Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Vol II (39) TB16

Cargado por

Ahmed DyalTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Vol II (39) TB16

Cargado por

Ahmed DyalCopyright:

Formatos disponibles

23

RD

INTERNATIONAL SYMPOSIUM ON BALLISTICS

TARRAGONA, SPAIN 16-20 APRIL 2007

ON THE NORMAL PERFORATION OF THICK METALLIC PLATES BY A

SHARP NOSE RIGID PROJECTILE*

X. L. Li

1,2+

, C.L. Liu

3

, F. L. Huang

2

, H. J. Wu

2

, Y. Z. Chen

1

, X.W. Chen

1,2

1

Institute of Structural Mechanics, China Academy of Engineering Physics,

P.O. Box 919-414, Mianyang City, Sichuan Province, 621900, China

2

State Key Lab of Explosion Science and Technology, Beijing Institute of Technology, 100088, China

3

Institute of Fluid Physics, China Academy of Engineering Physics,

P.O. Box 919-150, Mianyang City, Sichuan Province, 621900, China

+

corresponding author. E-mail: shirley_minnie@yahoo.com.cn

*

Supported by the State Key Lab of Explosion Science and Technology of Beijing Institute of

Technology under Contract No. KFJJ04-3 and the National Natural Science Foundation of China

under Contract No. 10672152

The normal perforation of thick metallic plate by sharp nose rigid

projectile is studied in the present paper based on the general penetration

resistance, which contains the terms of damping effect and the dummy

mass of projectile induced by the deceleration effect. The terminal

ballistic formulae with four dimensionless parameters are introduced,

i.e., the impact function I, geometry function N, the damp function

and the dimensionless target thickness . Theoretical predictions of

perforation dependent/independent of the damping function , show

good agreement with the individual published test data of different

projectiles and impact velocities as well as different targets.

INTRODUCTION

Dynamic cavity expansion model has been taken as one of the most effective

theoretical models in predicting the ballistic effect of dynamics of rigid projectile.

Penetration resistance includes not only the static strength term of target material and

flow stress term, but also the damping effect of target material. The effect of dummy

1173

TERMINAL BALLISTICS 1174

mass caused by hypervelocity impact becomes more and more distinct, while it is

always omitted in the formulation of dynamic cavity expansion theory because of

mathematical simplification. The general formula of penetration resistance is

(1) v e cv bv a & + + + =

2

Where a ,b ,c and are material coefficients and v is the velocity of cavity expansion. e

Based on the dynamic cavity-expansion model, the normal perforation of thick

metallic plate by sharp nose rigid projectile is studied in the present paper. Besides the

impact function I, geometry function N and dimensionless thickness of target , the

fourth dimensionless parameter, i.e., the damping function is introduced to predict

ballistic limit and residual velocity. Theoretical predictions of the model show good

agreement with the individual published test data.

THE THIRD DIMENSIONLESS NUMBER

The resulting axial resistant force on the projectile nose can be integrated from the

normal compressive stress and the tangential stress, which are formulated from the

dynamic cavity expansion analysis. We have

( ) [ ]

3 2

2

1

2

4

N V d D V Y C N V B AYN

d

F

x

&

+ + + =

(2)

Where Y and are yielding stress and density of target material, respectively. A, B, C

and D are dimensionless material constants of target. N

1

N

2

and N

3

are three

dimensionless parameters relating to nose shape of projectile and friction [1].

Based on the general expression of penetration resistance, Chen et al.[1]

introduced the third dimensionless parameter, i.e., the damping function, , besides the

impact function I and geometry function of projectile introduced early [2,3], N

AB

C

4

2

= (3)

On the normal perforation of thick metallic plates by a sharp nose rigid projectile 1175

Only three dimensionless numbers, i.e. the impact function I , geometry function

of projectile N and damp function , are dominant parameters to determine the

dimensionless depth of penetration (DOP) into a target impacted by a rigid projectile.

( ) [ ]

+ + =

+ N I

U

U d

N

I

N

I

N

d

X

1

2

2 1 ln

2

2

(4)

An actual equation of dimensionless DOP only exists in the case of 1 < ,

therefore the corresponding dimensionless penetration depth can be obtained

+ + =

1

1

N I

N

I

N

I

N

d

X

1 1

tan

/

tan

1

2

2 1 ln

2

(5)

PERFORATION OF THICK PLATES BY SHARP-NOSED PROJECTILE

The normal perforation of thick metallic plate by sharp-nose rigid projectile is

studied based on the general penetration resistance and above three dimensionless

parameters. For a projectile with sharp nose, plugging stage is usually omitted and only

penetration (or hole enlargement) dominates in the whole perforation process.

