Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Pressure Vessel Support

Cargado por

Andreea LucaDescripción original:

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Pressure Vessel Support

Cargado por

Andreea LucaCopyright:

Formatos disponibles

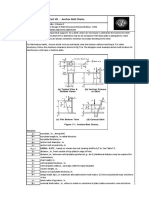

Design of Vessel Supports 167

I

=longitudinal bending at saddles (tension at top, compression at bottom)

S14 =circumferential stress

in stiffener

1 Id

L12 a L12

I,

4

L S , =longitudinal bending at

midspan

/

I 1 I

1 S5-, =tangential shear-results

in diagonal lines in shell

Se =tangential shear in head (A 5 R12)

/- Sl l =additional tension in head (A 5 R12)

\

I I '

Figure 3-43. Stress diagram

L s13 =circumferential compression

in plane of saddle

=circumferential bending at

horn of saddle

L

Mz is negative for

M2 is positive for

0 Hemi-heads.

0 If any of the below conditions are exceeded.

0 Flat heads where A/R <0.707.

0 100%-6% F&D heads where A/R <0.44.

0 2:l S.E. heads where A/R <0.363.

Figure 3-44. Moment diagram.

Previous Page

168 Pressure Vessel Design Manual

Longitudinal Forces, FL

Case 1: Pier Deflection

sa =s

Case 2: ExpansionIContraction

FLZ =PQO

sa=s

Case 3: Wind

F L ~ =F ~L = AiCfGqz

sa =1.33s

Case 4: Seismic

F L ~ =F, =ChW,

sa =1.33s

Case 5: Shippingrrransportation

FL5 (See Chapter 7. )

Sa =0.9Fy

Case 6: Bundle Pulling

F L ~ =Fp

Sa =0.9F,

Full load applies to fixed saddle only!

X =Fixed Saddle

K =Fixed Saddle

X

Note: For Cases 5 and 6, assume the vessel is cold and not pressurized.

Design of Vessel Supports 169

Transverse Load: Basis for Equations

Method I

6FB

E

w*= 2

WU

e Unit load at edge of base plate, w,,.

e Derivation of equation for WZ.

M

Z

c = -

Therefore

M 6FB

Z E2

- - - -

e Equiualent

E2

M=F B Z=-

6

3tal load Q Z .

This assumes that the maximum load at the edge of the

baseplate is uniform across the entire baseplate. This is

very conservative, so the equation is modified as follows:

e Using a triangular loading and 213 rule to dezjelop a

more realistic unvorm load

FB 3FB

(2/3)E - 2E

FI=---

Therefore the total load, QF, due to force F is

3FB 3FB

QF =w ~E =- E2 E =- E

Method 2

Q k

1 E 1

1 1

This method is based on the rationale that the load i

no longer spread over the entire saddle but is shifted o onc

side.

e Combined force, 9 2 .

Q2=JFT@

e Angle, 8.

F

8~ =(arctan)-

Q

e Modi$ed saddle angle, el.

81=2[J - 0 H

170 Pressure Vessel Design Manual

Types of Stresses and Allowables

e S I to SI : longitudinal bending.

Tension: SI , S7, or &+o x < SE

Compression: Se, S3, or 54 - oe <S,

where S, =factor "B" or S or t,E1/16r

whichever is less.

1. Compressive stress is not significant where R,/t <200

and the vessel is designed for internal pressure only.

2. When longitudinal bending at midspan is excessive,

move saddles away from heads; however, do not

exceed A 2 0.2 L.

3. When longitudinal bending at saddles is excessive,

move saddles toward heads.

4. I f longitudinal bending is excessive at both saddles and

midspan, add stiffening rings. If stresses are still exces-

sive, increase shell thickness.

e S.5 to S,v <0.8s: tangential .shear.

1. Tangential shear is not combined with other stresses.

2. I f a wear plate is used, t, may be taken as t,+t,, pro-

viding the wear plate extends W10 above the horn of

the saddle.

3. If the shell is unstiffened, the maximum tangential

shear stress occurs at the horn of the saddle.

4. If the shell is stiffened, the maximum tangential shear

occurs at the equator.

5 . When tangential shear stress is excessive, move saddles

toward heads, A s0. 5 R, add rings, or increase shell

thickness.

6. When stiffening rings are used, the shell-to-ring weld

must be designed to be adequate to resist the tangential

shear as follows:

allowable shear

<

Q . lb

r r in. circumference in. of weld

st=-.

e Sl 1 +a/ , <1.25 SE: additional .stress i n head.

1. S is a shear stress that is additive to the hoop stress in

the head and occurs whenever the saddles are

located close to the heads, A i 0. 5 R. Due to their

close proximity the shear of the saddle extends into

the head.

2. If stress in the head is excessive, move saddles away

from heads, increase head thickness, or add stiffening

rings.

e Sg and Sl o <1.5 S and 0.9Fy: circumferential bending at

horn of saddle.

1. If a wear plate is used, t, may be taken as t,+t, pro-

viding the wear plate extends W10 above the horn of

the saddle. Stresses must also be checked at the top of

the wear plate.

2. If stresses at the horn of the saddle are excessive:

a. Add a wear plate.

b. Increase contact angle 8.

c. Move saddles toward heads, A <R.

d. Add stiffening rings.

e S12 <0.5Fy or 1.5 S: circumferential compressioe stress.

1. If a wear plate is used, t, may be taken as t, +t,, pro-

viding the width of the wear plate is at least

b +1. 566.

2. If the shell is unstiffened the maximum stress occurs at

the horn of the saddle.

3. If the shell is stiffened the maximum hoop compression

occurs at the bottom of the shell.

4. If stresses are excessive add stiffening rings.

e ( +) SI 3 +o@ <1.5 S: circumferential tension stress-shell

e ( - ) S13 - oF <0.5Fy: circumferential compression stress-

e ( - )Sll - u, <0.9FY: circumferential compression stres.9 i n

stiffened.

shell stiffened.

stiffening ring.

Procedure for Locating Saddles

Trial 1: Set A=0.2 L and t3= 120" and check stress at the

horn of the saddle, Sg or Slo. This stress will govern for

most vessels except for those with large L/R ratios.

Trial 2: Increase saddle angle 8 to 150" and recheck stresses

at horn or saddle, S9 or Slo.

Trial 3: Move saddles near heads ( A =W2) and return 8 to

120". This will take advantage of stiffness provided by the

heads and will also induce additional stresses in the heads.

Compute stresses Sq, Sg, and Sg or Slo. A wear plate may

be used to reduce the stresses at the horn or saddle when

the saddles are near the heads (A <W2) and the wear

plate extends W10 above the horn of the saddle.

Trial 4: Increase the saddle angle to 150" and recheck

stresses Sd, Sg, and Sg or Slo. Increase the saddle angle

progressively to a maximum of 168" to reduce stresses.

Trial 5: Move saddles to A =0.2L and t3=120" and design

ring stiffeners in the plane of the saddles using the equa-

tions for S13 and S14 (see Note 7).

Design of Vessel Supports 171

Figure 3-45. Chart for selection of saddles for horizontal vessels. Reprinted by permission of the American Welding Society.

~ ~~ ~

Wind and Seismic Forces

Longitudinal forces, FL.

Seismic: UBC (see Procedure 3-3)

FL =ChWo

Wind: A X E 7-95 (Exposure C, Type 111)

FL =Af Cf G,qz

7sD2

where Af =3

4

Cf =0.8

G =0.85

q, =0.00256KzV21

K, =from Table 3-23

I =1.15

V =basic wind speed, 70 - 100 mph

(see Procedure 3-2)

Table 3-21

Seismic Factors, C, (For I =1 .O)

Zone cs

0

1

2A

2B

3

4

0

0.069

0.138

0.184

0.275

0.367

Table 3-22

Effective Diameter, De

Diameter (in.) D.

<36

36-54

54-78

78-1 02

>102

1.5D

1.37D

1.28D

1.2D

1.18D

172 Pressure Vessel Design Manual

Table 3-23

Coefficient, K,

Height (ft) Kz

0-1 5

20

25

30

40

50

60

0.85

0.9

0.94

0.98

1.04

1.09

1.13

0 Transverse forces, Ft , per saddle.

Seismic:

Ft =(ChWo)0.5

Wind:

Ft =(AfCfGdqz)O.5

Af = De( L +2H)

0 Total saddle reaction forces, Q.

Q=greater of Q1 or Qz

Longitudinal, Q1

Transverse, Qz

W, 3FtB

Q 2 = 3 - + ~

Shell Stresses

There are 14 main stresses to be considered in the design

of a horizontal vessel on saddle supports:

feners, tension

feners, compression

S1 =longitudinal bending at saddles without stif-

S2 =longitudinal bending at saddles without stif-

S3 =longitudinal bending at saddles with stiffeners

a,

Figure 3-46. Saddle reaction forces.

S4 =longitudinal bending at midspan, tension at

S5 =tangential shear-shell stiffened in plane of

S6 =tangential shear-shell not stiffened, A >lU2

S7=tangential shear-shell not stiffened except by

heads, A 5 W2

S8 =tangential shear in head-shell not stiffened,

A 5W2

S9 = circumferential bending at horn of saddle-

shell not stiffened, L ? 8R

SI 0 =circumferential bending at horn of saddle-

shell not stiffened, L c 8R

SI 1 =additional tension stress in head, shell not stif-

fened, A 5 lU2

S 12 =circumferential compressive stress-stiffened

or not stiffened, saddles attached or not

S13 =circumferential stress in shell with stiffener in

plane of saddle

S14 =circumferential stress in ring stiffener

bottom, compression at top

saddle

Longitudinal Bending

0 S I , longitudinal bending at saddles-without stiffeners,

tension.

