Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Scotchrap™ 52 Tape: Installation Techniques

Cargado por

HJDescripción original:

Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Scotchrap™ 52 Tape: Installation Techniques

Cargado por

HJCopyright:

Formatos disponibles

Scotchrap 52 Tape

Installation Techniques

This document provides general guidelines for application of the product. Minimum overlaps, temperature

limitations and general application guides are outlined.

Scotchrap

TM

52 Corrosion Protection Tape

Installation Techniques

1. Product

Scotchrap 52 Corrosion Protection Tape consists of a tough, flame retardant, all-weather, polyvinyl chloride

film backing coated with a thick, aggressive, temperature-stable, rubber mastic adhesive. Scotchrap 52 Tape

is formulated and designed to provide corrosion, moisture and abrasion protection to weather-exposed

piping systems. Scotchrap 52 is classified for use in both indoor and weather exposed outdoor

environments. Normal service temperature for Scotchrap 52 tape is -20C to 105C with allowable short-

term exposure up to 150C.

Scotchrap 52 Tape can be applied at temperatures ranging from 0C to 38C with relative humidity up to

90%. Surface moisture must be removed by wiping with a clean dry cloth prior to application of 52 tape.

For applications at 5C and colder, all overlap seams of 52 tape must be warmed with a heat gun to insure

proper seal. 3M CC Cleaning Solvent is recommended for clean up of mastic adhesive. Surface cleaning of

the Scotchrap 52 can be done with high-pressure water/steam cleaning equipment. Caution must be

exercised in selecting the spray nozzle and pressure to prevent cutting the Scotchrap 52 Tape and/or lifting

the 35 Seam Cover tape.

2. Installation

1. Cut section of 52 tape required.

2. Apply 52 tape around pipe circumference.

3. Overlap all seams.

4. At temperatures 5C and below, warm all seams and overlap areas with a heat gun (25C to 40C).

5. Use hand pressure to smooth tape and insure adhesion at each overlap.

6. Optional: Cover all seams with Scotch No. 35 tape.

35 Tape serves a cosmetic function by providing a "finished" or edgeless appearance to the 52 Tape.

Note: To calculate the length of tape to be cut from the roll use the following formula:

L = (D x 3,14) + X

Where: Pipe Diameter Minimum Overlap

L = length of tape needed 2,5 - 10,2 cm 2,5 cm

D = outside diameter of pipe (1.0 - 4.0 in.)

X = overlap distance (refer to table) >10,2 cm 5,0 cm

(4.0 in.)

Straight Section

Figure 1

Wrap straight sections of pipe using 53,3 cm

(21.0 inches) wide tape using a "cigarette style

wrap technique. Refer to Figure 1.

Begin wrapping thepipe as shown in Figure 2.

Figure 2

The initial seam should start at the overlap distance, X, past

the center of the pipe bottom. This will result in the outside

seam being positioned directly at the bottom of the pipe.

Refer to Figure 3.

Figure 3

When applying tape to sections of pipe greater than

53,3 cm (21.0 inches) in length, overlap each section of 52 tape

by a minimum of 2,5 cm (1.0 inch).

Refer to Figure 4.

Figure 4

Overlap adjoining section of 52 tape by a minimum of 2,5 cm (1.0 inch). Use hand pressure to smooth tape

and insure adhesion at overlap. Optional step: Apply a layer of 2,5 cm (1.0 inch) wide Scotch 35 tape over

all 52 tape seams. On straight section of pipe, cover longitudinal seams before circumferential seams. To

prevent end-lift, slippage of shrink back of the Scotch 35 tape, allow the last 7,6 cm (3.0 inch) of the tape to

relax prior to application. Do Not Stretch this portion of the Scotch 35tape. Use hand pressure to

smooth tape and insure adhesion.

