Documentos de Académico

Documentos de Profesional

Documentos de Cultura

TQM fundamentals for quality excellence

Cargado por

Pradeep Gs0 calificaciones0% encontró este documento útil (0 votos)

261 vistas113 páginasnice

Título original

Mba IV Total Quality Management [12mba42] Notes

Derechos de autor

© © All Rights Reserved

Formatos disponibles

PDF, TXT o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentonice

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

0 calificaciones0% encontró este documento útil (0 votos)

261 vistas113 páginasTQM fundamentals for quality excellence

Cargado por

Pradeep Gsnice

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

Está en la página 1de 113

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 1

Total Quality Management 12MBA42

TOTAL QUALITY MANAGEMENT

Sub Code: 12MBA42 IA Marks: 50

No. of Lecture Hrs/week: 04 Exam Hrs. 03 Hours

Total No. of Lecture Hrs. 56 Exam Marks: 100

Practical Component: 01 Hr/ Week

Module I (6 hours)

Introduction to TQM,Meaning of the terms quality, quality control and quality assurance,

importance of quality, quality dimensions of products and services, quality and competitive

advantage, cost of quality, TQM, Evolution of TQM, Basic principles of TQM, TQM VS

Traditional management, advantages of TQM

Module II (10 Hours)

Philosophical Framework to TQM Contribution of various gurus of TQM,Deming-Demings

chain reaction, Demings principles, deadly sins, PDCA cycle, Jurans Quality triology, Jurans

breakthrough sequence, Philips Crosby- Quality is free, Taguchis Quality loss function,

Ishikawas contributions and Quality Circles.

Module III (6 Hours)

Benchmarking Definition, reasons for benchmarking, types of benchmarking, process of

benchmarking what to benchmark, understanding current performance, planning, studying

others, using findings, Xerox model of Benchmarking, Advantages and pitfalls of benchmarking

Concept of Kaizen and its applications

Module IV (6 Hours)

Business Process Re-engineering (BPR) Introduction, Need for BPR, Implementing BPR, Steps

in BPR, Re-engineering vs. TQM, BPR Vs. Kaizen, Re-engineering the structure, change

management and BPR, BPR and IT, Advantages and Limitations, Indian examples of BPR

Module V (8 Hours)

Quality Management Systems(QMS) Introduction, meaning of QMS, ISO 9000, Benefits of ISO,

ISO 9000-2008 series, implementation of ISO 9000,Problems related to ISO 9000, QS 9000,

Need for QS 9000, QS 9000 series ENVIRONMENTAL MANAGEMENT SYSTEM (EMS),

ISO 14000 series, Benefits of ISO 14000, Integrating ISO 9000 & 14000, SEI-CMM level 5

Module VI (6 Hours)

Quality Awards : Introduction, Need for Quality Awards, Deming Prize and its features,

MBNQA and its features, European quality award and its features, Golden peacock award, TQM

models.

Module VII (8 Hours)

Quality Control tools: Introduction, 7 tools of quality control (Old & New), Poka-yoke, Quality

Function Deployment.

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 2

Module VIII (6 Hours)

Introduction to Six Sigma Historical developments, statistical framework for six sigma, DPU and

DPMO concepts, DMAIC methodology, Training for Six Sigma, Benefits of Six Sigma, Six

sigma and TQM.

Practical Component:

Students have to study any Indian organization which has won Deming prize and identify the

quality initiatives of that organization

Students are expected to study various quality awards given in India like CII Business excellence

award, Rajiv Gandhi national quality award and Tata groups Excellence Award and compare

with international awards

Students can identify any 2 products and 2 services and develop Quality attributes for the same.

Students can identify industry from any sector and conduct a benchmark study with respect to

best in the class.

RECOMMENDED TEXT BOOKS:

1. Management and Control of Quality, James R. Evans, 8/e 2012, Cengage Learning

2. Total Quality Management, Dale.H. Besterfield, 3rd Edition, Pearson Education

3. Total Quality Management Text and Cases, G. Nagalingappa&Manjunath VS, Excel books.

4. Total Quality Management, ShridharBhat, Himalaya Publication

REFERENCE BOOKS:

1. Total Quality Management by PoornimaM.Charantimath, Pearson Education.

2. Quality Control Handbook by JURAN, Mc.Graw Hill Publication

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 3

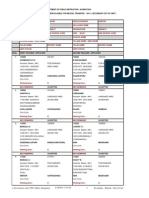

TABLE OF CONTENTS

MODULE NO CONTENT PAGE NO

1

Introduction to TQM 04 to 16

2

Philosophical Framework of TQM 17 to 36

3

Benchmarking 37 to 45

4

Business Process

Reengineering(BPR)

46 to 57

5

Quality Management

Systems(QMS)

58 to 74

6

Quality Awards 75 to 90

7

Quality Control 91 to 105

8

Six Sigma and other developments 106 to 113

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 4

MODULE I

Introduction to TQM,Meaning of the terms quality, quality control and quality assurance,

importance of quality, quality dimensions of products and services, quality and competitive

advantage, cost of quality, TQM, Evolution of TQM, Basic principles of TQM, TQM VS

Traditional management, advantages of TQM.

