Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Is 13235.1991 PDF

Cargado por

Anil MarturiTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Is 13235.1991 PDF

Cargado por

Anil MarturiCopyright:

Formatos disponibles

Disclosure to Promote the Right To Information

Whereas the Parliament of India has set out to provide a practical regime of right to

information for citizens to secure access to information under the control of public authorities,

in order to promote transparency and accountability in the working of every public authority,

and whereas the attached publication of the Bureau of Indian Standards is of particular interest

to the public, particularly disadvantaged communities and those engaged in the pursuit of

education and knowledge, the attached public safety standard is made available to promote the

timely dissemination of this information in an accurate manner to the public.

!"#$%&# '(%)

!"# $ %& #' (")* &" +#,-.

Satyanarayan Gangaram Pitroda

Invent a New India Using Knowledge

/0)"1 &2 324 #' 5 *)6

Jawaharlal Nehru

Step Out From the Old to the New

7"#1 &" 8+9&"), 7:1 &" 8+9&")

Mazdoor Kisan Shakti Sangathan

The Right to Information, The Right to Live

!"# %& ;<" =7"#" > 72 &(: ?0)"@" #AB 7" <&*" A*

Bhart+hariN,ti-atakam

Knowledge is such a treasure which cannot be stolen

IS 13235 (1991): Calculation of the Effects of

Short-circuit Currents [ETD 20: Electrical Installation]

- -

I ndian Standard

IS 13235 : 1991

EC Pub 885 ( 1988 )

( Superseding IS 6726 1

(Reaffkmed 1997)

CALCULATION OF THE EFFECTS OF

SHORT-CIRCUIT CURRENTS

( First Reprint FEBRUARY 1999 )

UDC 621-317-613

BUREAU OF INDIAN STANDARDS

MANAK BHAVAN, 9 BAHADUR SHAH ZAFAR MAR0

NEW DELHI 110002

December 199 1

Rice Group 10

( Reaffirmed 2002 )

IS 13235 I 1991

IECPob865(1986)

I ndian Standard

CALCULATION OF THE EFFECTS OF

SHORT-CIRCUIT CURRENTS

NATIONAL FOREWORD

This Indian Standard which is identical with IEC Pub 865 ( 1986 ) Calculation of the effects

of short-circuit currents, issued by the International Electrotechnical Commission ( IEC ) was

adopted by the Bureau of Indian Standards on the recommendations of the Electrical

Installations Sectional Committee ( ET 20 ) and approval of the Electrotechnical Division

Council.

An important criterion for the proper selection of a circuit-breaker or any other fault protective

devices for use at a point in an electrical circuit is the information on maximum fault current

likely at that point. The electromagnetic, mechanical and thermal stresses which a switchgear

and the associated apparatus have to withstand depends on the fault current.

of breaking and withstand capacities play a major role in

Proper selection

e health of the electrical installa-

tions. Realizing this need and to provr e +i uniform g P ide fo. calculation of short-circuit

currents, IS 5728 was brought out in 1970.# ;,

.,,

Subsequent to the preparation of this standa d, considerable information has been

collated the world over on calculation of fault levels under different and specific circumstances.

There was also a need to simplify calculation techniques in practical way commensurate with

the modern arithmetic tools available to engineers in the form of computers, digital transient

network analysers etc. With an objective to establish a general, practicable and concise

procedure for short-circuit current calculations IS 5728 has been taken up for revision, aligning

its contents with IEC 865 ( 1986 ).

This Indian Standard supplements the provisions of IS 13234 : 199l/IEC 909 (1988) by covering

standardized procedures for the calculation of the electromagnetic and thermal effects of fault

currents in electrical circuits.

1

As in the Original Standard, this Page is Intentionally Left Blank

1. scope

This standard contains standardized procedures for the calculation of the effects of the

short-circuit currents in two sections as follows:

Section One - The electromagnetic effect on rigid conductors and slack conductors.

Section Two - The thermal effect on bare conductors..

Only a.c. systems for rated voltages up to and including 72.5 kV are dealt with in this

.

standard.

2. Symbols

The symbols used in this standaragnd the quanti$es which they represent are given in the

following lists:

2.1 Symbols for Section One - Electromdgketic effects

k.

A

(I

4.

%

b

c

d

E

F

Fd

4

Fl

F

In2

F

m3

F,

4t

4

F

0

::

2

g

k3

i;

i, iz

J S

Js

k

k,,

1

4

m

m;

m,

n

4

Q.2

S

6

VF

Conductor cross-section

Centre-line distance between conductors

Effective conductor central distance, see Table I

Centre-line distance between conductors

Dimension of the sub-conductor perpendicular to the direction of the force

Factor for the influence of spacers or stiffening elemen:s, see Figure 3, page 29

Dimension of the sub-conductor in the direction of the force

Youngs modulus

Force acting between two parallel long conductors duringr short-circuit

Force on support of rigid conductors dur i ng a short-circuit (peak value)

Tension in a flexible conductor after a short-circuit

Force between main conductors

Force between main conductors durmga line-to-line short-circuit

Force acting on central main conductor during a balanced three-phase short-circuit

Force between sub-conductors

Static tension in a flexible conductor

Tension in a flexible conductor during a short-circuit

Force per unit length on outer phase flexible conductor caused by a short-circuit current

System frequency

Natural frequency of a main conductor

Basic frequency

Conventional value of acceleration of gravity

Three-phase symmetrical short-circuit current (r.m.s.)

Peak short-circuit current

Peak short-circuit current in case of a line-to-line short-circuit

Peak short-circuit current in case of a balanced three-phase short-circuit

Instantaneous values of the currents in the conductors

Second moment of conductor area

Second moment of sub-conductor area

Number of spacers or stiffening elements, see Figure 3

Factor for effective conductor central distance, see Figure I, page 28

Distance between supports

Distance between spacers or stiffening elements

Main conductor mass per unit length

Mass of sub-conductor per unit length

Total mass of onestiffening element or spacer between supports

Number of sub-conductors

Factor of plasticit see Table III

Yield point

+

Resultant spring constant of conductor dead end

Dead-time of three-phase auto-reclosure

Ratio between dynamic and static force on support, see Figure 4. page 30

mm2

m

m

m

m

N/m;

N

N

N

N

N

N

N

N

N

N/m

HZ

HZ

HZ

m/s2

kA

LA

LA

kA

kA

cm4

cm4

m

kg/:

kdm

kg

N/mm2

N/mm

S

.

IS 13235 : 1991

IECPub865(19S)

V,

Ratio between stress with and without unsuccessful three-phase auto-reclosure. see Figure 5,

page 30

V,

Ratio between dynamic and static conductor stress, see Figure 4, page 30

V

cls

Ratio between dynamic and static sub-conductor stress, see Figure 4

Z Section modulus

Z,

Section modulus for sib-conductor

a*

Factor for force on support, see Table II

Factor for main conductor stress, see Table II

Y

Factor for natural frequency estimat; 7, see Table II

E p, ly

Factor for peak short-circuit current

Factors for tensile force in flexible conductor, see Figure 6, page 3 I

um

Bending stress in main conductor

0,

Bending stress in sub-conductor

a,,,

Resulting conductor stress

2.2 Symbols for Section Two - Thermal effects

cm3

cm3

N/mm2

N/mm*

N/mm2

3.

. 3.1

3.2

3.3

3.4

3.5

3.6

3.7

Ik

Steady state short-circuit current (r.m.s.)

I[ Initial symmetrical short-circuit curient (r.m.s.)

I

I:Li

Thermal equivalent short-circuit current (r.m.s.)

Individual thermal equivalent short-circuit current at repeated short-circuits (m.s.)

I

thr

Rated short-time current (r.ma.)

m Factor for the heat effect of t&d.c. component, # Figure 7aj, page 32

ih

Factor for the heat effect of the a.c. component, see Figure 761, page 32

Thermal equivalent short-circ&t current density (r.m.s!)

