Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Milling Machines

Cargado por

Huma ArfanDescripción original:

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Milling Machines

Cargado por

Huma ArfanCopyright:

Formatos disponibles

Quadrumat Junior Laboratory mill

The Quadrumat Junior is a precision laboratory mill that yields flour and bran from

grain samples with extraordinary high capacity. The multi-step grinding process allows to

produce flours which are almost equal to commercially milled flours in ash content,

yield, and baking quality. The minimum sample requirement is 20 grams; howeer the

instrument can output !00 grams in approximately fie minutes with a flour yield of "!-

#0$.

Principle:

The closed grinding process ensures maximum separation of the endosperm from the

exosperm. The short grinding process corresponding to the elasticity of the bran preents

splitting up of the bran. %fter haing passed the last pair of rolls, the material drops into

the round sifter where it is separated into flour and bran.

Procedure:

1. Weighing: the minimum sample requirement is 20 grams, howeer the instrument can

output !00 grams in approximately fie minutes with a flour yield of "!-#0$.

2. Cleaning: clean the wheat to be milled by remoing dust, dirt, stones etc.

3. Tempering& the wheat sample must be conditioned before experimental milling. The

purpose of tempering is to bring particular wheat to the optimum conditions for

milling.i.e. to mellow the endosperm , so it fractures easily, and to toughen the bran, so it

does not splinter too much milling.

. !illing: put the sample into the hoper of the mill to start grinding and sifting process.

%t the completion of milling, the sifted flour falls into a flour drawer, and the bran is

collected in a separate bran drawer below the sifter outlet.

"pplication:

The Quadrumat Junior is ideal for wheat breeders and when operated in

con'unction with the #arinograph , $%ten&ograph , and "mylograph , it is

inaluable in the laboratory for the ealuation of extracted flour.

(e obtain laboratory flours which are almost equal to commercially produced

flours in ash content, yield, and baking quality - the multi-step grinding process

only needs a single passage.

The mill is suitable for wheat, spelt, rye, barley and rice.

"d'antage&:

)pecial features are&

*apacity !00 g in approx. ! min.

+ield "0 - #!$

(ith ,rabender

-

,ran .uster up to /0$

%sh 0.! - 0.#$ on dry basis

0ax. moisture 1! - 1/$

2asy operation

3uick and easy roll exchange

4ariable sifter screens

Quadrumat (enior Laboratory !ill

The Quadrumat (enior is a 5ilot 0ill for rapid milling of production equialent test

flour. 6t comes equipped with a 7- roll system which includes a break head and reduction

head. % total of 18 frames 9six siee frames, six collecting frames, and one transfer

frame: are stacked to yield flour products& break flour, reduction flour, bran and shorts.

Principle:

The 3uadrumat

-

)enior uses the same 7-roll principle as the ,rabender

-

3uadrumat

-

;unior with, howeer, two parallel 7-roll units&

% break head

% grinding or middlings reduction head

% bipartite plan sifter with the two sifter sections, stacked one aboe the other, separates

the fractions according to their granulation. 2ach sifter section produces either single

'oint flour or two separate flours.

Procedure:

1. Weighing: the minimum sample requirement is 20 grams, howeer the instrument can

output !00 grams in approximately fie minutes with a flour yield of "!-#0$.

2. Cleaning: clean the wheat to be milled by remoing dust, dirt, stones etc.

3. Tempering: the wheat sample must be conditioned before experimental milling. The

purpose of tempering is to bring particular wheat to the optimum conditions for

milling.i.e. to mellow the endosperm , so it fractures easily, and to toughen the bran, so it

does not splinter too much milling.

. !illing: put the sample into the hoper of the mill to start grinding and sifting process.

%t the completion of milling, four milling fractions i.e. break flour, reduction flour, bran,

shorts are obtained.

"pplication:

The ,rabender

-

3uadrumat

-

)enior is a laboratory mill for

manifold applications&

5reparation of production equialent test flours

.etermination of the milling properties of manifold sorts of grain 9wheat, rye, and

others:

.etermination of the potential yield

"d'antage&:

<igh performance and gentle milling by a 7-roll milling system with hardened,

profi le-ground rolls

2 x 8 successie roll passes in a single step

=o intermediate sifting required

)elf-cleaning sifter

2asy operation and handling

>ood reproducibility and constancy

Throughput / - 10 kg?h

+ield "! - #!$

(ith ,rabender- ,ran .uster up to /0$

(ith ,rabender

-

,ran .uster up to /0$

%sh 0.7! - 0."!$ on dry basis

5roduction of four milling products altogether

Cyclone (ample !ill

*yclone sample mill is designed fir grinding samples of grains, pellets, meals, feeds,

foarges.The mill is a hammer type cyclone mill built into a sound proof casing. The

cyclone principle makes the mill irtually self cleaning, thus increasing lab output,

efficiency, accuracy.

