined by the pr oces s a ccor ding to the

invention ca n be a dva nta g eous ly fur ther s ubj ected to knoW n

a mmoxida tion methods to pr oduce a cr y lonitr ile W ith a loW

content of pr opionitr ile, ty pica lly conta ining les s tha n 5000

ppm, even les s tha n 1000 ppm of pr opionitr ile, W hich is a

ty pica l s peci? ca tion level for a br oa d r a ng e of a pplica tions .

[ 009 8] Acr olein obta ined by the pr oces s a ccor ding to the

invention ca n be a dva nta g eous ly fur ther s ubj ected to knoW n

condens a tion r ea ction to pr oduce g luta r a ldehy de, for

exa mple a ccor ding to the pr oces s des cr ibed in the document

W O 2011/055051.

[ 009 9 ] Acr olein obta ined by the pr oces s a ccor ding to the

invention ca n be a dva nta g eous ly fur ther s ubj ected to knoW n

a ddition W ith methy l mer ca pta n to pr oduce methy lmer ca pto

pr opiona ldehy de us ed for ma nufa ctur ing methionine or its

s a lt or its hy dr oxy l a na log ue, 2- hy dr oxy - 4- methy lthio- bu

ty r ic a cid. Adva nta g eous ly , a cr olein is pur i? ed by a bs or ption

in W a ter a nd fur ther dis tilla tion befor e being r ea cted W ith

methy lmer ca pta n to y ield methy lmer ca ptopr opiona ldehy de.

Ins ofa r a s pr opa na l a mount is r educed to a minimum va lue,

methy lmer ca ptopr opiona ldehy de ca n be us ed W ithout pur i?

ca tion for the pr oduction of methionine or its s a lt or its

hy dr oxy a na log ue.

[ 0100] Another obj ect of the pr es ent invention is a pr oces s

for ma nufa ctur ing a cr y lic a cid fr om g ly cer ol cha r a cter ized in

tha t it compr is es a t lea s t the folloW ing s teps :

[ 0101] a ) dehy dr a tion of g ly cer ol to g ive a n a cr olein- r ich

s tr ea m conta ining pr opa na l,

[ 0102] b) s elective elimina tion of pr opa na l by pa s s ing the

s a id s tr ea m in g a s pha s e in the pr es ence of oxy g en thr oug h a

ca ta ly s t compr is ing a t lea s t moly bdenum a nd a t lea s t one

element s elected fr om P, Si, W , Ti, Z r , V , N b, Ta , Cr , Mn, Fe,

Co, N i, Cu, Z n, Ga , In, Tl, Sn, Ag , As , Ge, B, Bi, Cr , La , Ba Sb

Te, Ce, Pb;

[ 0103] c) oxida tion of the a cr olein to g ive a cr y lic a cid.

[ 0104] The ? r s t s tep a ) ma y be ca r r ied out in the g a s pha s e

or in the liq uid pha s e, pr efer a bly in the g a s pha s e. W hen the

dehy dr a tion r ea ction is ca r r ied out in the g a s pha s e, va r ious

pr oces s technolog ies ma y be us ed, na mely a ? xed bed pr o

ces s , W ith one or s ever a l r ea ctor s in pa r a llel, a ? uid bed

pr oces s or a cir cula ting ? uid bed pr oces s . It is a ls o pos s ible to

us e r ea ctor s of the pla te hea t excha ng e ty pe.

[ 0105] The exper imenta l conditions of the g a s - pha s e r ea c

tion a r e pr efer a bly a temper a tur e betW een 180 C. a nd 5000

C. , pr efer a bly betW een 250 a nd 400 C. a nd a pr es s ur e

betW een 1 a nd 5 ba r s . In the liq uid pha s e, the r ea ction is

pr efer a bly ca r r ied out a t a temper a tur e betW een 150 C. a nd

350 C. a nd a pr es s ur e W hich ma y r a ng e fr om 3 to 70 ba r .

[ 0106 ] Us e is g ener a lly ma de of g ly cer ol, or a mixtur e of

g ly cer ol a nd W a ter ha ving a W eig ht r a tio W hich ca n va r y

W ithin W ide limits , for exa mple fr om 0. 1 to 100, pr efer a bly

betW een 0. 5 a nd 4, in the r ea ctor .

[ 0107] The mixtur e of g ly cer ol a nd W a ter ma y be us ed in

liq uid for m or in g a s eous for m, pr efer a bly in the g a s pha s e

for m.

[ 0108] Accor ding to one embodiment of the invention, it is

pos s ible to us e >9 5% pur e g ly cer ol, tha t is to s a y W ith < 5%

Dec. 5, 2013

W a ter , a nd to blend the s a id g ly cer ol W ith a g a s mixtur e

compr is ing va por ized W a ter a nd iner t g a s , pos s ibly coming

for m a r ecy cle g a s , s o a s the r ea ction of conver ting g ly cer ol

into a cr olein is conducted in g a s pha s e.

