Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Solid State Structure

Cargado por

zidaaanDerechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Solid State Structure

Cargado por

zidaaanCopyright:

Formatos disponibles

Solid State Structure

http://www.steelguru.com/article/details/MjU=/Solid_State_Structure...

Hello Guest! | Log In | Register | Home | Profile | Jobs | Trade Lead | Forum | RSS

News Indian Global Raw Material Today News Technology Tales Stories CSR Announcement Resource Directories Events Featured Articles Glossary Links Reports

1 12 "!

PDF created with pdfFactory Pro trial version www.pdffactory.com

/ 20 144 06: 17 25 /0

Solid State Structure

http://www.steelguru.com/article/details/MjU=/Solid_State_Structure...

Technical Info Incoterms Associations More Import Duty Structure Baltic Archive Currency Code Currency Archive Metal Archive Most Read News Unit Converters: Area Angles Distance Energy Force Pressure Volume Weight Time Velocity Data Storage Numbers Fuel Temprature Search on News Title News Details Reports/Directory Glossary

Select Language chinese germany hindi italian japanese korean portuguese russian spanish turkish

Solid State Structure

2 12 "!

PDF created with pdfFactory Pro trial version www.pdffactory.com

/ 20 144 06: 17 25 /0

Solid State Structure

http://www.steelguru.com/article/details/MjU=/Solid_State_Structure...

532"(1 0/-+*( )(' %$"!

break-day.com/arabic ;?7><6 ;#%: 819 32"(1 0/-+*( 87/(' #%+.6 0-+. ! HG1 EDB1.. .A/(7@

Aluminum Products

aluminum.yieh.com Yieh Corp. specializes in Aluminum Sheet/Foil Extruded Tube & Profiles

Solid State Structure

In the previous pages, some of the mechanisms that bond together the multitude of individual atoms or molecules of a solid material were discussed. These forces may be primary chemical bonds, as in metals and ionic solids, or they may be secondary van der Waals forces of solids, such as in ice, paraffin wax and most polymers. In solids, the way the atoms or molecules arrange themselves contributes to the appearance and the properties of the materials. Atoms can be gathered together as an aggregate through a number of different processes, including condensation, pressurization, chemical reaction, electrodeposition, and melting. The process usually determines, at least initially, whether the collection of atoms will take to form of a gas, liquid or solid. The state usually changes as its temperature or pressure is changed. Melting is the process most often used to form an aggregate of atoms. When the temperature of a melt is lowered to a certain point, the liquid will form either a crystalline solid or and amorphous solid.

Amorphous Solids A solid substance with its atoms held apart at equilibrium spacing, but with no long-range periodicity in atom location in its structure is an amorphous solid. Examples of amorphous solids are glass and some types of plastic. They are sometimes described as supercooled liquids because their molecules are arranged in a random manner some what as in the liquid state. For example, glass is commonly made from silicon dioxide or quartz sand, which has a crystalline structure. When the sand is melted and the

3 12 "!

PDF created with pdfFactory Pro trial version www.pdffactory.com

/ 20 144 06: 17 25 /0

Solid State Structure

http://www.steelguru.com/article/details/MjU=/Solid_State_Structure...

liquid is cooled rapidly enough to avoid crystallization, an amorphous solid called a glass is formed. Amorphous solids do not show a sharp phase change from solid to liquid at a definite melting point, but rather soften gradually when they are heated. The physical properties of amorphous solids are identical in all directions along any axis so they are said to have isotropic properties, which will be discussed in more detail later . Crystalline Solids More than 90% of naturally occurring and artificially prepared solids are crystalline. Minerals, sand, clay, limestone, metals, carbon (diamond and graphite), salts ( NaCl, KCl etc.), all have crystalline structures. A crystal is a regular, repeating arrangement of atoms or molecules. The majority of solids, including all metals, adopt a crystalline arrangement because the amount of stabilization achieved by anchoring interactions between neighboring particles is at its greatest when the particles adopt regular (rather than random) arrangements. In the crystalline arrangement, the particles pack efficiently together to minimize the total intermolecular energy. The regular repeating pattern that the atoms arrange in is called the crystalline lattice. The scanning tunneling microscope (STM) makes it possible to image the electron cloud associated individual atoms at the surface of a material. Below is an STM image of a platinum surface showing the regular alignment of atoms.

Courtesy: IBM Research, Almaden Research Center. Crystal Structure Crystal structures may be conveniently specified by describing the arrangement within the solid of a small representative group of atoms or molecules, called the unit cell. By multiplying identical unit cells in three directions, the location of all the particles in the crystal is determined. In nature, 14 different types of crystal structures or lattices are found. The simplest crystalline unit cell to picture is the cubic, where the atoms are lined up in a square, 3D grid. The unit cell is simply a box with an atom at each corner. Simple cubic crystals are relatively rare, mostly because they tend to easily distort. However, many

PDF created with pdfFactory Pro trial version www.pdffactory.com

4 12 "!

