Documentos de Académico

Documentos de Profesional

Documentos de Cultura

The V Max Nomograph p4

Cargado por

shashimohanganjooTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

The V Max Nomograph p4

Cargado por

shashimohanganjooCopyright:

Formatos disponibles

The V

max

Nomograph

A Quick Reference Tool to Estimate Filter Sizing

The V

max

technique has been widely used to successfully describe

many of the filtration processes in the biopharmaceutical industry.

This document provides a quick reference chart to estimate filter

sizing requirements given knowledge of typical performance

parameters for an application.

Contributions to filter sizing arise from both filter capacity

limitations (V

max

) and flow-time (J

i

, t

B

) considerations. Scale down

filtration studies using data on Volume vs. time, lead to the calcu-

lation of the sizing parameters V

max

and J

i

. These parameters,

along with the design requirements (V

B

and t

B

), allow us to

estimate filter sizing for a given application.

V

max

Equation 1

Frequently, we need to ball-park the area

requirements for a typical process step, or assess

the impact of process (V

max

, J

i

) or design (V

B

, t

B

)

parameters on filter sizing. The nomograph in

Figure 1 is a handy reference chart, with an ability

to rapidly estimate filter area requirements for

various capacity, flow, time combinations.

A

min

1 1

V

B

V

max

J

i

x t

B

Capacity Flow-time

= + (1)

Key to Equations

A filtration area (mm

2

)

V process volume (L)

V

max

maximum capacity (normalized) that can

be filtered at time infinity (L/m

2

)

J

i

initial volumetric (normalized) flow rate

(L/m

2

min.)

t

B

process time (min.)

A P P L I C A T I O N N O T E

The nomograph represents a family of constant

A

min

/V

B

curves, which cover the range typically

encountered in filtration applications. The X Y

axes for the nomograph are V

max

and J

i

t

B

respectively.

Application experience allow for a better

estimation of sizing parameters such as V

max

or J

i

;

once these parameters are chosen, an estimate of

Figure 1: A Nomograph

10 100 1000 10000 100000

0.10

0.050

0.025

0.015

0.010

0.0050

0.0015

0.00075

0.0005

0.00035

0.00025

0.00015

0.00010

0.000075

0.00005

A

min

/V

B

10

100

1000

10000

100000

V

max

(L/m

2

)

=

J

i

*

t

B

(

L

/

m

2

)

0.0006

0.0010

0.0025

0.0035

0.0075

0

.

1

0

0

.

0

5

0

0

.

0

2

5

0

.

0

1

0

0

.

0

0

5

0

0

.

0

0

1

5

0

.

0

0

0

7

5

0

.

0

0

0

5

0

.

0

0

0

3

5

0

.

0

0

0

2

5

0

.

0

0

0

1

5

0

.

0

0

0

1

0

0

.

0

0

0

0

7

5

0

.

0

0

0

0

5

0

.

0

0

0

0

3

5

0

.

0

0

0

6

0

.

0

0

1

0

0

.

0

0

2

5

0

.

0

0

3

5

0

.

0

0

7

5

0

.

0

1

5

=

in m

2

/L

0.000035

*Note: For Millistak+ applications, X-axis represents

the throughput estimated from Pmax analysis.

Process

Intermediates

Viresolve

NFP

Millistak+

*

Process Intermediates

Viresolve NFR

Process

Intermediates (0.2 m)

Buffer (0.2 m)

Media (0.1 m)

the specific area for the application ie: A

min

/V

Batch

may be determined from the nomograph.

Note: the areas designated A

min

is the minimum

area required to complete filtration at the base

conditions (time, volume, pressure) and does not

include safety factors to account for process

variability or process expansion.

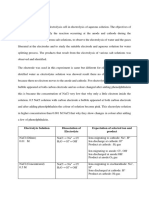

Figure 2: Example of Nomograph Use

Let us take the ltration of preltered serum free media through Durapore

0.1 m lters (CVVL).

