Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Pla

Cargado por

Serkan Gecim0 calificaciones0% encontró este documento útil (0 votos)

33 vistas6 páginasPoly(lacticacid) (PLA) is a compostable polymer derived from renewable sources. The main uses of PLA have been limited tomedical applications such as implant devices, tissue scaffolds, and internal sutures. Newtechniques which allow economical production of high molecular weight PLA polymer have broadened its uses.

Descripción original:

Derechos de autor

© © All Rights Reserved

Formatos disponibles

DOCX, PDF, TXT o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoPoly(lacticacid) (PLA) is a compostable polymer derived from renewable sources. The main uses of PLA have been limited tomedical applications such as implant devices, tissue scaffolds, and internal sutures. Newtechniques which allow economical production of high molecular weight PLA polymer have broadened its uses.

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como DOCX, PDF, TXT o lea en línea desde Scribd

0 calificaciones0% encontró este documento útil (0 votos)

33 vistas6 páginasPla

Cargado por

Serkan GecimPoly(lacticacid) (PLA) is a compostable polymer derived from renewable sources. The main uses of PLA have been limited tomedical applications such as implant devices, tissue scaffolds, and internal sutures. Newtechniques which allow economical production of high molecular weight PLA polymer have broadened its uses.

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como DOCX, PDF, TXT o lea en línea desde Scribd

Está en la página 1de 6

PLA

In a world that is becoming increasingly sensitive to the need to protect

ourenvironment, the ability to manufacture products from sustainable

resourcesand which are fully compostable at the end of their useful life, is an

excitingand attractive propositionThermoplastic polymers exhibit many

properties idealfor use in packaging and other consumer products,

suchas light weight, low process temperature (compared tometal and

glass), variable barrier properties to match end-use applications, good

printability, heat sealable, and easeof conversion into different forms.

Today, most plasticsare derived from non-renewable

crude oil and naturalgas resources. While some plastics are being recycled

andr eus ed, t he ma j or i t yar edi s pos edi nl andl l s duet oend-

us econtamination..

Poly(lacticacid)(PLA)isacompostablepolymerderi vedfrom renewable

sources (mainly starch and sugar). Untilthe last decade, the main uses of PLA

have been limited tomedical applications such as implant devices, tissue scaf-

folds, and internal sutures, because of its high cost, lowavailability and

limited molecular weight.

Recently,newtechniques which allow economical production of high

molecular weight PLA polymer have broadened its uses[2].Since PLA

is compostable and derived from sustain-able sources, it has been

viewed as a promising materialto reduce the societal solid waste disposal

problem[3,4].Its low toxicity[5],along with its environmentally

benigncharacteristics, has made PLA an ideal material for

foodpackaging and for other consumer products[6

Structural composition

The basic building block of PLA, lactic acid, can be pro-

ducedbycarbohydratefermentationorchemicalsynthesis.Currently, the

majority of lactic acid production is basedon the fermentation route.

Various purication technolo-gi es f or l act i c aci d and l act i de can be

f ound i n a r ecent review by Datta and Henry[2].One of the main

driversfor the recent expanded use of PLA is attributable to

theeconomi cal pr oduct i onof hi ghmol ecul ar wei ght PLApol y - mers

(greater than100,000Da). These polymers can beproduced using several

techniques, including azeotropic dehydrative condensation, direct condensation

polymer-ization, and/or polymerization through lactide

formation(Fi g. 1).Byandlarge,commerciallyavailablehighmolecularwei

ghtPLAresinsareproducedviathelactidering-openingpolymerization route

Fig. 1.Synthesis of PLA from l- and d-lactic acids. Adapted from Auras et al.

m a n u f a c t u r e o f P L A pol ymer resin

Conventional synthetic polymers rely on reserves of oil and gas for

theirmonomer source and energy to manufacture. These reserves of fossil

fueltake millions of years to regenerate and are a declining resource. In

contrast,the monomer used to manufacture poly(lactic acid) is obtained

from annuallyrenewable crops. Energy from the sun promotes

photosynthesis within theplant cells; carbon dioxide and water from the

atmosphere are converted intostarch. This starch is readily extracted

from plant matter and converted to afermentable sugar (e.g. glucose) by

enzymatic hydrolysis. The carbon andother elements in these natural

sugars are then converted to lactic acid throughfermentation

Producti on of lactic acid from renewabl e resources.

PLGA

Polyester PLGA is a copolymer of poly lactic acid (PLA) and poly glycolic acid

(PGA). It is the best defined biomaterial available for drug delivery with respect

to design and performance. Poly lactic acid contains an asymmetric _-carbon

which is typically described as the D or L form in classical stereochemical terms

and sometimes as R and S form, respectively. The enantiomeric forms of the

polymer PLA are poly D-lactic acid (PDLA) and poly L-lactic acid (PLLA).

PLGA is generally an acronym for poly D,L-lactic-co-glycolic acid where D-

and L- lactic acid forms are in equal ratio.

