Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Motor Kia Sportage

Cargado por

carbutz100%(3)100% encontró este documento útil (3 votos)

1K vistas36 páginas2002 ENGINES 2.0L 4-Cylinder - Sportage ENGINE IDENTIFICATION Engine can be identified by the eighth character of the Vehicle Identification Number (VIN) stamped on metal plate located on left side of dash panel. Engine is equipped with hydraulic lash adusters. No adustment is required.

Descripción original:

Derechos de autor

© © All Rights Reserved

Formatos disponibles

PDF, TXT o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documento2002 ENGINES 2.0L 4-Cylinder - Sportage ENGINE IDENTIFICATION Engine can be identified by the eighth character of the Vehicle Identification Number (VIN) stamped on metal plate located on left side of dash panel. Engine is equipped with hydraulic lash adusters. No adustment is required.

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

100%(3)100% encontró este documento útil (3 votos)

1K vistas36 páginasMotor Kia Sportage

Cargado por

carbutz2002 ENGINES 2.0L 4-Cylinder - Sportage ENGINE IDENTIFICATION Engine can be identified by the eighth character of the Vehicle Identification Number (VIN) stamped on metal plate located on left side of dash panel. Engine is equipped with hydraulic lash adusters. No adustment is required.

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

Está en la página 1de 36

2002 ENGINES

2.0L 4-Cylinder - Sportage

ENGINE IDENTIFICATION

Engine can be identified by the eighth character of the Vehicle Identification Number (VIN)

stamped on metal plate located on left side of dash panel. The VIN is also stamped into

passenger side of engine compartment bulkhead.

ENGINE IDENTIFICATION CODE

ADJST!ENTS

VALVE CLEARANCE ADJUSTMENT

This engine is equipped with hydraulic lash adusters. No adustment is required.

T"O#LE S$OOTING

To trouble shoot engine mechanical components! see appropriate table in T"#$%&E

'(##TIN) article in )ENE"*& IN+#",*TI#N.

"E!O%AL & INSTALLATION

FUEL PRESSURE RELEASE

To release fuel pressure! remo-e rear seat cushion and fuel pump access plate. .isconnect fuel

pump connector. 'ee Fig. 1 . 'tart and run engine until it stalls. Turn ignition off. #nce repairs

ha-e been completed! reconnect fuel pump connector and install access plate and rear seat

cushion.

NOTE' For repair pro(ed)re* not (o+ered in t,i* arti(le- *ee ENGINE

O%E"$AL ."OCED"ES arti(le in GENE"AL INFO"!ATION.

Application Cod

/.0& .#(1 2

NOTE' For rea**e/0ly re1eren(e- la0el all ele(tri(al (onne(tor*- +a())/

,o*e* and 1)el line* 0e1ore re/o+al. Al*o pla(e /ating /ar2* on

engine ,ood and ot,er /a3or a**e/0lie* 0e1ore re/o+al.

2002 4ia Sportage

2002 ENGINES 2.0L 4-Cylinder - Sportage

2002 4ia Sportage

2002 ENGINES 2.0L 4-Cylinder - Sportage

Hewlett-Packard

s!ado" 02 de agosto de 20#4 0$%4#%4# a.&. Page # ' 20## (itc)ell *epair In+or&ation Co&pany" LLC.

Hewlett-Packard

s!ado" 02 de agosto de 20#4 0$%4#%4, a.&. Page # ' 20## (itc)ell *epair In+or&ation Co&pany" LLC.

Fig. 1: Locating Fuel Pump Electrical Connector

Courtesy of KIA MOTO! AMEICA" I#C.

E#$I#E

emo%al & Installation

1. Release fuel pressure. See F'EL PE!!'E ELEA!E . Remove windshield washer

from hood. Remove hood. Disconnect battery cables. Remove battery cover, battery and

battery tray. Remove air inlet duct and air cleaner assembly. On A/T models, remove

accelerator cable and transmission control cable.

. On all models, pull bac! throttle shaft, and disconnect accelerator cable. Remove

resonance chamber mountin" bolt, chamber bolt and air silencer. Remove #A$ air hose,

breather hose and vacuum line from air inta!e tube.

%. Disconnect &A' sensor connector. (oosen air inlet hose clamp from &A' sensor.

Remove % bolts from air inta!e tube to throttle body. Remove air inta!e hose and air

inta!e tube as an assembly.

). Remove radiator cap. (oosen radiator drain plu", and drain en"ine coolant. Ti"hten

2002 4ia Sportage

2002 ENGINES 2.0L 4-Cylinder - Sportage

Hewlett-Packard

s!ado" 02 de agosto de 20#4 0$%4#%4# a.&. Page 2 ' 20## (itc)ell *epair In+or&ation Co&pany" LLC.

radiator drain plug. Loosen and remove upper radiator hose clamps, and remove upper

radiator hose. Remove 4 thermo-modulated fan nuts.

5. Remove 5 cooling fan shroud bolts. Remove fan and fan shroud as an assembly. Loosen

generator mounting bolts. Loosen generator drive belt by loosening adjusting bolt.

6. Remove fan pulley. Remove generator electrical connectors. Remove heater hoses from

pipes.

7. Label and disconnect all necessary electrical connectors, ires, hoses and control cables

for engine removal. !lug all fuel hoses to avoid lea"age. Remove radiator.

#. Raise and support vehicle. Remove undercover mounting bolts and undercover. Loosen

$%& idler pulley loc" nut, and remove $%& drive belt by loosening adjusting bolt. Remove

$%& idler pulley brac"et mounting bolts and $%& idler pulley brac"et.

'. Remove $%& compressor mounting bolts and $%& compressor. !osition $%& compressor

aay from engine. Loosen poer steering pump loc" bolt and mounting bolt, and remove

poer steering drive belt. Remove poer steering pump loc" bolt and mounting bolt.

!osition poer steering pump aay from engine.

(). Remove inta"e manifold support brac"et bolts and brac"et. Remove starter bolts. *nbolt

starter, and ire aside so there is no tension on ire harness. Remove converter inlet pipe

flange loc" nuts.

((. Remove front e+haust brac"et bolt. ,n -%. models, remove e+haust brac"et-to-clutch

housing mounting bolts and brac"et. ,n $%. models, remove converter housing mounting

bolts and brac"et. ,n -%. models, remove clutch housing-to-engine mounting bolts. ,n

$%. models, remove converter housing-to-engine mounting bolts.

(/. ,n all models, loer vehicle. ,n $%. models, remove 6 drive plate-to-tor0ue converter

bolts. ,n all models, support transmission, and connect engine hoist to engine. Remove

left side and right side engine mounting bolts.

(1. Lift engine up until free of frame, and move forard to clear transmission. 2isconnect 1

remaining electrical connectors at bac" of engine. &hec" for any other electrical iring

still connected to engine assembly and disconnect, if necessary. 3nsure engine is free of

any other components. Remove engine from vehicle.

Installation

.o install, reverse removal procedure. .ighten all bolts%nuts to specification. 4ee TORQUE

SPECIFICATIONS . &hec" fluid levels, and fill as necessary.

INTAKE MANIFOLD

Removal

(. Release fuel system pressure. 4ee FUEL PRESSURE RELEASE . 2isconnect negative

2002 4ia Sportage

2002 ENGINES 2.0L 4-Cylinder - Sportage

Hewlett-Packard

s!ado" 02 de agosto de 20#4 0$%4#%4# a.&. Page ' ( 20## )itc*ell +epair In,or&ation Co&pany" LLC.

!attery ca!le. *e&o-e 2 accelerator ca!le !racket-to-cylinder )ead co-er !olts. *e&o-e

air intake t.!e-to-cylinder co-er !olts. *e&o-e air intake t.!e-to-t)rottle !ody !olts.

Loosen cla&p +ro& air intake )ose to (ass /ir+ow 0(/12 sensor.

2. *e&o-e idler control -al-e )ose" !reat)er )ose and -ac..& line +ro& air intake t.!e.

*e&o-e air intake t.!e and air intake )ose as an asse&!ly. *e&o-e PC3 )ose +ro&

dyna&ic c)a&!er. *e&o-e radiator cap. Loosen radiator drain pl.g" and drain engine

coolant. 4ig)ten radiator drain pl.g.

5. *e&o-e p.rge solenoid -al-e -ac..& )ose +ro& dyna&ic c)a&!er. 6isconnect electrical

connector +ro& t)rottle position sensor. 6isconnect electrical connection +ro& idle air

control -al-e. *e&o-e )eater )oses +ro& pipes. *e&o-e engine-to-!ody gro.nd !olt at

intake &ani+old asse&!ly. *e&o-e )eater )oses +ro& !elow t)rottle !ody.

4. *e&o-e !rake !ooster -ac..& line. *e&o-e -ac..& )ose +ro& +.el press.re reg.lator.

*e&o-e dyna&ic c)a&!er s.pport !rackets and !olts. 6isconnect electrical connectors

+ro& +.el in7ectors !y p.s)ing on wire clips. *elease +.el syste& press.re. See FUEL

PRESSURE RELEASE .

