Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Thermodynamics of Petroleum Mixtures Containing Heavy Hydrocarbons. 3. Efficient Flash Calculation Procedures Using The Equation State

Cargado por

Michael ParkerTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Thermodynamics of Petroleum Mixtures Containing Heavy Hydrocarbons. 3. Efficient Flash Calculation Procedures Using The Equation State

Cargado por

Michael ParkerCopyright:

Formatos disponibles

948 Ind. Eng. Chem. Process Des. Dev.

1985, 2 4 , 948-954

Literature Cited

Bromely, L. A. A I CM J . 1973, 19, 313.

Chen. C. C.: Britt. H. I. : Boston. J . F.: Evans, L. B. AIChE J . 1982, 28. 588.

Robinson, D. R.; J encks, W. P. J . Am. Chem. SOC. 1965, 87, 2462.

Rudakov, E. S.; Lutsyk, A. I . Russ. J . Phys. Chem. 1979, 53, 731.

Setschenows .1- J . z . . Stoechiom. Verwandfschaftsl 1889* 4 ,

I I I .

Gamble, D. S. can. J.. Chem. 1967; 45, 2805.

auque, w. F.; hnung, E. w.; Kunzler, J, E,; Rubin, T, R, J , A ~ , them,

Soc. 1980, 82, 62.

Gordon, J . E. The Organic Chemlstry of Electrolytes; Wiley-Interscience:

New York, 1975; Chapter 1.

Hanson, C.; Ismail, H. A. M. J . Appi. Chem. Biotechnol. 1975, 25, 319.

ed.; Wlley: New York, 1969; Val. 19, p 441.

Librovich, N. 8.; Zarakhani. N. G.; Vlnnik, M. I. Russ. J . Phys. Chem. 1971,

45, 1257.

Libr, M, Reaction ~chenisms in Sulfwic Acid and Saong Acid

Solutions; Academlc Press: New York, 1971; p 19.

Moeller, T. Inorganic Chemistry; Wlley: New York, 1952: p 532.

Munro, D. C. Appl . Specwosc. 1968, 22, 199.

PRzer, K. S.; Roy, R. N.; Sylvester, L. F. J . Am. Chem. SOC. 1977, 99,

Wagman, D. D.; Evans, W. H.; Parker, V. 8.: Schumm, R. H.; Halow, I.;

Bailey, S. M.; Churney, K. L.; Nutail, R. J . J . Phys. Chem. Ref. Data

1982, 1 1 , 1.

Young, T. F.; Maranviile, L. F.; Smith, H. M. I n The Structure of Electrolytic

Solutions; Hamer, W. J ., Ed.; Wiley: New York, 1959; Chapter 4.

Zemaitis, J . F. I n Thermodynamics of Aqueous Solutions with Industrial

Applications, ACS Symposium Series No. 133; Newman, S., Ed.; Ameri-

can Chemical Soclety: Washington, D.C.. 1980; Chapter 10.

Zemaitis, J . F. Chem. Solve., Inc., Morristown, NJ , personal communication,

1982.

Received f or review March 7 , 1983

Accepted October 25, 1984

Kirk, R, E,; mmr, D. F, ~n ~ ~ ~ ~ ~ l o ~ e d ~ of Chemical Technow-, 2nd

Zarakhani, N. G.; Vinnik, M. I. RUSS. J. PhYS. Chem. 1963, 37, 260.

AQ3n

Ridd&J. A.; Bunger, W. 6. Organic Solvents, Physical Properties and

~et hods of Purification, 3rd ed.; Wiley-Interscience: New york. 1970; p Presented at the AIChE Annual Meeting, LOS Angeles, CA, Nov

78. 1982. Sessions on Computers in Process Design and Analysis.

Thermodynamics of Petroleum Mixtures Containing Heavy

Hydrocarbons. 3. Efficient Flash Calculation Procedures Using the

SRK Equation of State

Karen Schou Pedersen, t S Per Thomassen, and Aage Fredenslund

Instftuttet for Kemiteknik, Danmarks Teknlske H oj skol e, DK-2800 Lyngby, Denmark, and STA TOIL, Den Norske Stats

Oljeselskap as , N-400 7 Stavanger, Norway

Two methods for drastically reducing oil/gas flash calculation computing times using the SRK equation of state

are described. (1) The characterization procedure given in parts 1 and 2 of this series has been extended with

a procedure for grouping hydrocarbon fractions. The predictions of the phase behavior using a total of only six

hydrocarbon fractions (C1-C30+) are as accurate as when 40 hydrocarbon fractions are used. (2) The above-

mentioned characterization procedure uses binary interaction coefficients (kt values) equal to zero for all hydro-

carbon-hydrocarbon interactions. In naturally occurring oil and gas systems, the contents of non-hydrocarbons

(mainly N, and COP) are often below 10 mol % . For such mixtures it isfound that using kt =0 for all interactions

(also with the non-hydrocarbons) has virtually no effect onthe calculated results. Explicit useof the assumption

of zero ki / values leads to substantial savings in the flash calculation computer time.