S

thr

Rated short-time current de&ity (r.m.s.) for I s

&

Short-circuit duration

Tki

Individual short-circuit duration at repeated short-circuits

%

Rated short-time

2

Conductor temperature at the beginning of a short-circuit

* e

Conductor temperature at the end of a : nort-circuit

General definitions

kA

kA

kA

kA

kA

A/mm2

A/mm2

S

S

G

T

Main conductor

A conductor or a composed arrangement of a number of conductors carrying the total

current in one phase.

Sub-conductor

A conductor which carries a certain part of the total current in one phase and is a part of the

main conductor.

support

An insulating device between a live conductor and the earthed structure or between main

conductors.

Note. - Under action of electromagnetic forces, in the given position, the support might be exposed to bending,

tension and/or compression due to electromagnetic forces between the conductors.

Fixed support

A support of a conductor which does not permit the conductor to move angularly at the

supported point.

Simple support

A support which permits angular movement of the conductor.

Spacer E

! A mechanical element between conductors which, at the point of installation, prevents sub-

conductors be&g displaced towards each other.

Stiffening elemknt

A special spacer intended to prevent any movement between rigid sub-conductors at its

place.

I

IS 13235 : 1991

IECPab865(1986j

3.8 Rated short-time current

The r.m.s. current which the electrical equipment is able to withstand during the rated

short-time under specified conditions.

Notes 1. - It is possible to state several pairs of values of rated short-time current and short-time; for thermal effect

I s is used in most I EC specifications.

2. - The rated short-time current as well as the correspouding short-time are stated by the manufacturer of

the equipment.

3.9 Rated short-time current density and rated short-timefor conductors

The r.m.s. value of the current density which a conductor is able to withstand for the rated

short time.

Note. - The rated short-time current density is determined according to Clause 10.

3.10 Thermal equivalent short-circuit current

A constant r.m.s. value of current having the same thermal effect and the same duration as

the actual short-circuit current, which may comprise d.c. component and may subside in time.

Note. - If repeated short-circuits occur (i.e. rwated reclosures) YesuIting thermal equivalent short-circuit current

is evaluated (see Sub-clause 10.2).

3.11 Thermal equivalent short-circuit currentdensity

,,

The ratio of the thermal equivalent short-time current and the cross-section area of the

conductor.

3.12 Duration of short-circuit current

The time interval between the initiation of ti e short-circuit and the final breaking of the

current in all phases by the circuit-breakers or fuses.

NOW. - The time interval in which the current does not flow need qot be considered.

SECTION ONE - THE ELECTROMAGNETIC EFFECT ON RIGID CONDUCTORS

AND SLACK CONDUCTORS

4. General

With the calculation methods presented in this section, forces on insulators, stresses in rigid

conductors and tensile forces in slack conductors can be estimated.

5. Mechadcalforces due to short-circuit currents

5. I General

Currents in parallel conductors will induce electromagnetic forces between the conductors.

When the parallel conductors are long compared to the distance between them, the forces will

act evenly distributed along the conductors.

When the currents are in opposite directions the electromagnetic force is a repulsion which

tends to induce deformations that would increase inductance of the circuit.

The value of the force in a given direction can be calculated by considering the work done

in the case of a virtual displacement in the actual direction. As the work is done by the elec-

tromagnetic force, it must be equal to the change in the energy in the magnetic field caused by

this virtual displacement. This leads to the following equation for the force F, in direction x

(1)

where L is the self-inductance of the circuit and i the instantaneous value of the current. .

( mc page 11)

IS 13235 : 1991

IECPob845(1981)

For simple and idealized configurations, formulae for the calculation of inductance are

available. However, in most cases approximations are necessary to give practical calculation

methods.

The force between two conductors is proportional to the square of the current, or to the

product of the two currents. As the current is a function of time, the force will also be a

function of time. In the case of a short-circuit current without a d.c. component the force will

vary with twice the frequency of the current. A d.c. component in the short-circuit current will

give rise to an increase of the peak value of the force and to a component of force varying with

the same frequency as the current. The peak value of the force is of particular interest in the

case of mechanically rigid structures.

The force will result in bending stress on rigid conductors, tension stress and deflection in

flexible conductors and bending, compression or tension loads on the supports.

5.2 Calculation offorces

The calculation method in this section is based on the general equation (l), neglecting the

variations in distance during tkdshort-circuit. d

5,2.1 Forces between two parallel coh&uctors

The forces in newtons acting between two long. parallel conductors are given by the

formula:

F=0.2ilhA N

(2)

where I is the distance, in metres, between supports, il and i;! are the instantaneous values of

the currents in the conductors in kiloamperes, a is the centre-line distance between the

conductors in metres.

When the currents in the two conductors have the same direction, the forces are attractive.

When the direction of the currents is opposite, the forces are repulsive.

5.2.2 Calculation of peak force between the main conductors during a three-phase short-circuit

In a three-phase system with the conductors arranged at the same intervals on the same

plane, the maximum force acts on the central conductor during a three-phase short-circuit

and is:

F m3 - 0.2 i& -!- 0.87 N

(3)

as

where.63 in kiloamperes is the peak value of the a.c. component of the short-circuit current in

the case of a balanced three-phase short-circuit.

Nore. - Formula (3) can also be used for calculating the resulting peak force when the conductors arc in the comers

of an quilateral triangle and where 4 is the length of the side of the triangk.

52.3 Calculation of peak force between the main conductors during a two-phase short-circuit

The maximum force acting between the conductors carrying the short-circuit current

during a two-phase short-circuit is:

L

F

*2 1

m2 - 0.2 lP2 - N

as

where ip2.in kiloamperes is the peak short-circuit current in the case of a line-to-line short-

circuit.

.

(IEC page 13)

6

IS I3235 : 1991

TEClub865(1986),

5.2.4 Calculation ofpeak value offorces between rigid sub-conductors

The maximum force acts on the outer sub-conductors and is between two spacers:

when the short-circuit current is evenly distributed between the sub-conductors; n is the

number of sub-conductors, I, is the distance between spacers or stiffening elements, in metres,

and a, is the effective distance between sub-conductors, in metres.

52.5 Effective distance between conductors and sub-conductors

The forces between current-carrying conductors are dependent on the geometrical conligur-

ation and the profile of the conductors. For this reason a, has been introduced in Sub-

clauses 5.2.2, 5.2.3 and 5.2.4. However, if the dimensions of the cross-sections of the

conductors are smaller than the distance between the conductor centres, in Sub-clauses 5.2.2

and 5.2.3 a, may be replaced by a.

4

\

Some values for a, are given in Table I. For other Astances and conductor dimensions the

formula I 1.

c.

1

kt2 kt3 kt4 kt,

-P

-.+

a,

-+- + . . . + -

ai2 a13 aI4 ain

(6)

can be used

The values for k12, . . . . kin are to be taken from Figure 1, page 28.

Note. - The forces due to bends and the influence of a large amount of magnetic material close to the conductors

are usually of low importance. For the calculations, see existing publications.

6. Calculation of stresses in rigid conductors and forces on supports

6.1 General

The conductors may be supported in different manners, either fixed or simple or in 5:

combination of both, and may have two, three, four or several supports. Depending on the

kind of support and the number of supports, the stress in the conductors and the forces on the

supports will be different for the same short-circuit current. The formulas given also take the

elasticity of the supports into account.

The stresses in theconductors and the forces on supports also depend on the ratio between

the natural frequency of the mechanical system and the frequency of the electromagnetic

force. Especially in the case of resonance, or near to resonance, the stresses and forces in the

system may be amplified.

6.2 Calculation of stresses in iigid conductors

The assumption that the conductor,,is rigid means that the axial forces are disregarded.

Under this assumption the forces acting are bending forces and the general formula for the

bending stress in the supported main conductor is:

Frnl

urn= &rV,B -

N/mm2

,

8Z

(7)

where for F, either the value Fm3 (three-phase short-circuit) or Fm2 (line-to-line short-circuit)

is to be used.

, I

The bendingstress ida sub-conductor is:

*s a Gs V,

45

-

N/mm2

16z,

, (8)

IS 13235 : 1991

IECPnb865(1986)

e

where Zand Z, are section moduli, V,, V,, and Vr are factors taking into account the dyna-

mic phenomena and B is a correction factor depending on the type of supports, fixed or

simple, and the number of supports.

