Documentos de Académico

Documentos de Profesional

Documentos de Cultura

777D Off Highway Truck: Service Training Malaga

Cargado por

Evan AT YoelTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

777D Off Highway Truck: Service Training Malaga

Cargado por

Evan AT YoelCopyright:

Formatos disponibles

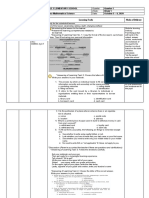

SUSPENSION CYLINDER

DURING COMPRESSION

Service Training

MALAGA

777D Off Highway Truck

Adolfo

August 1997

VIII SUSPENSION.

1. Components Layout

2. Operation

3. Maintenance

4. Testing & Adjusting

CHAPTER : SUSPENSION

777D Off Highway Truck

VIII1 Page:

S

U

S

P

E

N

S

I

O

N

C

Y

L

I

N

D

E

R

D

U

R

I

N

G

C

O

M

P

R

E

S

S

I

O

N

CHAPTER : SUSPENSION

777D Off Highway Truck

VIII2 Page:

S

U

S

P

E

N

S

I

O

N

C

Y

L

I

N

D

E

R

D

U

R

I

N

G

E

X

T

E

N

S

I

O

N

C

H

A

P

T

E

R

:

S

U

S

P

E

N

S

I

O

N

7

7

7

D

O

f

f

H

i

g

h

w

a

y

T

r

u

c

k

V

I

I

I

3

P

a

g

e

:

CENTERED

EXTENDING

COMPRESSING

SUSPENSION CYLINDER

BALL CHECK VALVE AND ORIFICE OPERATION

ROD

HOUSING

C

H

A

P

T

E

R

:

S

U

S

P

E

N

S

I

O

N

7

7

7

D

O

f

f

H

i

g

h

w

a

y

T

r

u

c

k

V

I

I

I

4

P

a

g

e

:

GREASE

VALVE

GLAND

TUBE

PISTON

CHARGING

VALVE

BALL

CHECK VALVE

WEAR

RING

FRONT SUSPENSION

CYLINDER

CHARGING

VALVE

BALL

CHECK

VALVE

ORIFICE

REAR SUSPENSION

CYLINDER

ORIFICES

C

H

A

P

T

E

R

:

S

U

S

P

E

N

S

I

O

N

7

7

7

D

O

f

f

H

i

g

h

w

a

y

T

r

u

c

k

V

I

I

I

5

P

a

g

e

:

SUSPENSION GAS

VOLUME CHANGE UNDER PRESSURE

.095 LITER

(.1 QUART)

OF

NITROGEN

2050 kPa

(300 psi)

1.9 LITERS

(2.0 QUARTS)

LOW OIL

100 kPa

(15 psi)

CHAPTER : SUSPENSION

777D Off Highway Truck

VIII6 Page:

FRONT SUSPENSION CHARGING SEQUENCE:

Check for and eliminate any oil or nitrogen leaks.

Make sure the truck is empty and on level ground.

Put the open end of the suspension charging lines into an approved container. Open the charging valves

and allow the oil and nitrogen to drain from the suspension cylinders into the container.

Position a thin strip of sheet metal on both suspension cylinders. Place a piece of masking tape on the

sheet metal with the top edge of the tape even with the top of the spindle. Put a line across the

tape 12.7mm (0.50in) below the top edge of the tape.

Cycle some oil through the charging lines to fill them with clean oil.

Inject oil into the cylinders until each cylinder extends to the line made on the masking tapE.

To prevent oil flow from the suspension cylinders, adjust the nitrogen cylinder regulated pressure to

4150 kPa (600 psi). Charge the cylinders until the gauge blocks (and shims if required) can be

installed between the spindle and the cylinder housing.

Drain nitrogen from the suspension cylinders until the cylinder housings rest on the gauge blocks and

the regulated nitrogen pressure is less than 2400 kPa (350 psi).