2.1.1. Physico-Chemical Properties

In order to design a better controlled drug delivery device, it is essential to

understand the physical, chemical and biological properties of PLGA. The

physicochemical properties of optically active PDLA and PLLA are nearly the

same. In general, the polymer PLA can be made in highly crystalline form

(PLLA) or completely amorphous (PDLA) due to disordered polymer chains.

PGA is void of any methyl side groups and shows highly crystalline structure in

contrast to PLA as shown in Figure 1. PLGA can be processed into almost any

shape and size, and can encapsulate molecules of virtually any size. It is soluble

in wide range of common solvents including chlorinated solvents,

tetrahydofuran, acetone or ethyl acetate [7,10]. In water, PLGA biodegrades by

hydrolysis of its ester linkages (Figure 2). Presence of methyl side groups in

PLA makes it more hydrophobic than PGA and hence lactide rich PLGA

copolymers are less hydrophilic, absorb less water and subsequently degrade

more slowly. Due to the hydrolysis of PLGA, parameters that are typically

considered invariant descriptions of a solid formulation can change with time,

such as the glass transition temperature (Tg), moisture content and molecular

weight. The effect of these polymer properties on the rate of drug release from

biodegradable polymeric matrices has been widely studied. The change in

PLGA properties during polymer biodegradation influences the release and

degradation rates of incorporated drug molecules. PLGA physical properties

themselves have been shown to depend upon multiple factors, including the

initial molecular weight, the ratio of lactide to glycolide, the size of the device,

exposure to water (surface shape) and storage temperature [11]. Mechanical

strength of the PLGA is affected by physical properties such as molecular

weight and polydispersity index. These properties also affect the ability to be

formulated as a drug delivery device and may control the device degradation

rate and hydrolysis. Recent studies have found, however, that the type of drug

also plays a role in setting the release rate [12]. Mechanical strength, swelling

behavior, capacity to undergo hydrolysis and subsequently biodegradation rate

of the polymer are directly influenced by the degree of crystallinity of the

PLGA, which is further dependent on the type and molar ratio of the individual

monomer components in the copolymer chain. Crystalline PGA, when co-

polymerized with PLA, reduces the degree of crystallinity of PLGA and as a

result increase the rate of hydration and hydrolysis. As a rule, higher content of

PGA leads to quicker rates of degradation with an exception of 50:50 ratio of

PLA/PGA, which exhibits the fastest degradation, with higher PGA content

leading to increased degradation interval below 50%. Degree of crystallinity and

melting point of the polymers are directly related to the molecular weight of the

polymer. The Tg (glass transition temperature) of the PLGA copolymers are

reported to be above the physiological temperature of 37 _C and hence are

glassy in nature, thus exhibiting fairly rigid chain structure. It has been further

reported that Tg of PLGAs decrease with a decrease of lactide content in the

copolymer composition and with a decrease in molecular weight [13] .

Commercially available PLGA polymers are usually characterized in terms of

intrinsic viscosity, which is directly related to their molecular weights.

Figure 1. Structure of poly lactic-co-glycolic acid (x is the number of lactic acid

units and y is number of glycolic acid units).

Figure 2. Hydrolysis of poly lactic-co-glycolic acid.

También podría gustarte

- Fourier Transform Infrared SpectrosDocumento6 páginasFourier Transform Infrared SpectrosSerkan GecimAún no hay calificaciones

- 6th Central Pay Commission Salary CalculatorDocumento15 páginas6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 6th Central Pay Commission Salary CalculatorDocumento15 páginas6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- J.p.holman Heat RansferDocumento8 páginasJ.p.holman Heat RansferSerkan GecimAún no hay calificaciones

- BesselDocumento62 páginasBesselRafael MapoAún no hay calificaciones

- Eg Reactor DesignDocumento4 páginasEg Reactor DesignSerkan GecimAún no hay calificaciones

- The Laplace TransformDocumento29 páginasThe Laplace TransformSerkan GecimAún no hay calificaciones

- Material Selection Processes in The Automotive Industry: December, 1993Documento48 páginasMaterial Selection Processes in The Automotive Industry: December, 1993Manica LucianAún no hay calificaciones

- HW6Documento3 páginasHW6Serkan GecimAún no hay calificaciones

- Aerospace IndustryDocumento14 páginasAerospace IndustrySerkan GecimAún no hay calificaciones

- Results and Discussion-Process ControlDocumento7 páginasResults and Discussion-Process ControlSerkan GecimAún no hay calificaciones

- Process Control ExperimentDocumento24 páginasProcess Control ExperimentSerkan GecimAún no hay calificaciones

- Kompozi̇t SunumumuzzzzzzDocumento16 páginasKompozi̇t SunumumuzzzzzzSerkan GecimAún no hay calificaciones

- PVC Properties and ManufacturingDocumento14 páginasPVC Properties and ManufacturingSerkan GecimAún no hay calificaciones

- Styrene MonomerDocumento13 páginasStyrene MonomerSerkan Gecim100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (119)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2099)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- Astm C361M-14Documento26 páginasAstm C361M-14diego rodriguez100% (1)

- Master Glenium SKY 8108: High Range Water Reducing AdmixtureDocumento2 páginasMaster Glenium SKY 8108: High Range Water Reducing Admixturedana setiawanAún no hay calificaciones