The factor pis to be taken from Table II and V,, V, and Vr from Figures 4 and 5, page 30.

The maximum possible values are V, - V,, - 1.

In the case of three-phase auto-reclosure, the factor Vr - 1.8 is to be applied, otherwise

If,- 1.

For further consideration see Sub-clause 6.4.

6.2.1 Permitted conductor stress

A single conductor is assumed to withstand the short-circuit forces when:

cm L 4 40.2

(9)

where R,o.J is the stress corresponding to the yield point.

The factor q is to be taken fr&r Table III. p

When a main conductor coysists of two or more sub-conductors the total stress in the

conductor is:

otot = urn + G (10)

Nore. - or,, is the algebraic sum of a,,, and crS independent of the loading atrections (see Figure 2, page 28). but the

location is to be considered.

The conductor is assumed to withstand the short-circuit forces when:

atot L 4 50.2

(11)

It is necessary to verify that the short-circuit does not affect the distance between sub-

conductors too much, otherwise a value

os L 40.2

(12)

is recommended.

In Table III the highest acceptable values for q for different cross-sections are given. For

q >1.0 small permanent deformations may occur (approximately 1% of the distance between

supports for q-values according to Table III) which do not jeopardize the safety of operation.

Note. - For the yield point of conductor materials, Q.2, the standards often state ranges with minimum and

maximum values. If only such limit values rather than actual readings are available, the minimum value

should be used in Sub-clause 6.2.1 and the maximum value in Sub-clause 6.3.

6.2.2 Section modulus of main conductors composed of sub-conductors with rectangular cross-

section

The bending stress and conseqnently the mechanical withstand of the conductor depend on

the section modulus.

If the stress occurs in accordance with Figure 2a), page 28, the section modulus 2 is equal to

the sum of the section moduli Z, of the sub-conductors (Z, with respect to the axis x-x).

If the stress occurs in accordance with Figure 2b)and in the case there is only one or no stiff-

ening element within a supported distance the section modulus 2 is equal to the sum of the

section modul! Z, of the sub-conductors (Z, with respect to the axis y-y).

When withiq a supported distance there are two or more stiffening elements, higher values

may be used. For main conductors composed of sub-conductors of rectangular cross-section

with a space between the bars equal to the bar thickness, 60% of the section modulus with

PI= Page 17 )

IS 13235 : 1991

IEC Pub 865 ( 1986

respect to the axis O-O may be used. For conductor groups having profile cross-section,

approximately 50% of the section modulus with respect to the axis O-O may be used. See

Table IV.

6.3 Calculation offorces on supports of rigid conductors

The dynamic force Fd is to be calculated from:

Fd = VF JraFrn

where for F, either the value Fm3 or F,.,Q is to be used.

The maximum possible values of I+ - V, can be estimated as follows:

v,* v,- 1 when o, + a, >0.8 Rpc.2

(13)

v,- VF-

O-8 Rp0.2

grn + 0s

when a,,, + o, d 0.8 R,,u.2

The value of VF. V, is not higher than 2.7 for a three-phase short-circuit, and 2.0 for a two-

phase short-circuit.

For further consideration.see Sub- &use 6.4. p

The factor a is dependent on the kind and the number of supports and is to be taken from

Table II. See Note 2 to Table II. Regarding permitted load on insulator, see Clause 8.

6.4 Calculation with special regard to conductor oscillation

The formulae in Sub-clauses 6.2 and 6.3 give bending stresses and forces on supports

achieved from a calculation of a load which is as- umed static. In Sub-clauses 6.2 and 6.3 three

factors, V,, VF and V, are introduced to take into account the natural frequency of the

conductor. Some figures are also given for V,, V, and V, which give the highest possible

stresses and forces.

6.4.1 Calculation_ojrelevant naturalfrequency

The relevant natural frequency of a single conductor can be calculated from:

(14)

The factor y is dependent on the kind and number of supports and is given in Table II.

For a main conductor composed of sub-conductors, J and m must apply to the main

conductor design. If the sub-conductors are of rectangular cross-section the relevant natural

frequency of the main conductor can also be calculated as:

where:

The factor c is to betaken from graph a) or b) of Figure 3, page 29. In the case of no stiff-

ening elements c = 1.

For the calculatid$ of sub-conductor stress, taking the relevant natural frequency into

account, the formula (14) is to be used. In this case replace Iby 4, m by mg and J by .I, and use

y = 0.356.

Note. - The second moments Jand J, are calculated according to Figures 2a)or 2b). page 28.

*

9

(IEC page 19)

J S 13235 : 1991

IEC Pub 865 ( 1986 )

6.4.2 Thefactors V,, V,, V,, and V,

The factors VF, V,, V,, and V, as functions of the ratio fC/ where f is the system frequency

in hertz, are a little different if a two-phase short-circuit is concerned and they are also

dependent on the mechanical damping of the conductor system. For practical calculations

these factors can be taken from Figure 4, page 30, for a multi-phase system. Excepted are

structures with small relevant natural frequencies of conductor fc/f <0.5, where K < 1.6; for

these structures VF = V, = V,, = 1 is to be applied.

For three-phase auto-reclosure the factor V, can be taken from Figure 5, page 30; in other

cases V, = 1.

7. Calculation of tensile forces in slack conductors (line conductors)

A short-circuit current in a slack conductor will cause a tensile force in the conductor which

NilI affect insulators, support structures and apparatus. It is necessary to distinguish between

the tensile force Ft during the &rt-circuit (de&ribed in Sub-clause 7.1) and the tensile force

F after the short-circuit, when .the conductor falls, back to its initial position (described in

Sub-clause 7.2). To determine t& dynamic stress of the supports, the higher value Ft or Ff is to

be used.

Note. - For span lengths exceeding 20 m the u;e of the following formulae is not recommended.

7.1 Tensile force Ft during the short-circuit

The force 4 is calculated with:

Ft = F,(l + W) N (17)

where F,, is the static tension in the conductor

9-3[d-55-1]

(18)

where g, M is the mass of the conductor per metre.

F;, is the force per metre in the outer phase conductor produced by the short-circuit current

and calculated according to

123

F&-O.15 - N/m

(1%

a

where Zk3 is the three-phase short-circuit current in kiloamperes (r.m.s.) and u, in metres, the

centre-line distance between conductors.

The factor vis a function of Cand cp and given in Figure 6, page 3 1.

(m I )2 400

Fit

1 100

-+-

lOS1 EA

(20)

I - distance betw&m supports,tin metres

9 - resulting spring constant of two conductor supports in newtons per millimetre

E - Youngs mpQulus in newtons per square millim+e

A - conductor s+are section in square millimetres

For insulators, damps, etc., of station components the value S - 100 N/mm may be used if

no more accurate value is known.

10

IS 13235 : 1991

IECPab865(1986)

7.2 Tensileforce Ff after the tiort-circuit ($a11 of span)

This force is only considered when:

F;,

> 0.6

g0

(21)

In this case is to be applied:

Ff = F&O 4-c if -!!- >2 (23)

g0

where Fst6c is the static tension in the conductor at a conductor-temperature of 60C.

Notes 1. - The resonance frequencies of these flexible conductors are low, and higher forces due to resonance are

not expected.

2. - Due to conductor motion the stres may be lower than,given by the formulae. The use of lower stress is

acceptable when it can be demons&t . ed etther by calct&rtion or by tests.

3. - In the case of twin-conductors whet&he single conductors touch each other effectively the tension force

Fr is higher than in formula (17).

8. Per@tted load on post insulators and terminals

The dynamic force Fd for rigid conductors and Ft and Ff for flexible conductors, shall not

be higher than the rated withstand value given by the support and insulator manufacturer. For

an insulator stressed by a bending force the rated withstand value is given for a force acting on

the insulator head. For a force acting at a point higher than the insulator head, a value lower

than the rated withstand value which gives a moment the insulator can withstand, is to be

used.

