Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Gamma Insulators

Cargado por

Arturo MoreiraDescripción original:

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Gamma Insulators

Cargado por

Arturo MoreiraCopyright:

Formatos disponibles

Products

Catalog

GAMMA INSULATORS CORPORATION is the Electrical Grade Porcelain and Composite

Insulator division of the multinational Corona Group, a 125 year old company with over

10,000 employees, and sales in excess of $1.5 Billion worldwide. Corona is one of the

largest and most stable platforms for insulator manufacturing in the world.

Coronas state of the art manufacturing facilities utilize the latest technologies and, are

all certified to the most recent ISO 9001, 14001 and OHSAS 18001 standards. We employ

world class manufacturing tools and management systems such as TPM, Lean

Manufacturing, DFSS and Six Sigma, among others to produce the best products with

the least impact on the environment.

LAPP INSULATORS by GAMMA

Lapp Insulators Company is known worldwide for superior performing products,

exacting standards, and an unmatched obsession with quality. So when Lapp chose

GAMMA to manufacture a product that would bear the Lapp name brand, they chose a

company that has experience selling to utilities, OEMs, and distributors in more than 20

countries worldwide, and could meet their high expectations.

GAMMA has been manufacturing insulators for Lapp's US and Canadian markets for

nearly 10 years.

GAMMA is one of the greenest insulator manufacturers in the world. We are a vertically

integrated company and control the process from the extraction of raw materials, to the

manufacture of the insulator. Few companies can make this claim, but our engineers

have made this possible.

We look forward to being your first choice for high performance electrical grade

insulators.

Sincerely,

Mauricio Yepes

CEO

Why GAMMA...

Experience

Time tested and customer approved, Gamma Insulator Company has been supplying insulators

for critical transmission and distribution line applications since 1962. That experience goes into

every insulator we manufacture making Gamma products an internationally recognized

insulator solution.

Quality, Service, and Support

We take pride in our people and our product. We believe that product quality is as dependent on

our people as much as it is in the process. While Gamma employs state of the art equipment and

utilizes the latest continual process techniques, we also invest in our people. The result is a

highly qualified and well trained work force that takes pride in their work, and is proud of the

result.

Location and Logistics

Gamma's manufacturing facility is ideally located to allow for the most responsive order

fulfillment in the industry. With an increasing global supply base, delivery of high quality

insulators can take weeks or even months. That time is shortened for insulators manufactured

by Gamma.

Located in Colombia South America, and nearly on the equator, Gamma's manufacturing facility

provides equal access to both Atlantic and Pacific Ocean ports. Minimal inland transportation

and the ability to ship our product east as easily as to go west, Gamma can react faster to more

customers, than any other insulator manufacturer in the world.

At GAMMA, we understand that the product sale is only the beginning of a relationship based on

total customer satisfaction.

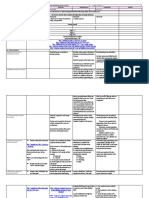

Dead Ends

Note 2: The insulators can be requested with extra hot-dip galvanized layer in caps and bolts for

contaminated areas

Note 1: ANSI 70 gray is standard. Brown available by request

RADIO INFLUENCE VOLTAGE DATA

Critical impulse flashover, negative

Maximum RIV at 1000 kHz, V

Low-frequency test voltage, RMS to ground

Low-frequency puncture voltage

MECHANICAL VALUES

Leakage distance

Low-frequency wet flashover

Low-frequency dry flashover

Mech, impact strength,inch.pounds

Combined M & E strength, pounds

Routine proof test load, pounds

Time load test value, pounds

Critical impulse flashover, positive

ELECTRICAL VALUES, kV

Dry arcing distance

CRTICAL DISTANCES, inches

ANSI CLASS (C29.2- 1992)

CATALOG REFERENCE NUMBER

Insulators

Dead Ends

Maximun working load, pounds

50

7.5

80

90

30

60

100

7

4

52-9A

6815-70

52-1

6605-70

100

7.5

50

80

100

30

60

6000 6000

5000 5000

10000 10000

45 45

5000 5000

6605-70

1

1

/

1

6

1

1

/

1

6

11/16

11/16

5

/

8

5

/

8

5 1/2"

1/2"

7/8"

6 1/2"

6815-70

4 3/4"

7/8"

6 1/4"

4.5

7

1/2"

Polymer

Dead Ends

Clevis - Tongue

Polymer Dead Ends

Test voltage, kV

Maximum RIV 1000 kHz, V

Length C, inches

Number of sheds, A

DIMENSIONS ACCORDING TO DRAWING

Total height H, inches

Low-frequency wet flashover

Critical impulse flashover positive

ELECTRICAL VALUES, kV

Typical application voltage

RADIO INFLUENCE DATA

MECHANICAL VALUES

Specified mechanical load (SML) pounds

Routine test load (RTL) pounds

Torsional load, lbf.ft

Dry arcing distance

CRITICAL DISTANCES, inches

Leakage distance

ANSI CLASS (C29.13 - 2000)

CATALOG NUMBER

Low-frequency dry flashover

15 20

< 10

30

13 16 9/10 20 7/10

4 6 9

14 3/4 18 5/8 22 3/8

145

85

15

215

120

25

265

150

35

15736 15736

7868 7868 7868

15736

35 35 35

7 1/2

16 2/16

11 3/8

24 13/16

15 3/8

36

DS-15 DS-28 DS-35

PS015 PS025 PS035

< 10 < 10

95 130 160

1 1/16"

H

A

C

3 1/2"

Note 1: Polymer housing: silicone high voltage

Note 2: End fitting: nodular iron galvanized

Clevis - Tongue

Polymer Dead Ends

Test voltage, kV

Maximum RIV 1000 kHz, V

Length C, inches

Number of sheds, A

DIMENSIONS ACCORDING TO DRAWING

Total height H, inches

Low-frequency wet flashover

Critical impulse flashover positive

ELECTRICAL VALUES, kV

Typical application voltage

RADIO INFLUENCE DATA

MECHANICAL VALUES

Specified mechanical load (SML) pounds

Routine test load (RTL) pounds

Torsional load, lbf.ft

Dry arcing distance

CRITICAL DISTANCES, inches

Leakage distance

ANSI CLASS (C29.13 - 2000)

CATALOG NUMBER

Low-frequency dry flashover

30 45

24 29

10 13

25 11/16 30 3/4

290

165

46

360

204

69

15736

7868 7868

15736

35 35

18 9/16

42 15/16

24

56 1/8

DS-46 DS-69

PS045 PS069

< 10 < 10

205 251

Note 1: Polymer housing: silicone high voltage

Note 2: End fitting: nodular iron galvanized

1 1/16"