Typical filtration pressure for this application is 15 psi.

Average normalized flux is known to be between 140 180 LMH/psi.

Typical Vmax ranges between 2,000 4,000 L/m

2

.

Process time is assumed to be 2 hours for the initial estimate.

J

i

x t

B

= 140 180 LMH/psi x 15 psi x 2h = 4,200 5,400 L/m

2

.

Figure 2 shows the graphical method to interpolate the specific area requirements.

>

>

>

>

>

Proceed vertically up the V

max

axis, at the appropriate V

max

value (For this case 2,000 4,000 L/m

2

) then do the

same on the horizontal J

i

*t

B

axis (140 180 LMH/psi x 15 psi x 2h = 4,200 5,400 L/m

2

). The specific area,

A

min

/V

B

, may be determined from the location of the intersection point of these two lines on the A

min

/V

B

curves.

For this case, the A

min

/V

B

may be estimated to be 0.00055 m

2

/L. This implies that to filter a 10,000 L batch, the

filtration area requirement may be calculated as:

A

min

= 10,000 L x (0.00055 m

2

/L) = 5.5 m

2

10 100 1000 10000 100000

0.10

0.050

0.025

0.015

0.010

0.0050

0.0015

0.00075

0.0005

0.00035

0.00025

0.00015

0.00010

0.000075

0.00005

A

min

/V

B

10

100

1000

10000

100000

V

max

(L/m

2

)

=

J

i

*

t

B

(

L

/

m

2

)

0.0006

0.0010

0.0025

0.0035

0.0075

0

.

1

0

0

.

0

5

0

0

.

0

2

5

0

.

0

1

0

0

.

0

0

5

0

0

.

0

0

1

5

0

.

0

0

0

7

5

0

.

0

0

0

5

0

.

0

0

0

3

5

0

.

0

0

0

2

5

0

.

0

0

0

1

5

0

.

0

0

0

1

0

0

.

0

0

0

0

7

5

0

.

0

0

0

0

5

0

.

0

0

0

0

3

5

0

.

0

0

0

6

0

.

0

0

1

0

0

.

0

0

2

5

0

.

0

0

3

5

0

.

0

0

7

5

0

.

0

1

5

=

in m

2

/L

0.000035

2,000 4,000 L/m

2

4

,

2

0

0

5

,

2

0

0

L

/

m

2

A

min

/V

B

= 0.00055 m

2

/L

Example: Serum Free Media

which translates into a 3 x 30-inch cartridge configuration.

Millipore, Durapore, Millipore Express, Millistak+, Polysep, Prostak, Viresolve, and V

max

are

registered trademarks of Millipore Corporation.

Lit. No. AN1200EN00 Rev. A 08/06 Printed in U.S.A. 06-329

2006 Millipore Corporation, Billerica, MA 01821 U.S.A. All rights reserved.

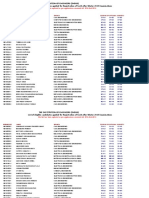

Final Final Filter J

i

,

Fluid Type Prefiltration Filtration Application V

max

, L/m

2

LMH/psi

Durapore 0.1 m Sterile and mycoplasma

PVDF filter (CVVL) reduction filtration 200 400 140 180

Double-layer Millipore Sterile and mycoplasma

Express

SHR 0.1 m reduction filtration 500 3,000 300 400

PES filter (CVEP)