Introduction

The first two articles of this series (Pedersen et al.,

1984a,b) presented a characterization method for heavy

hydrocarbons that, when applied with the SRK equation

of state, permits accurate predictions of the phase behavior

of the phase equilibria in gas condensates and heavy oils.

About 40 hydrocarbon fractions (pseudocomponents) were

used to represent a petroleum mixture. However, in many

practical applications, such as oil reservoir computer sim-

ulation studies and two-phase flow calculations, it is not

possible to include such a large number of components in

the calculations. In this work, methods for reducing the

number of pseudocomponents are investigated.

Not only computer storage facilities but also computing

time may be limiting factors. Michelsen and Heidemann

(1981) have shown that the computing time needed to

calculate a critical point by using a cubic, two-constant

I nstituttet for Kemiteknik.

*Present address: Calsep Aps, Lyngby Hovedgade 29, DK-2800

8 STATOIL.

Lyngby, Denmark.

equation of state can be considerably reduced if all the

binary interaction coefficients ( ki j values) are equated to

zero. Similar computational advantages exist in two-phase

flash calculations (Michelsen, 1983). The consequences

of using kij values equal to zero are examined with respect

to computing time and accuracy for oil/gas systems.

Data

In order to develop the procedure for reducing the

number of pseudocomponents and to study the effect of

that and the effect of equating the kij values to zero, it is

necessary to have available reliable analytical, volumetric,

and phase equilibrium data for many different gas con-

densates and heavy oils. Such data and procedures for

obtaining the data are given by Pedersen et al. (1984a,b).

Two additional analytical techniques have recently been

introduced. By use of vacuum distillation at a pressure

of 130 N/m2, the end point of the TBP distillation has

been extended approximately from CZ0 to Cs0. Enough

carbon number fraction is collected to permit measure-

ments of specific gravity and molecular weight. In addi-

tion, the PNA analysis has been improved. A liquid-liquid

chromatographic method which on a preparative scale

0196-4305/85/1124-0948$01.50/0 0 1985 American Chemical Society

Ind. Eng. Chem. Process Des. Dev., Vol. 24, No. 4, 1985 949

splits each carbon number fraction into a paraffinic (P)

+naphthenic (N) fraction and an aromatic (A) fraction

is used. Refractive indices are used to determine the

relative amounts of P and N. (For further details see

Pedersen et al., 1984a.)

Three analytical data sets on North Sea reservoir fluids

are listed in Table VII. Sample A is a typical gas con-

densate for which TBP data are available up to C30+.

Sample B is a heavy oil and sample C a heavy gas con-

densate. The Cg-Cm fractions of sample C have been split

in a P +N and an A fraction.

The data given in Table VI1may be used to characterize

the reservoir fluids as recommended by Pedersen et al.

( 1984a).

Recommended Characterization Procedure for the

SRK Equation of State

The components of a reservoir fluid may be classified

as follows: defined components for which there exists a

quantitative GC analysis and for which T,, P,, and w are

known; TBP fractions covering the true boiling point

fractions between C7 and ca. Cs0, each containing many

different components. Careful analysis has shown that for

the North Sea oils, the best results were obtained by using

the Cavett (1964) relations for T, and P,

T, =768.071 +1.7134T50 - (0.10834 X 10-2)TW2 +

(0.3889 x 10-6)T503 - (0.89213 X 10-2)T50API +

(0.53095 x 10*)T5,2API +(0.32712 x 10-7)T502AP12 (1)

log P, =2.829 +(0.9412 X 10-3)T5~-

(0.30475X 10-5)T502 +(0.15141 X 10-8)T503 - (0.20876 X

104)T5,API +(0.11048 x 10-7)T502API +

(0.1395 X 10-9)T502AP12 - (0.4827 X 10-7)T50AP12 (2)

and the Lee-Kesler relations (Kesler and Lee, 1976) for

w =[In PB~ - 5.92714 +6.09648/T~, +

0:

1.28862 hT B , - 0.169347T~,e]/[15.2518 -

15.6875/T~, - 13.4721 In TBr -k 0.43577T~,6] (3)

(for TB, <0.8)

w =-7.904 +0.1352K - 0.007465@ +8.359T~, +

(1.408 - 0.001063K)TBr (4)

(for TBr >0.8).

In eq 1 and 2, API =141.5/SG - 131.5, where SG is the

60 OF/60 O F specific gravity. The critical temperature, T,,

and the midvolume boiling point of the fraction, T50, are

given in OFand P, is psia. In eq 3 and 4, TBr is the reduced

boiling point, TB/T,, and PB, is the reduced pressure,

PB/Pc, where P B is the pressure at which the boiling point,

TB, has been measured. K is the Watson characterization

factor that equals TB1/3/sG, where TBis in O R and SG is

as above.

The results are improved if the PNA distribution of each

boiling point fraction is taken into consideration as sug-

gested by Erbar (1977).

TBP Residue. In the case of gas condensate, the molar

composition of the TBP residue is estimated by assuming

a logarithmic relationship between the molar content, zN,

of a fraction and the corresponding carbon number, CN,

for C N L 7.