1

8AH +6A2 - 3R2 +3H2

[ 3 L+4 H

Mi =6 Q

M1

Klr2t,

si =(+)-

0 S2, longitudinal bending at saddles-without stiffeners,

compression.

M1

K7r2ts

s2=(-)-

0 S3, longitudinal bending at saddles-with stifenem.

0 S4, longitudinal bending at midspan.

I

3L2 +6R2 - 6H2 - 12AL - 16AH

3L +4H

M2 =34

Tangential Shear

0 S5, tangential shear-shell stifened i n the plane of the

saddle.

Design of Vessel Supports 173

e S6, tangential shear-shell not stiffened, A >0.SR.

fi.=-[p] KzQ L-2A

rt, L +$H

e S7, tangential shear-shell not stiffened, A 5 0.SR.

K3Q

s7=-

dS

e Sg, tangential shear in head-shell not stiffened, A 5 0.5R.

K3 Q

S8 =-

r th

Note: If shell is stiffened or A >0.5R, S8 =0.

Circumferential Bending

e Sg, circumferential bending at horn of saddle-shell not

stiffened ( L 2 8R).

Note: t, =t, +t, and tf =tt +

wear plate extends W1O above horn of saddle.

only if A 5 0.5R and

Sl o, circumferential bending at horn of saddle-shell not

stiffened ( L <8R).

Q 12K6QR

4ts(b +1. 566) - Ltf

SlO =(-1

Note: Requirements for t, are same as for Sg.

Additional Tension Stress in Head

e SI 1, additional tension stress in head-shell not stifened,

A 5 0.5R.

Note: If shell is stiffened or A >0.5R, SI 1 =0.

Circumferential Tension/Compression

e S12, circumferential compression.

K5 Q

t,(b +1.56fi )

s12 =(-1

Note: t, =t, +t, only if wear plate is attached to shell and

width of wear plate is a minimum of b +1.56fi .

e S13, circumferential stress in shell with stiffener (see

Note 8).

Note: Add second expression if vessel has an internal

stiffener, subtract if vessel has an external stiffener.

e SI 4 , circumferential compressive stress in stiffener (see

Note 8).

Pressure Stresses

a h =a+, maximum circumferential stress in head is equal to

hoop stress in shell

174 Pressure Vessel Design Manual

Stress

s1+ox

COMBINED STRESSES

Al l owabl e Stress Al l owabl e

SE = - s2- Ue S, =

I TENSION I COMPRESSION i

s3+ox

s4+ox

SE = -S3-ue s, =

SE = - s4- Ue S, =

Contact Contact

Angl e f3 K1' K2 K3 K4 K5 K7 K8 Kg Angl e 0 K1* K2 K3 K5 K7 K8 Kg

120 0.335

122 0.345

124 0.355

126 0.366

128 0.376

130 0.387

132 0.398

134 0.409

136 0.420

138 0.432

140 0.443

142 0.455

144 0.467

146 0.480

148 0.492

150 0.505

~~ ~

1.171

1.139

1.108

1.078

1.050

1.022

0.996

0.971

0.946

0.923

0.900

0.879

0.858

0.837

0.81 8

0.799

~~

0.880

0.846

0.81 3

0.781

0.751

0.722

0.694

0.667

0.641

0.61 6

0.592

0.569

0.547

0.526

0.505

0.485

0.401

0.393

0.385

0.377

0.369

0.362

0.355

0.347

0.340

0.334

0.327

0.320

0.314

0.308

0.301

0.295

0.760

0.753

0.746

0.739

0.732

0.726

0.720

0.714

0.708

0.702

0.697

0.692

0.687

0.682

0.678

0.673

0.603

0.61 8

0.634

0.651

0.669

0.689

0.705

0.722

0.740

0.759

0.780

0.796

0.81 3

0.831

0.853

0.876

0.340

0.338

0.336

0.334

0.332

0.330

0.328

0.326

0.324

0.322

0.320

0.31 6

0.31 2

0.308

0.304

0.300

0.053

0.051

0.050

0.048

0.047

0.045

0.043

0.042

0.040

0.039

0.037

0.036

0.035

0.034

0.033

0.032

152

154

156

158

160

162

164

166

168

170

172

174

176

178

180

0.518 0.781 0.466

0.531 0.763 0.448

0.544 0.746 0.430

0.557 0.729 0.413

0.571 0.713 0.396

0.585 0.698 0.380

0.599 0.683 0.365

0.613 0.668 0.350

0.627 0.654 0.336

0.642 0.640 0.322

0.657 0.627 0.309

0.672 0.614 0.296

0.0687 0.601 0.283

0.702 0.589 0.271

0.718 0.577 0.260

0.289 0.669 0.894 0.298

0.283 0.665 0.913 0.296

0.278 0.661 0.933 0.294

0.272 0.657 0.954 0.292

0.266 0.654 0.976 0.290

0.261 0.650 0.994 0.286

0.256 0.647 1.013 0.282

0.250 0.643 1.033 0.278

0.245 0.640 1.054 0.274

0.240 0.637 1.079 0.270

0.235 0.635 1.097 0.266

0.230 0.632 1.116 0.262

0.225 0.629 1.137 0.258

0.220 0.627 1.158 0.254

0.216 0.624 1.183 0.250

0.031

0.030

0.028

0.027

0.026

0.025

0.024

0.024

0.023

0.022

0.021

0.020

0.01 9

0.01 8

0.01 7

'K, =3.14 if the shell is stiffened by ring or head ( A < Ri 2).

Fi gure 3-47. Coefficients.

Design of Vessel Supports 175

86

87

88

Table 3-24

Coefficients for Zick's Analysis (Angles 80' to 120")

0.1914 2.0264 1.7831 0.5808 0.9417 0.0216 0.0873 0.3575 0.3592 0.0873

0.1949 1,9891 1.7441 0.5741 0.9344 0.0215 0.0861 0.3637 0.3591 0.0861

0.1985 1.9528 1.7061 0.5675 0.9273 0.0212 0.0849 0.3700 0.3590 0.0849

I 85 I 0 1879 I 20648 1 18233 I 05877 I 09492 I 00221 1 00885 I 03513 I 03593 1 - 0 0 8 8 5 1

1. These coefficients are derived from Zick's equations.

2. The ASME Code does not recommend the use of saddles with an included angle, 8, less than 120-. Therefore the values in this table should be used for very

small-diameter vessels or to evaluate existing vessels built prior to this ASME recommendation.

3. Values of & for NR ratios between 0.5 and 1 can be interpolated.

176 Pressure Vessel Design Manual

30 16,700 27 24

36 15,700 33 27

42 15,100 38 30

48 25,330 44 33

54 26,730 48 36

60 38,000 54 39

66 38,950 60 42

A

G

9 4 16.5 120" 100

12 6 18.8 125" 170

20.0 123" 200

22.3 127" 230

22.7 121" 270 20

23 25.0 124" 31 0

26 27.2 127" 35D

~ ;:

G lLC_l_c,l

72 50,700 64 45 10 28 1 0.i75 27.6

78 56,500 70 48 11 0.75 31 29.8

30.2 84 57,525 74 51 12

90 64,200 80 54 13

96 65,400 86 57 14 39 34.7

ii ; 1 32.5

LO

Figure 3-48. Saddle dimensions.

122" 420

124" 71 0

121" 81 0

123" 880

125" 940

L

102 94,500 92 60 15

108 85,000 96 63 16

114 164,000 102 66 17

120 150,000 106 69 18

132 127,500 118 75 20

144 280,000 128 81 22

156 266,000 140 87 24

Tabl e 3-25

Slot Dimensions

42 Ib 0.500 37.0 1% 126" 1,350

44 37.3 123" 1,430

47 0.625 39.6 125" 1,760

49 40.0 122" 1,800

125" 2,180

124" 2,500

126" 2,730

55

60

66 51.6

I

Distance Between Saddles

Temperature

" F l o f t 20 ft 30 ft 40 ft 50 ft

- 50

100

200

300

400

500

600

700

800

900

0

0

0

0.250

0.375

0.375

0.500

0.625

0.750

0.750

0

0

0.250

0.375

0.625

0.750

1 .oo

1.125

1.250

1.375

0.25

0.125

0.375

0.625

0.875

1.125

1.375

1.625

1.625

2.000

0.25

0.125

0.375

0.750

1.125

1.500

1 375

2.125

2.375

2.500

0.375

0.250

0.500

1 .oo

1.375

1.625

2.250

2.625

3.000

3.375

Bolt diameter L See 4

+118 in. Table

Tabl e 3-26

Typical Saddle Dimensions.

Maximum

Vessel Operating Bolt Approximate

O.D. Weight A B C D E F G H Diameter e WeighVSet

Design of Vessel Supports 177

Notes

1. Horizontal vessels act as beams with the following

exceptions :

a. Loading conditions vary for full or partially full ves-

sels.

b. Stresses vary according to angle Q and distance "A."

c. Load due to weight is combined with other loads.

2. Large-diameter, thin-walled vessels are best supported

near the heads, provided the shell can take the load

between the saddles. The resulting stresses in the

heads must be checked to ensure the heads are stiff

enough to transfer the load back to the saddles.

3. Thick-walled vessels are best supported where the

longitudinal bending stresses at the saddles are about

equal to the longitudinal bending at midspan.