Durapore 0.1 m Sterile and mycoplasma

PVDF filter (CVVL) reduction filtration 2,000 4,000 140 180

Millipore Express SHR Sterile and mycoplasma

0.1 m PES filter (CVEP) reduction filtration 2,000 8,000 300 400

Durapore 0.1 mm Sterile and mycoplasma

PVDF filter (CVML) reduction filtration 800 1,000 80 90

none 1,000 6,000 400 500

Durapore 0.22 m

PVDF filter (CVGL) Sterile Filtration 5,000 10,000 250 300

Durapore 0.22 m

PVDF filter (CVGL) Sterile Filtration 1,500 3,000 250 300

Double-layer Millipore

Express SHC 0.5 +

0.2 m PES filter (CHGE) Sterile Filtration 2,000 5,000 650 700

Durapore 0.22 m

PVDF filter (CVGL) Sterile Filtration 2,000 4,000 250 300

Double-layer Millipore

Express SHC 0.5 + 0.2 m

PES filter (CHGE) Sterile Filtration 4,000 10,000 650 700

Viresolve NFR filter,

> 50 nm (CZRV) Large Virus Filtration 1,000 3,000 20 30

Viresolve NFP filter,

> 20 nm, (CVPV) Small Virus Filtration 60 1,000 3 8

Durapore 0.22 m

PVDF filter (CVGL) Sterile Filtration >>10,000 350

Millipore Express SHF

0.2 m PES filter (CGEP) Sterile Filtration >>10,000 800

Table 1: Recombinant Proteins

List of the typical streams encountered in recombinant protein processing with key sizing parameters.

Serum Free

Media

No

Prefiltration

Polysep

II 1.0 + 0.2+

0.1 m filter (CGW1)

Polysep II 1.0 + 0.2 +

0.1 m filter (CGW3)

Clarified

CHO

Cell Culture

Prostak

0.65 m MF

Cassette (SK2P)

or Centrifuge followed

by Millistak+

HC

(A1HC)

No Prefiltration

(Stream Dependent)

Process

Intermediates

Buffers

No

Prefiltration

To facilitate the use of the nomograph, it is useful to review key sizing

parameter ranges such as V

max

and J

i

for specific applications and

filters. Table 1 summarizes parameters for a number of commonly

encountered solutions:

También podría gustarte

- AN1025EN00Documento4 páginasAN1025EN00kitofanecoAún no hay calificaciones

- FiltrosDocumento8 páginasFiltrossaulookAún no hay calificaciones

- A Method For Assessing Membrane Fouling in Pilot-And Full-Scale SystemsDocumento7 páginasA Method For Assessing Membrane Fouling in Pilot-And Full-Scale SystemsShakeel ur Rehman LashariAún no hay calificaciones

- Sterile Filter Handling PDFDocumento60 páginasSterile Filter Handling PDFv9991 v9991Aún no hay calificaciones

- Electrodes and Coating 2Documento17 páginasElectrodes and Coating 2ElafanAún no hay calificaciones

- AB Emflon PFRDocumento2 páginasAB Emflon PFRsaulookAún no hay calificaciones

- Principles of effective steam-in-place (SIP) systemsDocumento7 páginasPrinciples of effective steam-in-place (SIP) systemsRamachandra Bhat HireAún no hay calificaciones

- Filter Integrity Testing SystemsDocumento11 páginasFilter Integrity Testing SystemsAndy RojasAún no hay calificaciones

- Filter Integrity Test MachineDocumento4 páginasFilter Integrity Test MachineAtul SharmaAún no hay calificaciones

- Radiography and BorescopeDocumento6 páginasRadiography and BorescopeNaufal AmmarAún no hay calificaciones

- Filter Integrity Testing in The Pharmaceutical Process Environment - AutomatDocumento15 páginasFilter Integrity Testing in The Pharmaceutical Process Environment - Automatapi-3739176Aún no hay calificaciones

- Filter Sizing Methods Application NoteDocumento6 páginasFilter Sizing Methods Application NoteNathan Korean KimAún no hay calificaciones

- 12 ElgaardDocumento45 páginas12 ElgaardLutvo CirakAún no hay calificaciones

- ACRE2c Bioreactors N Biosynthesis Rev4Documento93 páginasACRE2c Bioreactors N Biosynthesis Rev4Rathish RagooAún no hay calificaciones

- Bioreactor - Control of Air Pollution@@Documento39 páginasBioreactor - Control of Air Pollution@@LTE002Aún no hay calificaciones