(5)

A, and B1 are constants determined by a least-squares fit

to the experimental TBP data for the C,-C, fractions. Cm

is the heaviest carbon number fraction considered, and

molar fractions below 5 X lo4 are neglected. If the

measured TBP residue is larger than the one calculated

C N =A1 +B1 In ZN

Table I. Input to Flash Program for Sample A (Gas

Condensate)

components mol % wt % T,, K P,, atm w

NZ 0.64 0.63 126.2 33.5 0.040

co2 9.16 4.19 304.2 72.8 0.225

C1 68.80 38.83 190.6 45.4 0.008

c2-c3 13.54 16.85 335.7 45.2 0.123

c4-c6 3.94 9.20 450.7 34.3 0.225

c&10 2.30 8.57 565.0 31.6 0.408

cll-c15 0.94 5.13 653.3 25.1 0.656

c16-c48 0.68 6.60 766.2 14.8 1.085

Table 11. Input to Flash Program for Sample B (Heavy

Oil)

comDonents mol % wt % T,., K P,. atm w

N2 0.34 0.10

COZ 0.84 0.41

C1 49.13 8.69

c2-c3 10.76 4.26

c4-c6 7.34 5.69

CTc15 19.69 29.87

cl6-c26 7.80 23.56

C27--C76 4.10 26.31

126.2 33.5 0.040

304.2 72.8 0.225

190.6 45.4 0.008

338.2 45.0 0.126

464.6 33.2 0.242

620.3 25.3 0.628

759.4 14.9 1.039

939.0 9.8 1.488

from the obtained A, and B1 values, A, and B1 are changed

accordingly as explained in part 1 of this series.

For the heavy oil systems, a different characterization

procedure is used.

The TBP distillation curve is extrapolated to 100 wt %

distilled off by fitting a fifth degree polynomial to the

experimental TBP data plus the following two artificially

generated data points:

(6)

- 10-0.2127T 1.103SG-0.6495

T80wt% - 50wt %

- 101.083T 0.7097~~0.6717

TlciJwt%- 5Gwt% (7)

Tsowt%, Tam%, and TlmW% are the temperatures in K at

which 50, 80, and 100 wt % have been distilled off. SG

is the specific gravity of the TBP sample that roughly

corresponds to the C7+fraction of the total mixture.

The specific gravities of the subfractions of the TBP

residue are obtained by assuming a logarithmic depen-

dence of SG against carbon number.

For the boiling points, the values of Katz and Firooza-

badi (1978) are used up to C45. For gas condensates, the

relation

TB (K) =97.58MW0.3323SG0.0460g (8)

is used for the fractions heavier than C45. For the heavy

oils, the weight-based TBP curve is related to carbon

number fractions assuming 6K boiling point intervals per

carbon number for the C45+fractions.

The characterization procedure described above yields

equation of state input parameters for typically 80 com-

ponents or pseudocomponents. Obviously, for extensive

process calculations it is necessary to drastically reduce

this number.

Reduction of the Number of Components

A procedure has been developed whereby all the hy-

drocarbon segments of the C7+fractions are given ap-

proximately equal importance. This is accomplished via

a grouping of carbon number fractions on weight basis.

Typical groupings are shown in Tables I and 11, from which

it may be seen that Nz, COz, and CH4 (C,) are given sep-

arate status, ethane and propane are grouped together

(C2-C3), and so are c4s, ci s, and c6s. The c7+fraction

is divided into three (or more) groups, which on a weight

basis are of approximately equal size.

The group critical properties are computed as weight-

mean values:

950 Ind. Eng. Chem. Process Des. Dev., Vol. 24, No. 4, 1985

T,i = x;MWjT,j/&jMW; (9)

J J

Pci =Cx;MWjPC;/CxjMW;

J J

wi =Cx;MWjwj/Cx;MWj (11)

J I

Index i is a group of carbon number fractions containing,

e.g., C1.(methane) only, or Cz and CB, or C4, C5, and C6, etc.

Index J runs from the lowest to the highest carbon number

within a group i. For the C,+carbon number fractions,

Pcj, Tcj, and wj in eq 9-11 are computed by using eq 1-4.

Tables I and I1 give examples of input parameters to

SRK-flash calculations using six hydrocarbon fractions

corresponding to, respectively, sample A and B of Table

VII. Such inputs plus overall compositions, temperatures,

and pressures are all that is required for the flash calcu-

lations.

Flash Calculations Using the SRK Equation of

State with Interaction Coefficients Equal to Zero

written as follows (Soave, 1972):

The Soave-Redlich-Kwong equation of state may be

RT a

p=---

U(U +b) u - b

For mixtures, the constants a and b, are given by the

mixing rules

a =CCYgjaij (13)

I J

b =CYibi

i

Indices i and j indicate summation over all components

and/or groups of carbon number fractions. Usually, aij for

i #j is given by

aij =(aiiajj)li2(1 - ki j ) (15)

where the binary interaction coefficients ki j are small,

typically zero for hydrocarbon-hydrocarbon interactions

and in the range 0-0.15 for others. The pure-component

parameters aii and bi are given by

aii =(0.42748R2Tci2/Pci) X [l +mi(l - (T/Tci)'/2)]2

(16)

bi =0.07780RTci/Pci (17)

In eq 16, mi is given in terms of the acentric factor, wi.

mi =0.480 +1.574wi - 0.176wi2 (18)

If the characterization procedure described in the pre-

vious two sections is used in connection with the SRK

equation, all hydrocarbon-hydrocarbon kij values (eq 15)

are equal to zero. If in addition ki; values for the non-

hydrocarbon-hydrocarbon and non-hydrocarbon-non-

hydrocarbon interactions may be assumed equal to zero.

