Documentos de Académico

Documentos de Profesional

Documentos de Cultura

t3 Free Plans

Cargado por

DanDerechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

t3 Free Plans

Cargado por

DanCopyright:

Formatos disponibles

About the free plans:

T is a new designer who mainly focuses on high efficiency designs in wood and composites,

in power, sail and human power.

T is offering this plan to the public for promotional purposes, for a limited time.

The catch is anyone who downloads and builds the boat, agrees to send pictures and some

feedback on the build to T.

These images will eventually be collated on a webpage showcasing this design.

The feedback is also valued to be able to create plans that are as easy to use as possible.

The pictures and feedback can be sent to his email, which is on all the design sheets.

Naturally, T is also available for custom design work at tttangvald@gmail.com.

Item volume LCG TCG VCG

4.2 0.65 2.70 2151 0 -96 5816.3 0.0 -259.6

27.1 0.50 13.55 1937 0 -34 26246.4 0.0 -460.7

14.3 0.50 7.15 1801 0 165 12877.2 0.0 1179.8

2.1 0.53 1.11 1887 0 -44 2100.2 0.0 -49.0

3.3 0.53 1.75 1755 0 20 3069.5 0.0 35.0

4.2 0.53 2.23 1807 0 304 4022.4 0.0 676.7

10.1 0.53 5.35 2043 0 141 10936.2 0.0 754.8

0.8 0.53 0.42 2184 0 118 926.0 0.0 50.0

2.4 0.50 1.20 3585 0 158 4302.0 0.0 189.6

1.5 0.50 0.75 69 0 264 51.8 0.0 198.0

1.1 0.50 0.55 2051 0 279 1128.1 0.0 153.5

1.5 0.53 0.80 2026 0 78 1610.7 0.0 62.0

0.53

0.5 LCG TCG VCG

0.65 37.56 1946 0 67

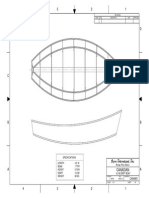

3.6 M utility pram

Mass moments of inertia not calculated

thickne density Mass (kg !moment "moment #moment

liters

$ull

keel

bottom

sides

keelson

chine los

rubrails

th!arts

corners bo! and stern

transom

bo! transom

knees

risers and th!art su""orts

material #"ecific densities

"ine

marine "l$!ood Total mass

hard!ood

Materials list

item quantity cost per item cost

2

1

1

1

7

7 M

Oarlocks 1 pair

Oarlock sockets 2 pair

100

20

Slow setting epoxy glue

high density epoxy filler

low density epoxy filler

vinegar

lacquer thinner

paint

thinner

rushes

sandpaper

!otal

" mM #$%&'( marine plywood

) mM #1%*'( marine plywood

1& x 20$ x $)+* mM #1' x &' x 12,( clear planed pine or hardwood

1& x 20$ x $0*+ mM #1' x &' x 10,( clear planed pine

1& x $7 x $0*+ mM #1' x 2' x 12,( clear planed pine

1& or 12 mM quarter round stainless steel ruing strip #optional( $$*0 mM #10, 11 1%2'(

10 or 12 mM three strand nylon rope

2+ x * mM stainless steel screws

*+ x + mM stainless steel screws

2-+ liters

2 liters

2 liters

* liters

* liters

The Boat

I designed this 3.6 metre (12') long utilitarian dinghy to be handy with from between 1 and four

people on board, although it can carry fie or een more people, depending on their indiidual

weights. !he main design priorities were to be reasonably light so as to be beach draggable by

one man, liftable by two, sturdy enough to withstand a bit of rough treatment, as well as the

ineitable beach goer who li"es to sit on upturned dinghies. #lso it ery much had to be $uic" and

easy to build, with a minimum of materials and comple% cuts and time & labour consuming 'igs. #ll

this whilst retaining good design characteristics balancing the need for stability and ease of

rowing.

I purposefully did not try to optimi(e it too much for any one design trait, maintaining a

more )*ac" of all trades+ design concept. !his fits well with the purpose of a general purpose

utilitarian dinghy. #lthough it rows $uite well, certainly far better than the ast ma'ority of dinghies

seen in ports, it is not a performance rowboat as it had to hae enough stability to be usable by

anyone. , -urthermore, the idea that a small outboard motor may be used was incorporated into

the re$uirements of the final shape. #lthough it could plane gien a big enough motor, the shape

is not meant for this at all, since the correct type of shape for decent planing is completely

unsuitable for rowing, and the principal intent is for this boat to be rowed and rowed well.

!herefore, if being used with an engine, any more than a few horsepower is wasted power,

weight, e%pense and hassle. # 1.. hp will wor" fine, certainly neer more than 3.. hp.

It could potentially be sailed $uite well too, although of course this would entail

mast partners & step and some lateral resistance, such as a daggerboard, leeboard(s) or ma"ing

the "eel 2. to 3. c/ deeper, as well as some "ind of rudder.

-eel free to contact me for recommendations on this "ind of conersion or a suitable sail plan.

!his construction guide I hae written with considerable detail with the noice builder in mind.

/ore e%perienced builders may find it a bit long winded therefore, but I thin" this is preferable to

leaing the first time builders guessing.

#lthough there are boats that are simpler to build, these usually ma"e certain concessions

in terms of design in order to facilitate construction as much as possible. !his boat ma"es no

concessions in hull form apart from the fact of the necessity of hard chines so it can be made out

of plywood, yet is still straightforward to build.

#nyone with reasonable woodwor"ing aptitude0 a familiarity with the operation of tools, measuring

techni$ues and dealing with wood should not hae any problems putting this boat together.

1o matter your s"ill leel it is highly recommended you read this entire boo"let before starting any

of the wor".

2ou should count on appro%imately 133 hours of wor" to complete this build. !he final hour

count will be highly dependant on the leel of finishing. !ypically for a good finish anywhere from

one $uarter to one third of the total hours go into finishing. !hat means a lot of sanding.

!he ery ne%t thing you should do after going through this boo"let is print out the 45/ and go to

the suppliers of all the materials and write down the prices. !his will enable you to find the best

prices for eerything as well as add up the total material cost of the boat before committing.

Some details

!his design is a bit unusual in that it has been designed to be built right side up and

without full moulds. !his saes on wasted material and allows the thwarts to be installed, setting

the final hull shape, before detaching the boat from the construction 'ig.

/ore e%perienced builders may want to adapt the construction process to their own preference.

!o these I say go ahead, and I would li"e to hear how the build went using a different method. 4ut

don't complain to me if it does not turn out well.

In theory since the s"in panels are pre cut to the e%act final shape, and this determines the

shape of the boat in all but two degrees of freedom, the boat could actually be built without any

sort of 'ig, setting the two final degrees of freedom by chec"ing that the bottom of the "eel is

perfectly straight in the %( plane when the thwarts are installed (should be automatic since the

thwarts dimensions and installation positions are also predetermined) and the twist by the corner

"nees. 6oweer I do not recommend attempting this, as the complications that could ensue could

easily dwarf any labour saed by s"ipping on the setting up of the building 'ig, as well as resulting

in a sub standard boat.

#nother simplification that has been applied is the elimination of all non essential beels.

5ut of the the main construction panels, only the bow transom needs to be beelled. #ll the other

main cuts are done with the saw straight up and down. (73 degrees)

!here are other beels to cut in the smaller pieces, but for all but the chine logs and hog, these

are at a constant angle and the angle is gien for each piece.

Preparations;

Workspace;

A flat working space at least 3 / % 8.. / (13' by 16') as an absolute

minimum preferably more, although only a section 1.3 / % 3.6 / (8' by 12') of this need be flat

and leel. # wooden floor is practical since it allows for easily screwing the moulds down firmly in

place and is easy to draw on.

In my case I had the unusual good situation to hae a perfectly flat and

een floor to build on. !his was because I had gone to great effort when I built our house to

ensure that this was so.

4ut, in general, a wooden floor, no matter how perfectly flat it may seem,

must be chec"ed with great thoroughness to see how flat and leel it really is. 1ormally it will be

close enough for some correcting shims to be able to correct the uneenness.

# common place to build a dinghy li"e this is in the garage. 4e aware that it

is pretty much guaranteed that the cement garage floor, een if it appears to be perfectly flat and

leel, will not be sufficiently so for the purpose of using it as a reference plane to build a boat on. If

it is $uite close shims can be used to correct at critical points.