H

A

C

Ball and Socket

Polymer Dead Ends

Test voltage, kV

Maximum RIV 1000 kHz, V

Low-frequency wet flashover

Critical impulse flashover positive

ELECTRICAL VALUES, kV

Typical application voltage

RADIO INFLUENCE DATA

MECHANICAL VALUES

Specified mechanical load (SML) pounds

Routine test load (RTL) pounds

Torsional load, lbf.ft

Dry arcing distance

CRITICAL DISTANCES, inches

Leakage distance

ANSI CLASS (C29.13 - 2000)

CATALOG NUMBER

Low-frequency dry flashover

15

< 10

145

85

15

15736

7868

35

7 1/2

16 2/16

DS-15

PS015B

95

A

91.0

Note 1: Polymer housing: silicone high voltage

Note 2: End fitting: nodular iron galvanized

Ball and socket

Polymer Suspensions

30

265

150

35

7868

15736

35

15 3/8

36

DS-35

PS035B

< 10

160

3 6/10"

21 1/10"

20 6/10"

Test voltage, kV

Maximum RIV 1000 kHz, V

Low-frequency wet flashover

Critical impulse flashover positive

ELECTRICAL VALUES, kV

Typical application voltage

RADIO INFLUENCE DATA

MECHANICAL VALUES

Specified mechanical load (SML) pounds

Routine test load (RTL) pounds

Torsional load, lbf.ft

Dry arcing distance

CRITICAL DISTANCES, inches

Leakage distance

ANSI CLASS (C29.13 - 2000)

CATALOG NUMBER

Low-frequency dry flashover

Note 1: Polymer housing: silicone high voltage

Note 2: End fitting: nodular iron galvanized

Ball and socket

30

265

150

35

8992

17984

35

15 3/8

36

DS-35

PS035B80

< 10

160

3 6/10"

21 1/10"

20 6/10"

Test voltage, kV

Maximum RIV 1000 kHz, V

Low-frequency wet flashover

Critical impulse flashover positive

ELECTRICAL VALUES, kV

Typical application voltage

RADIO INFLUENCE DATA

MECHANICAL VALUES

Specified mechanical load (SML) pounds

Routine test load (RTL) pounds

Torsional load, lbf.ft

Dry arcing distance

CRITICAL DISTANCES, inches

Leakage distance

ANSI CLASS (C29.13 - 2000)

CATALOG NUMBER

Low-frequency dry flashover

Note 1: Polymer housing: silicone high voltage

Note 2: End fitting: nodular iron galvanized

Polymer Suspensions

13 1/2"

11 13/16"

3 1/2"

Tongue - Tongue

Length C, inches 1113/16

Number of sheds 3

DIMENSIONS ACCORDING TO DRAWING

Total height H, inches 13 1/2

Low-frequency wet flashover

ELECTRICAL VALUES, kV

Typical application voltage

54

3 (Direct Current)

MECHANICAL VLAUES

Specified mechanical load (SML), pounds

Routine test load (RTL), pounds) 7868

15736

Torsional load, lbf.ft 35

Dry arcing distnace

CRITICAL DISTANCES, inches

Leakage distnace

7

12

PS003 CATALOG NUMBER

Low-frequency dry flashover 74

Application in metropolitan transportation

systems with direct current

Note 1: Polymer housing: silicone high voltage

Note 2: End fitting: nodular iron galvanized

Polymer Suspensions

Suspensions

GAMMA Porcelain Suspension Insulators

Transmission lines are often referred to as the backbone of the electrical system, and need rock

solid components to ensure long lasting reliability. Gamma's porcelain suspension insulators,

for use on high voltage and extra high voltage transmission lines, provide utilities with the

flexibility and reliability required for such critical applications.

Designed to meet and exceed both ANSI and IEC specifications, Gamma's porcelain suspension

insulators conform to the most current industry standards* for the greatest degree of flexibility

and consistency. However, that's where being Standard ends.

GAMMA MANUFACTURES ITS OWN PRODUCTS!! Gamma does not use subcontractors to

manufacture and brand label its product. Instead we use state of the art equipment and

processes to produce high quality porcelain suspension insulators, consistently, every time.

In addition, Gamma has the unique ability to control nearly every step of the process. In

conjunction with its parent company, The Corona Group** we extract, transport, and process

much of the raw material used in our insulators. We employ the engineering and technical

expertise required to support our products, and own the equipment necessary to ensure our

porcelain suspension insulators meets our high standards for quality and conformance.

Gamma's start to finish process ownership, state of the art manufacturing, and world class

technical capabilities produces porcelain suspension that utilities can rely on with confidence.

There is no mystery or guesses about where your Gamma Suspension Insulators come from,

they come from GAMMA!

*Standards

Gamma Suspension Insulators conform to

ANSI (C29.1 and C29.2)

**Gamma Insulators Corporation.

is the electrical grade insulator division of THE CORONA GROUP, a 125 year old multinational

corporation with sales in excess of $1.5 billion annually. Corona's state of the art manufacturing

facilities utilize the latest manufacturing technologies, and are all certified to the most recent

ISO 9001, 14001, and OHSAS 18001 standards. We employ world class manufacturing tools and

management systems such as TPM, Lean Manufacturing, DFSS, and Six Sigma, to name a few, in

order to produce the high quality products you've come to expect from Corona Companies.

Ball and Socket Type

Suspension Insulators

Note 4: Part numbers 8256 and 8257 comform to ANSI Class 52-3 specifications. However they carry higher strength

rating than that required by standard

50

10

125

110

130

50

80

7500

7500

10000

55

15000

50

10

50

10

50

10

125

110

130

50

80

125

110

130

80

50

9000

9000

12000

18000

10000

10000

13500

90

20000

125

110

130

80

50

12500

12500

15000

90

25000

ANSI CLASS (C29.2 - 1992) 52-3

11 13/16

7 3/4

8255

52-3 52-3

8256 8257

52-5

8258

5 3/4"

10 3/4"

RADIO INFLUENCE VOLTAGE DATA

Critical impulse flashover, negative

Maximum RIV at 1000 kHz, V

Low-frequency test voltage, RMS to ground

Low-frequency puncture voltage

MECHANICAL VALUES

Leakage distance

Low-frequency wet flashover

Low-frequency dry flashover

Mech, impact strength,inch.pounds

Combined M & E strength, pounds

Routine proof test load, pounds

Time load test value, pounds

Critical impulse flashover, positive

ELECTRICAL VALUES, kV

Dry arcing distance

CRITICAL DISTANCES, inches

CATALOG REFERENCE NUMBER

Maximum working load, pounds

Note 3: The insulators can be requested with zinc sleeve ball bolt for contaminated areas

Note 2: The insulators can be requested with extra hot-dip galvanized layer in caps and bolts for contaminated areas

Note 1: ANSI 70 gray is standard. Brown available by request

11 13/16

7 3/4

11 13/16

7 3/4

11 13/16

7 3/4

55

Clevis Type

Suspension Insulators

Note 3: Part numbers 8265 and 8267, can be requested with zinc sleeve ball bolt for contaminated areas

