Documentos de Académico

Documentos de Profesional

Documentos de Cultura

1304 Microline 6000 P Englisch

Cargado por

rrebollar0 calificaciones0% encontró este documento útil (0 votos)

23 vistas8 páginasLPKF MicroLine 6000 P laser system provides cost-effective industrial laser processing with highly precise results. Automatic beam adjustment allows automatic execution of the entire process sequence. Vision system monitors the relative position of the laser to the board and noticeably helps increase the number of accepts.

Descripción original:

Título original

1304 Microline 6000 p Englisch

Derechos de autor

© © All Rights Reserved

Formatos disponibles

PDF, TXT o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoLPKF MicroLine 6000 P laser system provides cost-effective industrial laser processing with highly precise results. Automatic beam adjustment allows automatic execution of the entire process sequence. Vision system monitors the relative position of the laser to the board and noticeably helps increase the number of accepts.

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

0 calificaciones0% encontró este documento útil (0 votos)

23 vistas8 páginas1304 Microline 6000 P Englisch

Cargado por

rrebollarLPKF MicroLine 6000 P laser system provides cost-effective industrial laser processing with highly precise results. Automatic beam adjustment allows automatic execution of the entire process sequence. Vision system monitors the relative position of the laser to the board and noticeably helps increase the number of accepts.

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

Está en la página 1de 8

Processing Sensitive Substrates with UV Laser

Quality in a New Dimension

LPKF MicroLine 6000 P

Cost-Effective Laser Processing

for Printed Circuit Boards

Demand-driven rhythm: todays sophisticated production plans are pushing processing

systems to their limits as product portfolios become more extensive and unexpected layout

changes become more frequent. At the same time, cutting quality requirements are increasing.

The LPKF MicroLine 6000 P laser system meets these requirements by providing cost-effective

industrial laser processing with highly precise results.

High Cutting Speed, Low Costs

The LPKF MicroLine 6000 P laser system increases

production planning while also lowering total cost of

ownership. These two goals were the focus in further

developing the system for model year 2012. The current

system masters the balance between high quality and

high throughput. The easy automation feature allows

automatic execution of the entire process sequence.

A Worthwhile Investment

Using the LPKF MicroLine 6000 P pays off quickly.

Its speed and precision create a decisive competitive

advantage, while dropping processing time for PCBs

and virtually eliminating tool costs in comparison to

conventional methods.

Turning challenges into advantages: the MicroLine

6000 P not only cuts rectangular boards but also

drills holes and makes cuts along any contours.

A vacuum table holds the boards securely in position.

In the cutting process itself, there are practically no

mechanical or thermal stresses on the component. A

vision system monitors the relative position of the laser

to the board and noticeably helps increase the number

of accepts.

Worldwide Support

With automatic beam adjustment, LPKF was able

to signicantly lower the calibration outlay during

installation and ongoing operation. The new LPKF

MicroLine 6000 P has a self-adjusting laser system

that becomes active under both thermal inuences and

component replacement. The laser beam always hits

its target without requiring manual setting.

All LPKF MicroLine customers have a direct line to

service locations in Germany, the USA and Asia, where

they receive support for new projects or processes and

prot from the extensive experience of our specialized

project engineers. These service centers also manage

employee training and service installed systems.

Minimum tool costs

Complex contours without set-up outlay

Flexible production planning

Low maintenance outlay in 24/7 operation

Limited production waste

LPKF MicroLine 6000 P

Easy Automation

Due to the integrated SMEMA interface, the LPKF

MicroLine 6000 P laser processing system easily

combines with all types of handling systems.

Clean Process

LPKF laser systems are always delivered with a high-

capacity exhaust and lter unit, keeping the work

environment and the laser optics clean and protecting

the components from contamination.

Automatic Beam Correction

Active elements in the beam path continuously detect

and optimize the position of the laser beam. This

enables the LPKF MicroLine 6000 P to achieve optimal

processing results, even after replacing components or

changing ambient conditions. The processing power is

also continuously detected and adapted to the chosen

process parameters.