[ 0109 ] Pr efer a bly , the s tep a ) is ca r r ied out in the pr es ence

of oxy g en, or a n oxy g en- conta ining g a s , a s des cr ibed in

a pplica tions W O 06 /087083 or W O 06 /114506 . The mola r

r a tio of the molecula r oxy g en to the g ly cer ol is g ener a lly

a r ound 0. 1 to 1. 5, pr efer a bly fr om 0. 5 to 1. 0.

[ 0110] The g ly cer ol dehy dr a tion r ea ction is g ener a lly ca r

r ied out over s olid a cid ca ta ly s ts . The ca ta ly s ts tha t a r e s uit

a ble a r e homog eneous or heter og eneous s ubs ta nces W hich

a r e ins oluble in the r ea ction medium a nd W hich ha ve a Ha m

mett a cidity , denoted HO, of les s tha n + 2. The ca ta ly s t W ill be

chos en a mong s uita ble ca ta ly s ts conta ining no moly bdenum.

[ 0111] A key pa r a meter lies in the concentr a tion of g ly cer ol

in the cha r g e. Expr es s ed in mole per cent, the concentr a tion of

g ly cer ol va r ies W idely fr om 0. 1 to 20. As is common in

r ea ctions of this ty pe, the y ield of the des ir ed pr oduct is a n

inver s e function of the concentr a tion. Fr om the point of vieW

of obta ining a r ea s ona ble ? oW r a te combined W ith a n a ccept

a ble y ield, the concentr a tion of g ly cer ol in the cha r g e is

a r ound 3 to 16 mol % . The concentr a tion is contr olled by the

a mount of W a ter a nd of iner t g a s pr es ent in the feed s tr ea m.

The pr efer r ed g a s eous diluent is nitr og en a lthoug h other

g a s es s uch a s ca r bon dioxide, helium, a r g on, etc. a r e a ls o

s uita ble. Of cour s e, W hen the des ir ed concentr a tion of g ly c

er ol per mits it, a ir r epr es ents a s uita ble diluted oxida nt.

[ 0112] The conta ct time expr es s ed in s econds is the r a tio

betW een the volume of the ca ta ly s t bed a nd the volume ( cor

r ected for nor ma l pr es s ur e a nd nor ma l temper a tur e) of the

g a s eous r ea cta nts convey ed per s econd. The a ver a g e temper a

tur e a nd pr es s ur e conditions in a bed ma y va r y depending on

the na tur e of the ca ta ly s t, the na tur e of the ca ta ly s t bed a nd the

s iZ e of the ca ta ly s t. In g ener a l, the conta ct time is fr om 0. 1 to

20 s econds a nd pr efer a bly fr om 0. 3 to 15 s econds .

[ 0113] In the pr oces s for ma nufa ctur ing a cr y lic a cid fr om

g ly cer ol of the invention, the s tep b) cons is ts in the s elective

elimina tion of pr opa na l a ccor ding to the a bove- des cr ibed

pr oces s , in the a cr olein- r ich s tr ea m coming fr om the s tep a ) to

g ive a n a cr olein- r ich s tr ea m W ith a loW content of pr opa na l,

fur ther oxidiZ ed in s tep c) into a cr y lic a cid.

[ 0114] Pr efer a bly , the ca ta ly s t us ed in the s tep b) is chos en

in the g r oup for med by the mixed meta l oxides conta ining a t

lea s t moly bdenum a nd heter opoly a cids conta ining a t lea s t

moly bdenum.

[ 0115] The g a s mixtur e r es ulting fr om the s tep c) is com

pos ed, a pa r t fr om a cr y lic a cid:

[ 0116 ] of lig ht compounds W hich a r e non- condens a ble

under the temper a tur e a nd pr es s ur e conditions nor ma lly

employ ed: nitr og en, unconver ted oxy g en, ca r bon monoxide

a nd ca r bon dioxide, W hich a r e for med in a s ma ll a mount by

? na l oxida tion or by r ecy cled in the pr oces s ,

[ 0117] of condens a ble lig ht compounds : in pa r ticula r

W a ter , g ener a ted by the dehy dr a tion r ea ction or pr es ent a s

diluent, unconver ted a cr olein, lig ht a ldehy des , s uch a s for m

a ldehy de a nd a ceta ldehy de, for mic a cid a nd a cetic a cid,

[ 0118] of hea vy compounds : fur fur a ldehy de, benZ a lde

hy de, ma leic a cid, ma leic a nhy dr ide, benZ oic a cid,

2- butenoic a cid, phenol, pr otoa nemonin, a nd the like.