OBJECTIVE

To Understand and appreciate

Concepts and Practices of TQM

Meaning of the terms quality,

Quality control and

Quality assurance,

Importance of quality,

Quality dimensions of products and services,

Quality and competitive advantage,

Cost of quality,

TQM, Evolution of TQM,

Basic principles of TQM,

TQM VS Traditional man

INTRODUCTION TO TQM

Total quality management (TQM) refers to methods used to enhance quality and

productivity in organizations, particularly businesses. TQM is a comprehensive system

approach that works horizontally across an organization, involving all departments and

employees and extending backward and forward to include both suppliers and

clients/customers.

TQM is only one of many acronyms used to label management systems that focus on

quality. Other acronyms that have been used to describe similar quality management

philosophies and programs include CQI (continuous quality improvement), SQC

(statistical quality control),QFD (quality function deployment), QIDW (quality in

daily work), and TQC (total quality control). Despite the ambiguity of the popularized

term "TQM," that acronym is less important than the substance of the management

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 5

ideology that underlies it. TQM provides a framework for implementing effective quality

and productivity initiatives that can increase the profitability and competitiveness of

organizations.

Although TQM techniques were adopted prior to World War II by a number of

organizations, the creation of the total quality management philosophy is generally

attributed to Dr. W. Edwards Deming (1900-1993). In the late 1920s, while working as a

summer employee at Western Electric Company in Chicago, he found worker motivation

systems to be degrading and economically unproductive; incentives were tied directly to

quantity of output, and inefficient postproduction inspection systems were used to find

flawed goods.

Deming teamed up in the 1930s with Walter A. Shewhart (1891-1967), a Bell Telephone

Company statistician whose work convinced Deming that statistical control techniques

could be used to supplant traditional management methods. Using Shewhart's theories,

Deming devised a statistically controlled management process that provided managers

with a means of determining when to intervene in an industrial process and when to

leave it alone. Deming got a chance to put Shewhart's statistical quality-control

techniques, as well as his own management philosophies, to the test during World War

II. Government managers found that his techniques could easily be taught to engineers

and workers, and then quickly implemented in overburdened war production plants.

One of Deming's clients, the U.S. State Department, sent him to Japan in 1947 as part of

a national effort to revitalize the war-devastated Japanese economy. It was in Japan that

Deming found an enthusiastic reception for his management ideas. Deming introduced

his statistical process control, or statistical quality control, programs into Japan's

ailing manufacturing sector. Those techniques are credited with instilling a dedication

to quality and productivity in the Japanese industrial and service sectors that allowed

the country to become a dominant force in the global economy by the 1980s.

While Japan's industrial sector embarked on a quality initiative during the middle

1900s, most American companies continued to produce mass quantities of goods using

traditional management techniques. America prospered as war-ravaged European

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 6

countries looked to the United States for manufactured goods. In addition, a domestic

population boom resulted in surging U.S. markets. But by the 1970s some American

industries had come to be regarded as inferior to their Asian and European competitors.

As a result of increasing economic globalization during the 1980s, made possible in part

by advanced information technologies, the U.S. manufacturing sector fell prey to

more competitive producers, particularly in Japan.

In response to massive market share gains achieved by Japanese companies during the

late 1970s and 1980s, U.S. producers scrambled to adopt quality and productivity

techniques that might restore their competitiveness. Indeed, Deming's philosophies and

systems were finally recognized in the United States, and Deming himself became a

highly sought-after lecturer and author. The "Deming Management Method" became the

model for many American corporations eager to improve. And total quality

management, the phrase applied to quality initiatives proffered by Deming and other

management gurus, became a staple of American enterprise by the late 1980s. By the

early 1990s, the U.S. manufacturing sector had achieved marked gains in quality and

productivity. By the late 1990s several American industries had surpassed their

Japanese rivals in these areas.

MEANING OF THE TERMS QUALITY, QUALITY CONTROL AND QUALITY

ASSURANCE

CONCEPTS OF QUALITY

Q- Quest for excellence

U- Understanding customers needs

A- Action to achieve customers appreciation

L- Leadership-determination to be a leader

I- Involving all people

T- Team spirit to work for a common goal

Y- Yardstick to measure progress

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 7

Quality Definitions

The ability of a product or service to meet customer needs

The totality of features and characteristics of a product or service that bears on its ability to

satisfy stated or implied needs-American Society for Quality

Meeting or exceeding customer requirements now and in the future.

This means that the product/service is fit for customers use, Fitness for use is related to benefits

received by the customer and to ensure customer satisfaction.

Quality control

Quality control denotes all those activities which are directed to maintain and improve quality.

Quality control involves.