5therwise you will hae to build a strongbac". !he purpose of the

strongbac" is to proide a perfectly rigid and planar irtual surface on which to build and to use as

the reference plane for the boat.

1ote that it is not in fact re$uired to build on a leel surface. 2ou could in

principle set up the 'ig at any angle, een flat on a wall, proided it is rigid and planar. 6oweer, it

is certainly an adantage to be able to use a bubble leel, particularly in the direction

perpendicular to the centreline. -or this reason0 if you can't get a wor" base that is leel in both

directions then at least set up so that the wor" is perfectly leel across the boat, preferably with

the bow uphill.

If you will be building oer the dirt then the strongbac" must be a self

contained rigid unit, so a bit more elaborate than if you can use ta"e adantage of the rigidity of

the wor"floor to hold the indiidual parts of the 'ig in position.

!he material for the 'ig can usually be scrounged from building sites' scrap

pile. !his saes on e%penses for something that will hae no further use after the boat is built,

apart from firewood.

# roof for shelter from the elements of some "ind is pretty much a must.

9et wood cannot be glued. If wet it must be dried and and murphy's law (a%iom 2) states that as

soon as it is dry it will start raining again. :o not haing a roof is a great way of ma"ing a boat

building pro'ect stretch into eternity, an all too common feature of amateur construction, so be

sure to aoid this easily aoidable pitfall.

Tools;

;e$uired0

<ircular saw

=lectric planer and>or handplane ('ac"plane)

/ini angle grinder ? plastic bac"ing plate for sandpaper discs

@rill(s)

@rill bit set and one 1A m/ (B') wood bit or auger

< clamps

#t least one framers clamp with an aperture of at least one meter (3 feet)

*igsaw

:et s$uare

Ceel

/easuring tape with millimetres

4eel gauge

<hal" line and chal"

6and saw

<hisels

6ammer

:crewdriers

4allpoint pen

:cissors

:patula

:$ueegees

1ice to hae0

!able saw

!hic"nesser

;outer ? D round bits

;asps

/aterials list0

!woEEEEEEEEEEEEsheets of 7 millimetre marine ply

5neEEEEEEEEEEEEsheet of 6 millimetre marine ply

5neEEEEEEEEEEEE1+ % A+ % 12' (1A % 233 % 36.8 m/) clear planed pine or

hardwood.

5neEEEEEEEEEEEE1+ % A+ % 13' (1A % 233 % 338. m/) clear planed pine .

:eenEEEEEEEEE1+ % 2+ % 12' (1A % 36 % 36.8 m/) clear planed pine.

Fuarter round stainless steel rubbing strip (optional)

:een metres of 13 or 12 m/ three strand nylon rope.

5arloc"s and oarloc" soc"ets.

133 2. m/ small screws

23 8. m/ long screws

=po%y glue aprro%imately two liters

<abosil>/icroballons aprro%imately two liters

/easuring and dispensing e$uipment

Ginegar four liters

Cac$uer thinner four liters

:tic"y tape

Hlastic bags

Irinding discs

:andpaper wet or dry 13 % 133 and 13 % 223 grit

Haint

!hinner

Haintbrushes

*ars for paintbrushes

/i%ing pots for paint and glue

Notes on the tools

!he circular saw is not in fact, re$uired as the whole boat could ery well be

all handEsawn, but gien that most eeryone has some "ind of access to electricity and gien the

tremendous saing of time, as well as the conenience of being able to set a gien beel angle

that is accurate and constant, I put it as a 're$uired' tool. If you do not hae one, thin" about

inesting in one as they are not usually ery e%pensie, and represent great alue considering the

amount of labour they sae. 5therwise, they are common enough that there should not be great

difficulty in borrowing one.

!he correct saw blade is important when cutting plywood, as if the teeth are

too big, they will lift up the top eneer end grains in a ery ugly way, which then has to be filled,

sanded and repaired on the boat afterwards. # blunt blade will also do this, een if the teeth are

not so big.

Iien that you will be cutting a reasonable amount of plywood and it is ery

important that the cuts be done neatly and accurately, don't hesitate to buy yourself a brand new

blade for the pro'ect. 63 teeth is small enough for perfect cuts in plywood, but will still let you rip

boards, 'ust a bit slower than if using a ripping blade.

I would not put as much importance on the electric planer as on the circular

saw. !hat is not because the electric planer is not e%tremely useful at saing effort but because in

this particular pro'ect there is not that much planing to do.

-or the screws it is a tremendous time saer to hae seeral drills, so each

drill can be set up with a different si(e drill bit or with the screwdrier tip. !his aoids haing to

swap bits multiple times for each screw.

In general, one has to drill three different si(e holes for each screw0 the

thinnest bit, whose si(e corresponds to the diameter of the screw inside the thread. !his hole

goes down to the depth at which the tip of the screw will end up. !h ne%t si(e of bit corresponds to

the outside diameter of the screw and goes right the way through the first layer of wood. !he final

bit is the same diameter as the head of the screw and is 'ust deep enough so the head is

countersun" enough to not be a nuisance when sanding and painting the boat. !here e%ist special

countersin" bits 'ust for this, but I don't thin" their relatiely high cost is 'ustified here when an

ordinary large metal drill bit gets the 'ob done 'ust fine. 5ften one can do the countersin" by 'ust

holding a big sharp bit in one's hand and twisting it bac" and forth.

1eertheless, in soft woods one can $uite often get away with fewer drilling

steps. :ometimes the thinnest deepest hole can be foregone and the screw will drill its own hole.

4e mindful though especially when near the end of a piece of wood that this can lead to crac"ing

the piece. #lso, the screw can countersin" itself with 'udicious use of the final tightening. !he hole

that is least li"ely to be optional, and the least recommended to omit is the medium si(e hole

through the first layer of wood.

Jsing a drill for driing saes a huge amount of time too, but here it is

important to use a ariable speed drill, or too many screws will get their heads stripped, or worse,

brea". If none of the aailable drills are ariable speed, they can still be

used to drie screws, but only partway, the screw being drien the last bit by hand.

4e sure to tape plastic around the handle and body of the drills, leaing

holes where the blower fan holes are, or it will oerheat. !his is so that you don't get the tool all

begrimed in a mi%ture of hardened epo%y and wor"shop dirt. #t least do it on any tools you may

hae borrowed.

/etal bits are the standard for haing a set of, from 1 m/ to 13 or 12 m/,

as they will bore any of the boat materials. !here should be seeral duplicates of all the smaller

bits as these are the ones most fre$uently bro"en. :pare bits need be stored in a 'ar full of oil, as

their high carbon steel rusts ery $uic"ly, and een a slightly rusty bit is ery much degraded in

terms of cutting ability. !hey can of course be sharpened and restored, but it is tedious chore that

is best aoided if possible.

-or the larger si(es, spade bits for boring only wood are the thing as they

cost 'ust a fraction of the same si(e metal bit, and there is usually no need to drill large holes into

metal.

<lamps you can neer hae too many of. -or this pro'ect an absolute

minimum of three < clamps should be at hand. /ore is better.

!he framer's clamp or two of them is for pulling the two hales of the

bottom together while twisting them up. If you do not hae any, the following solution will sae you

the e%pense of a tool that you may no longer eer need after building this boat0 get yourself two or

three truc"er's mechanical cinches. # lot of people carry some light duty ones around in the trun"

of their car to strap things securely onto the roof of the car. Hassing the webbing under the boat

and around so the ratchet leer is on top, more or less oer the centreline will get the 'ob done

tolerably. # hole or slot in the strongbac" will hae to be made, howeer to allow the strap to pass.

<are will hae to be ta"en too, to not soil the straps with epo%y.

!he leel should be a meter long. If it is a short one, tape it solidly to the

middle of a one or one and a half meter piece of straight rectangular metal piping or similar. Gerify

that the edges of this e%tender are in fact perfectly straight. ;egularly chec" the accuracy of the

leel. !his is done by finding something that apparently measures perfectly leel and then rotating

the leel e%actly 1A3 degrees around the ertical a%is and chec"ing to see if that e%act same

'leel' still measures as leel. If there is any discrepancy at all, the leel needs to be calibrated. If

the leel has been lengthened as suggested, it is easy to ad'ust fine shims at one end or the other

of the leel until it passes the test.