[ 0119 ] Then, the pr oces s for ma nufa ctur ing a cr y lic a cid

a ccor ding the invention fur ther compr is es the s teps of collect

ing the r es ulta nt a cr y lic a cid a s a s olution by us ing W a ter or a

s olvent, a nd then of pur ify ing the r es ulta nt s olution conta in

US 2013/0324758 A1

ing a cr y lic a cid by us ing for exa mple a dis tilla tion s tep for

r emoving loW - a nd hi g h- boiling point ma ter ia ls a nd/ or a cr y s

ta lliZ a tion s tep for pur ify ing a cr y lic a cid by cr y s ta lliZ ing it.

[ 0120] The a cr y lic a cid thus obta ined ca n be us ed to pr o

duce for exa mple poly a cr y lic a cids or s a lts a s W a ter - s oluble

poly mer s or W a ter - a bs or bent r es ins , by knoW n methods .

[ 0121] Accor ding to one pa r ticula r embodiment of the

invention, us e is ma de of a n inter media te s tep of pa r tia l con

dens a tion of W a ter a nd of the hea vy by - pr oducts der ived fr om

the dehy dr a tion s tep a ) , a s is des cr ibed for exa mple in the

pa tent a pplica tion W O 08/087, 315.

[ 0122] The s a id inter media te s tep ha s the a im of r emoving

mos t of the W a ter pr es ent a nd the hea vy by - pr oducts befor e

s ending the g a s eous s tr ea m compr is ing the a cr olein a nd a ll

non- condens a ble g a s es to the pr opa na l elimina tion s tep or to

the s tep for the oxida tion of a cr olein to g ive a cr y lic a cid. This

pa r tia l condens a tion of the W a ter thus ma kes it pos s ible to

a void da ma g e to the ca ta ly s t of the oxida tion of a cr olein to

g ive a cr y lic a cid a nd to a void, dur ing the s ubs eq uent s ta g es ,

the r emova l of la r g e a mounts of W a ter , W hich could W ell be

expens ive a nd r es ult in los s es of a cr y lic a cid. In a ddition, it

ma kes it pos s ible to r emove a por tion of the hea vy impur i

ties for med dur ing the dehy dr a tion of the g ly cer ol a nd to

fa cilita te pur i? ca tion oper a tions .

[ 0123] This inter media te s tep is ca r r ied out on a s epa r a ting

unit W hich is a condens a tion pla nt compr is ing a n a bs or ption

column coupled or not coupled to a n eva por a tor , one or mor e

hea t excha ng er s , one or mor e condens er s , a dephleg ma tor ,

a nd a ny item of eq uipment W ell knoW n to a per s on s killed in

the a r t W hich ma kes it pos s ible to ca r r y out a pa r tia l conden

s a tion of a n a q ueous s tr ea m.

[ 0124] It is ca r r ied out under conditions s uch tha t the

a cr olein- r ich s tr ea m is s epa r a ted into a n a cr olein- r ich g a s

eous pha s e a nd a n a cr olein- poor a q ueous pha s e.

[ 0125] Fr om 20 to 9 5% , pr efer a bly fr om 40 to 9 0% , of the

W a ter pr es ent in the s tr ea m is r emoved in the liq uid s tr ea m a nd

the a cr olein- r ich pha s e g ener a lly compr is es mor e tha n 80%

a nd pr efer a bly mor e tha n 9 0% of the a cr olein initia lly pr es ent

in the s tr ea m This r es ult is g ener a lly obta ined by loW er ing the

temper a tur e to a temper a tur e of 6 0 to 1200 C.

[ 0126 ] In one embodiment, the s tep of pa r tia l condens a tion

of W a ter a nd of the hea vy by - pr oducts der ived fr om the dehy

dr a tion s tep a ) is ca r r ied out befor e oper a ting the s tep b) of

s elective elimina tion of pr opa na l. In this embodiment, it is

pr efer r ed tha t the ca ta ly s t for pr opa na l elimina tion a nd the

ca ta ly s t for the oxida tion of a cr olein into a cr y lic a cid a r e

ins ta lled in the s a me r ea ctor . Gener a lly tW o s epa r a te r ea ction

Z ones W ith tW o s epa r a te cooling s y s tems a r e us ed for the 2

ca ta ly s ts . It is a ls o pos s ible tha t ca ta ly s ts a r e oper a ted in 2

s epa r a te r ea ctor s .