Note 1: ANSI 70 gray is standard. Brown available by request

Note 2: The insulators can be requested with extra hot-dip galvanized layer in caps and bolts for contaminated areas

110

50

10

50

80

125

130

7500

15000

10000

7500

55

52-4

7 3/4

11 13/16

8265

110

10

50

50

125

130

80

10000

90

13500

10000

20000

7 3/4

11 13/16

52-4

8267

Note 4: Part number 8267 comform to ANSI Class 52-4 specifications. However it carry higher strengh rating than that

required by standard

RADIO INFLUENCE VOLTAGE DATA

Critical impulse flashover, negative

Maximum RIV at 1000 kHz, V

Low-frequency test voltage, RMS to ground

Low-frequency puncture voltage

MECHANICAL VALUES

Leakage distance

Low-frequency wet flashover

Low-frequency dry flashover

Mech, impact strength,inch.pounds

Combined M & E strength, pounds

Routine proof test load, pounds

Time load test value, pounds

Critical impulse flashover, positive

ELECTRICAL VALUES, kV

Dry arcing distance

CRITICAL DISTANCES, inches

ANSI CLASS (C29.2- 1992)

CATALOG REFERENCE NUMBER

Maximum, working load, pounds

5 3/4"

10 3/4"

1/2"

11/16"

11/16"

5/8"

11/16"

FOG Ball and Socket type

Suspension Insulators

Note 3: The insulators can be requested with zinc sleeve ball bolt for contaminated areas

50

10

150

130

160

60

100

9000

12000

90

18000

50

10

50

10

150

130

160

100

60

150

130

160

60

100

10000

13500

20000

90

12500

15000

90

25000

9

17

8250

9

17

9

17

8251 8252

5 3/4"

10 3/4"

9000 10000 12500

Note 2: The insulators can be requested with extra hot-dip galvanized layer in caps and bolts for contaminated areas

Note 1: ANSI 70 gray is standard. Brown available by request

RADIO INFLUENCE VOLTAGE DATA

Critical impulse flashover, negative

Maximum RIV at 1000 kHz, V

Low-frequency test voltage, RMS to ground

Low-frequency puncture voltage

MECHANICAL VALUES

Leakage distance

Low-frequency wet flashover

Low-frequency dry flashover

Mech, impact strength,inch.pounds

Combined M & E strength, pounds

Routine proof test load, pounds

Time load test value, pounds

Critical impulse flashover, positive

ELECTRICAL VALUES, kV

Dry arcing distance

CRITICAL DISTANCES, inches

CATALOG REFERENCE NUMBER

Maximum working load, pounds

130

100

150

160

25000

12500

8262

50

10

50

10

50

10

150

130

160

100

60

9000

12000

90

18000

150

130

160

60

100

60

10000

13500

90

20000

15000

90

9

17

8260 8261

5/8"

10 3/4"

5 3/4"

12500 9000 10000

FOG Clevis type

Suspension Insulators

Note 3: The insulators can be requested with zinc sleeve ball bolt for contaminated areas

Note 2: The insulators can be requested with extra hot-dip galvanized layer in caps and bolts for contaminated areas

Note 1: ANSI 70 gray is standard. Brown available by request

RADIO INFLUENCE VOLTAGE DATA

Critical impulse flashover, negative

Maximum RIV at 1000 kHz, V

Low-frequency test voltage, RMS to ground

Low-frequency puncture voltage

MECHANICAL VALUES

Leakage distance

Low-frequency wet flashover

Low-frequency dry flashover

Mech, impact strength,inch.pounds)

Combined M & E strength, pounds

Routine proof test load, pounds

Time load test value, pounds

Critical impulse flashover, positive

ELECTRICAL VALUES, kV

Dry arcing distance

CRITICAL DISTANCES, inches

CATALOG REFERENCE NUMBER

Maximum working load, pounds

9

17

9

17

1/2"

11/6"

11/6"

Spools

Spool

Insulators

CATALOG REFERENCE NUMBER

ANSI CLASS (C29.3-1986 rev. 2002)

Transverse strength

MECHANICAL VALUES, pounds

ELECTRICAL VALUES, kV

53-1

2000

8

10

8441-70

Low-frequency dry flashover

Low-frequency wet flashover, vertical

Low-frequency wet flashover, horizontal

Note: ANSI 70 gray is standard. Brown or white available by request

20

53-2

12

15

8442-70

25

3000

53-5

18

25

320141-70

35

53-3

12

15

8443-70

25

4000

53-4

12

15

8444-70

25

4500

-

10

12

320333-70

22

3000 6000

8441-70

2 1/4

1 3/4

7/8

11/16

R 7/16

2

1

/

8

8443-70

3

1 3/4

15/16

3

/

4

R 7/16

3

3

/

1

6

11/16

8444-70 320141-70

4

1

/

8

2 7/8

4

15/16

R 7/16

11/16

320333-70

13/4

3

/

4

R 3/8

3

45/64

3

15/16

8442-70

3 1/8

1 3/4

15/16

3

/

4

R 11/16

11/16

3

|

4 1/8

2 7/8

15/16

R 5/8

3

3

/

4

11/16

Guy Strains

CATALOG REFERENCE NUMBER

ANSI CLASS (C29.4-1989 rev. 2002) 54-1

1 5/8

8502-70

Low-frequency dry flashover

Note: ANSI 70 gray is standard. Brown available by request

10000

54-2

8504-70

12000

1 7/8

54-3

8506-70

20000

54-4

25 30 35 40

12 15 18 23

8451-70

20000

2 1/4 3

CRITICAL DISTANCES, inches

Leakage distance

MECHANICAL VALUES, pounds

Tensile strength

ELECTRICAL VALUES, kV

Low-frequency wet flashover

Guy Strain

Insulators

|

8502-70 8504-70

8506-70 8451-70

1 3/4"

2 1/2"

1 3/4"

3 1/2" 2 1/2"

5/8"

2 7/8"

2 1/8"

4 1/4"

2 1/4"

3"

7/8"

2 3/8"

3 3/8"

5 1/2"

3 1/8"

1"

4 1/16"

3 1/2"

2 3/8"

6 3/4"

2 5/8"

1"

4 1/2"

Pins

Low - Medium Voltage Pin

Insulators

Note 2: Conductive Glaze - applied to head, side wire grooves and pin hole of one-piece units

Note 3: Neck Sizes - C & F conform to industry standards

Note 4: Pin Hole Sizes - Standard 1 to 15 kV and ref. 320275R-70, 1 3/8 for the rest of 23 kV & 35 kV units

Low-frequency test voltage, RMS to ground, kV

RADIO INFLUENCE VOLTAGE DATA

Maximum RIV at 1000 kHz, V

Note 1: ANSI 70 gray is standard. Brown or white available by request

CATALOG REFERENCE NUMBER

ANSI CLASS (C29.5-1984 rev. 2002)