If seeral measuring tapes are to be used, e%tend them all to the length of

the shortest one and carefully compare their measurements. =en one tenth of a per cent

difference will add up to seeral millimetres error oer the length of the boat. Fuite enough to

cause some serious headaches further along the building process.

#lso do not trust the hoo" at the end of the tape. /easure from the ten c/

mar" (say) and add this (13 c/) to the re$uired measure. !hen measure in the normal way and

see if the measure is e%actly the same. !he slots in the hoo" can get worn oer time.

If the hoo" is not a right angles (from haing been stepped on for e%ample)

then there will be an error which aries depending on the depth to which the hoo" is placed on the

wood.

!he spatula is for applying the thic"ened epo%y glue (also "nown as glop)

so should be narrow, no wider than . c/ and springy with an easy to clean finish.

!he s$ueegees are for applying filler oer the hull for a superior finish and

to seal and protect the plywood. !hus they should be of non stic" fle%ible plastic and as wide as

possible, say 1. or een 2. c/.

Notes on the materials

/arine plywood is a wonderful boatbuilding material0 has great mechanical

properties, dimensionally stable, and allows boats to be constructed much faster than when using

straight lumber. It is also ery durable proided a bit of care is proided.

I hae seen boats made with e%ternal grade plywood last for decades too,

and at a considerable price reduction, but it all comes down to how the plywood was glued up at

the factory. !o be safe I would only use e%terior plywood if I had seen it had passed the test of

time on another e%isting boat, and then made sure that I bought the e%act same plywood.

1ormally if the ply has suried seeral years in regular immersion without delaminating it will stay

together indefinitely. In any case, e%ternal plywood normally has a finish that is far inferior to

marine plywood.

:ome people chec" the reliability of the plywood bond by boiling a small

piece of it seeral hours in a pressure coo"er. !his test is somewhat flawed, but normally any

plywood that can surie three or four hours in a pressure coo"er will not delaminate eer.

It has become e%tremely common to see plywood boats that are

fiberglassed, either on 'ust the outside, or on both sides. @espite this being the most commonly

seen method of building I aoid, apart from in certain specific applications, this construction

method for a number of reasons.

-iberglass and epo%y is materially more e%pensie strength for strength

than plywood. !he time re$uired to add a layer of fiberglass is also considerable.

!he e%tra strength proided is ery slight compared to the e%tra weight. If

the layer is only on the outside, the implosion pressure stiffness is barely altered as is the

implosion pressure brea"ing point. -or e%plosion direction forces it will be significantly improed

but considering the weight increase, the same result would hae been achieed by increasing the

wood thic"ness a certain amount, with less total weight increase, and this has almost no effect on

build time.

If the layer is on both sides, then you get a significant increase in the both

the stiffness and strength in both the inward and the outward directions. 6oweer, 'ust increasing

the panel thic"ness the correct amount would achiee the same for about the same weight

increase but without the significant increase in material and labour cost of the fiberglass.

;eally the only situation where fiberglass sheathing on a plywood boat of

this si(e and construction type is 'ustified is where the boat is intended to ta"e a lot of abuse. !his

is because fiberglass is much harder than wood, so resists abrasion and dinging much better.

In this case, the intent of the boat is to be rugged and practical, but on the

assumption that a certain leel of care will be ta"en to aoid dinging it, smashing into things,

e%cessie amounts of careless dragging on the beach, etc, so the fiberglass is not needed.

9hen selecting the plywood always loo" through the pile and re'ect any

sheet with damage or a surface flaw. It is ery common for the first sheet on the top of the pile to

hae been damaged, so loo" at the sheets a couple down from the top.

1eer let the wor"ers at the lumberyard choose the lumber for you. Insist

on loo"ing through the pile and only getting the best pieces. !here can be no "nots or at least no

ma'or "nots. !he pieces must not be damaged nor warped.

It is a sad fact that there is no place left on earth that does not suffer from

the

effect of oer haresting of wood. !herefore the $uality of lumber worldwide

has been in steady decline for centuries and finding good wood is always becoming more and

more difficult as well as more and more e%pensie.

:o do the planet a big faour and plant a few trees to ma"e up for the wood

consumed in the dinghy. :eriously.

5n the wide pieces try to find the pieces that hae the growth rings going

as perpendicular to the main surfaces as possible. !his is called $uarter sawn and ma"es the

wood far less prone to warping and cupping. Jnfortunately, only a small percentage of lumber

ends up $uarter sawn and is instead slab sawn in bul", which is more economical for the

sawmills. #lso aoid ma'or amounts of sapwood and large "nots. 6eartwood is not important.

-or the "eel you can if you prefer, get a piece of hardwood instead of pine.

It costs more but is stronger and will ta"e more wear and tear.

#lso optional but a definite plus is a $uarter round metal protectie strip

running the full length of the underside of the "eel. If care is ta"en to always maintain the boat

upright when dragging up a beach, so the actual hull is not touching the grit, the only thing ta"ing

the abrasie wear will be this metal strip, tremendously prolonging the life of the boat. If you

decide this strip is too e%pensie you could compromise and 'ust put one meter of strip starting at

the aft end of the "eel. !his will still ta"e most of the wear if one lifts the bow slightly wheneer

dragging the boat.

Tolerances and dimensions

!he aboe picture should be what all your cuts loo" li"e.

1ote the cut is right to the mar"ed line.

#s an ordinary circular saw blade remoes e%actly 3 m/ of material always

chec" which is the offcut side of the mar"ed line. !his is the side of the line that the blade is going

to be on.

In the aboe image you see that the plywood closest to the iewer from the

line is the part to be used, the plywood on the other side of the line is the e%cess.

It is a good habit to identify the offcut side with a few crossEhatched lines,

so confusion is aoided, especially if two people are wor"ing.

:trie to wor" at half m/ tolerance. #nything more than one m/ tolerance

in your wor" is getting sloppy.

Keep in mind that precision in the beginning will ensure eerything falling

into place later on. #s wor" progresses one can rela% one's tolerances a bit, but at the beginning,

precise wor" is central to ensuring the boat comes together smoothly.

#lso, the angles shown on the blueprints are the beel angle, ie0 73

degrees means no beel. !herefore if your circular saw mar"s 3 when the blade is at right angles

you will hae to conert the angle to the correct reading on your tool. 5therwise, if your saw

mar"s 73 when the blade is set for no beel, you can 'ust use the angles as is.

:o for the case of saws that read 3 for no beel E here is an e%ample0 if the

plan specifies a .. degree beel you would set the saw at 3. degrees because 73 L .. M 3. .

Notes on working with epoxy

=po%y has become the absolute standard for wood composite construction.

Its material properties are specially formulated to mimic those of wood and thus minimi(e stress

strain discontinuities across bond surfaces.

# pair of well bonded wood surfaces using epo%y will generally fail

somewhere in the wood not across the glue interface. !his is because the epo%y bond strength is

higher than the strength of the lignin binding the celulose of the wood together.

#dditionally, epo%y has tremendous gap filling properties and contrary to

older generation wood adhesies (now all made obsolete by epo%y) can bond well een poorly

fitted 'oints.

# particularity of epo%y is that the two parts must be mi%ed together in

e%actly the correct proportions. !he label should specify the correct ratio and whether it is by

weight or by olume. !he yellow part is always less dense than the white part.

It is technically incorrect to refer to these as resin and hardener. Hutting

either more or less than the correct amount of )hardener+ will not ma"e it set faster or slower. In

either case it will ma"e it fail to reach the designed material properties. If you deiate from the

correct proportions it means that the e%cess molecules of that part will neer find their mate or

mates and be 'ust hanging around in li$uid form within the epo%y matri%, lowering the oerall

$uality of the set plastic.

Instead there e%ist different formulations that are designed to set at certain

rates. -or this boat you will want to get the "ind that is slow, especially if wor"ing in a hot place.

!his gies more wor"ing time to get eerything set up right.