Michelsens's (1983) simplified flash calculation procedure

described briefly below may be applied. Weshall later see

that k , =0 for all i - j interactions is a good approximation

for reservoir fluids even if they contain up to 10 mol %

N2 plus COz.

When k, =0, for all i and j , the mixing rule of eq 13 may

be written

a =a2 (19)

(y =Cyi(yi, (y. I = 11 (20)

with

1

Table 111. Deviations between Measured and Calculated

Saturation Points for 15 North Sea Reservoir Fluids"

3CH 6CH 10CH 20CH 40CH

fractns fractns fractns fractns fractns

AAD 18.1 5.6 5.0 5.2 5.0

BIAS -0.1 -3.2 -2.2 -2.5 -2.3

" CH: hydrocarbon; AAD: average absolute percent deviation;

BIAS: percent bias.

Table IV. Relative Computer Time for Flash Calculations

on Petroleum Mixtures"

3CH 6CH 10CH 20CH 40CH

program fractns fractns fractns fractns fractns

kij Z 0 0.08 0.16 0.25 0.46 1.00

kij =0 0.05 0.06 0.08 0.09 0.15

"CH: hydrocarbon; ki j #0: flash program with some of the

binary interaction coefficients different fromzero; ki, =0: flash

program with all binary interaction coefficients equal to zero.

With all kij =0 the fugacity coefficient for component

i is found to be given by

In +i ="( b RT - 1)- In (&(u - b)) -

Equation 21 is valid for both vapor and liquid phases. For

a vapor phase, vapor-phase properties uv, bv, and av are

used, and similarly uL, bL, and aL are used for the liquid

phase.

The equilibrium ratio, Ki =yi/xi, is given by

Ki =+?/c$? (22)

From eq 21 it may be seen that

Ki =Ki(T,P,aV,aL,bV,bL) (all i ) (23)

The volume, u, does not appear in eq 23 as u is given

implicitly by a, b, T, and P (see eq 12).

As may be readily shown (Michelsen 1983), a and b for

the feed (F), vapor (V), and liquid (L) are interrelated.

ffF =Pf f V +(1 - 6) aL (24)

b~=6bv +(1 - 6)bL (25)

P is the fraction of moles in the feed that appears in the

vapor phase. aF and bF are known.

Thus, in a flash calculation where T and P are specified,

Ki is a function of only three variables:

Ki =Ki(aV,bv,P) (all i) (26)

This means that, irrespective of the number of components

i, T, P, flash calculation procedures involving only three

variables can now be formulated. For multicomponent

mixtures such as reservoir fluids, this observation may be

used to improve drastically the efficiency of flash algor-

ithms. One such algorithm, i.e., the one used in this work,

is described in detail by Michelsen (1983).

Results

We examine separately the effect of reducing the num-

ber of components and of equating all ki j values to zero.

Reduction of the Number of Components. Dew and

bubble point calculations have been carried out for 15

reservoir fluids (the samples for which molar compositions

are given in the supplements to parts 1 and 2 of this series

and samples A-C of this work). The samples cover pe-

troleum mixtures ranging from light gas condensates to

heavy oils. Table I11 lists the deviations between exper-

imental and calculated saturation points using 3,6, 10, 20,

Ind. Eng. Chem. Process Des. Dev., Vol. 24, No. 4, 1985 951

:>

P

- Ex p er i men t

-.- 8 CH- f r a c t . ( k i j # O)

8 CH- f r l c t . ( k i j - 0 )

-

-

9

100 200 300 400

Pr essur e ( a t m)

Figure 1. Constant volume depletion results for sample A at T =

121 OC. Vapor and liquid densities have been determined by the

method of PBneloux et al. (1982).

100 200 300 400 500

Pr es s u r e ( at m)

Figure 2. Constant mass expansion results for sample C at T =129

"C. The SRK equation is used for the vapor densities and the

Alani-Kennedy equation (1960) for the liquid densities.

and 40 groups of carbon number fractions. The relative

flash calculation computer time is shown in Table IV. The

computer time (cpu s) needed to perform one flash cal-

culation for a mixture of eight components is given in

Table VI1 for five different computers.

Tables V and VI show measured and calculated phase

compositions of a gas condensate (Table VII, sample A)

and a heavy oil (Table VII, sample B) using 6 and 40

groups of hydrocarbon fractions.

Figures 1-4 present results of simulations of three PVT

experiments described in part 2 of these series using 6 and

40 hydrocarbon fractions. The pseudocomponents defined

for the total initial mixture are maintained for both the

gas and liquid phases for any further process calculations

on each separate phase.

