Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Wang Slag

Cargado por

Siddu RhDescripción original:

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Wang Slag

Cargado por

Siddu RhCopyright:

Formatos disponibles

309

APPLICATION OF GROUND GRANULATED BLAST FURNACE SLAG IN HIGH-PERFORMANCE CONCRETE IN CHINA

Wang Ling, Tian Pei, and Yao Yan China Building Materials Academy, PRC

Abstract

This paper introduces studies and the application of ground granulated blast furnace slag (GGBS) in China. The performance of GGBS is measured and the effect of GGBS on fresh concrete and harden concrete is analyzed. GGBS concrete is characterized by high strength, lower heat of hydration, and resistance to chemical corrosion.

1. Introduction

Annual granulated blast furnace slag (GBFS) production capacity in China is around 15 million tons. GBFS powder has been successfully applied as the raw material of cement block, pavement block, and slag cement. GBFS is usually used as additives in Portland cement production in China. Traditional production technology is to grind cement clinker, GBFS and gypsum together. Because GBFS is more difficult to grind than clinker, specific surface area of GBFS in cement is under 300 m2/g. The grain size of GBFS is mostly over 60 um; thus its activity in early age is limited and cannot been brought into full play. Concrete mixed with this kind of slag cement has some shortage, such as low early strength, poor durability, and ease of bleeding.

310

International Workshop on Sustainable Development and Concrete Technology

At present, with the quick development of high efficient grinding apparatus, GBFS is produced to ground granulated blast furnace slag. GGBFS is different to the GBFS used as additive in slag cement. Its specific surface is more than 350 m2/kg, some even more than 800 m2/kg. Nation standard GB18736-2001, Mineral Admixture for High-Performance Concrete (HPC), regulates the properties of GGBFS, which can be used in HPC. When used in concrete, it make concrete has good workability, high strength, and good durability. GBFS is a kind of industry waste. Through advanced processing technology, the material turns into GGBFS, which can act as an economical and ecological resource for modern concrete. Research, production and application of GGBFS in HPC promote the comprehensive utilization of slag into a new stage in China.

2. Influence of GGBFS on the Effect of Superplasticizer

2.1. Materials GGBFS: S1 (350 m2/kg), S2 (450 m2/kg), S3 (550 m2/kg), produced by Wuhan Iron & Steel Group Co. Cement Q: 42.5 portland cement, Jidong Cement Company Cement W1: 70%Q + 30%S1 Cement W2: 70%Q + 30%S2 Cement W3: 70%Q + 30%S3 Superplasticizer: o o BW (naphthalenesulfonic acid based admixture) SM (sulfonated melamine formaldehyde based admixture)

2.2. Influence of GGBFS on absorption to admixture Absorption of cement Q, W3, slag S1 and S3 were tested. W/S = 5, and admixture concentration is 2 g/L. The initial absorption volume and the admixture concentration after 1 hour are list in Table 1.

Wang Ling, Tian Pei, and Yao Yan

311

Apparently, the absorption of slag S1 and S3 to BW and SM are both smaller than cement Q. If the content of admixture is fixed, there would be much more superplasticizer to disperse the cement particle when use GGBFS to replace part of cement. That is to say, absorption of cement particle to superplasticizer will be larger. Table 1: Absorption of cement and slag to admixture Initial absorption (mg/g) Concentration of admixture after 1 hr (g/l) BW SM BW SM Cement Q 3.25 5.3 0.58 0.29 CementW3 3.12 4.4 0.62 0.42 Slag S1 (350) 2.61 2.14 Slag S3 (550) 2.80 2.38 2.3. Influence of GGBFS on - potential between cement particles The repulsion between cement particles can be expressed in -potential of cement particles. We tested -potential of a series of cement paste that included slag. The results are in Table 2. Table 2: Influence of GGBFS to -potential (mv) Admixture BW SM Q -37.25 -35.63 Q + 10%S1 -40.46 -38.67 W1 (Q + 30%S1) -42.49 -42.11 Q + 50%S1 -46.52 -47.19 W2 -42.93 -42.91 W3 -43.38 -43.54 With the increase of specific surface and content of the GGBFS, the -potential increases apparently. That means that the repulsion between cement particles increases too at that case. This is one of the reasons that GGBFS can improve workability of concrete. Influence of specific surface of GGBFS on paste workability is expressed in Figs. 1 and 2. Influence of GGBFS content on paste workability is expressed in Figs. 3 and 4.

312

International Workshop on Sustainable Development and Concrete Technology

From the four mentioned figures, we can find that: when add GGBFS (10%-30%) into cement, the saturation dosage of superplasticizer changes a little, the flow of cement paste improves and the loss of flow decrease at the recommended dosage of the two superplasticizers. When the specific surface of GGBFS changes from 350 to 550 m2/kg, the saturation dosage of superplasticizer is almost the same, the flow of cement paste improves and the loss of flow decrease.

