Documentos de Académico

Documentos de Profesional

Documentos de Cultura

560 000 GD P 007 - 1

Cargado por

Juan TorresTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

560 000 GD P 007 - 1

Cargado por

Juan TorresCopyright:

Formatos disponibles

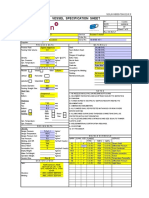

PROJECT NO.

C-560

MINERA CHINALCO PERU S.A.

TOROMOCHO PROJECT

Document No. 000-GD-P-007

Piping Material Classes

Aker Solutions

Owner Approval:

J.F. Wigle

333 E. Wetmore Rd., Ste. 600

Tucson, Arizona 85705

Date:

08/16/08

REV DATE BY CHK APPROVAL DESCRIPTION

A 02/14/08 DC JBS Issued for Internal Review

B 06/24/08 RLD CGB AIH Issued for Client Approval

C 08/07/08 RLD CGB JBS/AIH Reissued for Client Approval

D 08/18/08 RLD CGB JBS/AIH Issued for Design

E 12/04/08 AJY JMR JL/AIB Issued for Cost Estimate

F 04/07/09 HB CGB EH/JO/AF Re-issued for Design

G 8/20/09 AJY RLD JHL/RC Re-issued for Design

0 6/21/10 CED AJY JBS/RC Issued for Design

1 8/29/11 BS AJY RC General Update

DISTRIBUTION A B C D E F G 0 1 2 3 4 5 6

Client 6/25 8/9 8/21

Procurement

Field

Internal 02/14

8/21 12-10 04-07 8/24 6/24

AK Toronto

Note: Signed originals on file

Project C-560

General Specification 000-GD-P-007

Piping Material Classes

Rev 1

Q:\Shared\R0534200\01_Eng_Doc\05_Pip\01_Design_Criteria\02_Int_App\000-GD-P-007 Piping Material Classes\560-000-GD-P-007_1.doc

Page 2 of 15

TABLE OF CONTENTS

REVISION CONTROL

GENERAL NOTES

PIPING SERVICE AND MATERIAL CLASS TABLE

MATERIAL CLASSES MATRIX

PIPING MATERIAL CLASSES

GD07 VASI - VALVES AND SPECIALTY ITEMS

GD07 VALVES TABLE II TAILINGS BALL VALVES

GD07 VALVES TABLE III TAILINGS KNIFE GATE VALVES

GD07 FIG H FLANGE ADAPTER FOR BUTTERFLY VALVES

SD-P-102R, PIPE BRANCH REINFORCEMENT

Project C-560

General Specification 000-GD-P-007

Piping Material Classes

Rev 1

Q:\Shared\R0534200\01_Eng_Doc\05_Pip\01_Design_Criteria\02_Int_App\000-GD-P-007 Piping Material Classes\560-000-GD-P-007_1.doc

Page 3 of 15

SPECIFICATION GD-07 REVISION CONTROL

Note: Revisions shown at right are the controlling

revisions for the entire Spec. GD-07

A B C D E F G 0 1

Section Description

Section Revision No.

Note: Revisions shown below are for each Section of GD-07. If no changes

were made, the Sections last revision is retained for each subsequent issue

of the entire GD-07. At Rev 0, each Sections revision is advanced to Rev 0

and shall remain as such until changes are made, for each subsequent

issues of GD-07.

General Notes

A B C D E F G G 1

Piping Services and Material Class Table

A B C D E F G 0 1

Material Classes Matrix

A B C D E F G 0 1

Class A1 A B C D E F G 0 1

Class A3 A B C D E F G 0 1

Class A5 A B C D E F G 0 0

Class B1 A B C D E F G G G

Class F1 A B C D E F G G 0

Class F5 - - - - E F G 0 1

Class H1 A B C D - F G 0 1

Class H2 - - - - - - - - 0

Class J3 - - - - E F G 0 1

Class L1 - - - - E F G 0 1

Class L1B A B C D E F G 0 1

Class L1C - - - - - - - A 0

Class L2V A B C D E F G 0 1

Class L2W A B C D E F G 0 1

Class L3

- - - - E F G 0 1

Class L4

A B C D E F G 0 1

Class L5

A B C D E F G 0 1

Class L6

A B C D E F G 0 1

Class L8B

A B C D E F G 0 1

Class L9

A B C D E F G 0 1

Class L10

A B C D E F G 0 1

Class L13

A B C D E F G 0 1

Project C-560

General Specification 000-GD-P-007

Piping Material Classes

Rev 1

Q:\Shared\R0534200\01_Eng_Doc\05_Pip\01_Design_Criteria\02_Int_App\000-GD-P-007 Piping Material Classes\560-000-GD-P-007_1.doc

Page 4 of 15

SPECIFICATION GD-07 REVISION CONTROL

Note: Revisions shown at right are the controlling

revisions for the entire Spec. GD-07

A B C D E F G 0 1

Section Description

Section Revision No.

Class L18 (BEI)

- - - - - - - D 0

Class L19 (BEI)

- - - - - - - D 0

Class L20 (BEI)

- - - - - - - D 0

Class L25

A B C D E F G G 0

Class M1

- - - - E F G G 0

Class M2

A B C D E F G G 0

Class M3

A B C D E F G G 0

Class P1

A B C D E F G G 0

Class P2

A B C D E F G G 0

Class P4

- - - - E F G 0 1

Class P6

A B C D E F G 0 1

Class P7

A B C D E F G 0 1

Class P8

- - - - E F G 0 1

Class P12

A B C D E F G 0 1

Class P13

A B C D E F G 0 1

Class P14

A B C D E F G 0 1

Class P16

A B C D E F G G 0

Class PL8 (BEI)

- - - - - - - D 0

Class PL9 (BEI)

- - - - - - - D 0

Class R1

- - - - - F G 0 1

Class R2

A B C D E F G 0 1

Class S1

A B C D E F G 0 1

Class S2

A B C D E F G 0 1

Class S3

A B C D E F G 0 1

Class S6

- - - - E F G 0 1

Class S8

A B C D E F G 0 1

Project C-560

General Specification 000-GD-P-007

Piping Material Classes

Rev 1

Q:\Shared\R0534200\01_Eng_Doc\05_Pip\01_Design_Criteria\02_Int_App\000-GD-P-007 Piping Material Classes\560-000-GD-P-007_1.doc

Page 5 of 15

SPECIFICATION GD-07 REVISION CONTROL

Note: Revisions shown at right are the controlling

revisions for the entire Spec. GD-07

A B C D E F G 0 1

Section Description

Section Revision No.

Class S9

A B C D E F G 0 0

Class S9A

- - - - E - G 0 1

Class S10

A B C D E F G 0 0

Class S11

- - - - E F G 0 1

Class S12B

- - - - E F G 0 1

Class S14

- - - - - F G G G

Class S15

- - - - - F G G 0

Class T6

A B C D E F G 0 1

Class T26

A B C D E F G 0 1

Valves and Specialty Items

A B C D E F G 0 1

SD-P-102R, Pipe Branch Reinforcement

0 0 0 0 0 F G G G

Project C-560

General Specification 000-GD-P-007

Piping Material Classes

Rev 1

Q:\Shared\R0534200\01_Eng_Doc\05_Pip\01_Design_Criteria\02_Int_App\000-GD-P-007 Piping Material Classes\560-000-GD-P-007_1.doc

Page 6 of 15

Revision 1 Description

Note: Revisions shown below are the actual updates of each Section of Spec. GD-07.

Revision indicated above is the Revision issue of the entire Spec. GD-07

SECTION REV. DESCRIPTION

Piping Service &

Material Class

Table

1

General update; added SX Process Solution

Material Classes

Matrix

1

General update

Class A1 1

Added Ammoniated Vent (AMV), Process Drains (PD), Neutral

Slurry (SLN); changed valve from A-3 (Thrd) to A-6 (SW)

Class A3 1

Added Anhydrous Ammonia (AHA) service

Class A5 0

No change; corrected revision from G to 0

Class B1 G

No change

Class F1 1

Update commodity services; added valves, A-15A, C-23A, E-

18A, K-5, & P-1

Class F5 1

Updated commodity services; added D-1, C-42A

Class H1 1

Replaced valve code A-4 to A-15

Class H2 0

Added for Sodium Hydrosulfide (NaHS) service

Class J3 1

Replaced valve code A-30F-GO with A-29-GO (2 to 8 size

range).

Class L1 1

Deleted Carbon Eluant Solution (CES) on service block.

Revised Branch Reinforcement Table.

Class L1B 1

Updated commodity services; adjusted valve size range; added

Valve Code B-2-H; replaced Valve Code U-4 to U-4A and U-4-

GO to U-4A-GO; modified Note 4 and Branch Reinforcement

table.

Class L1C 1

Added Valve Code D-1

Class L2V 1

Added service abbreviation (PW) and DW; revised pipe Sch.

from 40 to 80 for pipe size to 2.

Class L2W 1

Changed Fitting ratings to CL300 malleable iron (was CL150).

Class L3 1

Added Fuel Oil Service (FO) and revised Waste Anti Freeze

abbreviation to (WF); modified Design Pressure; added A-61

and A-61-GO for HP Fuel oil transfer.

Project C-560

General Specification 000-GD-P-007

Piping Material Classes

Rev 1

Q:\Shared\R0534200\01_Eng_Doc\05_Pip\01_Design_Criteria\02_Int_App\000-GD-P-007 Piping Material Classes\560-000-GD-P-007_1.doc

Page 7 of 15

Revision 1 Description

Note: Revisions shown below are the actual updates of each Section of Spec. GD-07.

Revision indicated above is the Revision issue of the entire Spec. GD-07

SECTION REV. DESCRIPTION

Class L4 1

Updated commodity services; added Fuel Oil Underground

(FOU) service; added Note 8.

Class L5 1

Updated commodity services; adjusted valve size range; added

U-4A, C-91, K-4-H, K-5

Class L6 1

Updated commodity services.

Class L8B 1

Updated commodity services; ;increased size range for U-4A;

added A-16A. Modified Branch Reinforcement Table

Class L9 1

Added Gate Valve G-14.

Class L10 1

Added Valve code G-16, A-38, and N-4. Modified note 4 and

Branch Reinforcement Table.

Class L13 0

Updated commodity services.

Class L18 0

Added Notes for Valves (BEI Spec)

Class L19 0

Added Notes for Valves (BEI Spec)

Class L20 0

Removed HOLD on the Branch Reinforcement Table

Class M1 0

No Change, raised to Rev 0

Class M2

0

No Change, raised to Rev 0

Class M2

0

No Change, raised to Rev 0

Class P1 0

Update commodity services; added B-16 for AMV)

Class P2 0

No Change; raised to Rev 0. Not used

Class P4 1

Added K-1-P, K-4-GO

Class P6 1

Updated commodity services; modified valve types and ranges

Class P7 1

Updated commodity services, flange adapter description;

added Note 10 & A-15A/A-15A-GO.

Class P8 1

Update flange adapter description. MC not used.