- PP100 5 Quality CertificateDocumento1 páginaPP100 5 Quality CertificateEdson JesusAún no hay calificaciones

- Gas Filtration Sterile Micro Filtration For Bio Reactors F & S Vol 43, #4, May 06Documento4 páginasGas Filtration Sterile Micro Filtration For Bio Reactors F & S Vol 43, #4, May 06michael_payne3532Aún no hay calificaciones

- Incubator Shaker: MODEL NO. - ACM-22063-IDocumento8 páginasIncubator Shaker: MODEL NO. - ACM-22063-Iwatson123Aún no hay calificaciones

- XDR DatasheetDocumento7 páginasXDR DatasheetElmer QuispeAún no hay calificaciones

- Cleaning Validation Practices Using A Single Pot ProcessorDocumento9 páginasCleaning Validation Practices Using A Single Pot Processorjljimenez1969Aún no hay calificaciones

- Millipore Sterilization & IntegrityDocumento6 páginasMillipore Sterilization & IntegrityMohammed S.GoudaAún no hay calificaciones

- Upgrading Air Handling Unit Works at Sime Darby Medical CentreDocumento4 páginasUpgrading Air Handling Unit Works at Sime Darby Medical CentreRyan Au YongAún no hay calificaciones

- Clarify: 740 Premium SeriesDocumento7 páginasClarify: 740 Premium SeriesnodyyyAún no hay calificaciones

- Filtration Membranes in Cell CultureDocumento12 páginasFiltration Membranes in Cell CulturemailreemaAún no hay calificaciones

- Watson-Marlow Fittings-Gb-04 PDFDocumento35 páginasWatson-Marlow Fittings-Gb-04 PDFcalejandrotgAún no hay calificaciones

- Catalogue Waters 2011 - 2012Documento360 páginasCatalogue Waters 2011 - 2012patchris36Aún no hay calificaciones

- Evaluating 0.1 μm Filters for Cell Culture Media FiltrationDocumento1 páginaEvaluating 0.1 μm Filters for Cell Culture Media FiltrationAbhijit GhoshAún no hay calificaciones

- Complete Magnetic Filtration Mini-CatalogDocumento19 páginasComplete Magnetic Filtration Mini-Catalog15 FFAún no hay calificaciones

- Ami Ro System IomDocumento36 páginasAmi Ro System IomLiney Gutiérrez OrozcoAún no hay calificaciones

- HPLC CalculatorDocumento16 páginasHPLC Calculatorwindli2014Aún no hay calificaciones

- PALL Certificate of TestDocumento1 páginaPALL Certificate of TestcuongtdbsbAún no hay calificaciones

- Industrial RO System DubaiDocumento34 páginasIndustrial RO System DubaiaquaproAún no hay calificaciones

- PB Filter Press Sidebar Me1500 Me2500 en Web DataDocumento4 páginasPB Filter Press Sidebar Me1500 Me2500 en Web DataTiago J C MachadoAún no hay calificaciones

- Troubleshooting Common HPLC ProblemsDocumento19 páginasTroubleshooting Common HPLC ProblemslimereiAún no hay calificaciones

- Argos SBR: A Compact SBR System Offering Process Flexibility and Major Capital SavingsDocumento2 páginasArgos SBR: A Compact SBR System Offering Process Flexibility and Major Capital SavingsViorel HarceagAún no hay calificaciones

- Fundamentals of sterile filtration selection and implementationDocumento51 páginasFundamentals of sterile filtration selection and implementationEverton Monteiro0% (1)

- Filter PressDocumento5 páginasFilter PressMinol JayakodyAún no hay calificaciones

- Water Maze Delta-3000a 1Documento2 páginasWater Maze Delta-3000a 1Marcelita AraujoAún no hay calificaciones

- EDD Calibration TrimDocumento23 páginasEDD Calibration TrimAnonymous cXjAZTAún no hay calificaciones

- Design and Development of Reactor Level Control Valve PDFDocumento21 páginasDesign and Development of Reactor Level Control Valve PDFstephinjacobAún no hay calificaciones