CRITICAL DISTANCES, inches

55-2

6188R-70

Dry arcing distance

Leakage distance

Minimum pin height

MECHANICAL VALUES, pounds

Cantilever strength

ELECTRICAL VALUES, kV

Low-frequency puncture voltage

Critical impulse flashover, negative

Typical application voltage

Low-frequency dry flashover

Low-frequency wet flashover

Critical impulse flashover, positive

6184R-70 6184RA-70 6183R-70 7061R-70

4 1/2

7

4

2500

7.2

45

25

70

70

10

100

55-3 55-3 55-4 55-5

3 3/8 4 1/2 5 6 1/4

5 7 9 12

5 5 5 6

2500 2500 3000 3000

85

5

50

11.5 15 13.2 11.5

55

30

90

110

90

55

30

90

110

90

65

35

105

130

95

80

45

130

150

115

10 10 15

50 50 50

6184RA-70

3 3/8

3 3/4

4 3/4

2 1/4

R 1 7/10

R 9/16

7061R-70 6183R-70

6184R-70 6188R-70

|

3 1/2"

2 1/4"

3 1/4" 1 1/2"

3 3/4"

R 5/8"

R 5/8"

3 3/8"

4 3/4"

3 3/4" 1 1/2"

2 1/4"

R 6/10"

R9/16"

4"

4 3/8" 1 3/4"

5 19/32"

2 7/8"

R 9/16"

R 1"

4 7/8" 2"

RF 1"

RF 9/16"

4"

2 7/8"

7"

Low-frequency test voltage, RMS to ground, kV

RADIO INFLUENCE VOLTAGE DATA

Maximum RIV at 1000 kHz, V

Note 1: ANSI 70 gray is standard. Brown available by request

CATALOG REFERENCE NUMBER

ANSI CLASS (C29.5-1984 rev. 2002 / C29.6-1996 rev. 2002)

CRITICAL DISTANCES, inches

Dry arcing distance

Leakage distance

Minimum pin height

MECHANICAL VALUES, pounds

Cantilever strength

ELECTRICAL VALUES, kV

Low-frequency puncture voltage

Critical impulse flashover, negative

Typical application voltage

Low-frequency dry flashover

Low-frequency wet flashover

Critical impulse flashover, positive

320275R-70 8248R-70 10435R-70 8190R-70

8

15

22

200

55-6 56-1 56-2 56-3

7 8 1/4 9 1/2

13 17 21

7 1/2 6 7 8

3000 2500 3000 3000

23 34.5 23 23

100

50

150

170

135

95

60

150

190

130

110

70

175

225

145

125

80

200

265

165

15 22 30

100 100 100

Note 2: Conductive Glaze - applied to head, side wire grooves and pin hole of one-piece units

Note 3: Neck Sizes - C & F conform to industry standards

Note 4: Pin Hole Sizes - Standard 1 to 15 kV and ref. 320275R-70, 1 3/8 for the rest of 23 kV & 35 kV units

320275R-70 8248R-70

4 5/8

R 3/4 R 3/4

R 9/16

5 3/4

2

10435R-70

4

R 3/4

R 9/16

2

9

5 1/8

8190R-70

5 1/4

R 3/4

R 9/16

2

4

|

High Voltage Pin

Insulators

4 3/4"

3 1/2"

R 1"

5 1/2" 2 1/4"

R 5/8"

8 3/8"

3 1/2

Posts

CATALOG REFERENCE NUMBER

CRITICAL DISTANCES, inches

MECHANICAL VALUES, pounds

ELECTRICAL VALUES, kV

RADIO INFLUENCE VOLTAGE DATA

320331-70

Dry arcing distance 9

Leakage distance 15.5

Cantilever strength 3000

Typical application voltage 25

Low-frequency dry flashover 100

Low-frequency wet flashover 70

Critical impulse flashover, positive

Critical impulse flashover, negative

Low voltage puncture voltage

155

190

160

Low-frequency test voltage, RMS to ground, kV 20

Maximum RIV at 1000 kHz, V 100

Note: ANSI 70 gray is standard. Brown available by request

320331-70

2 7/8

6

1

R 1

R 3/4

7 1/2

|

Pinpost

Insulators

CATALOG REFERENCE NUMBER

CRITICAL DISTANCES, inches

MECHANICAL VALUES, pounds

ELECTRICAL VALUES, kV

RADIO INFLUENCE VOLTAGE DATA

Dry arcing distance 5 5 3/4 7 5/8

Leakage distance 7 1/2 11 15

Cantilever strength 2000 2000 1500

Typical application voltage 15 20 27

Low-frequency dry flashover 65 80 95

Low-frequency wet flashover 40 55 65

Critical impulse flashover, positive 100 110 140

Low-frequency test voltage, RMS to ground, kV 10 15 20

Maximum RIV at 1000 kHz, V 50 50 50

Note 1: ANSI 70 gray is standard. Brown available by request

Note 2: Available with short or long stud, sold separately

4315PX-70

4315X-70

4320PX-70

4320X-70

4327PX-70

4327X-70 4335X-70

4335PX-70

8.27

18.21

1000

35

110

80

165

22

100

4327PX-70 4327X-70

5 5/32

9 11/16

2 1/4

3/4 - 10 UF

R 1

R 1

5 5/32

9 11/16

2 7/8

3/4 - 10 UF

R 1

R 1

4320PX-70 4320X-70

5

9

3/4 - 10 UF

2 1/4

R 1

R 1

9"

5

2 7/8

3/4 - 10 UF

R 1

R 1

4315X-70 4315PX-70

4 4/5

7.8

2 7/8

3/4 - 10 UF

R 1

R 1

4 4/5

7.6

3/4 - 10 UF

2 1/4

R 1

R 1

R1"

R1"

3/4 - 10 UF

11"

2 9/10"

4 5/10"

4335PX-70 4335X-70

11"

3/4 - 10 UF

2 2/10

5 2/10

R1"

R1"

C Neck F Neck

C Neck F Neck

C Neck F Neck

C Neck F Neck

|

Distribution Post

Insulators

Tie Top Line Post

Insulators

57-1

CATALOG REFERENCE NUMBER

CRITICAL DISTANCES, inches

MECHANICAL VALUES, pounds

ELECTRICAL VALUES, kV

RADIO INFLUENCE VOLTAGE DATA

9325X-70

Dry arcing distance 6.5 9.5 12.2

Leakage distance 14 22.5 29.5

Cantilever strength 2800 2800 2800

Typical application voltage 25 35 46

Low-frequency dry flashover 90 115 135

Low-frequency wet flashover 60 70 100

Critical impulse flashover, positive 130 179 214

57-2

9335X-70

57-3

9345X-70

ANSI CLASS (C29.7-1996 rev. 2002)

Low-frequency test voltage, RMS to ground, kV 15 22 30

Maximum RIV at 1000 kHz, V 100 100 200

9325X-70

9335X-70 9345X-70

Note 1: ANSI 70 gray is standard, Brown abailable by request

Note 2: The insulators can be requested with M20 thread

Note 3: Available with short or long stud, sold separately

|

2 7/8"