Principle:

The *yclone )ample 0ill uses high elocity air flow, an abrasie surface, and centrifugal

forces to grind arious materials. The impeller is rotated at a high speed creating a high

elocity flow of air to propel the material particles against the abrasie surface. (hen

material is added to the 0ill, the rotation of the impeller and centrifugal force throw the

particles to the perimeter of the grinding chamber where the air flow pushes them along

the abrasie tungsten carbide surface. (hen the particles become small enough to

oercome their angular elocity, they moe with the air flow out of the grinding chamber

and are deposited in a sample collection bottle by the cyclone action. The air flow

preents material accumulation, and any need to clean out the 0ill between samples is

eliminated. The air flow also minimi@es heating of the material and aoids any thermal

degradation.

Aigure& *yclone )ample 0ill >rinding *hamber

Procedure:

1. 5lace the 0ill in the desired location. 4erify that a screen and the cyclone air separator

are in place, and then place the coer on top of the 0ill. )ecure the coer by tightening

two clamps on diagonally opposite sides of the 0ill simultaneously. Tighten the

remaining two clamps.

2. 5lug the 0ill into a suitable power outlet.

8. 5osition a sample collection bottle under the cyclone body by depressing the spring-

loaded bottle support, then turns the 0ill on.

7. (ith bin gate in place, slowly add 20 to 80 grams of sample into the sample bin. .o

not feed samples at a rate fast enough to slow the motor down. Berloading the motor

weakens the belts ery rapidly and lowers the rate that material can be fed into the 0ill

without further oerloading it.

!. (hen no more samples appear in the cyclone body leading into the sample collection

bottle, the 0ill can be turned off.

". )eal the bottle with the snap-cap, and then shake thoroughly to obtain a homogenous

mixture.

"pplication:

*yclone sample mill is designed fir grinding samples of grains, pellets, meals, feeds,

foarges.

The ground sample can be used for analysis such as =6C, falling no, glutamatic, D'eldhal

etc.

"d'antage&:

)obu&t !etal Con&truction: reliable operation, long instrument life.

)educed *u&t: cyclone outlet with filter bag to minimi@e dust.

(ound Proo+ Ca&ing: reduced noise leel.

Large (ample Capacity: reduces sampling error-fulfils falling no requirements.

,acuum #eed Control: air flow feeder regulate feeding and facilitates grinding.

-omogenou& particle &i.e: produces homogenous sample required fro =6C, falling no,

glutamatic analysis.

-igh !oi&ture /rinding: ad'ustable feed rate allows grinding of samples up to 2!$

moisture.

(el+ Cleaning0 cyclone design minimi@es cleaning between samples.

(a+e operation0 motor can not start until door is closed and immediately stops when door

is opened.

(a+ety precaution&:

1. (ear a dust mask and aoid inhaling dust.

2. 2quipment should be maintained on a regular sechedule.

8. (hen a belt breaks replace all the belta at the same time. 5roper tension of belts is

critical.

China atta cha1i

*hina atta chaki is used for grinding of grains like wheat, rice, corn. 6t produces whole

wheat flour haing high proportion of bran.

*hina atta chaki consists of&

1. <opper for feeding of grains

2. Cotaing blades ring; for grinding action

8. )iees of ariable si@e to get flour of different particle si@e.

7. 0otor for electric supply

!. *ollecting end to get flour

Principle:

The rotation of rotating blade ring and centrifugal force breaks the grains into fine

particles and then these are passed through siees to get flour of desired particle si@e.

Procedure:

1. clean the wheat to be milled by remoing dust, dirt, stones etc

2. *lean the mill and siees thoroughly with cleaning brush before operation.

8. 6nsert the siee in the mill.

7. attach a cloth bag with the receiing end to get flour

!. Turn on the mill and put the grains into hoper. %t the end of milling flour

will be collected in cloth bag attached with the collecting end.

"pplication:

The china atta chaki is used for the production of whole wheat flour, rice flour, corn flour

etc at domestic or small scale leel.

"d'antage&:

simple, easy to use

ery economical

less noise

safe to operate

less power consumption

ideal for general purpose grinding

(a+ety Precaution&:

1. *leaning of grains as well as of siees, mill is essential for efficient grinding.