- VERITAS PHARMACEUTICALS LIMITED MICROCRYSTALLINE CELLULOSE SPECIFICATIONDocumento1 páginaVERITAS PHARMACEUTICALS LIMITED MICROCRYSTALLINE CELLULOSE SPECIFICATIONShagorShagorAún no hay calificaciones

- Slurry Shield AdditivesDocumento8 páginasSlurry Shield AdditivesfabiodbdbAún no hay calificaciones

- 3rd Summative TestDocumento8 páginas3rd Summative TestAngelica ValdezAún no hay calificaciones

- Mechanical Design-Material PropertiesDocumento61 páginasMechanical Design-Material Propertiesgaza001Aún no hay calificaciones

- Fan - 2009 - 8 - ECTC 2009 - 2 RahimDocumento5 páginasFan - 2009 - 8 - ECTC 2009 - 2 RahimkraidonAún no hay calificaciones

- Adilabad ROB SCHDocumento17 páginasAdilabad ROB SCHKota RavichandAún no hay calificaciones

- MEPDG Manual of PracticesDocumento209 páginasMEPDG Manual of PracticesSri RamyaAún no hay calificaciones

- Dyeing Process of Cotton Fabric With Reactive DyesDocumento6 páginasDyeing Process of Cotton Fabric With Reactive DyesMianAbrarAnjumAún no hay calificaciones

- Civil Engineering MCQDocumento19 páginasCivil Engineering MCQSuhail RazaAún no hay calificaciones

- Sheet Pile WallDocumento11 páginasSheet Pile WallKhandaker Khairul AlamAún no hay calificaciones

- Expanded Silicone Rubber Sponge - Grades SIL10, SIL16, SIL24 & SIL33Documento3 páginasExpanded Silicone Rubber Sponge - Grades SIL10, SIL16, SIL24 & SIL33ari wiliamAún no hay calificaciones

- Acceptance Creiteria Asme IiiDocumento5 páginasAcceptance Creiteria Asme Iiimostafa aliAún no hay calificaciones

- Mechanical Design of Overhead LinesDocumento26 páginasMechanical Design of Overhead LinesAsheque Iqbal100% (1)

- Design of Biogas DigestersDocumento22 páginasDesign of Biogas DigestersSharath Chandra100% (5)

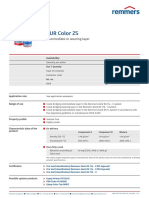

- PUR Color ZS PUR Color ZS: Intermediate or Wearing LayerDocumento5 páginasPUR Color ZS PUR Color ZS: Intermediate or Wearing LayerUrsulet SilviuAún no hay calificaciones

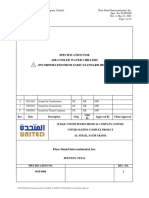

- 00-H-0008 Air-Cooled Water ChillersDocumento14 páginas00-H-0008 Air-Cooled Water Chillershabibansari2010Aún no hay calificaciones

- Chapter 13 Rock Physics at Laboratory Scale, From Textbook: Rock Quality, Seismic Velocity, Attenuation and AnisotropyDocumento47 páginasChapter 13 Rock Physics at Laboratory Scale, From Textbook: Rock Quality, Seismic Velocity, Attenuation and AnisotropyCamilo Cepeda UgaldeAún no hay calificaciones

- Strut and Tie Model Analysis of Prestressed Deep BeamsDocumento24 páginasStrut and Tie Model Analysis of Prestressed Deep BeamsKannan Chandrabhanu100% (1)

- Sand ManufacturingDocumento5 páginasSand ManufacturingJournalNX - a Multidisciplinary Peer Reviewed JournalAún no hay calificaciones

- Filter Paper TestDocumento14 páginasFilter Paper TestSallam MohammedAún no hay calificaciones

- Chemical Proces-WPS OfficeDocumento58 páginasChemical Proces-WPS OfficeMuhammad Ahmed50% (2)

- HHD-S Cavity anchor installation guideDocumento2 páginasHHD-S Cavity anchor installation guideIngeniero Miguel VillarroelAún no hay calificaciones

- DIY Homemade HHO Hydrogen Generator - RMCyberneticsDocumento6 páginasDIY Homemade HHO Hydrogen Generator - RMCyberneticsharisaryono100% (1)

- AVK Check ValvesDocumento4 páginasAVK Check ValvesgdpAún no hay calificaciones

- Design and Analysis of Tension MemberDocumento29 páginasDesign and Analysis of Tension MemberJhianne Dulpina RoqueAún no hay calificaciones

- Neutrophiles and ElectrophilesDocumento2 páginasNeutrophiles and Electrophileswhydaspam joeAún no hay calificaciones

- Parker Autoclave Engineers: Fluid Componets Product Catalog Feb. 2016Documento370 páginasParker Autoclave Engineers: Fluid Componets Product Catalog Feb. 2016mds9185Aún no hay calificaciones

- Weldment Deffect and Rejected by StationDocumento28 páginasWeldment Deffect and Rejected by StationHadi azfar channelAún no hay calificaciones