[ 0127] In a n a lter na tive for m, the s tep of pa r tia l condens a

tion of W a ter a nd of the hea vy by - pr oducts der ived fr om the

dehy dr a tion s tep a ) is ca r r ied out a fter oper a ting the s tep b) of

s elective elimina tion of pr opa na l. In this embodiment, pr opi

onic a cid der ived fr om the dehy dr a tion r ea ction a nd the pr o

pa na l elimina tion r ea ction ma y be ea s ily r emoved by the

pa r tia l condens a tion of W a ter fr om the a cr olein- r ich s tr ea m

befor e the oxida tion s ta g e. As mos t pa r t of a cr y lic a cid is a ls o

r emoved by the pa r tia l condens a tion of W a ter , r ea ction con

ditions a r e chos en to limit a s fa r a s pos s ible the conver s ion of

a cr olein in the pr opa na l elimina tion s tep.

[ 0128] Accor ding to the pr oces s of the invention, it is pos

s ible to obta in a cr y lic a cid ha ving a content of pr opionic a cid

loW er tha n 500 ppm.

Dec. 5, 2013

[ 0129 ] N oW , the pr es ent invention W ill be expla ined in

much deta il W ith r efer r ing s ever a l exa mples , but this inven

tion s hould not be limited to thos e des cr ibed in folloW ing

exa mples . In the folloW ing Exa mples a nd Compa r a tive

Exa mples , % mea ns mole % .

EXAMPLES

Pr epa r a tion of Ca ta ly s t

Exa mple 1

Cs PMo

[ 0130] 100 g of phos phomoly bdic a cid W a s dis s olved in

200 mL of deioniZ ed W a ter to obta in a n a q ueous s olution of

pho s phomoly bdic a cid, a nd then W a s mixed a t r oom temper a

tur e for 2 hour s .

32. 7 g of 48. 5 W t % Cs OH a q ueous s olution W a s diluted W ith

20 mL of deioniZ ed W a ter . The r es ulting Cs OH a q ueous s olu

tion W a s dr opped in the a bove a q ueous s olution of phos pho

moly bdic a cid, a nd then W a s mixed a t r oom temper a tur e for 2

hour s .

The r es ulting y elloW s lur r y W a s eva por a ted a t 6 00 C. by us e of

r ota r y - eva por a tor .

The obta ined poW der W a s dr ied a t 1200 C. for 10 hour s .

The compos ition of the r es ulta nt dr ied s lur r y is :

CS2. 5P1. 0MO 12

Subs eq uently , the r es ulta nt pr oduct W a s ca lcined in a ir a t 250

C. for 3 hour s .

Exa mple 2

Cs PW Mo

[ 0131] 50 g of phos photung s tomoly bdic a cid W a s dis s olved

in 20 mL of deioniZ ed W a ter to obta in a n a q ueous s olution of

phos photung s tomoly bdic a cid, a nd then W a s mixed a t r oom

temper a tur e for 2 hour s .

13. 4 g of 48. 5 W t % Cs OH a q ueous s olution W a s diluted W ith

50 mL of deioniZ ed W a ter . The r es ulting Cs OH a q ueous s olu

tion W a s dr opped in the a bove a q ueous s olution of phos pho

tung s tomoly bdic a cid, a nd then W a s mixed a t r oom temper a

tur e for 2 hour s .

The r es ulting y elloW s lur r y W a s eva por a ted a t 6 00 C. by us e of

r ota r y - eva por a tor . The obta ined poW der W a s dr ied a t 1200 C.

for 10 hour s .

The compos ition of the r es ulta nt dr ied s lur r y is :

CS2. 5P1. OW 6 MO6

Subs eq uently , the r es ulta nt pr oduct W a s ca lcined in a ir a t 250

C. for 3 hour s .

Exa mple 3

MoV PCuAs

[ 0132] 100 g of moly bdenum tr ioxide, 6 . 3 g of va na dium

pentoxide, 1. 1 g of copper oxide a nd 8. 0 g of 85 W t % or tho

phos phor ic a cid a nd 1. 8 g of 6 0 W t % a r s enic a cid W er e

dis per s ed in 1000 mL of deioniZ ed W a ter . The mixtur e W a s

r e? uxed for 6 hour s W hile a dding hy dr og en per oxide to y ield

a r eddis h- br oW n, tr a ns pa r ent s olution. After a little ins oluble

US 2013/0324758 A1

compound W a s r emoved fr om the obta ined s olution, the s olu

tion thus for med W a s eva por a ted to dr y nes s on a W a ter ba th.

The compos ition of the dr ied pr oduct is :

Subs eq uently , the r es ulta nt pr oduct W a s ca lcined under a ? oW

of a ir a t 310 C. for 5 hour s .

