Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Hydraulic Shovels

Cargado por

exaguamhDescripción original:

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Hydraulic Shovels

Cargado por

exaguamhCopyright:

Formatos disponibles

Hydraulic Shovels

Product Line

2

Hydraulic Shovels

Cat hydraulic shovels are versatile machines used to load

overburden and ore into haul trucks during the mining

process in surface mines of all types across the globe.

Utilizing proven Cat technology, each hydraulic excavator

model is designed to provide superior digging forces and

optimal cycle times while withstanding the rigors of any

digging environment encountered. Our substantial global

installed base validates our experience and expertise in

the hydraulic mining excavator market and reaffrms

our commitment to it. With the widest payload range in

the industry, Caterpillar is well-equipped to fulfll any

hydraulic excavator need that global mining customers

may have.

Machine Service & Support

Caterpillar factory-trained service engineers are available

throughout the world to provide our customers with the

support necessary to meet their production requirements.

Our service engineers have the knowledge and experience

to bring a successful result to the most demanding

projects. In addition, they are backed by Caterpillars

team of engineers, who have design-based knowledge not

available from other sources.

Built to Last

Proven success in nearly every surface mining application across the globe substantiates the durability of

Cat

hydraulic shovels. Our equipment is engineered to endure the most difcult digging environments and the

harshest conditions to afford our customers the greatest productivity. Simply stated, Cat hydraulic shovels are

built to last.

3

TriPower

Caterpillar uses a unique boom design that employs

rotatable triangular rockers to generate superior

mechanical leverage and control. This unique Caterpillar

design results in:

Increased effective lifting force

Constant boom momentum

Automatic constant bucket angle position in horizontal

and vertical direction

Automatic roll-back limiter

Furthermore, the TriPower system enables Cat face shovels

to use smaller-diameter boom cylinders. This beneft

results in fast lifting speeds to outperform the competition.

Efcient Drive Systems

Cat hydraulic shovels are equipped with one or two

diesel engines or an electric drive option. On models

equipped with two engines, the hydraulic excavator

remains operational with only a single engine running,

maintaining full availability. The electric drive is used on

mainly stationary-operated machines and offers superior

availability because it doesnt require time to refuel and

servicing the motor is minimized.

Pump Managing System

The pump managing system continuously evaluates

actual engine and hydraulic operating values against

set values and adjusts pump output for optimal

performance. This results in an effcient use of the

engine for greater productivity.

Superior Oil Cooling System

The cooling system utilizes dedicated pumps to provide

cooling capacity as needed, whether the engine is idling

or under load, whereas our competitors machines only

provide cooling when the engine is under load and the

excavator is working. Consequently, on Cat hydraulic

shovels, the hydraulic oil circulates through the cooling

system even when the excavator is waiting for the next

truck. This system provides a more effcient means of

cooling, particularly in demanding applications. The

radiator fan speed is thermostatically or electronically

controlled for greater effciency.

TriPower

Diesel engine drive system

4

Closed-Loop Swing Circuit

The Cat closed-loop swing circuit results in fast boom lift

motions during swing. The kinetic energy of the swing

motion is used during deceleration to support driving the

main and auxiliary pumps. Compared to open circuits,

the Cat closed-loop swing circuit is more energy-effcient,

generates less heat and delivers faster speeds.

Simple & Efcient Hydraulic System

The main hydraulic valve block is located on top of the

boom. This design reduces the total number of hoses that

are needed and ensures theyre neatly organized for safe

operation, easy inspection and fast service.

Because foat valves are used to lower the boom instead

of engaging pumps, the boom moves faster and other

operating functions can occur simultaneously, such

as bucket curl and stick in/out. This results in faster

cycle times.

Sturdy Undercarriage

Cat undercarriages are tough and long-lasting. Engineered

with extensive use of Finite Element Analysis (FEA),

the steel structure is optimized, travel motors are

well-protected by strong cover plates and hinged door

covers, and a unique robust track chain incorporates a

combined pad/link design on most models. A state-of-

the-art track-tensioning system automatically adapts

the tensioning of the tracks depending on operating

conditions, extending the track life even further.