Manual calibration work is almost completely

eliminated, enabling the system to rapidly resume

production following servicing.

Linear Actuators

Linear actuators for laser head movement are quick,

precise and maintenance-free, contributing to the

performance of the entire system.

Integration in MES Solutions

The MicroLine 6000 P seamlessly integrates into

existing manufacturing execution systems (MESs). The

laser system delivers operative parameters, machine

data, tracking & tracing values and information about

individual production runs.

Vacuum Table

The integrated homogenous exactly even levelled

vacuum system keeps sensitive components and

materials securely in place.

Material Position Detection

The vision system not only detects the contours of

entire panels, but also detects contour features of

individual components, increasing the chance of

making components from deformed originals that

still conform to standards.

Versatile

Easily combined with handling systems

Self-adjusting beam position

610 mm x 533 mm (24 x 21) operating range

Flex-Rigid Circuitry and Decap Applications

Thanks to its high level of process stability, the

UV laser of the LPKF MicroLine 6000 P cuts with

reliable depth monitoring, a critical precondition

for separating rigid components from the

exible components of ex-rigid circuitry.

When creating pockets, individual layers of a multilayer

are precisely cut out so as to embed components the

UV laser is exceptionally well-suited for this application.

Cutting Rigid and Flexible PCBs

Because the stress-free laser cutting process impairs

neither strip conductors nor components, cut edges

are much closer to the borders of the electronic layout.

The components get smaller, but there is still room on

the panel. Higher packing densities can be achieved

with the LPKF laser system because the system cuts

very close to the components.

In the industrial eld, the LPKF MicroLine 6000 P

systems are optimized for precise processing of

thin, exible material lines. These new capabilities

also make the system a perfect tool for a variety

of applications.

Broad Range of Materials

No thermal or mechanical stress

Particle-free cuts

Premium precision

Material processing with depth monitoring

Cutting Cover Layers

The level of integration required for complex electronic

products can only be achieved with the precision and

neness of laser technology. Cover layers protect

the surfaces of complex printed circuit boards. The

laser cuts cover layers with tiny openings and even

irregular contours without mechanical inuences.

More Flexibility

The UV laser wavelength makes the LPKF MicroLine

6000 P a multi-talented system. Since no tools

are required for xing or the cutting process and

only layout data need to be adapted, the system is

suitable for a wide variety of applications, such as:

Structuring of invisible conducting layers on plastic

or glass (TCO/ITO)

Precisely opening solder resists. Completely blank

pads come about through the laser process without

subsequent cleaning

Structuring, drilling and cutting ceramic base

materials

Fine structuring of metal layers (e.g., Cu, Ni, Au) on

fired ceramics (e.g., Al

2

O

3

).

L

P

K

F

A

G

,

1

0

0

1

5

6

8

3

-

2

4

0

9

1

3

-

E

N

P

h

o

t

o

s

m

a

y

a

l

s

o

s

h

o

w

o

p

t

i

o

n

a

l

a

c

c

e

s

s

o

r

i

e

s

.

w

w

w

.

j

e

n

k

o

-

s

t

e

r

n

b

e

r

g

.

d

e

MicroLine 6000 P series systems feature two variations: MicroLine 6120 P (6 watt laser source)

and MicroLine 6820 P (12 watt laser source).

Enjoy Worldwide Support

MicroLine UV laser system users all over the world enjoy a direct connection to our application centers in Germany,

the USA, Japan and China. There they receive support for their new project, new processes, and applications based

on LPKFs years of experience in laser material processing. Training for your operating staff and technical service

complete your relationship with the world leader in PCB laser processing. Please contact LPKF for application reports

and further information.

LPKF Laser & Electronics AG, Subject Specications and other product information subject to change without notice. Systems and products supplied by LPKF and its subsidiaries protected

by issued or pending US and other international patents. Product names are for identication purposes only and may be trademarks or registered brand names of the associated companies.