Exa mple 4

MoV PCuAs Sb

[ 0133] 300 g of moly bdenum tr ioxide, 11. 37 g of va na dium

pentoxide, 3. 31 g of copper oxide, 8. 32 g of copper a ceta te,

28. 82 g of85 W t % or thophos phor ic a cid a nd 24. 6 4 g of 6 0 W t

% a r s enic a cid W er e dis per s ed in 19 00 mL of deioniZ ed W a ter

a nd hea ted a t r e? ux a t 9 5 to 100 C. for s ix hour s to y ield a

r eddis h- br oW n, tr a ns pa r ent s olution. Subs eq uently , to the

s olution W a s a dded 1. 52 g of a ntimony tr ioxide a nd the r es ult

a nt s olution W a s fur ther hea ted a t r e? ux a t 9 5 to 100 C. for

thr ee hour s .

Then, the r es ulta nt s lur r y W a s hea ted in a W a ter ba th to be

eva por a ted a nd dr ied.

The compos ition of the dr ied pr oduct is :

Subs eq uently , the r es ulta nt pr oduct W a s ca lcined under a ? oW

of a ir a t 310 C. for 5 hour s .

Exa mple 5

MoV PCuSbCs

[ 0134] To 1200 mL of pur i? ed W a ter W er e a dded 200 g of

moly bdenum tr ioxide, 8. 84 g of va na dium penta oxide a nd

17. 6 1 g of 85 W t % or thophos phor ic a cid, a nd the s olution W a s

hea ted a t r e? ux a t 9 0 to 100 C. for ? ve hour s to y ield a

r eddis h- br oW n, tr a ns pa r ent s olution.

Subs eq uently , to the s olution W a s a dded 6 . 07 g of a ntimony

tr ioxide a nd the r es ulta nt s olution W a s fur ther hea ted a t r e? ux

a t 9 0 to 100 C. for tW o hour s to obta in a n a ntimony tr ioxide

dis s olved, hig hly da r k blue s olution.

Then, the r es ulting s olution W a s cooled to fr om 15 to 20 C.

To the s olution W er e g r a dua lly a dded a s olution of 13. 33 g of

ces ium a ceta te dis s olved in 150 mL of pur i? ed W a ter a nd a

s olution of 16 . 06 g of a mmonium a ceta te dis s olved in 150 mL

of pur i? ed W a ter a t the s a me time W ith a g ita tion. Then, to the

s lur r y W a s fur ther a dded a s olution pr epa r ed by dis s olving

11. 09 g of cupr ic a ceta te monohy dr a te in 170 mL of pur i? ed

W a ter a nd the r es ulta nt s olution W a s a g ed a t 15 to 20 C. for

one hour to y ield a g r eenblue s lur r y . Then, the r es ulta nt s lur r y

W a s hea ted in a W a ter ba th to be eva por a ted a nd dr ied. The

compos ition of the r es ulta nt dr ied s lur r y is :

M9 10V 0. 7P1. 1Cu0. 4Sb0. 3CSo. 5( N H4) 1. 5

Subs eq uently , the r es ulta nt pr oduct W a s ca lcined under a ? oW

of a ir a t 310 C. for 5 hour s .

Eva lua tion a nd Res ults

Exa mple 6

Selective Elimina tion of Pr opa na l in a n Acr olein

FloW

[ 0135] A s a mple of Cs PMo ca ta ly s t fr om exa mple 1 W a s

compa cted a nd cr us hed a nd s ieved to obta in pa r ticle s iZ e of

Dec. 5, 2013

35 to 48 mes h. A s ta inles s s teel tube ( inter na l dia meter 13

mm) W a s loa ded W ith 2. 0 ml of ca ta ly s t to for m a ? xed

ca ta ly tic bed.

An a q ueous s olution of a cr olein a nd pr opa na l W a s fed to a n

eva por a tor tog ether W ith nitr og en a nd W ith oxy g en a t 270 C.

in or der to for m a feed g a s W hich W a s pa s s ed thr oug h the ? xed

ca ta ly tic bed a t a tmos pher ic pr es s ur e. The ? xed ca ta ly tic bed

W a s hea ted W ith a n electr ic oven a t a temper a tur e of 270 C.

Feed g a s ha d a folloW ing compos ition in mol % : a cr olein:

pr opa na l: oxy g en: nitr og en: W a ter : 6 . 0: 0. 06 0: 3. 8: 14: 76 . Tota l

feed g a s ? oW W a s 31 nor ma l liter per hour . Ga s Hour ly Spa ce

V elocity ( GHSV ) W a s 15, 000 h_ l. GHSV is the r a tio of the

? oW of feed g a s ( expr es s ed in nor ma l liter per hour ) by the

volume of ca ta ly s t ( expr es s ed in liter ) . Fixed bed W a s oper

a ted for 5 hour s W ithout pr es s ur e incr ea s e in the r ea ctor .

