Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Especificacion Agua para Intercooler

Cargado por

Fabian MolinaDescripción original:

Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Especificacion Agua para Intercooler

Cargado por

Fabian MolinaCopyright:

Formatos disponibles

GE PACKAGED POWER, L.P.

A GE Energy Business

COPYRIGHT, 2007 GE PACKAGED POWER, L.P., ALL RIGHTS RESERVED. THIS TECHNICAL SPECIFICATION IS THE

PROPRIETARY AND/OR PROPERTY OF GE PACKAGED POWER, L.P., AND IS LOANED IN STRICT CONFIDENCE WITH THE

UNDERSTANDING THAT IT WILL NOT BE REPRODUCED NOR USED FOR ANY PURPOSE EXCEPT THAT FOR WHICH IT IS

LOANED. IT SHALL BE IMMEDIATELY RETURNED ON DEMAND, AND IS SUBJECT TO ALL OTHER TERMS AND CONDITIONS

OF ANY WRITTEN AGREEMENT OR PURCHASE ORDER WHICH INCORPORATES OR RELATES TO THE TECHNICAL

SPECIFICATION.

TS000533

REV A

Page 1 of 6

GEAE-523 Rev. H August 07

EQUIPMENT DATA SPECIFICATION

REQUIREMENTS FOR WATER FOR

INTERCOOLER AND HEAT EXCHANGERS

REV DESCRIPTION

A ORIGINAL ISSUE PER ECO 0040882 ISSUED: December 26, 2007

GE PACKAGED POWER, L.P.

A GE Energy Business

COPYRIGHT, 2007 GE PACKAGED POWER, L.P., ALL RIGHTS RESERVED. THIS TECHNICAL SPECIFICATION IS THE

PROPRIETARY AND/OR PROPERTY OF GE PACKAGED POWER, L.P., AND IS LOANED IN STRICT CONFIDENCE WITH THE

UNDERSTANDING THAT IT WILL NOT BE REPRODUCED NOR USED FOR ANY PURPOSE EXCEPT THAT FOR WHICH IT IS

LOANED. IT SHALL BE IMMEDIATELY RETURNED ON DEMAND, AND IS SUBJECT TO ALL OTHER TERMS AND CONDITIONS

OF ANY WRITTEN AGREEMENT OR PURCHASE ORDER WHICH INCORPORATES OR RELATES TO THE TECHNICAL

SPECIFICATION.

TS000533

REV A

Page 2 of 6

GEAE-523 Rev. H August 07

TABLE OF CONTENTS

1.0 SCOPE

2.0 REFERENCE DOCUMENTS

3.0 QUALITY

GE PACKAGED POWER, L.P.

A GE Energy Business

COPYRIGHT, 2007 GE PACKAGED POWER, L.P., ALL RIGHTS RESERVED. THIS TECHNICAL SPECIFICATION IS THE

PROPRIETARY AND/OR PROPERTY OF GE PACKAGED POWER, L.P., AND IS LOANED IN STRICT CONFIDENCE WITH THE

UNDERSTANDING THAT IT WILL NOT BE REPRODUCED NOR USED FOR ANY PURPOSE EXCEPT THAT FOR WHICH IT IS

LOANED. IT SHALL BE IMMEDIATELY RETURNED ON DEMAND, AND IS SUBJECT TO ALL OTHER TERMS AND CONDITIONS

OF ANY WRITTEN AGREEMENT OR PURCHASE ORDER WHICH INCORPORATES OR RELATES TO THE TECHNICAL

SPECIFICATION.

TS000533

REV A

Page 3 of 6

GEAE-523 Rev. H August 07

1.0 SCOPE

1.1 This specification covers the minimum general and specific requirements for the purity of Water

for intercoolers and heat exchangers. This is intended to be included as a component part of a GE

Packaged Power, L.P. (GE PPLP) gas turbine package.

1.2 The Customer shall comply with the GE PPLP Engineering technical specific for proper

operation and life of GE PPLP gas turbine package.

1.3 The most recent editions or revisions of the referenced documents shall, to the extent specified

herein, form a part of this specification.

