Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Gutter Machines

Cargado por

eventric0 calificaciones0% encontró este documento útil (0 votos)

130 vistas4 páginasDerechos de autor

© © All Rights Reserved

Formatos disponibles

PDF, TXT o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

0 calificaciones0% encontró este documento útil (0 votos)

130 vistas4 páginasGutter Machines

Cargado por

eventricCopyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

Está en la página 1de 4

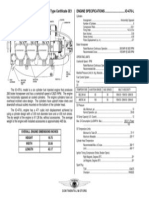

5", 6", or 7" K Ironman 5"/6" K Combo Ironman

5 1/2" Ironman Fascia

5", 6", 5/6" K Combo Ironman Jr.

6" Half Round Ironman

7" Ironman Box

Power Drive

Shear

Speed Controls

Recommended

Materials

3/4 HP, 110 Volt, single phase,

13.6 Amps, totally enclosed fan

cooled T.E.F.C. motor

Painted Steel

Aluminized Steel

Ternecoat Steel

Aluminum

Copper

24 gauge

24, 26 gauge

24 gauge

.027, .032

16 oz.-20 oz. 3/4 hard

Powered polyurethane drive rollers

via chains and sprockets

Approx. 35 ft per minute

Front pull guillotine

Push Button RUN/JOG controls

at entry and exit ends

5" K Panther 6" K Panther

Power Drive

Shear

Speed

Controls

Recommended

Materials

3/4 HP, high torque sealed motor. 1

HP reduction gear. Machine plugs

directly into 110-120 Volt outlet

.027, .032

26 gauge

16 oz. 3/4 hard

Aluminum

Painted Steel

Copper

12 drive forming rollers5 bottom,

7 top for the 5 K. 14 drive forming

rollers6 bottom, 8 top for the 6

K. Rollers are10-18 steel plated

.002 industrial hard chrome

Approx. 35 ft per minute

Front pull guillotine

Push button exit end controls with

jog feature. Emergency shut off

switch and jog feature at entry end

5" K Watertite

6" K Watertite

Power Drive

Shear

Controls

Recommended

Materials* 3/4 HP, 110 Volt, single phase,

13.6 Amps. Machine plugs

directly into 110-120 Volt outlet

.027, .032

26 gauge

16 oz. 3/4 hard

Aluminum

Painted Steel

Copper

12 drive forming rollers7 bottom,

5 top for the 5 K. 14 drive

forming rollers8 bottom and 6

top for the 6 K. Rollers are 10-18

steel plated .002 industrial hard

chrome

Manually Operated Guillotine Style

Drumswitch at exit end. Emergency

shut off switch at entry end Speed

Approx. 35 ft per minute

KWM Gutterman Inc. is the sole

manufacturer of Ironman, Panther,

and Watertite Gutter Machines.

They are a family owned and

operated manufacturer with over 45

years of experience.

KWMs modern manufacturing

facility supports highly trained

personnel and computer controlled

machine tools allowing them to

manufacture the highest quality

roll forming products.

5" K Grover 6" K Grover

Power Drive

Shear

Controls

1 HP, 110 Volt Single Phase. Ma-

chine Plugs directly into 110-120

Volt Outlet

Recommended

Materials

.027 to .032

26 gauge

16 oz-20 oz. 3/4 hard

Aluminum

Painted Steel

Copper

Spring loaded drive system, All pow-

ered roller stations, Single drive train

for each section of the machine

Pull Double Rack and Gear Shear

Push button exit end controls with jog

feature, Emergency shut off switch

5"/6" K Combo Mach II

NT 7" Commercial Box

Power Drive

Shear

Speed

Controls

Recommended

Materials

3/4 HP, 110 VAC, 60 HZ, 1 Ph,

11 Amps

24 gauge

24, 26 gauge

.027, .032

16 oz.-20 oz. 3/4 hard

Painted Steel

Aluminized Steel

Aluminum

Copper

Electronically Driven

Polyurethane Rollers

Approx. 50 ft per min

Forward pulling front pull guillotine

(easy cut shear)

Push Button RUN/JOG controls

at entry and exit ends

Building the fnest portable roll forming

machines since 1991. A strong commit-

ment to quality, service and on-time ship-

ments has made New Tech Machinerys

gutter machines the equipment of choice

for contractors and factories worldwide.