Class P12 1

Updated flange adapter description

Project C-560

General Specification 000-GD-P-007

Piping Material Classes

Rev 1

Q:\Shared\R0534200\01_Eng_Doc\05_Pip\01_Design_Criteria\02_Int_App\000-GD-P-007 Piping Material Classes\560-000-GD-P-007_1.doc

Page 8 of 15

Revision 1 Description

Note: Revisions shown below are the actual updates of each Section of Spec. GD-07.

Revision indicated above is the Revision issue of the entire Spec. GD-07

SECTION REV. DESCRIPTION

Class P13 1

Updated Flange Adapter descriptions

Class P14 1

Updated Flange Adapter descriptions

Class P16 0

No change: raised to Revision 0

Class PL8 0

Updated pipe description and added Note for valve description

Class PL9 0

Updated pipe description and added Note for valve description

Class R1 1

Modified Knife gate valves description and added Tag Nos.

Class R2 1

Updated valves type and size range.

Class S1 1

Updated commodity users; added flat faced flanges, A-15A, A-

15A-GO; extended E-18 size to 4; added Note 7.

Class S2 1

Updated commodity services; added C-21, A-15A & A-15A-GO;

revised 5D to 3D

Class S3 1

Update commodity services; added flat faced flanges option;

adjusted valve size range.

Class S6 1

Added ASLL

Class S8 1

Limited size range to 12 NPS; added bore notes to elbolets,

weldolets, and WN flanges; corrected A-29-GO to A-30-GO

Class S9 0

No change; raised to Rev 0 only

Class S9A 1

Added commodities ACH, N, A-24, SPH-24; changed gasket

rating to CL 600

Class S10 0

No change; raised to Rev 0 only.

Class S11 1

Corrected Notes 2 & 3 regarding oxygen service; added Class

300 flange, gasket, bolting to match ACL feed pumps discharge

flange.

Class S12B 0

Changed commodity service to high pressure gaseous oxygen

(GOXH); updated valves for oxygen service

Class S14 0

No change; raised to Rev 0 only

Project C-560

General Specification 000-GD-P-007

Piping Material Classes

Rev 1

Q:\Shared\R0534200\01_Eng_Doc\05_Pip\01_Design_Criteria\02_Int_App\000-GD-P-007 Piping Material Classes\560-000-GD-P-007_1.doc

Page 9 of 15

Revision 1 Description

Note: Revisions shown below are the actual updates of each Section of Spec. GD-07.

Revision indicated above is the Revision issue of the entire Spec. GD-07

SECTION REV. DESCRIPTION

Class S15 0

Updated commodity services.

Class T6 1

Revised pipe wall 8 to 12 for Class 600 service; updated

flanges from CL300 to CL600

Class T26 1

Updated Titanium material to Grade 12; adjusted 24 NPS to

1.25 wall; spec not used

Project C-560

General Specification 000-GD-P-007

Piping Material Classes

Rev 1

Q:\Shared\R0534200\01_Eng_Doc\05_Pip\01_Design_Criteria\02_Int_App\000-GD-P-007 Piping Material Classes\560-000-GD-P-007_1.doc

Page 10 of 15

Revision 1 Description

Note: Revisions shown below are the actual updates of each Section of Spec. GD-07.

Revision indicated above is the Revision issue of the entire Spec. GD-07

Valves and Specialty Items:

SECTION REV. DESCRIPTION

Ball Valves 1 Revised as noted on VASI

Butterfly Valves 1 Revised as noted on VASI

Check Valves 1 Revised as noted on VASI

Diaphragm

Valves

1 No Change

Globe Valves 1 Revised as noted on VASI

Gate Valves 1 Revised as noted on VASI

Hydrants 1 No Change

Knife Gate

Valves

1 Revised as noted on VASI

Needle Valves 1

No Change

Pinch Valves 1

No Change

Plug Valves 1

No Change

Dole Valves 1

No Change

Specialty Items 1 No changes

Project C-560

General Specification 000-GD-P-007

Piping Material Classes

Rev 1

Q:\Shared\R0534200\01_Eng_Doc\05_Pip\01_Design_Criteria\02_Int_App\000-GD-P-007 Piping Material Classes\560-000-GD-P-007_1.doc

Page 11 of 15

General Notes

G1 This specification is a part of General Specification 000-GD-P-006 Piping Design

Criteria and it includes the materials required for each piping class and the branch

connection requirements

G2 Branch connections shall be made in accordance with Standard Drawing SD-P-102R

(attached) and branch reinforcement tables as referenced in the Piping Material

Classes.

G4 Valves, requiring Gear Operators (not supplied as standard), are identified with "GO"

after the valve code designation on piping and instrument diagrams, and drawings.

G5 Underground carbon steel pipe shall be PLS X-TRU-COAT or Equal plastic coated

(30 mil minimum thickness). Fittings, joints and coating damage shall be single

wrapped (half overlap) in the field with yellow polyethylene corrosion protection tape

Polyken No. 900 or equal. Wrapped surfaces shall be primed with Polyken No. 927

Pipeline Primer.

G6 Minimum size for yard underground piping shall be 2 inches.

G7 Hydrostatic test pressures shall be a minimum of 1.5 times the design pressures

except as noted otherwise. The design pressures are shown in the Piping Line List.

G8 Lubricating oil, gear oil, and hydraulic oil lines shall be chemically cleaned per

General Specification 000-GC-P-009 requirements. Use factory annealed and pickled

stainless steel tubing and tube fittings in order to minimize or to eliminate field

pickling of carbon steel piping.

G9 Material Specification ASTM A106 Gr. B is an acceptable material substitution to

ASTM A53 Gr. B seamless or ERW, but not vice versa.

G10 Alloy stud bolts ASTM A193 Gr. B7 may be used in lieu of ASTM A307 Gr. B

machine bolt, but not vice versa.

G11 References to Manufacturer/Model numbers of Valves and Specialty items shall be

"or Approved Equal" basis.

G12 Sizes of pneumatic or hydraulic actuated valves shall be as specified on the Valves &

Specialty Items.

Project C-560

General Specification 000-GD-P-007

Piping Material Classes

Rev 1

Q:\Shared\R0534200\01_Eng_Doc\05_Pip\01_Design_Criteria\02_Int_App\000-GD-P-007 Piping Material Classes\560-000-GD-P-007_1.doc

Page 12 of 15

SERVICE COMMODITY SYMBOL MATERIAL CLASS

CONCENTRATOR

Concentrate CO L5 / P6 / P7 / R2

Cyclone Feed (SAG Mill Area) SL L5 / R1 (ceramic-lined)

Cyclone Overflow (SAG Mill Area) SL L5 / R1 (ceramic-lined)

Cyclone Underflow (SAG Mill Area) SL L5 / R1 (ceramic-lined)

Filtrate SL L5 / R2

Regrind Cyclone Feed SL L5 / R2

Flotation Tails TA L5 / R2 / P16 / P7

Tailings Thickener Underflow TA L1/L1B/L5/L18/L19/L20/P4/P7/PL

8/PL9/R2

Thickener Overflow TO L1B / L5 / P4 / P7 / R2

WATER, UNDERGROUND/ON GRADE

Cooling Water Return CWRU P6

Cooling Water Supply CWSU P6

Cooling Water (Medium Pressure) CWU L13 / P14

Fresh Water FRWU L13 / P7 / P14

Fire Protection Water FWU P12

Gland Seal Water GSWU L13

Process Water (Mill Water) PRU L13 / P6 / P7 / P14

Potable Water (Domestic Water) PWU P13

Raw Water (Low Pressure) RWU P6

Raw Water (Medium Pressure) RWU P14

Raw Water (High Pressure) RWU L10

WATER, ABOVEGROUND

Autoclave Seal Water ASW L1 / S9A

Cooling Water Return CWR L1 / L9/S1

Cooling Water Supply CWS L1/L9/P1/S1/S15

Fire Protection Water FPW L9

Fresh Water FRW L1/L1B/L8B/P1/P7/P14/S1

Gland Seal Water (Low Pressure; <150 psig)) GSW L1B /P14/ S1

Gland Seal Water (High Pressure) GSW L1B /P14/ S1

Process Water (Mill Water) PRW L1B/L10/P6/P14/R2

Potable Water (Domestic Water) PW L1B/L2V/P13

R.O. Water RO L1/L6/P1/P7/S1

Raw Water (Low Pressure) RW L1B/L5/L8B/L10/P7/P14/PL8/S1

Raw Water (High Pressure) RW L10

COMPRESSED GASES

Blower Air BA L8B/S1

High Pressure Gaseous Oxygen GOXH S1/S12B/T6/

S11(PLV Interface only)

Instrument Air IA L2W

Low Pressure Air LPA A1/L8B

Medium Pressure Air MPA L8B

Nitrogen N S9A

Plant Air PA L5/L8B / S1 (corrosive areas)

Project C-560

General Specification 000-GD-P-007

Piping Material Classes

Rev 1

Q:\Shared\R0534200\01_Eng_Doc\05_Pip\01_Design_Criteria\02_Int_App\000-GD-P-007 Piping Material Classes\560-000-GD-P-007_1.doc

Page 13 of 15

SERVICE COMMODITY SYMBOL MATERIAL CLASS

ACID SOLUTIONS AND REAGENTS

Ammonia (Aqueous) AA L6/F5

Alum AL L1B/P6/P19/S1

Ammonia Solution (concentrated NH

4

OH) AQA L6/S1

Anti-Scalant NaSH AS L1B

Acid Solution High (+10 g/L) ASH F1/F5/P7/S3

Acid Solution Low (-10 g/L) ASL F1/P4/P7/S1

Chemical Feed (for boiler) CF S1

Diluent DL S1

Flocculant FL L1B / P6 / P7

MIBC (Frother) MB L1/L1B/L4/P19

Milk of Lime ML L5/P6/P7/R2

Sodium Hydrosulfide (NaHS) NA H2/L1B/S1

Nitric Acid NAS F5 / S1

Potassium Amyl Xanthate PAX L4/P6/P7/P19

Aerofloat AF4-238 (secondary collector) RAF L1B/L4/P19

Sodium Silicate, Aluminum Silicate RSS L4/S1

Sulfuric Acid, Concentrated SAC H1

Caustic (sodium hydroxide) SH A1/S1

Zinc Cyanide ZC L4

HYDROCARBONS

Anti Freeze AF L1B/L3

Carbon Eluant Solution CES F5 / L1

Fuel Oil (diesel oil #2) (primary collector) FO L4/P19

Gasoline GAS L4

Grease GR L3 / L25 / S14 / S15

Hydraulic Oil,Low Pressure HOL L3 / L25/S14

Hydraulic Oil, High Pressure HOH L25 / S14 / S15

Lube Oil, High Pressure LOH L25 / S1/S14 / S15

Lube Oil, Low Pressure (Mill Return) LOL L3 / L6 / S2

Lube Oil, Low Pressure Pressure LOL L3 / L6

Natural Gas NG L6

Propane Gas PG L6

Waste Anti Freeze WF L3

Waste Oil WO L3

SEWERS & DRAINS

Chemical Waste and Vent CWV M3

Process Drain (gravity) PD F1/F5 P1 / P4 /P7/ S1/S3

(corrosive)

Process Drain (gravity) PD A1 / L1 (non-corrosive only) /

Process Vents PV (same as connected process )/S3

Sanitary Waste and Vent SS M1

Sanitary Sewer (Underground) SSU M2 / P6

Storm Drain ST P4

Non- Corrosive Vents VT H2/L1B

Project C-560

General Specification 000-GD-P-007

Piping Material Classes

Rev 1

Q:\Shared\R0534200\01_Eng_Doc\05_Pip\01_Design_Criteria\02_Int_App\000-GD-P-007 Piping Material Classes\560-000-GD-P-007_1.doc

Page 14 of 15

SERVICE COMMODITY SYMBOL MATERIAL CLASS

PROCESS SLURRIES

Slurry, Ammonium Dimolybdate ADM L1/S1/S2

Slurry, Acidic High Acid (+10 g/L) ASLH

F1/F5 / P4/P7/S1/S2/S3 (L.P.) /

S6 (H.P.)/S10

Slurry, Acidic Low Acid (-10 g/L) ASLL

F1/P6/P7/ S1/S2 (L.P.) / S6 (H.P.)