240 230 f l ui di t y ( m m )

f l ui di t y ( m m ) 240 220 200 180 160 140 120 W 1 W 2 W 3

220 210 200 190 180 0. 8 1 1. 2 B W( % ) w / c=0. 29 1. 4 W 1 W 2 W 3

0. 8

1. 2 S M( % ) w / c=0. 29

1. 4

Fig. 1: Influence of slag fineness to solution dosage of admixture

200

loss of fluidity after 1hr (mm)

45 w 1 w 2

184 f l ui di t y ( m m )

36 27

168

152 B W 136 S M

18 9

120 w 1 w 2 w 3

0 B W S M

Fig. 2: Influence of slag fineness to flow and flow loss of cement past

Wang Ling, Tian Pei, and Yao Yan

313

220 w / c=0. 29 sl ag 210

220 w/c=0.29 slag 200

f l udi t y ( m m )

190

fludity (mm)

200

180

10% 30%

160

180

50%

10% 30% 50%

140

170 0. 8 1 1. 2 BW ( % ) 1. 4

120 1 1.1 SM (%) 1.2 1.4

Fig. 3: Influence of slag content to solution dosage of admixture

55 sl ag 45 l oss of f l ui di t y af t er 1hr ( m m ) 10% 35 30% 50%

200

180

fluidity (mm0

160

140 BW 120 SM

25

15

100 10% 30% slag (%) 50%

BW

SM

Fig. 4: Influence of slag content to flow and flow loss of cement past

314

International Workshop on Sustainable Development and Concrete Technology

3. Application of GGBFS in High-Strength HPC

If the specific surface of GGBFS is grinded to 500-800m2/kg, it shows very different properties with lower fineness slag (<400 m2/kg). High specific surface slag can replace 20%-50% cement to mix high strength concrete (>C60). When it adds into concrete, workability and strength of concrete will change a lot. 3.1. Materials GGBFS: specific surface 400, 500, 700, and 800m2/kg, produced by Wuhan Iron & Steel Group Co. Cement: 42.5 portland cement, Jidong Cement Company Superplasticizer: JB-1 (naphthalenesulfonic acid based admixture) Sand: Mx = 2.9 Stone: 5-20-mm gravel

3.2. Test results Typical mix proportion of high strength HPC and the properties are in Table 3.

Table 3: Mix proportion (kg/m3) and properties of high strength HPC

No. Cement 1 2 3 4 5 6 7 500 350 350 350 600 480 420 150 Slag (m2/kg) 300 500 700 800 150 120 150 150 150 1085 665 1085 665 1085 665 1085 665 1134 610 1134 610 1134 610 Water Stone Sand Admixture Slump (%) 1.3 1.3 1.3 1.3 1.5 1.5 1.5 (cm) 23.0 22.0 23.0 23.0 22.5 24.0 24.5 Compressive strength (MPa) 3d 56.4 61.5 64.7 76.7 63.0 65.6 69.3 7d 60.0 70.0 74.2 88.3 71.2 79.9 83.2 28d 70.7 79.5 81.3 93.6 81.1 93.0 100.4 60d 74.1 84.3 84.1 99.0

150 150 150 150

180 150

Wang Ling, Tian Pei, and Yao Yan

315

From Table 3, we can see that strength of concrete at each age increase with the increase of GGBFS fineness when the substitute contents are the same. Control the cementitious materials to 500 kg/m3, compressive strength of 3 and 28 days are increase 9% and 12%, respectively, when using GGBFS of 400 m2/kg; and in the meantime the compressive strength of 3 and 28 days are increase 35% and 32%, respectively, when using GGBFS of 800 m2/kg. At very early age, the very fine GGBFS acts as assistant cementitious in concrete, it has pozzuolana role. On the other hands, GGBFS grain has a filling role, which can improve the hydration structure, the strength, and the durability of HPC.

4. Application of GGBFS in Middle-Strength HPC

Research on HPC in China is different to most of the European countries. It is believed that the range of HPC cannot be restricted only in high strength concrete. To make the C30-C50 concrete, high performance is also a focus of HPC research in China. Proportion of concrete of C10-C25, C30-C50, and C55-C75 are 31.6%, 67.1%, and 1.3%, respectively, in Beijing in the second quarter in 2003. Situation in the other province in China is almost the same. C30-C50 concrete is almost 70% of all concrete output. Slag in C30-C50 concrete should not have very high specific surface due to cost and economy reason. GGBFS with 350-500 m2/kg is very appropriate. 4.1. Materials GGBFS: specific surface 450 m2/kg, produced by Shougang Group Corporation Cement: 42.5 portland cement, Beijing Cement Company Superplasticizer: TK-1 (naphthalenesulfonic acid based admixture) Sand: Mx = 2.9 Stone: 5-25-mm gravel