Figure 1 shows measured and predicted liquid dropout

curves of a constant volume depletion process on sample

A. In this case the differences between the results for 6

and 40 CH fractions are so small that only one curve is

shown. Figure 2 shows results for a constant mass ex-

pansion process on sample C. Figures 3 and 4 present

952 Ind. Eng. Chem. Process Des. Dev., Vol. 24, No. 4, 1985

Table VII. Analytical Data for Samdes A. B. and C"

PNA distribution, mol %

sp grav

comDonents mol % (15 "Ci15 "C) MW P N A

0.64

9.16

68.80

8.43

5.11

0.81

1.45

0.52

0.53

0.63

0.83

0.95

0.52

0.26

0.20

0.17

0.16

0.15

0.11

0.086

0.078

0.068

0.050

0.046

0.035

0.025

0.034

0.023

0.017

0.018

0.014

0.012

0.013

0.047

0.34

0.84

49.23

6.32

4.46

0.86

2.18

0.93

1.33

2.06

3.33

4.06

2.76

1.33

1.79

1.70

1.81

1.46

1.49

1.08

1.13

0.99

0.88

Sample A (Gas Condensate)*

0.741

0.780

0.807

0.819

0.810

0.828

0.849

0.857

0.868

0.872

0.859

0.854

0.866

0.873

0.876

0.876

0.875

0.877

0.876

0.878

0.882

0.886

0.889

0.908

Sample B (Heavy Oil)*

96

107

121

134

147

161

175

190

206

222

237

251

263

339 G o +

0.7395

0.7518

0.7756

0.7930

0.7902

0.8060

0.8203

0.8311

0.8446

0.8515

0.8542

0.8561

0.8663

99

106

120

139

146

160

174

194

205

218

234

248

265

0.50

0.45

0.48

0.47

0.56

0.55

0.54

0.49

0.52

0.55

0.57

0.70 Cia+

0.56

0.58

0.58

0.57

0.62

0.59

0.57

0.57

0.53

0.53

0.56

0.58

0.57

0.42

0.38

0.27

0.30

0.27

0.24

0.22

0.27

0.20

0.19

0.20

0.11

0.39

0.33

0.30

0.33

0.31

0.33

0.32

0.31

0.32

0.31

0.30

0.28

0.28

0.08

0.17

0.25

0.23

0.17

0.21

0.24

0.24

0.28

0.26

0.23

0.19

0.05

0.09

0.12

0.10

0.07

0.08

0.11

0.12

0.15

0.16

0.14

0.14

0.15

c 19

c20+ 7.64 0.9350 465 0.56 0.20 0.24

sp grav (15 "C/15 "C)

. _

PNA distribution mol 70

total

components mol % fractn P +N A MW P N A

Sample C (Heavy Gas Condensate)

N2 0.12

CO2 2.49

C1 76.43

c2 7.46

c3 3.12

i-C, 0.59

i-C5 0.50

n-C5 0.59

c6 0.79

n-C, 1.21

Ind. Eng. Chem. Process Des. Dev., Vol. 24, No. 4, 1985 953

Table VI1 (Continued)

sp grav (15 OC/15 "C)

PNA distribution mol %

total

components mol % fractn P +N A MW P N A

C, 0.95 0.726 95 0.564 0.361 0.076

1.08

0.78

0.592

0.467

0.345

0.375

0.304

0.237

0.208

0.220

0.169

0.140

0.833

0.747

0.769

0.781

0.778

0.785

0.802

0.815

0.817

0.824

0.825

0.831

0.841

0.873

0.738

0.756

0.765

0.777

0.785

0.792

0.877

0.805

0.807

0.812

0.820

0.827

0.862

0.874

0.883

0.898

0.953

0.934

0.987

0.951

0.949

0.968

0.975

0.962

106

116

133

152

164

179

193

209

218

239

250

264

377

0.113

0.483

0.530

0.681

0.757

0.709

0.635

0.729

0.624

0.668

0.675

0.652

0.519

0.611

0.311

0.275

0.193

0.123

0.183

0.209

0.168

0.232

0.185

0.192

0.190

0.320

0.277

0.206

0.195

0.126

0.120

0.108

0.156

0.103

0.144

0.147

0.133

0.158

0.161

"P, paraffinic compounds; N, naphthenic compounds; A, aromatic compounds. bThe PNA analyses of samples A and B are only based on

measurements of refractive index.

Table VIII. TBP Data for Samde B"

u

5 ; 1.4

> .

El

5 1.3

-

0 >

..........

Ex p e r i me n t

4 0 CH- t r ac t i o n .

6 CH- f r ac t i o n s

- -

1.1

l '* I

1 1 , I

400 300 200 100 0

Pr es s u r e ( a t m )

Figure 3. Differential liberation results for sample B at T =93.3".

The SRK equation is used for the vapor densities and the Alani-

Kennedy equation (1960) for the liquid densities.

- .-

0 Ex p a r i me n 1

......... 40 CH- t r ac t i o n 1

6 CH- l r a c t i o n i

I I I I

4 00 300 200 100 0

Figure 4. Differential liberation results for sample B at T =93.3

"C. The oil density has been determined by using the Alani-Ken-

nedy equation (1960).

relative and absolute liquid volumes of sample B during

a differential liberation process.