=po%y of the "ind that interests us is a thermosetting, e%othermic polymeric

plastic deried from coal tar, although it is possible to derie it from a ariety of different plant

matter. !he molecules of either isolated part remain as a fluid, but when mi%ed together they are

strongly attracted to each other and loc" together as a solid. In so doing they create heat

(e%othermic) and this heat Eatomic motionE helps their mobility in finding corresponding pairing

molecules (thermosetting). !his is a positie feedbac" loop, only moderated by shedding the heat

off to the cooler surroundings. :mall amounts of mi% will thus reach an e$uilibrium temperature

differential aboe that of its immediate surroundings. 6oweer, a large enough amount

concentrated in a pot will reach an e$uilibrium temperature so high that it will spontaneously burn,

ruining the batch and potentially causing fires and>or in'ury. Carge amounts must therefore always

be $uic"ly transferred into shallow, preferably metallic, trays where the heat can be easily

dissipated

through the large surface area relatie to the mass.

=%citing stuff this chemistryN

It's actually more comple% than that but you don't need to "now any more

than this to start wor"ing with it.

/easuring out batches can be done many different ways0 counting

spoonfuls, cups with preEestablished mar"s on them, oersi(e syringes, scales and a print out of

different corresponding weights, measuring the depths with a dedicated little ruler in a cylindrical

pot, store bought epo%y dispensing pumps.. 9hicheer method you use be sure it is accurate,

reliable and relatiely $uic".

4e meticulous about aoiding cross contamination0 neer swap the lids to

the two pots L you will neer be able to open them againN 1eer put anything with een a small

amount of part # into the pot with part 4, or ice ersa. !his will damage the product. !herefore

hae two separate spoons or syringes etc one for each part and clearly mar"ed as such.

If you use the measuring cup to also mi% the batch in, always float the

yellow part on top of the white part0 since they hae $uite different densities they will not mi% until

physically stirred. !his gies you a second isual chec" that the ratio loo"s correct and a bit of

time before actually mi%ing to do anything else you may hae forgotten to prepare.

#lways mi% thoroughly to be $uite sure there are no unmi%ed poc"ets in the

batch. ;emember eery molecule of part # needs to react with eery molecule of part 4, so really

mi% it up. If you can see any uneenness in the colour it needs to be mi%ed more.

!here e%ist a tremendous ariety of addities that can be used to modify

the final properties and wor"ing characteristics of epo%y. /ainly fillers are used to increase the

iscosity of the mi% so that it does not run out of a 'oint before setting. !he bigger the gaps , the

higher the iscosity needs to be in order to assure this does not happen. # 'oint with oids will be

mar"edly wea"ened and may be inalid.

<ertain companies would li"e to hae you thin" you should buy all their

different additie powders, each speciali(ed for a certain application. Hractically though, in most

situations two powders are enough0 one high density and one low density.

6igh density is used for thic"ening when the 'oint is a high stress 'oint

(small bonding surface compared to load). 6igh density thic"ened epo%y does not increase in

bul", so retains a ma%imum of glue per olume of mi%. It is difficult to sand.

Cow density fillers are used for low stress bonds and for fairing and filling. It

bul"s up the mi% significantly, reducing weight as the filler has a ery low density as well as cost

as the filler is much cheaper than epo%y. It also creates a softer, easy to sand final result.

/i%ing the two fillers in determined proportions can proide the appropriate

glue characteristics for almost any gien application.

#t the other e%treme you can also thin epo%y with specially formulated

epo%y thinner, for enhanced penetration and wetting of the substrate although this is not usually

necessary. Cac$uer thinner will also thin out epo%y (cheaper) as well as clean the brushes.

-or cleaning hands and tools after a glue session get a gallon of cheap

inegar at the 'buy in bul" and sae' store. Hroided it is not already setting this is a non to%ic and

ery cheap way of cleaning up. #lways clean the spatula after use to sae the effort and ineitable

tool wear of chipping or grinding off hardened epo%y. # damaged edge on the spreading tool is

highly annoying as it creates ridges on the glop.

2ou may want to get plastic film gloes to aoid getting epo%y on your s"in.

#lthough there are certainly worse products out there, epo%y is to%ic, particularly the

yellow part. /any people eentually deelop a sensitiity to it after years of

handling and wor"ing with it. !he worst aspect of epo%y are the 4H# addities, although it is

possible to obtain 'food grade' (meaning suitable for water tan" construction not for literally

eatingN) epo%y without 4H#. !here should not be problems proided you follow certain guidelines.

1eat and tidy0 6ae a wor" plan. Know before hand what you will be doing

and what you will need to get it done. Keep the shop mess to tolerable proportions. 6ae a

dedicated space 'ust for preparing epo%y mi%es, where food, drin" and any other consumables

neer go. Keep rags, thinners and all the epo%y "it there so you don't lose them and can clean up

promptly. #lways be sure the pots are tamped shut and at no ris" of falling oer nor of getting

accidentally "ic"ed. 9hen adding in thic"ening powders be sure to be out of any drafts as these

e%tremely light powders will get blown all oer the place with the slightest bree(e. @o not breathe

in these thic"ening agents. # dust mas" is a wise precaution, as enough of this in the lungs can

cause silicosis of the lungs. 6aing warned about drafts "eep in mind that you still do need good

aeration to "eep any fumes from building up in the wor" shop.

9hen grinding epo%y, be sure to always wear a respirator or at least a dust

mas".

-illets are cured e%tra thic" applications of glop in the corners between

glued components, that increase glue area. !he way to apply them is to cut out a special throw

away 'spatula' from a piece of stiff cardboard, with the intended radius.

-or applying pure epo%y get a bunch of narrow cheap throw away brushes.

*ust because they are throw away does not mean they get used only once thoughN Iet deep

narrow 'ars, so you can let the brush soa" in lac$uer thinner to not harden and get reEused up to a

do(en times before it is too far gone to be of use.

Iet an old coat hanger or a piece of ductile wire to ma"e a paintbrush

hanger. :tart by straightening the wire out. /a"e a circular loop in it 'ust small enough to pass

through the mouth of the 'ar. 4end this loop so it is at right angles to the rest of the wire. -rom the

loop, at a distance about the same as the length of the brushes bend the wire at 73 degrees. <lip

the wire about three c/ away from this last bend. !he idea is that the loop sits in the bottom of the

'ar, as a stand for the rest of the wire which then goes on to support the brush by its handle hole.

#rrange so that when the paintbrush is hung on the holder, the tips of the

bristles are 13 to 1. m/ aboe the bottom of the 'ar. !his "eeps the bristles from getting all bent

out of shape and "eeps the brush out of the sediment that builds up at the bottom.

Hut lac$uer thinner in the 'ar 'ust up to the leel of the metal band on the

brush. Heriodically decant this lac$uer thinner into another 'ar and throw out the gun" at the

bottom. !his lac$uer thinner can then get used to gie the brush a preliminary rinse, getting rid of

the bul" of the epo%y. It this way you get the most out of the thinner, which is not cheap.

4e sure to always "eep the lids on the 'ars tight to "eep the thinner from

eaporating away. 5n the 'ar with brush, wrap it up tight with a plastic bag and a rubber band.

Foundation step; aking the !uilding "ig

In this section I will e%plain how to build the 'ig or strongbac" in three

different ways.

It is up to you to choose which is most appropriate for the "ind of floor you

will be building on. # tip for choosing between method 1 and 2 is to get a wide board with one

perfectly straight edge and put it on edge at arious angles across the floor where the boat will

ta"e shape. If the gap is between straight edge and floor is nowhere more than about one c/,

correctie shims can be used with method 1. 5therwise use method 2. /ethod 3 is if the floor is

oertly irregular.

9hicheer system you use, the first step is to cut out the "eel.

/ar" and draw the outline of the "eel on the board destined for this

purpose as per the measurements on design sheet .. @rill the hole for the painter. :aw the cure

of the top edge of the "eel. Ceae the front of the "eel uncut. !his can be cut off later, leaing this

e%cess on gies a place to drie a screw through the "eel and into the floor or strongbac" so the

"eel cannot slip around.

/ethod 10

<ut out the si% half moulds to the dimensions gien on design sheet 6,

without any beels.

@raw two perfectly straight and parallel lines on the floor, the width of the "eel apart, indicating

where the "eel goes. /ar" also where the aft end of the "eel goes.

In the case that the "eel is thic"er (wider) than the designed 1A m/ the correct amount must be

remoed from the inner end of each mould. It is not recommended to use wood less than 1A m/

thic" to ma"e the "eel.

:et the half moulds on the floor sandwiching the "eel at the correct

distances (chec" design sheet 6) being sure that they are all $uite s$uare to the "eel and at 73

degrees to the bottom edge of the "eel. /ould pairs 1 and 2 go in front of the measuring plane,

mould pair 3 goes behind.