5 7/8"

R 1"

9 3/16"

3/4"-10 UF

R 1"

6 1/8"

R 1"

12 7/16"

3/4"/10 UF

2 7/8"

R 1"

6 5/16"

2 7/8"

R 1"

15"

3/4"-10 UF

R 1"

CATALOG REFERENCE NUMBER

CRITICAL DISTANCES, inches

MECHANICAL VALUES, pounds

ELECTRICAL VALUES, kV

RADIO INFLUENCE VOLTAGE DATA

Dry arcing distance 14.5 17.25

Leakage distance 40 45

Cantilever strength 2800 2800

Typical application voltage 55 66

Low-frequency dry flashover 140 160

Low-frequency wet flashover 110 130

Critical impulse flashover, positive 230 265

57-4

8416X-70

57-5

8417X-70

ANSI CLASS (C29.7-1996 rev. 2002)

Low-frequency test voltage, RMS to ground, kV 44 44

Maximum RIV at 1000 kHz, V 200 200

Note 1: ANSI 70 gray is standard, Brown abailable by request

Note 2: The insulators can be requested with M20 thread

Note 3: Available with short or long stud, sold separately

8417X-70

7 1/2"

6"

2

1

1

/

4

"

3/4 - 10 UF

8416X-70

1 1/2"

1 1/2"

7"

6"

2

0

1

/

4

"

3/4 - 10 UF

Tie Top Line Post

Insulators

Clamp Tops

CATALOG REFERENCE NUMBER

CRITICAL DISTANCES, inches

MECHANICAL VALUES, pounds

ELECTRICAL VALUES, kV

RADIO INFLUENCE VOLTAGE DATA

Dry arcing distance 5 6.5 9.5 12.25

Leakage distance 10 14 22 29

Cantilever strength 2800 2800 2800 2800

Typical application voltage 20 25 35 45

Low-frequency dry flashover 70 80 110 125

Low-frequency wet flashover 50 60 85 100

Critical impulse flashover, positive 100 130 180 210

Note 1: ANSI 70 gray is standard. Brown available by request

Low-frequency test voltage, RMS to ground, kV 15 15 22 30

Maximum RIV at 1000 kHz, V 50 100 100 200

Note 2: LN = Lock nut / LNC= Lock nut with trunnion bolt

4220 LN-70

4220-70

4220 LNC-70

4225 LN-70

4225-70

4225 LNC-70

4235 LN-70

4235-70

4235 LNC-70

4245 LN-70

4245-70

4245 LNC-70

ANSI CLASS (C29.7-1996 rev. 2002)

Tensin strength 5000 5000 5000 5000

- 57-11 57-12 57-13

Note 3: Available with short or long stud, sold separately

4220-70

5/8 - 11 NC

5 13/16

9 5/16

3/4 - 10 UF

4225-70

5/8 - 11 NC

3/4 - 10 UF

6 1/8

10 43/64

4235-70

5/8 - 11 NC

3/4 - 10 UF

6 3/8

14 5/64

4245-70

3/4 - 10 UF

5/8 - 11 NC

6 5/8

16 5/8

|

Clamp Top

Insulators

Station Post

GAMMA Porcelain Station Post Insulators

Designed to meet and exceed ANSI specifications, Gamma's porcelain Station Post Insulators

conform to the most current industry standards* for the greatest degree of flexibility and

consistency. However, that's where being Standard ends.

GAMMA MANUFACTURES ITS OWN PRODUCTS!! Gamma does not use subcontractors to

manufacture and brand label its product. Instead we use state of the art equipment and

processes to produce high quality porcelain Station Post Insulators, consistently, every time.

In addition, Gamma has the unique ability to control nearly every step of the process. In

conjunction with its parent company, The Corona Group** we extract, transport, and process

much of the raw material used in our insulators. We employ the engineering and technical

expertise required to support our products, and own the equipment necessary to ensure our

porcelain Station Post Insulators meets our high standards for quality and conformance.

Gamma's start to finish process ownership, state of the art manufacturing, and world class

technical capabilities produces porcelain Station Post that utilities can rely on with confidence.

There is no mystery or guesses about where your Gamma Station Post Insulators come from,

they come from GAMMA!

*Standards

Gamma Station Post Insulators conform to

ANSI (C29.1 and C29.9)

**Gamma Insulators Corporation.

is the electrical grade insulator division of THE CORONA GROUP, a 125 year old multinational

corporation with sales in excess of $1.5 billion annually. Corona's state of the art manufacturing

facilities utilize the latest manufacturing technologies, and are all certified to the most recent

ISO 9001, 14001, and OHSAS 18001 standards. We employ world class manufacturing tools and

management systems such as TPM, Lean Manufacturing, DFSS, and Six Sigma, to name a few, in

order to produce the high quality products you've come to expect from Corona Companies.

Station Post

Insulators

7000

10000

6000

10000

2000

7000

105

30

95

5

50

ANSI CLASS (C29.9 - 1983) TR-202

CATALOG NUMBER

50

TR-205

8420

2000

8500

125

45

110

10

8425

Leakage distance 10 1/2 15 1/2

15 Voltage class 7.5

Note 1: Brown glaze or ANSI 70 gray glaze

Note 2: The insulators can be requested with M12 thread

Low frequency withstand, 10 sec. wet

Maximum RIV at 1000 kHz, V

Low frequency test voltage, RMS to ground, kV

Impulse flashover, positive

Cantilever strength, upright, pounds

Tensile strength, pounds

Torsion strength, inch - pounds

Compression strength, pounds

Impulse withstand

DIMENSIONS, inches

MECHANICAL VALUES

ELECTRICAL VALUES, kV

RADIO INFLUENCE VOLTAGE DATA

Cantilever strength, underhung, pounds 2000 2000

4 THREAD

" - 13NC

4 1/4"

3"

7"

7 1/2"

8420

4 THREAD

" - 13NC

4 1/4"

3"

7"

10"

8425

4 1/4"

3"

6 1/2"

4 THREAD

" - 13NC

14"

8428

8428

8000

10000

100

TR-208

2000

10000

15

24

150

60

170

23

2000

10000

15000

2000

12000

225

80

200

22

100

TR-210

8430

37

34.5

2000

3"

4 1/4"

7 1/2"

4 THREAD

" - 13NC

18"

8430

Small Station Post

Insulator

45 50 60

CATALOG NUMBER 8608 8609 8610

Note: ANSI 70 gray is standard. Brown available by request

Low-frequency withstand, 10 sec. wet

Cantilever strength, pounds

CRITICAL DISTANCES, inches

MECHANICAL VALUES

ELECTRICAL VALUES, kV

Tensile strength, pounds

Torsion strenght, inch-pounds

Compression strenght, pounds

Leakage distance 17 1/2 20 7/8 24 3/8

1200 1200

30 30

8607 8606

5000 5000

5000 3000

5000 10000

14 1/4 13 9/16

1000 900

5000 5000

5000 3000

5000 5000

1000

5000

5000

5000

3/8-16 Thread

(Galv. Steel) TYP

10"