/ 20 144 06: 17 25 /0

Solid State Structure

http://www.steelguru.com/article/details/MjU=/Solid_State_Structure...

crystals form body-centered-cubic (bcc) or face-centered-cubic (fcc) structures, which are cubic with either an extra atom centered in the cube or centered in each face of the cube. Most metals form bcc, fcc or Hexagonal Close Packed (hpc) structures; however, the structure can change depending on temperature. These three structures will be discussed in more detail on the following page. Crystalline structure is important because it contributes to the properties of a material. For example, it is easier for planes of atoms to slide by each other if those planes are closely packed. Therefore, lattice structures with closely packed planes allow more plastic deformation than those that are not closely packed. Additionally, cubic lattice structures allow slippage to occur more easily than non-cubic lattices. This is because their symmetry provides closely packed planes in several directions. A face-centered cubic crystal structure will exhibit more ductility (deform more readily under load before breaking) than a body-centered cubic structure. The bcc lattice, although cubic, is not closely packed and forms strong metals. Alpha-iron and tungsten have the bcc form. The fcc lattice is both cubic and closely packed and forms more ductile materials. Gamma-iron, silver, gold, and lead have fcc structures. Finally, HCP lattices are closely packed, but not cubic. HCP metals like cobalt and zinc are not as ductile as the fcc metals.

Primary Metallic Crystalline Structures (BCC, FCC, HCP)

As pointed out on the previous page, there are 14 different types of crystal unit cell structures or lattices are found in nature. However most metals and many other solids have unit cell structures described as body center cubic (bcc), face centered cubic (fcc) or Hexagonal Close Packed (hcp). Since these structures are most common, they will be discussed in more detail. Body-Centered Cubic (BCC) Structure The body-centered cubic unit cell has atoms at each of the eight corners of a cube (like the cubic unit cell) plus one atom in the center of the cube (left image below). Each of the corner atoms is the corner of another cube so the corner atoms are shared among eight unit cells. It is said to have a coordination number of 8. The bcc unit cell consists of a net total of two atoms; one in the center and eight eighths from corners atoms as shown in the middle image below (middle image below). The image below highlights a unit cell in a larger section of the lattice.

The bcc arrangement does not allow the atoms to pack together as closely as the fcc or hcp arrangements. The bcc structure is often the high temperature form of metals that are close-packed at lower temperatures. The volume of atoms in a cell per the total volume of a cell is called the packing factor. The bcc unit cell has a packing factor of 0.68. Some of the materials that have a bcc structure include lithium, sodium, potassium, chromium, barium, vanadium, alpha-iron and tungsten. Metals which have a bcc structure are usually harder and less malleable than close-packed metals such as gold. When the metal is deformed, the planes of atoms must slip over each other, and this is more difficult in the bcc structure. It should be noted that there are other important mechanisms for hardening materials, such as introducing impurities or defects which make slipping more difficult. These hardening mechanisms will be discussed latter. Face Centered Cubic (FCC) Structure The face centered cubic structure has atoms located at each of the corners and the centers of all the cubic

PDF created with pdfFactory Pro trial version www.pdffactory.com

5 12 "!

/ 20 144 06: 17 25 /0

Solid State Structure

http://www.steelguru.com/article/details/MjU=/Solid_State_Structure...

faces (left image below). Each of the corner atoms is the corner of another cube so the corner atoms are shared among eight unit cells. Additionally, each of its six face centered atoms is shared with an adjacent atom. Since 12 of its atoms are shared, it is said to have a coordination number of 12. The fcc unit cell consists of a net total of four atoms; eight eighths from corners atoms and six halves of the face atoms as shown in the middle image above. The image below highlights a unit cell in a larger section of the lattice.

In the fcc structure (and the hcp structure) the atoms can pack closer together than they can in the bcc structure. The atoms from one layer nest themselves in the empty space between the atoms of the adjacent layer. To picture packing arrangement, imagine a box filled with a layer of balls that are aligned in columns and rows. When a few additional balls are tossed in the box, they will not balance directly on top of the balls in the first layer but instead will come to rest in the pocket created between four balls of the bottom layer. As more balls are added they will pack together to fill up all the pockets. The packing factor (the volume of atoms in a cell per the total volume of a cell) is 0.74 for fcc crystals. Some of the metals that have the fcc structure include aluminum, copper, gold, iridium, lead, nickel, platinum and silver. Hexagonal Close Packed (HPC) Structure Another common close packed structure is the hexagonal close pack. The hexagonal structure of alternating layers is shifted so its atoms are aligned to the gaps of the preceding layer. The atoms from one layer nest themselves in the empty space between the atoms of the adjacent layer just like in the fcc structure. However, instead of being a cubic structure, the pattern is hexagonal. (See image below.) The difference between the HPC and FCC structure is discussed later in this section.