Connectors of rigid conductors shall be rated on the basis of Fd, while connectors for

flexible conductors &all be rated on the basis of force peaks of 1.5 Ft or 1 .O Ff.

Note. - The factor I.5 takes into account the effect of oscillations absorbed by the mass of the insulators.

SECTION TWO - THE THERMAL EFFECT ON BARE CONDUCTORS

9. General

This section gives calculation methods for the thermal effect on bare conductors. For cables

and insulated conductors reference is given to the appropriate I EC Technical Committee and

Sub-Committee*.

The heating of conductors due to short-circuit currents involves several phenomena of a

non-linear character and other factors that have to be either neglected or approximated in

order to make a mathematical approach possible.

For the purpose of this section the following assumptions have been made:

-

Proximity-effect (magnetic influence of nearby parallel conductors) has been disregarded.

--

l Technical Committee No. 20: Electric Cables. Sub-Committee 20A: High-voltage Cables.

.

11

(EC page 33)

IS 13235 : 1991

IECPob865( 1986)

- Resistance-temperature characteristic has been assumed linear.

- The specific heat of the conductor is considered constant,

- The heating is generally considered adiabatic.

10. Calculation of temperature rise

10.1 General

The loss of heat from a conductor during the short-circuit is very low, and the heating can

generally be considered adiabatic. The calculation in this section is based on adiabatic con-

ditions.

When repeated short-circuits occur with a short-time interval between them (i.e. rapid auto-

reclosure) the cooling down in the short dead-time is of relatively low importance, and the

heating can still be considered adiabatic. In cases where the dead-time interval is of longer

duration (i.e. delayed auto-reclosure) the heat loss may be taken into account.

The calculation does not taGinto account#he skin effect, i.e. the current is regarded as

evenly distributed over the conductor cross-sectionarea. This approximation is not valid for

large cross-sections, and there* for cross-sections above 600 mm2 the skin effect shall be

taken into account. For calculation, refer to the literature.

Note. - If the main conductor is composed of sub-conductors, uneven current distribution between the,sub-

conductors will influence the temperature rise of sub-conductors.

10.2 Calculation of thermal equivalent short-circuit current

The thermal equivalent short-circuit current is to be calculated using the short-circuit

current r.m.s. value and the factors m and n for the time-dependent heat effects of the d.c. and

a.c. components of the short-circuit current.

The thermal equivalent short-circuit current can be expressed by:

Ith = Ii,/-

(24)

where m and n are numerical factors, I[the r.m.s. value of the initial symmetrical short-circuit

current; in a three-phase system, the balanced three-phase short-circuit is decisive. The values

m and n are shown in Figure 7, page 32, as functions of the duration of the short-circuit

current. For a distribution network usually n = 1.

Nore. - The relation I[/ /k is dependent on the impedance between the short-circuit and the source.

When a number of short-circuits occur with a short time interval in between, the resulting

thermal equivalent short-circuit current is obtained from:

Ith==j/G (25)

where:

n

Tk- c Tki

(26)

I- I

10.3 Calculation oftemperature rise and rated short-time current densityfor conductors

The temperature rise in a conductor caused by a short-circuit is a function of the duration of

the short-circuit current, the thermal equivalent short-circuit current and the conductor

material.

By use of the graphs in Figure 8, page 33, it is possible to calculate the temperature rise of a

conductor when the short-time current density is known or vice versa.

.

Is 13235 : 1991

IEcPob86!5(I!X?6)

The highest recommended short-time temperature for different conductors is given in

Table V.

Note. - The maximumpermitted temperature of the support has to be taken into account.

10.4 Calculation of the thermal short-circuit strength for different durations of the short-circuit

current

Electrical equipment has suffkient thermal short-circuit strength as long as the following

relations hold for the thermal equivalent short-circuit current Zth:

or

Ith < Ithr

for Tk < &

CW

Ith < Ithr

for Tk > Tkr

Vb)

where Ztht is the rated short-time current and Tk, the rated short-time.

The thermal short-circuit strength fo&are conductogl is sufficient when the thermal equiv-

alent short-circuit current density Su, satisfies the follovkng relation:

1 i,

(28)

with Tkr - 1 sand for all Tk.

The rated short-time current density &hr is shown in Figure 8, page 33.

i

IS 13235 : 1991

IECPub&i5(1986)

0.8

0.6

1 2

4 6 8 10

add -

017m

FIG. 1. - Factor kl, for effective conductor central distance 4.

4

Direction

de la charge

-E

Loading

direction

. t

I

i

b)

Direction

de la charge

Loading

direction

FIG. 2. - Loading direction and bending axis with multiple conductor arrangements.

14

0 0.04 0.0%

0. 12

m, l (n m; I)-

&

IS 13235 : 1991

IECpPbt365(1986)

b)

0.0%

0. 12

m, l (n m; I )-

ow86

FIG. 3. - Factor c for the influenceof spacers or stiffening elements in formula (15).

a) direction of oscillation vertical to the surface, with k number of stiffening elements;,

b) vibration in any direction with k number of spacers or direction of vibration along

the surface with k number of stiffening elements;

c) arrangement of stiffening elements or spacers.

lb

IS 13235 : 1991

IECFab865(1986)

VF. VU. vi%

2.c

1s

C

t

,I

-

,

vu. VU!

/

c

L

L

se

i

1

fJ f-

OSlM6

FIG.~. -

Factors VF, V, and V,, to be used with the two-phase and three-phase short-circuits;

except arrangements with&< 0.5 in which K < 1.6.

FIG. 5. - iactor V, to be used with three-phase auto-reclosure.

(IEC page 30 y

16

IS 13235 : 1991

IECPub865(1986)

FIG.~. -

I O- ' 2 46810 2 4 6 810' 2 4 68102 2 4 68103

Factor w for tensile force in flexible conductors. The connection between the factors I,V, c

and cp is given by:

C=

(l+cpVG* VI

.P

2+(P+(Pw 1-v

( IEc pig= 31)

17

I S 13235 : 1991

IECPab865(1!M3fQ

6)

I

1 .o

0.8

n

0. 6

0. 4

0. 2

1.8

m

1. 4

0. 6

0,i 0. 2

.$

rk-

054/86

0. 01 0. 02 0. 05

0. 1 0. 2

0. 5

1

2 5 10 s

rk-------

OJ.r/86

FIG. 7. - a) Factor m, heat dissipation due to d.c. component.

b) Factor n, heat dissipation due to a.c. component.

(IEC page 32)

18

rs 13235: 1991

I;EcPub86!5(1986)

bi

S

thr

u-

I I

20 I

40

60

80

100 120 T

%-

056B4

FIG. 8. -

Relation betwee: rated short-time current density (Tkr = I s) and conductor tem-

perature.

a) Full lines: Copper

Dotted lines: Flat product of unalloyed steel and steel cables.

.

b) Numinium, ahminium alloy, aluminium conductor steel reintorced (ACSR).

IS 13235 : 1991

IECPub865(1986)

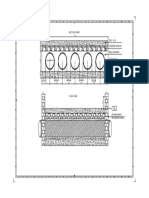

TABLE I

Effective conductor central distance a, in metres, for rectangular section dimensions

c

I

0.05 0.06 Rectangularsections

0.20

-

0.080

0.16

-

0.067

0.12 0.10 0.08

b

Ill

-J A

0.005 0.020 0.024 0.027 0.033 0.040

0.010 0.028 0.031 0.034 0.041 0.047

0.015 0.018 0.022

0.020 0.023 0.027

#'

- -

0.016 0.018

-

0.020

0.013

0.019

-

0.015

-

0.054

-

0.030

0.005

0.010

-

0.037

-

0.043

-

0.031

Q.017

.cs+

I h

-

0.014

d

fh 1

-JLd

0.005

0.010

-

0.022

-

0.026

( IEC page 35)

20

IS 13235 : 1991

IECPub865(19m)

TABLE II

Thefactors a. j? andy for different support arrangements

Type of beam and supports

Factor Factor Factor

.a

B Y

Single span beam

Continuous beams with

equidistant simple

supports

AandB

simple supports

f

A: 0.5

B: 0.5

1.0 0.157

A B

A: fixed support

B: simple support

0.73 0.245

AandB:

fixed supports

Two spans

0.73 0.245

Three or

more spans

0.73 0.356

Nom I. - Non-uniform span in continuous beams may be treated, with a sufftcient degree of accuracy, as though the

maximum span applied throughout. This means that:

-

the end supports are not subjected to greater stress than the inner ones;

- spans should not differ in length from adjacent ones by more than 20%. If that does not prove to be possible,

the conductors can be decoupled using flexible joints;

2. - The @alues are so calculated that a permissible plastic deformation occurs. They are so chosen that the same

q-value (see Sub-clause 6.2. I and Table 111) can be used for all conductor-support arrangements.