Elbows and Bends(Refer to Figure 5)

Method A

Figure 5

For pipes up to 30,0 cm (12.0 inches) in diameter,

wrap elbow and bends with 5,1 cm (2.0 inch)

wide rolls of 52 tape. Begin tape application a

minimum of 5,1 cm (2.0 inches) on to straight

section of pipe at one end of the bend. Apply 52

tape in half-lap layers over pipe bend. Continue

half-lap application until reaching 5,1 cm (2.0

inches) onto straight section of pipe on the

opposite side of the bend.

For pipes over 30,0 cm (12.0 inches) in diameter, follow above

instruction using 10,2 cm (4.0 inch) wide rolls of 52 tape. 52

tape must have a minimum overlap at the edges of 2,5 cm (1.0

inch).

Note: Apply tape with sufficient tension to conform smoothly (without wrinkles). Use hand

pressure to smooth tape and insure adhesion at each overlap.

Elbow and Bends(Refer to Figure 6) Figure 6

Method B - Repair Procedure

1. Pre-cut pattern to cover bend (see Figure 6).

2. Apply sections with minimum overlap of 2,5

cm (1.0 inch).

3. Overlap 52 tape a minimum of 2,5 cm

(1.0 inch) onto straight section of pipe.

Note: Apply tape with sufficient tension to conform smoothly (without wrinkles). Use hand

pressure to smooth tape and insure adhesion at each overlap.

Tapered Sections(Refer to Figure 7)

1. Apply narrow wrap 52 tape to small diameter pipe, overlapping reduction edge.

2. Cut O shape pattern from wide section of 52 tape, width of pattern should equal width of reducer plus

2,5 cm (1.0 inch). Apply pre-cut 52 tape around reducer section, overlapping large diameter pipe.

3. Apply 52 tapeto straight section of large diameter pipe, overlapping 52 tape applied in step 2.

4. Apply 52 tape straight section of small diameter pipe, overlapping 52 tape applied in step 1.

5. 52 tape must have a minimum overlap at the edges of 2,5 cm (1.0 inch).

Figure 7

Note: Apply tape with sufficient tension to conform smoothly (without wrinkles). Use hand

pressure to smooth tape and insure adhesion at each overlap.

Tee Sections (Refer to Figure 8) Figure 8

1. Wrap horizontal section of Tee first.

Cut away a half circle shape, in center, on

one edge of 52 tape to fit around vertical

section of Tee. Wrap 52 tape around

horizontal section. Cut away a second half

circle shape on following edge of 52 tape

to allow overlap of 52 tape.

2. Wrap vertical section. Pre-cut half-

circle shapes in 52 tape to saddle (cover)

edge of horizontal pipe. Apply tape

starting from center, remove liner or split

liner at center. Apply tape in both directions

around vertical pipe. Overlap edge of

horizontal pipe by 2,5 cm (1.0 inch).

3. Continue application of 52 tape

according to instructions for "Straight

Sections."

Note: Follow minimum overlap requirements. Apply tape with sufficient tension to conform

smoothly (without wrinkles). Use hand pressure to smooth tape and insure adhesion at each

overlap.

Transitions (Refer to Figure 9)

1. Apply narrow wrap of 52 tape

to small diameter pipe, overlapping

transition edge.

2. Apply wrap of 52 tape over end

section of large diameter pipe,

overlapping large diameter pipe by

a minimum of 2,5 cm (1.0 inch).

3. Apply narrow wrap of 52 tape

to straight section of large

diameter pipe, over lapping edge

of 52 tape applied in step 2.

4. Apply 52 tape to straight

sections of both pipes, overlapping 52 tape applied in above steps.

Note: Follow minimum overlap requirements. Apply tape with sufficient tension to conform

smoothly (without wrinkles). Use hand pressure to smooth tape and insure adhesion at each

overlap.

Repair Procedure (Refer to Figure 10) Figure 10

1. Remove dirt and foreign materials from

damaged cladding.

2. Wire brush all metal surfaces to remove salt

and corrosion. (3M Clean and Strip Products

for Metal are suitable for this purpose).

3. Clean cladding surface with 3M CC Cleaner at

least 5,1 cm (2.0 inches) beyond damaged

section.