8. 6isconnect +.el line +ro& press.re reg.lator. 6isconnect +.el ret.rn line +ro& +.el rail

asse&!ly. *e&o-e intake &ani+old s.pport !rackets 0side and rear2.

9. :sing wrenc)" re&o-e oil +ilter. *e&o-e !olts and n.ts +ro& intake &ani+old. *e&o-e !y-

pass pipe +ro& )eater )ose. *e&o-e intake &ani+old and gasket.

Installation

Clean gasket &ating s.r+aces. Install intake &ani+old wit) NE; gasket. Install !y-pass pipe.

Install intake &ani+old !olts and n.t" and tig)ten to speci+ication. See Fig. 2 . 4o co&plete

installation" re-erse re&o-al proced.re. 4ig)ten all !olts and n.ts to speci+ication. See

TORQUE SPECIFICATIONS .

2002 4ia Sportage

2002 ENGINES 2.0L 4-Cylinder - Sportage

Hewlett-Packard

s!ado" 02 de agosto de 20#4 0$%4#%4# a.&. Page 4 ( 20## )itc*ell +epair In,or&ation Co&pany" LLC.

Fig. 2: Intake Manifold Mounting Bolt Locations

Courtesy of KIA MOTOR AM!RICA" I#C.

!$%A&T MA#IFOL'

Re(o)al

6isconnect negati-e !attery ca!le. Loosen air intake )ose cla&ps" and re&o-e air intake )ose.

*e&o-e e<)a.st &ani+old )eat s)ield. *e&o-e 8 con-erter inlet pipe +lange lock n.ts. *e&o-e

e<)a.st &ani+old !olts. *e&o-e e<)a.st &ani+old and gasket.

2002 4ia Sportage

2002 ENGINES 2.0L 4-Cylinder - Sportage

Hewlett-Packard

s!ado" 02 de agosto de 20#4 0$%4#%4# a.&. Page ' ( 20## )itc*ell +epair In,or&ation Co&pany" LLC.

Installation

Ensure gasket mating surfaces are clean and flat. Install NEW gasket to cylinder head. Install

manifold. Tighten manifold bolts and nuts evenly to specification, starting from center bolt and

alternating outward. Install NEW gasket, and attach converter inlet pipe. To complete

installation, reverse removal procedure. See TORQUE SPECIFICATIONS .

CYLINDER HEAD

Removal

. !isconnect negative battery cable. "emove brake booster vacuum hose from dynamic

chamber. "emove fuel line from pressure regulator and return line located at rear of

dynamic chamber.

#. "emove engine$to$body ground wire from intake manifold and harness bracket. "emove

radiator cap. "emove radiator drain plug, and drain engine coolant. Tighten radiator plug.

%. "emove purge solenoid valve vacuum hose from dynamic chamber. &oosen clamps, and

disconnect upper radiator hose. "emove intake manifold support bracket bolts and bracket.

"emove converter inlet pipe flange lock nuts. "emove timing belt. See TIMING BELT .

'. "emove cylinder head cover. "emove cylinder head bolts in se(uence. See Fi! " .

!isconnect wire harness connectors on back of cylinder head. &ift cylinder head off

cylinder block with intake and e)haust manifolds attached, and remove cylinder head

assembly from vehicle.

Ins#e$tion

*arefully clean carbon and gasket material from all mating surfaces. *lean threads of cylinder

head bolts. +se tap to clean threads in engine block. *heck cylinder head for warpage and

cracks. "esurface or replace head if it is not within specification. *heck valve train components.

"eplace or resurface components if not within specification. See CYLINDER HEAD and

%AL%ES & %AL%E SPRINGS tables under EN,INE S-E*I.I*/TI0NS.

Installation

. Install cylinder head gasket. -lace cylinder head with manifolds installed over cylinder

block, and attach % wire harness connectors to back of head. Install cylinder head assembly

and cylinder head bolts. +sing % e(ual steps, tighten cylinder head bolts in specified

se(uence. See Fi! '( . See TORQUE SPECIFICATIONS .

#. Install timing belt. See TIMING BELT . Install converter inlet pipe flange lock nuts, and

tighten to specification. See TORQUE SPECIFICATIONS .

%. Install upper radiator hose, and tighten clamps. .ill radiator, and install cap. *onnect

vacuum hose from intake manifold to charcoal canister. *onnect purge solenoid vacuum

2002 -ia Sportage

2002 ENGINES 2.0L 4-Cylinder - Sportage

Hewlett-Packard

s!ado" 02 de agosto de 20#4 0$%4#%4# a.&. Page ' ( 20## )itc*ell +epair In,or&ation Co&pany" LLC.

hose to dynamic chamber. Install engine$to$body ground wire and harness bracket to

intake manifold.

'. Install fuel line to pressure regulator and return line to fuel rail. Install brake booster

vacuum hose to dynamic chamber. "econnect battery cable. Tighten bolts and nuts to

specification. See TORQUE SPECIFICATIONS .

Fig. 3: Cylinder Head Bolt Remoal Se!"en#e

Co"rte$y o% &IA 'OTORS A'ERICA( INC.

FRONT CRAN&SHAFT SEA)

Remoal

!isconnect negative battery cable. "emove engine undercover. "emove drive belts and

crankshaft pulley. "emove timing belt covers and timing belt. See TI'IN* BE)T . "emove

crankshaft sprocket pulley lock bolt and pulley. If necessary, remove crankshaft sprocket pulley

using steering wheel puller. "emove keyway. +sing seal remover, pry oil seal from oil pump

2002 -ia Sportage

2002 ENGINES 2.0L 4-Cylinder - Sportage

Hewlett-Packard

s!ado" 02 de agosto de 20#4 0$%4#%4# a.&. Page $ ( 20## )itc*ell +epair In,or&ation Co&pany" LLC.

housing. See Fig. + .

In$tallation

. /pply light coat of oil to lip of seal, and push seal over crankshaft. Tap seal into oil pump

body until it is flush with edge of pump body. !0 N0T bottom seal in pump body. /lign

keyway slots, and install crankshaft sprocket by tapping lightly using brass hammer.

#. Install keyway with tapered side toward oil pump body. Install crankshaft sprocket lock

bolt and tighten crankshaft pulley lock bolt to specification. See TORQUE

SPECIFICATIONS . Install timing belt. See TI'IN* BE)T . Install timing belt covers,

pulleys and drive belts. "econnect negative battery cable. Ensure timing is correct.

Fig. +: Remoing Front Oil Seal

Co"rte$y o% &IA 'OTORS A'ERICA( INC.

TI'IN* BE)T

Remoal

. !isconnect negative battery cable. "emove air duct mounting bolts at radiator. &oosen air

2002 -ia Sportage

2002 ENGINES 2.0L 4-Cylinder - Sportage

Hewlett-Packard

s!ado" 02 de agosto de 20#4 0$%4#%4# a.&. Page ' ( 20## )itc*ell +epair In,or&ation Co&pany" LLC.

d-ct cla&p at intake *o-sing. +e&o.e *ose ,ro& renosance c*a&!er. +e&o.e air inlet

d-ct. +e&o.e ,an s*ro-d &o-nting !olts. +e&o.e t*er&o-&od-lated n-ts. +e&o.e ,an

and ,an s*ro-d toget*er.

2. Loosen generator &o-nting !olts. Loosen generator dri.e !elt ,or& generator !y loosening

ad/-sting !olt" and re&o.e dri.e !elt. +e&o.e ,an p-lley.

0. +e&o.e splas* g-ard &o-nting !olts and splas* g-ard. Loosen 12C idler p-lley n-t.

+e&o.e 12C dri.e !elt !y loosening ad/-sting !olt. Loosen power steering p-&p lock !olt

and &o-nting !olt. +e&o.e power steering !elt. +e&o.e !olts and -pper ti&ing !elt

co.er. +e&o.e !olts and lower ti&ing !elt co.er.

4. Ens-re ca&s*a,t sprocket3s4 and cranks*a,t sprocket ti&ing &arks align. See Fig. 5 .

Ca&s*a,t sprocket ti&ing &arks are an 5I5 on intake ca&s*a,t sprocket" and an 5E5 on

e6*a-st ca&s*a,t sprocket. See Fig. 6 .

7. I, ti&ing !elt is to !e re-sed" &ark direction o, ti&ing !elt rotation on !elt !e,ore re&o.al.

Loosen ti&ing !elt tensioner lock !olt. )o.e tensioner away ,ro& !elt wit* spring ,-lly

e6tended. 8e&porarily tig*ten tensioner lock !olt w*ile tension is released ,ro& ti&ing

!elt. +e&o.e ti&ing !elt. See Fig. 7 .

2002 -ia Sportage

2002 ENGINES 2.0L 4-Cylinder - Sportage

Hewlett-Packard

s!ado" 02 de agosto de 20#4 0$%4#%4# a.&. Page ' ( 20## )itc*ell +epair In,or&ation Co&pany" LLC.

-ig. .% /ligning Cranks*a,t 0i&ing )arks

Co1rtesy o, 2I/ )303+S /)E+IC/" INC.