21

(II= PW 37)

4

2.00

1.70

d (;- - 0.05).

1.34

( m 0.075). 1.37

i

- O.loO), 1.40

- 0.12s). I.44

I

- 0.160). 1.48

- 0.200). 1.5 I

E

-L

1.83

1 d.+ I.50

I

fl&Z..

I.19

El

-L

A,

t

I.13

L

t 1

lsl3235:1B1

IEClob&S(l986)~

TABLE III

Acceptable q-values for diflerent cross-sections

i

Is 13235 : 1991

IECPnb&i5(1986)

TABLE IV

Section moduli Z in cubic centimetres of main conductors with two and more

stiffening element:

mxm

0.05x0.01 0.06x0.01 0.08x0.01 0.10x0.01 0.12x0.01

I

9.9 11.9 15.8 19.8 23.8

Fm{ &, 6.9 8.7 A.4 13.9 d t7.3 20.8

I 1..

31.7 39.6

__

TABLE V

Recommended highest conductor temperatures in the case of short circuit

Type of conductors

I

Max. recommended conductor temperature in case of

short-circuit

I

Mechanical loaded bare conductors, solid or

stranded, Al or Cu

Aluminium alloy

Loaded steel

Unloaded steel

Cables and conductors, paper and plastics insulated

2WC

l7OC

250C

3OOYz

l

* Recommended temperatures are dealt with by 1 EC Technical Committee NO. 20: Electric Cables, and Sub-Com-

mittee 20A: High-voltage Cables.

IS 13235 : 1991

IECPub865(1986)

APPENDIX

EXAMPLES OF CALCULATION OF THE EFFECTS OF SHORT-CIRCUIT CURRENTS

Example 1. Mechanical effects on single rigid conductors

Basis for the calculations in this example is a three-phase system with one bus-bar per phase. The

bus-bars are mounted on edge. The cross-section is 60 x 10 mm2 and the material is an Al-Mg-Si-

alloy.

The following data are given:

1 - l.Om E - 70 Ooo N/mm2

a - 0.2 m J = 0.5 cm4

$3

- 30kA z - l.Ocm3

m - 1.62 kg/m & RPo.2 - 12t$N/mmz up to 180 N/mm2

Number of spans: 3

* g.

.

The natural frequency of the bus-bars is:

fc

The ratio 7

is 1.05. This gives the following values to the factors VF; V, and Vr:

-6 $0.2 .

VF -1.8 if&vr<--

%I

(with the upper value of Q.2)

v, - 1.0

v,

- 1.0

Maximum force on the central bus-bar is:

& 0.2 0.87

2 1 1.0

- l l iP3 l - - 0.2 l 0.87 9 302 l

a o2 .

- 783 N

Maximum bending stress is:

- 71.5 N/mm2

Maximum bending force on the supports is:

&- VF &a&, = 1.8 . 1.0. 1.1 . 783 - 155ON

The bus-bars are assumed to withstand the short-circuit force if:

ad < q b.2 (with the lower value of Q.i,

For!a rectangular cross-section q - 1.5. This gives:

. 6

a, < 1.5 l 120 - 180 N/mm2

Conclusions:

;

The bus-bars will withstand the short-circuit force.

The supports have to withstand a dynamic bending force of 1550 N.

( m pais 43)

24

Is13235:1!m

lECPkb86!J (l986)

Example 2. Mechanical efkts on multiple rigid conductors

Basis for the calculations m this example is the same three-phase system as in example 1, with

three bus-bars per phase. Between two supports t@ere &re two spacers, The spacers are

0.06 m X 0.06 m. The cross-sections of the irAvidual bus-bars are & X 10 mm& The distance

betwken the indivtdual bus-bars is 10 mm. The other data are the same as in example 1.

The natural frequency of the main bus-bar is:

fc - cfo -41% -52.3 - 506 Hz

When c is taken from Figure 3b), page 29, wkh k - 2 as a functibn of the ratio:

m,

1.6 l 0.06. 2 _ oo4

- - 301.6. 1.0 nmil *

This gives c - 0.96.

The natural frequency of the individual bus-bars is:

fc A

The ratio - and T

f

gives the following values to the factors VF, V,. V, and V,:

v, - 1.8if yF* &< 0.8 (with the upper value of I+) 2)

aiot

.

v,

- 1.0

Km

- 1.0

v,

- 1.0

Maximum bending stress in the main bus-bar corresponding to one phase is:

am- V,

4Dl

V,B- * l

82

1.0 1.0 9 0.73

783 . 1.0

l -

8 . 3.0

23.8 N/mm2

When Zis found from Figure Zb), page 28.

z-3cm3

Maximum force between individual bus-blirs is:

-().2.1@0.5

-500N

0.02

Maximum bending stress* theindividual bus-bars is:

i

FIlr

- - 1.0. 1.0

4 ,v, 16z,

;; pa - 15.6N/mm2

l .

25

Is 13236 : 1991

lECPub86S(lp86)

Total bending stress in the bus-bar material is:

atot - q,, + us - 23.8 N/mm2 + 15.6 N/mm2 - 39.4 N/mm2

Maximum bending force on the supports is:

Fd- VF Y,o& - 1.8. 1.0. 1.1 l 783 - 1550N

The bus-bar is assumed to withstand the short-circuit force if:

qot - 39.4 N/mm2 < 1.5 - 120 N/mm2

a, - 15.6 N/mm2 < 120 N/mm2

>

(with the lower value of Rpo.2)

Conclusions:

The bus-bar will withstand the short-circuit force.

The supports have to withstand a bending force of 1550 N.

Example 3. Mechanical effects on slack conductors

Basis for the calculations in this example is a three-phase flexible bus-bar connection with one

all-aluminium stranded conduct r of A

&

- 240 mp2 per phase. The span length is I - 11.5 m. The

anchor points at each end of the span are pos&ulators on steel substructures with a resultant

spring constant of S - 100 N/m&Therefore the static tensions of the conductors Fst - 400 N may

be considered nearly invariable within a temperature range of -20C to 60C.

The following data are given additionally and necessarily:

Ikj- 15kA E = 60 000 N/mm* gn - 9.81 m/s2

a - 1.25m m =0.67 kg/m

The force Fr, is:

F&-O.15 s3= 0.15 g -27N/m

a .

The factor 9 is:

.-3[j/w -I]-3[j,/m-1] -9.68

The factor Cis:

c-

(mI)Z 400 (0.67.11.5)* 400

- I

- 3.95

F: 1 100 4003 1 100

10s 1+EA

+

10*100*11.5 60000*240

For c - 3.95 and (p - 9.68 Figure.6, page 3 1, shows y/ - 0.59.

The tension in the conductor during the short-circuit is given by:

h-&(1 +Q,@-400(1 +9.68.0.59)-2684N

Because:

, 6

27

--

-4.11 >2

gnm

9.8 100.67

a tensile force F;$ter the short-circuit can occur which is given by:

Ff-Fst m -400 &+8-3.95 -2284N

Is 13236: 1991

IltCRib865(~~

Conclusions:

The supports (post insulators and steel substructure) have to withstand a dynamic bending force

of 2 684 N, given by the conductor tension during the short circuit.

The clamping device for the conductor anchoring shall be rated on a basis of force peaks of

1.5.2684-4026N.

Example 4. Thermal effects on bare conductors

Basis for the calculation is the same three-phase system as in example 1.