However, "A" should not exceed 0.2 L.

4. Minimum saddle angle Q= EO", except for small ves-

sels. For vessels designed for external pressure only 0

should always =120". The maximum angle is 168" if a

wear plate is used.

5. Except for large L/R ratios or A >lU2, the governing

stress is circumferential bending at the horn of the

saddle. Weld seams should be avoided at the horn of

the saddle.

6. A wear plate may be used to reduce stresses at the horn

of the saddle only if saddles are near heads (A 5 W2),

and the wear plate extends W10 (5.73 deg.) above the

horn of the saddle.

7. If it is determined that stiffening rings will be required

to reduce shell stresses, move saddles away from the

heads (preferable to A=0.2 L). This will prevent

designing a vessel with a flexible center and rigid

ends. Stiffening ring sizes may be reduced by using a

saddle angle of 150".

8. An internal stiffening ring is the most desirable from a

strength standpoint because the maximum stress in the

shell is compressive, which is reduced by internal pres-

sure. An internal ring may not be practical from a pro-

cess or corrosion standpoint, however.

9. Friction factors:

S u f aces

Lubricated steel-to-concrete

Steel-to-steel

Lubrite-to-steel

0 Temperature over 500F

0 Temperature 500F or less

0 Bearing pressure less than 500psi

Teflon-to-Teflon

0 Bearing 800psi or more

0 Bearing 300psi or less

PROCEDURE 3-11

Friction

Factor,

0.45

0.4

0.15

0.10

0.15

0.06

0.1

DESIGN OF SADDLE SUPPORTS FOR LARGE VESSELS [4, 15-17, 211

Notation

A, =cross-sectional area of saddle, in.'

Ab =area of base plate, in.2

A,-=projected area for wind, ft2

A, =pressure area on ribs, in.2

A, =cross-sectional area, rib, in.2

Q =maximum load per saddle, lb

Qi =Qo+QK , 1b

4 2 =Qo +QL, 1b

QI, =load per saddle, operating, lb

QT =load per saddle, test, lb

QL =vertical load per saddle due to longitudinal loads, lb

QK =vertical load per saddle due to transverse loads, lb

FL =maximum longitudinal force due to wind, seismic,

pier deflection, etc. (see procedure 3-10 for

detailed description)

Fa =allowable axial stress, psi (see App. L)

N =number of anchor bolts in the futed saddle

a, =cross-sectional area of bolts in tension, i n2

Y =effective bearing length, in.

T =tension load in outer bolt, lb

nl =modular ratio, steel to concrete, use 10

F1, =allowable bending stress, psi

F, =yield stress, psi

f,, =saddle splitting force, lb

E,, =axial stress, psi

fb =bending stress, psi

f,, =unit force, Ib/in.

B, =bearing pressure, psi

M =bending moment, or overturning moment, in.-lb

I =moment of inertia, in.4

z =section modulus, in.3

r =radius of gyration, in.

K I =saddle splitting coefficient

178 Pressure Vessel Design Manual

32

30

28

26

24

22

20

18

16

0 . 6 r 0.75 0.875 1.0 1.125 1.25 1.375 1.5 1.625 1.75

I . n - . . . . . . . . - . - . -

Y I V I I I I i I I I I I i I 1 I J

Web and Rib Thickness, t, and J , in.

Figure 3-49. Graph for determining web and rib thicknesses.

D

I

I

A

4 Optional 168 saddle-optimum size for large vessels

Figure 3-50. Dimensions ot horizontal vessels and saddles.

Design of Vessel Supports 179

n =number of ribs, including outer ribs, in one saddle

P =equivalent column load, lb

d =distance from base to centroid of saddle arc, in.

W, =operating weight of vessel +contents, lb

W, =vessel weight full of water, Ib

UT =tension stress, psi

w =uniform load, lb

Forces and Loads

Vertical Load per Saddle

? F r ?

Longitudinal

0.5 0.5

Transverse

Figure 3-51. Saddle loadings.

For loads due to the following causes, use the given

formulas.

0 Operating weight.

wo

Q =-

O 2

0 Test weight.

0 Longitudinal wind or seismic.

0 Transverse wind or seismic.

Maximum Loads

Vertical.

greater of Q1, Qz, or QT

Q~=Q~+QR

QZ =Qo +QL

0 Longitudinal.

F L =greater of FL1 through FL(,

(see procedure 3- 10 for definitions)

Saddle Properties

0 Preliminary web and rib thicknw.r.es, t t c atid J . Froin

Figure 3-45:

J =t,

0 Number of ribs required, I I

A

n=- +l

24

Round up to the nearest even number.

0 Minimum width of .snddle at top, GT, in

where FL and F1, are in kips and ksi or 11) and psi, and J , 11.

A are in in.

Minimum wear plate diuiensiori,y,

Width:

H =GT +1. 56f i

Thickness:

(H - GT)'

2.43R

t, =

0 Moinent of inertici of saddle, I

0 Cross-sectional area of saddle (escliiding ,shell).

A, = A- A1

180 Pressure Vessel Design Manual

A

0

Q

to center

in.'

Y AY A V 1.

NO^: io for mangl es I bh3

12

Figure 3-52. Cross-sectional properties of saddles.

~~ ~~

Design of Saddle Parts

Web

Web is in tension and bending as a result of saddle split-

ting forces. The saddle splitting forces, fl,, are the sum of all

the horizontal reactions on the saddle.

e Saddle coefficient.

1 +cos j3 - 0.5 sin2B

j7 - j3 +sin j3 cos j3

Ki =

A'ote: j? is in radians. See Table 3-18.

fh

- E-

Varying unit radial

pressure

Figure 3-53. Saddle splitting forces.

Note: Circumferential bending at

horn is neglected for

this calculation.

Figure 3-54. Bending in saddle due to splitting forces.

e Saddle splitting force.

fi ,=K,(Q or QT)

e Tension stress.

Note: For tension assume saddle depth "h

maxi mum .

e Bending moment.

R si ne

d=B- -

e

6' is in radians.

M =fhd

e Bending stress.

fl , =I MC1 <0.66FY

Table 3-27

Values of kl

as W3

ki 20

0.204 120"

0.214 126'

0.226 132'

0.237 138"

0.248 144"

0.260 150"

0.271 156

0.278 162'

0.294 168"

Design of Vessel Supports 181

1 f b 1

b

Figure 3-55. Loading diagram of base plate.

Base plate with center web

e Area.

Ai, =A F

e Bearing pre,ssure.

Q

- AI,

B --

e Ba.se plate thickness.

QF

NOW M =-

8

Therefore

Assumes uniform load fixed in center.

Base plate analysis for offset web (see Figure 3-56)

e Overall length, L.

Web

ribs L, =n(G - t,)

=A - 2dl - 2J

EL =L, +L,

t

/

--d2

Figure 3-56. Load diagram and dimensions for base plate with an offset

web.

e Unit linear load, j i i .

f u =- Q lb/linear in.

CL

e Distance.7 el and &.

e Load.9 moment

we;

M=-

6

e Bending .stres.y, f;,.

6M

f h =

182 Pressure Vessel Design Manual

,

Anchor Bolts

fc

Pivot Pt.

Y , x , ,

I ,

Anchor bolts are governed by one of the three following

1. Longitudinal loud: If Qo >QL , then no uplift occurs,

and the minimum number and size of anchor bolts

should be used.

If Qo <QL , then uplift does occur:

load cases:

QL - Qo =load per bolt

N

2. Shear: Assume the fixed saddle takes the entire shear

load.

FL

- =shear per bolt

N

3. Trunszjerse load: This method of determining uplift

and overturning is determined from Ref. 21 (see

Figure 3-57).

M =(0.5F, or F*T)B

M

e=-

Q"

If e <%, then there is no uplift.

If e 2 %, then proceed with the following steps. This is an

iterative procedure for finding the tension force, T, in the

outermost bolt.

Step 1: Find the effective bearing length, Y. Start by calcu-

lating factors K1-3

K1 =3(e - 0.5A)

6n 1 at

K2 =-(f +e)

F

Step 2: Substitute values of K1-3 into the following equation

and assume a value of Y =%A as a first trial.

1 1

Figure 3-57. Dimensions and loading for base plate and anchor bolt

analysis.

Y 3+ K1Y2+ K2Y +K3 = O

If not equal to 0, then proceed with Step 3.

Step 3: Assume a new value of Y and recalculate the equa-

tion in Step 2 until the equation balances out to approxi-

mately 0. Once Y is determined, proceed to Step 4.

Step 4: Calculate the tension force, T, in the outermost bolt

or bolts.

A Y

Step 5: From Table 3-28, select an appropriate bolt material

and size corresponding to tension force, T.

Step 6: Analyze the bending in the base plate.

Distance, x =0.5A +f - Y

Moment, M =Tx

6M

Bending stress, fb =-

ti

Table 3-28

Allowable Tension Load on Bolts, Kips, per AlSC

Nom. Bolt

Dia., in. 1 1% 1% 1% 1%

Table 3-28

Allowable Tension Load on Bolts, Kips, per AlSC

Cross-sectional Area, ab, 0.3068 0.441 8 0.6013 0.7854 0.994 1.227 1.485 1.767

in.'

A-307 Ft =20 ksi 6.1 8.8 12.0 15.7 19.9 24.5 29.7 35.3

A-325 Ft=44ksi 13.5 19.4 26.5 34.6 43.7 54.0 65.3 77.7

Design of Vessel Supports 183

Ribs

Outside Ribs

r J I

& 0.5e or 1h ,I

rib spacing

A =

4 = ea pressure area, =0.5Fe

Fi gure 3-58. Dimensions of outside saddle ribs and webs.

area of rib and web, in.?