4. Wrap 52 tape aroundpipe, extending a

minimum of 5,1 cm (2.0 inches) beyond

damaged cladding.

5. Overlap 52 tape a minimum of 2,5 cm (1.0

inch) on pipes 10,2 cm (4.0 inches) or less in diameter. Overlap 52 tape a minimum of 5,1 cm (2.0 inches)

for all pipes >10,2 cm (4.0 inches) in diameter.

Note: Apply tape with sufficient tension to conform smoothly (without wrinkles). Use hand

pressure to smooth tape and insure adhesion at each overlap.

3M, Scotch and Scotchrap are trademarks of 3M

IMPORTANT NOTICE

All statements, technical information and recommendations

related to Seller's products are based on information

believed to be reliable, but the accuracy or completeness

thereof is not guaranteed. Before utilizing the equipment,

the user should determine the suitability of the product for

its intended use. The user assumes all risks and liability

whatsoever in connection with such use.

Any statements or recommendations of Seller which are

not contained in Seller's current publications shall have no

force or effect unless contained in an agreement signed by

an authorized officer of Seller. The statements contained

herein are made in place of all warranties, express or

implied, including but not limited to the implied warranties

of merchantability and fitness for a particular purpose,

which warranties are hereby expressly disclaimed.

SELLER SHALL NOT BE LIABLE TO BUYER OR ANY

OTHER PERSON UNDER ANY LEGAL THEORY,

INCLUDING BUT NOT LIMITED TO NEGLIGENCE OR

STRICT LIABILITY, FOR ANY INJURY OR FOR ANY

DIRECT, INDIRECT OR CONSEQUENTIAL DAMAGES

SUSTAINED OR INCURRED BY REASON OF THE USE

OF A PRODUCT OF SELLER THAT WAS DETERMINED

TO BE DEFECTIVE

Electrical Products Division

6801 River Place Blvd.

Austin, TX 78726-9000

Recycled paper

40% pre-consumer

10% post-consumer Austin,

Litho in USA

1996 3M

80-6108-5022-6

También podría gustarte

- Diesel Engines For Vehicles D2066 D2676Documento6 páginasDiesel Engines For Vehicles D2066 D2676Branislava Savic63% (16)

- The DIRKS Methodology: A User GuideDocumento285 páginasThe DIRKS Methodology: A User GuideJesus Frontera100% (2)

- Method Statement For 33 KV Cable Termination Size 3x300sqDocumento3 páginasMethod Statement For 33 KV Cable Termination Size 3x300sqbutunsona60% (10)

- Macramé for Beginners and Beyond: 24 Easy Macramé Projects for Home and GardenDe EverandMacramé for Beginners and Beyond: 24 Easy Macramé Projects for Home and GardenCalificación: 4.5 de 5 estrellas4.5/5 (7)

- Assignment November11 KylaAccountingDocumento2 páginasAssignment November11 KylaAccountingADRIANO, Glecy C.Aún no hay calificaciones

- EPMS System Guide For Subcontractor - V1 2Documento13 páginasEPMS System Guide For Subcontractor - V1 2AdouaneNassim100% (2)

- Strain GaugeDocumento4 páginasStrain GaugePURAPATAGONIAAún no hay calificaciones

- Application Instructions Denso Butyl Tape System1Documento4 páginasApplication Instructions Denso Butyl Tape System1Khoh Kai ShengAún no hay calificaciones

- Bondstrand - Instructions For Butt and Strap JointsDocumento2 páginasBondstrand - Instructions For Butt and Strap Jointsao185029Aún no hay calificaciones

- Application Instructions Petrolatum Tape SystemDocumento4 páginasApplication Instructions Petrolatum Tape Systemnikita6969Aún no hay calificaciones

- (How-To) Waterproofing Your Bathroom in 10 Steps: Why Choose Self-Adhesive Over Traditional Liquid Waterproofing?Documento15 páginas(How-To) Waterproofing Your Bathroom in 10 Steps: Why Choose Self-Adhesive Over Traditional Liquid Waterproofing?Dylan RamasamyAún no hay calificaciones