Perforation occurs when the nose tip of projectile reaches the rear surface of the target.

We define d H = is the dimensionless thickness of plate and H is the target

thickness. The residual or exit velocity of the projectile is assumed to be

r

V . The

boundary effect of rear free surface is negligible, eq.(5) is re-written as

+ +

+ +

=

N

I

N

I

N

I

N

I

N

I

N

I

1

tan

1

tan

1

2

2 1

2 1

ln

2

r

1 1

r r

(6)

Where

Y d AN

V M

I

r m

r

3

1

2

= is the impact function corresponding to the residual velocity

r

V .

Ballistic limit is achieved at critical perforation with zero residual/exit velocity,

i.e., 0

r

V . In that case, we have,

TERMINAL BALLISTICS 1176

+ + =

1

1

N I

N

I

N

I

N

BL BL BL 1 1

tan

/

tan

1

2

2 1 ln

2

(7)

where

Y d AN

V M

I

BL

m

BL

3

1

2

= corresponds to the ballistic limit . From eqs.(6) and (7), it

can be formulated as follows.

BL

V

+ +

+ +

=

+ +

N

I

N

I

N

I

N

I

N

I

N

I

N

I

N

I

N

I

1

tan

1

tan

1

2

2 1

2 1

ln

tan

1

tan

1

2

2 1 ln

BL

1 - 1

BL BL

1

r

1 r r

(8)

In general, the ballistic limit and residual velocity

BL

V

r

V may be solved with

Eq.(7) and Eq.(8), respectively. Some special simplified cases in engineering

application will be further given in next Section.

SPECIAL CASES OF PERFORATIONS

Case of 0 =

Without considering the damping effect in the perforation process, the simplified

ballistic limit and residual velocity are obtained from eqs.(7) and (8) respectively when

, which have the same forms as those in [4]. 0 =

= 1

2

exp

2

1 2

BL

N

BN

Y AN

V (9)

On the normal perforation of thick metallic plates by a sharp nose rigid projectile 1177

( )

=

N

V V

V

2

exp

2

BL

2

0

r

(10)

Case of 0 / N I

Usually a sharp nose projectile has a large value of geometry function , while it

perforates a metallic plate at a relative low impact velocity, i.e., with a small impact

function

N

I . Thus, we have [4]. It indicates that the value of damping

function is smaller for most of experimental results in the next section, i.e., .

With Comparing to

0 / N I

1 . 0 <

I and , the influence of damping function N on the penetration

capability is consistent and smaller, and its deviation from early analysis is lower than

15%. Thus, it may be further simplified as,

=

N

BN

Y AN

V

BL

2 1

2

1

(11)

( ) ( ) ( )

N

I

N

I

N

I

N

I

N

I

N

I

BL BL r r

1

2

1

2

1

2

(12)

If 01 . 0 < , the effect of damping function is regarded as completely ignored,

and much simpler formulae can be conducted from eqs.(11) and (12)

2

1

Y AN

V

BL

= (13)

2

BL

2

0

r

V V V = (14)

EXPERIMENTAL ANALYSIS

Experimental data from [5,6,7,8] are compared with the present analytical

predictions on ballistic limit and residual velocity.

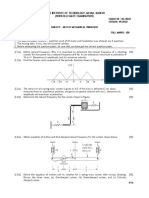

Figs.1-4 show the experimental results and corresponding theoretical predictions.

For an impact at higher velocity, a projectile always perforates a target plate with

TERMINAL BALLISTICS 1178

reserving most of the kinetic energy. In other words, with further increasing the impact

velocity, residual velocity of projectile will be rather close to the impact velocity which

being as an asymptote. Therein, the individual modeling of ballistic performance always

approach the test results as well at higher initial impact velocity. However, it is nearby

the ballistic limit that obvious difference may exist between the various theoretical

predictions and test results.

The present discussion focuses on the ballistic limit. According to Figs.1-4, it

improves the target resistance against penetration by introducing damping function ,

and thus, the ballistic limit increases while the residual velocity decreases a little bit

with comparing to that in Chen and Li [4]. However, after accounting for the dummy

mass, the ballistic limit may decrease and even become smaller than the prediction of

Chen and Li [4], while being more close to the test results. The dummy mass is

beneficial for improving the ballistic performance of projectile. In general, the damping

function conflicts with the dummy mass and compensate for each other in a

penetration. A theoretical prediction which takes into account and

simultaneously may become more appropriate in practice. It is worth mentioned that

dummy mass has little influence on the residual velocity and can be neglected for

perforation of metallic target by sharp nose projectile, which is determined by eq.(8).