3 7/10"

1"

2 1/4"

5 1/2"

8610

3/8-16 Thread

(Galv. Steel) TYP

9"

3 7/10"

1"

2 1/4"

5 1/2"

8609

3 7/10"

1"

7"

8"

3/8-16 Thread

(Galv. Steel) TYP

3/8-16 Thread

(Galv. Steel) TYP

2 1/4"

5 1/2"

3 7/10"

1"

6 3/4"

3/8-16 Thread

(Galv. Steel) TYP

2 1/4"

5 1/2"

3 7/10"

1"

2 1/4"

5 1/2"

8608 8607 8606

Studs

V-010187A

3/4

2.25sq x 0.81 x 0.19

3/4

3/4

Wood crossarm

CATALOG NUMBER

1 Med type positive lock washer

ACCESORIES

1 Square Washer

1 Standard square nut

1 Lock nut

Notes:

Dimensions in inches

Rating, kV: 35, 45, 55, 66

0.06 FLAT

BEARING

SURFACE

1.25

SERRATED

SURFACE

R 0.06

1.02

0.81

0.62

3/4 - 10

4.00

3/4 - 10

0.05

0.17

8.75

7.56

0.19

0.78 (25/32)

HEX MUST PASS

0.81 HOLE

SECTION A - A

Material: C-1038 steel

Minimun Brinnell 143

Hot dip galvanized

Line Post Long Stud

Fittings

A

A

V-011612A

3/4

2 x 2 x 11/16 x 1/8

5/8

5/8

Wood crossarm

CATALOG NUMBER

1 Med type positive lock washer

ACCESORIES

1 Square Washer

1 Regular square nut

1 Lock nut

Notes:

Dimensions in inches

Rating, kV: 15, 20, 25

3/4 - 10

1.02

0.81

5/8 - 11

4.0

8.75

0.65

REF.

Material: C-1038 steel

Minimun Brinnell 143

Hot dip galvanized

Line Post Long Stud

Fittings

1.25

SERRATED

SURFACE

A

A

SECTION A - A

V-74739

3/4

5/8

2.25 x 2.25 x 0.69 x 0.19

5/8

Metal crossarm

CATALOG NUMBER

1 LT type positive lock washer

ACCESORIES

1 LT type positive lock washer

1 Square washer

1 Regular hexagonal nut

Notes:

Dimensions in inches

Rating, kV: 15,20, 25

R 0.06

1.02

0.81

1.56

0.38

5/8 - 11

3/4 - 10

0.05

0.17

3.38

2.19

5/8 - 11 NUT MUST

PASS OVER HEX.

CORNERS AFTER GALV.

0.44

MUST FIT

7/16 WRENCH

Material: C-1038 steel

Minimun Brinnell 143

Hot dip galvanized

Line Post Short Stud

Fittings

1.25

SERRATED

SURFACE

V-301613

3/4

5/8

5/8

Metal crossarm

CATALOG NUMBER

1 Med type positive lock washer

ACCESORIES

1 Med type positive lock washer

1 Regular hexagonal nut

Notes:

Dimensions in inches

Rating, kV: 15, 20, 25

R 0.06

1.02

0.81

1.56 0.38

5/8 - 11

3/4 - 10

0.05

0.17

3.38

2.19

5/8 - 11 NUT MUST

PASS OVER HEX.

CORNERS AFTER GALV.

Material: C-1038 steel

Minimun Brinnell 143

Hot dip galvanized

Line Post Short Stud

Fittings

0.06 FLAT

BEARING

SURFACE

1.25

SERRATED

SURFACE

0.44

MUST FIT

7/16 WRENCH

V-301614

3/4

3/4

Metal crossarm

CATALOG NUMBER

2 Med type positive lock washer

ACCESORIES

2 Regular hexagonal nut

Notes:

Dimensions in inches

Rating, kV: 35, 45, 55, 66

1.25

SERRATED

SURFACE

R 0.06

1.02

0.81

1.56

0.12

0.50

3/4 - 10 THREAD

BOTH ENDS 0.05

0.17

3.38

2.19

3/4 - 10 NUT MUST

PASS OVER HEX.

CORNERS

0.56

MUST FIT

9/16 WRENCH

0.06 FLAT

BEARING

SURFACE

Material: C-1038 steel

Minimun Brinnell 143

Hot dip galvanized

Line Post Short Stud

Fittings

V-301616

7/8

7/8

Metal crossarm

CATALOG NUMBER

2 Lt type positive lock washer

ACCESORIES

1 Regular hexagonal nut

Notes:

Dimensions in inches

Rating, kV: 88

Material: C-1038 steel

Minimun Brinnell 143

Hot dip galvanized

R 0.06

1.19

1.06

2.81

0.25 0.38

7/8 - 9

THREAD

7/8 - 9

THREAD

0.05

0.17

4.80

3.44

7/8 - 9 NUT MUST

PASS OVER HEX.

CORNERS

0.62

MUST FIT

5/8 WRENCH

Line Post Short Stud

Fittings

1.25

SERRATED

SURFACE

0.06 FLAT

BEARING

SURFACE

Fiberglass

Guy Strain

GS15 - Series

Fiberglass Guy Strain Insulators

GS1512-XX

GS1518-XX

GS1524-XX

GS1530-XX

GS1536-XX

GS1542-XX

GS1554-XX

GS1560-XX

GS1578-XX

GS1590-XX

GS1596-XX

GS15120-XX

GS15144-XX

15000 (67) 12" (305)

15000 (67) 18" (457)

15000 (67) 24" (610)

15000 (67) 30" (762)

15000 (67) 36" (914)

15000 (67) 42" (1067)

15000 (67) 54" (1372)

15000 (67) 60" (1524)

15000 (67) 78" (1981)

15000 (67) 90" (2286)

15000 (67) 96" (2438)

15000 (67) 120" (3048)

15000 (67) 144" (3657)

L

1

5

.

8

8

RL STICK

G

M

G

M

L ASSEMBLY

CATALOG NUMBER LENGTH L, inches (mm) MECHANICAL STRENGTH CLASS, lbs (KN)

Note 1: XX code is the type of cast ductile iron, hot dip galvanized end fittings.