1. Setting of Quality targets

2. Appraisal of conformance (adhering to rules)

3. Taking any corrective action where any deviation is noticed

4. Planning for improvements in quality

Objectives of quality control

SQC (Statistical Quality control)

tems of the

manufactured product with the help of statistical knowledge.

assignable causes encountered in the production process.

Organising for quality control

Traditionally Quality control department has the role of a watchdog over production

department

employees

ch employee is responsible for quality

which is called as quality at source

Quality at source

ion b/n quality control department and production department

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 8

and product

rkers and managers to form a group called as Quality circle to analyze quality

problems and to solve quality problems.

Quality control strategy and policy

time which aims at continuous improvement of quality . To facilitate this Quality policy must

be formulated.

Quality assurance

quality

ntended to include of all activities performed to ensure that the product

performs to the customers expectations and many departments are involved in it.

Activities in Quality assurance

product

t

manuals

ndicates inadequate

quality

Quality assurance system

method of maintaining quality

as an assembly of elements such as organizational

structure, responsibilities, procedures, processes and resources for managing quality.

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 9

The quality assurance system must be documented in the form of a quality manual covering the

following areas:

The quality assurance system must be documented in the form of a quality manual covering the

following areas:

1. Quality planning

2. Quality advice and expertise

3. Training personnel

4. Purchase, process, service appraisal methodology

5. Customer complaints, warranty claims

6. Senior management

7. Marketing

8. Research and development

9. Product design

10. Production and operations

11. After sales/service

12. Stores/distribution/transport

Total quality control (TQC)

-wide-view of product quality to achieve competitive positions by

offering quality products to consumers covering from a shop floor to a board room is termed as

Total Quality control (TQC)

ality control is an effective system for integrating

quality development, quality maintenance and quality improvement efforts of the various groups

in an organization so as to enable marketing, engineering, production and service at the most

economic levels which allow for full customer satisfaction

Importance of quality

Producing superior quality products / service is vital to the continued growth success of a

company, therefore benefits of quality are given below.

1. It gives a positive company image

2. It improves competitive ability both nationally and internationally

3. It increases market share, which translates into improved profits

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 10

4. Overall it reduces costs which also results in profits

5. It reduces problems & avoids unnecessary costs

6. It creates an atmosphere for high employee morale, which improves productivity .

Quality Dimensions of products and services

Quality expected from a product (Tangible)

Eg: TV, Computers, Bikes

1. Performance: how well the product performs customers use eg: speed of a laser printer

2. Features: special characteristics that attracts a customer eg: power steering and central locking

system of an automobile

3. Reliability: frequency of malfunction, breakdown or repairs eg: cartridge of a xerox machine

4. Serviceability: speed , cost and convenience of repairs and maintenance eg: service of washing

machines

5. Durability: length of time of use before repairs/replacement eg: a car can be used for 5-10

years

6. Appearances: look, feel, taste , smell or sound of a product eg: look of a bike, smell of a

perfume, sound of a music system

7. Customer service: treatment received by customers before, during and after the product sale

eg: credit card

8. Safety: how well the product protects users during use eg: helmets

Quality concepts of Service

Quality expected from service sectors (Intangible)

Eg: Hotel, Hospitals, Banks

1. Reliability: consistency and dependability

2. Responsiveness: willingness to provide service

3. Competence: possession of skills and knowledge to perform

4. Access: approachability and ease of contact

5. Courtesy: politeness, respect, neatness and appearance

6. Communication: talking to customers in their language

7. Credibility: trust and belief

8. Security: freedom from danger, risk

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 11

9. Understanding the customer needs: learning customer requirement, providing individual

attention

10. Tangibles: physical evidence of service (facilities, tools and equipment) eg: a cinema theatre

with good seating arrangement

Quality and Competitive advantage.

1 Market route benefits

Continuous quality Improvement

Improved competitive position

Higher prices and increased market share

Increased revenue

Increased profits

2 Cost route benefits

Continuous quality Improvement

Improved defect-free output

Reduced costs of operations

Increased profits

Cost of quality

Cost of quality (COQ)/(COPQ) is the sum of cost incurred by an organization in preventing poor

quality. There are essentially 4 types of quality costs as below

These are certain costs which are associated with product and service quality. There are 4 major

categories of quality costs. They are

1. Prevention costs

2. Appraisal costs

3. Costs of internal failures

4. Costs of external failures

Prevention costs

Are associated with preventing defects before they happen. They include costs of

to increase quality of raw materials,

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 12

Appraisal costs

Internal failure costs

costs, replacement costs or new part costs

External failure costs

Total quality management

Total Quality covers

Earlier concept of quality related with a product is no more valid.

1. Quality is ultimately decided by all the processes which get included in the quality loop.

2. Total Quality covers every job , not just one involved in making of the product. Eg: secretaries

are expected not to make typing errors, accountants not to make accounting errors and CEOs are

expected not to make strategic errors.

3. Total quality recognizes each person is involved for the quality of the individual work and for

the quality of the team work.

Total means that everyone in organisation is involved in the final product or service to the

customer.