The hcp structure has three layers of atoms. In each the top and bottom layer, there are six atoms that arrange themselves in the shape of a hexagon and a seventh atom that sits in the middle of the hexagon. The middle layer has three atoms nestle in the triangular "grooves" of the top and bottom plane. Note that there are six of these "grooves" surrounding each atom in the hexagonal plane, but only three of them can be filled by atoms. As shown in the middle image above, there are six atoms in the hcp unit cell. Each of the 12 atoms in the corners of the top and bottom layers contribute 1/6 atom to the unit cell, the two atoms in the center of the hexagon of both the top and bottom layers each contribute atom and each of the three atom in the

PDF created with pdfFactory Pro trial version www.pdffactory.com

6 12 "!

/ 20 144 06: 17 25 /0

Solid State Structure

http://www.steelguru.com/article/details/MjU=/Solid_State_Structure...

middle layer contribute 1 atom. The image on the right above attempts to show several hcp unit cells in a larger lattice. The coordination number of the atoms in this structure is 12. There are six nearest neighbors in the same close packed layer, three in the layer above and three in the layer below. The packing factor is 0.74, which is the same as the fcc unit cell. The hcp structure is very common for elemental metals and some examples include beryllium, cadmium, magnesium, titanium, zinc and zirconium.

Similarities and Difference Between the FCC and HCP Structure

The face centered cubic and hexagonal close packed structures both have a packing factor of 0.74, consist of closely packed planes of atoms, and have a coordination number of 12. The difference between the fcc and hcp is the stacking sequence. The hcp layers cycle among the two equivalent shifted positions whereas the fcc layers cycle between three positions. As can be seen in the image, the hcp structure contains only two types of planes with an alternating ABAB arrangement. Notice how the atoms of the third plane are in exactly the same position as the atoms in the first plane. However, the fcc structure contains three types of planes with a ABCABC arrangement. Notice how the atoms in rows A and C are no longer aligned. Remember that cubic lattice structures allow slippage to occur more easily than non-cubic lattices, so hcp metals are not as ductile as the fcc metals.

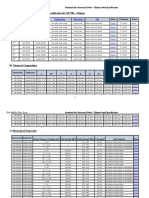

The table below shows the stable room temperature crystal structures for several elemental metals.

Metal

Crystal Structure

Atomic Radius (nm)

Aluminum

FCC

0.1431

Cadmium

HCP

0.1490

Chromium

BCC

0.1249

Cobalt

HCP

0.1253

PDF created with pdfFactory Pro trial version www.pdffactory.com

7 12 "!

/ 20 144 06: 17 25 /0

Solid State Structure

http://www.steelguru.com/article/details/MjU=/Solid_State_Structure...

Copper

FCC

0.1278

Gold

FCC

0.1442

Iron (Alpha)

BCC

0.1241

Lead

FCC

0.1750

Magnesium

HCP

0.1599

Molybdenum

BCC

0.1363

Nickel

FCC

0.1246

Platinum

FCC

0.1387

Silver

FCC

0.1445

Tantalum

BCC

0.1430

Titanium (Alpha)

HCP

0.1445

Tungsten

BCC

0.1371

Zinc

HCP

0.1332

A nanometer (nm) equals 10 -9 meter or 10 Angstrom units.

Solidification

The crystallization of a large amount of material from a single point of nucleation results in a single crystal. In engineering materials, single crystals are produced only under carefully controlled conditions. The expense of producing single crystal materials is only justified for special applications, such as turbine engine blades, solar cells, and piezoelectric materials. Normally when a material begins to solidify, multiple crystals begin to grow in the liquid and a polycrystalline (more than one crystal) solid forms. The moment a crystal begins to grow is know as nucleation and the point where it occurs is the nucleation point. At the solidification temperature, atoms of a liquid, such as melted metal, begin to bond together at the nucleation points and start to form crystals. The final sizes of the individual crystals depend on the number of nucleation points. The crystals increase in size by the progressive addition of atoms and grow until they impinge upon adjacent growing crystal.

PDF created with pdfFactory Pro trial version www.pdffactory.com

8 12 "!