- Carpet Installation Guide: HospitalityDocumento10 páginasCarpet Installation Guide: HospitalityLe Ngoc AnhAún no hay calificaciones

- Technical SpecificationsDocumento8 páginasTechnical SpecificationsSaud PathiranaAún no hay calificaciones

- Denso Petrolatum Products SpecDocumento4 páginasDenso Petrolatum Products SpecRoland NicolasAún no hay calificaciones

- Backer RodDocumento2 páginasBacker RodCassy AbulenciaAún no hay calificaciones

- Aashto T 152 PDFDocumento8 páginasAashto T 152 PDFMd Imtiazul AlamAún no hay calificaciones

- Denso SeaShield Series 2000HDDocumento4 páginasDenso SeaShield Series 2000HDAnonymous wKvJXBJ2iAún no hay calificaciones

- Masterflex Tapes, When Used To Protect Joints Above andDocumento1 páginaMasterflex Tapes, When Used To Protect Joints Above andMichael AlbuquerqueAún no hay calificaciones

- Strain Gauge InstallationDocumento5 páginasStrain Gauge InstallationAnonymous UoHUagAún no hay calificaciones

- How To Make A Quick & Easy Amtgard-Legal Hinged Mace' or Flail'Documento4 páginasHow To Make A Quick & Easy Amtgard-Legal Hinged Mace' or Flail'Rochelle DeAún no hay calificaciones

- PAL - Construction GuidelinesDocumento28 páginasPAL - Construction GuidelinesCarew Mohammed AbayomiAún no hay calificaciones

- Installation Instructions UTERMKIT Mk3Documento4 páginasInstallation Instructions UTERMKIT Mk3aleloc2000Aún no hay calificaciones

- Amiantit. Field Installation ProcedureDocumento37 páginasAmiantit. Field Installation ProcedureABAID ULLAHAún no hay calificaciones

- Wavistrong Supplemental Installation InstructionsDocumento13 páginasWavistrong Supplemental Installation Instructionsmg4myAún no hay calificaciones

- PSTC-14 - Adhesion of Pressure Sensitive Tapes To Fiberboard at 90°angle and Constant StressDocumento6 páginasPSTC-14 - Adhesion of Pressure Sensitive Tapes To Fiberboard at 90°angle and Constant StressChung LeAún no hay calificaciones

- English Solvent Welding Guide 12 2017Documento24 páginasEnglish Solvent Welding Guide 12 2017Richard EddingtonAún no hay calificaciones

- Technical Brochure Gre Site Activities: 44 Years ExperienceDocumento30 páginasTechnical Brochure Gre Site Activities: 44 Years ExperienceSebastian RajeshAún no hay calificaciones

- Density (Unit Weight), Yield, and Air Content (Gravimetric) of Concrete Fop For Aashto T 121 ScopeDocumento18 páginasDensity (Unit Weight), Yield, and Air Content (Gravimetric) of Concrete Fop For Aashto T 121 ScopeJoseAún no hay calificaciones

- Worldwide Engineering Standards: Tape Adhesion Test For Paint FinishesDocumento3 páginasWorldwide Engineering Standards: Tape Adhesion Test For Paint FinishesRicardo Bavasso100% (1)

- Kit Empalme 3M Resina Mineria 8096-2Documento8 páginasKit Empalme 3M Resina Mineria 8096-2Claudio Joaquin PérezAún no hay calificaciones

- How To Make A Quick & Easy Amtgard-Legal Shield'Documento5 páginasHow To Make A Quick & Easy Amtgard-Legal Shield'Rochelle DeAún no hay calificaciones

- Qcs 2010 Part 24.03 Dry Lining (WallboardDocumento5 páginasQcs 2010 Part 24.03 Dry Lining (WallboardRotsapNayrbAún no hay calificaciones

- Ruukki-Rainwater Systems Installation Instructions - AshxDocumento12 páginasRuukki-Rainwater Systems Installation Instructions - AshxAlin Ardelean0% (1)