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 13

Quality does not just mean luxury. The original definition was, quality means conformance to

requirements.

Todays marketplace is now demanding that we go beyond this definition. A powerful definition

of quality to meet these perceptions is quality means delighting the customer by continually

meeting and improving upon agreed requirements.

Management recognises that TQM will not happen by accident. TQM is a managed process

which involves people, systems and supporting tools and techniques.

TQM is therefore a change agent which is aimed at providing a customer-driven organisation.

TQM (Total quality management)

quality and achieve customer satisfaction

improvement or kaizen) and other is goal is customer satisfaction which involves meeting or

exceeding customer expectations

8 essentials of TQM

er selection and development

Evolution of TQM

In early 1990s F W Taylor the father of Scientific Management brought the concept of

product inspection .

In 1924 W Shewhart introduced statistical control charts to monitor production.

After the World War II a dramatic increase caused W Edwards Deming introduced

(SQC) methods to Japanese manufacturing.

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 14

Joseph Juran formulated his cost of quality concept emphasizing accurate and complete

identification and measurement of costs of quality.

In 1950s, Armand Fiegenbaum proposed quality control on the product design and

incoming raw material.

In 1960s, Philip Crosby coined the concept of Zero defects.

During 1970s there was a dramatic shift from reactive to proactive approach to quality,

this in turn giving importance to customer satisfaction with a drive of team work.

The US government ,safety regulations, product recall mandated by consumer product

safety commissions changed the society attitude from let the buyer beware to let the

producer beware.

Demings contribution to Japanese industry

(3 decades earlier) made the US companies seek his help and experience. As a result

Ford Motor ,General Motors and Procter and Gamble to take up revolution.

In 1985 ,NASA announced an excellence Award for quality and productivity.

The Malcolm Baldrige National Award was established in 1987.

In Japan, during the II World War the economy was completely disrupted.

In 1950 Dr Edward Deming ,introduced the SQC approach in Japan.

Dr K Ishikawa of Tokyo University gave his contributions.

As a result the rate of economic growth increased to 9 to 10 percent per year and the

national product doubled in 7 to 8 years .

From 1950 to 1970 ,in the course of 20 years the per capita income has increased roughly

by 4 times.

Walter Shewart ,the father of stastistical quality control, initiated the SQC movement

during 1947 48.

Dr Edward Deming also visited India in early 1950s

In 1982 due to the quality trigger in US the concept of quality circles came into

introduction in the public sector units like ,Bharat electronics and Bharat Heavy

Electricals.

QCFI Quality Circle Forum in India came into existence.

Prof. Ishikawa was invited to by CII confederation of Indian industries.

The year 1987 brought the ISO 9000 .

CII organized training course for ISO 9000 in 1989.

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 15

Companies practice TQM though Quality circles, Suggestion schemes, kaizen and JIT

Basic principles of TQM

Customer focused approach to all activities and processes in the organization should be

directed towards winning customer satisfaction.

Strategic planning and leadership :leadership should lead to strong customer orientation

in the organization and be willing to make long-term commitments to its customers,

employees, vendors, stockholders and to society.

Restructuring of vertical processes to cross functional horizontal processes to change

the work culture to teamwork and making everyone in the process responsible for the

quality.

Creating a culture of working through internal customer system, where each stage in the

processes and each person in the process can be linked as customers to each other.

Continuous improvement of all processes and activities ,leading to total customer

satisfaction and competitive advantage.

Training and development of people : it is the people who drive the processes under

TQM system. Therefore people should be trained and developed for understanding the

process of TQM,

Empowerment and teamwork of people : team approach to work and cross functional

process management is an important aspect of TQM work culture.

TQM V/S TRADITIONAL MANAGEMENT

TQM

Customer delight focused with respect to activities/processes.

Customer satisfaction through continuous improvement.

It is a proactive measure.

TQM aims at superior performance

Customer delight and benchmarking are the focus.

It is a self-driven and self-imposed culture.

Aims to satisfy all the stakeholders.

TRADITIONAL MANAGEMENT

Product/service focused.

Short term satisfaction.

It is often a corrective measure.

It aims at quality conformance.

State of control is the focus.

It is based on the QMS systems (ISO 9000).

Aims to satisfy customers essential needs.

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 16

ADVANTAGES OF TQM

Better product quality

Productivity improvement

Reduced quality costs

Increased market

Increased profitability

Reduced employee grievances

Effective teamwork

Enhancement of job interest

Improvement in human relation and work area morale

Participation culture

Customer satisfaction

Enhanced problem solving

Improved corporate health

Better image and goodwill.

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 17

Module 2: Philosophical Framework to TQM Contribution of various gurus of TQM,Deming-

Demings chain reaction, Demings principles, deadly sins, PDCA cycle, Jurans Quality triology,

Jurans breakthrough sequence, Philips Crosby- Quality is free, Taguchis Quality loss function,

Ishikawas contributions and Quality Circles.