Calculation with All Binary Interaction Coeffi-

cients Equal to Zero. As already indicated, wenormally

use ki j values equal to zero for interactions between hy-

drocarbons and nonzero values for interactions between

Pr es s u r e ( a t m )

temp, cum wt temp, cum wt temp, cum wt

"C % distilled "C % distilled "C % distilled

100 10.54 218 28.43 288 43.10

127 14.54 237 32.48 304 46.52

152 19.17 255 36.13 318 49.67

176 21.55 272 40.06 332 52.67

197 24.92

"specific gravity of TBP sample =0.8499 (15 "C/15 "C).

non-hydrocarbons and between hydrocarbons and non-

hydrocarbons. The influence on the predicted saturation

points of setting all ki j values equal to zero has been

checked for mixtures containing COz and N2 If COP +N2

constitutes less than 1.5 mol % of the total mixture, the

calculated saturation points deviate less than 170 from

those calculated with kij #0. For sample A, a gas con-

densate that contains about 10 mol % non-hydrocarbons,

the effect of kij =0 on the calculated dew points is 4.0%.

Relative computer times for flash calculations with the

kij =0 version are given in Table IV. Calculated phase

compositions of samples A and B at separator conditions

using the kj. =0 version are shown in Tables V and VI.

The simdations of PVT experiments mentioned in the

previous section have been repeated with the kij =0 ver-

sion. The liquid dropout curve obtained for sample A by

using six hydrocarbon fractions is shown in Figure 1. The

results of the constant mass expansion calculation on

sample C and those of the differential liberation calculation

on sample B are not shown because they are almost in-

distinguishable from the results with k, #0.

Discussion

I t is evident from Table IV that much computer time

may be saved in oil/gas flash calculations if the kij values

(see eq 15) are equated to zero for all i-j interactions. The

calculations performed on gas condensates and heavy oils

show that the kij =0 approximation has little influence

on the results for North Sea reservoir fluids, which seldom

contain more than 10 mol % CO, +N,. If the content of

COz and N, is less than 1.5 mol % , the influences on the

predicted phase behavior and saturation points are neg-

ligible; only the equilibrium ratio for CO,, KCo2, is affected

(see Table VI). If the content of COz +Nz approaches 10

mol 70, the ki, =0 and k , #0 versions of the programs

give saturation pressures that differ by 4%. This is the

case for sample A of Table VII. Only minor differences

are in this case observed in the two-phase region, except

for the calculated CO, concentrations.

954 Ind. Eng. Chem. Process Des. Dev., Vol. 24, No. 4, 1985

Table IX. Computer Time (cpu 8 ) Needed for One

One-Phase and One Two-Phase Flash Calculation on

Different ComputersD (Eight Component Mixture)

program one-phase two-phase

comwter version region region

IBM 3081 k,j f 0

k , =0

Burrough B-7800 k, , #0

k,, =0

VAX l l /750 k,, f 0

UNIVAC ll00/62 k , #0

k , =0

HP9020 k L J #

0.021

0.012

0.080

0.030

0.203

0.279

0.340

0.150

0.029

0.010

0.125

0.060

0.326

0.374

0.530

0.250

The two-phase calculation corresponds to the data and results

The above results indicate that one may take advantage

of the k,, =0 approximation in many applications where

flash calculations are needed for petroleum mixtures. This

conclusion does not apply to situations where mixtures

with appreciable contents of non-hydrocarbons are present,

e.g., COz injection studies.

Also, reducing the number of components (or pseudo-

components) greatly reduces the computer time needed

for flash calculations (see Table IV). The results obtained

show that a total of only six groups of carbon number

fractions gives saturation points and PVT properties that

are sufficiently accurate for many practical purposes. As

shown in Tables V and VI, the only discrepancy is the

content of heavy components in the vapor phase.

The liquid dropout curves predicted for samples A and

C deviate somewhat from the measured ones as seen in

Figures 1 and 2. Very accurate predictions are obtained

for the dew point of sample A, but there are some problems

with the liquid volumes. As the liquid phase only con-

stitutes a few volume percent of the total volume, our

results are satisfactory for most practical purposes. Sample

C is a heavy gas condensate for which wecalculate the

following critical properties: T, =43.8 "C; P, =416 atm.

The reservoir temperature is 129 "C, which means that

the mixture at the dew point in Figure 2 is nearly critical.

The near-critical condition is also reflected in the calcu-

lated phase compositions, which slightly below the dew

point were nearly identical. Problems with predictions of

densities are to be expected in the critical region, and we

attribute most of the discrepancies shown in Figure 2

hereto. I t is worth noting that no computational problems

were encountered in these flash calculations.

Conclusions

A simplified SRK calculation procedure (Michelsen,

1983) enables considerable savings in computer time for

mixtures for which all k, , values can be set to zero. The

computer time is only a weak function of the number of

components, and the storage requirements are drastically

reduced. Irrespective of the number of components, only

three variables need to be stored between the iterations.