- Balston Coalescing Compressed Air and Gas FiltersDocumento70 páginasBalston Coalescing Compressed Air and Gas FilterspraveenAún no hay calificaciones

- Dissolution CatalogueDocumento48 páginasDissolution Catalogueabhijit_gothoskar6039Aún no hay calificaciones

- Prominence Pumps PDFDocumento2 páginasProminence Pumps PDFsandAún no hay calificaciones

- Millipore UF Catalog PDFDocumento100 páginasMillipore UF Catalog PDFShawkatAún no hay calificaciones

- Cary SpecificationsDocumento8 páginasCary SpecificationsmafiwarsAún no hay calificaciones

- Wedeco UV Systems AQUADA Altima, Proxima, MaximaDocumento20 páginasWedeco UV Systems AQUADA Altima, Proxima, Maximaeddysoen100% (1)

- Search Iso 8573Documento2 páginasSearch Iso 8573Anonymous FZs3yBHh70% (1)

- Gea - STD Single Use Cip Sys - CipdDocumento6 páginasGea - STD Single Use Cip Sys - CipdTBAún no hay calificaciones

- PR 900 PDFDocumento26 páginasPR 900 PDFsanjay ukalkarAún no hay calificaciones

- Aeromatic Ltd. Fluid Bed DryerDocumento13 páginasAeromatic Ltd. Fluid Bed DryerDitha ParamitaAún no hay calificaciones

- WEDECO LBXSeriesDocumento8 páginasWEDECO LBXSeriesÁrpád VassAún no hay calificaciones

- GC SEPARATION OF MIXTURE COMPONENTSDocumento9 páginasGC SEPARATION OF MIXTURE COMPONENTSSomnath BanerjeeAún no hay calificaciones

- New Trends in Microbial Beer Stabilization Using CFS NEO Membrane TechnologyDocumento7 páginasNew Trends in Microbial Beer Stabilization Using CFS NEO Membrane TechnologyJaime JuradoAún no hay calificaciones

- PDA Publications: Expert Bio/Pharmaceutical Publications and Resources For The Pharmaceutical Manufacturing IndustryDocumento32 páginasPDA Publications: Expert Bio/Pharmaceutical Publications and Resources For The Pharmaceutical Manufacturing IndustryAbhishek SharmaAún no hay calificaciones

- ISO 8573 Purity Classes PDFDocumento1 páginaISO 8573 Purity Classes PDFOky Andytya PratamaAún no hay calificaciones

- HPLC Verification - Pic Added &shortendDocumento40 páginasHPLC Verification - Pic Added &shortendMD Fahad MiajiAún no hay calificaciones

- Autoklaf Page 3.bin PDFDocumento16 páginasAutoklaf Page 3.bin PDFNadya Rizky SAún no hay calificaciones

- Vertical KO Drum Sizing (Ver 1.0.0) : 1.0 DescriptionDocumento21 páginasVertical KO Drum Sizing (Ver 1.0.0) : 1.0 Descriptionrameshkarthik810Aún no hay calificaciones

- Filter Selection Guide-EDocumento78 páginasFilter Selection Guide-ENuñez JesusAún no hay calificaciones

- STATS Shortcut FormulaDocumento3 páginasSTATS Shortcut Formulajeet sighAún no hay calificaciones

- Daily Test Class 11 - 4thDocumento5 páginasDaily Test Class 11 - 4thDebby GraciaAún no hay calificaciones

- Unit 2Documento76 páginasUnit 2Mithila100% (1)

- Transportation Installation R2000iC210FDocumento25 páginasTransportation Installation R2000iC210FMeet PAtel100% (2)

- QNX Neutrino RTOS Building Embedded SystemsDocumento248 páginasQNX Neutrino RTOS Building Embedded SystemsLarken BradynAún no hay calificaciones