Following data are given:.

I g - 17kA

zk

- 17kA ip3 - 30kA

K * 1.25

=k

- 2.0s

Whent&-65Tand0, - 17OT, s;h, is found from Figure 86), page 33.

Stht - 80 A/mm*

This gives:

$7

?2

I:h~gSthtA80A/mlp*060mm. lOmm,-48kA

I

m and n are found from Figures 7~) and 76), page 32. The bus-bars have sufitient thermal strength

when:

Conclusion:

The bus-bars have sufftcient thermal strength.

i

27

Bureau of Indian Standards

BIS is a statutory institution established under the Bureau oflndian Standards Act, 1986 to promote harmonious

development of the activities of standardization, marking and quality certification of goods and attending to

connected matters in the country.

Copyright

BIS has the copyright of all its publications. No part of these publications may be reproduced in any form without

the prior permission in writing of BIS. This does not preclude the free use, in the course of implementing the

standard, of necessary details, such as symbols and sizes, type or grade designations. Enquiries relating to

copyright be addressed to the Director (Publications), BIS.

Review of Indian Standards

Amendments are issued to standards as the need arises on the basis of comments. Standards are also reviewed

periodically; a standard along with amendments is reaffirmed when such review indicates that no changes are

needed; if the review indicates that changes are needed, it is taken up for revision. Users of Indian Standards

should ascertain that they are in possession of the latest amendments or edition by referring to the latest issue

of CIS Handbook and Standards : Monthly Additions.

This Indian Standard has been developed f% Dot : No. ET$: 20 ( 2824 )

Amendments Issued Since Publication

Amend No. Date of Issue Text Affected

Headquarters:

BUREAU OF INDIAN STANDARDS

Manak Bhavan, 9 Bahadur Shah Zafar Marg, New Delhi 110002

Telephones : 323 01 31, 323 94 02, 323 33 75

Telegrams: Manaksanstha

( Common to

all offices )

Regional Offices: Telephone

Central : Manak Bhavan, 9 Bahadur Shah Zafar Marg 323 76 17

NEW !ELHI 110002 323 3841

Eastern : l/14 C. I. T. Scheme VII M, V. I. P. Road, Maniktola

CALCUTTA 700054

Northern : SC0 335-336, Sector 34-A, CHANDIGARH 160022

Southern : C. I. T. Campus! IV Cross Road, CHENNAI 600113

337 84 99, 337 85 61

337 86 26,337 86 62

1 60 38 43

60 20 25

2350216,2350442

235 15 19,235 23 15

Western : Manakalaya, E9!MIDC, Marol, Andheri (East)

MUMBAI 4OOOq3

8329295,8327858

8327891,8327892

Branches : AHMADABAD. BANGALORE. BHOPAL. BHUBANESHWAR.

COIMBATORE. FARIDABAD. GHAZIABAD. GUWAHATI. HYDERABAD. JAIPUR.

KANPUR. LUCKNOW. NAGPUR. PATNA. PUNE. THIRUVANANTHAPURAM.

Printed at New India Printing Press, Khuqs, India

También podría gustarte

- Engineering Method For Calculation of Short-CircuitDocumento7 páginasEngineering Method For Calculation of Short-CircuitnicklionsAún no hay calificaciones

- Title: Document/Drawing Approval/Comment Transmittal: Kind AttnDocumento2 páginasTitle: Document/Drawing Approval/Comment Transmittal: Kind AttnPritom AhmedAún no hay calificaciones

- Design of Electrical Systems for Large ProjectsDocumento19 páginasDesign of Electrical Systems for Large ProjectsKolimarla Keerthana JaikumarAún no hay calificaciones

- 220kV EHV Cable TrenchesDocumento1 página220kV EHV Cable TrenchesSiva Manasulo Sailu100% (1)

- NTDC Requirement For 132kV & 220kV GridsDocumento8 páginasNTDC Requirement For 132kV & 220kV GridsmuzammiliqbalAún no hay calificaciones

- CIVIL Drawings: 220/66kV ITI S/s Drawings Required Very Urgent Submissi On Date Engg Remarks Action byDocumento6 páginasCIVIL Drawings: 220/66kV ITI S/s Drawings Required Very Urgent Submissi On Date Engg Remarks Action byUmamaheshwarrao VarmaAún no hay calificaciones

- Surge Arrestor SelectionDocumento24 páginasSurge Arrestor SelectionAdetunji TaiwoAún no hay calificaciones

- GTP DrakeDocumento2 páginasGTP DrakeBalasubramanya BarkurAún no hay calificaciones

- 220 66kv Ss LayoutDocumento1 página220 66kv Ss LayoutNitin KumarAún no hay calificaciones

- JD-132-QA-E41-01 - TUBE SIZING 50 DGRDocumento14 páginasJD-132-QA-E41-01 - TUBE SIZING 50 DGRRami The OneAún no hay calificaciones

- Ard Sheet 1 Sem 6Documento1 páginaArd Sheet 1 Sem 6Sandip SharmaAún no hay calificaciones

- Technical Specification-ABT MeterDocumento17 páginasTechnical Specification-ABT MeterAnkit Airun100% (2)

- Cable Sheeth EarthingDocumento15 páginasCable Sheeth EarthingVaibhav Gholase100% (1)

- ILJIN Electric Power Cable Systems GuideDocumento34 páginasILJIN Electric Power Cable Systems GuidesajuaanalsaAún no hay calificaciones

- Info Iec60038 (Ed6.2) en DDocumento4 páginasInfo Iec60038 (Ed6.2) en DArief Muhammad LubisAún no hay calificaciones

- TAG BrochureDocumento12 páginasTAG BrochureRamphani NunnaAún no hay calificaciones

- SIP5 APN 037 - Selection of SIPROTEC5 Device With PMU Functionality PDFDocumento18 páginasSIP5 APN 037 - Selection of SIPROTEC5 Device With PMU Functionality PDFChintanPandyaAún no hay calificaciones

- Clearance IEC 61936Documento9 páginasClearance IEC 61936sparkCEAún no hay calificaciones

- ALCOA Bus Cond (6 AL Tube)Documento28 páginasALCOA Bus Cond (6 AL Tube)Sanj PandeyAún no hay calificaciones

- Is 3842 2 1966 PDFDocumento21 páginasIs 3842 2 1966 PDFSuraj GangwarAún no hay calificaciones

- Line Differential Protection and Control Red615 Ansi: Application ManualDocumento120 páginasLine Differential Protection and Control Red615 Ansi: Application ManualMir MuhammadAún no hay calificaciones

- Calculations-Slack Conductors - TemplateDocumento4 páginasCalculations-Slack Conductors - TemplateRomanistaPerSempreAún no hay calificaciones

- App12 KTH Master Thesis Comparison of A Three Phase Single Stage PV System in PSCAD - and PowerFactory PDFDocumento101 páginasApp12 KTH Master Thesis Comparison of A Three Phase Single Stage PV System in PSCAD - and PowerFactory PDFM. AliAún no hay calificaciones

- Erection of 230 KV Transmission LineDocumento310 páginasErection of 230 KV Transmission Lineleelapr84Aún no hay calificaciones

- Cable Design for Trapezoidally Shaped ConductorDocumento1 páginaCable Design for Trapezoidally Shaped ConductorkjkljkljlkjljlkAún no hay calificaciones

- Insulation Level and Clearances For 230 KV Air Insulated SubstationDocumento6 páginasInsulation Level and Clearances For 230 KV Air Insulated SubstationAlexandre Pereira100% (1)

- WBN028 - B1.47 - Mar21Documento63 páginasWBN028 - B1.47 - Mar21E PenaAún no hay calificaciones

- Data Sheet, Gad, Sizing Calculation, Terminal Arrangement, Support Details of Bus Duct For New IntakeDocumento2 páginasData Sheet, Gad, Sizing Calculation, Terminal Arrangement, Support Details of Bus Duct For New IntakeBasabRajAún no hay calificaciones

- EasergyMiCOM BR NRJED116740EN 102018 PDFDocumento24 páginasEasergyMiCOM BR NRJED116740EN 102018 PDFPushpendra Kumar SinghAún no hay calificaciones