2002 -ia Sportage

2002 ENGINES 2.0L 4-Cylinder - Sportage

Hewlett-Packard

s!ado" 02 de agosto de 20#4 0$%4#%4# a.&. Page #0 ( 20## )itc*ell +epair In,or&ation Co&pany" LLC.

Fig. 6: Aligning Camshaft Timing Marks

Courtesy of KIA MOTORS AMERICA I!C.

2002 Kia Sportage

2002 ENGINES 2.0L 4-Cylinder - Sportage

Hewlett-Packard

s!ado" 02 de agosto de 20#4 0$%4#%4# a.&. Page ## ' 20## (itc)ell *epair In+or&ation Co&pany" LLC.

Fig. 7: Exploded View Timing Belt & Components

Courtesy of KIA !T!"# AE"ICA$ I%C.

Inspe&tion

Check timing belt for cracks, peeling, abrasion marks or other damage. Check tensioner bearing

for looseness or roughness of rotation. Inspect tensioner spring for defects such as warping and

rust. Replace parts as necessary.

Inst'll'tion

1. Ensure camshaft and crankshaft timing marks are still aligned. Install belt around

crankshaft sprocket. Keep belt pulled tight on tension side of belt, and route belt around

camshaft sprocket(s. Ensure camshaft sprockets do not mo!e while installing timing belt.

". #oosen timing belt tensioner lock bolt, and allow spring to apply tension on belt. . Rotate

2002 Kia Sportage

2002 ENGINES 2.0L 4-Cylinder - Sportage

Hewlett-Packard

s!ado" 02 de agosto de 20#4 0$%4#%4# a.&. Page #2 ' 20## (itc)ell *epair In+or&ation Co&pany" LLC.

crankshaft clockwise 2 complete revolutions. Ensure timing marks are aligned. If timing

marks are not aligned, remove belt, realign all timing marks, and repeat procedure. Turn

crankshaft to align "S" mark of exhaust camshaft pulle with seal plate mating mark. See

Fig. 8

!. "heck timing belt deflection. "heck timing belt deflection with 22 lbs. #$% kg& of pressure

applied to belt. 'eflection should be .!%(.!!" #).*(+., mm&. If timing belt deflection is not

within specification, repeat steps 2 and ! and-or replace timing belt tensioner spring. If

timing belt deflection is within specification, reverse removal procedure to complete

installation.

Fig. 8: Aligning Camshaft "S" Timing Marks

Courtesy of KIA MOTORS AMRICA! I"C.

#$%RA&'IC 'AS# A%(&STR

2002 Kia Sportage

2002 ENGINES 2.0L 4-Cylinder - Sportage

Hewlett-Packard

s!ado" 02 de agosto de 20#4 0$%4#%4# a.&. Page #' ( 20## )itc*ell +epair In,or&ation Co&pany" LLC.

*e&o,al

Disconnect negative battery cable. Remove valve cover. Remove timing belt from camshaft

sprockets. See -I(ING .EL- . Remove camshaft bearing cap bolts evenly in 2-3 steps. See

/ig. 0 . Remove camshafts from cylinder head. Mark all parts for installation reference.

Remove Hydraulic ash !d"uster #H!$ from bores in cylinder head. %nspect face of H! for

&ear or damage' replace as necessary. Remove ()( rings. D) *)+ disassemble H!.

Installation

%nstall *,- ()( rings. .our clean engine oil into bores of cylinder head. !pply clean engine

oil to H!. %nstall H! into bores of cylinder head. D) *)+ damage ()( ring oil seal during

installation. H! should move freely in cylinder head bores. %nstall camshafts to cylinder head.

+ighten camshaft cap bolts to specification in se/uence. See /ig. #1 . See -2*34E

SPECI/IC5-I2NS . +o complete installation' reverse removal procedure.

C5(SH5/-

*e&o,al

Disconnect negative battery cable. Remove 0 bolts and upper timing belt cover. Remove timing

belt. See -I(ING .EL- . Remove cylinder cover. Remove camshaft pulleys. Remove

camshaft sprockets. Remove camshaft cap bolts in se/uence. See /ig. 0 . Remove camshafts

from cylinder head. Mark all parts for installation reference.

2002 Kia Sportage

2002 ENGINES 2.0L 4-Cylinder - Sportage

Hewlett-Packard

s!ado" 02 de agosto de 20#4 0$%4#%4# a.&. Page #4 ( 20## )itc*ell +epair In,or&ation Co&pany" LLC.

Fig. 9: Camshaft Bearing Cap Bolt Removal Sequence

Courtesy of KIA !"!RS A#RICA$ I%C.

Inspection

Check camshaft for wear or damage, replace if necessary. Check camshaft runout, lobe height

and camshaft oil clearance. Repair or replace as necessary. See CAS&AF" table under

ENGINE SECI!IC"#I$NS.

Installation

osition camshafts in cylinder head. "pply a liberal amount of clean engine oil to %ournals,

bearings and camshaft oil seal. lace camshaft in position with dowel pin facing straight up.

"pply sealant to both front camshaft cap surfaces and camshaft position sensor mounting cap.

osition camshaft caps according to cap number, with arrows pointing toward front of cylinder

2002 Kia Sportage

2002 ENGINES 2.0L 4-Cylinder - Sportage

Hewlett-Packard

s!ado" 02 de agosto de 20#4 0$%4#%4# a.&. Page #' ( 20## )itc*ell +epair In,or&ation Co&pany" LLC.

head. Install camshaft caps. Tighten camshaft cap bolts to specification in 2 or 3 steps in

sequence. See -ig. #' . See ./+01E SPECI-IC2.I/NS . To complete installation, reverse

removal procedure.

C+2N3SH2-. +E2+ /IL SE2L

+e&o4al

Disconnect negative battery cable. Raise and support vehicle. Remove transmission. or !"T,

see appropriate article in #$%T#&'S. or ("T, see (%T)!(TI# TR(*S!ISSI)*

R'!)+($ , I*ST($$(TI)* article in TR(*S!ISSI)* S'R+I#I*-. !ar. all parts for

installation reference. Remove clutch assembly and fly/heel. Remove rear cover. %sing a seal

remover, remove oil seal from rear of cylinder bloc..

Installation

To install, lubricate seal lip /ith light coat of engine oil. Tap seal into oil seal holder until it is

flush /ith edge of rear cover. #lean old sealant from cran.shaft bolts and bolt holes. (pply ne/

sealant to cran.shaft bolts. Install fly/heel and clutch assembly. To complete installation,

reverse removal procedure. Tighten bolts to specification. See ./+01E

SPECI-IC2.I/NS .

52.E+ P1)P

+e&o4al

0. Remove undercover. Remove radiator cap. Drain cooling system. Remove upper and

lo/er radiator hoses. Remove coolant reservoir tan. hose. Remove air inlet duct. Remove

fan and fan shroud together. $oosen generator mounting bolt and ad1usting bolt. Remove

drive belt.

2. Remove fan pulley. Remove fan brac.et assembly. Remove upper and lo/er timing belt

covers. Turn cran.shaft so *o. 0 cylinder is at TD#. $oosen tensioner loc. bolt, and pry

tensioner a/ay. Retighten tensioner bolt. If reusing timing belt, mar. belt direction of

rotation for installation reference. Remove timing belt, and place aside. See .I)ING

6EL. . $oosen tensioner bolt, and release tensioner. Remove /ater pump. -ig. #0 .

Remove 2 tensioners from /ater pump. Remove gas.et and clean gas.et mating surface of

engine bloc..

Installation

NOTE: Rear crankshaft oil seal can be removed without removing oil pan or

crankshaft.

2002 ia !portage

2002 ENGINES 2.0L 4-Cylinder - Sportage

Hewlett-Packard

s!ado" 02 de agosto de 20#4 0$%4#%4# a.&. Page #' ( 20## )itc*ell +epair In,or&ation Co&pany" LLC.

Ensure all gasket mating surfaces are clean. Install NEW water pump gasket on water pump.

Install water pump. To complete installation, reverse removal procedure. Tighten bolts to

specification. See TORQUE SPECIFICATIONS . Check ignition timing and adust if

necessar!.

Fig. 10: Exploded View Of Wae! P"#p $ Relaed Co#po%e%&

Co"!e&' of (IA )OTORS A)ERICA* INC.

OI+ PAN $ OI+ ,AFF+E

Re#o-al

". #isconnect negative batter! cable. $emove top % bolts on intake manifold bracket. $aise

and support vehicle. #rain engine oil, and reinstall drain plug. $emove engine and

2002 ia !portage

2002 ENGINES 2.0L 4-Cylinder - Sportage

Hewlett-Packard

s!ado" 02 de agosto de 20#4 0$%4#%4# a.&. Page #$ ( 20## )itc*ell +epair In,or&ation Co&pany" LLC.

transmission splash shields. On 4WD models, support front axle housing. Remove front

axle housing mounting bolts, and left bushing from axle housing mount. Carefully lower

front axle housing.

2. On 2WD models, remove front left bushing from axle housing mount. Carefully lower

front axle housing. On all models, remove gusset plate mounting bolts from one side of

motor, and remove gusset plate. Remove gusset plate mounting bolts from other side of

motor, and remove other gusset plate.