According to the definition of

m

M

m

M

I and , the ratio of N N I (including N I

r

and

N I

BL

) is independent of modified mass of projectile.

The general formula of penetration resistance, which contains the terms of

damping effect and dummy mass of projectile, had been proposed in 50s of last century,

and the damping coefficient C can be defined by dynamic cavity expansion theory.

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

V

r

(

k

m

/

s

)

V

i

(km/s)

Piekutowski et al[1996]

Model without additive mass

Model wIith 5% additive mass

Model with 10% additive mass

Chen & Li [2003]

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

V

r

(

k

m

/

s

)

V

i

(km/s)

Piekutowski et al [1996]

Model without additive mass

Model with 5% additive mass

Model with 10% additve mass

Chen & Li [2003]

Figure 1. Prediction of residual velocity and test data [5]

On the normal perforation of thick metallic plates by a sharp nose rigid projectile 1179

0.2 0.4 0.6 0.8 1.0 1.2

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

Roisman et al [1999](Oblique impact)

Model without additive mass

Model with 5% additive mass

Model with 10% additvie mass

Chen & Li [2003]

V

r

(

k

m

/

s

)

V

i

(km/s)

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

V

r

(

k

m

/

s

)

V

i

(km/s)

Rosenberg et al [1988]

Model without additive mass

Model with 5% additive mass

Model with 10% additive mass

Chen & Li [2003]

Figure 2. Prediction of residual velocity Figure 3. Prediction of residual velocity

and test data [6] and test data [7]

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

V

r

(

k

m

/

s

)

V

i

(km/s)

Forrestal et al [1990]

H=12.7mm

Model without additive mass

Chen &Li [2003]

H=50.8mm

Model without additive mass

Chen &Li [2003]

H=76.2mm

Model without additive mass

Chen &Li [2003]

Figure 4. Prediction of residual velocity and test data [8]

However, the dummy mass coefficient D has not yet been discussed in detail up to now.

Through fitting the test data, we may evaluate the influence of dummy mass term on

penetration/perforation reversely. As shown in Figs. 1-4, accompanied with the

damping effect, the residual velocity and ballistic limit lead to good predictions of

experimental results if the mass of projectile increase by 5%-10%. In other words, the

dummy mass may contribute to the mass of projectile from 5% to 10%. Thus the value

of can be deduced by D ( )

3

3

m

4 / DN d M M + = and varies between 1 and 2.

TERMINAL BALLISTICS 1180

CONCLUSIONS

The normal perforation of thick metallic plate by sharp nose rigid projectile is

studied in the present paper based on the general penetration resistance, which contains

the terms of damping effect and the dummy mass of projectile induced by the

deceleration effect. The terminal ballistic formula with four dimensionless parameters is

introduced, i.e., the impact function I, geometry function N, the damp function and

the dimensionless target thickness . Theoretical predictions of perforation dependent /

independent of the damping function , show good agreement with the individual

published test data of different projectiles and impact velocities as well as different

targets. At the same time, the contribution of dummy mass caused by deceleration effect

to penetration/perforation performance is quantitatively estimated.

REFERENCES

[1] Chen XW, Li XL, Chen YZ, Wu HJ , Huang FL, The Third Dimensionless Parameter in the

Penetration Dynamics of Rigid Projectiles, Acta Mechanica Sinica. (in Chinese), in press, 2006.03.

[2] Chen XW, Li QM, Deep penetration of a non-deformable projectile with different geometrical

characteristics, Int J Impact Eng., 27,61937 (2002)

[3] Li QM, Chen XW, Dimensionless formulae for penetration depth of concrete target impacted by a

non-deformable projectile, Int J Impact Eng., 28, 93116 (2003)

[4] Chen XW, Li QM, Perforation of a thick plate by rigid projectiles, Int J Impact Eng., 28,74359 (2003)

[5] Piekutowski AJ , Forrestal MJ , Poormon KL, Warren TL, Perforation of aluminum plates with ogive-

nose steel rods at normal and oblique impacts, Int J Impact Eng., 18, 877-87 (1996)

[6] Roisman IV, Weber K, Yarin Al, Hohler V, Rubin MB, Oblique penetration of a rigid projectile into a

thick elastic-plastic target: theory and experiment, Int J Impact Eng., 22, 707-26 (1999)

[7] Rosenberg Z, Forrestal MJ , Perforation of aluminium plates with conical-nosed rods-additional data

and discussion, J Appl Mech Trans ASME., 55, 236-8 (1988)