Grover Machines are innovative, du-

rable, and dependable! With decades of

experience in the roll forming industry,

Grover continues to set high standards.

Their complete line of gutter, down-

spout, and elbow machines have set

them apart from the competition.

6" K Mach II 5" K Mach II

Speed Approx. 30 ft per minute

1700K 5" K Knudson 1770A 5" K Knudson

Power Drive

Shear

Speed

Controls

Recommended

Materials

100 to 115 VAC/200 to 230 VAC +/-

10%, 15 Amps

26 gauge

26 gauge

.027, .032

16 oz.-20 oz. 3/4 hard

Painted Steel

Aluminized Steel

Aluminum

Copper

8 powered roll-forming stations.

4 station auxiliary box forming units.

Gear/Sprocket/Roller Chain Drive

Approx. 35 ft per minute

Manually Operated Guillotine Style

Directional Guard/Electric Motor

Control: 3 position drum switch E-stop

switches, exit-end safety switch

Reliability, durability, and toughness:

Thats Knudsons reputation. Contractors

around the world have chosen Knudson

machines to fuel their businesses for

nearly 50 yrs. One of the frst seamless

gutter machines ever built was a Knudson,

and its design serves as an industry

benchmark to this day.

EL2002 Portable Elbow 1700K 6" K Knudson

Contractors: Dont forget to ask about special

industry rates on gutter materials and accessories.

19 Skokie Valley Road

Lake Bluff, IL 60044

1-888-909-RAIN toll free

847-283-0006 local

847-283-0007 fax

www.GutterSupply.com

Reasons to Buy a Gutter Machine Reasons to Buy at RainTrade

Control Your Business - You decide when the job gets done

Increase Cash Flow - No tying up your money waiting on subcontractors

Increase Profts - Lower cost per foot / Cut out the middle man

Quality Control - Fewer call backs

True Seamless Gutters - Less labor and less waste. Save time and money

100% Tax Deductible

Experienced and Knowledgeable Staff 30 yrs. + Exp.

Service - Factory Trained Technicians On Staff

Fast Delivery and Low Prices

Large Selection

Financing Available

BBB Accredited Business

Current sale promotions, individual machine specifcations

and unbiased industry related gutter machine articles are

just a few of the items youll fnd at GutterSupply.com.

GutterSupply.com has everything you need to know

about gutter machines including machine set up, maintenance,

transport and installation.

Protect your investment

with a canvas cover

Gutter Machine Covers

5/6 Mini Coil Cradle 5/6 Full Size HD Coil Cradle

Run Out Stands

Run out stands support the gutter

as it runs out of the machine

All-in-One Adjustable Coil Cradle:

Adjustable for 5 & 6 Coil.

Holds up to 150 lbs. of Gutter Coil.

Lightweight (36 lbs.), foor mounted

Holds a Full Size Gutter Coil.

Adjustable for 5 & 6 Coil.

Floor Mounted (Please Call for

Machine Mount Option)

También podría gustarte

- Arvel Gentry-10-Sailing - To - WindwardDocumento3 páginasArvel Gentry-10-Sailing - To - WindwardTom Bee100% (1)

- Arvel Gentry - Studies of Mast Section AerodynamicsDocumento10 páginasArvel Gentry - Studies of Mast Section AerodynamicsklzsailingAún no hay calificaciones

- UPU Member Countries Addressing StructureDocumento296 páginasUPU Member Countries Addressing StructureBaehaqqi ImamAún no hay calificaciones

- Current LogDocumento6 páginasCurrent LogDominic Isaac AcelajadoAún no hay calificaciones

- Using An Airless Paint Sprayer - tcm96-1128824Documento6 páginasUsing An Airless Paint Sprayer - tcm96-1128824ravi00098Aún no hay calificaciones

- Canine Food Allergy (Dr. Jigar K Patel)Documento3 páginasCanine Food Allergy (Dr. Jigar K Patel)Jigar PatelAún no hay calificaciones

- FREE FLIGHT RESOURCE LIST VENDORS, PUBLICATIONS, WEBSITESDocumento6 páginasFREE FLIGHT RESOURCE LIST VENDORS, PUBLICATIONS, WEBSITESsuttipong_polmagAún no hay calificaciones