<hec" that the outer top corners of each mould pair are at the same height.

Jse the leel for this and chec" at the same time that the distance from the top of the "eel to the

top of the moulds is indeed as specified on design sheet 6.

If it is not, cut out a number of thin shims and thin wedges from scrap

lumber to correct the height of eerything until all measures correctly and is leel.

!hen screw the moulds down to the floor or glue them in place with a blob

of glop near each end. If there are any shims put the glue there so nothing can moe. #oid

glueing the "eel to the floor or the moulds. !he "eel gets 'ust one screw forward so it can't moe

fore and aft. !he moulds "eep it in place side to side.

If the "eel is not aligned with the guidelines all the way along, correct it by

nailing a little bloc" of wood along one side or other of the "eel, in order to force it into

place.

OOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOO

/ethod 2 0

Keel not yet in place

!his is much the same as the first e%cept that now we will put the "eel on

top of a strongbac". !he strongbac" is any piece of stiff lumber at least as long as the "eel. !he

length can built up out of seeral shorter pieces by butting the pieces together and nailing

more wood on either side solidly. It can be as rough as you li"e, only one

face matters0 the upper face upon which the "eel sits. !his face if not already perfect needs to be

cleaned up, inspected for any foreign ob'ects that could damage the plane, and planed till it is

ruler straight.

5n this face you mar" the two parallel lines as before as well as the line

across indicating the aft corner of the "eel.

1ote the height of the strongbac" at the position of where each mould pair

will go. !his is how much needs to be added on to the ertical mould measurements shown on

design sheet 6. 1otches as appropriate need to be cut away on each mould to accommodate the

strongbac". @on't worry about a good fit between the moulds and the strongbac"0 what matters is

that the moulds press against the "eel itself, "eeping the "eel aligned with the two lines.

#lign the "eel to its mar"s, screw the "eel to the strongbac" at the front and

position eerything perfectly as in system one and screw or glue each piece to the floor.

OOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOO

/ethod 30

!his is for if the ground is too uneen or actual soil. It is the way to ma"e

the 'ig hae autonomy from the ground, although it is still prudent to attach it to sta"es in the

ground or otherwise "eep it from shifting and potentially twisting.

How it looks with the keel in place

Hroceed the same as in method 2 but using fie e%tra pieces of rough, but

rigid

lumber to put the mould and strongbac" on as per aboe illustration. 1ail

eerything together with cheap nails.

Step #ne; easuring$ arking$ cutting out and assem!ly of all Panels

Hlywood panels do not come necessarily perfectly s$uare, so chec" the

corners with the large set s$uare and by ta"ing diagonals. <hoose the best corner to use as the

origin when mar"ing the panel ordinates and decide which side is the better side. #rrange so that

if there is a better side, the better side faces the outside of the boat. If no corner is perfectly

s$uare, measure diagonals and mar" a new end that is indeed s$uare. Jse the plane to shae off

to the line you mar"ed.

-or the 7 m/ panels, the panels are pressed against one another ma"ing

$uite sure they cannot shift accidentally before finishing the measuring and mar"ing process and

that the edge used for measuring off is indeed ruler straight.

/ar" a tic" line with the pen eery 333 m/ from the origin on both edges of

the plywood panel. <onnect the corresponding mar"s with the chal" line.

/ar" off the ordinates along each line. It is most helpful to hae a helper for

this read out the numbers and moe the end of the tape along. !his easy tas" saes a lot of time

and ma"es mista"es less li"ely.

!he mar"s must be made neatly parallel and at right angles to the side of

the plywood sheet, neer as an 'P'.

<hec" that all is properly mar"ed and draw the straight lines with a straight

edge. Jse the best piece of narrow stoc" to draw the cures 'oining up all the other mar"s. Cightly

drie nails on one side or the other as re$uired to force the batten to follow the mar"s e%actly.

@on't worry about these little holes in the plywood, they will get filled up with epo%y later.

If the batten does not want to follow the mar"s or the mar"s do not appear

to be fair, chec" the measurements. #ll these cures are by design smooth gentle cures without

harsh "in"s or sudden changes in curature.

5nce all the lines are mar"ed, annotate the pieces and edges as necessary

to identify the correct orientation, side that faces out, and any beels that need be cut.

9hen cutting at 73 degrees always erify that it really is so with the set

s$uare against the saw base plate and the saw disc. <hec" this before plugging in. <hec" also

that the beel angle screw is firmly tightened so that ibrations cannot ma"e it loosen, allowing the

beel setting of the saw to ary as the cut is being made.

;emember that the !ow transom !e%els are additi%e, all other beels are

subtractie.

5nce all the pieces hae been carefully cut out, chec" that they are indeed

accurately sawn. If not use the plane with a fine setting to shae down to the mar"ed lines. !he

"eel line is the most critical0 een a small deiation here will radically alter the shape of the hull.

Hlace the panels that ma"e up the bottom and the sides on a flat section of

floor. 9here the glue 'oins will be glued protect the floor by taping plastic sheeting. !his also

ensures that the panels do not get accidentally bonded to the floor.

<hec" that eery piece is oriented correctly, including the 'oining pieces.

@raw mar"s so that the 'oining pieces can be lined up correctly. <hec" that the edges ma"e fair

cures when the arious pieces are 'oined up as they will remain.

/i% up a batch of epo%y and paint pure epo%y on all bonding surfaces. @o

not neglect the end grain faces of the actual panels. 1ow with the remainder of the epo%y, mi% in

enough filler (half and half light>dense) to get a "etchup li"e consistency. :pread this out with the

spatula, diiding it among the bond surfaces, including the ends of the panels that will come

together. Hress the 'oins together with heay items. <hec" that the pieces do not moe around or

creep. !he epo%y creates a highly lubricated interface at first so this is $uite a problem. <oming

bac" a few hours later to see that the pieces hae crept out of alignment due to, for e%ample, an

imperceptible slope of the floor and has now set up roc" hard is discouraging to say the leastN Jse

temporary tac"s, nails, small screws or whateer it ta"es to ensure nothing can moe around.

Keep pets and children away from the wor" area tooN

Heavy pails of paint as clamping weights

# small amount of epo%y should s$uee(e out all the way around the 'oin0

this indicates a good bond, free of oids.

<lean up this e%cess now with the spatula and sae yourself the effort of

unnecessary grinding later.

Just enough!

Step Two; &eel$ Bottom and &eelson'

2ou should now hae the "eel held in position by the half moulds and the

"eel aligned on its mar"s as per the foundation step.

2ou will notice that the moulds are slightly proud of the "eel. !his is correct

and is because the panels are not beelled. !he bottom panels contact the "eel on their edge

close to the centreline of the "eel. # straightedge on the top of any half mould should touch the

"eel at this contact line.

Iet one of the battens and draw a centreline running down the full length.

!his will be the "eelson or hog. /ar" off the beels and plane till the angles ary correctly along

the length.

@raw a line one centimetre away from the edge of the "eel line on both

bottom panels on their outside face. !his is to gie a isual chec" that the bottom panels are

indeed correctly centred on the "eel.

Hut the panels into position on the "eel. 9eigh them down so they start to

conform to their correct final bend and twist. #t the bac" where the curature is less the panels

should already be in their correct position, touching each other on the centreline of the "eel, in

contact with the "eel. <hec" that the upper bac" edges at the centreline is aligned directly aboe

the aftmost top edge of the "eel. 1otice that due to the angles, the panels will protrude beyond the

end of the "eel about 1.. m/ at the bottom when the top edge is actually in line with the aft end of

the "eel.

@rie in two small screws near the stern, staggered slightly, through the

bottom panels and into the "eel.

1ow wor"ing forward finish bending the panels into place. 1ear the bow

$uite some force will be re$uired. 9eights can be used to help coerce the panels into the correct

place. !he two sides of the bottom must touch each other the whole way along their length, must

rest on the "eel on their whole length and be in full contact with each half mould. 5nce they are

li"e this and are symmetrically aligned on the "eel (chec" those lines you drew on the underside

of the bottom), screw the panels onto the moulds with two long screws into each half mould.

<hec" that the "eelson is beelled correctly by springing it into place.