[8] Forrestal MJ , Luk VK, Perforation of aluminium armor plates with conical-nose projectiles, Mech

Mater 1990

También podría gustarte

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (344)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2099)

- Vibrational Diagnostics of Rotating Machinery Malfunctions AGNES MUSZYNSKADocumento31 páginasVibrational Diagnostics of Rotating Machinery Malfunctions AGNES MUSZYNSKAtylerdurdane100% (1)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (73)

- PHYC2121 General Physics 1 WEEK 11-20 WEWODocumento28 páginasPHYC2121 General Physics 1 WEEK 11-20 WEWORina Finees OlegarioAún no hay calificaciones

- Aerodynamic Flutter BannerDocumento11 páginasAerodynamic Flutter BannerRavi TejaAún no hay calificaciones

- Shock and Vibration Response Spectra Study Course - Tom IrvineDocumento268 páginasShock and Vibration Response Spectra Study Course - Tom IrvinebackvlackoAún no hay calificaciones

- EMC Filter Design With RB Common Mode ChokesDocumento22 páginasEMC Filter Design With RB Common Mode Chokeskaem1189Aún no hay calificaciones

- MCQ On VibrationsDocumento18 páginasMCQ On VibrationsAbhijit Dakare100% (4)

- Lindsay I Smith - A Tutorial On Principal Components AnalysisDocumento27 páginasLindsay I Smith - A Tutorial On Principal Components Analysisorestistsinalis100% (1)

- Chapter 12. FEMA 751-TextoDocumento64 páginasChapter 12. FEMA 751-TextoPaul RuizAún no hay calificaciones

- Harmonically Excited VibrationDocumento61 páginasHarmonically Excited VibrationSiddharth MohanAún no hay calificaciones

- Resonance and Analysis of Barton's Pendulum PDFDocumento17 páginasResonance and Analysis of Barton's Pendulum PDFmailbox_afeef2Aún no hay calificaciones

- Seismic Soil-Structure Interaction in BuildingsDocumento14 páginasSeismic Soil-Structure Interaction in Buildingsahha65100% (2)

- Seakeeping RAODocumento5 páginasSeakeeping RAOEgwuatu UchennaAún no hay calificaciones

- Optimization of Two Component Ceramic Armor For A Given ImpactDocumento6 páginasOptimization of Two Component Ceramic Armor For A Given ImpactsummerfarAún no hay calificaciones

- Composite 121Documento61 páginasComposite 121Ahmed DyalAún no hay calificaciones

- Aerodynamics Aeronautics and Flight Mechanics PDFDocumento94 páginasAerodynamics Aeronautics and Flight Mechanics PDFfatemeagAún no hay calificaciones

- ANSYS 10.0 Workbench Tutorial - Description of TutorialsDocumento7 páginasANSYS 10.0 Workbench Tutorial - Description of TutorialssangeethsreeniAún no hay calificaciones

- Pakistan Mirrored To Dutch EyesDocumento152 páginasPakistan Mirrored To Dutch EyesAhmed DyalAún no hay calificaciones

- Al7075 t651Documento5 páginasAl7075 t651Ahmed DyalAún no hay calificaciones

- Aero PrimerDocumento15 páginasAero Primernavendu123Aún no hay calificaciones

- IFEM Ch07 PDFDocumento19 páginasIFEM Ch07 PDFNitzOOAún no hay calificaciones

- ANSYS AutodynDocumento22 páginasANSYS AutodynAhmed Dyal100% (1)

- ANSYS Autodyn-1Documento11 páginasANSYS Autodyn-1Ahmed DyalAún no hay calificaciones

- 1239Documento6 páginas1239Ahmed DyalAún no hay calificaciones

- 2005/2006 AIAA Foundation Cessna/ONR Student Design Build Fly Competition Design ReportDocumento59 páginas2005/2006 AIAA Foundation Cessna/ONR Student Design Build Fly Competition Design ReportAhmed DyalAún no hay calificaciones

- Imp Fluent TutorialDocumento48 páginasImp Fluent TutorialAhmed DyalAún no hay calificaciones

- C Programming Basics For Udfs: C Fluent Inc. January 11, 2005Documento20 páginasC Programming Basics For Udfs: C Fluent Inc. January 11, 2005Saravanan PalanisamyAún no hay calificaciones

- C Programming Basics For Udfs: C Fluent Inc. January 11, 2005Documento20 páginasC Programming Basics For Udfs: C Fluent Inc. January 11, 2005Saravanan PalanisamyAún no hay calificaciones