/ S10

Slurry, Spent Carbon

CS F5 / P6

Slurry, Ammoniated Moly SAM S1/S2

Slurry, Concentrate Low Pressure SL L5 / P7 / S2

Slurry, Acidic SLA S2

Slurry, Cold Autoclave Feed (H.P., Acidic) SLAC

S11 (@ Autoclave interface) /

S12B (@pump discharge to

autoclave)/T6

Slurry, Pressure Leach Flash

SLAF S3/S10

Slurry, Pressure Leach, Low Pressure Hot (not at PLV) SLAH S2 / S10 / T6

Slurry, Pressure Leach, High Pressure Hot (at PLV only) SLAH T6

Slurry, Gypsum SLG F1/L5/P7

Slurry, Neutral SLN A1/F1/L1C/L5/P7

Slurry, Residue (Tailings)

SLT S2 / P7 (non-acidic)

Slurry, Neutral (intermittent service - floor sumps)

SU F5/L4/L5 / P1 / R2 / P7

PROCESS VENTS

Ammoniated Vent AMV A1/F1/L6/P1/S1

Ammonia Vent (NH

3

) PV F1/L1/L8B/P1/S1

Hydrogen Sulfide Vent (H

2

S) PV F1

Sulfuric Acid Vent (H

2

SO

4

) PV F1

Autoclave Vent PVA

S1/S3 / S9A /T6 (@ PLV vent,

Class 600) /

STEAM & CONDENSATE

Boiler Blowdown, Low Pressure LBD A1

Condensate, Low Pressure LCD A1/A3/L1/L6/S1

Boiler Feed water, Low Pressure LPF A1

Steam, Low Pressure (103 kPag to 1241 kPag) LPS A1/S1

Boiler Blowdown, Medium Pressure MBD A3 / A5

Condensate, Medium Pressure MPC A3

Boiler Feed Water, Medium Pressure MPF A3 / A5

Steam, Medium Pressure (above 1241 to 3447 kPag) MPS A1/A3/S1/S3/S8/S11

Project C-560

General Specification 000-GD-P-007

Piping Material Classes

Rev 1

Q:\Shared\R0534200\01_Eng_Doc\05_Pip\01_Design_Criteria\02_Int_App\000-GD-P-007 Piping Material Classes\560-000-GD-P-007_1.doc

Page 15 of 15

SERVICE COMMODITY SYMBOL MATERIAL CLASS

PROCESS SOLUTIONS

Acidic Barren Solution

ABS F5 / P4/P7/S1

Autoclave Coolant (High Pressure)

ACH

S9 (H.P. to PLV) / S11(PLV) /

S12B

Ammonium Condensate

ACO A1/L6/S1

Autoclave Coolant (Low Pressure, <150 psig)

ACL S1 / S3 / P6 (Tank OFlows)

Ammoniated Moly Solution

AMS P7/S1

Ammonium Sulfate Solution

ASU S1

Sodium Hypochlorite

CLO S1

Carbon Strip Solution

CSS F5 / S1

Carbon Wash Solution

CSW F1/S1

Eluent Solution

ELS F1 / F5 /S1

Process Condensate

PCO F1/F5/S1

Pregnant Solution (High Acid)

PSH

P7 (L.P.) / P8 (H.P.) / S1 / F5 or

P6 for tank overflows

Pregnant Solution (Low Acid)

PSL

L1C/P7 (L.P.) / S1 / F1 or P6 for

tank overflows

Sulfuric Acid Dilute (<50% conc.) SAD F5

Sodium Sulfate Solution

SSS L6/S1

SX PROCESS SOLUTIONS

Acidic Barren Solution ABS F5/S1/P7 (L.P.)/ P8 (H.P.)

Organic, Acidified Crud ACC S1

Organic, Ammoniated Crud AMC S1

Caustic Scrub Solution CSS S1

Reagent SX Diluent DIL S1/L6

Purified Rich Strip Solution PRS S1

Pregnant Solution High Acid PSH F5/S1/P7 (L.P.)/ P8 (H.P.)

Rich Strip Solution RS S1

Organic, SX Stripped Barren SBO S1

Organic, SX Scrubbed Loaded SLO S1

Sodium Sulfate Solution SSS S1 / L6

Organic, SX Loaded SXLO S1

Reagent SX Tertiary Amine Extractant TAE S1/L6

Reagent - Tridecanol TDA S1/L6

Organic, SX Washed Barren WBO S1

Project C-560

General Spcification 000-GD-007

Piping Material Classes

Rev.1

1/2" - 2" 2 1/2" - 24"

A1 150 RF B31.1 1897 343 See spec. A53B Black CS Sch 80 SW

(2.5 - 6) Sch40 BW

(8 - 24) Std.Wt BW

1.6 See material class for details.

A3 300 RF B31.1 3448 399 See Spec A106B Black CS Sch 80 SW Sch 40 BW 1.6 See material class for details.

A5 600 RF B31.1 4724 343 See spec. A106B Black CS Sch 80 SW Sch 40 BW 1.6 See material class for details.

B1 150 FF B31.3 1379 38 See spec.

Copper Type L,

ASTM B88

NONE Potable (Domestic) Water

F1 150 FF B31.3 See Spec 93 See Spec

D2997 FRP

(Vinyl Ester)

NONE

Misc acid solutions & Vents

See spec for details.

F5 150 FF B31.3 See Spec 93 See Spec

D2997 FRP

(Vinyl Ester)

NONE

Misc acid solutions & Vents

See spec for details.

H1 150 RF B31.3 1965 38 1655 @ 93 A53B Black 1 & 1-1/2 XH SW 2" - 24" XH BW 3.2 Concentrated H

2

SO

4

J3 300 RF B31.3 4138 38 See spec.

A106B CS

Prepared for Oxygen

Service

1/2" to 3/4" Sch 160 PE

1 to 2 Sch 80 PE

Std Wt. BW 1.6

HP Gaseous Oxygen; Prepared for

Oxygen Service

L1 150 FF B31.3 1034 121 See spec. A53B Black CS Sch 80 T&C Std Wt. BW 1.6 Misc. Water & Solutions

L1B 150 FF B31.3 1035 38 See spec. A53B Black CS Sch 40 T&C Std Wt. BW 1.6 Misc. Water & Solutions

L1C 150 FF B31.3 1035 38 See spec. A53B Black CS (1 - 2) Std Wt. PE (3 - 6) Std Wt. BW 1.6 Slurry Neutral

L2V 150 FF B31.3 1035 121 862 @ 121 A53B C.S. Galvanized Sch 40 T&C Std. Wt. Cut-Grvd Ends 0 Potable/Domestic Water

L2W 150 FF B31.3 862 121 862 @ 121

(1/2" - 2") A53B CS Galv.

(3" - 24") A53B Black CS

Sch 40 T&C Std Wt. BW 0 Instrument Air

1/2" to 3"

1" to 14" Socket Cement

1" to 14" Socket Cement

Wall Thickness /End

Preparation

MATERIAL CLASSES RATING MATRIX

Class

Pressure

Class

Design

Press

kPag

ANSI

Code

Design

Temp

C

Press/Temp

Rating

kPag/C

Material

ASTM

Notes

C.A.

mm

1 of 6

Q:\Shared\R0534200\01_Eng_Doc\05_Pip\01_Design_Criteria\02_Int_App\000-GD-P-007 Piping Material Classes\GD07 MATRIX_1.xls

Project C-560

General Spcification 000-GD-007

Piping Material Classes

Rev.1

1/2" - 2" 2 1/2" - 24"

Wall Thickness /End

Preparation

MATERIAL CLASSES RATING MATRIX

Class

Pressure

Class

Design

Press

kPag

ANSI

Code

Design

Temp

C

Press/Temp

Rating

kPag/C

Material

ASTM

Notes

C.A.

mm

300 RF B31.3 2587 149 2070@191 A53 B Black CS Sch 80 PE Std Wt. BW 1.6

LP Lube Oil, Waste Oil, Anti- Freeze,

Grease.

300 RF B31.3 4715 149 See spec. A53 B Black CS Sch 80 PE Std Wt. BW 1.6

Pressure rating is for high pressure

overland fuel oil transfer only.

L4 150 RF B31.3 1896 149 See spec. A53B. Black CS Sch 40 SW Std BW 1.6 Fuel Oil, Diesel Oil, Reagents.

L5 150 FF B31.3 1034 121 See spec. A53B. Black CS Sch 40 T&C

Cut-Groove Ends

^Std Wt. (up to 20")

XH (22" to 24")

1.6

Concentrate/Neutral Slurries,

Overflows & Underflows

L6 150 RF B31.3 1895 38 See spec. A53B. Black CS Sch 40 PE Std BW 1.6

Natural Gas, Propane, Ammonia

Solution, ammoniated Vent

L8B 150 FF B31.3 1034 149 See spec. A53B Black CS Sch 80 T&C

Butt Welding

Std. Wt. (3" to 24")

Sch 10 (26" To 36")

Std Wt (42" to 48")

1.6 PA, BA, LPA, MPA

L9 150 FF B31.3 1207 38 862 @ 121 A53B BlackCS Sch 40 T&C Std. Wt. Grvd Ends 1.6 Fire Protection (A/G)

L10 300 RF B31.3 3200 38 See spec. CS, API 5L Gr X56 Sch 80 T&C See Spec. 1.6 Raw Water ( High Pressure)

L13 150 FF B31.3 1034 24 See spec.

A53B CS

with external coating.