Outside Ribs

e Axial load, P.

P =B,A,

e Compressiue stress, J,.

P

f a =A,

e Radius of gyration, r

r=g

e Slenderness ratio, f21lr.

l l / r =

F, =(See App. L.)

e Unit force, f;,

FI,

f,, =

e Bending moment, M.

M =0.5f,,ell

e Bending stress, fh =0.66 Fy.

MC1

f b =-

I

e Combined stress.

f a f h

F a F h

-+-< 1

Inside Ribs

Inside rib

t

1 eo1 1

A, =

A+ =a pressure area, F x e

'I

L

rib spacing 1

area of rib and web, in.2

J G3

l2 =moment of inertia, 1

12

C2 =0.5Gb

Fi gure 3-59. Dimensions of inside saddle ribs and webs.

e A d load, P.

P =B,A,

e Compressiue stre.as, fn.

P

f a =A,

e Radius of gyration, r.

e Slenderness ratio, &/ r.

Czlr =

Fa =

e Unit force,f;,.

FL

f --

- 2A

184 Pressure Vessel Design Manual

e Bending moment, M.

M =f,&e

e Bending stress, fb.

MC2

I

e Combined stress.

f b =-

f a f h

F a F b

- +- <I

Notes

1. The depth of web is important in developing stiffness

to prevent bending about the cross-sectional axis of

the saddle. For larger vessels, assume 6 in. as the

minimum depth from the bottom of the wear plate

to the top of the base plate.

2. The full length of the web may be assumed effective

in carrying compressive stresses along with ribs. Ribs

are not effective at carrying compressive load if they

are spaced greater than 25 times the web thickness

apart.

3. Concrete compressive stresses are usually considered

to be uniform. This assumes the saddle is rigid enough

to distribute the load uniformly.

4. Large-diameter horizontal vessels are best supported

with 168" saddles. Larger saddle angles do not effec-

tively contribute to lower shell stresses and are more

difficult to fabricate. The wear plate need not extend

beyond center lines of vessel in any case or 6" beyond

saddles.

5. Assume fixed saddle takes all of the longitudinal

loading.

PROCEDURE 3-12

DESIGN OF BASE PLATES FOR LEGS [ZO, 211

Notation

Y =effective bearing length, in.

M =overturning moment, in.-lb

' =axi al load, lb

ft =tension stress in anchor bolt, psi

A =actual area of base plate,

A, = area required, base plate, in.

f; =ultimate 28-day strength, psi

f, =bearing pressure, psi

fl =equivalent bearing pressure, psi

Fb =allowable bending stress, psi

Ft =allowable tension stress, psi

F, =allowable compression stress, psi

E, =modulus of elasticity, steel, psi

E, =modulus of elasticity, concrete, psi

n =modular ratio, steel-concrete

n' =equivalent cantilever dimension of base plate, in.

B, =allowable bearing pressure, psi

M h =bending moment, in.-lb

2

K1,2,3 =factor

T=tension force in outermost bolt, lb

C =compressive load in concrete, lb

V =base shear, Ib

N =total number of anchor bolts

Nt =number of anchor bolts in tension

Ab =cross-sectional area of one bolt, in.

2

A, =total cross-sectional area of bolts in tension, in.2

(Y =coefficient

T, =shear stress

Calculations

e Axiul loading only, no moment.

Angle legs:

P

f --

- BD

L =greater of m, n, or n'

-

Beam legs:

P

A A-

- 0.7fL

- 0.95d

2

m=

Design of Vessel Supports 185

Assumed

load area

B E A M

A N G L E

For pipe legs;

m=

assume B =D

D - 0.707 W

2

P I P E

Figure 3-60. Dimensions and loadings of base plates.

B - 0.8d

2

n =

b - t,

2(d - 2tf)

CY=

or from Table 3-29

Pipe legs:

B - 0.707W

2

m=

0 Axid loud plus bending, load condition #I, full compres-

sion, up/$, e 5 D/6.

Eccentricity:

M D

P - 6

e=- <-

Loadings:

1

fl =P[l + A D2

6e(D - 2a)

Moment:

Thickness:

0 Axial load plus bending, loud condition #2, partial corn-

pre,rsion, up&, e >D/6.

Eccentricity:

M D

e =- - > -

P 6

186 Pressure Vessel Design Manual

Load Condition #1

Load Condition #2

I- =I- X

Full compression, no uplift, e 2 D/6 Partial compression, uplift, e >D/6

Figure 3-61. Load conditions on base plates.

Tabl e 3-29

Values of n for Beams

Tabl e 3-30

Average Properties of Concrete

Column Section

W14~73O- Wl 4~145

W14 x 132 - W14 x 90

W1 4 ~5 3 - W1 4 ~4 3

W1 2 ~3 3 6 - Wl 2 ~6 5

w14 x 82- w14 61

~1 2 x 5 8 - ~1 2 x 5 3

W12 x 50- W12 x 40

W10 x 11 2 - W10 x 49

n

5.77

5.64

4.43

4.77

4.27

3.61

3.92

3.68

Column Section

W10 x 45 -W10 x 33

wax 67- wa X 31

wa X 2a -wa X 24

W6 x 25 - W6 x 15

W6 x 16 -W6 x 9

W5 x 19 - W5 x 16

W4 x 13

n

3.42

3.14

2.77

1.77

1.91

1.53

-

2.38

Coefficient:

E

E,

n =2 (see Table 3-30)

Dimension:

f =0.5d+z

By trial and error, determine Y, effective bearing length,

utilizing factors K1-3.

Factors:

K I = 3(e +: )

Ult f; Allowable

Water 28-Day Compression, Allowable Coefficient,

ContenUBag Str (psi) F, (psi) B, (Psi) n

7.5 2000 aoo 500 15

6.75 2500 1000 625 12

6 3000 1200 750 10

5 3750 1400 938 a

Reprinted by permission of J ohn Wiley & Sons, Inc.

By successive approximations, determine distance Y.

Substitute K1-3 into the following equation and assume

an initial value of Y = A as a first trial.

Tension force:

D Y

_ - _ -

T=(- )P[b ---+f $ 1

2 3

Bearing pressure:

+ -=z f:,

YB

f, =

Design of Vessel Supports 187

tE - t iwv

B -1

I

B

Figure 3-62. Dimensions for base plates-beams.

Dimensions for Type 1+2) Bolt Base Plate Dimensions for Type 2-(4) Bolt Base Plate

Column Min Plate Max

Size D, in. 6, in. E, in. W, in. Thk, in. Bolt 4, in.

Column D, 6, G, E, W, Min Plate Max Bolt

Size in. in. in. in. in. Thk, in. 4, in.

w4 8 8 4 % % %

W6 8 8 4 % % 74

10 10 6 '/4 % 74

W10-33thru45 12 12 6 74

W10-49thru 112 13 13 6 5/16 74 1

W12- 40th~ 50 14 10 6 5/16 % 1

W12-53thru58 14 12 6 % 1

W12-65 thru 152 15 15 8 5/16 % 1%

1

W8

w4 10 10 7 7 2 %

W6 12 12 9 9 5/16 %

W8 15 15 11 11 % 74

W10-33thru45 17 15 13 11 YE 78

W10-49thru112 17 17 13 13 %

W12-53thru58 19 17 15 13 YE 1

W12-65thru152 19 19 15 15 % 1

W12-40thru50 19 15 15 11 1

1

1

1

174

174

1 Y2

1%

1 Y2

;w

Angle Legs Pipe Legs

Figure 3-63. Dimensions for base plates-angle/pipe.

188 Pressure Vessel Design Manual

Dimensions for Angle Legs

Dimensions for Pipe Legs

Min. Plate

Lea Size D X m Thk

~~

Min. Plate

Leg Size D E m Thk

L2 in. x 2 in. 4 in. 1.5 1 % in.

L2% in. x 2% in. 5 in. 1.5 1.25 % in.

L3 in. x 3 in. 6 in. 1.75 1.5 % in.

L4 in. x 4 in. 8 in. 2 2 % in.

L5 in. x 5 in. 9 in. 2.75 2 Y8 in.

L6 in. x 6 in. 10 in. 3.5 2 % in.

-~ ~ ~

3in. NPS 7% in. 4% in. 2.5 in. % in.

4in. NPS 8% in. 5% in. 2.7 in. % in.

6in. NPS 10 in. 7 in. 2.7 in. % in.

8in. NPS 11% in. 8% in. 2.7 in. ?, in.

loin. NPS 14 in. 10 in. 3.2 in. '/8 in.

12 in. NPS 16 in. 12 in. 3.5 in. 1 in.

Moment: I where M is greater of MT or M,.

x =0.5D +f - Y

Mt =TX

Y - a

fl = f c ( , )

Thickness:

0 Anchor bolts.

Without uplift: design anchor bolts for shear only.

V

Ts =&

With uplift: design anchor bolts for full shear and tension

force, T.

PROCEDURE 3-13

DESIGN OF LUG SUPPORTS

Notation

~~ ~ ~~

Q =vertical load per lug, lb

Qa =axial load on gusset, Ib

Qb =bending load on gusset, lb

n =number of gussets per lug

F, =allowable axial stress, psi

F1, =allowable bending stress, psi

f, =axial stress, psi

fb =bending stress, psi

A =cross-sectional area of assumed column, i n2

Z =section modulus, in.3

w =uniform load on base plate, lbhn.