/ 20 144 06: 17 25 /0

Solid State Structure

http://www.steelguru.com/article/details/MjU=/Solid_State_Structure...

a) Nucleation of crystals, b) crystal growth, c) irregular grains form as crystals grow together, d) grain boundaries as seen in a microscope. In engineering materials, a crystal is usually referred to as a grain. A grain is merely a crystal without smooth faces because its growth was impeded by contact with another grain or a boundary surface. The interface formed between grains is called a grain boundary. The atoms between the grains (at the grain boundaries) have no crystalline structure and are said to be disordered. Grains are sometimes large enough to be visible under an ordinary light microscope or even to the unaided eye. The spangles that are seen on newly galvanized metals are grains. Rapid cooling generally results in more nucleation points and smaller grains (a fine grain structure). Slow cooling generally results in larger grains which will have lower strength, hardness and ductility. Dendrites In metals, the crystals that form in the liquid during freezing generally follow a pattern consisting of a main branch with many appendages. A crystal with this morphology slightly resembles a pine tree and is called a dendrite, which means branching. The formation of dendrites occurs because crystals grow in defined planes due to the crystal lattice they create. The figure to the right shows how a cubic crystal can grow in a melt in three dimensions, which correspond to the six faces of the cube. For clarity of illustration, the adding of unit cells with continued solidification from the six faces is shown simply as lines. Secondary dendrite arms branch off the primary arm, and tertiary arms off the secondary arms and etcetera. During freezing of a polycrystalline material, many dendritic crystals form and grow until they eventually become large enough to impinge upon each other. Eventually, the interdendriticspaces between the dendrite arms crystallize to yield a more regular crystal. The original dendritic pattern may not be apparent when examining the microstructure of a material. However, dendrites can often be seen in solidification voids that sometimes occur in castings or welds, as shown to the right.. Shrinkage Most materials contract or shrink during solidification and cooling. Shrinkage is the result of:

9 12 "!

PDF created with pdfFactory Pro trial version www.pdffactory.com

/ 20 144 06: 17 25 /0

Solid State Structure

http://www.steelguru.com/article/details/MjU=/Solid_State_Structure...

Contraction of the liquid as it cools prior to its solidification Contraction during phase change from a liquid to solid Contraction of the solid as it continues to cool to ambient temperature. Shrinkage can sometimes cause cracking to occur in component as it solidifies. Since the coolest area of a volume of liquid is where it contacts a mold or die, solidification usually begins first at this surface. As the crystals grow inward, the material continues to shrink. If the solid surface is too rigid and will not deform to accommodate the internal shrinkage, the stresses can become high enough to exceed the tensile strength of the material and cause a crack to form. Shrinkage cavitation sometimes occurs because as a material solidifies inward, shrinkage occurred to such an extent that there is not enough atoms present to fill the available space and a void is left.

Anisotropy and Isotropy

In a single crystal, the physical and mechanical properties often differ with orientation. It can be seen from looking at our models of crystalline structure that atoms should be able to slip over one another or distort in relation to one another easier in some directions than others. When the properties of a material vary with different crystallographic orientations, the material is said to be anisotropic . Alternately, when the properties of a material are the same in all directions, the material is said to be isotropic. For many polycrystalline materials the grain orientations are random before any working (deformation) of the material is done. Therefore, even if the individual grains are anisotropic, the property differences tend to average out and, overall, the material is isotropic. When a material is formed, the grains are usually distorted and elongated in one or more directions which makes the material anisotropic. Material forming will be discussed later but lets continue discussing crystalline structure at the atomic level.

More Articles

Grade A Architecture: The World's Most Spectacular University Buildings India design engineers opting parallel flange sections to save cost An end to gray monotony - The world's most colorful high rises Johns Hopkins University aims to design earthquake resistant architecture Ruukki corrosion protected galvannealed PHS steels for car safety POSCO war zone - Will fight POSCO till last breath Yamal Peninsula Railway Line JFE Steel broadens iron powder range for high performance Powder Metallurgy parts World longest bullet train begin operation in China Steely Beauties - BMZ calendar for 2013 Tailor welding coils with the fiber delivered laser - Tailor welding coils with the fiber delivered laser Did you know? Farmers in Vidarbha region struggling with drought Steel Spirit How ThyssenKrupp CSA is wrecking lives and the environment ArcelorMittal Orbit Is Global Warming Causes Black Sea to Freeze Schubert Club Band Shell Parliament Library Building Domes New Beijing Poly Plaza Cable-Net Wall Singapore - Helix Pedestrian Bridge -

PDF created with pdfFactory Pro trial version www.pdffactory.com

10 12 "!

/ 20 144 06: 17 25 /0

Solid State Structure

http://www.steelguru.com/article/details/MjU=/Solid_State_Structure...