OBJECTIVE

To Understand and appreciate the:

Philosophical Framework of TQM

Contributions of various gurus of TQM,Deming-Demings chain reaction, Demings principles,

deadly sins, PDCA cycle,

Jurans Quality triology, Jurans breakthrough sequence,

Philips Crosby- Quality is free,

Taguchis Quality loss function,

Ishikawas contributions and Quality Circles.

PHILOSOPHICAL FRAMEWORK TO TQM

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 18

Gurus

Shewhart

Deming

Juran

Fiegenbaum

Ishikawa

Crosby

Taguchi

Principles and Practices

Leadership

Customer satisfaction

Employee involvement

Supplier partnership

Tools and techniques

Benchmarking

Information technology

Quality management systems

Environmental management system

Quality by design

Management tools

Statistical process control

Quality engineering

CONTRIBUTION OF VARIOUS GURUS OF TQM

CONTRIBUTOR CONTRIBUTIONS

Deming 14 points, theory on special & common

causes of variation

Juran Quality is fitness for use, quality trilogy

,cost of quality

Feigenbaum Quality is a total field, customer defines

quality

Crosby Quality is free, zero defects

Ishikawa Cause and effect diagrams, quality circles

Taguchi Taguchi loss function

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 19

Figure 1 DEMING W EDWARDS

DEMING W EDWARDS

An associate of Shewhart, worked in Western electric company as a statistician.

He was invited to Japan to led the quality movement.

He modified PDCA cycle of Shewhart to the Plan ,Do ,Study and act.(PDSA).

He also advocated intensive use of Statistics and control charts and focused on product

improvement and service conformance by reducing variations in the process.

He joined the US census bureau in the year 1939 and proved that quality control methods

could lower costs even in an exclusive service organization.

Deming stressed on the importance of suppliers and customers for the business

development and improvement.

He believed that people do their best and it the system that must change to improve

quality.

This 14 points formed the basis for this advice to Japanese top management.

The 14 points are applicable to every industry in product and service sector

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 20

DR WALTER A SHEWHART

Worked in Western electric company and AT&T,USA.

He advocated Statistical quality

Control (SQC) and acceptable

Quality level (AQL).AQL is the foundation of today's SIX SIGMA.

He is considered to be the father figure of SQC, who developed control charts for quality

assessment and improvements.

DrShewhart also developed the Plan,Do,Check,Act (PDCA) cycle for continuous

improvement, which is in use even today

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 21

JOSEPH M JURAN

Juran also joined Western electric company and developed Statistical quality control

handbook.

JUSE invited him to Japan in 1954.

He identified fitness quality and popularized the same.

Jurans fitness of quality

1. Quality of design- through market research, product and concept.

2. Quality of conformance through management, manpower and technology.

3. Availability through reliability, maintainability an logistics support.

4. Full service through promptness, competence and integrity.

Jurans quality planning road map

1. Identify your customers

2. Determine their needs

3. Translate into your language.

4. Develop a product that can respond to the needs.

5. Develop processes which are able to produce those product features.

6. Prove that the processes can produce the product.

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 22

7. Transfer the result in plans to the operating forces

PHILIP B CROSBY

Crosby was vice President of international telephone and telegraph(ITT).

He four absolutes of quality are very relevant to TQM.

Four absolutes of quality

1. Quality is conformance to requirements, nothing more or nothing less and certainly not

goodness or elegance.

2. Quality has to be achieved by prevention and not by appraisal.

3. The performance standard must be zero and not something close to it.

4. The measurement of quality is the price of nonconformance ,ie, how much the defects in

design, manufacture, installation and service cost the company.

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 23

ARMAND V FEIGENBAUM

He was the president of American Society of Quality control.

He said Quality is in its essence way of managing the organization.

Feigenbaums cycle time reduction methodology

1. Define process

2. List all the activities.

3. Flowchart the process.

4. List the elapsed time for each activity.

5. Identify non value adding tasks.

6. Eminent all possible non value adding tasks.

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 24

KAORU ISHIKAWA

A quality guru from Japan.

He advocated the use of cause and effects diagrams to provide a true representation of the

organizational impacts and producers.

He developed fishbone or Ishikawa diagram for cause and effect analysis.

DEMINGS CHAIN REACTION

The theory states that improvements in quality leads to lower costs because they result in

less rework, fewer delays ,and better use of time and materials.

Lower costs ,in turn, lead to productivity improvements.

With better quality and lower prices, a firm can achieve a higher market share and thus

stay in business, providing more and more jobs.

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 25

DEMINGS 14 PRINCIPLES

1) Create constancy of purpose for improvement of product and service. importance of

stability in jobs ,long term plans as investment in innovation, training, R&D.

2) Adopt the new philosophy for economic stability. Customer driven approach as zero

defects,JIT.

3) Cease dependence on mass inspection to achieve quality. results in

bottleneck ,increases cost, measures only causes ,divides the responsibility between

production and quality people. Use appropriate tools to create a balance between quality

and production

4) End the practice of awarding business on price tag alone. Instead, minimize total cost -

move towards a single supplier for any item, on trust.