Adjust the regulated nitrogen supply to 2400 kPa (350 psi). Open the charging valves and allow the

nitrogen to flow into the cylinders. Leave the valves open for approximately five minutes to

allow the nitrogen charge pressure to equalize in the two suspension cylinders.

Remove the nitrogen charging group from the suspension cylinders and install the charging valve caps.

Start the engine and raise the dump body to remove the gauge blocks.

CHAPTER : SUSPENSION

777D Off Highway Truck

VIII7 Page:

REAR SUSPENSION CHARGING SEQUENCE:

Check for and eliminate any oil or nitrogen leaks.

Make sure the truck is empty and on level ground.

Put the open end of the suspension charging lines into an approved container. Open the charging valves

and allow the oil and nitrogen to drain from the suspension cylinders into the container.

Position a thin strip of sheet metal on both suspension cylinders. Place a piece of masking tape on the

sheet metal strips with the top edge of the tape even with the top of the cylinder housing. Put

a line across the tape12.7 mm (0.5 in.) below the top edge of the tape. Place another piece of

masking tape on the sheet metal strips and make a line on the tape 101.6 mm (4 in.) below the

top of the cylinder housing. Put another line across the tape 114.3 mm (4.5 in.) below the top

of the cylinder housing (adjust the lower two dimensions for temperature if required).

Cycle some oil through the charging lines to fill them with clean oil.

Inject oil into the cylinders until each cylinder extends to the line made on the masking tape.

To prevent oil flow from the suspension cylinders, adjust the nitrogen cylinder regulated pressure to

2400 kPa (350 psi). Charge the cylinders with nitrogen until the top of the cylinder housing is

located within the two lines made on the lower piece of masking tape. Leave the valves open

for approximately five minutes to allow the nitrogen charge pressure to equalize in the two

suspension cylinders.

Remove the nitrogen charging group from the suspension cylinders and install the charging valve caps.

CHAPTER : SUSPENSION

777D Off Highway Truck

LAB EXERCISES

LAB B

FRONT SUSPENSION CYLINDER CHARGING WORKSHEET

Machine Model _______777D_______________Date_____________________________________

Serial Number ___________________________ Service Meter Hours________________________

Oil Charge Dimension ____________

Nitrogen Charge Dimension Temperature Correction:

Shop Temperature 10 C Outside Temperature -50 C Temperature Difference ________

Temperature Difference X = Shim Thickness ___________________

Corrected Nitrogen Charge Dimension _______________ Nitrogen Charge Pressure _____________

Chrome Length Measurement

After Gauge Block is Removed: * Left Front _____________ Right Front ____________

Wiped Chrome Dimension After Operation: Left Front _____________ Right Front ____________

* dimension between top of spindle and bottom of cylinder housing

SHIMS FOR TEMPERATURE CORRECTION

Shim Thickness

mm/5.5 C

Truck Model (in./10 F)

776D/777D 2.54mm(0.10in)

CHAPTER : SUSPENSION

777D Off Highway Truck

VIII9 Page:

POSTTEST

SUSPENSION SYSTEM POSTTEST

Directions: Modified True/False. If a question is false, underline or circle the word or words that make

the statement incorrect and replace with word(s) to make the statement correct.

Example: F 1. This is an engine class.

1. After the front suspension cylinders are charged with nitrogen and the gauge blocks are

removed, the exposed chrome length will usually be less than the gauge block dimension.

2. Before charging the suspension cylinders with nitrogen, the nitrogen charge hoses must be

pressurized to prevent high pressure oil in the cylinders from flowing into the nitrogen

charge hoses.

3. Always charge two suspension cylinders at the same time.

4. If the truck is in the shop and the temperature outside is 16 C (60 F) colder, the suspension

cylinder nitrogen charge length will be greater.

5. If the truck is in the shop and the temperature outside is 16 C (60 F) colder, the suspension

cylinder oil charge length will be greater.

6. Suspension cylinders will compress faster than they extend because of the ball check valve

located in the cylinder rod.

7. A blue/black patch of stain on the suspension cylinder chrome is caused by heat between the

rod and the wear band. The stain can be polished off and does not affect the wear life of the

suspension cylinder.

