Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Heavy Duty

Cargado por

manu_chat0 calificaciones0% encontró este documento útil (0 votos)

20 vistas2 páginasHeavy Duty Track is designed to meet the needs of T, R, N, M, and H-Series machines. It features: Redesigned links, pins, and bushings for enhanced strength, durability. 20% additional rail wear material for extended system life.

Descripción original:

Título original

HeavyDuty

Derechos de autor

© © All Rights Reserved

Formatos disponibles

PDF, TXT o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoHeavy Duty Track is designed to meet the needs of T, R, N, M, and H-Series machines. It features: Redesigned links, pins, and bushings for enhanced strength, durability. 20% additional rail wear material for extended system life.

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

0 calificaciones0% encontró este documento útil (0 votos)

20 vistas2 páginasHeavy Duty

Cargado por

manu_chatHeavy Duty Track is designed to meet the needs of T, R, N, M, and H-Series machines. It features: Redesigned links, pins, and bushings for enhanced strength, durability. 20% additional rail wear material for extended system life.

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

Está en la página 1de 2

Heavy Duty Track

A Sealed and Lubricated Track for Medium Size

T, R, N, M, and H-Series Track-Type Tractors

Increased durability and wear life

T, R, N, M, and H-Series machines, because of their versatility, are used in all types of underfoot conditions.

This tests the limits of undercarriage structural reliability, wear life, and sealability. Heavy Duty Track is

designed to meet the needs of T, R, N, M, and H-Series machines. It is strong enough for aggressive impact

applications, yet has the necessary wear material for long life in abrasive conditions.

It features:

Redesigned links, pins, and bushings for enhanced strength, durability, and retention.

20% additional rail wear material for extended system life.

*

*Results may vary.

2

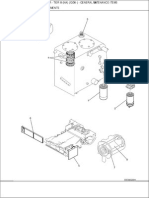

3

4

1

1. Wider pin boss

2. Wider bushing strap

3. Longer track pin and bushing

4. More rail wear material

Heavy Duty Track

PEHP5031-02

www.cat.com

2008 Caterpillar All Rights Reserved Printed in USA

CAT, CATERPILLAR, their respective logos, Caterpillar Yellow and the POWER EDGE trade dress, as well as

corporate and product identity used herein, are trademarks of Caterpillar and may not be used without permission.

Partnership to extend

system life

When you buy a Cat undercarriage system,

you get the support of our Custom Track Ser-

vice (CTS) professionals who have tools

to help you manage your undercarriage

system. They monitor and inspect your track

regularly and provide reports listing service

options that help you make informed deci-

sions concerning service. This allows you to

schedule maintenance and not be blind-sided

by costly, unscheduled downtime.

When your track does need repair, we have

the trained professionals, proper equipment,

and excellent parts availability to get you up

and running quickly and done right the rst

time.

CAT

DEALERS DEFINE WORLD-

CLASS PRODUCT SUPPORT.

We offer you the right parts and service

solutions, when and where you need them.

The Cat Dealer network of highly trained

experts can help you maximize your equipment

investment.

HEAVY DUTY COMPONENT COMPARED TO SALT*

BENEFIT

Structural enhancements

Link bushing strap 65% wider Greater bushing retention

Increased strength

Link pin boss 20% wider Increased pin retention

Bushing 10% longer More press ft area

Increased retention

Pin 14% longer More press ft area

Increased retention

Wear life enhancement

Link rail 20% more wear material Extended link/roller system life

*SALT stands for Sealed and Lubricated Track.

Comparison percentages based on D6H.

Link top view

Link side view

Link

65% wider

bushing

strap

20% wider

pin boss

20% more

rail wear

material

Pin and

Bushing

10% longer

bushing

14% longer

pin

Innovative design

Heavy Duty Track is more than an enhancement of conventional Sealed & Lubricated Track. It is a

completely new design, engineered to match the requirements of medium size T, R, N, M & H-Series

machines. It features redesigned links, pins, and bushings that signicantly offset the effects of high

impact loads and stresses. Additionally, 20% more wear material has been added to the links for

increased wear life.

Combined structural and wear life enhancements result in lower owning and operating

costs through:

Enhanced track joint retention and sealability.

Stronger components that resist cracking and breakage.

Extended system wear life.

Expect longer life

In most underfoot conditions, you can expect Heavy Duty Track to extend undercarriage system life an

average 20%.