;emember that the "eelson stops 7 m/ short at the bac" end and 11 m/

short of the front edge to gie space for the transoms. /ar" a line either side of the "eelson

chec"ing that it is indeed well centered. /ar" where the "eelson must start at the aft end 7 m/

forward of the aft edge of the bottom.

5nce it fits right, weight it down into place and, starting aft, drill straight

down through the bottom and into the "eel. It is important not to miss the "eel, which is why so

much care went into lining eerything up so well with all the mar"s. :crew it in place succesiely

with the long screws right the way through into the "eel. Hut in a screw eery 33 c/ about, e%cept

forward of the painter hole where two screws are recommended. 4e sure not to screw through the

painter hole and that the frontmost screw is not so far forward that it will hae to be sawn when

the front of the "eel is trimmed to its final shape later.

1ow that this dry run is done, ta"e it all apart 'ust leaing the "eel and

moulds in place, and prepare enough glue to bond the bottom onto the "eel. !he glue must be

applied generously since the panels are not beelled, so there is all that gap to fill. 9et the bond

area first in the usual manner then heap on a big bead of thic"ened (high density) epo%y.

Heap on at least this much epoxy on the top of the keel

9ithout delay get the bottom panels bac" into place, starting at the stern as

before and putting screws in all the holes preiously made, thus guaranteeing that the panels

assume the correct position as preiously determined. <hec" that all is correct on the underside

while scraping off e%cess glue.

/i% more epo%y as needed to bond the "eelson into place. :tarting at the

bac", screw it in place with the long screws in the premade holes.

Ilue in the usual manner 0 wetting bonding surfaces then applying a bead

of thic"ened high density glop to the underside of the transom.

Ilue the transom into place, chec"ing that it is perfectly aligned with the

after edges of the bottom all the way along. Hrop it so it can't fall oer. Hlace bloc"s under the

bottom panels if needed to lift up the bottom panels so they are at the same angle as the bottom

of the transom. 2ou want to be sure there are no gaps between the transom and the bottom and

that the transom is flush with the bac" edges of the bottom panels along the whole width of the

boat.

<lean up the e%cess epo%y.

Io around and scrape away all e%cess glue, then create a nice fillet on

either side of the "eelson. 4e careful to not "noc" oer the transomN

<hoose two battens to ma"e the chine logs. If you hae a tablesaw run

them through at the angle indicated in design sheet Q. 5therwise use the circular saw steady as

you can. !hen with the plane continue the beelling process so that it aries smoothly along the

length, and measures correctly at the control points. #s you can see on design sheet Q, the

control points are at, one meter, and at two meters bac" from the bow end. 2ou will notice the

angle barely changes until that last meter at the bow. If you are a couple degrees off, don't worry

too much as you can still "noc" it bac" a bit (or fill with epo%y when the sides go on) after it is

glued in place.

getting the bevel angle to change along the length with the plane

68 degree bevel all the way down

<lamp the chine logs into place. /ar" the angles at the front that the bow

transom will ma"e and carefully cut the front few c/s off creating both beels at once, such that

the log will stop neatly against the bow transom when the bow transom is in place. !his is a

deceptiely difficult cut to ma"e, but if you don't get it right the first time there is enough e%cess at

the stern to let you ma"e a new cut a couple of c/s bac", shifting the whole log forward this

amount. 2ou can transfer these angles to the other chine log and cut that one at once now that

you see the correct angles.

/ar" at the bac" the point at which the log must end and trim with the

handsaw.

HreEdrill and put in the screws ma"ing sure the chine log is e%actly aligned

with the edge of the bottom all the way along. @o not try and sae time by doing this while glueing

at the same time. It will almost certainly end up ta"ing more time in the end, apart from

guaranteeing a mess.

Ilue the chine log into place. If you are building on the floor or low, you will

hae to screw temporarily from the top with long screws. In this case, these screws will be

remoed later and permanent screws put in from the bottom, so ma"e sure these screws now

hae their heads free of glue, or they will be difficult to e%tract. :ee in the ne%t picture how the

outside lower edge of the chine logs lines up with the upper outside edge of the bottom.

Aft end

Step Four; Sides and Bow Transom.

<hec" that the bow transom fits perfectly pressing up against the ends of

both chine logs and the "eelson with the front face aligning e%actly with the front top edge of the

bottom panels. <orrect if necessary0 gaps can be filled with epo%y when the bow transom is

installed, e%cess wood must be trimmed bac" now with the grinder and a sharp chisel.

:et this transom aside.

@o a dry run with both sides of the boat putting in enough screws to fi% the

sides in their correct position with the lower inner edge of the side coinciding e%actly with the

upper outer edge of the bottom, and the aft edge flush with the aft side of the transom. 5ne screw

should go through the side and into the transom to secure their correct relationship. 9or" from the

aft end propping the other end up temporarily and ad'usting it up and down so the bottom of the

side comes onto the chine log correctly.

;emoe the sides and glue. If you are wor"ing alone you will hae to start

in the middle to hold the side at its point of balance and find the correct screw hole made earlier.

#im to end up with a screw eery about 33 c/. /a"e sure they are slightly countersun" so as to

not cause trouble later when finishing the hull.

<lean up e%cess glue and create a small fillet aboe the chine log.

1ow you can go straight onto the bow transom. 9hilst holding it so it is

perfectly aligned all the way around with the sides and bottoms, get at least one screw through

the side and into the bow transom up high. 1otice that the aft top edge of the transom is higher

than the inner top side edges. !his is because it is not yet beelled. 2ou will beel this edge later

with the plane. !he front top edge of the transom should howeer be aligned with the front top

inner corner of the sides.

<lean up thoroughly around the transom to not hae problems fitting in the

corner pieces that go all around the edge of (both) transoms, solidly bonding the transoms to the

rest of the hull.

Step Fi%e; Final details'

2ou can, once the sides and bow are cured, install the rubbing strips or you

can install the thwarts first.

I will describe the gunwales first.

!a"e two battens and router them on the two outboard edges each with a

$uarter round 12 or 1A m/ radius router bit. !hese are so simple a dry run should not be

neccesary. Ilue them onto the sides so that their upper edge lines up with the sheerline. :tart at

the bow with a clamp, and go down the side getting it into place with the rest of the clamps. !hen

go bac" again and put in small screws eery 33 c/ or so from the inside. Iet one done, remoe

the clamps and repeat on the other side for the other one.

4e sure to clean up all e%cess epo%y. 2ou can ta"e adantage of this

e%cess epo%y to get the upper edge of the side panels coated in epo%y which will seal and protect

the plywood sides.

9hen the glue is hard, carefully saw off the e%cess rubbing strip stic"ing

out from the ends of the boat.

!hat's it for the big wor"0 all the rest is now the fiddly bits, which ta"e time,

but are essential to ma"e the boat strong and functional.

<ut out the thwarts as per the design sheet A out of the remaining wide

plan", respecting the beel angles. /ar" a line at right angles across the plan" defining the center

of the thwart and use this as a base for your measurements. If your stoc" is not 1AA m/ wide and

you would rather not change it to 1AA m/ then you must transfer the measurements as if it was

1AA otherwise the ends will be at the wrong angle.

-or e%ample, if the plan" is 176 m/ wide, mar" a line 8 m/ away from

each edge and put the sheet measurements along these lines which are 1AA m/ apart.

/ar" on the undersides of the thwarts a line about eight or ten c/ away

from the ends. 9rite in pencil Rdo not pass with routerNS. ;oute the bottom edges with a 12 m/

radius $uarter round router bit up to these lines. @o not router all the way to the ends of the

thwartN

!urn the thwarts right side up and change to a 6 m/ radius $uarter round

router bit and router the top edges, this time going all the way to the ends. !he top round ma"es

the seats comfortable. !he bottom round is cosmetic ma"ing the seats appear thinner and more

delicate than they really are. If you don't hae a router use the plane and sandpaper on a wooden

bloc" for the top edges. Jse the plane on the bottom edge holding it a shallow angle. !he illusion

does not wor" if this chamfer is so steep that you can see the underside of this face.

/easure the distances from the aft face of the transom to the centres of

each thwart by placing a straight stic" across the boat. /easure on both sides so the stic" is

straight across the boat. /ar" these points on the hull.

Ceaing the stic" in place, measure from the bottom of the stic" the

indicated distance ( refer to design sheet 2) straight down to the side of the boat where the top of

the thwart needs to go and put a hori(ontal mar" there. !his mar"s the height of the top surface of

the thwart.