316

International Workshop on Sustainable Development and Concrete Technology

4.2. Test results The fresh and hardened concrete properties of GGBFS concrete (C30-C50) were tested and illustrated in Figs. 4-6. Strength of concrete with different slag content is according to substitute content and water cementitious ratio. When the substitute content is higher, the early strength is lower, but the 28- and 60-day strength is almost the same. Table 4: Influence of GGBFS to compressive strength of middle strength HPC (cementitious materials 390 kg/m3, W/B = 0.46) Compressive strength (MPa) Substitute content of GGBFS (%) 3d 7d 28d 60d 45 19.8 30.6 53.8 60.5 50 18.3 29.8 53.3 56.5 55 18.0 29.4 51.9 60.7 60 17.0 29.4 50.6 56.2 65 14.7 28.1 49.2 53.8 Table 5: Influence of GGBFS to compressive strength of middle strength HPC (cementitious materials 438 kg/m3, W/B = 0.40) Compressive strength (MPa) Substitute content of GGBFS (%) 3d 7d 28d 60d 45 27.2 36.1 57.3 67.4 50 26.6 35.5 58.9 63.5 55 25.8 35.0 58.0 66.4 60 24.1 34.0 56.5 64.4 65 23.8 32.6 57.8 68.0 Table 6: Influence of GGBFS to compressive strength of middle strength HPC (cementitious materials 500 kg/m3, W/B = 0.35) Compressive strength (MPa) Substitute content of GGBFS (%) 3d 7d 28d 60d 45 34.4 45.6 65.6 73.6 50 31. 43.8 67.6 72.3 55 30.9 44.7 68.0 71.8 60 28.7 40.9 64.4 76.3 65 28.6 41.6 61.8 75.4

Wang Ling, Tian Pei, and Yao Yan

317

Curing temperature is a key factor of strength of slag concrete, especially to the early strength. If the temperature is raised, strength at 1 day may be bigger than reference concrete. So curing of GGBFS concrete should be controlled under fit temperature and wet condition. GGBFS concrete is more sensitive to curing condition than Portland cement concrete. Due to lower hydration rate of slag, curing time should be prolonged than portland cement concrete. GGBFS HPC is an important breakthrough to traditional concrete in China. It is characterized by energy savings, cement savings, low cost, environmental protection, and environmental and social benefits as well as economic profit. This kind of new building material can be called green concrete. It has good properties and its application should be more widespread.

También podría gustarte

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2104)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (895)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- Number CardsDocumento21 páginasNumber CardsCachipún Lab CreativoAún no hay calificaciones

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- Calculation ReportDocumento157 páginasCalculation Reportisaacjoe77100% (3)

- Bosch KE-Jetronic System DescriptionDocumento3 páginasBosch KE-Jetronic System DescriptionJack Tang50% (2)

- En 1993 09Documento160 páginasEn 1993 09Vio ChiAún no hay calificaciones

- Powerplant QuestionsDocumento19 páginasPowerplant QuestionsAshok KumarAún no hay calificaciones

- Energy BodiesDocumento1 páginaEnergy BodiesannoyingsporeAún no hay calificaciones

- Report - Plaster Moulds Using Recycled Gypsum From Waste PlasterboardDocumento41 páginasReport - Plaster Moulds Using Recycled Gypsum From Waste PlasterboardSiddu RhAún no hay calificaciones

- Profile Banana Packhouse 01Documento7 páginasProfile Banana Packhouse 01Siddu RhAún no hay calificaciones

- DPR Cashew AgartalaDocumento18 páginasDPR Cashew AgartalaSiddu RhAún no hay calificaciones

- EOEpdf Web Site-25aprDocumento5 páginasEOEpdf Web Site-25aprSiddu RhAún no hay calificaciones

- Residential Green Build ReportDocumento64 páginasResidential Green Build ReportSiddu RhAún no hay calificaciones

- 23 - 4 - Miami Beach - 09-78 - 0054Documento9 páginas23 - 4 - Miami Beach - 09-78 - 0054Siddu RhAún no hay calificaciones

- Sustainable Economic Development in Northern Afghanistan (Gtz-Nawi)Documento2 páginasSustainable Economic Development in Northern Afghanistan (Gtz-Nawi)Siddu RhAún no hay calificaciones

- Diagnostic Study Report On Moga, PunjabDocumento66 páginasDiagnostic Study Report On Moga, PunjabSiddu RhAún no hay calificaciones