E,=modulus of elasticity of vessel shell at design

E, =modulus of elasticity of compression plate at design

I =moment of inertia of compression plate, in.4

temperature, psi

temperature, psi

M h =bending moment, in.-lb

M, =internal bending moment in compression plate,

e =log base 2.71

in.-lb

K =spring constant or foundation modulus

=damping factor

Design of Vessel Supports 189

Design of Gussets

4 =Bolt

Single gusset

Fb=0.6Fy

hole diameter

Q, =Q sin 0

Q b =Q COS ti

L

--i f b

h

sin 0

m=-

Base plate

P

Double gusset

b sin 0

2

c=-

Figure 3-64. Dimensions and forces on a lug support.

Assume gusset thickness from Table 3-31.

Qd =Q sin 8

6

Q, =Q case

b si n8

c=-

2

A =t,C

F, =Q.4Fy

190 Pressure Vessel Design Manual

Design of Base Plate

Single Gusset

e Bending. Assume to be a simply supported beam.

e Bearing.

Q

a1

w=-

Wd'

Mb =-

2

e Thickness required base plate.

where Mk, is greater moment from bending or bearing.

4

Bearing

- w - Ib/in

Figure 3-65. Loading diagram of base plate with one gusset.

Double Gusset

e Bending. Assume to be between simply supported and

fixed.

Bending

e

*

Bearing

Iblin 9

Figure 3-66. Loading diagram of base plate with two gussets.

e Bearing.

e Thickness required base plate.

(b - 4)Fb

where Mb is greater moment from bending or bearing.

Compression Plate

Single Gusset

I '

\ R

Figure 3-67. Loading diagram of compression plate with one gusset.

Design of Vessel Supports 191

Assume thickness t, and calculate I and Z:

tcy3

I=--.

12

2

Z=t ' Y

6

f

Mx =q

<0.6FY

Mx

fb =-

Z

Note: These calculations are based on a beam on elastic

foundation methods.

Double Gusset

f =- Qe

2h

E,,t

K =-

H2

I = - - tcy3

12

p+ 4E,I

f

M - - [l +(e-Bx(cos Bx - sin Bx))]

-48

Bx is in radians. See Procedure 5-2.

Mx

Z

f b =- <0.6FY

A R

Figure 3-68. Loading diagram of compression plate with two gussets.

Table 3-31

Standard Lug Dimensions

X h t, =t b Capacity (b)

Type e b Y

1 4 6 2 6 6 % 23,500

2 4 6 2 6 9 7/16 45,000

3 4 6 2 6 12 Yi 45,000

70,000

70,000

70,000

5 5 7 2.5 7 18

4 5 7 2.5 7 15 9/16

%

7 6 8 3 a 24 % 100,000

I 1

6 5 7 2.5 7 21 4 6

192 Pressure Vessel Design Manual

PROCEDURE 3-14

DESIGN OF BASE DETAILS FOR VERTICAL VESSELS #1

[ 5, 10, 14, 18, 191

Notation

Ab =required area of anchor bolts,

Bd =anchor bolt diameter, in.

B, =allowable bearing pressure, psi (see

Table 3-35)

b, =bearing stress, psi

C =compressive load on concrete, lb

d =diameter of bolt circle, in.

db =hameter of hole in base plate of compres-

sion plate or ring, in.

FLT =longitudinal tension load, lb/in.

FL C = longitudinal compression load, lb/in.

F b =allowable bending stress, psi

F, =allowable compressive stress, concrete, psi

F, =allowable tension stress, anchor bolts, psi

F, =minimum specified yield strength, psi

fb=bending stress, psi

f, =compressive stress, concrete, psi

f, =equivalent tension stress in anchor bolts,

(see Table 3-35)

(see Table 3-33)

psi

Mb =overturning moment at base, in.-lb

M, =overturning moment at tangent line, in.-lb

M, =unit bending moment in base plate,

My =unit bending moment in base plate, radial,

circumferential, in. -lb/in.

in. -1 b/in .

H =overall vessel height, ft

6 =vessel deflection, in. (see Procedure 4-4)

M, =bending moment per unit length in.-lb/in.

N =number of anchor bolts

n =ratio of modulus of elasticity of steel to con-

P =maximum anchor bolt force, Ib

PI =maximum axial force in gusset, lb

E =joint efficiency of skirt-head attachment

R,=root area of anchor bolt, i n2 (see

crete (see Table 3-35)

weld

Table 3-32)

r =radius of bolt circle, in.

Wb=weight of vessel at base, lb

W, =weight of vessel at tangent line, lb

w = width of base plate, in.

Z1 =section modulus of skirt, in.3

S, =allowable stress (tension) of skirt, psi

S, =allowable stress (compression) of skirt, psi

G =width of unreinforced opening in skirt, in.

y1,yz =coefficients for moment calculation in com-

C,,CT,J ,Z,K =coefficients (see Table 3-38)

pression ring

S =code allowable stress, tension, psi

t, =equivalent thickness of steel shell which

T =tensile load in steel, lb

u =Poissons ratio, 0.3 for steel

B =code allowable longitudinal compressive

El =modulus of elasticity, psi

represents the anchor bolts in tension, in.

stress, psi

Design of Vessel Supports 193

Lap welded Butt welded

E =0.5

Pedestal

T

Small-diameter

vessels only

E =0.7

Shear ring or

slip band

Fi gure 3-69. Skirt types.

Type 3: Chairs

Conical

m

Type 1: Without gussets

h. =2 in.

c, =1 h in.

Bolt 6 +%in.

Ship loose

and attach

in field

7

lbyl

bolt 0 +1 in

Type 2: With gussets

hh - 2 in.

cmn e 1% in.

b

Type 4: Top ring

5 in. minimum

Bond+ 1i n.

Washer

& Boll +1 in.

Fi gure 3-70. Base details of various types of skirt-supported vessels.

194 Pressure Vessel Design Manual

Table 3-32

Bolt Chair Data

Table 3-35

Average Properties of Concrete

Y4-1 o 5.50 0.302 2 3.50 1.5

1-8 5.50 0.551 2 3.50 1.5

1 Ye-7 5.50 0.693 2 3.50 1.5

11/4-7 5.50 0.890 2 3.50 1.5

1 Y2-6 5.75 1.294 2.25 3.50 2

174-5 6.00 1.744 2.5 4.00 2.25

1%-5 6.25 2.049 2.63 4.00 2.5

24% 6.50 2.300 2.75 4.00 2.5

2'/,4'/2 7.00 3.020 3 4.50 2.75

2Y2-4 7.25 3.71 5 3.25 4.50 3

~7~4-4 7.50 4.618 3.50 4.75 3.25

3 4 8.00 5.621 3.75 5.00 3.50

7/8-9 5.50 0.419 2 3.50 1.5

17*+ 5.50 1.054 2.13 3.50 1.75

15/8-5'/2 5.75 1.515 2.38 4.00 2

Table 3-33

Number of Anchor Bolts, N

Skirt Diameter (in.) Minimum Maximum

24-36 4 4

42-54 4 8

6C-78 8 12

84-1 02 12 16

108-1 26 16 20

132-1 44 20 24

Table 3-34

Allowable Stress for Bolts, F,

Diameter Allowable Stress

Spec (in.) (KSO

A-307 All

A-36 All

A-325 c1-1/2"

A-449 c1"

1-1/8 to 1-112"

1-5/8 to 3'

20.0

19.0

44.0

39.6

34.7

29.7

Ult

28-Day Allowable

Water Str Compression, Fc Allowable Coefficient,

ContenVBag (psi) (Psi) B, (Psi) n

7.5 2000 800 500 15

6.75 2500 1000 625 12

6 3000 1200 750 10

5 3750 1400 938 8

Reprinted by permission of J ohn Wiley & Sons, Inc.

Table 3-36

Bending Moment Unit Length

~ ~_ _ _ _ _ _ _ _ _ _ _

0 0 -o.5fce2

0.333 0.0078fcb2 -o.428fce2

0.667 0.0558fcb2 -o.227fce2

1.5 0.123fcb2 -0.1 24fce2

2.0 0.1 31fcb2 -0.1 25fce2

3.0 0.1 33fcb2 -o.125fce2

cy, 0.1 33fcb2 -o.i25fcez

0.5 0.0293fcb2 -0.31 9fct2

1 .o 0.0972fcb2 -0.1 1 9fC@

Reprinted by permission of J ohn Wiiey & Sons, Inc.

Table 3-37

Constant for Moment Calculation, y1 and y2

bl e Y1 Y2

1 .o

1.2

1.4

1.6

1.8

2.0

cy,

0.565

0.350

0.21 1

0.125

0.073

0.042

0

0.135

0.115

0.085

0.057

0.037

0.023

0

Reprinted by permission of J ohn Wiley & Sons, Inc.

Table 3-38

Values of Constants as a Function of K

K C C ct J z K c c ct J z

0.1 0.852 2.887 0.766 0.480 0.55 2.113 1.884 0.785 0.381

0.15 1.049 2.772 0.771 0.469 0.6 2.224 1.765 0.784 0.369

0.2 1.218 2.661 0.776 0.459 0.65 2.333 1.640 0.783 0.357

0.25 1.370 2.551 0.779 0.448 0.7 2.442 1.510 0.781 0.344

0.3 1.510 2.442 0.781 0.438 0.75 2.551 1.370 0.779 0.331

0.35 1.640 2.333 0.783 0.427 0.8 2.661 1.218 0.776 0.31 6

0.4 1.765 2.224 0.784 0.416 0.85 2.772 1.049 0.771 0.302

0.45 1.884 2.113 0.785 0.404 0.9 2.887 0.852 0.766 0.286

0.5 2.000 2.000 0.785 0.393 0.95 3.008 0.600 0.760 0.270

Reprinted by permission of J ohn Wiley & Sons, Inc.