*

The greatest benets are realized in aggressive, high impact applications such as:

Logging/reforestation.

Side-sloping work.

Rocky conditions.

Any uneven terrain with wide track shoes (specifcally LGP machines).

También podría gustarte

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- Understanding ISO 4406 CodesDocumento2 páginasUnderstanding ISO 4406 CodesOwen Hizriawan100% (3)

- Analyse de Cycle de Vie-L PDFDocumento29 páginasAnalyse de Cycle de Vie-L PDFmanu_chatAún no hay calificaciones

- Current Best PracticesDocumento8 páginasCurrent Best Practicesmanu_chatAún no hay calificaciones

- Tanques Hidroneumaticos WellmateDocumento1 páginaTanques Hidroneumaticos Wellmatemanu_chatAún no hay calificaciones

- Heavy DutyDocumento2 páginasHeavy Dutymanu_chatAún no hay calificaciones

- Selectind AccelerometersDocumento8 páginasSelectind Accelerometersmanu_chatAún no hay calificaciones

- Acera Mark 8 Excavator Tier III Maintenance ItemsDocumento645 páginasAcera Mark 8 Excavator Tier III Maintenance Itemsmanu_chat97% (35)

- F. Is.20. Quejas Sobre El Freno Motor. Edicion 1. (Ingles)Documento9 páginasF. Is.20. Quejas Sobre El Freno Motor. Edicion 1. (Ingles)manu_chat0% (1)

- Generators Provide Power : in This IssueDocumento12 páginasGenerators Provide Power : in This Issuemanu_chatAún no hay calificaciones

- CM3002 Sensors in CMDocumento3 páginasCM3002 Sensors in CMmanu_chatAún no hay calificaciones

- Too Much VibrationDocumento8 páginasToo Much Vibrationmanu_chatAún no hay calificaciones

- CM5012 Petrochem RefineryDocumento2 páginasCM5012 Petrochem Refinerymanu_chatAún no hay calificaciones

- CM1010 Utilizing SDGEDocumento3 páginasCM1010 Utilizing SDGEmanu_chatAún no hay calificaciones

- CM1010 Utilizing SDGEDocumento3 páginasCM1010 Utilizing SDGEmanu_chatAún no hay calificaciones

- 60 Question For Lube SuppliersDocumento12 páginas60 Question For Lube SuppliershungAún no hay calificaciones

- CM1004 Balance UnbalancedDocumento4 páginasCM1004 Balance Unbalancedmanu_chatAún no hay calificaciones

- CM3067 On-Line GearboxesDocumento8 páginasCM3067 On-Line Gearboxesmanu_chatAún no hay calificaciones

- Story of Vibration AnalysisDocumento14 páginasStory of Vibration AnalysisCrusherjpAún no hay calificaciones

- MINING TRUCK 793 C (Camion Minero)Documento24 páginasMINING TRUCK 793 C (Camion Minero)Christian KariAún no hay calificaciones

- Principios de ElectricidadDocumento15 páginasPrincipios de Electricidadmanu_chatAún no hay calificaciones

- Motor Acert C4.C6Documento20 páginasMotor Acert C4.C6manu_chatAún no hay calificaciones

- NPR Information in SISDocumento10 páginasNPR Information in SISmanu_chatAún no hay calificaciones

- Codigos STWDocumento37 páginasCodigos STWmanu_chat100% (1)

- T7 CompressorDocumento4 páginasT7 Compressormanu_chatAún no hay calificaciones

- T400 Datasheet APACDocumento3 páginasT400 Datasheet APACmanu_chatAún no hay calificaciones

- Iso1219 SymbolsDocumento20 páginasIso1219 Symbolsjafornelas100% (2)

- Flir 12 Things To Consider Before Buying An Infrared CameraDocumento19 páginasFlir 12 Things To Consider Before Buying An Infrared Cameramanu_chatAún no hay calificaciones

- 2 Future of MonitoringDocumento4 páginas2 Future of MonitoringWILLSONQYAún no hay calificaciones

- Software APT-Maintenance BrochureDocumento2 páginasSoftware APT-Maintenance Brochuremanu_chat100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (73)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2219)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (119)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2099)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- Reaction PaperDocumento2 páginasReaction PaperRonald CostalesAún no hay calificaciones

- Julia Warner 2018Documento1 páginaJulia Warner 2018Julia WarnerAún no hay calificaciones