5) Improve Constantly and forever the system of production and service. Enterprise

systems and services must keep growing in order to catch up with the competitive

market.

6) Institute modern methods of training on the job.

7) Adopt and Institute modern methods of supervision and leadership.

8) Drive out fear : Change and survive.

9) Break down barriers between departments and staff . The workers in design, sales, and

production must work together to face problems and resolve them. open communication

,sharing knowledge.

10) Eliminate the use of slogans and posters . Slogans do it right the first time;;

concentrate on the root cause.

11) Eliminate work standards and numerical quotas. This focuses on quantity rather than

quality of product. Ex Targets

12) Remove barriers that hinder the hourly worker. Eliminate Monotonous tasks, Abolish

annual or merit rating.

13) Institute a vigorous program of education and training. A person must grow after

joining a company, and letting them learn new technology and techniques will increase

employee longevity.

14) Create a situation in top management that will push every day on the above

points. Just like products and services, every employee in a company must work to

accomplish the transformation.

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 26

DEMINGS DEADLY SINS

1. Lack of constancy of purpose; short term focus

2. Emphasis on short term profits; cost cutting to meet the quarterly dividend pay.

3. Over reliance on performance appraisals; self-centered NO mutual teamwork.

4. Mobility of management (job hopping); long-term plans are not effective

5. Overemphasis on visible figures; targets cannot give customer satisfaction.

6. Excessive medical costs for employee health care; absenteeism and health care costs

7. Excessive costs of warranty and legal costs ;

DEMING WHEEL/CYCLE(P-D-C-A)

The PDCA cycle is also known as a problem solving process

Plan

A plan can be to initiate a new process or improve an existing one

it should be based upon customer needs, and

resolve to more effectively fulfill the organizations mission

Do

Carry out the process /activities as per the plan

Check

Review the gathered data to determine if the planned and implemented change has

created the quality improvement intended

Act

Take action, either to implement the change or change variables to see if the process can

be made more effective, or

Standardize the new, successful process.

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 27

DEMINGS TRIANGLE

DEMINGS THEORY OF VARIANCE

The basic assumption of this theory is variation from the standard activity as a major

source of problems for all process.

Variance increases uncertainty and reduces control over the processes.

TQM assigns managers the task of finding the source of their variance and eliminating it

so that the process can be improved.

All the variance can be categorized into two :

Controlled variance and uncontrolled variance.

1 Controlled variance is a variation from standard process that a worker can correct/manage.

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 28

2 Uncontrolled variance is a variation from the standard process due to the impact of some

factor outside the limits of the employee.

Variances can be corrected by workers or managers by changing its common

causes/special causes.

Common causes are as follows

Weakness in the product design

Equipment malfunctions

Poor maintenance of machineries

Incomplete/inaccurate documents maintenance.

Special causes are short term variations in an operating process as follows

Lack of knowledge/skill and competency

Worker negligence

JURAN- QUALITY TRILOGY

Quality trilogy includes the following sequence of events:

1 Quality planning

2 Quality control

3 Quality improvement

Quality planning

1 Identify the customer both the external and internal.

2 Determine the customer needs

3 Develop product features that respond needs.

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 29

4 Establish quality goals that meet the needs of customers and suppliers.

5 Develop a process that can produce the needed product

6 Prove the process capability.

Quality Control

1. Choose control subjects.

2. Choose the units of measurement.

3. Establish the measurement

4. Establish the standards of performance

5. Measure actual performance

6. Interpret the difference between the actual and the standard.

7. Take action on the difference

Quality improvement

1. Prove the need for improvement

2. Identify the specific projects for improvements.

3. Organize to guide the projects.

4. Organize for diagnosis for discovery of causes

5. Find the causes

6. Provide remedies

7. Prove that the remedies are effective under operating conditions.

8. Provide control mechanisms.

JURANS BREAKTHROUGH SEQUENCE

Juransbreakthrough sequence identifies a set of actions directed towards achieving major

leaps in quality.

The following are the steps

Step 1 :proof of need.

Identifies some fault in the current process that requires an immediate change.it

identifiescosts of not changing that exceed the costs of change.

Step 2 : project identification

Identifies specific project to bring about improvements which acts as a catalyst.

Step 3: organizing for improvements.

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 30

Organizes for successful completion of the selected projects. TOP MANAGEMENT

COMMITTEE resources ;task forces

Step 4 : diagnostic journey

Traces the root cause from the symptoms (systematic causes, random causes, wilful

causes)

Step 5 : Remedial action

The project team identifies a set of alternatives and select the appropriate one .it further

includes implementation and introducing inspection and testing

Step 6 :Resistance to change

Fear of unknown techniques, fear of excel in new environment create resistance among

the employees. Formulate actions to overcome fear.

Step 7 : Holding on to gains

Freeze the new methods and techniques to prevent any return back to old methodology.