. Remove transmission under!over bolts, and remove engine under!over. Remove oil pan

mounting bolts. "eparate oil pan from oil baffle and remove oil pan. Remove oil pan.

Remove oil strainer assembly. Remove baffle bolt, and remove oil baffle.

Inspection

Remove oil, dirt and sealant from oil pan mounting bolts, oil pan and oil baffle. #nspe!t oil pan

for !ra!$s, deformation and%or damaged drain plug threads. Che!$ oil baffle for damage or

!ra!$s. Repair or repla!e as ne!essary.

Installation

&pply a !ontinuous bead of sili!one sealant along inside of bolt holes of oil baffle and oil pan.

#nstall oil baffle. #nstall oil baffle mounting bolt. #nstall oil strainer assembly. #nstall oil pan.

#nstall oil pan mounting bolts in se'uen!e. "ee Fig. 16 . (ighten bolts to spe!ifi!ation. "ee

TORQUE SPECIFICATIONS . (o !omplete installation, reverse removal pro!edure.

OVERHAUL

CYLINDER EAD

C!lin"e# ea"

)nsure all mating surfa!es are !lean. Che!$ !ylinder head for warpage. Resurfa!e !ylinder head

if warpage ex!eeds spe!ifi!ation. Che!$ manifold !onta!t surfa!es for warpage. Resurfa!e

manifold surfa!es or repla!e !ylinder head if warpage ex!eeds spe!ifi!ation. Che!$ !ylinder

head height. "ee CYLINDER EAD table under )*+#*) ",)C#-#C&(#O*". #f

measurements are not as spe!ified, repla!e !ylinder head.

$al%e Sp#ings

)nsure valve spring free length and out.of.s'uare are within spe!ifi!ation. "ee $AL$ES &

NOTE: DO NOT bend oil pan or oil baffle while separating, remoing or

!leaning !omponents"

#$$# %ia &portage

2002 ENGINES 2.0L 4-Cylinder - Sportage

Hewlett-Packard

s!ado" 02 de agosto de 20#4 0$%4#%42 a.&. Page #' ( 20## )itc*ell +epair In,or&ation Co&pany" LLC.

$AL$E SPRIN'S table under ENGINE SPECIFICATIONS. Replace valve spring as

necessary.

$al%es

Chec valve !ace angle" #argin thicness and ste# dia#eter. Service $r replace valves i!

#easure#ents are n$t %ithin speci!icati$n. See $AL$ES & $AL$E SPRIN'S table under

ENGINE SPECIFICATIONS.

$al%e '(i"es

&. Chec valve ste#'t$'valve guide $il clearance. Ensure valve guide inside dia#eter is

%ithin speci!icati$n. See CYLINDER EAD table under ENGINE SPECIFICATIONS.

(. T$ replace valve guide" c$#pletely disasse#ble cylinder head. See ENGINE

O)ER*A+, PROCE-+RES article in GENERA, INFOR.ATION. *eat cylinder head

t$ &/01F 2/31C4. 5$ring !r$# c$#busti$n cha#ber side $! cylinder head" install )alve

Guide Re#$ver 2O6&73'&(3'3384 int$ valve guide. -rive valve guide $ut $! cylinder

head.

7. I! necessary" install ne% circlip $n guide. +sing pr$per c$#p$nents $! )alve Guide

Installer 2O6//7'&(3'AAO4" ad9ust installer guide depth t$ speci!icati$n using depth

#icr$#eter $r caliper.

0. Insert guide int$ pre'ad9usted installer. -rive guide int$ heated cylinder head !r$#

ca#sha!t side until guide circlip and:$r installer c$ntact cylinder head. Ensure valve guide

installed height is %ithin speci!icati$n. I! installed height is n$t %ithin speci!icati$n" ad9ust

$r replace valve guide $r cylinder head as necessary. See CYLINDER EAD table under

ENGINE SPECIFICATIONS.

$al%e Seat

)alve seat replace#ent in!$r#ati$n is n$t available !r$# #anu!acturer. Inspect valve seat !$r

r$ughness and da#age. Chec valve seat angle and seat %idth. .easure seat c$ntact %idth $n

valve" and n$te that seat c$ntact p$siti$n sh$uld be in center $! valve !ace" and 783 degrees

ar$und valve !ace. Service seat i! angle and %idth are n$t %ithin speci!icati$n. See

CYLINDER EAD table under ENGINE SPECIFICATIONS. .easure valve installed height

a!ter servicing valve seat.

$al%e Seat Co##ection Angles

&. .easure seat c$ntact %idth $n valve. See CYLINDER EAD table under ENGINE

N-.E% Intake and e/*a0st 1al1e g0ides co&e in di,,erent s*apes and

lengt*s.

2002 2ia Sportage

!""! ENGINES !."L #$C%lind& $ Spo&tag

'(ltt$Pac)a&d

*+,ado- "! d ago*to d !"1# "./#1/#! a.0. Pag 11 2 !"11 Mitc3ll Rpai& In4o&0ation Co0pan%- LLC.

SPECIFICATIONS. Ensure valve/seat contact position is at center of valve face. If width

and position are not within specifications, cut seats as follows.

. If seat contact position is too hi!h, correct it usin! "#$de!ree stone. Finish an!le usin! %&$

de!ree stone until contact width is corrected.

'. If seat contact position is too low, correct usin! '&$de!ree stone (inta)e* or +&$de!ree

(e,haust*. Finish an!le usin! %&$de!ree stone until contact width is corrected. Seat valve

to valve seat usin! lappin! co-pound.

Val-e 'tem Installed (eight

+. After servicin! valves, valve seats and valve !uides, -easure valve ste- installed hei!ht.

See V*&VE IN'T*&&E. (EI)(T ta.le. If installed valve ste- hei!ht is within

standard specification, no ad/ust-ent is necessar0.

. If installed valve hei!ht e,ceeds standard specification .ut does not e,ceed service li-it

specification, install ad/ustin! shi- on sprin! seat to .rin! installed hei!ht .ac) within

standard specification.

'. If valve ste- installed hei!ht e,ceeds specification, replace valve. If valve ste- installed

hei!ht still e,ceeds li-it, replace c0linder head. See V*&VE IN'T*&&E. (EI)(T

ta.le.

V*&VE IN'T*&&E. (EI)(T

13&IN.E" %

*pplication In. (mm)

Inta)e

Standard

(+*

+.%'$+.%"1 ('".'1$

'1.1*

Service 2i-it

(*

+.%3& ('1.31*

E,haust

Standard

(+*

+.%'+$+.%"" ('".'"$

'1."*

Service 2i-it

(*

+.%3% ('1.3"*

(+*

If installed hei!ht e,ceeds standard specification .ut is less that service li-it, ad/ust

with washer on sprin! seat area of c0linder head.

(*

If installed hei!ht e,ceeds service li-it, replace c0linder head.

N-.E% /0ring disasse&!ly" &atc* &ark co&ponents ,or reasse&!ly

2002 1ia Sportage

!""! ENGINES !."L #$C%lind& $ Spo&tag

'(ltt$Pac)a&d

*+,ado- "! d ago*to d !"1# "./#1/#! a.0. Pag !" 2 !"11 Mitc3ll Rpai& In4o&0ation Co0pan%- LLC.

!iston 5 &onnecting Rod $ssembly

1. *efore removin" rod cap from cran!shaft, measure and record rod side play. See

&,663&.768 R,24 table under +,-#,+ S.+$#'#$AT#O,S. +nsure all rods,

pistons, and caps are mar!ed for installation reference before removal.

. *efore removin" rod from cran!shaft, chec! and record rod bearin" oil clearance. See

&R$694:$;., -$76 5 &,663&.768 R,2 <3$R7684 table under +,-#,+

S.+$#'#$AT#O,S.

%. To install, ensure parts are matched to cylinder. +nsure piston, rod, rin"s and bearin"s are

properly fitted and in appropriate positions. #nstall piston and rod assembly into bloc!.

!iston !in Replacement

1. &atch mar! piston pin and rod piston for reassembly reference. /sin" arbor press and

piston pin removal/installation set, press piston pin throu"h rod and out of piston.

. $hec! piston0to0pin clearance, and rod0to0pin interference fit. See !74.,64, !764 5

R7684 table under +,-#,+ S.+$#'#$AT#O,S. +nsure piston mar! and rod

identification mar! are in proper position. .ress pin into piston and rod until pin is

centered. .iston should pivot freely.

;itting !istons

1. +nsure pistons are not scored or dama"ed. &easure piston diameter on piston s!irt

at .1234 516.21 mm7 below oil rin" land. See !74.,64, !764 5 R7684 table under

+,-#,+ S.+$#'#$AT#O,S.

. $hec! piston0to0cylinder wall clearance in % different vertical places of piston travel. #f

clearance is not within specification, rebore cylinders to fit ,+8 oversi9e pistons.

%. /sin" ,+8 piston rin", measure piston rin" side clearance around entire piston

circumference. #f clearance is not within specification, replace piston. See !74.,64,

!764 5 R7684 table under +,-#,+ S.+$#'#$AT#O,S.