T: Thimble Eye

C: Clevis with pin and clip

R: Clevis with roller pin and clip

Example: TC (Thimble eye - Clevis with pin and clip) end

GAMMA Insulators Corp

www.gammainsulators.com

www.gamma.com.co

También podría gustarte

- Electrical Network Monitoring & Control Solution: Avoiding Blackouts in Industrial Plants!Documento14 páginasElectrical Network Monitoring & Control Solution: Avoiding Blackouts in Industrial Plants!Naseer HydenAún no hay calificaciones

- Classification of InsulatorsDocumento1 páginaClassification of Insulatorsmjv362Aún no hay calificaciones

- Products CatalogDocumento96 páginasProducts CatalogDaniel Uculmana LemaAún no hay calificaciones

- Bee4173 - Power System Operation & ControlDocumento7 páginasBee4173 - Power System Operation & Controlsemuty92Aún no hay calificaciones

- Pfisterer Railway InsulatorsDocumento31 páginasPfisterer Railway InsulatorsthangbinhbkAún no hay calificaciones

- Catalogue Long RodDocumento10 páginasCatalogue Long RodTravis WoodAún no hay calificaciones

- Grid Converters for Photovoltaic and Wind Power SystemsDe EverandGrid Converters for Photovoltaic and Wind Power SystemsCalificación: 4.5 de 5 estrellas4.5/5 (4)

- Panel Construction - Remote End - Rev-A - 03.06.2013Documento4 páginasPanel Construction - Remote End - Rev-A - 03.06.2013ADE mrtAún no hay calificaciones

- By Matthew Clayton Such 2013Documento306 páginasBy Matthew Clayton Such 2013Fajar AriAún no hay calificaciones

- Power Line Carrier Detailed DocumentDocumento51 páginasPower Line Carrier Detailed DocumentmuzammiliqbalAún no hay calificaciones

- Microgrid ThesisDocumento163 páginasMicrogrid ThesisAshik AhmedAún no hay calificaciones

- Current Interruption Transients CalculationDe EverandCurrent Interruption Transients CalculationCalificación: 4 de 5 estrellas4/5 (1)

- 132KV Line Remote End - Rev-A - 03.06.2013Documento48 páginas132KV Line Remote End - Rev-A - 03.06.2013ADE mrtAún no hay calificaciones

- Power Control SystemDocumento29 páginasPower Control SystemJames XgunAún no hay calificaciones

- PPC Insulator - Solid CoreDocumento16 páginasPPC Insulator - Solid CoreAriel Ghigliotto100% (1)

- The Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsDe EverandThe Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsAún no hay calificaciones

- 11kV Outdoor Switchgear PDFDocumento48 páginas11kV Outdoor Switchgear PDFMekonnen ShewaregaAún no hay calificaciones

- PVS 100 120 TL - BCD.00662 - EN - Rev IDocumento4 páginasPVS 100 120 TL - BCD.00662 - EN - Rev IAl RAAún no hay calificaciones

- PVS-100 PVS-120 Product Presentation Turkey Feb.2018Documento69 páginasPVS-100 PVS-120 Product Presentation Turkey Feb.2018Comsip400Aún no hay calificaciones

- Qcs 2014 - Sec21 p12 - Emergency LightingDocumento7 páginasQcs 2014 - Sec21 p12 - Emergency Lightingchandra100% (2)

- SIP 2008 - 09 Busbar Differential ProtectionDocumento40 páginasSIP 2008 - 09 Busbar Differential ProtectionJîhenzebMensûrAún no hay calificaciones

- ABB TransformersDocumento18 páginasABB TransformersEng HamiedAún no hay calificaciones

- Optical Current Transformer 1 1Documento20 páginasOptical Current Transformer 1 1shubham jaiswalAún no hay calificaciones

- NOJA-5012-04 NOJA Power OSM Single Triple Brochure - enDocumento12 páginasNOJA-5012-04 NOJA Power OSM Single Triple Brochure - eniam_dausAún no hay calificaciones

- Info Iec61189-2 (Ed2.0) enDocumento9 páginasInfo Iec61189-2 (Ed2.0) enhendro suprianto nugrohoAún no hay calificaciones

- Application Notes: Application Notes P34X/En Ap/F33 Micom P342, P343Documento178 páginasApplication Notes: Application Notes P34X/En Ap/F33 Micom P342, P343Dinesh MadabattulaAún no hay calificaciones

- Power Cables Cable Accessories Cable Monitoring & Maintenance SystemsDocumento58 páginasPower Cables Cable Accessories Cable Monitoring & Maintenance Systemsfigv1975Aún no hay calificaciones

- EPCOS Power Factor Correction Product ProfileDocumento104 páginasEPCOS Power Factor Correction Product ProfileJavierRuizThorrensAún no hay calificaciones

- Nader NDW3 Series Products SpecificationDocumento117 páginasNader NDW3 Series Products SpecificationaktrctqAún no hay calificaciones

- Manual Gerador 37383Documento102 páginasManual Gerador 37383Sidney Chaves de Lima100% (1)

- EATON Protection and Control RelaysDocumento8 páginasEATON Protection and Control RelaysRazvan MaresAún no hay calificaciones

- P633 BrochureDocumento24 páginasP633 BrochureShuhan Mohammad Ariful HoqueAún no hay calificaciones

- Modular Multi Level Converter: Modeling, Analsyis and Control: - A New Technology For HVDC ApplicationsDocumento1 páginaModular Multi Level Converter: Modeling, Analsyis and Control: - A New Technology For HVDC ApplicationsSri MadisettyAún no hay calificaciones

- Modular Multilevel ConverterDocumento11 páginasModular Multilevel Converterchientdh2Aún no hay calificaciones

- RUS USDA C84 Voltage TolerancesDocumento47 páginasRUS USDA C84 Voltage Toleranceskcirrenwod100% (1)

- 5.6. Schematic - Bus Coupler-J2.10Documento32 páginas5.6. Schematic - Bus Coupler-J2.10Mèo Mập Ú NuAún no hay calificaciones

- Challenges IEC 61850 Substation CommissioningDocumento7 páginasChallenges IEC 61850 Substation CommissioningchupzptAún no hay calificaciones

- Earthing in Electrical Network Purpose Methods and MeasurementDocumento8 páginasEarthing in Electrical Network Purpose Methods and MeasurementVinay ArukapalliAún no hay calificaciones

- RP12 16Documento48 páginasRP12 16ferdad100% (1)

- Design of RC Snubbers For PCT Applications - ABBDocumento9 páginasDesign of RC Snubbers For PCT Applications - ABBBruno LambertAún no hay calificaciones

- Knowledge is "Real Power": Introduction to Power QualityDe EverandKnowledge is "Real Power": Introduction to Power QualityAún no hay calificaciones

- 7SA513 ManualDocumento396 páginas7SA513 Manualionecir100% (1)

- Adaptive 100 Stator Earth Fault Protection CIGRE PaperDocumento7 páginasAdaptive 100 Stator Earth Fault Protection CIGRE PaperVivek SinghAún no hay calificaciones

- ICREST'21 ProceedingsDocumento150 páginasICREST'21 ProceedingsGovanazziAún no hay calificaciones

- Siemens STEP Series Basics of Switchboards PDFDocumento60 páginasSiemens STEP Series Basics of Switchboards PDFHussamAún no hay calificaciones