<ut out all si% risers. !hey are all the same, apart from the two for the bow

thwart which need a 6 m/ 'og cut out to fit oer the 'oining piece in the side panel. !he front

thwart too will need a 6 m/ 'og ta"en out. Hut this thwart in its correct longitudinal position and

mar" where the 'og has to start and cut it out with the circular saw with the same beel setting

used to cut the ends of the thwarts in the first place. -inish the last bit with the handsaw. <hec"

that it does indeed drop into place now.

<hec" that the thwarts all fit correctly in place. It may be that some will

push the sides of the boat out or they may be a small gap which means the sides of the boat need

to be pulled slightly together at that point. Jse some rope around the hull or the framer's clamp for

this. It should not be more than about . m/ though.

Coo" oer the boat with the thwarts temporarily in their correct positions

(fore and aft, up and down, and at the correct angle0 they must be hori(ontal when the boat is

floating) !he sides of the boat should be symmetrical and hae no bumps or hollows0 'ust a nice

flowing cure from end to end. If you cut out all the panels precisely and aligned eerything

correctly this is what should happen.

!race the undersides of each thwart mar"ing where they start and end.

;emoe the thwarts and install all the risers according to these lines with the same amount of

riser e%tending in front of the thwart as behind. Ilue them in place as usual with two small screws

each. <lean up.

<ut out the seat supports.

Ilue the thwarts in their correct positions with two screws at each end

going down into the riser. !his must be strong because the seats may be used to lift the boat by.

Ilue in place the seat supports with one clamp each. 1o screws are

needed here, but chec" that they do not start leaning oer as the glue sets. 4e meticulous with

cleaning and filleting the epo%y, here is a hard to sand place.

Ilue in place the four thwart "nees. !hese get one screw each from the

outside through the sides of the boat, 'ust under the rubbing strip. /a"e a batch of glop with about

2>3 light density 1>3 high density filler and create a big fillet around each "nee where the glue 'oins

are.

<ut out the little battens that 'oin the $uarter "nees to the hull.

Ilue each "nee in place flush with the top edges of side and top edge of

transoms with two screws each side down into the supporting batten, and each batten with two

screws into the hull.

!hese $uarter "nees are the usual handhold wheneer moing the boat

around out of the water so they must be strong. Carge fillets can used as well. 6oweer you finish

the glue 'oin be sure to be thorough because sanding in these corners is e%tremely aw"ward. 2ou

want to ma"e sure that you really only hae to do a little light sanding here, 'ust thorough enough

for the paint to stic".

1ow sit in both rowing positions and find where your feet naturally rest.

Hlace a light mar" there for each foot at the right position and angle for you. /easure these mar"s

both sides and ta"e the aerage measurements and now mar" in bold the definitie foot rest

positions so they are symmetrical about the centreline. Ilue in place the four foot rests one pair

for each rowing position. Io through the offcuts and find pieces that loo" li"e they will be

comfortable to push against. <ut them to around 1. or 1A c/ long. # piece of tape is enough to

hold them in place while the glue sets. It is a nice touch to add in more foot rests for anyone else

who might row this boat and who has longer or shorter legs. If you do not "now their leg

measurements 'ust add in the other foot rests parallel to the first eight or ten c/ away, 'ust far

enough that no matter which one you use the ne%t one does not dig into the an"les.

1ow that the "nees are all in place you can unscrew and free the boat from

its 'ig.

4ut there are still a couple more carpentry tas"s0

!he corner pieces that go around each transom.

<ut out these eight pieces. !he angles are gien in design sheet Q. 2ou will

hae to measure and mar" the end cuts and beels. I do not include this because it will depend

on the final dimensioning of the wood used for the chine logs and "eelson. It is not strictly

necessary to put screws in these pieces although it won't hurt haing them for greater 'oin

security. 2ou can often use a prop and wedge or a weight to "eep each piece in place while the

glue sets. ;emember that the wet epo%y ma"es the pieces ery slippy and that what seems to

wor" dry may creep or slip once the glue is on.

;emoe the temporary screws in the chine logs.

!urn the boat oer and put in a screw eery 33 c/ about through the

bottom and into the chinelog. 4e sure to aim right. Keep chec"ing after each screw to ma"e sure it

is not coming through on the inside. If one does, 'ust ta"e it out and moe it along a few c/. Jse

the mista"e as a hint on which way to correct so it does not happen again

oops missed!

<ut off the front end of the "eel following the mar" you already made with a

handsaw.

Io around the boat with the planer on a ery fine setting and the abrasie

disc grinder, "noc"ing bac" all the unfinished beels on the top of the bow transom, the aft ends of

the bottom and a slight amount on the aft ends of the sides as well as the front edges of both

bottom and sides so they are flush with the bow transom. 2ou will also want to chec" the chine all

around and plane anything that protrudes beyond the prolongation of its neighbouring panel. 4e

careful not to damage the planer on any screwsN

1ow cut out a female filleter from cardboard and fill the gap along each

chine with glop. !his seals up the endgrain of the plywood and finishes the chine off. 9hile at it fill

in all the screwheads and any blemishes you may find. 5nce this has hardened go bac" with the

grinder and a fine disc and some 133 grit sandpaper on a sanding bloc" and round it off eenly to

a radius of about . m/. If you did a good 'ob filleting the glue to start with, 'ust a $uic" once oer

with the sanding bloc" will suffice.

Step Six; Finishing'

9hat leel of finishing you decide on is up to you, it can go from a light

sanding and a couple coats of enamel, all the way up to full epo%y sealing followed by urethane

primer, topcoat and clearEcoat all e%tensiely sanded with eer finer grades of sandpaper, applied

by spray and finally buffed with wa%. If you go with the latter option you can be sure that people

will notice your new boatN !hey may hae to put on their sunglasses too wheneer you approach.

:ince there are too many options to fully describe in detail I will instead gie

some general recommendations and guidelines for a successful finish.

It is important to "eep in mind that the main function of finishing is not to

prettify but to protect the boat, e%tending the lifespan of the boat. !he greater the effort gone to in

finishing the more years the boat will last E up to a point.

1o matter the leel of finishing, count on haing to repaint the boat once a

year if the boat sees eeryday use. !his is part of the regular maintenance schedule of any boat.

In the tropics, aoid any dar" colour as they will get ery hot in the sun and

not do the structure of the boat any good. =po%y degrades at high enough temperatures too.

-urthermore the boat may een get so hot that bare or bi"inied bottoms

may not want to sit in it which may not be the intended outcomeN

It is a good idea to start by painting the whole boat inside and out with a

thinned coat of epo%y followed by a regular coat of epo%y. !his proides superb waterproofing and

an e%cellent base for the ne%t layers of coating. 6oweer, if using modern urethane or two part

epo%y paint, the paint itself is a ery good sealant so preEsealing in epo%y is not necessary.

;ather it is 'ust e%tra protection.

-or the ultimate finish I would paint in thinned epo%y and then follow that

with a meticulously applied e%tremely thin layer of low density glop applied with a wide s$ueegee

oer the whole boat. !hen this is all sanded bac" with wet and dry sandpaper so the surface

becomes utterly smooth and all traces of wood grain are gone.

=en if you are not aiming for this leel of perfection, a bare minimum is to

go around the boat applying glop light to each screw head and any other surface blemish so the

surface is smooth and een. !ry and apply as eenly as possible to sae yourself as much

subse$uent smoothing with the sandpaper and sanding bloc". #lso be sure to grind bac" any

screw points that may hae po"ed through anywhere. 4e aware that grinding metal, een

stainless steel, will create a fine spray of metal particles which will eentually corrode and create

haoc with your paint, so be diligent about remoing all traces before painting.

<rucial for any paint 'ob is preparation and sanding. #ll surfaces to be

painted must be thoroughly sanded and then all dust remoed with a clean rag and some thinner.

In between coats eerything must be sanded again to proide good grip for the ne%t coat.

:ome e%ceptions to this is when using two part paints which will dry no

matter how thic" the layer one can "eep adding layers without stopping. #s soon as the first layer

is hard enough to not get dragged around by the brush the ne%t coat can go on. !here is a

window of time that can be used in other words to sae on a sanding operation.