1.6 Water (Underground)

L18 900 RF B31.11 11000 20 15000@38

API 5L X52

(Unlined)

0 Tailings, Thickener Underflow

L19 600 RF B31.11 7000 20 15300@38 API 5L X52 0 Tailings, Thickener Underflow

L20 900 RF B31.11 11000 20 15300@38 A53B Black CS 0

Tailing, Thickener, Underflow, Process

Drain, Process Vent

L3

Std Wt BW

See Spec L18

See Spec L19

Std. Wt. BW

(1" to 12")

2 of 6

Q:\Shared\R0534200\01_Eng_Doc\05_Pip\01_Design_Criteria\02_Int_App\000-GD-P-007 Piping Material Classes\GD07 MATRIX_1.xls

Project C-560

General Spcification 000-GD-007

Piping Material Classes

Rev.1

1/2" - 2" 2 1/2" - 24"

Wall Thickness /End

Preparation

MATERIAL CLASSES RATING MATRIX

Class

Pressure

Class

Design

Press

kPag

ANSI

Code

Design

Temp

C

Press/Temp

Rating

kPag/C

Material

ASTM

Notes

C.A.

mm

L25 2500 RF B31.3 40414 38 36414@100 A53 B Black CS

XXH, PE

(1/2" to 2")

0.8 HP Hydraulic Oil, grease

M1 Atm UPC Gravity Ambient

GRAVITY/

AMBIENT

Drain: Cast Iron

Vent: CS, Galv.

Drain: No-hub CI Serv.

Wt.; Vent: Std. Wt. T&C

Drain: No-hub CI Serv.

Wt.; Vent: Std. Wt. T&C

0 Inside buildings, above ground

M2 Atm UPC Gravity Ambient

GRAVITY/

AMBIENT

PVC, SDR35 --

4" - 15" Bell x Spigot with

rubber ring gaskets

0 Outside buildings, buried/underground

M3 Atm UPC Gravity Ambient

GRAVITY/

AMBIENT

PP, Sch40 -- 1-1/2" - 6" Fusion weld 0 Corrosive chemical waste and vents

P1 150 FF B31.3 1034 93 See spec. CPVC 0

RO water, Slurry Floor Sump, CWS,

CWR, Tank Oflows.

P2 150 FF B31.3 1034 60 See spec. PVC 0 Corrosive drains, effluents

P4 150 B31.3 448 23 See spec.

HDPE, PE3408 per ASTM

D3350

0 Storm & Process Drains

P6 150 FF B31.3 690 23 414@60

HDPE, PE3408 per ASTM

D3350

0

Filtrate, Process Water, Cooling Water

Supply & Return

P7 150 RF B31.3 1103 23 552 @ 60

HDPE, PE3408 per ASTM

D3350

0

Concentrate, Cyclone Feed, Thickener

OFlow, water

P8 150 B31.3 1379 23 1379 @ 23

HDPE, PE3408 per ASTM

D3350

0 High pressure clear solutions

P12 150

B31.3

NFPA 24

1034 23 1034 @ 23

FM Approved HDPE Class

150 per ASTM D3350

0 Fire Protection Water (U/G)

P13 150 FF B31.3 1034 23 1034@23

Sch 80 PVC;

HDPE per ASTM D3350

2 Sch 80 PVC, SC

3 to 24 HDPE Class 150

BF

0 Underground Potable Water

See Spec

See Spec

4 to 24 HDPE Class 150 BF

Sch. 80

Sch. 80

See Spec

See Spec

3 of 6

Q:\Shared\R0534200\01_Eng_Doc\05_Pip\01_Design_Criteria\02_Int_App\000-GD-P-007 Piping Material Classes\GD07 MATRIX_1.xls

Project C-560

General Spcification 000-GD-007

Piping Material Classes

Rev.1

1/2" - 2" 2 1/2" - 24"

Wall Thickness /End

Preparation

MATERIAL CLASSES RATING MATRIX

Class

Pressure

Class

Design

Press

kPag

ANSI

Code

Design

Temp

C

Press/Temp

Rating

kPag/C

Material

ASTM

Notes

C.A.

mm

P14 150 RF B31.3 1034 23 See spec.

HDPE, PE3408 per ASTM

D3350

- 3 to 24 HDPE SDR11 BF 0

Process Water, Fresh Water,

Raw water, Cooling Water (Med.

Pressure)

P16

AWWA

C207

B31.3 1379 23 See spec.

HDPE, PE3408 per ASTM

D3350

0 Tailings Thickener UFlow

PL8 12 B31.11 600 20 1035@38 A53 B Black CS

Sch 80 T&C (1" to 1.5")

(Unlined)

Std. Wt. (2" to 26")

Flanged Ends,

Polyurethane Lined

0 Tailing, Thickener, Underflow

PL9 900 RF B31.11 11000 20 15300@38

API 5L X52

Polyurethane Lined

0 Tailing, Thickener, Underflow

R1 150 FF B31.3 1035 60 1035 @ 60

A53B / API 5L CS

Natural Rubber-Lined

Ceramic-Lined

0

Cyclone Feed

CS Ceramic-lined x Flanged Ends

R2 150 FF B31.3 1035 60 1035 @ 60 A53B CS Rubber-Lined 0

Straight pipe: Victaulic Grooved End x

Flanged End

S1 150RF B31.3 See spec 38 1207 @ 149 A312 TP316LSS Sch 40S SW Sch 10S BW 0.8 Misc. acidic & basic solutions

S2 150 RF B31.3 1586 38

1586 @ 38

1207 @ 149

A312 TP316LSS 1.6 Misc Process Slurries

S3 150 RF B31.3 See spec 38 862 @ 149 Alloy 20 per ASTM B464 ( 1 ) Sch 40S SW (2 24) Sch 10S BW 0.8

Acidic Scrubber Effluents, Corrosive

Vents; High acidic solutions; Sulfuric

Acid

S6 300 RF B31.3 4137 38 See spec. Alloy 20 per ASTM B464 Sch 80S SW

Sch 40S 2.5-12; 0.25 wall

to 24BW

1.6

High pressure Acidic solution,

Autoclave Coolant.

S8 300 RF B31.3 4138 40 4138 @ 38 A312 TP316L SS 0.8 High Pressure Gaseous Oxygen

S9 300 RF B31.3 4138 38 See spec. A312, TP316L SS Sch 80S -- 0.8

Pressure Leach Vessel Agitator Seal

Water, Gland Water Solution,

Autoclave Coolant (high pressure)

3" to 14" Rubber-Lined

16" to 42" Ceramic-Lined

(See Spec for Lining Thickness)

1" to 1-1/2" Threaded

2" to 36" Rubber-Lined Grooved Ends or

Grooved x Flanged Ends

2" to 30" SDR 9 BF

Flanged Ends

(See Spec)

Sch 40S BW (1"12)

Sch 20 BW (12" to 24")

1/2 to 12 Sch40S BW

4 of 6

Q:\Shared\R0534200\01_Eng_Doc\05_Pip\01_Design_Criteria\02_Int_App\000-GD-P-007 Piping Material Classes\GD07 MATRIX_1.xls

Project C-560

General Spcification 000-GD-007

Piping Material Classes

Rev.1

1/2" - 2" 2 1/2" - 24"

Wall Thickness /End

Preparation

MATERIAL CLASSES RATING MATRIX

Class

Pressure

Class

Design

Press

kPag

ANSI

Code

Design

Temp

C

Press/Temp

Rating

kPag/C

Material

ASTM

Notes

C.A.

mm

S9A 600 RF B31.3 4138 38 See spec. A312, TP316L SS 0.8

Misc. Clear Acidic Solutions, Pressure

Leach Vessel Agitator Seal Water,

Gland Water Solution

S10 150 RF B31.3 1034 121 1517 @ 121

A790 Gr. S32205 Duplex

SS

to 1

Sch 80S SW

2 to 12

Sch 40S BW

3.2

Acidic Slurry (high & low acid), Hot

Autoclave Slurry, Pressure Leach

Flash Slurry

S11 600 RF B31.3 4500 255 6986 @ 260

Duplex Stainless Steel

ASTM A790 Gr. S32550

3.2

High Pressure, Acidic, Cold Autoclave

Feed Slurry at Autoclave interface only

S12B 600 RF B31.3 4310 38 4800 @ 38 A312, Gr. TP316L SS

Sch 160S (1/2 to 3/4)

Sch 80S (1 to 1-1/2)

(2-12) Sch 80S BW 3.2

High Pressure, Acidic, Cold Autoclave

Feed Slurry

S14 21 MP 36.19 21 90 31500 @ 90 A312, Gr. TP316L SS SEE SPEC SEE SPEC 0

S.S. tubing for Grease, Hydraulic Oil,

and Lube Oil High Pressure

S15 35 MP 36.19 35 90 52500 @ 90 A312, Gr. TP316L SS SEE SPEC SEE SPEC 0

S.S. tubing for Grease, Hydraulic Oil,

and Lube Oil High Pressure

T6 600 RF B31.3 4300 255 4485 @ 260

Titanium per ASTM B862

Gr. 12 EFW

3.2

Autoclave Flash Vessel Vent, H.P. Hot

Autoclave Slurry,Pressure Leach HP

Hot Slurry

T26 600 RF B31.3 3792 221 See spec.

Titanium per ASTM B862

Gr. 12 EFW

2.38 Autoclave Hot, Acidic slurry service

See Spec

See Spec

( 12) Sch 80S

Sch 160S SW ( )

Sch 80S (1-12)

5 of 6

Q:\Shared\R0534200\01_Eng_Doc\05_Pip\01_Design_Criteria\02_Int_App\000-GD-P-007 Piping Material Classes\GD07 MATRIX_1.xls

Project C-560

General Spcification 000-GD-007

Piping Material Classes

Rev. 0

Symbol Description Notes Symbol Description Notes

BF BUTT FUSION

B & S BELL AND SPIGOT

BW BUTT WELDING

CF COMPRESSION FITTINGS

FLG FLANGED

FW FUSION WELD

SC SOLVENT CEMENT

SJ SOLDER JOINT

SW SOCKET WELDING

THD THREADED

CONNECTIONS LEGEND

Q:\Shared\R0534200\01_Eng_Doc\05_Pip\01_Design_Criteria\02_Int_App\000-GD-P-007 Piping Material Classes\GD07 MATRIX_1.xls

Page 6 of 6

Project C-560

General Specification 000-GD-P-007

Piping Material Classes

Rev 1

Q:\Doc_Control\R0534200\01_Eng_Doc\05_Pip\01_Design_Criteria\GD07 A1_1_1.doc

Page 1 of 4

CLASS REV

PIPING MATERIAL CLASSES

A1 1

Sheet 1 of 4

SERVICE: Corr Allow.: 1.6 mm Design Code: ANSI B31.1

Design Press./Temp. Press./Temp. Rating (Note 1)

Press., kPag Temp., C Press., kPag Temp., C

1897 343 1897 -29 to 38

1172 260

Ammoniated Vent (AMV)

Ammonium Condensate (ACO)

Caustic-Sodium Hydroxide (SH)

Low Pressure (LBD)

Low Pressure Feedwater (LPF)

Low Pressure Condensate, (LCD)

Low Pressure Steam, (LPS),103 kPag to 1241 kPag

Process Drains (PD)

Slurry, Neutral (SLN)

862 343 (Max)

Nominal Pipe Size,

Inches

1

/

2

3

/

4

1 1

1

/

2

2 2

1

/

2

3 4 6 8 10 12 14 16 18 20 24

CONSTRUCTION

Socket-weld joints - pipe,

fittings, and valves. Flanged

and S.W. specialty items

Butt weld joints - pipe and fittings. Flanged valves and specialty items.

C.S. ASTM A53 Gr. B, Seamless C.S. ASTM A53 Gr. B, ERW

PIPE

Sch. 80, P.E. Sch. 40, B.E. Std. Wt., B.E.