2.0 REFERENCE DOCUMENTS

2.1 ASTM D512 Standard Test Method for Chloride Ion in Water

2.2 ASTM D516 Standard Test Method for Sulfate Ion in Water

2.3 ASTM D859 Standard Test Method for Silica in Water

2.4 ASTM D1066 Standard Practice for Sampling Steam

2.5 ASTM D1125 Standard Test Method for Electrical Conductivity and Resistively of

Water

2.6 ASTM D3370 Standard Test Method for Sampling Water from closed Conduits

2.7 ASTM D4191 Standard Test Method for Sodium in Water by Atomic Absorption

Spectrograph

2.8 ASTM D4192 Standard Test Method for Potassium in Water by Atomic Absorption

Spectrograph

2.9 ASTM D5907 Standard Test Method for Filterable and Non-Filterable Matter in Water

2.10 ASTM D5464 Standard Test Method for pH of Water with Low Conductivity

2.11 EPA Environmental Protection Agency Test Methods

2.11.1 EPA 120.1 Conductance, Specific Conductance at 25C

2.11.2 EPA 150.1 pH Electrometric

2.11.3 EPA 160.3 Residue, Non-Filterable and Total Suspended Solids

2.11.4 EPA 200.7 Metals & Trace Elements

2.11.5 EPA 325.3 Chloride, Titrimetric Mercuric Nitrate

GE PACKAGED POWER, L.P.

A GE Energy Business

COPYRIGHT, 2007 GE PACKAGED POWER, L.P., ALL RIGHTS RESERVED. THIS TECHNICAL SPECIFICATION IS THE

PROPRIETARY AND/OR PROPERTY OF GE PACKAGED POWER, L.P., AND IS LOANED IN STRICT CONFIDENCE WITH THE

UNDERSTANDING THAT IT WILL NOT BE REPRODUCED NOR USED FOR ANY PURPOSE EXCEPT THAT FOR WHICH IT IS

LOANED. IT SHALL BE IMMEDIATELY RETURNED ON DEMAND, AND IS SUBJECT TO ALL OTHER TERMS AND CONDITIONS

OF ANY WRITTEN AGREEMENT OR PURCHASE ORDER WHICH INCORPORATES OR RELATES TO THE TECHNICAL

SPECIFICATION.

TS000533

REV A

Page 4 of 6

GEAE-523 Rev. H August 07

2.11.6 EPA 375.4 Sulfate, Turbidimetric

3.0 QUALITY

User shall develop water chemistry regiment that meets or exceeds the following performance characteristics

requirements when tested in accordance with the designated test methods:

3.1 Total Dissolved Solids < 5,000 ppm

3.2 Total Suspended Solids < 50 ppm

3.3 Maximum Particle Size 50 microns

3.4 Cooling Tower System

3.4.1 2.0 mils/yr or less on unpretreated mild steel coupons (no visible pitting)

3.4.2 0.2 mils/yr or less for 90/10 copper/nickel coupons (no visible pitting)

3.4.3 0.1 mils/yr or less for stainless steel (316 grade) coupons (no visible pitting)

3.4.4 10

4

colony-forming units or less heterotrophic bacteria (planktonic) and 10

5

colony forming units

or less heterotrophic bacteria (sessile)

3.4.5 No visible deposition as determined by heat exchanger inspection.

3.5 Closed Cooling System

3.5.1 0.5 mils/yr or less on unpretreated mild steel coupons (no visible pitting)

3.5.2 0.1 mils/yr or less for 90/10 copper/nickel coupons (no visible pitting)

3.5.3 0.1 mils/yr or less for stainless steel (316 grade) coupons (no visible pitting)

3.5.4 10

3

colony-forming units or less heterotrophic bacteria (planktonic) and 10

5

colony forming units

or less heterotrophic bacteria (sessile)

3.5.5 No visible deposition as determined by heat exchanger inspection.

3.6 Corrosion monitoring should conform to ASTM Standard 2688-94 or CTI Testing

Procedures (Corrosion Coupon Testing)

3.7 Microbiological testing should conform to ATP methods. GE Water & Process Technologies

MB013 and MB014 attached for reference.

GE PACKAGED POWER, L.P.

A GE Energy Business

COPYRIGHT, 2007 GE PACKAGED POWER, L.P., ALL RIGHTS RESERVED. THIS TECHNICAL SPECIFICATION IS THE

PROPRIETARY AND/OR PROPERTY OF GE PACKAGED POWER, L.P., AND IS LOANED IN STRICT CONFIDENCE WITH THE

UNDERSTANDING THAT IT WILL NOT BE REPRODUCED NOR USED FOR ANY PURPOSE EXCEPT THAT FOR WHICH IT IS

LOANED. IT SHALL BE IMMEDIATELY RETURNED ON DEMAND, AND IS SUBJECT TO ALL OTHER TERMS AND CONDITIONS

OF ANY WRITTEN AGREEMENT OR PURCHASE ORDER WHICH INCORPORATES OR RELATES TO THE TECHNICAL

SPECIFICATION.