- Dev - Mag - 09Documento26 páginasDev - Mag - 09georgpiorczynskiAún no hay calificaciones

- Daily production planning and capacity analysisDocumento27 páginasDaily production planning and capacity analysisahetAún no hay calificaciones

- Quasi VarianceDocumento2 páginasQuasi Varianceharrison9Aún no hay calificaciones

- List of Eligible Candidates Applied For Registration of Secb After Winter 2015 Examinations The Institution of Engineers (India)Documento9 páginasList of Eligible Candidates Applied For Registration of Secb After Winter 2015 Examinations The Institution of Engineers (India)Sateesh NayaniAún no hay calificaciones

- SM Maintenance Instructions: Author: Lars Rydén, Konecranes AB, SwedenDocumento132 páginasSM Maintenance Instructions: Author: Lars Rydén, Konecranes AB, SwedenDan VekasiAún no hay calificaciones

- Foundation DetailsDocumento29 páginasFoundation DetailsSUSOVAN BISWASAún no hay calificaciones

- D200801 Slope and Offset Adjustment For A Pressure SensorDocumento4 páginasD200801 Slope and Offset Adjustment For A Pressure SensorBrian McMorrisAún no hay calificaciones

- Adobe After Effects CS3 Keyboard Shortcuts GuideDocumento14 páginasAdobe After Effects CS3 Keyboard Shortcuts GuideBrandon Sirota100% (1)

- SCADADocumento14 páginasSCADANunna BaskarAún no hay calificaciones

- KENWOOD TK 7302 Manual - ADocumento2 páginasKENWOOD TK 7302 Manual - AMas IvanAún no hay calificaciones

- The Iec GooseDocumento2 páginasThe Iec GooseGalo VacaAún no hay calificaciones

- Primary Reformer TubesDocumento10 páginasPrimary Reformer TubesAhmed ELmlahyAún no hay calificaciones

- Tensile Properties of Ground Coffee Waste Reinforced Polyethylene CompositeDocumento4 páginasTensile Properties of Ground Coffee Waste Reinforced Polyethylene CompositemhmmdzulvaAún no hay calificaciones

- Line Tension and Pole StrengthDocumento34 páginasLine Tension and Pole StrengthDon BunAún no hay calificaciones

- Lec11 Amortized Loans Homework SolutionsDocumento3 páginasLec11 Amortized Loans Homework SolutionsJerickson MauricioAún no hay calificaciones

- The Tom Bearden Website-StupidityDocumento7 páginasThe Tom Bearden Website-StupiditybestiariosAún no hay calificaciones

- Discussion Exp 2 Chm674Documento4 páginasDiscussion Exp 2 Chm674Eva Lizwina MatinAún no hay calificaciones

- Ska611hdgdc (210) (12BB) (2384×1303×35) (680 700)Documento2 páginasSka611hdgdc (210) (12BB) (2384×1303×35) (680 700)Marko Maky ZivkovicAún no hay calificaciones

- Engineering Circuit Analysis 7th Edition: Chapter 17 SolutionDocumento50 páginasEngineering Circuit Analysis 7th Edition: Chapter 17 SolutionTaif ArifAún no hay calificaciones

- Binder 1Documento36 páginasBinder 1BobbyAún no hay calificaciones

- EDOC-Benefits & Advantages of Applying Externally Gapped Line ArrestersDocumento20 páginasEDOC-Benefits & Advantages of Applying Externally Gapped Line ArrestersEl Comedor BenedictAún no hay calificaciones

- EECIM01 Course MaterialDocumento90 páginasEECIM01 Course Materialsmahesh_1980Aún no hay calificaciones

- Manual 2012-08 EDocumento59 páginasManual 2012-08 EfiorelaAún no hay calificaciones

- P18 Probability in The CourtroomDocumento14 páginasP18 Probability in The CourtroomYehiaAún no hay calificaciones

- Kotlin Programs - StudentsDocumento74 páginasKotlin Programs - Studentsgandem gowhithAún no hay calificaciones