NIPPLE Use Pipe

FITTINGS

Class 3000 ANSI B16.11

Socket weld, C.S. ASTM

A105

Butt welding fittings, ANSI B16.9, C.S. ASTM A234 Gr. WPB, (Sch. same

as pipe), B.E.

UNION

Class 3000 ANSI B16.11

Socket weld, C.S. ASTM

A105, Steel to steel seats

Use Flanges

BRANCH CONNECTION See Branch Reinforcement Table BR-A1.

SOCKOLET

ELBOLET S.W.

LATROLET S.W.

C.S. ASTM A105 3000#

WELDOLET

ELBOLET B.W.

C.S. ASTM A105, Std. Wt. x (Branch pipe Sch.) Bore

ANSI B16.5, C.S. ASTM A105

Blind Flange, Class 150 R.F.

Class 150 R.F. Slip-on

Class 150 Lap J oint

FLANGES

(Note 2)

Class 150 R.F. Socket Weld

Weld neck, Class 150 R.F. (Class 300 R.F. for Orifice Flanges), (Sch.

same as Pipe) bore.

STUB END

(Note 2)

C.S. ASTM A234 WPB, Sch. (Same as pipe), ANSI B16.9, Short Pattern

BOLTING Alloy stud bolts ASTM A193 Gr. B7 with heavy hex nuts ASTM A194 Gr. 2H

GASKETS

For services above 149C saturated steam and any temperature superheated steam:

Ring type, Spiral Wound Compression gasket (4.4 mm nom. thk.) 316 S.S. with mica paper filler.

GARLOCK Guardian Style 556 or Equal. Pressure class to suit flange.

CHECK VALVE C-5 C-15

GLOBE VALVE E-4 E-12

GATE VALVE G-4 G-12 G-12-GO

BALL VALVE A-6 A-16

Nominal Pipe Size Inches

1

/

2

3

/

4

1 1

1

/

2

2 2

1

/

2

3 4 6 8 10 12 14 16 18 20 24

Project C-560

General Specification 000-GD-P-007

Piping Material Classes

Rev 1

Q:\Doc_Control\R0534200\01_Eng_Doc\05_Pip\01_Design_Criteria\GD07 A1_1_1.doc

Page 2 of 4

CLASS REV

PIPING MATERIAL CLASSES

A1 1

Continuation Sheet Sheet 2 of 4

Nominal Pipe Size Inches

1

/

2

3

/

4

1 1

1

/

2

2 2

1

/

2

3 4 6 8 10 12 14 16 18 20 24

SAMPLE VALVE

Y-STRAINER SPY-1 SPY-2

SIMPLEX BASKET

STRAINER

SPY-28

SPECTACLE BLIND C.S. ASTM A515 Gr. 70, Class 150 ANSI B16.5, 0.0625" C.A. ANSI B31.1

TRAPS SPT-1 SPT-2

Nominal Pipe Size, Inches

1

/

2

3

/

4

1 1

1

/

2

2 2

1

/

2

3 4 6 8 10 12 14 16 18 20 24

Notes:

1. Pressure ratings shown on the pressure and temperature ratings are limited by:

a) Steel Valves per ANSI B16.34.

b) Flanges per ANSI B16.5.

2. For services 149C and under, slip on flanges are preferred except when adjacent to welding fittings.

3. For services above 149C, weld neck flanges shall be used. Use weld neck flanges when adjacent to welding fittings on all services.

Use Lap joint flanges only when necessary.

Project C-560

General Specification 000-GD-P-007

Piping Material Classes

Rev 1

Q:\Doc_Control\R0534200\01_Eng_Doc\05_Pip\01_Design_Criteria\GD07 A1_1_1.doc

Page 3 of 4

CLASS REV

PIPING MATERIAL CLASSES A1 1

Sheet 3 of 4

SERVICE:

Corr. Allow.: 1.6 mm Design Code: ANSI B31.1

See Sheet 1

Design Press./Temp. Press./Temp. Rating (Note 1)

Press., kPag Temp., C Temp., C Press., kPag

862 343 -28.9 to 38 1965

260 1172

343 (Max) 1896

Nominal Pipe Size

Inches

26 28 30 36 42

CONSTRUCTION

Butt weld joints - pipe and fittings. Flanged valves and specialty items.

C.S. EFW Pipe ASTM A672 Gr. B60, Class 23, B. E.

PIPE

Std. Wt. XH

NIPPLE Use Pipe

FITTINGS Butt welding fittings, ANSI B16.9, C.S. ASTM A234 Gr. WPB, (Sch. same as pipe), B.E.

UNION Use Flanges

BRANCH CONNECTION See Branch Reinforcement Table BR-A1.

SOCKOLET

ELBOLET S.W.

LATROLET S.W.

C.S. ASTM A105

WELDOLET

ELBOLET B.W.

Std Wt. x Std

Wt. Bore

XH x

Bore to

match

pipe

ANSI B16.47 Type Series A (MSS-SP-44), C.S. ASTM A105

Blind Flange, Class 150

FLANGES (Note 2)

Weld neck, Class 150 R.F. (Class 300 R.F. for Orifice Flanges), (Same as Pipe) bore.

STUB END N/A

BOLTING Alloy stud bolts ASTM A193 Gr. B7 with heavy hex nuts ASTM A194 Gr. 2H

For services above 149C saturated steam and any temperature superheated steam:

Ring type, Spiral Wound Compression gasket (4.4 mm nom. thick.) 316 S.S. with mica paper filler.

GARLOCK Guardian Style 556 or Equal. Pressure class to suit flange.

GASKETS

For services up to 149C saturated steam; others to 343C:

1.6 mm thick Non-Asbestos Composition, GARLOCK BLUE-GARD Style 3000. Pressure Class to suit

flange.

CHECK VALVE C-15

GATE VALVE G-12-GO

Nominal Pipe Size

Inches

26 28 30 36 42

Project C-560

General Specification 000-GD-P-007

Piping Material Classes

Rev 0

Q:\Doc_Control\R0534200\01_Eng_Doc\05_Pip\01_Design_Criteria\GD07 A1_1_1.doc

Page 4 of 4

BRANCH REINFORCEMENT

TABLE BR-A1

PIPE SIZE

HEADER

Inches

2 &

Under

2

3

4

6

8

10

12

14

16

18

20

24

26

28

30

36

42

2 &

Under

T

W

W

W

W

W

W

W

W

W

W

W

W

W

W

W

W

W

2

T

T

10

10

10

10

10

10

13

16

16

25

25

25

25

25

25

3

T

T

10

10

10

10

10

13

16

19

25

25

25

38

38

38

4

T

T

10

10

10

10

16

19

25

38

25

38

38

38

38

6

T

T

10

10

10

16

25

38

50

38

50

64

50

64

8

T

T

10

13

19

38

50

75

64

75

89

38

89

B

10

T

T

13

25

38

38

89

75

89

100

75

100

R

12

T

T

25

50

75

114

89

100

125

89

125

A

14

T

T

64

75

125

100

114

140

100

140

N

16

T

T

89

140

114

140

165

114

165

C

18

T

T

165

125

150

178

125

190

H

20

Dimensions in mm

T

T

150

178

200

150

200

24

T

T

W

240

190

250

26

T

T

W

190

280

28

T

T

216

292

30

T

T

318

36

T

T

42

T

NOTES: For details see Aker Solutions Standard Dwg. SD-P-102R; dimensions are in mm.

Project C-560

General Specification 000-GD-P-007

Piping Material Classes

Rev. 1

Q:\Shared\R0534200\01_Eng_Doc\05_Pip\01_Design_Criteria\02_Int_App\000-GD-P-007 Piping Material Classes\GD07 A3_1_1.docage 1 of 4

REV

PIPING MATERIAL CLASSES

CLASS

A3

1

Sheet 1 of 2

Corr. Allow.: 1.6 mm Design Code: ANSI B31.1

Design Press./Temp. Press./Temp. Rating (Note 1)

Press., kPag Temp., C Press., kPag Temp., C

5103 (up to 8)

4828(10 to 16)

4724(18 to 24)

-29 to 38

SERVICE:

Anhydrous Ammonia (AHA

Boiler Blowdown, Medium Pressure (MBD)

Condensate, Medium Pressure (MPC)

Steam, Medium Pressure (abv 1241 to 3447 kPag) (MPS)

Boiler Feedwater, Medium Pressure (MPF)

3448 399

4138 260

Design Pressure 5172 kPag (max)

Nominal Pipe Size, Inches

1 1

1

/

2

2 2

1

/

2

3 4 6 8 10 12 14 16 18 20 24

CONSTRUCTION

Socket-weld joints - pipe,

fittings, and valves. Flanged

and S.W. specialty items

Butt weld joints - pipe and fittings. Flanged valves and specialty items.

C.S. ASTM A106 Gr. B, Seamless

PIPE

Sch. 80, P.E. Sch. 40, B.E.

NIPPLE Use Pipe

FITTINGS

Class 3000 ANSI B16.11

Socket weld, C.S. ASTM

A105

Butt welding fittings, ANSI B16.9, C.S. ASTM A234 Gr. WPB, (Sch. same

as pipe), B.E.

UNION

Class 3000 NSS-SP-83

Socket weld, C.S. ASTM

A105, Steel to steel seats

Use Flanges

BRANCH CONNECTION See Branch Reinforcement Table BR-A3.

SOCKOLET

ELBOLET S.W.

LATROLET S.W.

C.S. ASTM A105 3000#

WELDOLET

ELBOLET B.W.

C.S. ASTM A105, Sch. 40 x (Branch pipe Sch.) Bore

ANSI B16.5, C.S. ASTM A105

Blind Flange, Class 300 R.F.

Class 300 R.F. Slip-On or Lap J oint Class 300

FLANGES

(Note 2)

Class 300 R.F. Socket Weld

Weld Neck, Class 300 R.F., (Sch. same as Pipe) bore.

C.S. ASTM A234 , Sch. (Same as pipe), ANSI B16.9

STUB END (note 2)

Short Pattern Long Pattern

BOLTING Alloy stud bolts ASTM A193 Gr. B7 with heavy hex nuts ASTM A194 Gr. 2H

GASKETS

For services above 149 saturated steam and any temperature superheated steam:

Ring type, Spiral Wound Compression gasket (4.4 mm nom. thick.) 316 S.S. with mica paper filler.

GARLOCK style RW 316L / VC or Equal, ANSI Class 300 R.F. Flange.