PHILIP B. CROSBY

4 Absolutes of Quality Management:

Quality is defined as conformance to requirements , not goodness

The system for achieving quality is prevention, not appraisal

The performance standard is zero defects, not that is close enough

The measurement of quality is the price of non-conformance, not indexes

Crosbys 6 Cs

Comprehension (understanding)

Commitment (by all)

Competence (Attitude, skill and knowledge)

Correction (Elimination of errors)

Communication (Support of all people, customers and suppliers)

Continuance (improvement)

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 31

CROSBYS QUALITY VACCINE (CROSBYS TRIANGLE)

Integrity, Policies

Integrity represents an honest attempt by the management to eliminate bureaucracy, improve

performance and satisfy customers.

Systems and operations

Focus on designing new systems and operations to maintain the firms new quality environment.

Communication

Refers to the flow of information ( internal&external) both between the functional

departments ,firm ,suppliers and customers. The vaccine requires regular exchange of

information about

quality problems ,

performance on quality characteristics,

progress towards quality goals and

opportunities for improvement

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 32

CROSBY QUALITY IS FREE

Crosby's prescription for quality improvement was a 14 step program.

His belief was that a company that established a quality program will see savings more

than pay off the cost of the quality program ("quality is free").

Crosbys 14 Steps for quality improvement

1. Management commitment

2. Quality improvement team

3. Quality measurement

4. Cost of quality

5. Quality awareness

6. Corrective action

7. Zero Defects program

8. Supervisor training

9. Zero defects day

10. Goal setting

11. Error cause removal

12. Recognition

13. Quality councils

14. Do it all over again

TAGUCHIS QUALITY LOSS FUNCTION

Taguchis asserts the quality of a product is a function of key product characteristics

(performance characteristics ).

The ideal value is its target value.

Taguchis Quality loss function estimates loss to society from the failure of a product to

meet its target value for a particular performance characteristic.

A high quality product assures target values consistently throughout its life span under

all operating conditions

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 33

This loss can be incurred by the

1 Consumers (short product life, repair costs),

2 Company (increased scrap, rework and warranty costs) and

2 Society ( pollution , safety)

Quality loss function is expressed as

L=C (X-T)2

Where L = Total Loss

C= a constant

X= actual average value of quality

characteristics and

T= target value of quality characteristic

ISHIKAWA AND QUALITY CIRCLES.

Dr Ishikawa was instrumental to formulate

1 The concept of CWCQ (companywide quality control)

2 The audit process for selection a company to Deming award.

3 Teambased problem solving

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 34

4 Quality circles.

5 Cause and effect charts or fish bone diagrams

6 Bottom up view of quality

QUALITY CIRCLE

A quality circle or quality control circle (Q.C Circle) is a small group of employees 8 to

10 (average number of nine) who volunteer to meet regularly with a facilitator to solve

work related problems in their work area. The group with their leader usually meetonce

a week after their working hours.

Purpose:

To undertake work related projects designed to improve working conditions, enhance

mutual self developmentand to advance the company, all by using quality control

concepts.

HOW QC CIRCLE WORKS

Formation of QC circle

Registration of QC circle

Improvement of activities

QC circle grand meeting of each division

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 35

QC circle grand meeting of plant

Companywide QC circle grand meeting

Improvement of activities

Selection of the problem

Study the problem

Planning for improvement

Execution of the improvement

Confirmation of effect

Conclusion

Presentation

Characteristics of Quality circles.

Small group of employees : 8 to 10

Members are from the same work area or doing similar type of work

Membership of the quality circle is voluntary

Members meet regularly for about an hour every week

Members meet to identify, analyze and resolve work(quality) related problems.

Members resolve work related problems leading to improvement.

Quality circles enrich the work life of the employees.

Benefits of Quality Circles

Tangible benefits

Better quality

Improved productivity

Higher safety(reduced number of accidents)

Greater cost effectiveness

Better housekeeping

Increased profitability

Waste reduction

Reduced absenteeism

Reduced grievances.

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 36

Intangible benefits

Enriched quality of work life.

Attitudinal changes

Harmony ,mutual trust

Effective team working

Participative culture

Human resource development

Promotion of job knowledge

Greater sense of belonging.

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 37

Module 3

Benchmarking Definition, reasons for benchmarking, types of benchmarking, process of

benchmarking what to benchmark, understanding current performance, planning, studying

others, using findings, Xerox model of Benchmarking, Advantages and pitfalls of benchmarking

Concept of Kaizen and its applications

OBJECTIVE

To understand the meaning of Benchmarking

To identify the various reasons for benchmarking,

To list the types of benchmarking,

To explore the process of benchmarking

To know what to benchmark,

To understand current performance, planning, studying others, using findings,

To appreciate Xerox model of benchmarking,

To realize the advantages and pitfalls of benchmarking

To recognize the Concept of Kaizen and its applications

BENCHMARKING DEFINITION

Benchmarking is the process of continually searching for the best methods, practices

and processes, and adapting their good features and implementing them to become the

best of the best.