8. Greasing the front suspension cylinders too fast can cause the wiper seal to be forced out of

the bottom of the cylinder housing.

También podría gustarte

- Modular Mining Systems The Ultimate Step-By-Step GuideDe EverandModular Mining Systems The Ultimate Step-By-Step GuideAún no hay calificaciones

- The Death of Reliability: Is it Too Late to Resurrect the Last, True Competitive Advantage?De EverandThe Death of Reliability: Is it Too Late to Resurrect the Last, True Competitive Advantage?Aún no hay calificaciones

- 777D Off Highway Truck: Service Training MalagaDocumento16 páginas777D Off Highway Truck: Service Training MalagaEvan AT Yoel100% (1)

- Failure Analysis Report EX1296 - Final Drive LH NoiseDocumento11 páginasFailure Analysis Report EX1296 - Final Drive LH Noiseputri lestariAún no hay calificaciones

- KowaDocumento46 páginasKowaRenzo Martin Manini RojasAún no hay calificaciones

- Sis 2.0 PDFDocumento4 páginasSis 2.0 PDFDahi Med100% (1)

- Catalog Mining Truck 793f CaterpillarDocumento28 páginasCatalog Mining Truck 793f CaterpillardiegoAún no hay calificaciones

- Belaz Competitive Bulletin - 20180403Documento19 páginasBelaz Competitive Bulletin - 20180403PATRICIO CARRASCOAún no hay calificaciones

- Optimizing Mining Truck PerformanceDocumento2 páginasOptimizing Mining Truck PerformanceSunilkumar ReddyAún no hay calificaciones

- PC2000 11Documento6 páginasPC2000 11arun_anuAún no hay calificaciones

- Labor Guidelines Overview For Dealer 22.09.15 TRGDocumento17 páginasLabor Guidelines Overview For Dealer 22.09.15 TRGJean Claude Eid100% (1)

- SOS Fluid Analysis: Maintenance Products & ServicesDocumento53 páginasSOS Fluid Analysis: Maintenance Products & ServicesVane Gamboa MedinaAún no hay calificaciones

- Komatsu Dump Truck HD1500-8Documento6 páginasKomatsu Dump Truck HD1500-8Johnny ZhangAún no hay calificaciones

- Fuel Consumption Figures: A25E - A40E, A25F - A40F, A25G - A45G, A60HDocumento4 páginasFuel Consumption Figures: A25E - A40E, A25F - A40F, A25G - A45G, A60HJoshua SimamoraAún no hay calificaciones

- Section 1 - Assembly IntroductionDocumento3 páginasSection 1 - Assembly IntroductionLuis TorresAún no hay calificaciones

- Truck Body and Canopy - RemoveDocumento5 páginasTruck Body and Canopy - RemoveBelimar CostaAún no hay calificaciones

- 3.1 Components ActuatorDocumento10 páginas3.1 Components ActuatorAyman EsaAún no hay calificaciones

- Komatsu D475A-5E0 Crawler DozerDocumento6 páginasKomatsu D475A-5E0 Crawler Dozereplim6050% (2)

- R996B - EnglishDocumento20 páginasR996B - EnglishHelio RibeiroAún no hay calificaciones

- Liebherr R9100 Ilovepdf CompressedDocumento22 páginasLiebherr R9100 Ilovepdf CompressedMohamed Badian TraoreAún no hay calificaciones

- The Impact of Payload Truck Factor Use in Mine Performance - Articulo PDFDocumento7 páginasThe Impact of Payload Truck Factor Use in Mine Performance - Articulo PDFJhan Carlos Huayra GabrielAún no hay calificaciones

- 01 AfricanMarket E KomatsuDocumento17 páginas01 AfricanMarket E Komatsugirish_patkiAún no hay calificaciones

- OTRG Case Study Diffusion Tyre Explosion PDFDocumento18 páginasOTRG Case Study Diffusion Tyre Explosion PDFjorge dazaAún no hay calificaciones