2. .o not oerload the mill.

8. Bbsere all the safety and operating instructions supplied by the manufacturer.

También podría gustarte

- 100 DialogsDocumento38 páginas100 DialogsTramVu100% (2)

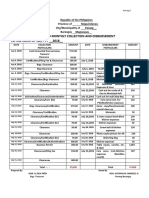

- Itemized Monthly Collection & DisbursementDocumento25 páginasItemized Monthly Collection & DisbursementCyrus John VelardeAún no hay calificaciones

- Design of Rice MillDocumento13 páginasDesign of Rice MillChie Chie100% (1)

- The Origins of Brewing Technology in MesopotamiaDocumento20 páginasThe Origins of Brewing Technology in MesopotamiaHathor83Aún no hay calificaciones

- How To Start A Hotel BusinessDocumento25 páginasHow To Start A Hotel BusinessAshwani KhadoliaAún no hay calificaciones

- Rice Corn MillDocumento14 páginasRice Corn MillJay Pee ZeyAún no hay calificaciones

- Jollibee Foods Corporation SWOT MatrixDocumento3 páginasJollibee Foods Corporation SWOT MatrixKaye Velarde50% (2)

- MILLING ProcessDocumento27 páginasMILLING ProcessSakinala Raj KumarAún no hay calificaciones

- Commercial Cooking Grade 8 Lesson 1 (Powerpoint)Documento57 páginasCommercial Cooking Grade 8 Lesson 1 (Powerpoint)Madinne Pauline Tolentino100% (8)

- AldiDocumento16 páginasAldiCam NhungAún no hay calificaciones

- EYO Scouting 14-Week CalendarDocumento17 páginasEYO Scouting 14-Week Calendarjeff_cunningham_11Aún no hay calificaciones

- Cheese Making Made Easy: Make your own favorite cheesesDe EverandCheese Making Made Easy: Make your own favorite cheesesAún no hay calificaciones

- Post-Harvest Technologies of Corn: Pampanga State Agricultural UniversityDocumento51 páginasPost-Harvest Technologies of Corn: Pampanga State Agricultural UniversityLoreen100% (1)

- Cafe Coffee DayDocumento27 páginasCafe Coffee DayTanmeet KaurAún no hay calificaciones

- Lecture PPT of Alligation and Mixture (2) SolutionsDocumento40 páginasLecture PPT of Alligation and Mixture (2) SolutionsVicky Guleria100% (2)

- Wheat MillingDocumento11 páginasWheat MillingFaizanAhmadAún no hay calificaciones

- Teaching Manual Rice MillingDocumento12 páginasTeaching Manual Rice MillingChui Tai LauAún no hay calificaciones

- Rice MillingDocumento32 páginasRice MillingReymart EboraAún no hay calificaciones

- Barley Flour Mill DPR by NIFTEMDocumento28 páginasBarley Flour Mill DPR by NIFTEMManav AggarwalAún no hay calificaciones

- Process Parameter in Blow RoomDocumento7 páginasProcess Parameter in Blow RoomKhan Ali100% (2)

- Mini Flour MillDocumento10 páginasMini Flour Millgirish SharmaAún no hay calificaciones

- Organization ChartDocumento11 páginasOrganization ChartChristine KingAún no hay calificaciones

- Parboiling Dryer PlantDocumento25 páginasParboiling Dryer PlantShivaz SharmaAún no hay calificaciones

- Caso 1Documento4 páginasCaso 1mayerli fonsecaAún no hay calificaciones

- Blow RoomDocumento123 páginasBlow RoomNahom Daniel100% (8)

- Wheat MillingDocumento7 páginasWheat MillingEdward Appenteng MensahAún no hay calificaciones

- Wheat MillingDocumento8 páginasWheat MillingEdward Appenteng MensahAún no hay calificaciones

- Maize - Dry MillingDocumento9 páginasMaize - Dry MillingAFIFAH AMIRATUL MUFIDAHAún no hay calificaciones

- 2.A - 3 - ICC Draft Standard 192 - Bastak - Final 230505Documento14 páginas2.A - 3 - ICC Draft Standard 192 - Bastak - Final 230505msradymnAún no hay calificaciones

- Plant Visit SagaDocumento6 páginasPlant Visit SagaSalah Eldin Abdalla100% (3)

- Milling HandoutDocumento6 páginasMilling HandoutRica de los SantosAún no hay calificaciones

- Process Parameter in Blow RoomDocumento19 páginasProcess Parameter in Blow RoomakmaluzirAún no hay calificaciones