Worldwide (LPKF Headquarters)

LPKF Laser & Electronics AG Osteriede 7 30827 Garbsen Germany

Phone +49 (5131) 7095-0 Fax +49 (5131) 7095-90 info@lpkf.com

www.lpkf.com

North / Central America

LPKF Laser & Electronics North America

Phone +1 (503) 454-4200 Fax +1 (503) 682-7151 sales@lpkfusa.com

www.lpkfusa.com

China

LPKF Tianjin Co., Ltd.

Phone +86 (22) 2378-5318 Fax +86 (22) 2378-5398 sales@lpkf.cn

www.lpkf.cn

LPKF Laser & Electronics AG sells and markets products and provides support

in over 50 diffe rent countries. Find your nearest partner at www.lpkf.com.

Hong Kong

LPKF Laser & Electronics (Hong Kong) Ltd.

Phone +852-2545-4005 Fax +852-2545-4006 hongkong@lpkf.com

www.lpkf.com

Japan

LPKF Laser & Electronics K.K. Japan

Phone +81 (0) 45 650 1622 Fax +81 (0) 45 650 1624 info.japan@lpkf.com

www.lpkf.com

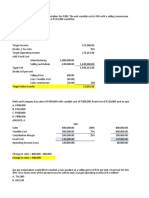

Technical Data: LPKF MicroLine 6000 P

Max. material size (X/Y/Z) 533 mm x 610 mm x 50 mm (21 x 24 x 2)

Max. recognition area (X/Y) 533 mm x 610 mm (21 x 24)

Data input formats Gerber, X-Gerber, DXF, HPGL, Sieb & Meier, Excellon, ODB ++

Max. structuring speed Depends on application

Accuracy 20 m (0.8 mil)*

Diameter of focussed laser beam 20 m (0.8 mil)

Laser wavelength 355 nm

System dimensions (W/H/D) 1,800 x 1,770 x 1,440 mm (70.8 x 69.7 x 56.7)

Weight

~

1,900 kg (4,190 lbs)

Operating conditions

Power supply 400 V, 3 phases, 5.6 kW**

Cooling Air-cooled (internal cooling cycle)

Ambient temperature 71.6 F 4 F

Humidity < 60 % (noncondensing)

Required accessoires Exhaust unit, compressed air supply (0.6 MPa)

Hardware and software requirements Standard industry PC and CAM system software included

* Positioning accuracy ** Includes exhaust unit (1.2 kW)

También podría gustarte

- AC Axial Fans: Max. M /HDocumento3 páginasAC Axial Fans: Max. M /HrrebollarAún no hay calificaciones

- Datasheet PDFDocumento34 páginasDatasheet PDFYounes Ez-zaydyAún no hay calificaciones

- Lithium Battery Cross ReferenceDocumento2 páginasLithium Battery Cross ReferencerrebollarAún no hay calificaciones

- MODEL TL-5101: Memory BackupDocumento2 páginasMODEL TL-5101: Memory BackuprrebollarAún no hay calificaciones

- 1864228Documento2 páginas1864228rrebollarAún no hay calificaciones

- 2071 In001 - en PDocumento20 páginas2071 In001 - en PrrebollarAún no hay calificaciones

- MODEL TL-5101: Memory BackupDocumento2 páginasMODEL TL-5101: Memory BackuprrebollarAún no hay calificaciones

- Datasheet-TB6560 3axis Stepper Motor Driver: Sunwind Electronics Company LTDDocumento6 páginasDatasheet-TB6560 3axis Stepper Motor Driver: Sunwind Electronics Company LTDAdelAún no hay calificaciones

- Tb6560 PDFDocumento1 páginaTb6560 PDFrrebollarAún no hay calificaciones

- Datasheet LS14250 Lithium Batery (Li-SOCl2)Documento2 páginasDatasheet LS14250 Lithium Batery (Li-SOCl2)RafaelAyresGonçalvesAún no hay calificaciones

- Datasheet LS14250 Lithium Batery (Li-SOCl2)Documento2 páginasDatasheet LS14250 Lithium Batery (Li-SOCl2)RafaelAyresGonçalvesAún no hay calificaciones

- Tsxplp01 TSX 37Documento1 páginaTsxplp01 TSX 37rrebollarAún no hay calificaciones