TS000533

REV A

Page 5 of 6

GEAE-523 Rev. H August 07

3.8 GE PPLP recommends all users to engage qualified water treatment professionals to design and

maintain treatment system to provide the above performance characteristics. Should the user so

desire, GE Water & Process Technologies can provide this service.

Note: The above, coupled with the following component characteristics, provides all required

information to develop the water chemistry to meet the Required Water Performance

Characteristics.

GE PACKAGED POWER, L.P.

A GE Energy Business

COPYRIGHT, 2007 GE PACKAGED POWER, L.P., ALL RIGHTS RESERVED. THIS TECHNICAL SPECIFICATION IS THE

PROPRIETARY AND/OR PROPERTY OF GE PACKAGED POWER, L.P., AND IS LOANED IN STRICT CONFIDENCE WITH THE

UNDERSTANDING THAT IT WILL NOT BE REPRODUCED NOR USED FOR ANY PURPOSE EXCEPT THAT FOR WHICH IT IS

LOANED. IT SHALL BE IMMEDIATELY RETURNED ON DEMAND, AND IS SUBJECT TO ALL OTHER TERMS AND CONDITIONS

OF ANY WRITTEN AGREEMENT OR PURCHASE ORDER WHICH INCORPORATES OR RELATES TO THE TECHNICAL

SPECIFICATION.

TS000533

REV A

Page 6 of 6

GEAE-523 Rev. H August 07

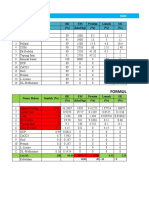

LM Heat Exchange Characteristics (Maximum values are given below.

It is recommended that site-specific data be obtained for the LMS Intercooler.)

Component

Heat Exchanger

Interface Material

Metal Interface

Maximum

Temperature (F)

Water Velocity

Flow Rate (GPM)

Water Velocity

within Heat

Exchanger (FPS)

Max Heat Rejection

BTU/Min)

LMS100

Intercooler

Cu/Ni 192 6000 6.8 2,200,000

LMS100 Mineral

Lube Oil Cooler

Admiralty 116 720 6.9 70,000

LMS100 Synthetic

Lube Oil Cooler

* (See note)

316 SS 117 100 6.2

7,800

Component

Component

Component

Component

Component

* Note: For units produced before to 2Q08, Customers should check with GE to confirm material in SLO system.

Units built prior to 2Q08 contain 304SS instead of 316SS. GE will be releasing a bulletin to provide customers the

option of changing to 316SS

También podría gustarte

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (119)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2099)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- CSWIP 3.1 Multiple Choice-5Documento32 páginasCSWIP 3.1 Multiple Choice-5randhir kumar jhaAún no hay calificaciones

- Test Bank For Organic Chemistry, 7e Marc Loudon, Jim Parise Test BankDocumento8 páginasTest Bank For Organic Chemistry, 7e Marc Loudon, Jim Parise Test BankNail BaskoAún no hay calificaciones

- Stoichiometry & The Mole Concept - TeachifyMe PDFDocumento5 páginasStoichiometry & The Mole Concept - TeachifyMe PDFMuhammad Tauseef100% (2)

- Exploring The Future Role of Hydrogen in Power Generation White Paper Burns McDonnell 22115Documento6 páginasExploring The Future Role of Hydrogen in Power Generation White Paper Burns McDonnell 22115Vikas SareenAún no hay calificaciones

- Chapter 16 LQDocumento4 páginasChapter 16 LQ叶子临Aún no hay calificaciones

- Lubriplate Synxtreme Fg/220 Series: ISO-9001 Registered Quality System. ISO-21469 CompliantDocumento2 páginasLubriplate Synxtreme Fg/220 Series: ISO-9001 Registered Quality System. ISO-21469 Compliantnalky1975Aún no hay calificaciones

- Msds (Sodium Hydrochlorite) PDFDocumento6 páginasMsds (Sodium Hydrochlorite) PDFAyman Medaney100% (1)