Monitoring and Diagnostic System

Enhancing diagnostic capabilities and providing detailed

troubleshooting functions, the Board Control System uses

sensors throughout the machine to monitor operating

data, record faults, and notify the operator audibly and

visually. This promotes the earliest possible detection of

faults and allows for timely maintenance planning and

assistance for speedy repair.

Main hydraulic valve block

Sturdy undercarriage

5

Electro-Hydraulic Control System

All larger-model Cat hydraulic shovels use an

electro-hydraulic control system that electronically

relays actuating signals from hand levers. Simplifed

troubleshooting and advanced diagnostic routines

lead to increased uptime. The design delivers fast and

precise machine reactions, which reduce operator fatigue

and increase effciency. For greater comfort, joystick

preferences are operator-adjustable. And since no

hydraulic lines are inside or underneath the cab, its a more

comfortable and clean work environment.

Machine Accessibility

Systems throughout Cat hydraulic shovels are designed for

easy access, enhancing serviceability.

Hydraulic Valve Block The valve block is located on

the boom where its cleanly laid out and easily accessed

by walkways on both sides. This reduces the number of

hoses leading from the superstructure.

Superstructure Exceptional accessibility is provided

to systems like the swing motor, swing gearbox and

rotary distributor in the well-organized superstructure.

The engine is accessible from three sides on most models.

Cat hydraulic shovels are equipped with retractable access

ladders. A less steep 45 folding stairway is available

as an option. An exit harness kit or a kick-down type,

cage-equipped ladder allows for safe egress in case of

emergency.

Board Control System

Accessibility

6

Safe, Comfortable Cab Design

Cat hydraulic excavator cabs have a falling object

protection system (FOPS) and meet DIN ISO 3449

standards. They are equipped with comfortable multi-

adjustable chairs, ample legroom, excellent visibility,

temperature control, sound abatement and ergonomically-

designed controls.

Windows: Safety glass is used for all windows and

armored glass for the windshield.

Seating: The pneumatically-cushioned, multi-adjustable

seat enhances operator productivity and includes a safety

switch in the cushion that automatically neutralizes the

hydraulic controls when the operator leaves the seat.

Display: A large, transfective color screen displays

monitoring and diagnostic data for convenient

troubleshooting and service assistance.

Five languages can be selected: English, French,

German, Spanish and Russian.

Safe Bucket Control

The TriPower roll-back limiter prevents

the bucket from being curled back too

far and minimizes the potential for

material to spill onto the attachment

or the cab. Lifting the bucket

automatically in constant-angle

position requires just a single

lever actuation.

Emergency Shut-Offs

An easily-accessible, standard shut-off switch located

in the cab shuts down the electrical system in case of

emergencies. Additional shut-off switches are located on

the machine (e.g., in the machine house) or are accessible

from the ground with pull ropes.

Safe, comfortable cab design

7

93.6 tonne (103 ton) payload capacity largest hydraulic

excavator in the market

Operating weight: 980 tonnes (1,080 tons)

Engine output: 3 360 kW (4,500 hp)

Standard bucket size: 52 m

3

(68 yd

3

)

3-pass load Cat 795F and Unit Rig MT4400

4-pass load Cat 797F, Unit Rig MT5500 and

Unit Rig MT6300

Available in electric or diesel drive

5-circuit hydraulic system

Closed-loop swing circuit with torque control

All major components are stress-relieved after welding

to minimize internal stresses

Automatic central lubrication system

Rugged, high-stability undercarriage

Spacious cab with ergonomically-designed controls

for added operator comfort

6090

8

50 tonne (55 ton) payload capacity

Operating weight: 525-534 tonnes (579-589 tons)

Engine output: 1 880 kW (2,520 hp)

Standard bucket size: 28 m

3

(36 yd

3

)