In or der to cha r a cter ize the compos ition of the g a s ? oW out the

r ea ctor , pr oducts W er e condens ed in a condens er cha r g ed W ith

deminer a liZ ed W a ter . Liq uid a q ueous pha s e a nd g a s eous

vents W er e q ua ntita tively a na ly Z ed by g a s chr oma tog r a phs

( HP 6 89 0 Ag ilent, FFAP column, FID detector , CP49 00

V a r ia n, Silica plot a nd Molecula r Sieve 5 A, TCD detector s ) .

Pr opor tions of pr oducts W er e cor r ected in fa ctor s fr om the

r es ults of the g a s chr oma tog r a ph to deter mine a bs olute

a mounts of pr oducts .

The conver s ion ( % ) of ma ter ia l ( a cr olein or pr opa na l) , a nd the

y ield of obj ective s ubs ta nce ( % ) a nd the r ela tive r a te of con

ver s ion a r e deter mined by folloW ing eq ua tions :

The conver s ion( % ) ofma ter ia l: ( mole number of ma te

r ia l r ea cted/mole number of ma ter ia l s upplied) ><

100

The y ield( % ) of a cr y lic a cid: ( mole number of a cr y lic

a cid obta ined/mole number of a cr olein s up

plied) >< 100

The y ield( % ) ofpr opionic a cid: ( mole number ofpr o

pionic a cid obta ined/mole number ofpr opa na l

s upplied) >< 100

The r ela tive r a te of pr opa na l elimina tion: conver s ion

ofpr opa na l/conver s ion of a cr olein

Res ults a r e s hoW n in ta ble 1.

Exa mple 7

[ 0136 ] The s a me exper iment a s in exa mple 6 W a s r epr o

duced, W ith a g a s hour ly s pa ce velocity of 14, 000 h' 1 a nd

va por iZ er a nd oven temper a tur es of 300 C. Fixed bed W a s

oper a ted for 5 hour s W ithout pr es s ur e incr ea s e in the r ea ctor .

Res ults a r e s hoW n in ta ble 1.

Exa mple 8

[ 0137] The s a me exper iment a s in exa mple 6 W a s r epr o

duced, W ith a g a s hour ly s pa ce velocity of 4, 400 h- 1 a nd

va por iZ er a nd oven temper a tur es of 270 C. Fixed bed W a s

oper a ted for 5 hour s W ithout pr es s ur e incr ea s e in the r ea ctor .

Res ults a r e s hoW n in ta ble 1.

Exa mple 9

[ 0138] The s a me exper iment a s in exa mple 6 W a s r epr o

duced, W ith a g a s hour ly s pa ce velocity of 4, 400 h' 1 a nd

US 2013/0324758 A1

va por iZ er a nd oven temper a tur es of 300 C. Fixed bed W a s

oper a ted for 5 hour s W ithout pr es s ur e incr ea s e in the r ea ctor .

Res ults a r e s hoW n in ta ble 1.

Exa mple 10

[ 0139 ] The s a me exper iment a s in exa mple 6 W a s r epr o

duced, W ith Cs PW Mo ca ta ly s t of exa mple 2 a nd W ith a g a s

hour ly s pa ce velocity of 5, 500 h- 1 a nd va por is er a nd oven

temper a tur es of 250 C. Fixed bed W a s oper a ted for 5 hour s

W ithout pr es s ur e incr ea s e in the r ea ctor .

Res ults a r e s hoW n in ta ble 1.

Exa mple 11

[ 0140] The s a me exper iment a s in exa mple 6 W a s r epr o

duced, W ith MoV PCuAs ca ta ly s t of exa mple 3 a nd W ith a g a s

hour ly s pa ce velocity of 5, 000 h- 1 a nd va por is er a nd oven

temper a tur es of 350 C. Fixed bed W a s oper a ted for 5 hour s

W ithout pr es s ur e incr ea s e in the r ea ctor .

Res ults a r e s hoW n in ta ble 1.

Dec. 5, 2013

TABLE 2

Exa mple 12 13 14

Ca ta ly s t MoV PCuAs MoV PCuAs Sb MoV PCuSbCs

GHSV h' l 4, 700 4, 400 5, 500

V a por is er a nd oven 385 345 250

temper a tur e ( C. )

Pr opa na l conver s ion ( % ) 9 7 14 9 8

Pr opionic a cid y ield ( % ) 14 14 13

Acr olein conver s ion ( % ) 23 < 5 29

Acr y lic a cid y ield ( % ) 20 1 15

Rela tive r a te ofpr opa na l 4. 2 >3 3. 4

elimina tion

Exa mple 15

[ 0144] The s a me exper iment a s in exa mple 6 W a s r epr o

duced, W ith FeMo ca ta ly s t fr om MAPCO, r efer ence MFM3

MS, a nd W ith a g a s hour ly s pa ce velocity of 10, 000 h- 1 a nd

TABLE 1

Exa mple 6 7 8 9 10 11

Ca ta ly s t Cs PMo Cs PMo Cs PMo Cs PMo Cs PW Mo MoV PCuAs

GHSV 1151 15, 000 14, 000 4, 400 4, 400 5, 500 5, 000

V a por is er a nd oven 270 300 270 300 250 350

temper a tur e ( C. )