- Installation Instruction Sheet: Cassette TypeDocumento2 páginasInstallation Instruction Sheet: Cassette TypepepondeAvilesAún no hay calificaciones

- Standard ProceduresDocumento15 páginasStandard ProceduresViraci100% (1)

- Butt WrapFiberglassJointManual Pages 37 41Documento5 páginasButt WrapFiberglassJointManual Pages 37 41anon_913434021Aún no hay calificaciones

- Esd 4873 Au 5 - 09 PDFDocumento13 páginasEsd 4873 Au 5 - 09 PDFGeorge IstrateAún no hay calificaciones

- 55 Watt Gas CO2 Laser TubeDocumento66 páginas55 Watt Gas CO2 Laser TubeFitzwalter100% (1)

- Construction of Post Tension Slab System.: MaterialsDocumento13 páginasConstruction of Post Tension Slab System.: Materialsdindo lauron100% (1)

- 8A FittingInstrPneumSealDocumento4 páginas8A FittingInstrPneumSealnakul164Aún no hay calificaciones

- DTS617/DTB617 Deadbreak Bolted Tee Connector: Power Systems Installation InstructionDocumento10 páginasDTS617/DTB617 Deadbreak Bolted Tee Connector: Power Systems Installation InstructionMuhammad Lathieful HaqAún no hay calificaciones

- Density (Unit Weight), Yield, and Air Content (Gravimetric) of Concrete Fop For Aashto T 121 ScopeDocumento10 páginasDensity (Unit Weight), Yield, and Air Content (Gravimetric) of Concrete Fop For Aashto T 121 Scopedinal031Aún no hay calificaciones

- Repairing A Hole in Plasterboard: Shopping ListDocumento2 páginasRepairing A Hole in Plasterboard: Shopping ListFeri HandoyoAún no hay calificaciones

- Strain Gauge InstallationDocumento4 páginasStrain Gauge InstallationChetan B ArkasaliAún no hay calificaciones

- Cl20702 705 Manual Mup HiDocumento33 páginasCl20702 705 Manual Mup HiRamadan RashadAún no hay calificaciones

- Paint CureDocumento8 páginasPaint CurekhurshedlakhoAún no hay calificaciones

- Denso Valve Flange Tape Wrapping SpecDocumento3 páginasDenso Valve Flange Tape Wrapping SpecNaufal Firmansyah100% (1)

- Correct Procedure For Flange BoltingDocumento7 páginasCorrect Procedure For Flange BoltingAkshay KalraAún no hay calificaciones

- Pella Windows InstallationDocumento8 páginasPella Windows InstallationFrank SmithAún no hay calificaciones

- General Construction Tips Dagey RocksDocumento23 páginasGeneral Construction Tips Dagey Rocksbiker110Aún no hay calificaciones

- 11 KV 92-Ogxxx-3 Pilc To PilcDocumento5 páginas11 KV 92-Ogxxx-3 Pilc To PilcRa'fat HerzallahAún no hay calificaciones

- 5 Thread Makeup & Installation Procedure: 5.1 ScopeDocumento6 páginas5 Thread Makeup & Installation Procedure: 5.1 ScopeJorge Castro CucurellaAún no hay calificaciones

- Saunders HC4 Diaphragm Valves Installation and Maintenance Instructions Manual ValvesDocumento6 páginasSaunders HC4 Diaphragm Valves Installation and Maintenance Instructions Manual ValvesJose Gregorio FerrerAún no hay calificaciones

- KNO3 / Sorbitol J-425 Segmented 3-Grain Motor Construction TutorialDocumento19 páginasKNO3 / Sorbitol J-425 Segmented 3-Grain Motor Construction TutorialMark D VillanuevaAún no hay calificaciones

- Arm A Flex Duct Work Manual UkDocumento16 páginasArm A Flex Duct Work Manual UkLuis Gabriel BautistaAún no hay calificaciones

- AI316Documento4 páginasAI316pvalverdea2014Aún no hay calificaciones

- Butt&Wrap ProcedureDocumento5 páginasButt&Wrap ProcedureMAGUNAM100% (1)