3-pass load Cat 785D and Unit Rig MT3300

4-pass load Cat 789C and Unit Rig MT3700

Available in diesel drive

5-circuit hydraulic system

Closed-loop swing circuit with torque control

All major components are stress-relieved after welding

to minimize internal stresses

Automatic central lubrication system

Spacious cab with ergonomically-designed controls

for added operator comfort

Rugged, high-stability undercarriage

Optional face shovel or backhoe conguration

6050

61 tonne (67 ton) payload capacity

Operating weight: 562-565 tonnes (620-622 tons)

Engine output: 2 240 kW (3,000 hp)

Standard bucket size: 34 m

3

(44.50 yd

3

)

3-pass load Cat 789C and Unit Rig MT3700

4-pass load Cat 793D and Unit Rig MT4400

Available in diesel or electric drive

5-circuit hydraulic system

Closed-loop swing circuit with torque control

All major components are stress-relieved after welding

to minimize internal stresses

Automatic central lubrication system

Spacious cab with ergonomically-designed controls

for added operator comfort

Rugged, high-stability undercarriage

Optional face shovel or backhoe conguration

6060

9

30 tonne (34 ton) payload capacity

Operating weight: 287-290 tonnes (316-319 tons)

Engine output: 1 140 kW (1,530 hp) /1 008 kW

(1,350 hp)

Standard bucket size: 17 m

3

(22.20 yd

3

)

3-pass load: Cat 777F Mining Truck

4-5-pass load Cat 785D and Unit Rig MT3300

Available in electric or diesel drive

5-circuit hydraulic system

Closed-loop swing circuit with torque control

All major components are stress-relieved after welding

to minimize internal stresses

Automatic central lubrication system

Spacious cab with ergonomically-designed controls for

added operator comfort

Rugged, high-stability undercarriage

Optional face shovel or backhoe conguration

6030

40 tonne (44 ton) payload capacity

Operating weight: 397 tonnes (438 tons)

Engine output: 1 516 kW (2,032 hp) /1 492 kW (2,000 hp)

Standard bucket size: 22 m

3

(28.80 yd

3

)

3-pass load Cat 777F Mining Truck

4-pass load Cat 789C, Cat 785D and Unit Rig MT3300

Available in electric or diesel drive5-circuit

hydraulic system

Closed-loop swing circuit with torque control

All major components are stress-relieved after welding

to minimize internal stresses

Automatic central lubrication system

Spacious cab with ergonomically-designed controls

for added operator comfort

Rugged, high-stability undercarriage

Optional face shovel or backhoe conguration

6040

10

18 tonne (20 ton) payload capacity

Operating weight: 172 tonnes (190 tons)

Engine output: 858 kW (1,150 hp)

Standard bucket size: 10 m

3

(13.10 yd

3

)

3-pass load Cat 773F

4-pass load Cat 775F

Available in electric or diesel drive

3-circuit hydraulic system

Closed-loop swing circuit with torque control

All major components are stress-relieved after welding

to minimize internal stresses

Automatic central lubrication system

Spacious cab with ergonomically-designed controls

for added operator comfort

Rugged, high-stability undercarriage

Optional face shovel or backhoe conguration

12.6 tonne (13.8 ton) payload capacity

Operating weight: 105 tonnes (116 tons)

Engine output: 522 kW (700 hp) /477 kW (640 hp)

Standard bucket size: 7.0 m

3

(9.2 yd

3

)

2-3-pass load Cat 770

3-4-pass load Cat 772

Utilized in both quarry and mine site applications

3-circuit hydraulic system

Triple-race swing roller bearing

Closed-loop swing circuit with torque control

Automatic central lubrication system

Spacious cab with ergonomically-designed controls

for added operator comfort

Rugged, high-stability undercarriage

Optional face shovel or backhoe conguration

6018

6015

11

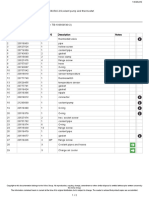

Excavator

PRODUCT

OPERATING

WEIGHT

SHOVEL BACKHOE OUTPUT

785D

MT3300

789C

MT3700

793D

MT4400

795F

MT5500

797F

MT6300

6090

980 tonnes

(1,080 tons)

52 m

3

(68.0 yd

3

)

N/A

3 360 kW

(4,500 hp)