Making of a Car - BMW 1 Series - 2012 BMW 1-Series Hatchback BMW The True Cost of Coal - Jharia Coal Mine, India London 2012 Olympic medals - - Rio Tinto metals on the podium Men of Steel - The story of the steel workers of Redcar - Final Major Project by Mr David Lee, BA Photojournalism Wimbledon roof I A marvel in steel structure - Sourced from : JSW Severfield Structurals Ltd BlueScope Steel wins Insurance Award for Durable Housing Canadian Institute of Steel Construction has honored innovative steel construction projects Ferment takes root in Nelson sculpture garden Annual Technical Fest of BHU-Metallurgy concluded on April 3rd Men of steel:The founding history of POSCO Cradle of Champions monument by Gerdau Ameristeel at Fort Worth Gotthard the longest railway tunnel in the world End of an era - Shougang closes Bejing steel plant Global crude steel production estimates for 2010 Sweet Home Alabama - Grand opening for ThyssenKrupp Hyundai Motor Corporation I - Cutting edge and very green ArcelorMittal Orbit - High observation tower Jinso Pavilion - Bags Dutch National Steel Prize 2010 Top 10 steel skyscrapers -

...More Articles

This is alternative content.

PDF created with pdfFactory Pro trial version www.pdffactory.com

11 12 "!

/ 20 144 06: 17 25 /0

Solid State Structure

http://www.steelguru.com/article/details/MjU=/Solid_State_Structure...

Lorin Anodized Products

lorin.com For Architectural Applications Visit our website for Solutions

Industrial Engineering Steel Prices and News Packaging manufacturer Booking.com JLMOP

Copyright 2004 - 2011 SteelGuru and respective copyright holders. All rights reserved. Site optimized for Internet Explorer 7.0 and above. Disclaimer|Copyright Policy|Privacy Policy|About us|Feedback|Contact us|FAQ|Site Map|Know about SteelGuru

12 12 "!

PDF created with pdfFactory Pro trial version www.pdffactory.com

/ 20 144 06: 17 25 /0

También podría gustarte

- Roof Truss Design LoadsDocumento51 páginasRoof Truss Design LoadsFeigyl Miro100% (4)

- Steam Reformer Pigtail Failures PDFDocumento5 páginasSteam Reformer Pigtail Failures PDFHariharasudhanAún no hay calificaciones

- Fatigue Life Estimates Using Goodman DiagramsDocumento11 páginasFatigue Life Estimates Using Goodman Diagramsloveleshvarma100% (1)

- Self Help Handbook 2015 PDFDocumento30 páginasSelf Help Handbook 2015 PDFHomitchi SorinaAún no hay calificaciones

- Articulado PDFDocumento90 páginasArticulado PDFMiguel Fuentes100% (1)

- ZincDocumento29 páginasZinczidaaanAún no hay calificaciones

- SulfurDocumento20 páginasSulfurzidaaanAún no hay calificaciones

- CNC G-Code Programming Tutorial, Course, Examples, and ProgramsDocumento5 páginasCNC G-Code Programming Tutorial, Course, Examples, and Programszidaaan0% (1)

- Aama 501.2-83Documento3 páginasAama 501.2-83Abdul Raqeeb67% (3)

- Pile Soil InteractionDocumento250 páginasPile Soil Interactionnallay1705100% (3)

- API RP505 Classfication SelectedDocumento2 páginasAPI RP505 Classfication SelectedSing Yew LamAún no hay calificaciones

- Bioreactor and SterilizationDocumento22 páginasBioreactor and SterilizationMuhd Shukri100% (2)

- 2015 Oil Seals by Design Web CatalogueDocumento341 páginas2015 Oil Seals by Design Web CatalogueEUROPARTS67% (3)

- Structure of MetalsDocumento13 páginasStructure of Metalshammad00Aún no hay calificaciones

- Mech1006 Materials & Mechanics: Metallography & Microstructure: Lab Session M, 2013, DR A WojcikDocumento19 páginasMech1006 Materials & Mechanics: Metallography & Microstructure: Lab Session M, 2013, DR A WojcikLoc Nguyen100% (1)

- 03-MS-ME - The Structure of Crystalline SolidsDocumento83 páginas03-MS-ME - The Structure of Crystalline Solidsfarah Al-zgoulAún no hay calificaciones

- Overall Heat Transfer CoefficientDocumento3 páginasOverall Heat Transfer CoefficientcordobaluisfAún no hay calificaciones

- TinDocumento16 páginasTinzidaaanAún no hay calificaciones

- SUPPLY OF LABOR MATERIALS EQUIPMENT FOR STAINLESS STEEL TANKSDocumento2 páginasSUPPLY OF LABOR MATERIALS EQUIPMENT FOR STAINLESS STEEL TANKSWilliam LimAún no hay calificaciones

- Structure and Chemistry of Crystalline Solids - B. Douglas, S. Ho (Springer, 2006) WWDocumento355 páginasStructure and Chemistry of Crystalline Solids - B. Douglas, S. Ho (Springer, 2006) WWluis peixotoAún no hay calificaciones

- Ceramic Pigments and GlassesDocumento19 páginasCeramic Pigments and GlassesalbaqueAún no hay calificaciones

- Optical Properties of Thin FilmDocumento66 páginasOptical Properties of Thin FilmOmed Ghareb80% (5)

