Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Risk Asses24 - Boiler Drums

Cargado por

Rochdi Bahiri0 calificaciones0% encontró este documento útil (0 votos)

67 vistas3 páginasTítulo original

Risk Asses24- Boiler Drums

Derechos de autor

© © All Rights Reserved

Formatos disponibles

PDF, TXT o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

0 calificaciones0% encontró este documento útil (0 votos)

67 vistas3 páginasRisk Asses24 - Boiler Drums

Cargado por

Rochdi BahiriCopyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

Está en la página 1de 3

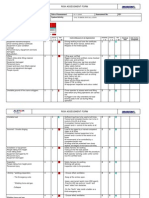

RISK ASSESSMENT FORM

Location: Terga Date of Assessment: 23-11-2009 Assessment No: 024

Assessor(s): FRIDI.ALI System/Activity: BOILER DRUMS

P

r

o

b

a

b

i

l

i

t

y

&

F

r

e

q

u

e

n

c

y

Definite 5 5 10 15 20

High 4 4 8 12 16

Moderate 3 3 6 9 12

Low 2 2 4 6 8

Negligable 1 1 2 3 4

1 2 3 4

Minor Serious Major Catastrophic

Severity

Key to Priorities

Medium Priority (5 days) High Priority (2-3 days) Immediate

Hazards Identified (include the exposed groups)

Probability

1 - 5

Severity

1 - 4

Risk

1 - 20

Control Measures to be Implemented

Probability

1 - 5

Severity

1 - 4

Risk

1 - 20

Residual

Risk

Date Action

Completed

Equipment transfer

Driver working without certificate

Equipment in poor condition

Leakage

Personnel injury, Equipment and tools

damaged.

Soil pollution.

4 3 12 Driving working must have the certificate.

Inspect the driver license, before drive.

Respect of the limited speed.

2 2 4

Lifting

Object strike while lifting material

Crane tilt

Equipment damaged

Personnel injury.

Impact and injury from lifted material

Crane and equipment damaged

People injured.

4 3 12 Lifting gear certified

Riggers trained and certified, crane checked

before use, and certified.

Barricade lifting area, tag lines provided.

Riggers to wear hi-visible vest and blue

colour safety helmet.

Hand signal clear and correct

Expound the requirement to the operator

Ensure there nobody under the lifting object

Not lifting in bad weather such as strong

wind, heavy rain etc...

Not lifting at night

Never refit the lifting equipment.

Obtain PTW for lifting

All equipment inspected and colour coded.

2 3 6

Unstable ground of the crane outriggers 3 3 9 Crane operator to assess work and lifting

area before any lifting operations are carried

out.

Outrigger to be fully extended and load

bearing pads to be use during lifting

operation.

2 3 6

RISK ASSESSMENT FORM

Unstable load 3 2 6 Sufficient tag lines to be used at all times.

Trained and competent banks man to be in

control of the lift at all times.

A competent trained supervisor to be

present and in control of the works at all

times

2 2 4

Waste control

Environment pollution from waste material

and leakage

Soil polluted by leakage waste material

2 4 8 Waste material recycle bin will set up and

clear up regularly

Prior to use, vehicle must inspected, to

unsure no leakage.

2 2 4

-Activity: *welding preparation.

- The Emergency exits

* Welding fume and gas.

-Collapse

4 4 16 - Ensure effect ventilation.

-Keep all the entries open.

-keep a permanent watch (one HSE agent).

-Free the (02) two exits on south and

west sides from obstacles.

-On the North side install a ladder as a

third emergency exit.

2 2 4

Welding at height 3 3 9 All welding operations at height are to be

fully sheeted in with a fire blanket.

The area below the work place to be

checked for flammable materials before

commencing any work cordoned off.

A fire watcher and fire extinguishers to be in

place below the work area.

All equipments to be inspected and left in

safe conditions at break times and at the end

of each shift.

2 3 6

Installation of equipment

People falling from height

Tools falling down

Equipment damaged by hit

Personnel injury

Equipment damaged

4 3 12 Safety harness for working

Tools put into the tools pocket

Installation in accordance with the procedure

Multi-operator working under unifier control

Use the certified tools

2 2 4

Inspection

People falling from height pinch

Personnel injury

4 3 12 Safety harness for working

Working with gloves

Inspection refer to the procedure

2 2 4

RISK ASSESSMENT FORM

También podría gustarte

- Risk Assessment For Sand BlastingDocumento8 páginasRisk Assessment For Sand BlastingRochdi Bahiri69% (16)

- Kaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Documento3 páginasKaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Ogunwa EmmanuelAún no hay calificaciones

- Risk Assesment 16 - Pre - Assembly and Erection ofDocumento7 páginasRisk Assesment 16 - Pre - Assembly and Erection ofRochdi BahiriAún no hay calificaciones