- Why Wind Turbine Gearboxes FailDocumento4 páginasWhy Wind Turbine Gearboxes FailasantonyrajAún no hay calificaciones

- Mode Selection For D375A-6Documento2 páginasMode Selection For D375A-6alcowo100% (3)

- REHS2516-11 Procedure To Measure Bearing Movement in The Upper and The Lower Articulation HitchDocumento11 páginasREHS2516-11 Procedure To Measure Bearing Movement in The Upper and The Lower Articulation HitchCarlosAún no hay calificaciones

- FPO User Manual: Mining Fleet Productivity OptimizationDocumento32 páginasFPO User Manual: Mining Fleet Productivity OptimizationRicardo ManríquezAún no hay calificaciones

- VIMS ParameterDocumento65 páginasVIMS ParameterTLK ChannelAún no hay calificaciones

- 1721 SlidDocumento206 páginas1721 SlidNova kurniawan 34Aún no hay calificaciones

- Backhoe Loaders WebDocumento4 páginasBackhoe Loaders WebjogremaurAún no hay calificaciones

- HD785 7 PDFDocumento16 páginasHD785 7 PDFraden eko jati kurniawanAún no hay calificaciones

- BELAZDocumento7 páginasBELAZphucdc095041Aún no hay calificaciones

- CAT®Mining Trucks PayloadDocumento14 páginasCAT®Mining Trucks PayloadMatheus RibeiroAún no hay calificaciones

- Reference Guide To Mining Machine ApplicationsDocumento54 páginasReference Guide To Mining Machine ApplicationsYohanes WibowoAún no hay calificaciones

- Bearing CapacityDocumento36 páginasBearing CapacityAjay SinghAún no hay calificaciones

- BP - Electrical System With Extreme ConditionsDocumento17 páginasBP - Electrical System With Extreme Conditions----Aún no hay calificaciones

- PC5500 SN 15032 Operation and Maintenance ManualDocumento527 páginasPC5500 SN 15032 Operation and Maintenance ManualFernando Pérez Sarria100% (1)

- Analisis de Motor de Traccion 730EDocumento29 páginasAnalisis de Motor de Traccion 730ERimbertAún no hay calificaciones

- Armado 784 y 785c InglésDocumento349 páginasArmado 784 y 785c InglésFelipeNicolasSilvaAún no hay calificaciones

- Pareto 1 - 27 Mei 2019Documento302 páginasPareto 1 - 27 Mei 2019SARTONO INDO FRANSAún no hay calificaciones

- Failure Analysis Report EX3059 - Shaft Swing Machinery Rear FracturedDocumento11 páginasFailure Analysis Report EX3059 - Shaft Swing Machinery Rear Fracturedputri lestariAún no hay calificaciones

- Reusable Gear Guide HTT - GG1 - 0711Documento18 páginasReusable Gear Guide HTT - GG1 - 0711sphiri600100% (1)

- Mechanical TrucksDocumento97 páginasMechanical TrucksGustavo Rathgeb100% (1)

- H E Parts Brochure Wheel GroupsDocumento7 páginasH E Parts Brochure Wheel GroupsSebastiao DuarteAún no hay calificaciones

- Cat Overload PolicyDocumento7 páginasCat Overload Policyait mimouneAún no hay calificaciones

- Compressed Air System r2 HandoutDocumento80 páginasCompressed Air System r2 HandoutjAún no hay calificaciones

- Opencast Mining Equipment Technology Trends: Reenergising Indian Coal SectorDocumento30 páginasOpencast Mining Equipment Technology Trends: Reenergising Indian Coal SectorSubhra MondalAún no hay calificaciones

- Omm - HD785-5 LC PDFDocumento154 páginasOmm - HD785-5 LC PDFnurdinzaiAún no hay calificaciones

- AA02083G Approved GE LubesDocumento4 páginasAA02083G Approved GE LubesSebastiao Duarte100% (1)

- AFA Guidelines For Analyzing Duo-Cone Seal FailuresDocumento4 páginasAFA Guidelines For Analyzing Duo-Cone Seal FailuresGracia SediAún no hay calificaciones