- Industrial HygieneDocumento31 páginasIndustrial HygieneGautam SharmaAún no hay calificaciones

- Active Directory Command Line OneDocumento9 páginasActive Directory Command Line OneSreenivasan NagappanAún no hay calificaciones

- Dissertation ErsatzteilmanagementDocumento7 páginasDissertation ErsatzteilmanagementWriteMyEnglishPaperForMeCanada100% (1)

- Vlsi Implementation of Integer DCT Architectures For Hevc in Fpga TechnologyDocumento12 páginasVlsi Implementation of Integer DCT Architectures For Hevc in Fpga TechnologyRaghul VishnuAún no hay calificaciones

- Grant Park Platform Bedroom Set Furniture RowDocumento1 páginaGrant Park Platform Bedroom Set Furniture Rowjyzjz6sr65Aún no hay calificaciones

- HEN SPF Roof Manual Spray Polyurethane FoamDocumento77 páginasHEN SPF Roof Manual Spray Polyurethane FoamDavaakhuu ErdeneeAún no hay calificaciones

- Sample Lab ReportDocumento4 páginasSample Lab ReportHolley WrightAún no hay calificaciones

- UntitledDocumento47 páginasUntitledAndy SánchezAún no hay calificaciones

- Results Part III - Part III-March 2017 - ElectricalDocumento3 páginasResults Part III - Part III-March 2017 - ElectricalTharaka MunasingheAún no hay calificaciones

- Computer Science: FieldsDocumento2 páginasComputer Science: FieldstdoraxAún no hay calificaciones

- Sources of Release Schedule For Hazardous Area ClassificationDocumento1 páginaSources of Release Schedule For Hazardous Area ClassificationMachmud Ragil'sAún no hay calificaciones

- 6303A HP Flare Drain DrumDocumento16 páginas6303A HP Flare Drain DrumMohammad MohseniAún no hay calificaciones

- OceanPixel Abundo Marine Renewable Energy An Emerging OptionDocumento96 páginasOceanPixel Abundo Marine Renewable Energy An Emerging OptionjopaypagasAún no hay calificaciones

- PV Design WorksheetDocumento4 páginasPV Design WorksheetLarry Walker II100% (1)

- Plett DawsonDocumento270 páginasPlett DawsonRaghu0% (1)

- Introduction To PLCsDocumento42 páginasIntroduction To PLCsArun Kumar YadavAún no hay calificaciones

- Hughes Brothers PDFDocumento52 páginasHughes Brothers PDFJavier MaldonadoAún no hay calificaciones

- Gillette and The Men's Wet Shaving Market: Group 8 Section BDocumento12 páginasGillette and The Men's Wet Shaving Market: Group 8 Section BAmit Hemant JainAún no hay calificaciones

- Aksin Et Al. - The Modern Call Center - A Multi Disciplinary Perspective On Operations Management ResearchDocumento24 páginasAksin Et Al. - The Modern Call Center - A Multi Disciplinary Perspective On Operations Management ResearchSam ParkAún no hay calificaciones

- Advances in Remediation-eBookDocumento88 páginasAdvances in Remediation-eBookalinerlfAún no hay calificaciones

- Conceptual Design Deliverables Latest Rev2Documento14 páginasConceptual Design Deliverables Latest Rev2dhanu_lagwankarAún no hay calificaciones

- CV Summary for IT Position Seeking Recent GraduateDocumento5 páginasCV Summary for IT Position Seeking Recent Graduateeang barangAún no hay calificaciones

- 13-2021مواصفات الفنية لقطع غيار المكيفاتDocumento4 páginas13-2021مواصفات الفنية لقطع غيار المكيفاتTawfeeq Al-HababbiAún no hay calificaciones

- Performance Estimation of Ofdm-Wimax Network: Vishal Sharma & Navneet KaurDocumento8 páginasPerformance Estimation of Ofdm-Wimax Network: Vishal Sharma & Navneet KaurTJPRC PublicationsAún no hay calificaciones

- Nord Motors Manual BookDocumento70 páginasNord Motors Manual Bookadh3ckAún no hay calificaciones

- SPW3 Manual Rev 5Documento713 páginasSPW3 Manual Rev 5JPYadavAún no hay calificaciones

- LogDocumento27 páginasLogmilli0chilliAún no hay calificaciones

- Method Statement For Cable & TerminationDocumento6 páginasMethod Statement For Cable & TerminationRajuAún no hay calificaciones