Design of Vessel Supports 195

1 - TRIAL 1

ANCHOR BOLTS: EQUIVALENT AREA METHOD

T d

%--

F.G

%IN

R, (Table3-33)

Use( )

wb I I

2 Approximate K Udng Alkrrrbba Coefflclents

cc

1

IK--

1 +I?. Ct

nFc J

I 2

Jd I

4 Number of Anchor Bohr Rwulrsd

I I

8 Cunprowtve Lo8d In Concrete

7 Stroaa In Comrete

C =T +Wb I

I

8 Fiecheck K UJ ng Actual f.8nd 1,

K--

1

1 +L

1. Cakulrte rellmlna K valuo bud on a l h b k r .

2. Make prdkl nrry &tion of anchor bdtr and width of baw

d.tr

3. &k&e h d S and w-.

4. Cakukto K baaed on actual *oases and compare wl t h valuo

od In Stop 2.

5. EG encr excoeds .01, aoloct a new K batweon both vahm and

rOPO.1 S t v 2-6. (W Note 6.)

I

TRIAL 2

I1 Data

12 Approxlmate K UJng Alkwabba

I

3 Tendk Load In Steel

4 Number of Anchor Bo b Required

in.2

bolts

5 Stress In Equlvaknt Steal Band

6 Compre8dvo Load In Concrete

7 Strem In Concrete

I

See example of completed form on nexl page.

196 Pressure Vessel Design Manual

ANCHOR BOLTS: EQUIVALENT AREA METHOD EXAMPLE

33b.7

4 Number of Anchor Bdtr Required

PROCEDURE

TRIAL 1

I

I p c = Mi64

I

I Tendk Load In Steal

r - - .-.- .

I Numkr of Anchor Bolts Raaulrod

1. Calculate rei hi nar K value bsmd on ai kwabks.

2. Make p r el h f wy w L k n of anchor bolts and width of bsse

3. %%ate loads and stresses.

4. Calculate K based on actucrl stresses and compare with vrlue

ed In Step 2.

5. iT~ence ex- .o1, wlsct a new K between both valuer and

repeat Steps 2-8. (See Note 6.)

I TRIAL 2

I12 Approxinuto K Udng A l k waMr

I

I

I3 Tmdb Load in Steel

Design of Vessel Supports 197

bIfcf x .E

M Maximum

bearing load

fc P1

Figure 3-71. Loading diagram of base plate with gussets and chairs.

Type 1: Without Chairs or Gussets

K =from Anchor Bolts.

e =

f, =from Anchor Bolts.

d=

e Bending moment per unit length.

M, =0.5f,12

e Maximum bearing load.

2Kd +w

b, =f c( 2Kd ) i B, (see Table 3-35)

e Thickness required.

Type 2: With Gussets Equally Spaced, Straddling

Anchor Bolts

e With same number as anchor bolts

nd

b=-

N

c

b

-

M,=greater of M, or My from Table 3-36

/6M,

tb =\ig

Figure 3-72. Dimensions of various base plate configurations.

e With twice as many gussets as anchor bolts.

nd

2N

c

b

b =-

-

M, =greater of M, or My from Table 3-36

Type 3 or 4: With Anchor Chairs or Full Ring

e Between gussets.

P =F,R,

Pb

M=8

198 Pressure Vessel Design Manual

0 Between chairs

M, =greater of M, or My from Table 3-36

Top Plate or Ring (Type 3 or 4)

e Minimum required height of unchor chair (Type 3 or 4) .

hlllin =7.296d <18in.

H

0 Minimum required thickness of top plate of unchor chair.

Top plate is assumed as a beam, e x A with partially ftved

ends and a portion of the total anchor bolt force P/3,

distributed along part of the span. (See Figure 3-73.)

0 Bending moment, M,, in top ring (Type 4).

b

e

-

y1= (see Table 3-37)

y2 =(see Table 3-37)

1. If a =t / 2 and b/e >1, My governs

M, =p 4n [(1+u)log@ +(1 - n)]

2. If a #U2 but b/e >1, My governs

3. If b/e <1. invert b/e and rotate axis X-X and Y-Y 90"

4n

r D 1

Figure 3-73. Top plate dimensions and loadings.

Washers

X

Figure 3-74. Compression plate dimensions.

0 Minimum required thickness of top ring (Type 4).

Gusset s

e Type 2. Assume each gusset shares load with each adjoin-

ing gusset. The uniform load on the base is fc, and the area

supported by each gusset is x b. Therefore the load on

the gusset is

PI=f,Cb

Thickness required is

tg =

Pi(6a - 2e)

Fhe2

e Type 3 or 4.

3

>- in.

P

t --

' - 18,000e 8

Design of Vessel Supports 199

Skirt

0 Thickness required in skirt at compression plate or ring

due to muximum bolt load reaction.

For Type 3:

- 1 .0

For Type 4:

Consider the top compression ring as a uniform ring with

N number of equally spaced loads of magnitude.

Pa

h

-

See Procedure 5-1 for details.

The moment of inertia of the ring may include a portion of

the skirt equal to 16t,k on either side of the ring (see

Figure 3-75).

0 Thickness required at opening of skirt.

Note: If skirt is stiffened locally at the opening to compen-

sate for lost moment of inertia of skirt cross section, this

portion may be disregarded.

G= width of opening, in.

1 48Mh

f b =n D - 3 G [ o +Wh]

Actual weights and moments at the elevation of the open-

ing may be substituted in the foregoing equation if

desired.

P[a,,

Pa

h

-

Pa

h

-

h / I I 1

Figure 3-75. Dimensions and loadings on skirt due to load P.

Skirt thickness required:

f b fl,

4,640,000

whichever is greater

Determine allowable longitudinal stresses.

Tension

St =lesser of 0.6F, or 1.33s

Compression

S, =0.333 F,

=1.33 x factor B

tskEl

--

-

16 R

=1.33s

whichever is less.

Longitudinal forces

Skirt thickness required

whichever is greater.

0 Thickness required at skirt-head attachment due to Mt .

Longitudinal forces

Skirt thickness required

FL C

or 0.707SCE

F LT

tsk =0.707 StE

whichever is greater.

200 Pressure Vessel Design Manual

Notes

~~

1. Base plate thickness:

0 If t 5 & in., use Type 1.

0 If

0 If t >3 in., use Type 3 or 4.

2. To reduce sizes of anchor bolts:

in. <t 5 3 in., use Type 2.

0 Increase number of anchor bolts.

0 Use higher-strength bolts.

0 Increase width of base plate.

3. Number of anchor bolts should always be a multiple of

4. If more anchor bolts are required than spacing

allows, the skirt may be angled to provide a larger

bolt circle or bolts may be used inside and outside of

the skirt. Arc spacing should be kept to a minimum if

possible.

4. The base plate is not made thinner by the addition of a

compression ring. th would be the same as required for

chair-type design. Use a compression ring to reduce

induced stresses in the skirt or for ease of fabrication

when chairs become too close.

5 . Dimension a should be kept to a minimum to reduce

induced stresses in the skirt. This will provide a more

economical design for base plate, chairs, and anchor

bolts.

6. The value of K represents the location of the neutral

axis between the anchor bolts in tension and the con-

crete in compression. A preliminary value of K is esti-

mated based on a ratio of the allowable stresses of the

anchor bolts and concrete. From this preliminary value,

anchor bolt sizes and numbers are determined and

actual stresses computed. Using these actual stresses,

the location of the neutral axis is found and thus an

actual corresponding K value. A comparison of these

K values tells the designer whether the location of the

neutral axis he assumed for selection of anchor bolts

was accurate. In successive trials, vary the anchor bolt

sizes and quantity and width of base plate to obtain an

optimum design. At each trial a new K is estimated and

calculations repeated until the estimated K and actual

K are approximately equal. This indicates both a

balanced design and accurate calculations.

7 . The maximum compressive stress between base plate

and the concrete occurs at the outer periphery of the

base plate.

8. For heavy-wall vessels, it is advantageous to have the

center lines of the skirt and shell coincide if possible.

For average applications, the O.D. of the vessel and

O.D. of the skirt should be the same.

9. Skirt thickness should be a minimum of R/200.

PROCEDURE 3-15

DESIGN OF BASE DETAILS FOR VERTICAL VESSELS #2

Notation

~

E =joint efficiency

E 1 =modulus of elasticity at design temperature, psi

AI, =cross-sectional area of bolts, in.2

d =diameter of bolt circle, in.

Wl, =weight of vessel at base, lb

WT =weight of vessel at tangent line, Ib

w =width of base plate, in.

S =code allowable stress, tension, psi

N =number of anchor bolts

F: =allowable bearing pressure, concrete, psi

F, =minimum specified yield stress, skirt, psi

F, =allowable stress, anchor bolts, psi

fLT = axial load, tension, Ib/in.-circumference

fIdc =axial load, compression, lb/in.-circumference

FT =allowable stress, tension, skirt, psi

F, =allowable stress, compression, skirt, psi

Fl, =allowable stress, bending, psi

f, =tension force per bolt, lb

f, =bearing pressure on foundation, psi

Mb =overturning moment at base, ft-lb

MT =overturning moment at tangent line, ft-lb

Allowable Stresses

*0.6F, =

1.33s =

FT =lesser of

F, = lesser of

*0.333FY =

1.33 Factor B =

tskEl -

0 - -

16 R

1.33s =

Design of Vessel Supports 201

Bun welded Lap welded

E =0.7 E =0.5

at= IT/, in. 2 i n. llh in.? Minimums

-

1% =YIS in. minimum

3 x 3 x % in.

minimum

Ih-1 in.