- Introduction To Textile GinningDocumento44 páginasIntroduction To Textile GinningMujahid MehdiAún no hay calificaciones

- Barley Flour Mill DPR by NIFTEMDocumento28 páginasBarley Flour Mill DPR by NIFTEMManav AggarwalAún no hay calificaciones

- MillingDocumento3 páginasMillingRayhanul KarimAún no hay calificaciones

- Content: Introduction Training Objective Schedule Work Details Training OutcomeDocumento45 páginasContent: Introduction Training Objective Schedule Work Details Training Outcomevineet chavanAún no hay calificaciones

- Mixing:: Basic Tasks of Blow RoomDocumento9 páginasMixing:: Basic Tasks of Blow RoommohitAún no hay calificaciones

- Q4 AFA Agricrop 10 Week 7Documento4 páginasQ4 AFA Agricrop 10 Week 7Eden SumilayAún no hay calificaciones

- Grain Seprator and WashingDocumento19 páginasGrain Seprator and Washingsourabhsdn76Aún no hay calificaciones

- Prof YmDocumento80 páginasProf YmGourav Katyal100% (1)

- RICE MILL MACHINERY AND EQUIPMENT - PPTX v111Documento60 páginasRICE MILL MACHINERY AND EQUIPMENT - PPTX v111diomedes pataniAún no hay calificaciones

- Corn MillingDocumento22 páginasCorn MillingNoshaba FiazAún no hay calificaciones

- TT 403 Ginning TechnologyDocumento45 páginasTT 403 Ginning Technologymt khan100% (2)

- Blow RoomDocumento42 páginasBlow RoomSiva Jagadish Kumar MAún no hay calificaciones

- Lab Manual BWI and MOGDocumento5 páginasLab Manual BWI and MOGAlecsNicoleN.CabahugAún no hay calificaciones

- Basic Operations in The BlowroomDocumento7 páginasBasic Operations in The BlowroomVikrant KanugondaAún no hay calificaciones

- Cornmeal-Masa: Food and Agriculture Organization of The United NationsDocumento6 páginasCornmeal-Masa: Food and Agriculture Organization of The United NationsairineAún no hay calificaciones

- NAME Eng. Waziri Maulidi Discipline Bioprocess and Postharvest EngineeringDocumento5 páginasNAME Eng. Waziri Maulidi Discipline Bioprocess and Postharvest Engineeringwaziri maulidiAún no hay calificaciones

- Report Mill and Boiler FinalDocumento35 páginasReport Mill and Boiler FinalMuhammad Nur ShidiqAún no hay calificaciones

- Manufacturing Process AttaDocumento3 páginasManufacturing Process AttaPramod Chamaria67% (6)

- EA448 Lab 5 Sieve Analysis ProcedureDocumento8 páginasEA448 Lab 5 Sieve Analysis ProcedureEllz LahCe Gimotea BaluyutAún no hay calificaciones

- Raw Paddy UnitDocumento5 páginasRaw Paddy Unitgepin35032Aún no hay calificaciones

- Cashew ProcessDocumento10 páginasCashew ProcessAratiAún no hay calificaciones

- 4b. Rice MillingDocumento11 páginas4b. Rice MillingTakudzwa TamirepiAún no hay calificaciones

- Textile Technology Internship ReportDocumento24 páginasTextile Technology Internship Reportgunashekarkalluri100% (1)

- Shaw Flour MillDocumento7 páginasShaw Flour MillSunil Shaw100% (1)

- Definition and Operation of A Bioethanol Production FacilityDocumento6 páginasDefinition and Operation of A Bioethanol Production FacilityScribdTranslationsAún no hay calificaciones

- Blow RoomDocumento2 páginasBlow RoomRobotrix100% (1)

- Lecture 2 Sugar-1Documento55 páginasLecture 2 Sugar-1mail3temuAún no hay calificaciones

- Cane, Hareve, Weighing&handlling Plant (1)Documento55 páginasCane, Hareve, Weighing&handlling Plant (1)Gebeyehu GetachewAún no hay calificaciones

- Term Paper MidtermDocumento15 páginasTerm Paper MidtermMahonyAún no hay calificaciones

- Milling of RiceDocumento18 páginasMilling of RiceArush SidanaAún no hay calificaciones

- Industrial Processes: Week-2.1 Rice MillingDocumento8 páginasIndustrial Processes: Week-2.1 Rice MillingarkinkozAún no hay calificaciones

- Chapter 16 Rice MillingDocumento85 páginasChapter 16 Rice MillingRyza MartizanoAún no hay calificaciones