- Traffic Policer DocumentationDocumento17 páginasTraffic Policer Documentationcsk275% (4)

- Carburetor TechnologyDocumento4 páginasCarburetor TechnologyPer ForsbergAún no hay calificaciones

- Civil Government of Virginia: A Text-book for Schools Based Upon the Constitution of 1902 and Conforming to the Laws Enacted in Accordance TherewithDe EverandCivil Government of Virginia: A Text-book for Schools Based Upon the Constitution of 1902 and Conforming to the Laws Enacted in Accordance TherewithAún no hay calificaciones

- Catalogo ParkerDocumento524 páginasCatalogo ParkerViníciusE.FláviaAún no hay calificaciones

- Selden Yacht Catalogue MarineriggingDocumento101 páginasSelden Yacht Catalogue MarinerigginglmarinegroupAún no hay calificaciones

- Essential guide to compressed air systems design, operation, and maintenanceDocumento7 páginasEssential guide to compressed air systems design, operation, and maintenanceNicole WheelerAún no hay calificaciones

- Business Plan: Establishment AND Operation OFA Vehicle Wheel Alignment AND Wheel Balancing Business IN Kampala, UgandaDocumento26 páginasBusiness Plan: Establishment AND Operation OFA Vehicle Wheel Alignment AND Wheel Balancing Business IN Kampala, UgandaHerbert BusharaAún no hay calificaciones

- MC160n Maintenance ManualDocumento206 páginasMC160n Maintenance Manualedijhon5815Aún no hay calificaciones

- O470u PDFDocumento1 páginaO470u PDFeljonny01Aún no hay calificaciones

- Fair Lease AgreementDocumento10 páginasFair Lease AgreementenidgodtreeAún no hay calificaciones

- Linear & Manual - ActuatorDocumento20 páginasLinear & Manual - ActuatorsviswaAún no hay calificaciones

- Engine Control SystemDocumento694 páginasEngine Control Systemthar tharAún no hay calificaciones

- MC8085Documento7 páginasMC8085Bhavani BhavanAún no hay calificaciones

- Onan Electronic Ignition UpgradeDocumento4 páginasOnan Electronic Ignition Upgradesurpluselect100% (1)

- AC Bus Electrical Circuit Diagrams ManualDocumento235 páginasAC Bus Electrical Circuit Diagrams ManualGMCAún no hay calificaciones

- Making A Fiberglass MoldDocumento2 páginasMaking A Fiberglass MoldmostlimbAún no hay calificaciones

- Statutory Demand Letter Template: WWW - Thelegalstop.co - UkDocumento1 páginaStatutory Demand Letter Template: WWW - Thelegalstop.co - UkmartinAún no hay calificaciones

- Manual RadioShack For PRO 2017Documento32 páginasManual RadioShack For PRO 2017Benjamin Dover0% (1)

- PluginTutorial V01Documento92 páginasPluginTutorial V01Vincenzo PaternòAún no hay calificaciones

- HP2070 Parts ListDocumento3 páginasHP2070 Parts ListZaidu zamaan100% (1)

- Akai S5000 Version 2.0 Software AddendumDocumento47 páginasAkai S5000 Version 2.0 Software AddendumStanleyAún no hay calificaciones

- Camaro RPO - VIN DecodeDocumento13 páginasCamaro RPO - VIN Decodedjsanchez2Aún no hay calificaciones

- Service BulletinDocumento5 páginasService Bulletinohromeo100% (1)

- TIG Welding Tips for Aluminum and SteelDocumento5 páginasTIG Welding Tips for Aluminum and SteelKentDemeterioAún no hay calificaciones

- ES and ESS Stunner ManualDocumento28 páginasES and ESS Stunner ManualDarwin TierraAún no hay calificaciones

- RD125C Crankcase Cylinder Exploded View DiagramDocumento44 páginasRD125C Crankcase Cylinder Exploded View DiagramFede BonagliaAún no hay calificaciones

- The Prepaid CardDocumento3 páginasThe Prepaid Cardgoofy101Aún no hay calificaciones

- 121 Master CatalogDocumento60 páginas121 Master CatalogericlearnAún no hay calificaciones