- 765kV Greater Noida-Mainpuri Line - Rev 0Documento24 páginas765kV Greater Noida-Mainpuri Line - Rev 0Abhisek SurAún no hay calificaciones

- Suspension Cable Tension Vs Tower Height SpreadsheetDocumento10 páginasSuspension Cable Tension Vs Tower Height Spreadsheettanujaayer100% (1)

- Cavan-Tyrone and Meath-Cavan 400kv Transmission CircuitsDocumento224 páginasCavan-Tyrone and Meath-Cavan 400kv Transmission CircuitsroyclhorAún no hay calificaciones

- KC Agarwal HitsDocumento18 páginasKC Agarwal HitskittyAún no hay calificaciones

- 11kV SPBD General ArrangementDocumento12 páginas11kV SPBD General ArrangementNihar SenapatiAún no hay calificaciones

- Calculating transformer loss cost ratesDocumento3 páginasCalculating transformer loss cost ratesRatana KemAún no hay calificaciones

- PVsyst Training Part IDocumento96 páginasPVsyst Training Part IBarun BiswasAún no hay calificaciones

- Siemens H-Pos Technical DatasheetDocumento2 páginasSiemens H-Pos Technical DatasheetSri RamAún no hay calificaciones

- Arrester - Characteristics - For - ATPDraw - Users (Ajuste Cebado) 5kaDocumento11 páginasArrester - Characteristics - For - ATPDraw - Users (Ajuste Cebado) 5kagilbertomjcAún no hay calificaciones

- SWCC-Water Cooled CableDocumento8 páginasSWCC-Water Cooled CableElafanAún no hay calificaciones

- 110kV 1250A isolator technical parametersDocumento19 páginas110kV 1250A isolator technical parametersneerajAún no hay calificaciones

- Is 9921 5 1985 PDFDocumento13 páginasIs 9921 5 1985 PDFsridharAún no hay calificaciones

- Diagram Satu Garis Gitet 275Kv Pangkalan Susu: ACSR.2x435 ACSR.2x435 MMDocumento1 páginaDiagram Satu Garis Gitet 275Kv Pangkalan Susu: ACSR.2x435 ACSR.2x435 MMULTG BinjaiAún no hay calificaciones

- Vol-2B Tech Spec.220kV XLPE Cable MedhaDocumento43 páginasVol-2B Tech Spec.220kV XLPE Cable MedhaamolAún no hay calificaciones

- Control & Relay Panel SectionDocumento80 páginasControl & Relay Panel SectionPremBhushanAún no hay calificaciones

- CT Calculation P142 For Stabilizing ResistorsDocumento12 páginasCT Calculation P142 For Stabilizing ResistorsJay WinAún no hay calificaciones

- 303 Revision of Qualification Procedures For HV and EHV AC Extruded Underground Cable SystemsDocumento92 páginas303 Revision of Qualification Procedures For HV and EHV AC Extruded Underground Cable SystemsepriAún no hay calificaciones

- 380KV Gis Expansion of Al Dhahiyah BSP - CT & PT Sizing CalculationDocumento24 páginas380KV Gis Expansion of Al Dhahiyah BSP - CT & PT Sizing CalculationJay WinAún no hay calificaciones

- 24 - 400 - 220 - KV - SS HW PDFDocumento28 páginas24 - 400 - 220 - KV - SS HW PDFgaurang1111Aún no hay calificaciones

- Differential Protection For Power TF With RET670Documento14 páginasDifferential Protection For Power TF With RET670muhammad awais100% (1)

- Restricted Earth Fault Protection-Lv (Mcag14) : Stabilising Voltage CalculationDocumento3 páginasRestricted Earth Fault Protection-Lv (Mcag14) : Stabilising Voltage CalculationarsathnmaAún no hay calificaciones

- 400kv 404 Line Bay Cable SchduleDocumento31 páginas400kv 404 Line Bay Cable SchdulemanishAún no hay calificaciones

- Calculation of Positive Sequence ImpedanceDocumento14 páginasCalculation of Positive Sequence ImpedancesathiyaseelanAún no hay calificaciones

- KSH International Enamelled Copper Conductors/Strips BrochureDocumento2 páginasKSH International Enamelled Copper Conductors/Strips Brochurekshintl100% (1)

- D04 BuscouplerDocumento65 páginasD04 BuscouplerபாரதிAún no hay calificaciones

- Busbar Design PARWDocumento14 páginasBusbar Design PARWJuju R ShakyaAún no hay calificaciones

- A New Approach To Determine Base Intermediate and Peak-Demand in An Electric Power SystemDocumento5 páginasA New Approach To Determine Base Intermediate and Peak-Demand in An Electric Power SystemPramod B.Wankhade100% (1)

- Draw No - MEG-2113-KYE-CS-301 - 275kV Single Line DiagramDocumento1 páginaDraw No - MEG-2113-KYE-CS-301 - 275kV Single Line DiagramMohamad HishamAún no hay calificaciones

- 51 Sdms 01rev022 For Distribution TransformerDocumento20 páginas51 Sdms 01rev022 For Distribution Transformernadeem UddinAún no hay calificaciones

- Power-system protection A Complete GuideDe EverandPower-system protection A Complete GuideCalificación: 1 de 5 estrellas1/5 (1)

- The Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsDe EverandThe Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsAún no hay calificaciones

- What Is The Difference Between 0.2 and 0.2S Class CT - QuoraDocumento3 páginasWhat Is The Difference Between 0.2 and 0.2S Class CT - QuoraAnil MarturiAún no hay calificaciones

- What Is A High Speed Earth Switch, and How Does It Work - Quora PDFDocumento2 páginasWhat Is A High Speed Earth Switch, and How Does It Work - Quora PDFAnil MarturiAún no hay calificaciones

- Road Culvert DrawingDocumento1 páginaRoad Culvert DrawingAnil MarturiAún no hay calificaciones

- 6 - Section DGset R4Documento12 páginas6 - Section DGset R4Anil MarturiAún no hay calificaciones

- Impact of VT Burden Rating on AccuracyDocumento2 páginasImpact of VT Burden Rating on AccuracyRuben Dario ToroAún no hay calificaciones

- Gmail - Your Sunday Ride To PorurDocumento2 páginasGmail - Your Sunday Ride To PorurAnil MarturiAún no hay calificaciones

- Sales Brochure Mod LIC-s JA6-080218Documento2 páginasSales Brochure Mod LIC-s JA6-080218Anil MarturiAún no hay calificaciones

- What Is A High Speed Earth Switch, and How Does It Work - Quora PDFDocumento2 páginasWhat Is A High Speed Earth Switch, and How Does It Work - Quora PDFAnil MarturiAún no hay calificaciones

- SF6 Properties and Use in MV and HV SwitchgearDocumento26 páginasSF6 Properties and Use in MV and HV SwitchgearPradeep_Vashist100% (1)

- Lics Jeevan Akshay Vi Uin 512n234v06Documento5 páginasLics Jeevan Akshay Vi Uin 512n234v06Rahul KolateAún no hay calificaciones

- Abirami AnthathiDocumento24 páginasAbirami Anthathijekay2ab92% (12)

- AathichudiDocumento16 páginasAathichudiமுரளி கிருஷ்ணன் alias முகி100% (9)

- SL No Description As Per Annexure: 12 Offered by Us Remarks Qty Units Qty UnitsDocumento5 páginasSL No Description As Per Annexure: 12 Offered by Us Remarks Qty Units Qty UnitsAnil MarturiAún no hay calificaciones

- Bahubali 2Documento1 páginaBahubali 2Anil MarturiAún no hay calificaciones

- AP TRANSCO site level formation cutting and filling reportDocumento1 páginaAP TRANSCO site level formation cutting and filling reportAnil MarturiAún no hay calificaciones

- Level Sheet For Road 2 Level B H L Actual Level Average Level Filling QTYDocumento21 páginasLevel Sheet For Road 2 Level B H L Actual Level Average Level Filling QTYAnil MarturiAún no hay calificaciones