CHECK VALVE C-5 C-17

GLOBE VALVE E-4 E-13 E-13-GO

Nominal Pipe Size, Inches

1 1

1

/

2

2 2

1

/

2

3 4 6 8 1

0

12 14 16 18 20 24

Project C-560

General Specification 000-GD-P-007

Piping Material Classes

Rev. 1

Q:\Shared\R0534200\01_Eng_Doc\05_Pip\01_Design_Criteria\02_Int_App\000-GD-P-007 Piping Material Classes\GD07 A3_1_1.docage 2 of 4

REV

PIPING MATERIAL CLASSES

CLASS

A3

1

Continuation Sheet Sheet 2 of 2

Nominal Pipe Size, Inches

1 1

1

/

2

2 2

1

/

2

3 4 6 8 10 12 14 16 18 20 24

GATE VALVE G-4 G-16 G-16-GO

Y-STRAINER SPY-1 SPY-3

SPECTACLE BLIND C.S. ASTM A515 Gr. 70, Class 300 ANSI B16.5, 1.6 mm C.A. ANSI B31.1

Paddle Blank

Paddle Spacer

TRAPS SPT-7

AIR VENTS SPV-2

Nominal Pipe Size, Inches

1 1

1

/

2

2 2

1

/

2

3 4 6 8 10 12 14 16 18 20 24

Notes:

1. Pressure ratings shown on the pressure and temperature ratings are limited by:

a) Steel Valves per ANSI B16.34.

b) Flanges per ANSI B16.5.

2. For services 149C and under, slip on flanges are preferred except when adjacent to welding fittings. For services above 149C,

weld neck flanges shall be used. Use weld neck flanges when adjacent to welding fittings on all services. Use Lap joint flanges only

when necessary.

Project C-560

General Specification 000-GD-P-007

Piping Material Classes

Rev. 1

Q:\Shared\R0534200\01_Eng_Doc\05_Pip\01_Design_Criteria\02_Int_App\000-GD-P-007 Piping Material Classes\GD07 A3_1_1.docage 3 of 4

PIPING MATERIAL SPECIFICATION A3 - FITTINGS

Socketweld Buttweld

Caps X Caps X

Coupling X Concentric Swage BLE X PSE X

Reducing Coupling X - Optional Eccentric Swage BLE X PSE X

Union X Concentric Swage BLE X TSE X

Plug Threaded X - Optional Eccentric Swage BLE X TSE X

Concentric Swage PE X - Default Concentric Reducer X

Eccentric Swage PE X Eccentric Reducer X

Concentric Swage PLE X TSE X 90 Degree Elbow X

Eccentric Swage PLE X TSE X 45 Degree Elbow X

90 Degree Elbow X Tee X

45 Degree Elbow X Reducing Tee X

Tee X Lateral X

Reducing Tee X

Lateral X

Pipe Nipples X

Project C-560

General Specification 000-GD-P-007

Piping Material Classes

Rev. 1

Q:\Shared\R0534200\01_Eng_Doc\05_Pip\01_Design_Criteria\02_Int_App\000-GD-P-007 Piping Material Classes\GD07 A3_1_1.doc

Page 4 of 4

BRANCH REINFORCEMENT

TABLE BR-A3

PIPE SIZE

Inches

2 &

under

2 3 4 6 8 10 12 14 16 18 20 24

2 &

Under

T W W W W W W W W W W W W

2 T T W W W W W W W W W W

3 T T W W W W W W W W W

4 T T W W W W W W W W

6 T T W W W W W W W

8 T T W W W W W W

10 T T W W W W W

12 T T W W W W

14 T T W W W

16 T T W W

18 T T W

20 T T

B

R

A

N

C

H

24 T

NOTES: For details see Aker Solutions Standard Drawing SD-P-102R.

Project C-560

General Specification 000-GD-P-007

Piping Material Classes

Rev. 1

Q:\Doc_Control\R0534200\01_Eng_Doc\05_Pip\01_Design_Criteria\GD07 A5_0_1.doc

Page 1 of 4

PIPING MATERIAL CLASSES

CLASS

A5

REV

0

Sheet 1 of 2

Corr. Allow.: 1.6 mm Design Code: ANSI B31.1

Design Press./Temp. Press./Temp. Rating (Note 1)

Press., kPag Temp., C Press., kPag Temp., C

SERVICE:

Boiler Blowdown, Medium Pressure (MBD)

Boiler Feedwater, Medium Pressure (MPF)

4724 343

4.724

3.483

-29 to 343

399 (Max)

Nominal Pipe Size, Inches 1 1 2 2 3 4 6 8 10 12 14 16 18 20 24

CONSTRUCTION

Socket weld joints - pipe,

fittings, and valves. Flanged

and S.W. specialty items

Butt weld joints - pipe, fittings and valves. Flanged specialty items.

C.S. ASTM A106 Gr. B, Seamless

PIPE

Sch. 80, P.E. Sch. 40, B.E.

NIPPLE Use Pipe

FITTINGS

Class 3000 ANSI B16.11

Socket weld, C.S. ASTM

A105

Butt welding fittings, ANSI B16.9, C.S. ASTM A234 Gr. WPB, (Sch. same

as pipe), B.E.

UNION

Class 3000 MSS-SP-83

Socket weld, C.S. ASTM

A105, Steel to steel seats

Use Flanges

BRANCH CONNECTION See Branch Reinforcement Table BR-A5.

SOCKOLET

ELBOLET S.W.

LATROLET S.W.

C.S. ASTM A105 3000#

WELDOLET

ELBOLET B.W.

C.S. ASTM A105, Sch. 40 x (Branch pipe Sch.) Bore

ANSI B16.5, C.S. ASTM A105

Blind Flange, Class 600 R.F. FLANGES

Class 600 R.F. Socket Weld Weld Neck, Class 600 R.F., (Sch. same as Pipe) bore.

STUB END

BOLTING Alloy stud bolts ASTM A193 Gr. B7 with heavy hex nuts ASTM A194 Gr. 2H

GASKETS

Ring type, Spiral Wound Compression gasket (4.4 mm nom. thick.) 316 S.S. with mica paper filler.

GARLOCK style RW 316L / VC or Equal, ANSI Class 600 R.F. Flange.

CHECK VALVE C-5 C-18 (Sch. 40 Bore)

GLOBE VALVE E-4, E-9, E-10 E-14 E-14-GO

GLOBE STOP-CHECK

(NON-RETURN) VALVE

E-26A (Sch 40

Bore)

E-26 (Sch 40 Bore)

GATE VALVE G-4 G-17 G-17-GO (Sch 40 Bore)

Y-STRAINER SPY-1 SPY-4

SPECTACLE BLIND

C.S. ASTM A515 Gr. 70, CLASS 600 ANSI B16.5, 0.0625" C.A.,

ANSI B31.1

Paddle Spacer, Blind Paddle

TRAPS SPT-3

Nominal Pipe Size, Inches 1 1 2 2 3 4 6 8 10 12 14 16 18 20 24

Continuation Sheet Sheet 2 of 2

Project C-560

General Specification 000-GD-P-007

Piping Material Classes

Rev. 1

Q:\Doc_Control\R0534200\01_Eng_Doc\05_Pip\01_Design_Criteria\GD07 A5_0_1.doc

Page 2 of 4

PIPING MATERIAL CLASSES

CLASS

A5

REV

0

Nominal Pipe Size, Inches 1 1 2 2 3 4 6 8 10 12 14 16 18 20 24

Notes:

1. Pressure ratings shown on the pressure and temperature ratings are limited by:

a) Steel Valves per ANSI B16.34, or pipe, whichever is lower

b) Flanges per ANSI B16.5, or pipe, whichever is lower.

Project C-560

General Specification 000-GD-P-007

Piping Material Classes

Rev. 1

Q:\Doc_Control\R0534200\01_Eng_Doc\05_Pip\01_Design_Criteria\GD07 A5_0_1.doc

Page 3 of 4

PIPING MATERIAL SPECIFICATION A5 - FITTINGS

Socketweld Buttweld

Caps X Caps X

Coupling X Concentric Swage BLE X PSE X

Reducing Coupling X - Optional Eccentric Swage BLE X PSE X

Union X Concentric Swage BLE X TSE X

Plug - Threaded X - Optional Eccentric Swage BLE X TSE X

Concentric Swage PE X - Default Concentric Reducer X

Eccentric Swage PE X Eccentric Reducer X

Concentric Swage PLE X TSE X 90 Degree Elbow X

Eccentric Swage PLE X TSE X 45 Degree Elbow X

90 Degree Elbow X Tee X

45 Degree Elbow X Reducing Tee X

Tee X Lateral X

Reducing Tee X

Lateral X

Pipe Nipples X

Project C-560

General Specification 000-GD-P-007

Piping Material Classes

Rev. 1

Q:\Doc_Control\R0534200\01_Eng_Doc\05_Pip\01_Design_Criteria\GD07 A5_0_1.doc

Page 4 of 4

BRANCH REINFORCEMENT

TABLE BR-A5

HEADER

PIPE SIZE

Inches

2 &

Under

2 3 4 6 8 10 12 14 16 18 20 24

2 &

Under

T W W W W W W W W W W W W

2 T T W W W W W W W W W W

3 T T W W W W W W W W W

4 T T W W W W W W W W

6 T T W W W W W W W

8 T T W W W W W W

10 T T W W W W W

12 T T W W W W

14 T T W W W

16 T T W W

18 T T W

20 T T

B

R

A

N

C

H

24 T

NOTES: For details see Aker Solutions Standard Drawing SD-P-102R.

Project C-560

General Specification 000-GD-P-007

Piping Material Classes

Rev. 1

Q:\Doc_Control\R0534200\01_Eng_Doc\05_Pip\01_Design_Criteria\GD07 B1_G_1.doc

Page 1 of 1

REV CLASS

B1 G

PIPING MATERIAL CLASSES

Sheet 1 of 1

Corrosion Allow.: 0.00 mm

Design Code: ANSI B31.3

Design Press. /Temp.

Press. /Temp. Rating

Press., kPag

Temp.,

C

Press., kPag

Temp.,

C

1379

-29 to 38

SERVICE:

Potable Water (Cold or Hot) (Domestic Water) (PW)

Water treatment indoor (WT)

1379

38

1034 121 (Max)

NOMINAL PIPE SIZE, IN.

1

1

2

2

3

CONSTRUCTION

Solder joints - pipe, fittings, and valves. Flanged and

threaded joint specialty items and equipment connections.

Use 95-5 tin-antimony solder. Solder flux shall be non-toxic

& in paste form.

TUBE

Water tube copper, ASTM B88 Type L Hard Temper

NIPPLES

Use Tube

FITTINGS

ANSI B16.22 Solder joint, Copper, ASTM B88

ANSI B16.22 Solder joint, Brass, ground joint. UNION

Dielectric Union- Screwed FPT Galvanized iron body, solder

joint copper tail-piece, dielectric insulating sleeve. (Used at

steel piping interface).

BRANCH CONNECTION

Use Fittings

ANSI B16.24, Class 150, bronze,

ASTM B62 UNS C83600, or

ASTM B61 UNS C92200

BLIND, Flat faced

FLANGES

SCREWED, Flat faced

BOLTING

Carbon Steel steel machine bolts per ASTM B307 Gr. B.,

hexagonal. head with heavy hexagonal nuts.

GASKETS

1.6 mm thick non-asbestos composition, GARLOCK BLUE-

GARD Style 3000, Class 150 Full Face

CHECK VALVE

C-2

GLOBE VALVE

E-1

GATE VALVE

G-1

STRAINER

SPY-8

SPY-9

AIR VENTS

SPV-1

BACKFLOW PREVENTER

SPZ-8 SPZ-7

NOMINAL PIPE SIZE, IN.