- Risk Assesment 16 - Pre - Assembly and Erection ofDocumento7 páginasRisk Assesment 16 - Pre - Assembly and Erection ofRochdi BahiriAún no hay calificaciones

- 2.0 Windsock Wind SpeedsDocumento1 página2.0 Windsock Wind SpeedsSoham Mukherjee100% (2)

- HSE Q&A Hseprof ComDocumento12 páginasHSE Q&A Hseprof ComUzma AhmedAún no hay calificaciones

- Instructions For Using The Risk Assessment FormDocumento9 páginasInstructions For Using The Risk Assessment FormMalik Khuram ShazadAún no hay calificaciones

- Construction Safety RulesDocumento12 páginasConstruction Safety Rulesmelantnor_19Aún no hay calificaciones

- Assad Ullah Jan: ObjectiveDocumento6 páginasAssad Ullah Jan: ObjectiveManda Khel Apna DesAún no hay calificaciones

- JSA-03 Shed DismantlingDocumento3 páginasJSA-03 Shed DismantlingSwaroop Cherry0% (1)

- Tower Scaffolds: What You Need To DoDocumento3 páginasTower Scaffolds: What You Need To DoMario Marasigan100% (1)

- Hip & Jsa For Abqq-472Documento13 páginasHip & Jsa For Abqq-472javithAún no hay calificaciones

- Ocp BatchingDocumento1 páginaOcp BatchingAarya Mishra TiwariAún no hay calificaciones

- HSE guidance on safety devices for rapid roller doorsDocumento11 páginasHSE guidance on safety devices for rapid roller doorsmsc920138Aún no hay calificaciones

- Spray Booth Risk AssessmentDocumento3 páginasSpray Booth Risk AssessmentJohn Geddes100% (1)

- Job Hazard Analysis For Desalination of First Effect RetubingDocumento7 páginasJob Hazard Analysis For Desalination of First Effect Retubingmc chesterAún no hay calificaciones

- TCL Air Conditioner User ManualDocumento37 páginasTCL Air Conditioner User ManualLevi M. VillanuevaAún no hay calificaciones

- Weekly Safety Management Walkthrough Report: Gas Compression Project DepartmentDocumento12 páginasWeekly Safety Management Walkthrough Report: Gas Compression Project DepartmentSheri DiĺlAún no hay calificaciones

- Confined Space Entry Safety AnalysisDocumento2 páginasConfined Space Entry Safety AnalysisDheeraj Kapoor /QOGIL/QuippoworldAún no hay calificaciones

- Suroj Buildcon Pvt. LTD.: Job Safety AnalysisDocumento6 páginasSuroj Buildcon Pvt. LTD.: Job Safety AnalysisKiran ChenchalaAún no hay calificaciones

- Hand Trolley PDFDocumento1 páginaHand Trolley PDFcityofdarwingisAún no hay calificaciones

- Work at Height Rescue PlanDocumento4 páginasWork at Height Rescue PlanDarrel Lutchman100% (1)

- PPE Notice PolicyDocumento1 páginaPPE Notice PolicyLenaj EbronAún no hay calificaciones

- Caretaker Risk Assessment - Working at HeightDocumento8 páginasCaretaker Risk Assessment - Working at HeightLina MarcelaAún no hay calificaciones

- Working at Height Is One of The Hazardous OccupationsDocumento6 páginasWorking at Height Is One of The Hazardous OccupationsHemaAún no hay calificaciones

- Suspended From Man-Rider (Vertical Rescue Plan)Documento1 páginaSuspended From Man-Rider (Vertical Rescue Plan)Paul100% (1)

- JHA For Work PermitDocumento1 páginaJHA For Work PermitShahid RazaAún no hay calificaciones

- Part 3 ObservationsDocumento7 páginasPart 3 ObservationsAmjadAún no hay calificaciones

- Water Tank Cleaning TRADocumento5 páginasWater Tank Cleaning TRAyehia sayedAún no hay calificaciones

- MSU Vehicle Fueling SOPDocumento2 páginasMSU Vehicle Fueling SOPsarge18100% (1)

- Job Hazard Analysis for Confined Space EntryDocumento6 páginasJob Hazard Analysis for Confined Space EntryArun ArunbolluAún no hay calificaciones

- Asian Paints - Prem Gloss EnamelDocumento1 páginaAsian Paints - Prem Gloss EnamelwilliumstAún no hay calificaciones

- Safety ProgramDocumento21 páginasSafety ProgramSits RdddAún no hay calificaciones

- Qatar Liquefied Gas Company Limited JSA for Cutting, Grinding and WeldingDocumento5 páginasQatar Liquefied Gas Company Limited JSA for Cutting, Grinding and WeldingMohammad Fazal KhanAún no hay calificaciones