!iston Rings

#nsert ,+8 piston rin" into cylinder, and measure rin" end "ap. -rind rin" ends to e:pand rin"

"ap to specification or replace piston rin" if rin" end "ap is e:ceeds specification. See

!74.,64, !764 5 R7684 table under +,-#,+ S.+$#'#$AT#O,S.

&onnecting Rod <earings

$hec! cran!shaft connectin" rod ;ournals for wear, out0of0round, taper and undersi9e. &achine

reference.

())( Kia !portage

2002 ENGINES 20L !"C#lin$e% " S&o%ta'e

(e)lett"Pa*+a%$

s,-a$o. 02 $e a'osto $e 20/! 001!/1!2 am Pa'e 2/ 2 20// Mit*3ell Re&ai% In4o%mation Com&an#. LLC

or replace crankshaft, connecting rod and/or bearings as necessary. See CRANKSHAFT,

MAIN & CONNECTING RO !EARINGS table under ENGINE SPECIFIC!I"NS.

C"an#s$a%t & Main !&a"ings

#. $efore re%o&ing %ain caps, %easure and record crankshaft end play. 'sing Plastigage,

%easure and record %ain bearing oil clearance. (" N"! rotate crankshaft )hen

%easuring oil clearances.

*. +e%o&e crankshaft fro% engine. ,easure and record each %ain -ournal dia%eter in *

places. See CRANKSHAFT, MAIN & CONNECTING RO !EARINGS table under

ENGINE SPECIFIC!I"NS. ,achine or replace crankshaft as necessary. ,ain bearing

upper hal&es are groo&ed. Check bearings for )ear, replace if necessary.

.. ,ain bearing caps are %arked for installation in original positions. !ighten bearing cap

bolts in se/uence and to specification. See TORQUE SPECIFICATIONS . See Fig. '( .

T$")st !&a"ings

Check crankshaft end play )ith crankshaft bearings and caps installed, but )ithout connecting

rods attached to crankshaft. +eplace thrust bearing if end play is not )ithin specification. See

CRANKSHAFT, MAIN & CONNECTING RO !EARINGS table under ENGINE

SPECIFIC!I"NS. Ensure thrust bearings are installed )ith oil groo&e facing crankshaft.

"&ersi0e thrust bearings are a&ailable.

C*lin+&" !lo,#

Check cylinder bore out1of1round, taper, and piston1to1cylinder bore clearance. Check head

gasket surface for )arpage. If )arpage is not )ithin specification, %achine or replace cylinder

block as necessary. See C-LINER !LOCK table under ENGINE SPECIFIC!I"NS.

ENGINE OILING

ENGINE LU!RICATION S-STEM

"il pressure is pro&ided by a rotor1type pu%p. (ri&en by the crankshaft, pu%p dra)s oil fro%

oil pan through oil strainer. Fro% oil pu%p, oil is sent through oil filter then to cylinder block

and up to cylinder head. "il drains back to oil pan. See Fig. '' .

C"an#,as& Ca.a,it*

"il pan capacity is 2.2 /ts. 32.#456. "il filter capacity is .*# /ts. 3.*756.

Oil P"&ss)"&

2002 Kia Sportage

2002 ENGINES 20L !"C#lin$e% " S&o%ta'e

(e)lett"Pa*+a%$

s,-a$o. 02 $e a'osto $e 20/! 001!/1!2 am Pa'e 22 2 20// Mit*3ell Re&ai% In4o%mation Com&an#. LLC

With engine at operating temperature, oil pressure should be 43-57 psi (3.0-4.0 kg/cm

2

at

3000 !"#.

Oil P)ess*)e Relie+ %alve

"ressure relie$ %al%e is located in oil pump bod& and is not ad'ustable.

Fi! '', C)oss-Se$tional %ie. O+ Enine Oil Ci)$*it

2002 Kia Sportage

2002 ENGINES 2.0L 4-Cylinder - Sportage

Hewlett-Packard

s!ado" 02 de agosto de 20#4 0$%4#%42 a.&. Page 2' ( 20## )itc*ell +epair In,or&ation Co&pany" LLC.

Courtesy of KIA MOTORS AMERICA, INC.

OIL PUMP

Reo!"#

. "emove radiator cap, and drain coolant. !isconnect negative battery cable. "emove

timing belt. See TIMIN$ %ELT under "E102/& 3 INST/&&/TI0N. "emove oil

pan and oil baffle. See OIL PAN & OIL %AFFLE .

#. "emove power steering pump bolts. "emove power steering pump bracket bolts. "emove

power steering pump bracket. "emove timing belt pulley from crankshaft. "emove

remaining oil pump bolts. "emove oil pump. "emove 404 ring from oil pump.

%. *arefully clean all gaskets and sealant from mating surfaces without damaging

sealing5mating surfaces. "emove all sealant from components and bolts. *heck oil pump

clearances. See OIL PUMP SPECIFICATIONS table. "eplace oil pump as necessary.

See Fig. '( .

I)st"##"tio)

. +se NEW gasket when installing oil pump. Tighten oil pump bolts to specification. See

TOR*UE SPECIFICATIONS . /pply light oil coat of clean oil to oil seal lip, and tap

oil seal into oil pump body until it is flush with edge of pump body. !0 N0T bottom seal

in pump body.

#. /lign keyway slots, and install crankshaft sprocket by tapping lightly using brass hammer.

Install keyway with tapered side toward oil pump body. Install crankshaft sprocket lock

bolt, and tighten to specification. See TOR*UE SPECIFICATIONS . To complete

installation, reverse removal procedure.

2002 Kia Sportage

2002 ENGINES 2.0L 4-Cylinder - Sportage

Hewlett-Packard

s!ado" 02 de agosto de 20#4 0$%4#%42 a.&. Page 24 ( 20## )itc*ell +epair In,or&ation Co&pany" LLC.

Fig. ,-: E./loded 0ie1 O% Oil P"m/

Co"rte$y o% &IA 'OTORS A'ERICA( INC.

OI) PU'P SPECIFICATIONS

TORQUE SPECIFICATIONS

A//li#ation 'a.im"m Clearan#e 2 In. 3mm4

Inner ,ear Tip$To$0uter ,ear *learance .667 8.9:

0uter ,ear$To$-ump ;ody *learance .669 8.#6:

,ear Side$To$-ump ;ody *learance .66' 8.6:

-ressure Spring &ength .7< 8'=.'<:

2002 Kia Sportage

2002 ENGINES 20L !"C#lin$e% " S&o%ta'e

(e)lett"Pa*+a%$

s,-a$o. 02 $e a'osto $e 20/! 001!/1!2 am Pa'e 25 2 20// Mit*3ell Re&ai% In4o%mation Com&an#. LLC

TORQUE SPECIFICATIONS

Application Ft. Lbs. (N.m)

-.C /racket /olt '2 0412

-.C Co&pressor )o3nting /olt #4 0212

-.C 5ensioner /racket /olt #4 0212

-.C Idler P3lley Lock N3t 24 0'22

/ypass Pipe /olt #4 0212

Ca&s*a,t Cap /olt

0#2

#6 0222

Ca&s*a,t P3lley Lock /olt 42 0162

Cl3tc* 0).52. Con7erter 0-.52 Ho3sing /olt

#4 && 40 0#042

#0 && 24 0'42

6 && 60 INCH 0$2

Connecting +od N3t 10 06$2

Cooling 8an -sse&!ly /olt 2$ 0'$2

Cooling 8an N3t #6 0222

Cranks*a,t 9a&per P3lley /olt ## 0#12

Cylinder Head /olt

022 0'2

62 0442

9yna&ic C*a&!er /olt.N3t #6 0222

9yna&ic C*a&!er S3pport /racket /olt #4 0212

Engine-to-/ody Gro3nd :ire /olt #4 0212

Engine /racket /olt '2 0412

Engine Hanger /olt #6 0222

Engine )o3nt N3t 24 0'42

Engine S3pport /olt 24 0'42

E;*a3st /racket /olt 20 02$2

E;*a3st 8lange Lock N3t 24 0'#2

E;*a3st )ani,old N3t '# 0422

E;*a3st )ani,old Heat S*ield /olt #4 0212

8ront -;le Ho3sing )o3nting /olt 44 0612

Generator /racket /olt '2 0412

Generator )o3nting /olt

/otto& '2 0412

5op #6 0222

Generator Strap /olt '2 0412

())( Ki' #port'ge

"##" E!$I!ES ".#% &'Cylin(er ' S)ortage

*e+lett',a-kar(

s./a(o #" (e agosto (e "#0& #1:&0:&" a.m. ,age "6 2 "#00 Mit-hell Re)air Information Com)any %%C.