- LNG Ships: by F. R. ChowdhuryDocumento6 páginasLNG Ships: by F. R. ChowdhuryThusitha DalpathaduAún no hay calificaciones

- Material Science and MetallurgyDe EverandMaterial Science and MetallurgyCalificación: 2 de 5 estrellas2/5 (1)

- Chapter 3Documento59 páginasChapter 3XAún no hay calificaciones

- Crystal StructureDocumento30 páginasCrystal StructureSujit Singh100% (1)

- Crystalline Materials3Documento32 páginasCrystalline Materials3Abdel-Menam AlhaddadAún no hay calificaciones

- Structures of METAL and CERAMICSDocumento25 páginasStructures of METAL and CERAMICSSeanne CruzAún no hay calificaciones

- Fundametals of material science week 1Documento6 páginasFundametals of material science week 1Hanin AqilahAún no hay calificaciones

- Crystal Structure AnalysisDocumento7 páginasCrystal Structure Analysiskarl zurcAún no hay calificaciones

- Structure of Engineering MaterialsDocumento12 páginasStructure of Engineering Materialsjust_killing_pplAún no hay calificaciones

- FPEM1013 Chapter 1Documento24 páginasFPEM1013 Chapter 1ahmedhaid1312Aún no hay calificaciones

- Crystal Structure of Metals: Chapter TwoDocumento19 páginasCrystal Structure of Metals: Chapter TwoRitika JainAún no hay calificaciones

- Rangkuman Materi Crystalline Structure (IBE) Ahmad Naufal Waliyyuddin - 1513623068Documento12 páginasRangkuman Materi Crystalline Structure (IBE) Ahmad Naufal Waliyyuddin - 1513623068Ahmad NaufalAún no hay calificaciones

- How Do Atoms Arrange Themselves To Form Solids?: Chapter Outline Types of SolidsDocumento7 páginasHow Do Atoms Arrange Themselves To Form Solids?: Chapter Outline Types of SolidsAbhijith MadabhushiAún no hay calificaciones

- Periodic Table Crystal StructureDocumento6 páginasPeriodic Table Crystal StructurearamontanaAún no hay calificaciones

- Structures and Properties of CeramicsDocumento38 páginasStructures and Properties of CeramicsArjayAún no hay calificaciones

- The Chemistry of Engineering Materials 20192020Documento19 páginasThe Chemistry of Engineering Materials 20192020potassiumAún no hay calificaciones

- 1) Atonomic Number: Each Chemical Element Is Characterized by The Number of Protons in TheDocumento2 páginas1) Atonomic Number: Each Chemical Element Is Characterized by The Number of Protons in TheRiyanitaAún no hay calificaciones

- Lecture Note EEE 3515 Stenza 1Documento17 páginasLecture Note EEE 3515 Stenza 1md kayesAún no hay calificaciones

- 06 - Uet FM LecDocumento48 páginas06 - Uet FM LecAbcAún no hay calificaciones

- The Chemistry of Engineering Materials ChapterDocumento7 páginasThe Chemistry of Engineering Materials Chaptercory kurdapyaAún no hay calificaciones

- Module Test 7Documento3 páginasModule Test 7Dobal PunioAún no hay calificaciones

- 3Documento67 páginas3Louise UmaliAún no hay calificaciones

- Keanu Husein Material TestingDocumento2 páginasKeanu Husein Material TestingKeanu MitchellAún no hay calificaciones

- NPTEL Mechanical Forming Materials StructuresDocumento12 páginasNPTEL Mechanical Forming Materials Structuresaghosh704Aún no hay calificaciones

- Metallic Crystal Structures (BCC, FCC, HCPDocumento10 páginasMetallic Crystal Structures (BCC, FCC, HCPRaniya Nur NAún no hay calificaciones

- CH 2Documento19 páginasCH 2Abdul RashidAún no hay calificaciones

- Chapter 3. The Structure of Crystalline SolidsDocumento45 páginasChapter 3. The Structure of Crystalline SolidsDiego AbadAún no hay calificaciones

- Crystal StructureDocumento8 páginasCrystal StructurekdAún no hay calificaciones

- Chapter 3Documento26 páginasChapter 3Bala SubramanianAún no hay calificaciones

- Chapt 04Documento22 páginasChapt 04chengliangAún no hay calificaciones

- ScientificDocumento12 páginasScientificbalajiAún no hay calificaciones

- Crystal StructuresDocumento87 páginasCrystal Structuresrogerio-camposAún no hay calificaciones

- Lec1-Crystalline Structure of Metals and AllotropyDocumento30 páginasLec1-Crystalline Structure of Metals and Allotropysamurai7_77Aún no hay calificaciones