- Confined Space Entry Rescue Plan 1Documento11 páginasConfined Space Entry Rescue Plan 1patrick ruwonaAún no hay calificaciones

- Bench Grinder: DO NOT Use This Machine Unless A Teacher Has InstructedDocumento2 páginasBench Grinder: DO NOT Use This Machine Unless A Teacher Has InstructedNabil Qayyum Roslee100% (1)

- Basic Safety Instructions For All Employees Visiting or Working in The Construction of The HgpepDocumento42 páginasBasic Safety Instructions For All Employees Visiting or Working in The Construction of The Hgpepmalik jahanAún no hay calificaciones

- Job Safety Analysis Sheet: Manual ExcavationDocumento1 páginaJob Safety Analysis Sheet: Manual ExcavationSafety ProfessionalAún no hay calificaciones

- Tower Crane Work Permit ChecklistDocumento1 páginaTower Crane Work Permit Checklistfaisal nadeemAún no hay calificaciones

- Confined Space AwarenessDocumento49 páginasConfined Space Awarenesstejas gajelli100% (1)

- Confined Space SlideDocumento65 páginasConfined Space SlideSyahrul AnisAún no hay calificaciones

- JSA - Crane Setuppdf PDFDocumento12 páginasJSA - Crane Setuppdf PDFChoko ChokriAún no hay calificaciones

- SAUDI ARAMCO HOMEOWNERSHIP SITE DEVELOPMENT AND HOUSING UNIT – INCREMENT II LOADING AND UNLOADING OF PRECAST ELEMENTSDocumento3 páginasSAUDI ARAMCO HOMEOWNERSHIP SITE DEVELOPMENT AND HOUSING UNIT – INCREMENT II LOADING AND UNLOADING OF PRECAST ELEMENTSImamul HaqueAún no hay calificaciones

- Job Safety Analysis For Pump Installation in Ts3 Area: Hcu & Lobs Revamp ProjectDocumento5 páginasJob Safety Analysis For Pump Installation in Ts3 Area: Hcu & Lobs Revamp ProjectShilpiengg SafetyAún no hay calificaciones

- JSA For Refurbishing and Repainting 23oct2017 (Woqod LPG Plant) UpdatedDocumento13 páginasJSA For Refurbishing and Repainting 23oct2017 (Woqod LPG Plant) UpdatedJoseph PerezAún no hay calificaciones

- Shailesh Job Safety Analysis in Steel Manufacturing Unit and Recommendations To Improve The Work Safety EnvironmentDocumento21 páginasShailesh Job Safety Analysis in Steel Manufacturing Unit and Recommendations To Improve The Work Safety EnvironmentNandini RajAún no hay calificaciones

- Job Safety Analysis (JSA) - Night Work DateDocumento2 páginasJob Safety Analysis (JSA) - Night Work Datenabeel100% (2)

- ScaffoldingDocumento16 páginasScaffoldingHSEAún no hay calificaciones

- Nitoproof 230Documento2 páginasNitoproof 230Balasubramanian Ananth50% (2)

- Job Safety Analysis (Jsa) Work Sheet: Risk Matrix Project /job DetailsDocumento4 páginasJob Safety Analysis (Jsa) Work Sheet: Risk Matrix Project /job Detailsnasar_mahsood100% (2)

- Building De-Dusting JSADocumento3 páginasBuilding De-Dusting JSAJayesh J PillaiAún no hay calificaciones

- Job Safety Analysis Sheet: Arc Welding, Cutting, GrindingDocumento1 páginaJob Safety Analysis Sheet: Arc Welding, Cutting, GrindingGudduAún no hay calificaciones

- Compulsory Ppe As Needed Ppe: Safe Operating Procedures SOP 02 - Bench GrinderDocumento2 páginasCompulsory Ppe As Needed Ppe: Safe Operating Procedures SOP 02 - Bench GrinderMuhammad Oji L100% (1)

- Breaker Machine Safety ChecklistDocumento1 páginaBreaker Machine Safety ChecklistNair R RakeshAún no hay calificaciones

- 039 G HSE Bulletin Safe Crane OperationsDocumento1 página039 G HSE Bulletin Safe Crane OperationsOws AnishAún no hay calificaciones

- Cable Laying Safety MeasuresDocumento5 páginasCable Laying Safety MeasuresDwitikrushna RoutAún no hay calificaciones

- Chain Pulley Block or Chain Hoist Safety Dos and Don'tsDocumento5 páginasChain Pulley Block or Chain Hoist Safety Dos and Don'tsAkram BadranAún no hay calificaciones

- Shifting of Material & Equipment.: Job Safety Analysis JobDocumento6 páginasShifting of Material & Equipment.: Job Safety Analysis JobPrabir PujariAún no hay calificaciones