)usset *late +olt ,- ./01

Ignition Coil Mounting +olt 28 .-01

Intake Manifol3 +olt4"ut 25 .--1

Intake Manifol3 Su66ort +ra7ket +olt ,- ./01

Main +earing Ca6 +olt

./1

5, .801

Oil *um6 +olt

.01

8 mm 25 .--1

28 mm ,- ./01

*4S +ra7ket +olt ,- ./01

*4S Mounting +olt ,8 ./-1

*4S *um6 'o7k +olt ,8 ./-1

Se6erator *late +olt 28 .-01

S6ark *lug 2292: .209-,1

Starter +olt ,/ ./51

Timing +elt *ulley 'o7k +olt 2-8 .25-1

Timing +elt Tensioner 'o7k +olt ,, ./01

;ater Inlet *i6e +olt 28 .-01

;ater *um6 +olt 25 .--1

I."/ 0bs. #..m&

A77elerator Ca<le Mounting +olt 58 .:1

Air #ose Mounting +olt 58 .:1

Air Intake #ousing +olt ,8905 ./951

Cooling Fan Shrou3 +olt :- .81

Cylin3er #ea3 Co=er +olt 58 .:1

>haust *rote7tor "ut ,0 ./1

Fresh Air %u7t +olt 8/ .281

Oil )auge Tu<e +olt 58 .:1

Oil Strainer Mounting +olt 8/ .?1

Camshaft *osition Sensor +olt 8/ .281

Ra3iator Mounting +olt :- .81

Rear Co=er +olt 8/ .281

Stiffener *late Mounting +olt 8/ .?1

Timing +elt Co=er +olt 8/ .281

Transmission &n3er7o=er +olt 8/ .?1

&n3er7o=er Mounting +olt :- .81

())( Ki' #port'ge

"##" E!$I!ES ".#% &'Cylin(er ' S)ortage

*e+lett',a-kar(

s./a(o #" (e agosto (e "#0& #1:&0:&" a.m. ,age "1 2 "#00 Mit-hell Re)air Information Com)any %%C.

$ig. 1%& Camshaft 'earing Cap 'olt (ightening )e*uence

Courtesy of KI+ ,-(-R) +,ERIC+, I.C.

6#7

-ig)ten in se89ence. See $ig. 1% .

627

-ig)ten in se89ence. See $ig. 1/ .

617

-ig)ten in t)ree e89al steps.

647

-ig)ten in se89ence. See $ig. 10 .

6:7

-ig)ten in se89ence. See $ig. 11 .

())( Ki' #port'ge

2112 ,*2%*,S 2.1 3-4ylinder - Sportage

He&lett-.ackard

s5bado' 12 de agosto de 2163 17836832 a.m. .age 29 : 2166 Mitchell Repair %nformation 4ompany' 4.

Fig. 14: Cylinder Head Bolt Tightening Sequence

Courtesy of KIA !T!"S A#"ICA$ I%C.

())( Ki' #port'ge

"##" E!$I!ES ".#% &'Cylin(er ' S)ortage

*e+lett',a-kar(

s./a(o #" (e agosto (e "#0& #1:&0:&" a.m. ,age "3 2 "#00 Mit-hell Re)air Information Com)any %%C.

Fig. 1&: ain Bearing Ca' Bolt Tightening Sequence

Courtesy of KIA !T!"S A#"ICA$ I%C.

())( Ki' #port'ge

2112 ,*2%*,S 2.1 3-4ylinder - Sportage

He&lett-.ackard

s5bado' 12 de agosto de 2163 17836832 a.m. .age 31 : 2166 Mitchell Repair %nformation 4ompany' 4.

Fig. 16: Oil Pan Bolt Tightening Sequence

Courtesy of KIA OTO!S A"!ICA# I$C.

ENGINE SPECIFICATIONS

%"$"!A& SP"CIFICATIO$S

C!A$KS'AFT# AI$ ( CO$$"CTI$% !O) B"A!I$%S

A**lication S*ecification

Displacement 122 Cu. In. (2.0L)

Bore 3.39" (86.1)

Stroe 3.39" (86.1)

Compression !atio 9.2"1

Compression #ressure

188 psi (13.22 $%cm

2

)

&uel S'stem S&I

A**lication In. +,,-

Crans(a)t

2002 Kia Sportage

"##" E!$I!ES ".#% &'Cylin(er ' S)ortage

*e+lett',a-kar(

s./a(o #" (e agosto (e "#0& #1:&0:&" a.m. ,age 40 2 "#00 Mit-hell Re)air Information Com)any %%C.

End Play

Standard .00'#-.00$# 7.0$8-.#90:

Ser4ice Li&it .0#2 7.'0:

)a;i&<& +<no<t .00#2 7.0'0:

)ain =o<rnal 6earings

=o<rnal >ia&eter 2.'?8$-2.'@04 7?8.8'@-

?8.8?4:

1ndersiAe # - .0#0B 7.2? &&:

No. #" 2" 4" ? 2.'?0#-2.'?09

7?8.@8'-?8.$#0:

No. ' 2.'488-2.'?0 7?8.@9$-

?8.$0?:

1ndersiAe 2 - .020B 7.?0 &&:

No. #" 2" 4" ? 2.'40'-2.'4#0

7?8.444-?8.4@#:

No. ' 2.'400-2.'40$

7?8.4'@-?8.4?4:

1ndersiAe ' - .0'0B 7.$? &&:

No. #" 2" 4" ? 2.''04-2.''##

7?8.#82-?8.2#0:

No. ' 2.''02-2.''08

7?8.#9$-?8.20?:

=o<rnal /<t-/,-+o<nd C .aper .0002 7.00?:

/il Clearance

Standard

No. #" 2" 4" ? .00#0-.00#$ 7.02?-

.04':

No. ' .00#2-.00#8 7.0'0-

.049:

Ser4ice Li&it .00'#- 7.090:

Connecting +od 6earings

=o<rnal >ia&eter 2.00??-2.00@# 7?0.840-

?0.8??:

=o<rnal /<t-/,-+o<nd C .aper .0002 7.00?:

/il Clearance

Standard .002-.008 7.0?-.2':

Ser4ice Li&it .00'# 7.090:

2002 Kia Sportage

"##" E!$I!ES ".#% &'Cylin(er ' S)ortage

*e+lett',a-kar(

s./a(o #" (e agosto (e "#0& #1:&0:&" a.m. ,age 4" 2 "#00 Mit-hell Re)air Information Com)any %%C.

CO$$"CTI$% !O)S

PISTO$S# PI$S ( !I$%S

A**lication In. +,,-

2ore Diameter

#onnecting Rod 2earing 2ore

304

5iston 5in 2ore .6789:.6770 320.;6;:

20.;;;4

!a<imum 2end

324

.==2; 3.=9>4

!a<imum T/ist

324

.==9; 3.2=04

Side 5lay

Standard .==>.===003.0=:.==264

Service $imit .=02 3.3=4

304

Information is not available from manufacturer.

324

!a<imum bend or t/ist per 0.;9? 38= mm4 of rod length.

A**lication In. +,,-

5istons

#learance

Standard .==0;:.==2> 3.=>6:.=704

Service $imit .==8; 3.084

Diameter 3.3637:3.36>> 368.;>3:68.;7>4

5ins

Diameter .6787:.6770 320.;69:20.;;;4

5iston it .===2:.===> 3.==8:.=0=4

Rod it .===>:.===00 3.=0=:.=284

Rings

*o. 0

'nd -ap

Standard .==7:.=02 3.08:.3=4

Service $imit .=3; 30.=4

Side #learance

Standard .==0:.==3 3.=28:.=974

Service $imit .==7 3.084

*o. 2

2002 Kia Sportage

"##" E!$I!ES ".#% &'Cylin(er ' S)ortage

*e+lett',a-kar(

s./a(o #" (e agosto (e "#0& #1:&0:&" a.m. ,age 44 2 "#00 Mit-hell Re)air Information Com)any %%C.

CYLINDER BLOCK

VALVES & VALVE SPRINGS

E%d .ap

Sa%da!d .00/0.011 2.300.456

Se!-i7e +i#i .048 21.06

Side Clea!a%7e

Sa%da!d .0010.004 2.0390.0:56

Se!-i7e +i#i .005 2.196

No. 4 2Oil6

E%d .ap

Sa%da!d .00/0.03/ 2.300.:16

Se!-i7e +i#i .048 21.06

Application In. (mm)

C'li%de! ,o!e

Sa%da!d ;ia#ee! 4.4/9/04.4/55

2/9.8880/5.0306

)axi#"# Tape! .000: 2.01/6

)axi#"# O"0Of0Ro"%d .000: 2.01/6

)axi#"# ;e7< Wa!page

216

.005 2.196

216

Repla7e =lo7< if #o!e >a% .00/? 230 ##6 i& !e#o-ed.

Application Speciication

Val-e&

Fa7e A%gle 19@

Aead ;ia#ee!

216

)i%i#"# )a!gi%

I%a<e .044? 2./1 ##6

Ex>a"& .049? 2./8 ##6

)i%i#"# Refi%i&> +e%g>

I%a<e 1.0533? 2104.1/ ##6

Ex>a"& 1.0831? 2104.81 ##6

I%&alled Aeig>

236

Val-e Sea Co%a7 Wid> .01:0.054? 21.1801.50

##6

2002 Kia Sportage

"##" E!$I!ES ".#% &'Cylin(er ' S)ortage

*e+lett',a-kar(

s./a(o #" (e agosto (e "#0& #1:&0:&" a.m. ,age 4& 2 "#00 Mit-hell Re)air Information Com)any %%C.