- Crystal: Name: Avinda Arista Putri Class: 1C NIM: 201710140311143Documento57 páginasCrystal: Name: Avinda Arista Putri Class: 1C NIM: 201710140311143Rizal MawardiAún no hay calificaciones

- Semiconductors Materials, Crystallographic Terms, Crystal LatticesDocumento36 páginasSemiconductors Materials, Crystallographic Terms, Crystal LatticesSalaar KhanAún no hay calificaciones

- CRYSTALLINE AND AMORPHOUS SOLIDSDocumento26 páginasCRYSTALLINE AND AMORPHOUS SOLIDSঅবান্তরমূলAún no hay calificaciones

- Atomic Bonds, Crustals, Specific Heat .. (CSE)Documento14 páginasAtomic Bonds, Crustals, Specific Heat .. (CSE)AISHEE DIBAAún no hay calificaciones

- Structures and Properties of Metals and CeramicsDocumento38 páginasStructures and Properties of Metals and CeramicsDan CostelloAún no hay calificaciones

- Chapter 3Documento86 páginasChapter 3Jose L. Rosado100% (1)

- States of Aggregation: AND Crystal StructuresDocumento29 páginasStates of Aggregation: AND Crystal StructuresaderancAún no hay calificaciones

- Lattice Structures & Metal DuctilityDocumento9 páginasLattice Structures & Metal DuctilityKASHFI UDDINAún no hay calificaciones

- Material Science and Engineering: "Metals"Documento31 páginasMaterial Science and Engineering: "Metals"Baltazar MharkAún no hay calificaciones

- EMG 1204 Lecture 3Documento15 páginasEMG 1204 Lecture 3James musambakiAún no hay calificaciones

- Material Engineering NotesDocumento117 páginasMaterial Engineering NotesSudhir KumarAún no hay calificaciones

- Close-Packing and Interstitial SitesDocumento3 páginasClose-Packing and Interstitial SitesBIBI HUDAAún no hay calificaciones

- Lecture 5 Chapter 4 Crystal StructureDocumento41 páginasLecture 5 Chapter 4 Crystal StructureDhruv SahniAún no hay calificaciones

- Crystal StructureDocumento41 páginasCrystal StructureNiraj SuroopjeetAún no hay calificaciones

- Chapter 3. Structure of CrystalsDocumento4 páginasChapter 3. Structure of CrystalsRaunak RajpurohitAún no hay calificaciones

- Metallic and Ionic Solids (Autosaved)Documento25 páginasMetallic and Ionic Solids (Autosaved)Asmaa HatemAún no hay calificaciones

- LectureDocumento31 páginasLectureCadaon KatherineAún no hay calificaciones

- Crystal Structures of Metallic ElementsDocumento5 páginasCrystal Structures of Metallic ElementsabutaflahAún no hay calificaciones

- Svprecis 12th Chemistry Unit No 1 The Solid StateDocumento11 páginasSvprecis 12th Chemistry Unit No 1 The Solid Stateapi-252136290Aún no hay calificaciones

- Metallurgy and Heat Treatment Chapter OverviewDocumento30 páginasMetallurgy and Heat Treatment Chapter Overviewsureshkanna2Aún no hay calificaciones

- Effect of Welding On Microstructure and Mechanical Properties of An Industrial Low Carbon Steel PDFDocumento5 páginasEffect of Welding On Microstructure and Mechanical Properties of An Industrial Low Carbon Steel PDFzidaaanAún no hay calificaciones

- Friction Stir Welding A Brief DiscrptionDocumento7 páginasFriction Stir Welding A Brief DiscrptionzidaaanAún no hay calificaciones

- Experimental Analysis of TIG Welding and Comparison Between Activated-TIG and TIG On Duplex Stainless Steel (2205)Documento8 páginasExperimental Analysis of TIG Welding and Comparison Between Activated-TIG and TIG On Duplex Stainless Steel (2205)zidaaanAún no hay calificaciones

- Butterfly: Butterflies Butterflies Are Part of The Class of Insects in The Order Lepidoptera, Along With The Moths. AdultDocumento2 páginasButterfly: Butterflies Butterflies Are Part of The Class of Insects in The Order Lepidoptera, Along With The Moths. AdultzidaaanAún no hay calificaciones

- Machine Design Jindall (Part Of)Documento187 páginasMachine Design Jindall (Part Of)zidaaanAún no hay calificaciones

- Lecture1 PDFDocumento7 páginasLecture1 PDFarunAún no hay calificaciones

- Lecture1 PDFDocumento7 páginasLecture1 PDFarunAún no hay calificaciones

- Electrical Discharge MachiningDocumento6 páginasElectrical Discharge MachiningzidaaanAún no hay calificaciones