- Eliminator Torsion Axles: Shock Cord Cross SectionDocumento23 páginasEliminator Torsion Axles: Shock Cord Cross SectionRaju ManjuAún no hay calificaciones

- Sheriffs LawsuitDocumento37 páginasSheriffs LawsuitTheCullmanTribuneAún no hay calificaciones

- IO-470-L Type Certificate 3E1 ENGINE SPECIFICATIONS ............................... IO-470-LDocumento1 páginaIO-470-L Type Certificate 3E1 ENGINE SPECIFICATIONS ............................... IO-470-Leljonny01Aún no hay calificaciones

- Trespass Exclusion NoticeDocumento1 páginaTrespass Exclusion NoticebperkyAún no hay calificaciones

- Jet Pump - InstallationDocumento12 páginasJet Pump - InstallationRaja Pathamuthu.G100% (2)

- Greenbook ManualDocumento890 páginasGreenbook Manualnimaboat4589Aún no hay calificaciones

- Modifying a GM DIS ignition module for direct coil controlDocumento5 páginasModifying a GM DIS ignition module for direct coil controlJameel KhanAún no hay calificaciones

- Whole Home Repair Guidelines 2022Documento10 páginasWhole Home Repair Guidelines 2022PennCapitalStarAún no hay calificaciones

- Operator'S Manual: 5-1/2 In. 18 Volt Circular Saw P501Documento40 páginasOperator'S Manual: 5-1/2 In. 18 Volt Circular Saw P501jahemscbdAún no hay calificaciones

- Allen Heat GL3300Documento20 páginasAllen Heat GL3300fprkAún no hay calificaciones

- Sharp XE-A22S Cash Register XE-A22SDocumento120 páginasSharp XE-A22S Cash Register XE-A22SReyna CoreaAún no hay calificaciones

- 5.1. Carburetors and Their SystemsDocumento48 páginas5.1. Carburetors and Their SystemsGODAún no hay calificaciones

- C20X and C50X Series Manual - EnglishDocumento86 páginasC20X and C50X Series Manual - EnglishCheme Plata100% (1)

- Baron 58P - Chapter 06 01062020R00 PDFDocumento3 páginasBaron 58P - Chapter 06 01062020R00 PDFAlex AbadAún no hay calificaciones

- Coleman RV 12 Volt Thermistat ACDocumento18 páginasColeman RV 12 Volt Thermistat ACsthoma20100% (1)

- Obdii DodgeDocumento23 páginasObdii Dodgeapocriff2100% (2)

- EMJ CORPORATION Et Al v. HUDSON SPECIALTY INSURANCE COMPANY Et Al ComplaintDocumento18 páginasEMJ CORPORATION Et Al v. HUDSON SPECIALTY INSURANCE COMPANY Et Al ComplaintACELitigationWatchAún no hay calificaciones

- Training LCD Sony AZ3FK PDFDocumento39 páginasTraining LCD Sony AZ3FK PDFVictor Avendaño Grillo100% (1)

- Current AccountsDocumento8 páginasCurrent AccountsAnonymous fcqc0EsXHAún no hay calificaciones

- The Motor Vehicles ActDocumento64 páginasThe Motor Vehicles ActSheldon Thomas DlimaAún no hay calificaciones

- Manual Fresadora X4 SyilDocumento78 páginasManual Fresadora X4 SyilCarlosAún no hay calificaciones

- Sail TrimmingDocumento2 páginasSail Trimmingdanut_docAún no hay calificaciones

- Basic Electronic Circuit Design - Diy Electronic Circuit - Part 15Documento5 páginasBasic Electronic Circuit Design - Diy Electronic Circuit - Part 15ReneAún no hay calificaciones

- Coyotes: General Biology, Management & Harvest StrategiesDocumento6 páginasCoyotes: General Biology, Management & Harvest StrategiesRonal Huaracco AnampaAún no hay calificaciones

- 4G CAC KPI Report Site 180421_STP_SUKAWATI_4GDocumento16 páginas4G CAC KPI Report Site 180421_STP_SUKAWATI_4Ghela2709Aún no hay calificaciones

- 1997 Chevrolet Suburban PDFDocumento433 páginas1997 Chevrolet Suburban PDFAlberto CalvarioAún no hay calificaciones