- Pub 8 Oj 3156 RCDocumento57 páginasPub 8 Oj 3156 RCSiddu RhAún no hay calificaciones

- Physico-Chemical Characterization of Distillery Effluent and Its Dilution Effect at Different LevelsDocumento11 páginasPhysico-Chemical Characterization of Distillery Effluent and Its Dilution Effect at Different LevelsSiddu RhAún no hay calificaciones

- 1st Unseen Passage For Class 5 in EnglishDocumento7 páginas1st Unseen Passage For Class 5 in EnglishVibhav SinghAún no hay calificaciones

- Moc3040 MotorolaDocumento3 páginasMoc3040 MotorolaBryanTipánAún no hay calificaciones

- Mediator Analysis of Job Embeddedness - Relationship Between Work-Life Balance Practices and Turnover IntentionsDocumento15 páginasMediator Analysis of Job Embeddedness - Relationship Between Work-Life Balance Practices and Turnover IntentionsWitty MindsAún no hay calificaciones

- NCRA Membership InformationDocumento1 páginaNCRA Membership Informationbkharkreader1301Aún no hay calificaciones

- Capacity Analysis of Kashmir Highway IslamabadDocumento71 páginasCapacity Analysis of Kashmir Highway Islamabadm saadullah khanAún no hay calificaciones

- WicDocumento6 páginasWicGonzalo Humberto RojasAún no hay calificaciones

- WT Capability Statement PE 2020Documento1 páginaWT Capability Statement PE 2020Muhannad SuliemanAún no hay calificaciones

- Biography Worksheet: Name: Gerardo Angeles MartinezDocumento1 páginaBiography Worksheet: Name: Gerardo Angeles MartinezAlejandro AngelesAún no hay calificaciones

- SAP Solution Manager - CHARM - Retrofit - Change Request Management Enhanced RetrofitDocumento61 páginasSAP Solution Manager - CHARM - Retrofit - Change Request Management Enhanced RetrofitARPITA BISWASAún no hay calificaciones

- MidsemDocumento6 páginasMidsemAravind SomasundaramAún no hay calificaciones

- Drsent PT Practice Sba OspfDocumento10 páginasDrsent PT Practice Sba OspfEnergyfellowAún no hay calificaciones

- A New Procedure For Generalized Star Modeling Using Iacm ApproachDocumento15 páginasA New Procedure For Generalized Star Modeling Using Iacm ApproachEdom LazarAún no hay calificaciones

- Sensor de Temperatura e Umidade CarelDocumento1 páginaSensor de Temperatura e Umidade CarelMayconLimaAún no hay calificaciones

- History of Psychotherapy FinalDocumento38 páginasHistory of Psychotherapy FinalMarco BonettiAún no hay calificaciones

- (Ug, PG & PHD) Fellowship: Tih-Iot Chanakya GroupDocumento3 páginas(Ug, PG & PHD) Fellowship: Tih-Iot Chanakya GroupVijay M.MAún no hay calificaciones

- IES OBJ Civil Engineering 2000 Paper IDocumento17 páginasIES OBJ Civil Engineering 2000 Paper Itom stuartAún no hay calificaciones

- Unit 7 ActivitiesDocumento8 páginasUnit 7 ActivitiesleongeladoAún no hay calificaciones

- Hexoloy SP Sic TdsDocumento4 páginasHexoloy SP Sic TdsAnonymous r3MoX2ZMTAún no hay calificaciones

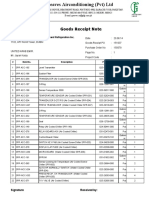

- Goods Receipt Note: Johnson Controls Air Conditioning and Refrigeration Inc. (YORK) DateDocumento4 páginasGoods Receipt Note: Johnson Controls Air Conditioning and Refrigeration Inc. (YORK) DateSaad PathanAún no hay calificaciones

- LQZLQM ) So"L/L6H Klans LN : Sfof (No K - Of) HGSF) Nflu DFQDocumento5 páginasLQZLQM ) So"L/L6H Klans LN : Sfof (No K - Of) HGSF) Nflu DFQSAJAL KOIRALAAún no hay calificaciones

- 19 Uco 578Documento20 páginas19 Uco 578roshan jainAún no hay calificaciones

- Ateneo de Naga University: Professional Training For Teacher 4.0Documento10 páginasAteneo de Naga University: Professional Training For Teacher 4.0Rosemarie BrionesAún no hay calificaciones

- Hume 100 ReviewerDocumento7 páginasHume 100 ReviewerShai GaviñoAún no hay calificaciones

- Mining Discriminative Patterns To Predict Health Status For Cardiopulmonary PatientsDocumento56 páginasMining Discriminative Patterns To Predict Health Status For Cardiopulmonary Patientsaniltatti25Aún no hay calificaciones