1

1

2

2

3

Project C-560

General Specification 000-GD-P-007

Piping Material Classes

Rev. 1

Q:\Doc_Control\R0534200\01_Eng_Doc\05_Pip\01_Design_Criteria\GD07 F1_0_1.doc

Page 1 of 2

PIPING MATERIAL CLASSES

CLASS

F1

REV

0

Sheet 1 of 2

Corr. Allow.: 0.000 mm Design Code: ANSI B31.3

Design Press./Temp. Press./Temp. Rating (Note1)

Press., kPag Temp., C Press., kPag Temp., C

Design Pressure -29 to38

SERVICE:

(For Acid Services):

Ammoniated Vent (AMV)

Acid Solution, High (ASH), (+10 g/L)

Acidic Slurry, High Acid (ASHL), (+10 g/L)

Acidic Slurry, Low Acid (ASLL) (-10 g/L)

Process Condensate (PCO)

Process Drain (PD)

Ammonia Vent (PV)

Hydrogen Sulfide Vent (H

2

S) (PV)

Sulfuric Acid Vent (H

2

SO

4

) (PV)

Slurry, Gypsum (SLG)

Slurry, Neutral (SLN)

1034 (1" to 10")

690 (12" to 14")

93

Design Pressure

80 (Max)

(Note 3)

Nominal Pipe Size Inches 1 1 2 2 3 4 6 8 10 12 14

CONSTRUCTION

Vinyl Ester-polyester adhesive socket cement joints except at flanged

valve and equipment connections.

PIPE (Note 4)

Fiberglass Reinforced Polyester pipe, manufactured from vinyl ester

resin by centrifugal casting process, inner corrosion barrier of 100 mil

minimum thickness, and a 10 mil resin rich external corrosion barrier

with ultraviolet (UV) inhibitor. Standard Specification per ASTM D2997.

Fiber Glass Systems/Smith Fibercast Centricast Plus CL-2030 Piping

Systems or Approved Equal.

NIPPLE (Note 4) Use Pipe

FITTINGS (Note 4)

Socket Cement Ends, Fiberglass Reinforced Polyester Vinyl Ester

Fittings compatible with pipe, manufactured either by compression

molding or contact molding. Standard Specification per ASTM D5685.

Fiber Glass Systems/Smith Fibercast Centricast Plus CL-2030 Piping

Systems or Approved Equal.

UNION Use Flange

BRANCH CONNECTION Straight Tee: Use Tee Fitting Reducing: Use Saddle

Blind Flange: ANSI B16.5 Class 150 FF bolt hole patterns, Fiberglass

Reinforced Vinyl Ester polyester.

FLANGES

Socket Cement Ends: ANSI B16.5 Class 150 FF bolt hole patterns.

Fiberglass Reinforced Vinyl Ester polyester.

BOLTING

Stainless Steel Type 316 stud bolts, ASTM A193 Gr. B8M with S.S. Type

316 heavy hex nuts ASTM A194 Gr. 8M.

3.2 mm thick Neoprene Rubber gasket, 60 Shore A Durometer

hardness, GARLOCK Style #7986 or Equal, Class 150 F.F. (For fluids

compatible with Neoprene)

GASKETS

3.2 mm thick Garlock Stress Saver 100% pure PTFE bonded to EPDM

elastomer, Class 150 F.F., Class 150 F.F. (For fluids not compatible with

Neoprene but compatible with PTFE).

BALL VALVE (Note 2)

A-85 / A-15A

A-

85

-

G

O

BUTTERFLY VALVE

(Note 2)

B-35-GO (FRP) or B-4-GO (SS)

CHECK VALVE C-10 C-23A

Nominal Pipe Size inches 1 1 2 2

3 4 6 8 10 12 14

Continuation Sheet Sheet 2 of 2

Project C-560

General Specification 000-GD-P-007

Piping Material Classes

Rev. 1

Q:\Doc_Control\R0534200\01_Eng_Doc\05_Pip\01_Design_Criteria\GD07 F1_0_1.doc

Page 2 of 2

PIPING MATERIAL CLASSES

CLASS

F1

REV

0

Nominal Pipe Size inches 1 1 2 2

3 4 6 8 10 12 14

GLOBE VALVE E-18A

KNIFE GATE VALVE K-5 K-5-GO

PINCH VALVE P-1

SPECTACLE BLIND ASTM A240, Grade 316, Class 150 F.F. ANSI B16.5

Paddle Spacer,

Blind Paddle

Notes:

1. Pressure ratings shown on the pressure and temperature ratings are limited by FRP pipe for cyclic conditions.

2. Do not use Butterfly Valves for sludge service. Use Ball Valves.

3. Maximum operating temperature shall be limited by the specific application, which shall be in accordance with the FRP

manufacturers recommendations. Refer to the manufacturers application guide to establish the maximum operating

temperature. The maximum operating temperature per manufacturers recommendation shall be stated in service section if

different from the maximum specified in the pressure/temperature rating.

4. Minimum available pipe size for Fiber Glass System Centricast Plus CL-2030 FRP is 1.

PIPING MATERIAL SPECIFICATION F1 - FITTINGS

Socket Cement Welded

Caps X

Coupling X

Eccentric Reducer

Concentric Reducer X

90 Degree Elbow X

45 Degree Elbow X

Tee X

Reducing Tee X

Lateral X

Saddle X

Pipe Nipples

Project C-560

General Specification 000-GD-P-007

Piping Material Classes

Rev. 1

Q:\Doc_Control\R0534200\01_Eng_Doc\05_Pip\01_Design_Criteria\GD07 F5_1_1.doc

Page 1 of 2

PIPING MATERIAL CLASSES

CLASS

F5

REV

1

Sheet 1 of 2

Corr. Allow.: 0.000 mm Design Code: ANSI B31.3

Design Press./Temp. Press./Temp. Rating (Note1)

Press., kPag Temp., C Press., kPag Temp., C

Design Pressure -29 to38

SERVICE:

(For high acid services):

Acid Solution, High (+10 g/L) (ASH)

Slurry, Acidic High Acid (+10 g/L) (L.P.) (ASLH)

Process Condensate (PCO)

Slurry, Neutral (SU), (floor sumps)

-----------------------------------------------------------------------

Acidic Barren Solution (ABS)

Slurry Spent Carbon (CS)

Process Drain (Corrosive), (PD)

Pregnant Solution (High Acid), (PSH)

Sulfuric Acid Dilute (<50%) (SAD)

1034 (1" to 10")

690 (12" to 14")

93

Design Pressure

80 (Max)

(Note 3)

Nominal Pipe Size Inches 1 1 2 2 3 4 6 8 10 12 14

CONSTRUCTION

Vinyl Ester-polyester adhesive socket cement joints except at flanged

valve and equipment connections.

PIPE (Note 4)

Fiberglass Reinforced Polyester pipe, manufactured from vinyl ester

resin by centrifugal casting process, inner corrosion barrier of 100 mil

minimum thickness, and a 10 mil resin rich external corrosion barrier

with ultraviolet (UV) inhibitor. Standard Specification per ASTM D2997.

Fiber Glass Systems/Smith Fibercast Centricast Plus CL-2030 Piping

Systems or Approved Equal.

NIPPLE (Note 4) Use Pipe

FITTINGS (Note 4)

Socket Cement Ends, Fiberglass Reinforced Polyester Vinyl Ester

Fittings compatible with pipe, manufactured either by compression

molding or contact molding. Standard Specification per ASTM D5685.

Fiber Glass Systems/Smith Fibercast Centricast Plus CL-2030 Piping

Systems or Approved Equal.

UNION Use Flange

BRANCH CONNECTION Straight Tee: Use Tee Fitting Reducing: Use Saddle

Blind Flange: ANSI B16.5 Class 150 FF bolt hole patterns, Fiberglass

Reinforced Vinyl Ester polyester.

FLANGES

Socket Cement Ends: ANSI B16.5 Class 150 FF bolt hole patterns.

Fiberglass Reinforced Vinyl Ester polyester.

BOLTING

Stainless Steel Type 316 stud bolts, ASTM A193 Gr. B8M with S.S.

Type 316 heavy hex nuts ASTM A194 Gr. 8M.

3.2 mm thick Neoprene Rubber gasket, 60 Shore A Durometer

hardness, GARLOCK Style #7986 or Equal, Class 150 F.F. (For fluids

compatible with Neoprene)

GASKETS

3.2 mm thick Garlock Stress Saver 100% pure PTFE bonded to EPDM

elastomer, Class 150 F.F., Class 150 F.F. (For fluids not compatible with

Neoprene but compatible with PTFE).

BALL VALVE (Note 2) A-85

A-

85-

GO

BUTTERFLY VALVE

(Note 2)

B-35-GO (FRP) or B-6-GO (2205 Duplex SS)

CHECK VALVE C-43 C-42/C-42A

KNIFE GATE VALVE K-6-GO, K-6-P

Nominal Pipe Size Inches 1 1 2 2 3 4 6 8 10 12 14

Continuation Sheet Sheet 2 of 2

Project C-560

General Specification 000-GD-P-007

Piping Material Classes

Rev. 1

Q:\Doc_Control\R0534200\01_Eng_Doc\05_Pip\01_Design_Criteria\GD07 F5_1_1.doc

Page 2 of 2

PIPING MATERIAL CLASSES

CLASS

F5

REV

1

Nominal Pipe Size Inches 1 1 2 2 3 4 6 8 10 12 14

SPECTACLE BLIND Alloy 20; ASTM B463 Gr. A20, Class 150 F.F. ANSI B16.5, ANSI B31.3.

Paddle Spacer,

Blind Paddle

DIAPHRAGM D-1

Notes:

1. Pressure ratings shown on the pressure and temperature ratings are limited by FRP pipe for cyclic conditions.

2. Do not use Butterfly Valves for sludge service. Use Ball Valves.

3. Maximum operating temperature shall be limited by the specific application, which shall be in accordance with the FRP

manufacturers recommendations. Refer to the manufacturers application guide to establish the maximum operating

temperature. The maximum operating temperature per manufacturers recommendation shall be stated in service section if

different from the maximum specified in the pressure/temperature rating.

4. Minimum available pipe size for Fiber Glass System Centricast Plus CL-2030 FRP is 1.

5. When handling Slurries, such as ASLH, use two 45

o

Elbows instead of one 90

o

Elbow.

PIPING MATERIAL SPECIFICATION F5 - FITTINGS

Socket Cement Welded

Caps X

Coupling X

Eccentric Reducer

Concentric Reducer X

90 Degree Elbow X

45 Degree Elbow X

Tee X

Reducing Tee X

Lateral X

Saddle X

Pipe Nipples

Project C-560

General Specification 000-GD-P-007

Piping Material Classes

Rev. 1

Q:\Shared\R0534200\01_Eng_Doc\05_Pip\01_Design_Criteria\02_Int_App\000-GD-P-007 Piping Material Classes\GD07 H1_1_1.doc

Page 1 of 3

REV

PIPING MATERIAL CLASSES

CLASS

H1

1

Sheet 1 of 2

Corr. Allow.: 3.2 mm Design Code: ANSI B31.3

Design Press. /Temp. Press. /Temp. Rating (Note 1)

Press., kPag Temp., C Press., kPag Temp., C

SERVICE:

Concentrated Sulfuric Acid, 93% to 98% (AMB. TEMP.)