- Abb VFD Acs550 01Documento320 páginasAbb VFD Acs550 01Anil SankhlaAún no hay calificaciones

- Lithium Battery Cross ReferenceDocumento2 páginasLithium Battery Cross ReferencerrebollarAún no hay calificaciones

- Electronic Control: TumblerDocumento71 páginasElectronic Control: TumblerrrebollarAún no hay calificaciones

- Electronic Control: TumblerDocumento71 páginasElectronic Control: TumblerrrebollarAún no hay calificaciones

- Alj Quick Guides EDC Dryer Controls 120V / 24V Changing Price (Manually)Documento2 páginasAlj Quick Guides EDC Dryer Controls 120V / 24V Changing Price (Manually)rrebollarAún no hay calificaciones

- ABB Drives ACS580 Manual 2017Documento278 páginasABB Drives ACS580 Manual 2017rrebollarAún no hay calificaciones

- Alj Quick Guides EDC Dryer Controls 120V / 24V Changing Price (Manually)Documento2 páginasAlj Quick Guides EDC Dryer Controls 120V / 24V Changing Price (Manually)rrebollarAún no hay calificaciones

- 520 qs001 - en eDocumento36 páginas520 qs001 - en errebollarAún no hay calificaciones

- Control Valve ICSDocumento72 páginasControl Valve ICSrrebollarAún no hay calificaciones

- e 02Documento96 páginase 02rrebollarAún no hay calificaciones

- Brochure Panels en PDFDocumento17 páginasBrochure Panels en PDFrrebollarAún no hay calificaciones

- Delta VFD-M ManualDocumento173 páginasDelta VFD-M Manualpanait_a,alexandru100% (1)

- General Purpose 6-Pin Phototransistor Optocouplers: 4N25 4N26 4N27 4N28 4N35 4N36 4N37 H11A1 H11A2 H11A3 H11A4 H11A5Documento12 páginasGeneral Purpose 6-Pin Phototransistor Optocouplers: 4N25 4N26 4N27 4N28 4N35 4N36 4N37 H11A1 H11A2 H11A3 H11A4 H11A5rrebollarAún no hay calificaciones

- Kepco Gives You Zero-Up Programmability in An Affordable Power ModuleDocumento6 páginasKepco Gives You Zero-Up Programmability in An Affordable Power ModulerrebollarAún no hay calificaciones

- e 02Documento96 páginase 02rrebollarAún no hay calificaciones

- RKW Progspecs PDFDocumento7 páginasRKW Progspecs PDFrrebollarAún no hay calificaciones

- Rear Window Defogger Tab Adhesive TDSDocumento1 páginaRear Window Defogger Tab Adhesive TDSrrebollarAún no hay calificaciones

- Simatic Hmi Memory Card MMC-Card Simatic Hmi Memory Card SD-Card CF-Card PC-Card USB-Stick MLFB Comfort PanelsDocumento8 páginasSimatic Hmi Memory Card MMC-Card Simatic Hmi Memory Card SD-Card CF-Card PC-Card USB-Stick MLFB Comfort PanelsrrebollarAún no hay calificaciones

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (119)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2099)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- Experienced Leadership Driving Growth at Adlabs EntertainmentDocumento38 páginasExperienced Leadership Driving Growth at Adlabs EntertainmentvelusnAún no hay calificaciones

- Ultrasonic Inspection Standards for Wrought MetalsDocumento44 páginasUltrasonic Inspection Standards for Wrought Metalsdomsoneng100% (1)

- Superior University: 5Mwp Solar Power Plant ProjectDocumento3 páginasSuperior University: 5Mwp Solar Power Plant ProjectdaniyalAún no hay calificaciones

- Incident Report Form: RPSG-IMS-F-24 Accident and Investigation Form 5ADocumento2 páginasIncident Report Form: RPSG-IMS-F-24 Accident and Investigation Form 5ARocky BisAún no hay calificaciones

- Wordbank Restaurants 15Documento2 páginasWordbank Restaurants 15Obed AvelarAún no hay calificaciones