- DigSilent TechRef - LogdipDocumento17 páginasDigSilent TechRef - LogdipАлишер ГалиевAún no hay calificaciones

- High-Voltage Circuit-Breakers 3AP1/2 72.5 KV Up To 550 KV: Answers For EnergyDocumento12 páginasHigh-Voltage Circuit-Breakers 3AP1/2 72.5 KV Up To 550 KV: Answers For EnergySung Hye ChoiAún no hay calificaciones

- 2.0 Selección de PararrayosDocumento23 páginas2.0 Selección de PararrayosWilder Benites VillanuevaAún no hay calificaciones

- ABB 63 WPO BreakerCoordination FinalDocumento4 páginasABB 63 WPO BreakerCoordination FinalCA Cole100% (1)

- MICOM P34x - EN - O - F33Documento440 páginasMICOM P34x - EN - O - F33msaini2009Aún no hay calificaciones

- Nulec - AutorecloserDocumento27 páginasNulec - AutorecloserSatyaAún no hay calificaciones

- Guia de Logicas Inputs y Outputs 1Documento53 páginasGuia de Logicas Inputs y Outputs 1abadnundAún no hay calificaciones

- Deetap ® Du: Off-Circuit Tap-ChangerDocumento6 páginasDeetap ® Du: Off-Circuit Tap-ChangervitalstyleAún no hay calificaciones

- Types KBCH 120, 130, 140 Differential Protection For Transformers and GeneratorsDocumento20 páginasTypes KBCH 120, 130, 140 Differential Protection For Transformers and Generatorsjjcanoolivares100% (1)

- Current Transformer - Electrical Notes & ArticlesDocumento35 páginasCurrent Transformer - Electrical Notes & ArticlesBlake100% (1)

- ManualDocumento2070 páginasManualRenan de FaveriAún no hay calificaciones

- Arteche CT Trfmvo enDocumento28 páginasArteche CT Trfmvo enochocomikeAún no hay calificaciones

- Real-Time Simulation Technology for Modern Power ElectronicsDe EverandReal-Time Simulation Technology for Modern Power ElectronicsAún no hay calificaciones

- Field Study 1-Act 5.1Documento5 páginasField Study 1-Act 5.1Mariya QuedzAún no hay calificaciones

- TNEB Thermal Power PlantDocumento107 páginasTNEB Thermal Power Plantvicky_hyd_130% (1)

- Bar Exam Questions Week 1Documento30 páginasBar Exam Questions Week 1Mark Bantigue100% (1)

- Ear CandlingDocumento2 páginasEar CandlingpowerleaderAún no hay calificaciones

- ЗОШИТ для ДЗ №2 Microsoft WordDocumento44 páginasЗОШИТ для ДЗ №2 Microsoft WordдимаAún no hay calificaciones

- Leadership Roles and Management Functions in Nursing Theory and ApplicationDocumento2 páginasLeadership Roles and Management Functions in Nursing Theory and Applicationivan0% (3)

- Manufacturer: Jaguar Model: S-Type 2,5 Engine Code: JB Output: 147 (200) 6800 - 6/9/2022 Tuned For: R-Cat Year: 2002-05 V9.200Documento2 páginasManufacturer: Jaguar Model: S-Type 2,5 Engine Code: JB Output: 147 (200) 6800 - 6/9/2022 Tuned For: R-Cat Year: 2002-05 V9.200Official Feby AfriwanAún no hay calificaciones

- Fpubh 10 1079779Documento10 páginasFpubh 10 1079779Dona WirdaningsiAún no hay calificaciones

- LUBRICANTCOOLANT Answer With ReflectionDocumento5 páginasLUBRICANTCOOLANT Answer With ReflectionCharles Vincent PaniamoganAún no hay calificaciones

- Modeling, Control and Simulation of A Chain Link Statcom in Emtp-RvDocumento8 páginasModeling, Control and Simulation of A Chain Link Statcom in Emtp-RvBožidar Filipović-GrčićAún no hay calificaciones

- Tokyo Fact SheetDocumento17 páginasTokyo Fact Sheethoangnguyen2401Aún no hay calificaciones

- Nutritional Classification of BacteriaDocumento7 páginasNutritional Classification of BacteriaRalphpinno SanchezAún no hay calificaciones

- High Pressure Processing of Food - Principles, Technology and ApplicationsDocumento758 páginasHigh Pressure Processing of Food - Principles, Technology and ApplicationsEduardo Estrada100% (1)

- ASTM Standards For WoodDocumento7 páginasASTM Standards For WoodarslanengAún no hay calificaciones

- Fire CodeDocumento1 páginaFire CodeShainette VillarazaAún no hay calificaciones

- Q1 GRADE 10 SYNCHRONOUS REVISED Fitness-Test-Score-CardDocumento1 páginaQ1 GRADE 10 SYNCHRONOUS REVISED Fitness-Test-Score-CardAlbert Ian CasugaAún no hay calificaciones

- Bradycardia AlgorithmDocumento1 páginaBradycardia AlgorithmGideon BahuleAún no hay calificaciones

- UntitledDocumento8 páginasUntitledapi-86749355Aún no hay calificaciones

- Cameron Scanner 2000 Hardware User Manual PDFDocumento11 páginasCameron Scanner 2000 Hardware User Manual PDFPes SilvaAún no hay calificaciones

- PsychodramaDocumento5 páginasPsychodramaAkhila R KrishnaAún no hay calificaciones

- Principles in Biochemistry (SBK3013)Documento3 páginasPrinciples in Biochemistry (SBK3013)Leena MuniandyAún no hay calificaciones

- Biecco Lawrie Ece Gec Reyrolle Burn Jyoti SwitchgearDocumento18 páginasBiecco Lawrie Ece Gec Reyrolle Burn Jyoti SwitchgearSharafat AliAún no hay calificaciones

- Daily Lesson Log Personal Dev TDocumento34 páginasDaily Lesson Log Personal Dev TRicky Canico ArotAún no hay calificaciones

- Chrono Biology SeminarDocumento39 páginasChrono Biology SeminarSurabhi VishnoiAún no hay calificaciones

- Cupping TherapyDocumento6 páginasCupping TherapymsbunnileeAún no hay calificaciones

- Cystostomy NewDocumento32 páginasCystostomy Newkuncupcupu1368Aún no hay calificaciones

- Standard Practice For Magnetic Particle Testing For AerospaceDocumento16 páginasStandard Practice For Magnetic Particle Testing For AerospaceSaul RuizAún no hay calificaciones

- Pressure MeasurementDocumento293 páginasPressure MeasurementGlen Lauren PerezAún no hay calificaciones

- G1 CurvedDocumento16 páginasG1 CurvedElbert Ryan OcampoAún no hay calificaciones

- 04 TitrimetryDocumento7 páginas04 TitrimetryDarwin Fetalbero ReyesAún no hay calificaciones