Figure 3-76. Typical dimensional data and forces for a vertical vessel

supported on a skirt.

Fk =500 psi for 2000 lb concrete

750 psi for 3000 lb concrete

O.125tsk -

Factor A =~ -

R

Factor B =from applicable material

chart of ASME Code, Section 11,

Part D, Subpart 3

Anchor Bolts

a Force per bolt due to uplift.

e Required bolt area, Ah.

Ab = - = f S

Fs

Use ( ) diameter bolts

Note: Use four %-in.-diameter bolts as a minimum.

Base Plate

a Bearing pressure, fc (average at bolt circle).

e Required thickness of base plate. th.

Skirt

e Longitudinal forces, f L T and fLc.

48Mb Wb

fLT =- - -

fLC =( - 1 7 - -

rD2 XD

48Mb Wb

r D TD

Notes

1. This procedure is based on the neutral axis method

and should be used for relatively small or simple ver-

tical vessels supported on skirts.

2. If moment ML is from seismic, assume Wb as the oper-

ating weight at the base. If Mb is due to wind, assume

empty weight for computing the maximum value of fLT

and operating weight for fLc.

202 Pressure Vessel Design Manual

e Thicknew required of skirt at base plate, t&.

I

f LT

t,k =greater of - =

FT

f1,C

or - =

FC

e Tliickries~ reyiiiretl of skirt at skirt-head attachment.

Longitudinal forces:

Thickness required:

~L T -

0.707 FTE -

t,k =greater of

0.707 FcE -

or

REFERENCES

1.

2 .

3.

4.

5.

6.

-

1 .

8.

9.

10.

11.

12.

ASCE 7-95, Minimum Design Loads for Buildings

and Other Structures, American Society of Civil

Engineers.

Recommended Practice #11, Wind and Earthquake

Design Standards, Chevron Corp., San Francisco,

CA, March 1985.

Unqororni Building Code, 1997 Edition, International

Conference of Building Officials, Whittier, CA, 1997.

Bednar, H. H., Pressure Vessel Design Handbook, Van

Nostrand Reinhold Co., 1981, Section 5.1.

Brownell, L. E., and Young, E. H., Process Equipment

Verign, Tohn Wiley and Sons, Inc., 1959, Section 10.2~.

Fowler, D. W., New Analysis Method for Pressure

Vessel Column Supports, Hydrocarbon Processing,

May 1969.

Manual of Steel Construction, 8th Edition, American

Institute of Steel Construction, Inc., 1980, Tables

C1.8.1 and 3-36.

hark, R. J ., Fomnulns fi)r Stress and Strain, 4th

Edition, McGraw Hill, 1971, Table VIII, Cases 1, 8, 9

and 18.

Wolosewick, F. E., Support for Vertical Pressure

Vessels, Petroleum Refiner, J uly 1981, pp. 137-140,

Blodgett, O., Design of Weldments, The J ames F.

Lincoln Arc Welding Foundation, 1963, Section 4.7.

Local Stresses in Spherical and Cylindrical Shells Due

to External Loadings, WRC Bulletin #107, 3rd revised

printing, April 1972.

Bijlaard, P. P., Stresses from Radial Loads and

External Moments in Cylindrical Pressure Vessels,

August 1981, pp. 101-108.

13.

14.

15.

16.

17.

18.

19.

20.

21.

Welding Journal Research Supplement, December

Bijlaard, P. P., Stresses from Radial Loads and

External Moments in Cylindrical Pressure Vessels.

Welding Journal Research Supplement, December

Megyesy, E. F., Pressure Vessel Handbook, 3rd Edition,

Pressure Vessel Handbook Publishing Co., 1975, pp.

72-85.

Zick, L. P., Stresses in Large Horizontal Cylindrical

Pressure Vessels on Two Saddle Supports, Welding

Research Journal Supplement, September 1951.

Moody, G. B., How to Design Saddle Supports,

Hydrocarbon Procesing, November 1972.

Wolters, B. J ,, Saddle Design-Horizontal Vessels

over 13 Feet Diameter, Fluor Engineers, Inc.,

Irvine, CA, 1978.

Committee of Steel Plate Producers, Steel Plate

Engineering Datu, Volume 2, Useful Information on

the Design of Plate Structures, American Iron and

Steel Institute, Part VII.

Gartner, A. I ., Nomographs for the Solution of Anchor

Bolt Problems, Petroleum Refiner, J uly 1951, pp.

101-106.

Manual of Steel Construction, 8th Edition, American

Institute of Steel Construction, Inc., 1980, Part 3.

Blodgett, O., Design of Welded Structures, The J ames

F. Lincoln Arc Welding Foundation, 7th printing, 1975,

Section 3. 3.

1955, pp. 608-617.

1954, pp. 615-623.

También podría gustarte

- Pressure Vessel and Stacks Field Repair ManualDe EverandPressure Vessel and Stacks Field Repair ManualCalificación: 4 de 5 estrellas4/5 (4)

- The Stress Analysis of Pressure Vessels and Pressure Vessel Components: International Series of Monographs in Mechanical EngineeringDe EverandThe Stress Analysis of Pressure Vessels and Pressure Vessel Components: International Series of Monographs in Mechanical EngineeringS. S. GillCalificación: 3.5 de 5 estrellas3.5/5 (3)

- Design of Saddle Support For Horizontal Pressure VesselDocumento5 páginasDesign of Saddle Support For Horizontal Pressure Vesselsebastian9033100% (1)

- Lug Support DesignDocumento11 páginasLug Support Designimrancenakk100% (6)

- Skirt Support DesignDocumento8 páginasSkirt Support Designimrancenakk100% (2)

- Load Cases and How They Are Handled by PV EliteDocumento7 páginasLoad Cases and How They Are Handled by PV Elitearmvasi100% (1)

- Saddle CalculationDocumento7 páginasSaddle CalculationMichael HaiseAún no hay calificaciones

- WRC 107Documento2 páginasWRC 107mit1111chinAún no hay calificaciones

- PV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Documento32 páginasPV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Priyo Jati WahyonoAún no hay calificaciones

- Basic PV Elite TrainingDocumento54 páginasBasic PV Elite TrainingMinh Tran100% (3)

- Saddle 1Documento3 páginasSaddle 1RUDHRA DHANASEKARAún no hay calificaciones

- Tutorial of WRC 107 For TrunnionDocumento9 páginasTutorial of WRC 107 For TrunnionAlvin SmithAún no hay calificaciones

- Zick Analysis For Saddle SupportDocumento8 páginasZick Analysis For Saddle Supportfuransu777100% (1)

- WRC107 297Documento4 páginasWRC107 297MasoodMiyanAún no hay calificaciones

- Lug SupportDocumento2 páginasLug SupportSachin5586Aún no hay calificaciones

- WRC 107 CalculationsDocumento4 páginasWRC 107 CalculationsSakthi VelAún no hay calificaciones

- Local Stresses WRC107Documento19 páginasLocal Stresses WRC107naeand67% (3)

- Saddle AnalysisDocumento17 páginasSaddle AnalysisAntonio Perez Zornoza100% (1)

- Calcu Nozzle NeckDocumento15 páginasCalcu Nozzle Necksachmaya0% (1)

- WRC Load AnalysisDocumento5 páginasWRC Load Analysisyogacruise100% (1)

- Saddle DesignDocumento6 páginasSaddle DesignPankajDhobleAún no hay calificaciones

- Hemispherical Head Design Tool: Pressure Vessel Engineering LTDDocumento1 páginaHemispherical Head Design Tool: Pressure Vessel Engineering LTDExsan OthmanAún no hay calificaciones

- Nozzle FEA CalculationDocumento64 páginasNozzle FEA CalculationberylqzAún no hay calificaciones

- Sample Design Calculation - Vessel Supported On LugsDocumento4 páginasSample Design Calculation - Vessel Supported On LugsAbhay Upadhyay0% (1)

- Horizontal Vessel Loading Calculation ProcedureDocumento20 páginasHorizontal Vessel Loading Calculation ProcedurepandianAún no hay calificaciones

- Saddle Reaction Summary - For Empty CaseDocumento12 páginasSaddle Reaction Summary - For Empty CasesridharAún no hay calificaciones

- Flat Plate - Roark & YoungDocumento15 páginasFlat Plate - Roark & YoungPrasad Pingle0% (1)

- PV Elite WebinarDocumento24 páginasPV Elite WebinarAndrea Hank LattanzioAún no hay calificaciones

- Pressure Vessel Design and AnalysisDocumento30 páginasPressure Vessel Design and AnalysisAlok SaxenaAún no hay calificaciones

- Saddle 3Documento3 páginasSaddle 3RUDHRA DHANASEKAR100% (1)

- SaddlesDocumento14 páginasSaddlescoldness_13Aún no hay calificaciones

- Pressure Vessel Design - Guides and ProceduresDocumento71 páginasPressure Vessel Design - Guides and Proceduresmatteo_123482% (62)

- Pressure Vessels Field Manual: Common Operating Problems and Practical SolutionsDe EverandPressure Vessels Field Manual: Common Operating Problems and Practical SolutionsCalificación: 4 de 5 estrellas4/5 (12)