- AA02193C STRG Pin Wear Checks and SizesDocumento8 páginasAA02193C STRG Pin Wear Checks and SizesSebastiao DuarteAún no hay calificaciones

- Idler Groups: The Widest ChoiceDocumento8 páginasIdler Groups: The Widest ChoiceBaggerkingAún no hay calificaciones

- Persentasi Kelompok 1Documento132 páginasPersentasi Kelompok 1Elsa Qorirotul Aini Susilo100% (1)

- 777DDocumento3 páginas777DsuperbludnikAún no hay calificaciones

- START Facilitator GuideDocumento97 páginasSTART Facilitator Guidekohoman3232Aún no hay calificaciones

- ISolutions Lifecycle Cost ToolDocumento8 páginasISolutions Lifecycle Cost ToolpchakkrapaniAún no hay calificaciones

- PC 3000 PDFDocumento8 páginasPC 3000 PDFDashzeveg BayrsaikhanAún no hay calificaciones

- Bearing For Cement Industry - NDocumento20 páginasBearing For Cement Industry - NAjanta Bearing100% (1)

- Performance Report: Komatsu 1500-7Documento14 páginasPerformance Report: Komatsu 1500-7DAnielAún no hay calificaciones

- Sistema de Suspension PDFDocumento10 páginasSistema de Suspension PDFDaniel Alejandro100% (1)

- Cat Application GoodyearDocumento51 páginasCat Application GoodyearEvan AT Yoel50% (2)

- Catalogo CAT Pernos y AccesoriosDocumento72 páginasCatalogo CAT Pernos y AccesoriosEvan AT Yoel100% (3)

- Caterpillar Master Glossary Spanish-SpainDocumento102 páginasCaterpillar Master Glossary Spanish-SpainEvan AT Yoel100% (1)

- 301.5 MHEX: Service Training MalagaDocumento3 páginas301.5 MHEX: Service Training MalagaEvan AT Yoel0% (1)

- 777D Off Highway Truck: Service Training MalagaDocumento17 páginas777D Off Highway Truck: Service Training MalagaEvan AT YoelAún no hay calificaciones

- 994F Wheel Loader 44200001-UP (MACHINE) POWERED by 3516 Engine (SEBP3851 - 50) - Systems & ComponentsDocumento58 páginas994F Wheel Loader 44200001-UP (MACHINE) POWERED by 3516 Engine (SEBP3851 - 50) - Systems & ComponentsEvan AT YoelAún no hay calificaciones

- Power Train: - 170 - STMGXXX 4/97Documento66 páginasPower Train: - 170 - STMGXXX 4/97Evan AT YoelAún no hay calificaciones

- Presiones de Sisytema de Direccion 992kDocumento10 páginasPresiones de Sisytema de Direccion 992kEvan AT YoelAún no hay calificaciones

- High Pressure Fuel Line Failures - QST30 NDocumento18 páginasHigh Pressure Fuel Line Failures - QST30 NEvan AT Yoel67% (3)

- B-Uhb-M: Outstanding Barrier Metallized BOPP FilmDocumento2 páginasB-Uhb-M: Outstanding Barrier Metallized BOPP FilmSayed FathyAún no hay calificaciones

- Rittal KX CatalogDocumento144 páginasRittal KX Cataloggstefan8970Aún no hay calificaciones

- Asme Sa264 PDFDocumento11 páginasAsme Sa264 PDFtariqkhanAún no hay calificaciones

- Phase IV Welder Module 1.1Documento23 páginasPhase IV Welder Module 1.1Magdi SiamAún no hay calificaciones

- Vulcan Locomotives CatalogDocumento153 páginasVulcan Locomotives CatalogMacindoe1Aún no hay calificaciones

- Thermal Systems: Innovation. AvailabilityDocumento16 páginasThermal Systems: Innovation. AvailabilitypatelchiragisAún no hay calificaciones