- Embedded Systems: Martin Schoeberl Mschoebe@mail - Tuwien.ac - atDocumento27 páginasEmbedded Systems: Martin Schoeberl Mschoebe@mail - Tuwien.ac - atDhirenKumarGoleyAún no hay calificaciones

- HealthFlex Dave BauzonDocumento10 páginasHealthFlex Dave BauzonNino Dave Bauzon100% (1)

- Vydyne® R533H NAT: Ascend Performance Materials Operations LLCDocumento4 páginasVydyne® R533H NAT: Ascend Performance Materials Operations LLCJames FaunceAún no hay calificaciones

- CVP Solution (Quiz)Documento9 páginasCVP Solution (Quiz)Angela Miles DizonAún no hay calificaciones

- AutocadDocumento8 páginasAutocadbrodyAún no hay calificaciones

- CELF Final ProspectusDocumento265 páginasCELF Final ProspectusDealBookAún no hay calificaciones

- UPGRADEDocumento2 páginasUPGRADEVedansh OswalAún no hay calificaciones

- Storage Reservior and Balancing ReservoirDocumento19 páginasStorage Reservior and Balancing ReservoirNeel Kurrey0% (1)

- Exercise Manual For Course 973: Programming C# Extended Features: Hands-OnDocumento122 páginasExercise Manual For Course 973: Programming C# Extended Features: Hands-OnAdrian GorganAún no hay calificaciones

- 2011 Mid America - WebDocumento156 páginas2011 Mid America - WebFaronAún no hay calificaciones

- SEEPZ Special Economic ZoneDocumento2 páginasSEEPZ Special Economic ZonetarachandmaraAún no hay calificaciones

- BIU and EU functions in 8086 microprocessorDocumento12 páginasBIU and EU functions in 8086 microprocessorDaksh ShahAún no hay calificaciones

- What Role Can IS Play in The Pharmaceutical Industry?Documento4 páginasWhat Role Can IS Play in The Pharmaceutical Industry?Đức NguyễnAún no hay calificaciones

- HSPA+ Compressed ModeDocumento10 páginasHSPA+ Compressed ModeAkhtar KhanAún no hay calificaciones

- HPE Alletra 6000-PSN1013540188USENDocumento4 páginasHPE Alletra 6000-PSN1013540188USENMauricio Pérez CortésAún no hay calificaciones

- E200P Operation ManualDocumento26 páginasE200P Operation ManualsharmasourabhAún no hay calificaciones

- TicketDocumento2 páginasTicketbikram kumarAún no hay calificaciones

- Advanced Microcontrollers Grzegorz Budzyń Lecture 8 - ARM Based MCUs and APs PDFDocumento103 páginasAdvanced Microcontrollers Grzegorz Budzyń Lecture 8 - ARM Based MCUs and APs PDFtudor11111Aún no hay calificaciones

- DS 20230629 SG3300UD-MV SG4400UD-MV Datasheet V16 ENDocumento2 páginasDS 20230629 SG3300UD-MV SG4400UD-MV Datasheet V16 ENDragana SkipinaAún no hay calificaciones

- Chapter 1 - Introduction To Computer NetworksDocumento32 páginasChapter 1 - Introduction To Computer NetworksHuluAún no hay calificaciones

- Machine Design - LESSON 4. DESIGN FOR COMBINED LOADING & THEORIES OF FAILUREDocumento5 páginasMachine Design - LESSON 4. DESIGN FOR COMBINED LOADING & THEORIES OF FAILURE9965399367Aún no hay calificaciones

- Syllabus - Mech 3rd YearDocumento130 páginasSyllabus - Mech 3rd YearAbhishek AmarAún no hay calificaciones

- PaySlip ProjectDocumento2 páginasPaySlip Projectharishgogula100% (1)

- Bolsas Transfer FKDocumento7 páginasBolsas Transfer FKBelèn Caridad Nelly Pajuelo YaipènAún no hay calificaciones

- Kuliah Statistik Inferensial Ke4: Simple Linear RegressionDocumento74 páginasKuliah Statistik Inferensial Ke4: Simple Linear Regressionvivian indrioktaAún no hay calificaciones