CYLINDER !EAD

&alve Springs

'ree (ength

Inner ".)*+, -./.0 mm1

Inner 2inimum ".)/), -.3.+* mm1

4uter ".5.*, -.*.0* mm1

4uter 2inimum ".5%), -./.3" mm1

4ut64f6S7uare

Inner

-"1

4uter .05., -"..5 mm1

-"1

Information is not available from manufacturer.

-%1

8eight measured from top of installed valve to spring seat. See VALVE

INS"ALLED !EIG!" table under C9(IN#E$ 8E:# under 4&E$8:;(.

Application Speciication

C!linder 8ead 8eight 5.%3)65.%3/, -"...*+6".).0+

mm1

2a<imum Warpage -:ll 2achined Surfaces1

-"1

.00+, -."5 mm1

&alve Seat

Seat :ngle )5=

2argin Thickness 2inimum

Intake .0.., -./) mm1

E<haust .0.5, -./* mm1

Seat Contact Width .0)36.0+., -"."*6".+0 mm1

&alve >uides

&alve >uide I.#.

Intake ? E<haust .%.++6.%.3), -+.0"6+.0.

mm1

&alve >uide Installed 8eight

-%1

.))*6.)+*, -"".)06"".*" mm1

&alve Stem6To6>uide 4il Clearance

Intake .00"06.00%), -.0%56.0+"

mm1

E<haust .00"%6.00%+, -.0.06.0++

mm1

Service (imit .003*, -.%0" mm1

2002 Kia Sportage

2002 EN"#NE! 2.0$ %&'(linder & !portage

)ewlett&*ackard

s+bado, 02 de agosto de 20-% 0.:%-:%2 a.m. *age /0 1 20-- 2itchell Repair #nformation 'ompan(, $$'.

C&/"0&-(

(1)

DO NOT machine more than .008" (.20 mm) from deck or manifold surfaces.

(2)

Measured from top of installed uide to sprin seat.

&ppli!ation #n. 1mm2

!ournal Diameter 1.1"8"#1.1"$" (2$.$%$#

2$.$&')

Ma(imum !ournal Out#Of#)ound .002 (.0*0)

Ma(imum !ournal )unout .002 (.0*0)

Oil +learance .001'#.00%% (.0%&#.08')

,tandard -o.e /eiht 1.""%" ('*.0*2)

Minimum -o.e /eiht 1."&*8 (''.8*1)

"##" Kia S)ortage

2002 ENGINES 2.0L 4-Cylinder - Sportage

Hewlett-Packard

s!ado" 02 de agosto de 20#4 0$%4#%42 a.&. Page '( ) 20## *itc+ell ,epair In-or&ation Co&pany" LLC.

También podría gustarte

- Apex'i Super ITC English ManualDocumento37 páginasApex'i Super ITC English ManualAkemi SeagalAún no hay calificaciones

- Torque Motor KiaDocumento54 páginasTorque Motor KiaIvan Montaluisa67% (3)

- En Tech E4wdDocumento1 páginaEn Tech E4wdwirelesssoulAún no hay calificaciones

- Mazda Pick-Ups 1972-93 B2000 and B2200 Engines (With Timing Belt)Documento1 páginaMazda Pick-Ups 1972-93 B2000 and B2200 Engines (With Timing Belt)Migue KuroAún no hay calificaciones

- 4g93 1996 Diagrama EléctricoDocumento5 páginas4g93 1996 Diagrama EléctricoRodríguez Andrés100% (1)

- Automatic A/C Circuit Diagram for 2004 Hyundai Santa Fe BaseDocumento75 páginasAutomatic A/C Circuit Diagram for 2004 Hyundai Santa Fe Basejuan50% (2)

- Hyundai ExcelDocumento7 páginasHyundai ExcelJin Tedy Summer Sayas Ayala100% (1)

- Engine Mechanical: Precautions and Preparations Timing ChainDocumento88 páginasEngine Mechanical: Precautions and Preparations Timing ChainJames HavocAún no hay calificaciones

- Sincronizacion de Motor Suzuki j24bDocumento15 páginasSincronizacion de Motor Suzuki j24bAndrés Sanín100% (2)

- HYUNDAI I10 1.1 12V G4HG: Timing Belt: Removal/installationDocumento12 páginasHYUNDAI I10 1.1 12V G4HG: Timing Belt: Removal/installationArmando joseAún no hay calificaciones

- Mazda l3 With TC Engine Workshop Manual PDFDocumento70 páginasMazda l3 With TC Engine Workshop Manual PDFJuan Idrovo100% (1)

- Honda BalladeDocumento5 páginasHonda BalladeManzini Mbongeni0% (1)

- Verna WorkshopDocumento1230 páginasVerna WorkshopYasser NassarAún no hay calificaciones

- Overhaul Guide for B3 EngineDocumento44 páginasOverhaul Guide for B3 EnginesatthatAún no hay calificaciones

- Diagrams Sistema Eléctrico / Wiring Diagram Electrical System Hino 300 XZU600 / XZU700 /WU600 / WU700Documento17 páginasDiagrams Sistema Eléctrico / Wiring Diagram Electrical System Hino 300 XZU600 / XZU700 /WU600 / WU700JC Ramos100% (1)

- Engine Mechanical (2Rz-Fe, 3Rz-Fe) : Service DataDocumento4 páginasEngine Mechanical (2Rz-Fe, 3Rz-Fe) : Service DataDavid R PaucaraAún no hay calificaciones

- Mitsubishi Galant 4g63 Engine Repair ManualDocumento29 páginasMitsubishi Galant 4g63 Engine Repair ManualMoaed Kanbar100% (1)

- Terracan BodyDocumento137 páginasTerracan BodyIvan Alexandru50% (2)

- Toyota 2L Engine MechanicalDocumento68 páginasToyota 2L Engine Mechanicalgoogilee94% (18)

- Engine Mechanical System ManualDocumento5 páginasEngine Mechanical System ManualJC Ramos25% (4)

- Toyota 2E, 2E-E, 2E-TE (1.3 L) Engine - Review and Specs, ServiceDocumento10 páginasToyota 2E, 2E-E, 2E-TE (1.3 L) Engine - Review and Specs, ServiceBoncu BoncuAún no hay calificaciones

- 1 - A - Manual de Taller Motor D4B Del Hyundai H1 (Inglés) (001-086)Documento86 páginas1 - A - Manual de Taller Motor D4B Del Hyundai H1 (Inglés) (001-086)Lala Céspedes100% (1)

- 1989 Nissan Sentra 1.6L Automatic Manual Transmission OverhaulDocumento29 páginas1989 Nissan Sentra 1.6L Automatic Manual Transmission OverhaulRubenAún no hay calificaciones

- Mitsubishi 4G9 4G92 4G93 4G94 Series Engine Repair ManualDocumento112 páginasMitsubishi 4G9 4G92 4G93 4G94 Series Engine Repair Manualyosbal carballoAún no hay calificaciones

- Toyota 2TRDocumento3 páginasToyota 2TRAllvaro Torrico100% (1)

- 1997 Terios j100 PDFDocumento1009 páginas1997 Terios j100 PDFmarcelo ustarez100% (1)

- Toyota Avanza 2015-5Documento1 páginaToyota Avanza 2015-5José Luis100% (1)

- Toyota 1kd-ftv Pares de AprieteDocumento1 páginaToyota 1kd-ftv Pares de AprieteTAMIRU TESFAYEAún no hay calificaciones

- Diagramas Electricos Toyota Yaris l4-1.5l (1nz-Fe) 2007 FreeDocumento33 páginasDiagramas Electricos Toyota Yaris l4-1.5l (1nz-Fe) 2007 FreeEDWINAún no hay calificaciones

- Engine mechanical guideDocumento204 páginasEngine mechanical guidehectorgonzalezm100% (6)

- Cooling System: Engine - 2Tr-Fe Engine EG-18Documento2 páginasCooling System: Engine - 2Tr-Fe Engine EG-18Maxi SardiAún no hay calificaciones

- Festiva-Pride Engine PartsDocumento66 páginasFestiva-Pride Engine Partsacchacal100% (1)

- M2000 J1-26 Pin Connector Wiring DiagramDocumento2 páginasM2000 J1-26 Pin Connector Wiring DiagramRoland AchaiAún no hay calificaciones

- Nissan Seccion MT Standar Fs5w71c, Fs5r30a, Fs5w71c, Fs5r30aDocumento64 páginasNissan Seccion MT Standar Fs5w71c, Fs5r30a, Fs5w71c, Fs5r30aAlex BassocoAún no hay calificaciones

- Yaris SDSDocumento10 páginasYaris SDSGilbert Vasquez SagunAún no hay calificaciones

- 2zr Fe Engine Mechanical Cylinder Head Gasket Installation 2009 Matrix PDFDocumento7 páginas2zr Fe Engine Mechanical Cylinder Head Gasket Installation 2009 Matrix PDFruben carranza100% (1)

- Mitsubishi Orion EngineDocumento5 páginasMitsubishi Orion Enginenew0% (3)

- Platinum Sprint 500 Wiring Rev F PDFDocumento1 páginaPlatinum Sprint 500 Wiring Rev F PDFHAYNER86Aún no hay calificaciones