- Eagle PDFDocumento6 páginasEagle PDFzidaaanAún no hay calificaciones

- Eagle PDFDocumento6 páginasEagle PDFzidaaanAún no hay calificaciones

- Antenna: Science and EngineeringDocumento1 páginaAntenna: Science and EngineeringzidaaanAún no hay calificaciones

- Cobalt - The silvery-gray metal elementDocumento6 páginasCobalt - The silvery-gray metal elementzidaaanAún no hay calificaciones

- Aluminium OxideDocumento3 páginasAluminium OxidezidaaanAún no hay calificaciones

- PlasterDocumento3 páginasPlasterzidaaanAún no hay calificaciones

- Tungsten CarbideDocumento3 páginasTungsten CarbidezidaaanAún no hay calificaciones

- BainiteDocumento3 páginasBainitezidaaanAún no hay calificaciones

- Eddy-Current Testing - Wikipedia, The Free Encyclopedia PDFDocumento3 páginasEddy-Current Testing - Wikipedia, The Free Encyclopedia PDFzidaaanAún no hay calificaciones

- Very Important On Bead GeometryDocumento10 páginasVery Important On Bead GeometryzidaaanAún no hay calificaciones

- SnakeDocumento12 páginasSnakezidaaanAún no hay calificaciones

- PoisonDocumento7 páginasPoisonzidaaanAún no hay calificaciones

- Eddy-Current Testing - Wikipedia, The Free Encyclopedia PDFDocumento3 páginasEddy-Current Testing - Wikipedia, The Free Encyclopedia PDFzidaaanAún no hay calificaciones

- CarbonDocumento19 páginasCarbonzidaaanAún no hay calificaciones

- Polarity (Mutual InductanceDocumento3 páginasPolarity (Mutual InductancezidaaanAún no hay calificaciones

- TitaniumDocumento17 páginasTitaniumzidaaanAún no hay calificaciones

- A Comparative Investigation On The Effects of Nanocellulose From BacteriaDocumento13 páginasA Comparative Investigation On The Effects of Nanocellulose From BacteriaPaloma GuardeziAún no hay calificaciones

- EdDocumento1 páginaEdpandirajaAún no hay calificaciones

- Site Plan 02 Puerto Baru Rev.04Documento1 páginaSite Plan 02 Puerto Baru Rev.04TaihimyAún no hay calificaciones

- 04-87RA9001-01 Installation Junction Box Main Field Signals 9000 SeriesDocumento1 página04-87RA9001-01 Installation Junction Box Main Field Signals 9000 SeriesRonaldAún no hay calificaciones

- Intl Warranty PDF t65 HeatersDocumento1 páginaIntl Warranty PDF t65 HeatersMVPlanzaroteAún no hay calificaciones

- Carsoquat™ CT 425 Carsoquat™ CT 429: Cetrimonium ChlorideDocumento2 páginasCarsoquat™ CT 425 Carsoquat™ CT 429: Cetrimonium ChlorideTAPaolaAún no hay calificaciones

- Wieland ConnectorsDocumento900 páginasWieland ConnectorsswasthikamanaramAún no hay calificaciones

- Summary of Procedure For ASTM D 698Documento2 páginasSummary of Procedure For ASTM D 698Miller De Leon Cutora100% (1)

- Grammar Worksheet: If You Turn Off The Lights, You Will Save EnergyDocumento2 páginasGrammar Worksheet: If You Turn Off The Lights, You Will Save EnergybkksmkturenAún no hay calificaciones

- Service Manual: Air ConditionerDocumento70 páginasService Manual: Air Conditionerboroda2410Aún no hay calificaciones

- Engineering Management Painting SpecificationsDocumento15 páginasEngineering Management Painting SpecificationsPaula MontalvoAún no hay calificaciones

- Micro Electro Mechanical Systems: S. MeenatchisundaramDocumento15 páginasMicro Electro Mechanical Systems: S. MeenatchisundaramkksundariAún no hay calificaciones

- Block Diagram Pulp PT TELDocumento1 páginaBlock Diagram Pulp PT TELEra MileniaAún no hay calificaciones

- Plastic ShredderDocumento23 páginasPlastic ShredderJojimar JulianAún no hay calificaciones

- Quartz ToleranceDocumento36 páginasQuartz Tolerancenick10686Aún no hay calificaciones

- MasterPel SP 6000 - BASF July 2018 - en - NZDocumento2 páginasMasterPel SP 6000 - BASF July 2018 - en - NZDan IonelAún no hay calificaciones

- Lec-2 Structural Steel PropertiesDocumento10 páginasLec-2 Structural Steel PropertiesRifat HasanAún no hay calificaciones

- Atlas Copco LSV-LSF UsDocumento4 páginasAtlas Copco LSV-LSF Usovi_julianAún no hay calificaciones

- Standard Specification For GB 700Documento12 páginasStandard Specification For GB 700Ma'arif Nuzul AddibAún no hay calificaciones