- Complete Book of Sewing Techniques: More Than 30 Essential Sewing Techniques for You to MasterDe EverandComplete Book of Sewing Techniques: More Than 30 Essential Sewing Techniques for You to MasterCalificación: 3.5 de 5 estrellas3.5/5 (2)

- Complete Book of Sewing Techniques, New 2nd Edition: More Than 30 Essential Sewing Techniques for You to MasterDe EverandComplete Book of Sewing Techniques, New 2nd Edition: More Than 30 Essential Sewing Techniques for You to MasterCalificación: 4 de 5 estrellas4/5 (3)

- Duct Tape Engineer: The Book of Big, Bigger, and Epic Duct Tape ProjectsDe EverandDuct Tape Engineer: The Book of Big, Bigger, and Epic Duct Tape ProjectsCalificación: 5 de 5 estrellas5/5 (1)

- Art Deco Rose Quilt Pattern: A quick & easy quilting projectDe EverandArt Deco Rose Quilt Pattern: A quick & easy quilting projectAún no hay calificaciones

- Qt-Iii: Cold Shrink Silicone Rubber TerminationDocumento8 páginasQt-Iii: Cold Shrink Silicone Rubber TerminationHJAún no hay calificaciones

- Qt-Iii: Cold Shrink Silicone Rubber TerminationDocumento8 páginasQt-Iii: Cold Shrink Silicone Rubber TerminationHJAún no hay calificaciones

- MOST Safety Manual V1.3Documento48 páginasMOST Safety Manual V1.3HJAún no hay calificaciones

- Instrucalc 1Documento2 páginasInstrucalc 1HJ100% (1)

- Qt-Iii: Cold Shrink Silicone Rubber TerminationDocumento8 páginasQt-Iii: Cold Shrink Silicone Rubber TerminationHJAún no hay calificaciones

- 7650 EdDocumento8 páginas7650 EdHJAún no hay calificaciones

- Hoffman JB Corrosion 3Documento2 páginasHoffman JB Corrosion 3HJAún no hay calificaciones

- Qt-Iii: Cold Shrink Silicone Rubber TerminationDocumento10 páginasQt-Iii: Cold Shrink Silicone Rubber TerminationHJAún no hay calificaciones

- Continuous Hinge "FTC" Boxes: FinishDocumento2 páginasContinuous Hinge "FTC" Boxes: FinishHJAún no hay calificaciones

- Hoffman JB Corrosion 2Documento2 páginasHoffman JB Corrosion 2HJAún no hay calificaciones

- Free-Standing Type 4 Enclosures: Application Finish Modification Services™ ProgramDocumento6 páginasFree-Standing Type 4 Enclosures: Application Finish Modification Services™ ProgramHJAún no hay calificaciones

- 01-Flame Detection Paper - GPDocumento6 páginas01-Flame Detection Paper - GPHJAún no hay calificaciones

- Continuous Hinge "CH" Boxes: Modification Services™ Program FinishDocumento2 páginasContinuous Hinge "CH" Boxes: Modification Services™ Program FinishHJAún no hay calificaciones

- Instrumentation TextbookDocumento166 páginasInstrumentation TextbookGerman ToledoAún no hay calificaciones

- 21-1001 Xwatch)Documento16 páginas21-1001 Xwatch)HJAún no hay calificaciones

- Wireway Fill Tables: StandardsDocumento4 páginasWireway Fill Tables: StandardsHJAún no hay calificaciones

- Technical Bulletin: Catalytic Gas Sensor Life ExpectancyDocumento1 páginaTechnical Bulletin: Catalytic Gas Sensor Life ExpectancyHJAún no hay calificaciones

- FluteDocumento13 páginasFlutefisher3910% (1)

- HangersSupportsReferenceDataGuide PDFDocumento57 páginasHangersSupportsReferenceDataGuide PDFIndra RosadiAún no hay calificaciones