- Toyota 2AZ-FE Engine Assemblyy InfoDocumento10 páginasToyota 2AZ-FE Engine Assemblyy Infomatderis100% (1)

- Preparation 1zr-Fe Engine Mechanical Equipment PDFDocumento1 páginaPreparation 1zr-Fe Engine Mechanical Equipment PDFAlbert BriceñoAún no hay calificaciones

- Important Manual InstructionsDocumento644 páginasImportant Manual InstructionsSIVA SAKTHI TRAVELS100% (7)

- 1y 2y 3y 4yDocumento5 páginas1y 2y 3y 4yBeloforteAún no hay calificaciones

- Motor Ka24de Nissan Frontier 2.4l ManualDocumento52 páginasMotor Ka24de Nissan Frontier 2.4l ManualIsaac ArispeAún no hay calificaciones

- Mazda bt50 Workshop Manual1149Documento1 páginaMazda bt50 Workshop Manual1149Leo Villa0% (1)

- Nissan Altima ECU GuideDocumento8 páginasNissan Altima ECU GuideJimmy Aleman67% (3)

- Opel Astra G 1.6 Technical Specs and Service Data Manual 2000-2005Documento2 páginasOpel Astra G 1.6 Technical Specs and Service Data Manual 2000-2005Mircea PetrescuAún no hay calificaciones

- Engine Zna RichDocumento40 páginasEngine Zna RichEMILIO “ER NEGRO MECANICO” GONZALEZ100% (9)

- Especifcaciones NISSAN TERRANO TD27Documento2 páginasEspecifcaciones NISSAN TERRANO TD27rob2rto83% (6)

- Engine 1.6L (Steem G16) PDFDocumento18 páginasEngine 1.6L (Steem G16) PDFAry Duran0% (1)

- 5.7l-Engine Repair ProcDocumento21 páginas5.7l-Engine Repair ProcfinjaegerAún no hay calificaciones

- 2.5L 4-CYL - VIN (P) : 1993 Jeep CherokeeDocumento19 páginas2.5L 4-CYL - VIN (P) : 1993 Jeep CherokeeAlberto DelcastillooAún no hay calificaciones

- 2148361Documento11 páginas2148361Robert TuckerAún no hay calificaciones

- Motor Volkswagen GolfDocumento22 páginasMotor Volkswagen GolfcarbutzAún no hay calificaciones

- 4.0L V8 - VINS (K, U) Selected Block: Removal & InstallationDocumento19 páginas4.0L V8 - VINS (K, U) Selected Block: Removal & InstallationsixdownAún no hay calificaciones

- Engine Identification: Removal (Carbureted Models)Documento18 páginasEngine Identification: Removal (Carbureted Models)(Obr-Bto) Francisco Antonio Lizardo SalasAún no hay calificaciones

- 4.2L EngineDocumento28 páginas4.2L Engineadnmb100% (6)

- 24L FourDocumento28 páginas24L FourIqbal NugrohoAún no hay calificaciones

- Windstar 2000-2001 3.8 v6Documento77 páginasWindstar 2000-2001 3.8 v6pegoAún no hay calificaciones

- 2.4l 5 Cyl Vin 55Documento25 páginas2.4l 5 Cyl Vin 55Rogério MorenoAún no hay calificaciones

- Engine - Repair - 1999-2000 Engine - Repair - AAA, AFP VR6Documento19 páginasEngine - Repair - 1999-2000 Engine - Repair - AAA, AFP VR6Dany Pistiner100% (3)

- Manual Puesta A Punto - FEDERAL MOGULDocumento107 páginasManual Puesta A Punto - FEDERAL MOGULjsdrums100% (2)

- K 98 MCC 7Documento383 páginasK 98 MCC 7Мария ЗинченкоAún no hay calificaciones

- Motor Volkswagen GolfDocumento22 páginasMotor Volkswagen GolfcarbutzAún no hay calificaciones

- Hyundai KM 170 A 177Documento61 páginasHyundai KM 170 A 177carbutzAún no hay calificaciones

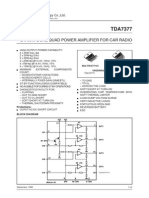

- 2 X 3 W Dual/Quad Power Amplifier For Car Radio: ProtectionsDocumento10 páginas2 X 3 W Dual/Quad Power Amplifier For Car Radio: ProtectionsJosé VidalAún no hay calificaciones

- Bonluck MCI LZ Falcon 45 Operator & Maintenance ManualDocumento116 páginasBonluck MCI LZ Falcon 45 Operator & Maintenance ManualCarl Von RydingAún no hay calificaciones

- 6T70/6T75 6T70/6T75 : The Future Future Is Now Is NowDocumento14 páginas6T70/6T75 6T70/6T75 : The Future Future Is Now Is NowMarcos Montes100% (1)

- 391 Diesel Operator Manual 3918071001 EN 09-2010Documento284 páginas391 Diesel Operator Manual 3918071001 EN 09-2010Luis Miron100% (1)

- AGT1500 Turbine TechnologyDocumento2 páginasAGT1500 Turbine TechnologySehun CheonAún no hay calificaciones

- Question Bank On LHB Design CoachesDocumento30 páginasQuestion Bank On LHB Design CoachesCRS Tirupati100% (1)

- Screenshot 2023-02-23 at 7.47.54 PM PDFDocumento129 páginasScreenshot 2023-02-23 at 7.47.54 PM PDFAhmad GaberAún no hay calificaciones

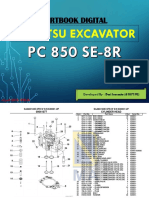

- Partbook PC850SE-8RDocumento573 páginasPartbook PC850SE-8RHeng Heng100% (1)

- What Is This? This Is A... 10 PointsDocumento11 páginasWhat Is This? This Is A... 10 PointsCantika PutriAún no hay calificaciones

- PT Cruiser Error CodesDocumento19 páginasPT Cruiser Error CodesChris GreekAún no hay calificaciones

- Jake BrackDocumento6 páginasJake BrackDaniel DiazAún no hay calificaciones

- Calibracion Valvulas Motor c12 CaterpillarDocumento5 páginasCalibracion Valvulas Motor c12 CaterpillarEduardo TorresAún no hay calificaciones

- Kerax AnglDocumento8 páginasKerax AnglGustavo Torres Gonzalez100% (1)

- w164 Wiring Diagram of Rear Signal Acquisition and Actuation Module Sam Control UnitDocumento10 páginasw164 Wiring Diagram of Rear Signal Acquisition and Actuation Module Sam Control Uniteriks pakuls50% (2)

- Teste Freio e Acumulador 938HDocumento10 páginasTeste Freio e Acumulador 938HCesar AugustoAún no hay calificaciones

- Https Vahan - Parivahan.gov - in Vahanservice Vahan Ui Onlineservice Form 23 RC Report - XHTMLDocumento1 páginaHttps Vahan - Parivahan.gov - in Vahanservice Vahan Ui Onlineservice Form 23 RC Report - XHTMLzaid AhmedAún no hay calificaciones

- JAC Pick-Ups ManualDocumento49 páginasJAC Pick-Ups ManualDavid CoboAún no hay calificaciones

- Linhai UTV 1100 Diesel Manual enDocumento108 páginasLinhai UTV 1100 Diesel Manual enAlin IagerAún no hay calificaciones

- Wheel Loader Parts CatalogDocumento212 páginasWheel Loader Parts CatalogssinokrotAún no hay calificaciones

- Concept Design of Twist Beam Rear AxlesDocumento5 páginasConcept Design of Twist Beam Rear AxlesArunKumarAún no hay calificaciones

- SEBP7406Documento118 páginasSEBP7406Joseph Cristhian Huilcapaz CondoriAún no hay calificaciones

- 5664 3 4CX Eco T4 FINALDocumento8 páginas5664 3 4CX Eco T4 FINALAndrei AndreiAún no hay calificaciones

- One Cylinder ModelsDocumento4 páginasOne Cylinder ModelsPaul MartinAún no hay calificaciones

- Bulletin MTB-200917G PDFDocumento3 páginasBulletin MTB-200917G PDFІгор БородакевичAún no hay calificaciones

- VW Polo Sedan 1.6 Manual Guide 2006Documento2 páginasVW Polo Sedan 1.6 Manual Guide 2006avm4343Aún no hay calificaciones

- Egr - Fault CodesDocumento12 páginasEgr - Fault CodesManuel FernandezAún no hay calificaciones

- Real Time Simulation and Parametric Optimization Applied To Racing Cars The BMW Team Brasil Case PDFDocumento47 páginasReal Time Simulation and Parametric Optimization Applied To Racing Cars The BMW Team Brasil Case PDFDebra JacksonAún no hay calificaciones

- SK135SR 3Documento8 páginasSK135SR 3Ono MatshitaAún no hay calificaciones

- Installation Recommendations For Timing Systems On GM1 (1) .4 1Documento2 páginasInstallation Recommendations For Timing Systems On GM1 (1) .4 1DAún no hay calificaciones

- 2016 Mini Buggy GK005Documento1 página2016 Mini Buggy GK005clauuss81Aún no hay calificaciones