- Technical Engineering Collage Department of Petrochemical Engineering Practical of Refinery Experiment NoDocumento4 páginasTechnical Engineering Collage Department of Petrochemical Engineering Practical of Refinery Experiment NoSafwan BakrmanyAún no hay calificaciones

- Sugarcane TechnologiesDocumento10 páginasSugarcane TechnologiesYogesh KamatAún no hay calificaciones

- Lab Mill ProcedureDocumento12 páginasLab Mill ProcedureElbert Leo AstilleroAún no hay calificaciones

- Milling of WheatDocumento26 páginasMilling of WheatAry An ChaharAún no hay calificaciones

- Unit 6Documento14 páginasUnit 6abdulrahman saadAún no hay calificaciones

- ObjectivesDocumento1 páginaObjectivesSheqyn IeinAún no hay calificaciones

- Automation in Cashew ProcessingDocumento40 páginasAutomation in Cashew ProcessingShivayogi PujarAún no hay calificaciones

- Illustrated Catalogue of Cotton MachineryDe EverandIllustrated Catalogue of Cotton MachineryAún no hay calificaciones

- Nutrition Essential OilDocumento2 páginasNutrition Essential OilHuma ArfanAún no hay calificaciones

- Microvawe OvenDocumento1 páginaMicrovawe OvenHuma ArfanAún no hay calificaciones

- Pak Css 2013Documento2 páginasPak Css 2013Huma ArfanAún no hay calificaciones

- Accagenonlinedoc 23967652 1Documento2 páginasAccagenonlinedoc 23967652 1Huma ArfanAún no hay calificaciones

- Steve Scott's Approach To f7Documento2 páginasSteve Scott's Approach To f7Zohaib AslamAún no hay calificaciones

- D 13Documento2 páginasD 13Huma ArfanAún no hay calificaciones

- Unit 3 Agricultural Systems Management Reliability of Agricultural SystemsDocumento22 páginasUnit 3 Agricultural Systems Management Reliability of Agricultural Systemsthirumangai6Aún no hay calificaciones

- Math 3 LM Draft 4.10.2014Documento367 páginasMath 3 LM Draft 4.10.2014Golden SunriseAún no hay calificaciones

- List of Phrasal VerbsDocumento38 páginasList of Phrasal Verbsfparker001100% (1)

- Colby Sorensen ResumeDocumento3 páginasColby Sorensen Resumeapi-439012737Aún no hay calificaciones

- Chapter-1-2 FinaleDocumento15 páginasChapter-1-2 FinaleMarites Semira CastilloAún no hay calificaciones

- Business Plan Example Sports CafeDocumento12 páginasBusiness Plan Example Sports CafeDo Van TuAún no hay calificaciones

- Act 4 URC Jollibee TinsDocumento6 páginasAct 4 URC Jollibee TinsXiedrick SibongaAún no hay calificaciones

- Full Download Financial Accounting 4th Edition Spiceland Solutions ManualDocumento35 páginasFull Download Financial Accounting 4th Edition Spiceland Solutions Manualelizabethrotner100% (26)

- LN - GJ-Bu 1Documento315 páginasLN - GJ-Bu 1EduardoOrtizAún no hay calificaciones

- Practices of Poverty Measurement and Poverty Profile of NepalDocumento41 páginasPractices of Poverty Measurement and Poverty Profile of NepalAsian Development BankAún no hay calificaciones

- Lowes Part01Documento60 páginasLowes Part01Seymour Acheson BlackmanAún no hay calificaciones

- SITHKOP002 Assessment 2 - ProjectDocumento30 páginasSITHKOP002 Assessment 2 - ProjectYusra javaidAún no hay calificaciones

- Report On FMCG SectorDocumento29 páginasReport On FMCG Sectoraqas_khanAún no hay calificaciones

- Project Report: National Food LimitedDocumento37 páginasProject Report: National Food LimitedRukhsar Abbas Ali .Aún no hay calificaciones

- Brand Audit BrandingDocumento8 páginasBrand Audit Brandingcasey_d_roweAún no hay calificaciones

- Agro-Industrial Supply Chain Management: Concepts and ApplicationsDocumento71 páginasAgro-Industrial Supply Chain Management: Concepts and ApplicationsFelipe BezerraAún no hay calificaciones

- Kraft Celebration Tour - 09 - Ontario 1Documento3 páginasKraft Celebration Tour - 09 - Ontario 1NorthbaynuggetAún no hay calificaciones

- Pizza Report PDFDocumento7 páginasPizza Report PDFjuhi agarwalAún no hay calificaciones