- Operating-Manual VSH200 F-011819 19.1Documento98 páginasOperating-Manual VSH200 F-011819 19.1Yoyon HaryonoAún no hay calificaciones

- CoroGuide Users ManualDocumento9 páginasCoroGuide Users ManualRacareanu Delis RobertAún no hay calificaciones

- Starting and Charging Systems: Chapter 5 Part CDocumento5 páginasStarting and Charging Systems: Chapter 5 Part CJoão T. AbreuAún no hay calificaciones

- Manual of PT502Documento16 páginasManual of PT502Abiodun Salami100% (1)

- 2016 Holmatro US Catalog - 2016Documento92 páginas2016 Holmatro US Catalog - 2016Forum Pompierii100% (1)

- ANSI ISEA Z89 1 2014 American National PDFDocumento41 páginasANSI ISEA Z89 1 2014 American National PDFTeam SHEQMS100% (3)

- Lab 8.4.2Documento8 páginasLab 8.4.2Luis David López TelloAún no hay calificaciones

- v06 Oi Mediaclave enDocumento87 páginasv06 Oi Mediaclave enBenjamin TantiansuAún no hay calificaciones

- Buma 30033 - Funds of Bpo 102Documento69 páginasBuma 30033 - Funds of Bpo 102Hilary OdinadaAún no hay calificaciones

- QUOTATION 20265-TLDM CablingDocumento2 páginasQUOTATION 20265-TLDM CablingMaaeglobal ResourcesAún no hay calificaciones

- Centrifugal Juicer Extractor Santos 68Documento4 páginasCentrifugal Juicer Extractor Santos 68Sce Dgp100% (1)

- Main Specifications of FOMA 905i SeriesDocumento5 páginasMain Specifications of FOMA 905i SeriesAditya R. AchitoAún no hay calificaciones

- Installation Guide of Petroleum Underground TanksDocumento32 páginasInstallation Guide of Petroleum Underground TanksPn Ekanayaka100% (1)

- Amc CrowerDocumento3 páginasAmc CrowerPablo Etp100% (1)

- Bolt Torque and Tap Check: Understanding ASTM A325, A490 Bolts and Derrick ConstructionDocumento20 páginasBolt Torque and Tap Check: Understanding ASTM A325, A490 Bolts and Derrick Constructionbudymood100% (3)

- Humidity Sensor ManualDocumento28 páginasHumidity Sensor ManualXANPHOXYL KIBETAún no hay calificaciones

- Section 0 Principles of Product SafetyDocumento40 páginasSection 0 Principles of Product Safetyjohnline67% (3)

- HW 3 SolutionsDocumento12 páginasHW 3 SolutionsB . HassanAún no hay calificaciones

- Yad - Display GTK+ Dialogs in Shell Scripts: OptionsDocumento43 páginasYad - Display GTK+ Dialogs in Shell Scripts: Optionsdarinel8Aún no hay calificaciones

- D10T2 PDFDocumento28 páginasD10T2 PDFfmboy700Aún no hay calificaciones

- (FBM230231232233) User's GuideDocumento240 páginas(FBM230231232233) User's Guidemissoum mohamed100% (3)

- "Netphone"-Reintegrating The Net Phone: Complexities Currently FacedDocumento8 páginas"Netphone"-Reintegrating The Net Phone: Complexities Currently FacedbharathkvAún no hay calificaciones

- Q A P (QAP) - S Inverter: Uality Ssurance LAN OlarDocumento5 páginasQ A P (QAP) - S Inverter: Uality Ssurance LAN Olarsasikumar100% (2)

- ECS 3-17-1 - 2 - 8009766bDocumento5 páginasECS 3-17-1 - 2 - 8009766bFlorin Daniel AnghelAún no hay calificaciones

- DSL Forum Technical Report TR-120 ADSL/ADSL2plus Loop CharacteristicsDocumento5 páginasDSL Forum Technical Report TR-120 ADSL/ADSL2plus Loop CharacteristicsRicardo Arce ValdovinosAún no hay calificaciones

- Align images and adjust brightness in Photoshop: Core scan exampleDocumento31 páginasAlign images and adjust brightness in Photoshop: Core scan exampleemilia597Aún no hay calificaciones

- ZTE NGN Total SolutionDocumento8 páginasZTE NGN Total SolutionEbere ObiaAún no hay calificaciones