- Risk Assessment Form Gaz Turbine InstallationDocumento6 páginasRisk Assessment Form Gaz Turbine InstallationRochdi Bahiri100% (1)

- A Case Study of 3-MW Scale Grid-Connected Solar Photovoltaic Power Plant at Kolar, KarnatakaDocumento38 páginasA Case Study of 3-MW Scale Grid-Connected Solar Photovoltaic Power Plant at Kolar, KarnatakaAnant Joshi67% (3)

- Project Finance and Merchant PowerDocumento76 páginasProject Finance and Merchant Powersimplyanks_5100% (2)

- Risk Asses 118-Transformers Oil TreatmentDocumento5 páginasRisk Asses 118-Transformers Oil TreatmentRochdi BahiriAún no hay calificaciones

- Readme 1 STDocumento1 páginaReadme 1 STRochdi BahiriAún no hay calificaciones

- Evaluate economic feasibility of power plant projectsDocumento7 páginasEvaluate economic feasibility of power plant projectsfundu123Aún no hay calificaciones

- Power Electronics For Modern Wind Turbines-Frede Blaabjerg Zhe ChenDocumento68 páginasPower Electronics For Modern Wind Turbines-Frede Blaabjerg Zhe Chennelber_xAún no hay calificaciones

- What Is Quadrature Axis Reactance PDFDocumento11 páginasWhat Is Quadrature Axis Reactance PDFRochdi BahiriAún no hay calificaciones

- Audit of Power Purchase AgreementsDocumento6 páginasAudit of Power Purchase AgreementsRochdi BahiriAún no hay calificaciones

- Epc Contracts in The Power SectorDocumento30 páginasEpc Contracts in The Power SectorIwan Anggara100% (2)

- Risk Asses 116 - Boiler Hydro Test LP3Documento5 páginasRisk Asses 116 - Boiler Hydro Test LP3Rochdi BahiriAún no hay calificaciones

- Pump Efficiency For Single Stage Centrifugal PumpsDocumento8 páginasPump Efficiency For Single Stage Centrifugal PumpsPerrobast100% (1)

- Risk Asses23 - Generator RotorDocumento3 páginasRisk Asses23 - Generator RotorRochdi BahiriAún no hay calificaciones

- Primavera: Contract Manager Functional OverviewDocumento22 páginasPrimavera: Contract Manager Functional OverviewIgor ČučekAún no hay calificaciones

- TSA Appendices State - 16 09 2014 - WPDocumento24.221 páginasTSA Appendices State - 16 09 2014 - WPRochdi BahiriAún no hay calificaciones

- Lettre Recommandation Orascom ConstructionDocumento1 páginaLettre Recommandation Orascom ConstructionRochdi BahiriAún no hay calificaciones

- Financial Analysis of Projects I - OutlineDocumento2 páginasFinancial Analysis of Projects I - OutlineRochdi BahiriAún no hay calificaciones

- 308 BeheraDocumento6 páginas308 BeheraRajneesh VachaspatiAún no hay calificaciones

- Financing and Performance Contracting For EE Projects OutlineDocumento1 páginaFinancing and Performance Contracting For EE Projects OutlineRochdi BahiriAún no hay calificaciones

- Install NotesDocumento1 páginaInstall NotesRochdi BahiriAún no hay calificaciones

- BRD - Lean Manufacturing CaseDocumento62 páginasBRD - Lean Manufacturing CaseRochdi BahiriAún no hay calificaciones

- Hawk 4000 Controls: HAWK 4000 Boiler Control System Sample SpecificationsDocumento4 páginasHawk 4000 Controls: HAWK 4000 Boiler Control System Sample SpecificationsRochdi BahiriAún no hay calificaciones

- Primavera Project Planner p3Documento300 páginasPrimavera Project Planner p3MARIANO100% (19)

- Dampers ExplanationDocumento7 páginasDampers ExplanationRochdi BahiriAún no hay calificaciones

- P6 Reference ManualDocumento550 páginasP6 Reference Manualsaluthomas100% (22)

- Project and O&M CostDocumento2 páginasProject and O&M CostRochdi BahiriAún no hay calificaciones

- 750-326 OM Blowdown Separator 04-10Documento8 páginas750-326 OM Blowdown Separator 04-10Rochdi BahiriAún no hay calificaciones

- Boiler Design StepDocumento3 páginasBoiler Design StepRochdi BahiriAún no hay calificaciones

- Wmu 2013 - PPT - FinalDocumento103 páginasWmu 2013 - PPT - FinalRochdi BahiriAún no hay calificaciones

- Risk Asses23 - Generator RotorDocumento3 páginasRisk Asses23 - Generator RotorRochdi BahiriAún no hay calificaciones