For mixtures of hydrocarbons, COz, and N2 in which the

COz +N2 content does not exceed 10 mol % , all k, values

can be set to zero without significant influence on the

predicted phase behavior.

I n addition, a new procedure has been developed that

allows reservoir fluids to be represented by a total of six

hydrocarbon pseudocomponents only. I t has been shown

of Table V.

that six pseudocomponents are sufficient to represent

densities and saturation points as well as what was pre-

viously reported in parts 1 and 2 of this series using 40

hydrocarbon fractions.

Acknowledgment

Wethank Arne Hole of Statoil and M. L. Michelsen of

Instituttet for Kemiteknik for their continued interest in

this work.

Nomenclature

a

A1

API

b

R,

CN

k ,

K

K,

m

MW

P

R

SG

T

T B

T50

T50 wt %

XI

Y1

21

CY

P

41

Br

F

i, j

L

V

W

C

SRK parameter defined in eq 12

parameter defined in eq 5

API specific gravity (=141.5/SG-131.5)

SRK parameter defined in eq 12

parameter defined in eq 5

carbon number

binary interaction coefficient

Watson characterization factor (TB'/3/sG)

equilibrium factor, component i

SRK parameter defined in eq 18

molecular weight

pressure

gas constant

specific gravity

temperature

normal boiling point

midvolume boiling point

midweight boiling point

liquid-phase mole fraction of component i

vapor-phase mole fraction of component i

feed mole fraction of component i

Greek Symbols

parameter defined in eq 20

vapor mole fraction

acentric factor

fugacity coefficient of component i

Subscri pt s

reduced boiling point

critical property

feed

component or carbon number group indices

liquid

vapor

Registry No. C02, 124-38-9; N2, 7127-31-9.

Literature Cited

Alani, H. G.; Kennedy, H. T. Pet . Trans., Am. Inst. Mi n. Eng. 1960, 219,

200.

Cavett, R. H. "Physical Data for Distillation Calculations - Vapor-Liquid

Equiiibrla", presented at the 27th Midyear Meeting, API Division of Refin-

ing, San Francisco, May 15, 1964.

Erbar, J . H. Gas Processors Association, Tulsa, OK, 1977, Research Report

13.

Katz, D. L.; Firoozabadi, A. Pet . Techno/. 1978, 20, 1649.

Kesler, M. G.; Lee, B. I . Hydrocarbon Process. 1978, 55, 153.

Michelsen, M. L.; Heidemann, R. A. AI ChEJ. 1981, 27, 521.

Michelsen, M. L. "Simplified Flash Calculations for Cubic Equations of State",

SEP 8313; Instituttet for Kemiteknik: Lyngby. Denmark, 1983.

Pedersen, K. S.; Thomassen, P.; Fredenslund, Aa. a. Ind. Eng. Chem. Pro-

cess Des . Dev. 1984, 23, 163-170. b. Ind. Eng. Chem. Process Des.

Dev., 1984, 23, 566-573.

PEneloux, A,; FrBze. P. Nuid Phase Equilib. 1982, 8 . 7.

Soave, G. Chem. Eng. Sci . 1972, 27, 1197.

Received for reuiew October 3, 1983

Revised manuscript received October 2, 1984

Accepted October 23, 1984

También podría gustarte

- 2013WaterQuality ICACCI PDFDocumento6 páginas2013WaterQuality ICACCI PDFThokozaniMpofuAún no hay calificaciones

- Pipe NetDocumento99 páginasPipe NetSARFRAZ ALI100% (1)

- M26 - Members GPSADocumento32 páginasM26 - Members GPSAMichael ParkerAún no hay calificaciones

- Two Phase Blowdown From PipelinesDocumento34 páginasTwo Phase Blowdown From PipelinesMichael ParkerAún no hay calificaciones

- Effects of Temperature and Pressure On The Upper Explosive Limit of Methane-Oxygen MixturesDocumento5 páginasEffects of Temperature and Pressure On The Upper Explosive Limit of Methane-Oxygen MixturesMichael ParkerAún no hay calificaciones

- Natural Gas Interchangeability in China: Some Experimental ResearchDocumento5 páginasNatural Gas Interchangeability in China: Some Experimental ResearchMichael ParkerAún no hay calificaciones

- Calculation of Phase Diagrams of Gas-HydratesDocumento9 páginasCalculation of Phase Diagrams of Gas-HydratesMichael ParkerAún no hay calificaciones

- Natural Gas As Feedstock in Towngas ProductionDocumento30 páginasNatural Gas As Feedstock in Towngas ProductionMichael ParkerAún no hay calificaciones

- CAG Gas Quality Airtricity Response 180708Documento8 páginasCAG Gas Quality Airtricity Response 180708Michael ParkerAún no hay calificaciones

- FTPDocumento10 páginasFTPMichael ParkerAún no hay calificaciones

- Volumetric Property Improvement For The Soave-Redlich-Kwong Equation of StateDocumento11 páginasVolumetric Property Improvement For The Soave-Redlich-Kwong Equation of StateMichael ParkerAún no hay calificaciones