- 10 1 1 116 824Documento8 páginas10 1 1 116 824Ahmed DyalAún no hay calificaciones

- Modeling of Pulsatile Blood Flow in An Axisymmetric Tube With A Moving IndentationDocumento22 páginasModeling of Pulsatile Blood Flow in An Axisymmetric Tube With A Moving IndentationAhmed DyalAún no hay calificaciones

- 0780360125Documento39 páginas0780360125Ahmed DyalAún no hay calificaciones

- Aerodynamics Aeronautics and Flight Mechanics PDFDocumento94 páginasAerodynamics Aeronautics and Flight Mechanics PDFfatemeagAún no hay calificaciones

- Aerodynamics Aeronautics and Flight Mechanics PDFDocumento94 páginasAerodynamics Aeronautics and Flight Mechanics PDFfatemeagAún no hay calificaciones

- Mechanik Lammert ContentDocumento3 páginasMechanik Lammert Contentapi-129423309Aún no hay calificaciones

- Module 3: The Damped Oscillator-II Lecture 3: The Damped Oscillator-IIDocumento5 páginasModule 3: The Damped Oscillator-II Lecture 3: The Damped Oscillator-IIMahendra PanwarAún no hay calificaciones

- Ekeeda - Applied Electronics and Instrumentation EngineeringDocumento110 páginasEkeeda - Applied Electronics and Instrumentation EngineeringekeedaAún no hay calificaciones

- N-Eupex y N-Eupex Ds - CatalogoDocumento25 páginasN-Eupex y N-Eupex Ds - CatalogoJohn Salazar0% (1)

- Forced Vibration of Euler-Bernoulli Beams by Means of Dynamic Greens FunctionsDocumento17 páginasForced Vibration of Euler-Bernoulli Beams by Means of Dynamic Greens FunctionsKannan SreenivasanAún no hay calificaciones

- BSC Grade System Pt. Ravishankar Shukla University PDFDocumento66 páginasBSC Grade System Pt. Ravishankar Shukla University PDFparmeshwar singhAún no hay calificaciones

- ESE Online Test Series: 2015 Conventional Paper: E & T: Electronics & Telecommunication EnggDocumento3 páginasESE Online Test Series: 2015 Conventional Paper: E & T: Electronics & Telecommunication EnggPraveen Kumar ArjalaAún no hay calificaciones

- Simple Harmonic MotionDocumento8 páginasSimple Harmonic MotionPratul NijhawanAún no hay calificaciones

- 342 B.sc.b.ed. Mdsu PDF 4yrDocumento135 páginas342 B.sc.b.ed. Mdsu PDF 4yrDINESH SALVIAún no hay calificaciones

- Creating Motion in SolidWorks-Motion DriversDocumento58 páginasCreating Motion in SolidWorks-Motion DriversManuj AroraAún no hay calificaciones

- Unit 2 Tutorial Solution Ahmed SirDocumento21 páginasUnit 2 Tutorial Solution Ahmed Sir20MEB005M SHAHIRIYAR SHAFIAún no hay calificaciones

- ME7327 MECHANICAL VIBRATION Question PaperDocumento2 páginasME7327 MECHANICAL VIBRATION Question PaperFaisal RahmaniAún no hay calificaciones

- The Damper Levels Influence On Vehicle Roll, Pitch, Bounce and Cornering Behaviour of Passenger Vehicles PDFDocumento78 páginasThe Damper Levels Influence On Vehicle Roll, Pitch, Bounce and Cornering Behaviour of Passenger Vehicles PDFDebra JacksonAún no hay calificaciones

- Vibration BySK MondalDocumento25 páginasVibration BySK MondalRahul KumarAún no hay calificaciones

- Schnorr Disk SpringsDocumento48 páginasSchnorr Disk SpringsFabrizio GrassoAún no hay calificaciones

- Mechanical-Shock Fragility of Products, Using Shock MachinesDocumento8 páginasMechanical-Shock Fragility of Products, Using Shock MachinesAlevj Db0% (1)

- Coupled PendulumsDocumento7 páginasCoupled PendulumsMatthew BerkeleyAún no hay calificaciones

- Pendulums - Noise, Mass, and Non-LinearityDocumento7 páginasPendulums - Noise, Mass, and Non-LinearityJohnHaineAún no hay calificaciones

- A Guide to Linear Dynamic Analysis with DampingDocumento15 páginasA Guide to Linear Dynamic Analysis with DampingPrashanth ReddyAún no hay calificaciones

- Lecture3 DKPDocumento2 páginasLecture3 DKPRishu AhujaAún no hay calificaciones