3 passes 3-4 passes 4 passes

6060

562-565 tonnes

(620-622 tons)

34 m

3

(44.5 yd

3

)

34 m

3

(44.5 yd

3

)

2 240 kW

(3,000 hp)

3 passes 3-4 passes 5 passes 6 passes

6050

525-534 tonnes

(579-589 tons)

26 m

3

(34 yd

3

)

28 m

3

(36.6 yd

3

)

1 880 kW

(2,520 hp)

3 passes 4 passes 4-5 passes 6-7 passes 7-8 passes

6040

397 tonnes

(438 tons)

22 m

3

(28.8 yd

3

)

22 m

3

(28.8 yd

3

)

1 492-1 516 kW

(2,000-2,032 hp)

4 passes 5 passes 5-6 passes

6030

287-290 tonnes

(316-319 tons)

16.5 m

3

(21.6 yd

3

)

17 m

3

(22.2 yd

3

)

1 008-1 140 kW

(1,350-1,530 hp)

4-5 passes 6 passes

6018

172-175 tonnes

(190-193 tons)

10 m

3

(13.1 yd

3

)

10 m

3

(13.1 yd

3

)

858 kW

(1,150 hp)

7-8 passes

6015

105 tonnes

(116 tons)

7 m

3

(9.2 yd

3

)

6.0/7.0 m

3

(7.8-9.2 yd

3

)

477-522 kW

(640-700 hp)

6090

3-pass load Cat 795F and Unit Rig MT4400

4-pass load Cat 797F, Unit Rig MT5500 and Unit Rig MT6300

6060

3-pass load Cat 789C and Unit Rig MT3700

4-pass load Cat 793D and Unit Rig MT4400

6050

3-pass load Cat 785D and Unit Rig MT3300

4-pass load Cat 789C and Unit Rig MT3700

6040

3-pass load Cat 777F

4-pass load Cat 785D, Cat 789C and Unit Rig MT3300

6030

3-pass load Cat 777F

4-5 pass load Cat 785D and Unit Rig MT3300

6018

3-pass load Cat 773F

4-pass load Cat 775F

6015

2-3 pass load Cat 770

3-4 pass load Cat 772

4-5 pass load Cat 773F

#20 #24

For more complete information on Cat products, dealer services, and industry solutions,

visit us on the web at mining.cat.com and www.cat.com

2011 Caterpillar Inc.

All rights reserved

Materials and specications are subject to change without notice. Featured machines in

photos may include additional equipment. See your Cat dealer for available options.

CAT, CATERPILLAR, their respective logos, Caterpillar Yellow and the Power Edge trade

dress, as well as corporate and product identity used herein, are trademarks of Caterpillar and

may not be used without permission.

AEXQ0597

Hydraulic Shovels Product Line

También podría gustarte

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2099)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (73)

- Toro WheelHorse Accessories Interchange 2000-1955-2000Documento110 páginasToro WheelHorse Accessories Interchange 2000-1955-2000Kevins Small Engine and Tractor Service100% (2)

- Centrifugal and Reciprocating Pump Failure AnalysisDocumento16 páginasCentrifugal and Reciprocating Pump Failure AnalysisSamsudin Ahmad75% (4)

- 44 Manual Nissan Sentra 2013Documento195 páginas44 Manual Nissan Sentra 2013David100% (1)

- Pid Legend PDFDocumento1 páginaPid Legend PDFSocMed Dtk UI0% (1)

- Parts Manual: D6T Track-Type TractorDocumento54 páginasParts Manual: D6T Track-Type TractorFabio MacielAún no hay calificaciones

- N74 Engine Technical OverviewDocumento51 páginasN74 Engine Technical OverviewChris Ce100% (3)

- Compact and Efficient: Rotary KilnsDocumento4 páginasCompact and Efficient: Rotary KilnsNhaca100% (1)

- TMTW Orbital Motor Repair InstructionDocumento24 páginasTMTW Orbital Motor Repair InstructionServicio TLMAún no hay calificaciones