- IGCSE EdExcel 9 1 Chemistry Topic 1 Principles of ChemistryDocumento115 páginasIGCSE EdExcel 9 1 Chemistry Topic 1 Principles of ChemistryRobnawaz KhanAún no hay calificaciones

- Chemetall - (Data Sheet) Oakite 33Documento3 páginasChemetall - (Data Sheet) Oakite 33Pubcrawl100% (1)

- Fragmentation of Organic Compounds in EI-MSDocumento18 páginasFragmentation of Organic Compounds in EI-MSMoustafa ElsadanyAún no hay calificaciones

- As and A Level Chemistry Core Practical 4 Hydrolysis Student Teacher Technician WorksheetsDocumento5 páginasAs and A Level Chemistry Core Practical 4 Hydrolysis Student Teacher Technician WorksheetsonehllznAún no hay calificaciones

- Assessment of Vanadium in Stream Sediments From River Mbete, Loum Area (Pan-African Fold Belt, Cameroon) : Implications For Vanadium ExplorationDocumento14 páginasAssessment of Vanadium in Stream Sediments From River Mbete, Loum Area (Pan-African Fold Belt, Cameroon) : Implications For Vanadium ExplorationInternational Journal of Innovative Science and Research TechnologyAún no hay calificaciones

- How Much Caffeine in Your Cup? Measuring Levels in Tea SamplesDocumento9 páginasHow Much Caffeine in Your Cup? Measuring Levels in Tea SamplesKim TaesiAún no hay calificaciones

- Grade 12 Chem Final ExamDocumento3 páginasGrade 12 Chem Final Examabdimoh7522Aún no hay calificaciones

- Analisis Del Carbono Organico TotalDocumento6 páginasAnalisis Del Carbono Organico TotalCarlos Alberto Ormeño OrtizAún no hay calificaciones

- Bamboo Fiber & It'S Processing: by Amol V. Talware (Final T.C.)Documento27 páginasBamboo Fiber & It'S Processing: by Amol V. Talware (Final T.C.)Aditya Bhansali100% (1)

- Conversion of Crude Glycerol to BiodieselDocumento12 páginasConversion of Crude Glycerol to BiodieselIngJesusGutierrezZenilAún no hay calificaciones

- Boiler Water ChemistryDocumento60 páginasBoiler Water ChemistryBhargav Chaudhari93% (14)

- First LE Exam Reviewer Answer KeyDocumento2 páginasFirst LE Exam Reviewer Answer KeyLeah Ann Mari BongcoAún no hay calificaciones

- Flame Resistant Cable LSZHDocumento2 páginasFlame Resistant Cable LSZHshinojbaby4148Aún no hay calificaciones

- Vapour Pressure LabDocumento8 páginasVapour Pressure LabTuqeer MuhammadAún no hay calificaciones

- Millar 2017Documento54 páginasMillar 2017Krishna DangiAún no hay calificaciones

- Organic Chemistry Worksheet 4Documento4 páginasOrganic Chemistry Worksheet 4tun1123tAún no hay calificaciones

- Experiment 6 - Comparative Investigation of Organic CompoundsDocumento6 páginasExperiment 6 - Comparative Investigation of Organic CompoundsIson Dy100% (2)

- OCLAB Exercise 5Documento5 páginasOCLAB Exercise 5Kay AbawagAún no hay calificaciones

- Nomenclature of Polyfunctional Organic CompoundsDocumento19 páginasNomenclature of Polyfunctional Organic CompoundsH to O ChemistryAún no hay calificaciones

- 2022 Thermodynamic Analysis of Gold Leaching by Copper-Glycine-Thiosulfate Solutions Using Eh-pH and Species Distribution DiagramsDocumento11 páginas2022 Thermodynamic Analysis of Gold Leaching by Copper-Glycine-Thiosulfate Solutions Using Eh-pH and Species Distribution DiagramsaucapuriAún no hay calificaciones

- Construction and Building Materials: David O. Koteng, Chun-Tao ChenDocumento7 páginasConstruction and Building Materials: David O. Koteng, Chun-Tao ChenMarden Rengifo RuizAún no hay calificaciones

- KANDUNGAN ZAT MAKANAN BAHAN PAKAN UNGGASDocumento5 páginasKANDUNGAN ZAT MAKANAN BAHAN PAKAN UNGGASIrma Rahayu NingrumAún no hay calificaciones

- Chemistry Diagnostic TestDocumento3 páginasChemistry Diagnostic TestJohn John RoacheAún no hay calificaciones