9ith enamels (oil based paint) also there is this window, starting about two

hours after application, depending on the actual paint and the conditions. 2ou "now it's ready the

moment it is )tac" free+. 6oweer, since enamels do depend on drying processes, you can only

apply two consecutie coats in this manner or the first coat will neer fully dry.

#nother "ey to a $uality paint 'ob is many thin layers of paint. @on't pay any

attention to paint labels saying 'do not dilute'. I find that in almost eery case the paint goes on far

better after thinning. In the case of enamels .T mineral spirits is usually about right, but try a little

at a time (in a separate pot) and see where the sweet spot is where the flow of the paint is 'ust

right.

-or urethane paints in the tropics the dilution ratio is about 133T. 1o that's

not a typo. It's got to be the consistency of water, otherwise you'll get horrible brush mar"s. !he

brush must be a high $uality brush or that e%pensie paint will hae been completely wasted. !he

hardener must be slow if painting by brush, especially in a hot climate, or else you don't physically

hae the time to "eep up with the wet edge. =en doing all that, one has to wor" e%tremely fast in

narrow bands so the wet edge does not start dragging and a bottle of thinner be "ept close by to

"eep on topping up the ratio in the paint pot. !hese thinners eaporate ery $uic"ly. Pylene is the

thinner for urethane, but you can get away with lac$uer thinner if you want to cut costs, and are

willing to sacrifice a little of the final result's shine. 4ut as mentioned before, you can 'ust "eep on

applying coats until the 'ob is done in one fell swoop.

It is always a good idea, particularly with the high end paints to do a test bit,

een on an offcut of the boat to see that there won't be any bad surprises. #nd by bad surprises I

mean potentially haing a disaster which re$uires sanding the whole boat down

and starting oer which is a frustrating and than"less tas" best aoided at

any cost.

#nother thing is do not waste your money on fancy )marine+ paint. !here is

no difference between urethanes worth paying double for. Iet your urethane at the auto body

shop, get a middle of the road price brand or een a generic brand and you'll end up with a top

notch finish for half the price of that 'marine' stuff proided you do your prep well.

ne liter of car urethane and a camel hair brush resting on a paint pot!

"irst coat of urethane goes onto the primer!

It's worth also loo"ing into some of the epo%y paints. !hese are two part,

hard as nails and hae e%cellent build. !here is een a two part epo%y paint which dilutes with

water which I highly recommend.

5nce done painting you can finally install the metal band on the underside

of the "eel if you hae it.

#ars and #arlocks;

5arloc"s are meant to go 2. c/ behind the rear edge of the thwart, but

since the stoc" you use for this may be a slightly different width I specify the distance from the

centres of the thwarts. ;efer to design sheet 2. If your arms are unusually long or short this may

be altered slightly, but generally this measurement is correct and will be good for anyone,

including children.

9hen buying the oarloc"s do not buy the closed loop "ind which should be

internationally banned. Iet the classic open style where you can ship an oar in an instant, with a

smartly e%ecuted moement, leaing the oarloc" in place ready for the oar to be rapidly deployed

again. !he closed "ind will not allow this, instead sliding down the oar all the way to the blade in

the water and must be retrieed usually re$uiring both hands and put bac" in its soc"et.

#lso chec" while still in the store if you can, that both oarloc"s can in fact

be easily inserted into any of the oarloc" soc"ets. :ome of these made in china parts are so

sloppily machined that they won't fit together properly and bind or een not enter all the wayN

5nly get bron(e or stainless steel oarloc"s and soc"ets. 4e sure the

oarloc"s hae a small hole at the bottom end of the pin. !his is to tie a short piece of strong line or

sin"hole chain through, the other end being tied to any ob'ect that is s"inny

enough to pass through the oarloc" soc"et, but that will not let the oarloc" from actually getting

lost if for whateer reason it should get "noc"ed oerboard. 9hen ta"en in, the oarloc"s will hang

from this small chain inside the boat, ready at hand to be reE inserted into position $uic"ly. 9hen

leaing the boat in $uestionable areas be sure to remoe the oarloc"s and ta"e them with youN

If you are on a tight budget you may consider fashioning rigid wooden

oarloc"s as in the e%ample in the photos, out of hardwood, but they are more aw"ward to use.

!he height of the thwarts is important too. It is upsetting to see how many

dinghies hae thwarts that are far too high0 this ma"es the boat less stable, e%poses more of the

body to windage and forces a terrible rowing posture. Hroided you installed the thwarts as

specified you should find that the rowing position feels natural on either of the two seats, and you

can pull well.

;owing is an art and sport as well as a practical science and there is much

to it. It is well worth the time to read up on some of the finer points of rowing.

!his free boo" ;owing and :culling aailable on the internet and can be

downloaded and will gie you an idea as to the magnitude of the sub'ect, for while anyone can

learn to generally row about in a dinghy in a short time, the perfectioning of the techni$ue is

something that can be deeloped continually during one's lifetime.

!he oars must be 2.8 / (A') long. If the oars are not this length you will not

be rowing correctly or efficiently.

!he oars that are li"ely offered at the chandlers are certain to be of the

glorified butter paddle ariety. !his can be improed by 'udiciously planing away all the e%cess

wood down at the blade end as well as tapering the shaft away from the oarloc". It should re$uire

ery little effort in order to raise the blades out of the water when you are rowing.

!he length howeer must be 2.8 / and if this is not aailable you will hae

to lengthen the loom to the correct length. !he ones in the photo hae been lengthened and

balanced.

#lternatiely you can contact me and order plans for well balanced built up

1orwegian style oars e%actly matched to this boat.

(httpU>>archie.org>details>rowingandsculli33woodgoog in case the aboe

lin" does not wor"

;eaders who do a want a classy performance rowing boat may want to

hae a loo" at my designs V 6328

and V 6133

<ontact !W at 0 tttangaldXyahoo.com

También podría gustarte

- Instant Boatbuilding with Dynamite Payson: 15 Instant Boats for Power, Sail, Oar, and PaddleDe EverandInstant Boatbuilding with Dynamite Payson: 15 Instant Boats for Power, Sail, Oar, and PaddleCalificación: 4.5 de 5 estrellas4.5/5 (3)

- Simple Boat-Building - Rowing Flattie, V-Bottom Sailing Dinghy, Moulded Pram, Hull for OutboardDe EverandSimple Boat-Building - Rowing Flattie, V-Bottom Sailing Dinghy, Moulded Pram, Hull for OutboardAún no hay calificaciones

- Crouch HydroDocumento12 páginasCrouch HydroKeith WilliamsAún no hay calificaciones

- Boat Building Simplified - Being a Practical Guide to the 'Ashcroft' Method of Building, Rowing, Sailing and Motor BoatsDe EverandBoat Building Simplified - Being a Practical Guide to the 'Ashcroft' Method of Building, Rowing, Sailing and Motor BoatsCalificación: 1 de 5 estrellas1/5 (1)

- Duck SkiffDocumento61 páginasDuck SkiffKay Pratt100% (2)

- DolphinDocumento5 páginasDolphinAlphamatrix01Aún no hay calificaciones

- Mason 33 Practical ReviewDocumento5 páginasMason 33 Practical ReviewManuelPérez-Sola100% (1)

- Canoe and Kayak Building the Light and Easy Way: How to Build Tough, Super-Safe Boats in Kevlar, Carbon, or FiberglassDe EverandCanoe and Kayak Building the Light and Easy Way: How to Build Tough, Super-Safe Boats in Kevlar, Carbon, or FiberglassAún no hay calificaciones

- Introduction to Yacht Design: For boat owners, buyers, students & novice designersDe EverandIntroduction to Yacht Design: For boat owners, buyers, students & novice designersAún no hay calificaciones

- Project PaltusDocumento22 páginasProject PaltusJoao CalinhoAún no hay calificaciones

- Le Ptit GrosDocumento10 páginasLe Ptit GrosKeith Williams100% (1)

- Julie SkiffDocumento4 páginasJulie SkiffDan100% (1)

- Practical Boat Building for Amateurs: Full Instructions for Designing and Building Punts, Skiffs, Canoes, Sailing Boats, Etc.De EverandPractical Boat Building for Amateurs: Full Instructions for Designing and Building Punts, Skiffs, Canoes, Sailing Boats, Etc.Aún no hay calificaciones

- Building A Wood Epoxy SharpieDocumento12 páginasBuilding A Wood Epoxy SharpieAmy Rodriguez0% (2)