(SAC)

1965 38

1965

-29 to 38

Nominal Pipe Size,

Inches

1 1 2 3 4 6 8 10 12 14 16 18 20 24

CONSTRUCTION

Socket weld joints pipe, &

fittings. Flanged valves &

specialty items. (Note 6)

Butt weld joints - pipe and fittings. Flanged valves and specialty items.

PIPE (Note 2) C.S. SCH XH P.E. Carbon Steel, ASTM A53B Seamless, Extra Heavy, B.E.

NIPPLE Use Pipe

FITTINGS

Socket Weld Fittings, Class

3000 ANSI B16.11.

Butt welding fittings, ANSI B16.9, C.S. ASTM A234 WPB, Extra Heavy,

B.E.

UNION Use Flanges

BRANCH CONNECTION Use Fittings

Use Tees for full size and one size reduction. Use weldolets for smaller

branch reduction.

SOCKOLET

ELBOLET S.W.

LATROLET S.W.

C.S. ASTM 105 3000#

WELDOLET

ELBOLET B.W.

C.S. ASTM A105, Extra Heavy x (Branch pipe Sch.) Bore

ANSI B16.5, C.S. ASTM A105

Blind Flange, Class 150 R.F.

FLANGES

Socket Weld, Class 150

R.F.

Weld Neck, Class 150 R.F., Extra Heavy

BOLTING S.S. Type 316 stud bolts, ASTM A193 Gr. B8M with S.S. Type 316 heavy hex nuts ASTM A194 Gr. 8M.

GASKET

1.6 mm thick restructured fluorocarbon, GARLOCK BLUE GYLON Style 3504 or equal, ANSI Class 150

R.F. flange.

BALL VALVE (Note 3) A-15

CHECK VALVE C-8A C-42

GLOBE VALVE E-7

GATE VALVE (Note 3) G-6 G-6-GO

FLANGE SAFETY SHIELD

(Note 5)

Flange: SPZ-4A Valve Bonnet: SPZ-4B

Nominal Pipe Size, in 1 1 2 3 4 6 8 10 12 14 16 18 20 24

Project C-560

General Specification 000-GD-P-007

Piping Material Classes

Rev. 1

Q:\Shared\R0534200\01_Eng_Doc\05_Pip\01_Design_Criteria\02_Int_App\000-GD-P-007 Piping Material Classes\GD07 H1_1_1.doc

Page 2 of 3

REV

PIPING MATERIAL CLASSES

CLASS

H1

1

Continuation Sheet Sheet 2 of 2

Notes:

1. Pressure ratings shown on the pressure and temperature ratings are limited by:

a) Valves per ANSI B16.34

b) Flanges per ANSI B16.5.

2. Minimum allowable pipe size for this material class is 25 mm (1"). For smaller piping use Material Class S3, Alloy 20. Transition joint

between S3 and H1 shall be 25 mm (1") Alloy 20 flange.

3. Use Ball Valve at loading and unloading stations.

4. Observe maximum allowable velocities for concentrated sulfuric acid as follows:

Pipe Size Maximum Velocity

Up to 50 mm (2") 0.601 m/s

Above 50 mm (2") 1.219 m/s

5. Provide flange shield at all flanged joints and at valve bonnets.

6. Screwed connections are permissible only for services 345 kPag & under. Where equipment connections are available only in

screwed connection and the pressure is expected to be more than 345 kPag, the threaded connection must be made up dry (no

thread dressing) and the joint be seal welded to avoid potential leakage.

Project C-560

General Specification 000-GD-P-007

Piping Material Classes

Rev. 1

Q:\Shared\R0534200\01_Eng_Doc\05_Pip\01_Design_Criteria\02_Int_App\000-GD-P-007 Piping Material Classes\GD07 H1_1_1.doc

Page 3 of 3

PIPING MATERIAL SPECIFICATION H1 - FITTINGS

Socketweld Buttweld

Caps X Caps X

Caps - Optional threaded X Lateral X

Coupling X Concentric Swage BLE x PSE X

Reducing Coupling X Eccentric Swage BLE x PSE X

Union X Concentric Swage BLE x TSE X

Plug - Threaded X - Optional Eccentric Swage BLE x TSE X

Concentric Swage PE X - Default Concentric Reducer X

Eccentric Swage PE X Eccentric Reducer X

Concentric Swage PLE x TSE X 90 Degree Elbow X

Eccentric Swage PLE x TSE X 45 Degree Elbow X

90 Degree Elbow X Tee X

45 Degree Elbow X Reducing Tee X

Tee X

Reducing Tee X

Lateral X

Pipe Nipples X

Project C-560

General Specification 000-GD-P-007

Piping Material Classes

Rev. 1

Q:\Doc_Control\R0534200\01_Eng_Doc\05_Pip\01_Design_Criteria\GD07 H2_0_1.doc

REV

PIPING MATERIAL CLASSES

CLASS

H2

0

Sheet 1 of 2

Corr. Allow.: 3.2 mm Design Code: ANSI B31.3

Design Press. /Temp. Press. /Temp. Rating (Note 1)

Press., kPag Temp., C Press., kPag Temp., C

SERVICE:

Sodium Hydrosulfide (NaHS) (NA)

(See Note 4)

1035 38

1035

-29 to 38

Nominal Pipe Size,

Inches

1 1 2 3 4 6 8 10

CONSTRUCTION

Socket weld joints pipe, &

fittings. Flanged valves &

specialty items. (Note 6)

Butt weld joints - pipe and fittings. Flanged valves and specialty items.

PIPE (Note 2) C.S. SCH 80 P.E. Carbon Steel, ASTM A53B Seamless, Sch 80, B.E.

NIPPLE Use Pipe

FITTINGS

Socket Weld Fittings, Class

3000 ANSI B16.11.

Butt welding fittings, ANSI B16.9, C.S. ASTM A234 WPB, (Sch. Same

as pipe), B.E.

UNION Use Flanges

BRANCH CONNECTION Use Fittings

Use Tees for full size and one size reduction. Use weldolets for smaller

branch reduction.

SOCKOLET

ELBOLET S.W.

LATROLET S.W.

C.S. ASTM 105 3000#

WELDOLET

ELBOLET B.W.

C.S. ASTM A105, Extra Heavy x (Branch pipe Sch.) Bore

ANSI B16.5, C.S. ASTM A105

Blind Flange, Class 150 R.F. FLANGES

Socket Weld, Class 150 R.F. Weld Neck, Class 150 R.F., Extra Heavy

BOLTING S.S. Type 316 stud bolts, ASTM A193 Gr. B8M with S.S. Type 316 heavy hex nuts ASTM A194 Gr. 8M.

GASKET

1.6 mm thick restructured fluorocarbon, GARLOCK BLUE GYLON Style 3504 or equal, ANSI Class 150

R.F. flange.

BALL VALVE (Note 2) A-15 A-15-GO

BALL VALVE (Note 5) A-37 for <1

CHECK VALVE C-21 C-23

GLOBE VALVE E-18

FLANGE SAFETY

SHIELD (Note 3)

Flange: SPZ-4A Valve Bonnet: SPZ-4B

Nominal Pipe Size, in 1 1 2 3 4 6 8 10

Notes:

1. Pressure ratings shown on the pressure and temperature ratings are limited by:

a) Valves per ANSI B16.34

b) Flanges per ANSI B16.5.

2. Use Ball Valve at loading and unloading stations.

3. Provide flange shield at all flanged joints and at valve bonnets.

4. No Copper, Zinc, Aluminum or their alloys (bronze, brass, galvanized metals, etc.) for item in contact with the contained fluid.

5. Use A-37 socket weld ends where required

Page 1 of 2

Project C-560

General Specification 000-GD-P-007

Piping Material Classes

Rev. 1

Q:\Doc_Control\R0534200\01_Eng_Doc\05_Pip\01_Design_Criteria\GD07 H2_0_1.doc

Page 2 of 2

PIPING MATERIAL SPECIFICATION H2 - FITTINGS

Socketweld Buttweld

Caps X Caps X

Caps - Optional threaded X Lateral X

Coupling X Concentric Swage BLE x PSE X

Reducing Coupling X Eccentric Swage BLE x PSE X

Union X Concentric Swage BLE x TSE X

Plug - Threaded X - Optional Eccentric Swage BLE x TSE X

Concentric Swage PE X - Default Concentric Reducer X

Eccentric Swage PE X Eccentric Reducer X

Concentric Swage PLE x TSE X 90 Degree Elbow X

Eccentric Swage PLE x TSE X 45 Degree Elbow X

90 Degree Elbow X Tee X

45 Degree Elbow X Reducing Tee X

Tee X

Reducing Tee X

Lateral X

Pipe Nipples X

Project C-560

General Specification 000-GD-P-007

Piping Material Classes

Rev. 1

Q:\Doc_Control\R0534200\01_Eng_Doc\05_Pip\01_Design_Criteria\GD07 J 3_1_1.doc

PIPING MATERIAL CLASSES

CLASS

J3

REV

1

Sheet 1 of 4

Corr. Allow.: 1.6 mm Design Code: ANSI B31.3

Design Press./Temp. Press./Temp. Rating (Note 1)

Press., kPag Temp., C Press., kPag Temp., C

Design Pressure -29 to 38

Service:

High Pressure Gaseous Oxygen GOXH

(See Note 3)

4138

(Max)

38

(Max)

3483 93 (Max)

Nominal Pipe Size, Inches

1

/

2

3

/

4

1 1

1

/

2

2 2

1

/

2

3 4 6 8 10 12 14 16 18 20 24

CONSTRUCTION

Socket weld joints - pipe, fittings,

and valves. Flanged and S.W.

specialty items

Butt weld joints - pipe and fittings. Flanged valves and specialty items.

C.S. ASTM A106 Gr. B, Seamless, Prepared for Oxygen service (Note 3)

PIPE

Sch. 160,

P.E.

Sch. 80, P.E. Std. Wt., B.E.

NIPPLE Use Pipe

FITTINGS

Class 3000 ANSI B16.11 Socket

weld, C.S. ASTM A105, Prepared

for Oxygen service (Note 3)

Butt welding fittings, ANSI B16.9, C.S. ASTM A234 Gr. WPB, (Sch. same

as pipe), B.E., Prepared for Oxygen service (Note 3)

UNION

Class 3000 MSS-SP-83 Socket

weld, C.S. ASTM A105, Steel to

steel seats, Prepared for Oxygen

service (Note 3)

Use Flanges

BRANCH CONNECTION See Branch Reinforcement Table BR-J 3.

SOCKOLET

ELBOLET S.W.

LATROLET S.W.

C.S. ASTM A105 3000#,

Prepared for Oxygen service

(Note 3)

WELDOLET

ELBOLET B.W.

C.S. ASTM A105, Std. Wt. x (Branch pipe Sch.) Bore

Prepared for Oxygen service (Note 3)

ANSI B16.5, C.S. ASTM A105, Prepared for Oxygen service (Note 3)

Blind Flange, Class 300 R.F.

Class 300 R.F. Slip-On

Class 300 Lap J oint