Pr opa na l conver s ion ( % ) 9 0 82 9 9 100 9 2 6 5

Pr opionic a cid y ield ( % ) 10 12 11 9 13 15

Acr olein conver s ion ( % ) 11 25 28 6 5 53 < 5

Acr y lic a cid y ield ( % ) 7 22 13 6 4 36 5

Pr opa na l elimina tion ( r ela tive r a te) 7. 9 3. 2 3. 5 1. 5 1. 7 >13

Exa mple 12 va por is er a nd oven temper a tur es of 305 C. Fixed bed W a s

oper a ted for 5 hour s W ithout pr es s ur e incr ea s e in the r ea ctor .

[ 0141] The s a me exper iment a s in exa mple 6 W a s r epr o- Res ults a r e s hown in ta ble 3,

duced, W ith MoV PCuAs ca ta ly s t of exa mple 3 a nd W ith a g a s

hour ly s pa ce velocity of 4, 700 h' 1 a nd va por is er a nd oven

temper a tur es of 385 C. Fixed bed W a s oper a ted for 5 hour s

W ithout pr es s ur e incr ea s e in the r ea ctor .

Res ults a r e s hoW n in ta ble 2.

Exa mple 13

[ 0142] The s a me exper iment a s in exa mple 6 W a s r epr o

duced, W ith MoV PCuAs Sb ca ta ly s t of exa mple 4 a nd W ith a

g a s hour ly s pa ce velocity of 4, 400 h' 1 a nd va por is er a nd oven

temper a tur es of 345 C. Fixed bed W a s oper a ted for 5 hour s

W ithout pr es s ur e incr ea s e in the r ea ctor .

Res ults a r e s hoW n in ta ble 2.

Exa mple 14

[ 0143] The s a me exper iment a s in exa mple 6 W a s r epr o

duced, W ith MoV PCuSbCs of exa mple 5 a nd W ith a g a s

hour ly s pa ce velocity of 5, 500 h' 1 a nd va por is er a nd oven

temper a tur es of 250 C. Fixed bed W a s oper a ted for 5 hour s

W ithout pr es s ur e incr ea s e in the r ea ctor . Res ults a r e s hoW n in

ta ble 2.

Exa mple 16

[ 0145] The s a me exper iment a s in exa mple 15 W a s r epr o

duced, W ith a g a s hour ly s pa ce velocity of 20, 000 h' 1 a nd

va por is er a nd oven temper a tur es of 330 C. Fixed bed W a s

oper a ted for 5 hour s W ithout pr es s ur e incr ea s e in the r ea ctor .

Res ults a r e s hoW n in ta ble 3.

Exa mple 17

[ 0146 ] The s a me exper iment a s in exa mple 16 W a s r epr o

duced, W ith a feed g a s compos ition in mol % : a cr olein: pr o

pa na l: oxy g en: nitr og en: W a ter : 6 . 2: 0. 06 2: 6 . 7: 6 9 : 18. In this

exper iment a much loW er concentr a tion of W a ter W a s us ed

compa r ed to exa mple 16 . Fixed bed W a s oper a ted for 5 hour s

W ithout pr es s ur e incr ea s e in the r ea ctor .

Res ults a r e s hoW n in ta ble 3.

Exa mple 18

[ 0147] The s a me exper iment a s in exa mple 6 W a s r epr o

duced, W ith pr opy lene oxida tion ca ta ly s t ba s ed on BiMoFe

tha t W a s pr epa r ed a ccor ding to exa mple 1 of Eur opea n Pa tent

EP 807 46 5 B1. Ga s hour ly s pa ce velocity W a s 5, 800 h- 1 a nd

va por is er a nd oven temper a tur es W er e s et to 325 C. Fixed

US 2013/0324758 A1

bed W a s oper a ted for 5 hour s W ithout pr es s ur e incr ea s e in the

r ea ctor .

Res ults a r e s hown in ta ble 3.

Exa mple 19

Compa r a tive

[ 0148] The s a me exper iment a s in exa mple 6 W a s r epr o

duced W ith TiO2 ca ta ly s t ( ST31119 fr om N or pr o s a int

Goba in) . Fixed bed W a s oper a ted for 5 hour s W ithout pr es s ur e

incr ea s e in the r ea ctor .