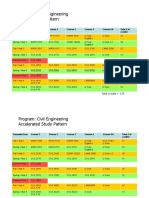

- HKUST 4Y Curriculum Diagram CIVLDocumento4 páginasHKUST 4Y Curriculum Diagram CIVLfrevAún no hay calificaciones

- VRARAIDocumento12 páginasVRARAIraquel mallannnaoAún no hay calificaciones

- Ticket: Fare DetailDocumento1 páginaTicket: Fare DetailSajal NahaAún no hay calificaciones

- Army Aviation Digest - Apr 1971Documento68 páginasArmy Aviation Digest - Apr 1971Aviation/Space History LibraryAún no hay calificaciones

- PRESENTACIÒN EN POWER POINT Futuro SimpleDocumento5 páginasPRESENTACIÒN EN POWER POINT Futuro SimpleDiego BenítezAún no hay calificaciones

- 2.ed - Eng6 - q1 - Mod3 - Make Connections Between Information Viewed and Personal ExpiriencesDocumento32 páginas2.ed - Eng6 - q1 - Mod3 - Make Connections Between Information Viewed and Personal ExpiriencesToni Marie Atienza Besa100% (3)

- Saudi Methanol Company (Ar-Razi) : Job Safety AnalysisDocumento7 páginasSaudi Methanol Company (Ar-Razi) : Job Safety AnalysisAnonymous voA5Tb0Aún no hay calificaciones

- Writ Petition 21992 of 2019 FinalDocumento22 páginasWrit Petition 21992 of 2019 FinalNANDANI kumariAún no hay calificaciones

- Lecture 19 Code Standards and ReviewDocumento27 páginasLecture 19 Code Standards and ReviewAdhil Ashik vAún no hay calificaciones

- Study and Interpretation of The ScoreDocumento10 páginasStudy and Interpretation of The ScoreDwightPile-GrayAún no hay calificaciones

- Catalogo PukangDocumento41 páginasCatalogo PukangClarita Muller LeigueAún no hay calificaciones

- CandyDocumento24 páginasCandySjdb FjfbAún no hay calificaciones

- Fuentes v. Office of The Ombudsman - MindanaoDocumento6 páginasFuentes v. Office of The Ombudsman - MindanaoJ. JimenezAún no hay calificaciones

- Canon I-SENSYS MF411dw Parts CatalogDocumento79 páginasCanon I-SENSYS MF411dw Parts Catalogmarian100% (1)

- Population Second TermDocumento2 páginasPopulation Second Termlubna imranAún no hay calificaciones

- A. Computed Only For A 2x2 Table B. 0 Cells (,0%) Have Expected Count Less Than 5. The Minimum Expected Count Is 3,40Documento1 páginaA. Computed Only For A 2x2 Table B. 0 Cells (,0%) Have Expected Count Less Than 5. The Minimum Expected Count Is 3,40harvey777Aún no hay calificaciones

- Chapter 30 - HypertensionDocumento70 páginasChapter 30 - HypertensionSakaC.TanayaAún no hay calificaciones

- Sage TutorialDocumento115 páginasSage TutorialChhakuli GiriAún no hay calificaciones

- Agrinome For Breeding - Glossary List For Mutual Understandings v0.3 - 040319Documento7 páginasAgrinome For Breeding - Glossary List For Mutual Understandings v0.3 - 040319mustakim mohamadAún no hay calificaciones

- Investigation Data FormDocumento1 páginaInvestigation Data Formnildin danaAún no hay calificaciones

- 9701 Nos Ps 23Documento5 páginas9701 Nos Ps 23Hubbak KhanAún no hay calificaciones

- Exclusive GA MCQs For IBPS Clerk MainDocumento136 páginasExclusive GA MCQs For IBPS Clerk MainAnkit MauryaAún no hay calificaciones

- Work Sample 2 - Eoc and CrucibleDocumento35 páginasWork Sample 2 - Eoc and Crucibleapi-259791703Aún no hay calificaciones

- Formato MultimodalDocumento1 páginaFormato MultimodalcelsoAún no hay calificaciones