- Qa QCDocumento4 páginasQa QCexaguamhAún no hay calificaciones

- AppendixI PDFDocumento2 páginasAppendixI PDFexaguamhAún no hay calificaciones

- BMiller CoreValues 2015Documento19 páginasBMiller CoreValues 2015exaguamhAún no hay calificaciones

- PC2000-8Documento10 páginasPC2000-8Deden WahyudiyantoAún no hay calificaciones

- PC2000-8Documento10 páginasPC2000-8Deden WahyudiyantoAún no hay calificaciones

- AppendixI PDFDocumento2 páginasAppendixI PDFexaguamhAún no hay calificaciones

- Guia de Usuario RotaryDocumento20 páginasGuia de Usuario Rotaryexaguamh100% (1)

- AppendixI PDFDocumento2 páginasAppendixI PDFexaguamhAún no hay calificaciones

- Silver Crest Mines SG testing reportDocumento1 páginaSilver Crest Mines SG testing reportexaguamhAún no hay calificaciones

- HP-360 Single Arm Touchless Car Wash MachineDocumento2 páginasHP-360 Single Arm Touchless Car Wash MachineMizanur RahmanAún no hay calificaciones

- Broaching PDFDocumento7 páginasBroaching PDFBalaji Karunakaran100% (1)

- trsl0261 0510Documento2 páginastrsl0261 0510Darrinel Perez CcordovaAún no hay calificaciones

- Service Parts List: Diesel EngineDocumento44 páginasService Parts List: Diesel Enginepedro perezAún no hay calificaciones

- SPC4 M33Documento1 páginaSPC4 M33zliangAún no hay calificaciones

- FESCO Fire PumpsDocumento24 páginasFESCO Fire PumpsZeeshan HameedAún no hay calificaciones

- Work Holding Devices-Milling, Shaping, Planing & Slotting MachinesDocumento25 páginasWork Holding Devices-Milling, Shaping, Planing & Slotting MachinesMukhil Rajasekaran33% (3)

- TLZ THLZDocumento69 páginasTLZ THLZwiemez100% (1)

- Appendix VI Diagram For Class I, Div. 1 Lighting InstallationDocumento3 páginasAppendix VI Diagram For Class I, Div. 1 Lighting InstallationcassianohcAún no hay calificaciones

- Husqvarna 449/511 BrochureDocumento48 páginasHusqvarna 449/511 BrochureJoergAún no hay calificaciones

- Valvula TermostáticaDocumento2 páginasValvula TermostáticaSuyla CabralAún no hay calificaciones

- Tractor FORD 4000 4Documento8 páginasTractor FORD 4000 4Alex CastilloAún no hay calificaciones

- كارير كونسيلد الجديدDocumento45 páginasكارير كونسيلد الجديدEZAY ازايAún no hay calificaciones

- 172389682Documento10 páginas172389682mohalonsoAún no hay calificaciones

- Engine Design ReportDocumento7 páginasEngine Design Reportapi-251800888Aún no hay calificaciones

- Overview of Mechanical Equipment in RefineryDocumento54 páginasOverview of Mechanical Equipment in RefineryShantanu Samajdar0% (1)

- Is 1855-1977 Specification For Stranded Steel Wire Ropes For Winding and Man-Ridiing Haulages in MinesDocumento12 páginasIs 1855-1977 Specification For Stranded Steel Wire Ropes For Winding and Man-Ridiing Haulages in MinesDeepjyoti DasAún no hay calificaciones

- Motorbike SpecificationsDocumento3 páginasMotorbike SpecificationsMaira ShafiqAún no hay calificaciones

- Preciso Adjustment Ring Replacement v1.2Documento6 páginasPreciso Adjustment Ring Replacement v1.2ipaqiAún no hay calificaciones

- Wa0001 PDFDocumento25 páginasWa0001 PDFMuntandwe georgeAún no hay calificaciones

- Sae J708 1999 (En)Documento13 páginasSae J708 1999 (En)Oh No PotatoAún no hay calificaciones

- Test2see3433 QuestionDocumento2 páginasTest2see3433 QuestionFizah Abdul RahmanAún no hay calificaciones