- Design of Circular DomesDocumento8 páginasDesign of Circular Domesrshyams100% (1)

- Anchor ChairDocumento3 páginasAnchor ChairrsubramaniAún no hay calificaciones

- Silletas - Tanques API Metodo AISCDocumento5 páginasSilletas - Tanques API Metodo AISCHEINER_PAún no hay calificaciones

- Topic2 FatigueDocumento36 páginasTopic2 Fatigue777894292Aún no hay calificaciones

- AISI - Anchor Chair DesignDocumento3 páginasAISI - Anchor Chair DesignJoséSebastián86% (7)

- Portland Cement AssociationDocumento23 páginasPortland Cement AssociationDhm KrinisAún no hay calificaciones

- 3 Saddle SupportsDocumento15 páginas3 Saddle Supportswasif78Aún no hay calificaciones

- Tubular Truss ExampleDocumento12 páginasTubular Truss ExampleMock Khang Hi100% (1)

- Zick Analysis of SaddlesDocumento6 páginasZick Analysis of SaddlesVitor OlivettiAún no hay calificaciones

- Pressurised Systems: Vessel With Various Types of Stiffeners Located in The Cylindrical & Conical PartsDocumento9 páginasPressurised Systems: Vessel With Various Types of Stiffeners Located in The Cylindrical & Conical PartsJoemarie Martinez100% (1)

- Chapter 7Documento30 páginasChapter 7momanonaAún no hay calificaciones

- Fea Report Rev 4Documento16 páginasFea Report Rev 4Tauqeer AhmedAún no hay calificaciones

- Me 16 Achapter 2Documento43 páginasMe 16 Achapter 2trulyyoursAún no hay calificaciones

- ME301chapter10 PDFDocumento28 páginasME301chapter10 PDFPablo De Lera RodríguezAún no hay calificaciones

- Chap06 Fatigue PDFDocumento30 páginasChap06 Fatigue PDFAlex IskandarAún no hay calificaciones

- 2:5 Design For Cyclic Loading: 1. Completely Reversing Cyclic Stress and Endurance StrengthDocumento8 páginas2:5 Design For Cyclic Loading: 1. Completely Reversing Cyclic Stress and Endurance StrengthasmauzumAún no hay calificaciones

- Exp 6Documento23 páginasExp 6Ruban AvadiarAún no hay calificaciones

- Fatigue IDocumento22 páginasFatigue IamdevaAún no hay calificaciones

- Report Fatigue PDFDocumento21 páginasReport Fatigue PDFHassan Aero100% (1)

- Fatigue Failures of Welded Conveyor DrumsDocumento11 páginasFatigue Failures of Welded Conveyor DrumsWashington MoraisAún no hay calificaciones

- Unit 5Documento8 páginasUnit 5Dalton ChanAún no hay calificaciones

- Strut BucklingDocumento9 páginasStrut BucklingEvonYong100% (1)

- FatigueDocumento18 páginasFatigueykhamidi3889Aún no hay calificaciones

- Mechanical SpringsDocumento33 páginasMechanical SpringsAhmedOMAún no hay calificaciones

- Stresses in Flywheel RimDocumento16 páginasStresses in Flywheel RimHarikumar A100% (1)

- Helical Extension SpringsDocumento10 páginasHelical Extension SpringsDhatchina MoorthyAún no hay calificaciones

- Soil Mechanics - Stress and StrainDocumento50 páginasSoil Mechanics - Stress and Strainujosec6138Aún no hay calificaciones

- Guy Mast AnalysisDocumento9 páginasGuy Mast AnalysisAndreea LucaAún no hay calificaciones

- Wire Rope-Steel TechnicalDocumento37 páginasWire Rope-Steel TechnicalAndreea LucaAún no hay calificaciones

- Hollow Section capacities-AS4100Documento182 páginasHollow Section capacities-AS4100Andreea LucaAún no hay calificaciones

- International Steel Grade Comparison ChartDocumento1 páginaInternational Steel Grade Comparison Chart마사유삼숟딘Aún no hay calificaciones

- Hollow Section capacities-AS4100Documento182 páginasHollow Section capacities-AS4100Andreea LucaAún no hay calificaciones

- STAAD (X) Tower TutorialsDocumento54 páginasSTAAD (X) Tower TutorialsAndreea Luca100% (2)

- Hollow Section capacities-AS4100Documento182 páginasHollow Section capacities-AS4100Andreea LucaAún no hay calificaciones

- Business Proposal New VentureDocumento18 páginasBusiness Proposal New VentureBramhananda ReddyAún no hay calificaciones

- Permatex, Inc - Ultra Gasket Sealant 1ozDocumento3 páginasPermatex, Inc - Ultra Gasket Sealant 1ozjaredf@jfelectric.comAún no hay calificaciones

- Parle G ReportDocumento7 páginasParle G ReportnikhilAún no hay calificaciones

- XII Biology Practicals 2020-21 Without ReadingDocumento32 páginasXII Biology Practicals 2020-21 Without ReadingStylish HeroAún no hay calificaciones

- Form No. 2E Naya Saral Naya Saral Its - 2E: (See Second Proviso To Rule 12 (1) (B) (Iii) )Documento2 páginasForm No. 2E Naya Saral Naya Saral Its - 2E: (See Second Proviso To Rule 12 (1) (B) (Iii) )NeethinathanAún no hay calificaciones

- Arc Welding Rod Chart byDocumento1 páginaArc Welding Rod Chart bytayyab aliAún no hay calificaciones

- Ans Sheet Chemical 23111Documento96 páginasAns Sheet Chemical 23111Aejaz MujawarAún no hay calificaciones

- Chapter 2 - Alkanes PDFDocumento54 páginasChapter 2 - Alkanes PDFSITI NUR ALISSA BINTI AHMAD RASMANAún no hay calificaciones

- Pathology SEQ Answers - Adaptive Responses & Cell InjuryDocumento7 páginasPathology SEQ Answers - Adaptive Responses & Cell InjurysugandiAún no hay calificaciones

- Importance of The On Board Crew Trainings and Drills For The Improvement of The Vessels' SafetyDocumento8 páginasImportance of The On Board Crew Trainings and Drills For The Improvement of The Vessels' SafetyilgarAún no hay calificaciones

- Reviewer Crim 3 FinalsDocumento6 páginasReviewer Crim 3 FinalsMaria Rafaella P. DadoAún no hay calificaciones

- Pamphlet InsideDocumento1 páginaPamphlet Insideapi-2408549370% (1)

- Tokyo Fact SheetDocumento17 páginasTokyo Fact Sheethoangnguyen2401Aún no hay calificaciones

- Assignment 1 Front SheetDocumento9 páginasAssignment 1 Front SheetBách PhạmAún no hay calificaciones

- Mechanical Pumps: N. HilleretDocumento12 páginasMechanical Pumps: N. HilleretAmrik SinghAún no hay calificaciones

- GST15!16!17-Bad Debt Relief RecoverDocumento10 páginasGST15!16!17-Bad Debt Relief RecoverDaud Farook IIAún no hay calificaciones

- General Leasing and Managing AuthorityDocumento14 páginasGeneral Leasing and Managing AuthorityKatharina SumantriAún no hay calificaciones

- Cystostomy NewDocumento32 páginasCystostomy Newkuncupcupu1368Aún no hay calificaciones

- Two Drugs Are No More Effective Than One To Treat Common Kidney DiseaseDocumento3 páginasTwo Drugs Are No More Effective Than One To Treat Common Kidney DiseaseGlogogeanu Cristina AndreeaAún no hay calificaciones

- KDIGO 2023 CKD Guideline Public Review Draft 5 July 2023Documento339 páginasKDIGO 2023 CKD Guideline Public Review Draft 5 July 2023oscar coreaAún no hay calificaciones

- D435L09 Dental Trauma-2C Cracked Teeth - 26 Root FractureDocumento73 páginasD435L09 Dental Trauma-2C Cracked Teeth - 26 Root FractureD YasIr MussaAún no hay calificaciones

- Mary Kay FinalDocumento17 páginasMary Kay Finalharsh0695Aún no hay calificaciones

- Mammalian Temperature Regulation - 12Documento13 páginasMammalian Temperature Regulation - 12wadson chirwaAún no hay calificaciones

- CV TemplateDocumento5 páginasCV TemplateLopezDistrict FarmersHospitalAún no hay calificaciones

- Case StudyDocumento3 páginasCase StudyMarlon MagtibayAún no hay calificaciones

- CSA11 CholelithiasisDocumento3 páginasCSA11 CholelithiasisBerlon LacsonAún no hay calificaciones

- Fire CodeDocumento1 páginaFire CodeShainette VillarazaAún no hay calificaciones

- National Vital Statistics Reports: Births: Final Data For 2019Documento51 páginasNational Vital Statistics Reports: Births: Final Data For 2019Simon ReichAún no hay calificaciones

- Victron Orion-Tr - Smart - DC-DC - Charger-Manual Non IsolatedDocumento19 páginasVictron Orion-Tr - Smart - DC-DC - Charger-Manual Non IsolatedThomist AquinasAún no hay calificaciones

- TEC3000 Series On/Off or Floating Fan Coil and Individual Zone Thermostat Controllers With Dehumidification CapabilityDocumento48 páginasTEC3000 Series On/Off or Floating Fan Coil and Individual Zone Thermostat Controllers With Dehumidification CapabilityIvar Denicia DelgadilloAún no hay calificaciones