The s a me exper iment W a s a ls o r epr oduced W ith a g a s hour ly

s pa ce velocity of 3, 700 h' 1 a nd va por is er a nd oven temper a

tur es of 300 C. Fixed bed W a s oper a ted for 5 hour s W ithout

pr es s ur e incr ea s e in the r ea ctor .

Res ults a r e s hoW n in ta ble 3.

W e obs er ved tha t pr opa na l is not s electively elimina ted a s

a cr olein is mor e conver ted tha n pr opa na l.

TABLE 3

Fxa mnle

19

15 16 17 18 ( Compa r a tive)

Ca ta ly s t FeMo BiMoFe TiO2

GHSV h l 10, 000 20, 000 20, 000 5, 800 15, 000, 700

V a por is er a nd oven 305 330 330 325 270 300

temper a tur e ( C. )

Pr opa na l conver s ion 9 8 9 9 9 9 9 6 < 5 16

( % )

Pr opionic a cid y ield 3 6 6 8 0 8

( % )

Acr olein conver s ion 9 < 6 11 < 5 < 5 30

( % )

Acr y lic a cid y ield 0. 5 2 2 3 0 1

( % )

Rela tive r a te of 11 >15 9 >19 0 6

pr opa na l elimina tion

Exa mple 20

Compa r a tive

[ 0149 ] The s a me exper iment a s in exa mple 6 W a s r epr o

duced W ith FePSr ca ta ly s t pr epa r ed a ccor ding to exa mple 3 of

W O2009 /44081, W ith a g a s hour ly s pa ce velocity of 4, 000

h' 1 a nd va por is er a nd oven temper a tur es of 280 C.

Fixed bed W a s oper a ted for 2 hour s , a nd the exper iment ha d to

be s topped beca us e of s ever e pr es s ur e incr ea s e in the ca ta ly tic

bed, due to ta r like pr oducts for ma tion.

Exa mple 21

Acr olein Pr oduction fr om Gly cer ol

[ 0150] A PW /Ti dehy dr a tion ca ta ly s t W a s pr epa r ed a s fol

loW s : 89 mg of 85% phos phor ic a cid ( Aldr ich) a nd 2. 33 g of

a mmonium meta tung s ta te ( Fluka ) W er e dis s olved in 7. 5 g of

deioniZ ed W a ter to obta in a n a q ueous s olution of tung s to

phos phor ic a cid. 7. 6 g of the r es ulting a q ueous s olution W a s

then s pr a y ed onto 1 5. 4 g of TiO2 poW der obta ined by g r inding

a na ta s e ty pe TiO2 pellets ( ST31119 fr om N or pr o Sa int

Goba in) to 35 to 48 mes h. The r es ulting poW der W a s dr ied a t

1 10 C. for 2 hour s a nd then W a s ? r ed in nitr og en a tmos pher e

a t 5000 C. for 3 hour s to obta in a tita nia ca r r ier s uppor ting

Dec. 5, 2013

10% of tung s tophos phor ic a cid. This tita nia ca r r ier W a s

s ieved to obta in a pa r ticle s iZ e of 35 to 48 mes h.

A s ta inles s s teel tube ( inter na l dia meter 13 mm) W a s loa ded

s ucces s ively W ith 2. 4 ml of Cs PMo ca ta ly s t fr om exa mple 1

a nd W ith 9 . 6 ml of PW /Ti ca ta ly s t to for m a ? xed ca ta ly tic

bed.

An a q ueous s olution of g ly cer in ( a t a concentr a tion of 50% by

W eig ht) W a s fed to a n eva por a tor a t a How r a te of 12. 4 g /hr

tog ether W ith nitr og en ( 14. 4 N L/hr ) a nd W ith oxy g en ( 0. 9 5

N L/hr ) a t 280 C. s o tha t g ly cer in W a s g a s i? ed a nd the r es ult

ing g a s i? ed g ly cer in W a s pa s s ed thr oug h the ? xed ca ta ly tic

bed, ? r s t thr oug h the PW / Ti ca ta ly s t bed then thr oug h Cs PMo

ca ta ly s t bed. The ? xed ca ta ly tic bed W a s hea ted W ith a n

electr ic oven a t a temper a tur e of 280 C. Feed g a s ha d a

folloW ing compos ition in mol % : g ly cer ol: oxy g enznitr og en:

W a ter : 6 . 2: 3. 5: 58. 5: 31. 5. Ga s Hour ly Spa ce V elocity

( GHSV ) of the ? r s t ca ta ly s t W a s 2, 500 h- 1 a nd tha t of the

s econd ca ta ly s t W a s 10, 000 h_ l. GHSV is the r a tio of the How

of feed g a s ( expr es s ed in nor ma l liter per hour ) by the volume