- A Square E Systems: EmailDocumento6 páginasA Square E Systems: EmailMktg ChiragelectronicsAún no hay calificaciones

- TRUMPF Express 1 15 enDocumento32 páginasTRUMPF Express 1 15 enSadeq NeiroukhAún no hay calificaciones

- Typy of ChutesDocumento49 páginasTypy of Chutesscribd19711Aún no hay calificaciones

- Limts&fitsDocumento48 páginasLimts&fitsSa RaAún no hay calificaciones

- Brooks-Mite Purgemeter: Data SheetDocumento4 páginasBrooks-Mite Purgemeter: Data SheetraulAún no hay calificaciones

- Trumpf TLF Laser Kap4 eDocumento13 páginasTrumpf TLF Laser Kap4 eAnonymous PIqdeNp867% (3)

- V Packing SealDocumento10 páginasV Packing SealBobby ArbianugrohoAún no hay calificaciones

- Metal PressworkDocumento32 páginasMetal PressworkLihle Ayabonga NcambacaAún no hay calificaciones

- Influence of process parameters on drilling characteristics of Al 1050 sheet with thickness of 0.2 mm using pulsed Nd׃YAG laserDocumento7 páginasInfluence of process parameters on drilling characteristics of Al 1050 sheet with thickness of 0.2 mm using pulsed Nd׃YAG laserzainalsonAún no hay calificaciones

- Experimental and Numerical Analysis of Aluminum Alloy Aw5005 Behavior Subjected To Tension and Perforation Under Dynamic LoadingDocumento15 páginasExperimental and Numerical Analysis of Aluminum Alloy Aw5005 Behavior Subjected To Tension and Perforation Under Dynamic LoadingmuitefaAún no hay calificaciones

- BO Modeler V3-N1 2007 JanFebDocumento29 páginasBO Modeler V3-N1 2007 JanFebColin 't HartAún no hay calificaciones

- Freebird PDFDocumento5 páginasFreebird PDFHHOLIAún no hay calificaciones

- Corrosion Rate Measurements in Steel Sheet Pile Walls in A Marine EnvironmentDocumento17 páginasCorrosion Rate Measurements in Steel Sheet Pile Walls in A Marine EnvironmentMamoudou SAGNONAún no hay calificaciones

- Bajaj Price List 2008Documento75 páginasBajaj Price List 2008nishant1420Aún no hay calificaciones

- Optimization of Industrial Processes ForDocumento202 páginasOptimization of Industrial Processes ForArne BeningAún no hay calificaciones

- Press Tool Theory - 1Documento144 páginasPress Tool Theory - 1Abhishek AbhiAún no hay calificaciones

- School of Civil Engineering &cotm Departement of Cotm Building Construction - I Chapter-5Documento49 páginasSchool of Civil Engineering &cotm Departement of Cotm Building Construction - I Chapter-5Anonymous oUoJ4A8xAún no hay calificaciones

- S96029-F07C-ITP-006 Rev0-OSM Exhaust Duct WorkDocumento2 páginasS96029-F07C-ITP-006 Rev0-OSM Exhaust Duct WorktinzarmoeAún no hay calificaciones

- Catalog Suruburi KrinnerDocumento49 páginasCatalog Suruburi KrinnergabisolomonAún no hay calificaciones

- Chennai Companies 2021Documento8 páginasChennai Companies 2021Campaign Media0% (1)

- Can-Ulc-S601 StandardDocumento10 páginasCan-Ulc-S601 StandardDymac IndiaAún no hay calificaciones

- Simulation of A Vehicle Hood in Aluminum and SteelDocumento16 páginasSimulation of A Vehicle Hood in Aluminum and SteelShrikant SuryavanshiAún no hay calificaciones

- Cracking Continuous A: in Zinc Layers On Galvanized SheetsDocumento17 páginasCracking Continuous A: in Zinc Layers On Galvanized SheetsAlex GarciaAún no hay calificaciones

- Grade 5 Week 1 WHLPDocumento22 páginasGrade 5 Week 1 WHLPRomnick ArenasAún no hay calificaciones