- Estimating Gas Hydrate Inhibitor Loss: A Case StudyDocumento4 páginasEstimating Gas Hydrate Inhibitor Loss: A Case StudyMichael ParkerAún no hay calificaciones

- Density Functional Theory QuantumDocumento282 páginasDensity Functional Theory QuantumMichael Parker50% (2)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (121)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2104)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- Calculation ReportDocumento157 páginasCalculation Reportisaacjoe77100% (3)

- HCH - 15 04 004Documento5 páginasHCH - 15 04 004NarvaxisAún no hay calificaciones

- n4 HandoutDocumento2 páginasn4 HandoutFizzerAún no hay calificaciones

- 5 Grade: Daily MathDocumento130 páginas5 Grade: Daily MathOLIVEEN WILKS-SCOTT100% (3)

- Brp-Rotax Chassis Approval FormDocumento3 páginasBrp-Rotax Chassis Approval Formdelta compAún no hay calificaciones

- Manual HobartDocumento39 páginasManual HobartВолодимир БроAún no hay calificaciones

- Electronic Parts Catalog - Option Detail Option Group Graphic Film Card DateDocumento2 páginasElectronic Parts Catalog - Option Detail Option Group Graphic Film Card DatenurdinzaiAún no hay calificaciones

- CoolonDocumento2 páginasCoolonAnySikaAún no hay calificaciones

- Kunst 1600 Case AnalysisDocumento3 páginasKunst 1600 Case AnalysisrakeshAún no hay calificaciones

- Topic 3 Intellectual RevolutionDocumento20 páginasTopic 3 Intellectual RevolutionOlive April TampipiAún no hay calificaciones

- Corrosion Protection PT Tosanda Dwi SapurwaDocumento18 páginasCorrosion Protection PT Tosanda Dwi SapurwaYoga FirmansyahAún no hay calificaciones

- CNC Milling ReportDocumento15 páginasCNC Milling ReportStarscream Aisyah78% (37)

- Antenna Systems - Standard Format For Digitized Antenna PatternsDocumento32 páginasAntenna Systems - Standard Format For Digitized Antenna PatternsyokomaAún no hay calificaciones

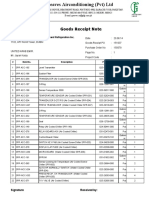

- Goods Receipt Note: Johnson Controls Air Conditioning and Refrigeration Inc. (YORK) DateDocumento4 páginasGoods Receipt Note: Johnson Controls Air Conditioning and Refrigeration Inc. (YORK) DateSaad PathanAún no hay calificaciones

- Electro TechniquesDocumento2 páginasElectro TechniquesPinkk DaisyfieldAún no hay calificaciones

- TR60 RIGID ENG. 6/13/03 10:38 AM Page 1: Performance DataDocumento2 páginasTR60 RIGID ENG. 6/13/03 10:38 AM Page 1: Performance Databayu enasoraAún no hay calificaciones

- Manish Kumar: Desire To Work and Grow in The Field of MechanicalDocumento4 páginasManish Kumar: Desire To Work and Grow in The Field of MechanicalMANISHAún no hay calificaciones

- Concrete Casting - Pump Station ADocumento13 páginasConcrete Casting - Pump Station ABright MuzaAún no hay calificaciones

- 02 Lab 1.HCIDocumento2 páginas02 Lab 1.HCILopao SerojemAún no hay calificaciones

- Emerson Mentor MP ManualDocumento182 páginasEmerson Mentor MP ManualiampedrooAún no hay calificaciones

- Why We Need A Flying Amphibious Car 1. CarsDocumento20 páginasWhy We Need A Flying Amphibious Car 1. CarsAsim AhmedAún no hay calificaciones

- 2018-2019 Annual Algebra Course 1 Contest: InstructionsDocumento2 páginas2018-2019 Annual Algebra Course 1 Contest: InstructionsNaresh100% (1)

- 22 Thành NG Quen Thu C Trên Ielts - FirefighterDocumento2 páginas22 Thành NG Quen Thu C Trên Ielts - FirefighterNinh NguyễnAún no hay calificaciones

- OB Case Study Care by Volvo UK 2020Documento1 páginaOB Case Study Care by Volvo UK 2020Anima AgarwalAún no hay calificaciones

- MidsemDocumento6 páginasMidsemAravind SomasundaramAún no hay calificaciones

- Bilateral Transfer of LearningDocumento18 páginasBilateral Transfer of Learningts2200419Aún no hay calificaciones

- Be and Words From The List.: 6B Judging by Appearance Listening and ReadingDocumento3 páginasBe and Words From The List.: 6B Judging by Appearance Listening and ReadingVale MontoyaAún no hay calificaciones

- En DAY4 David Chen Building The AI Computing Platform For Pervasive Intelligence enDocumento8 páginasEn DAY4 David Chen Building The AI Computing Platform For Pervasive Intelligence endieuwrignAún no hay calificaciones

- Types of ComputersDocumento7 páginasTypes of ComputersSyed Badshah YousafzaiAún no hay calificaciones

- UntitledDocumento5 páginasUntitledapril montejoAún no hay calificaciones