- Lightning Arresters Sl. No. Description Lightning Arresters: Peak Peak PeakDocumento3 páginasLightning Arresters Sl. No. Description Lightning Arresters: Peak Peak PeakAnil MarturiAún no hay calificaciones

- Gajwel Retrofit Scope InputDocumento14 páginasGajwel Retrofit Scope InputAnil MarturiAún no hay calificaciones

- CTS - 110kV Metering BayDocumento1 páginaCTS - 110kV Metering BayAnil MarturiAún no hay calificaciones

- 125mvar, 400Kv Bus Reactor Bay Extn. at 400/220/132Kv Gajwel Substation, Medak Dist, Telangana StateDocumento1 página125mvar, 400Kv Bus Reactor Bay Extn. at 400/220/132Kv Gajwel Substation, Medak Dist, Telangana StateAnil MarturiAún no hay calificaciones

- Principal: Vasavi College of Engineering (Autonomous)Documento1 páginaPrincipal: Vasavi College of Engineering (Autonomous)Anil MarturiAún no hay calificaciones

- 0.2S Class SpecificationDocumento15 páginas0.2S Class SpecificationAnil MarturiAún no hay calificaciones

- Recharge Invoice 766982908Documento1 páginaRecharge Invoice 766982908Anil MarturiAún no hay calificaciones

- EPC Division Stationary Inventory ListDocumento1 páginaEPC Division Stationary Inventory ListAnil MarturiAún no hay calificaciones

- Recharge Invoice 766982908Documento1 páginaRecharge Invoice 766982908Anil MarturiAún no hay calificaciones

- 12-II.2. Tower SpottingDocumento16 páginas12-II.2. Tower Spottingashok10577Aún no hay calificaciones

- Sizing Battery Banks For Switchgear and Control Applications by HandDocumento4 páginasSizing Battery Banks For Switchgear and Control Applications by HandAnil MarturiAún no hay calificaciones

- 09 Manual ReluxSuiteDocumento105 páginas09 Manual ReluxSuiteAxel Ramses Valencia JacquesAún no hay calificaciones

- SBI Clerk Vacancies 2015 16Documento2 páginasSBI Clerk Vacancies 2015 16Naga RajAún no hay calificaciones

- Walk-In For Electrical Engineers - Leads at Cyient, Hyderabad On 10jan16 - Hyderabad - Secunderabad - Cyient Limited - 5-To-10 Years of ExperienceDocumento4 páginasWalk-In For Electrical Engineers - Leads at Cyient, Hyderabad On 10jan16 - Hyderabad - Secunderabad - Cyient Limited - 5-To-10 Years of ExperienceAnil MarturiAún no hay calificaciones

- Magnetostatics and Magnetic Fields ExplainedDocumento5 páginasMagnetostatics and Magnetic Fields ExplainedAwais YousafAún no hay calificaciones

- EM InductionDocumento20 páginasEM InductionSakib Ex-rccAún no hay calificaciones

- June 2020 QP IAL Mechanics 2Documento32 páginasJune 2020 QP IAL Mechanics 2Daniel KimAún no hay calificaciones

- Finite Element Analysis of Fluid and Solid Mechanics Problems Using AnsysDocumento59 páginasFinite Element Analysis of Fluid and Solid Mechanics Problems Using AnsysRebeca CruzAún no hay calificaciones

- ENGR1003 Finals Week 1Documento40 páginasENGR1003 Finals Week 1celinewinchester7Aún no hay calificaciones

- Nonlinear Dynamics of A Duffing-Like Negative StifDocumento13 páginasNonlinear Dynamics of A Duffing-Like Negative StifPietro TestaAún no hay calificaciones

- 4PH1 2P Que 20190615 PDFDocumento20 páginas4PH1 2P Que 20190615 PDFMd. Kutub UddinAún no hay calificaciones

- Data - Sheet - 3D - 50-200 - 15Documento6 páginasData - Sheet - 3D - 50-200 - 15SajidAún no hay calificaciones

- HeatTransferModuleUsersGuide PDFDocumento580 páginasHeatTransferModuleUsersGuide PDFjmiscAún no hay calificaciones

- Topic 1 (Introduction and Friction) Part 1Documento21 páginasTopic 1 (Introduction and Friction) Part 1Brix DavidAún no hay calificaciones

- GovernorStability, Pressure Rise& Speed RiseDocumento5 páginasGovernorStability, Pressure Rise& Speed Risejhaamit4Aún no hay calificaciones

- Chapter Ii - Fluid StaticsDocumento72 páginasChapter Ii - Fluid StaticszetseatberhanuAún no hay calificaciones

- Ijcrr: A Study On Magnetorheological Fluid (MRF) DamperDocumento8 páginasIjcrr: A Study On Magnetorheological Fluid (MRF) Damperaakrit paiAún no hay calificaciones

- University of Ghana: InstructionsDocumento15 páginasUniversity of Ghana: InstructionsAlexander AsonkeyAún no hay calificaciones

- Unit 16 Plastic AnalysisDocumento34 páginasUnit 16 Plastic AnalysisTam AlasadiAún no hay calificaciones

- Ujian 1 BNJ 20103 Dinamik SEMESTER 1 SESSI 2017/2018: Answer All QuestionsDocumento3 páginasUjian 1 BNJ 20103 Dinamik SEMESTER 1 SESSI 2017/2018: Answer All QuestionsJimmy KudiAún no hay calificaciones

- Formulacion de Capacidad PortanteDocumento11 páginasFormulacion de Capacidad PortanteJhon KenyiAún no hay calificaciones

- Effects of Variable-Volume Helmholtz Resonator On Air Mass Flow Rate of Intake Manifold - SpringerLinkDocumento7 páginasEffects of Variable-Volume Helmholtz Resonator On Air Mass Flow Rate of Intake Manifold - SpringerLinksunziv19Aún no hay calificaciones

- How Rebar Distribution Affects Concrete Beam Flexural StrengthDocumento10 páginasHow Rebar Distribution Affects Concrete Beam Flexural Strengthtoma97Aún no hay calificaciones

- BEAM SampleDocumento70 páginasBEAM SampleAira Joyce Salazar100% (1)

- Introduction To Heat TransferDocumento15 páginasIntroduction To Heat TransferRishabh KumarAún no hay calificaciones

- IACMAG-008 - Full - Paper - Comparative Study of Consititutive Models For Lateritic Soils in GoaDocumento13 páginasIACMAG-008 - Full - Paper - Comparative Study of Consititutive Models For Lateritic Soils in GoaSmita HaldankarAún no hay calificaciones

- Experimental Thermal and Fluid Science: A.L. Neckel, M. GodinhoDocumento10 páginasExperimental Thermal and Fluid Science: A.L. Neckel, M. GodinhoPett PeeveAún no hay calificaciones

- BS EN 1992-1-1:2004 Slenderness criteria for isolated compression membersDocumento2 páginasBS EN 1992-1-1:2004 Slenderness criteria for isolated compression membersLại Tiến PhongAún no hay calificaciones

- Irc Gov in SP 064 2005 PDFDocumento20 páginasIrc Gov in SP 064 2005 PDFSiva Prasad Mamillapalli100% (1)

- Lesson 5: Elastic and Inelastic Collisions: MicroscopicDocumento3 páginasLesson 5: Elastic and Inelastic Collisions: Microscopicjayson bullenaAún no hay calificaciones

- Shell and TubeDocumento66 páginasShell and TubeEdgar Enrique Diaz Marquina0% (1)

- Effect of Tapered Thickness On The Logitudinal Free Vibrations of Cantilever BeamDocumento14 páginasEffect of Tapered Thickness On The Logitudinal Free Vibrations of Cantilever BeamAbanoub MakkarAún no hay calificaciones

- Solution To Problem 110 Normal Stress - Strength of Materials ReviewDocumento5 páginasSolution To Problem 110 Normal Stress - Strength of Materials ReviewNagaraj Muniyandi100% (1)

- Composite Bonded Joints AnalysisDocumento64 páginasComposite Bonded Joints Analysisjunjie yi100% (1)