It is defined as measuring our performance against that of best-in-class companies,

determining how the best-in-class achieve those performance levels and using the

information as a basis for our own company's targets, strategies and implementation

EG: Microsoft, FMCG-HLL, Toyota, Ford

REASONS FOR BENCHMARKING

It acts as a tool to achieve business and competitive objectives.

It is a powerful and effective tool to take up right decisions and align with the

organizational strategies.

It helps organizations to take right decisions in choosing the appropriate markets.

It guides the organization to determine the strengths they need to gain competitive

advantage.

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 38

Benchmarking helps organization to develop strengths and reduce weakness.

Benchmarking helps organization to set goals based on the external environment.

TYPES OF BENCHMARKING

Performance or operational benchmarking

Process or functional benchmarking

Strategic benchmarking

Performance or operational benchmarking

Involves pricing, technical quality, features and other performance characteristics of products

and services

It also involves comparing competitors products, process and analyzing them

Process or functional benchmarking

Analyses work processes such as billing, order entry or employee training, manufacturing,

work /job design, techniques, procedure/process, sequence of operations.

This identifies the most effective best practices in companies that perform similar functions

Eg: Best practices of L.L.Beancompany was adopted by Xerox which reduced the cycle time

by 50 %

Strategic benchmarking

Examines the winning strategies of other companies and to construct a key success factor(KSF)

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 39

BENCHMARKING PROCESS

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 40

1 Getting started

Planning (work technique)

Organizing and ( funds, technical team, technology vendor, training team, top management)

Managing for benchmarking (adopting changes and adjustments)

2 Preparing to benchmark

Identify key processes which processes is to improved

Form team core workmen

Understand your own process KRA s strength /weakness

3 Conducting research

Collect information who is best and what is best org; brand image, market position,

competitive secret, competitors ,

4 Selecting whom to benchmark

Establish relationship

Plan to collect and share information

5 Collecting and sharing information

Surveys

Site visits

Determine any third parties( to collect the data)

6 Analyzing adapting and improving

Compare data

Plan to surpass

Implement and monitor

improve

Performance Measure Examples

Accounting

Percentage of Late Payments

Time to Respond to Customer Requests

Number of Billing Errors

Number of Payroll Errors

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 41

Information Services

Number of Errors / Code Line

Percent of Reports Received on Schedule

Number of Rewrites

Number of Errors Found After

Marketing

Accuracy of Forecast

Number of Incorrect Order Entries

Overstocked Supplies

Contact Errors

Purchasing

Purchase Order Errors

Downtime Due to Shortages

Excess Inventory

Cycle Time (from start of purchase to receipt in-house)

Product Engineering

Project Completion Cycle Times

Engineering Changes/ Document

Number of Errors Found During Design Review

Number of Errors Found in Design Evaluation

Quality Control

Percentage of Lots Rejected in Error

Number of Engineering Changes Detected After Design Review

Errors in Reports

Cycle Time for Corrective Action

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 42

XEROX 12-STEP BENCHMARKING PROCESS

Phase 1: Planning

1. Identify what to benchmark;

2. Identify comparative companies;

3. Determine data collection method & collect data.

Phase 2: Analysis

4. Determine current performance gap;

5. Project future performance levels.

Phase 3: Integration

6. Communicate finding and gain acceptance;

7. Establish functional goals.

Phase 4: Action

8. Develop action plans;

9. Implement specific actions & monitor progress;

10. Recalibrate benchmarks.

Phase 5: Maturity

11. Attain leadership position ;

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 43

12. Fully integrate practices into processes.

ADVANTAGES OF BENCHMARKING

It promotes a thorough understanding of company's processes, strength & weaknesses is well

understood.

2. Saves time and money as known practices are adopted as adopts the practices followed by

superiors competitors rather than invention

3. Identifies non-value added activities and plans for process improvement

4. Enables comparison of performance measures in different dimensions, like Return on assets,

cycle time, delivery time and etc..

5. It focuses on processes and not on products, it is not restricted to a company boundary

6. It allows organizations to set realistic ,new performance targets to do things in a better way

7. It defines specific gaps in performance and to select that process for improvement, and

redesigning the process

8. It provides a basis for training human resources

9.Brings in new changes and ideas.

10.It is a ongoing system.

11. It helps to set goals with reference to external perspective.

LIMITATIONS OF BENCHMARKING

it focus on the process not the situation.

It creates arrogance against competitors.

Best practices is not static , but a moving target.

Benchmarking is not a panacea (solution) that can replace all other quality efforts

Benchmarking is not a instant pudding. It will not the improve performance , if top

management is not providing all the resources and not adopting quality culture

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 44

KAIZEN AND ITS APPLICATIONS

Kaizen is a Japanese word for improvement, change for the better, or continuous

improvement.

the concept of Kaizen has evolved since the 1950s into a business strategy of making

small, but continuous changes for the better in company operations.

These changes can range from manufacturing steps to productivity, inventory or quality

control matters.

Kaizen involves every employee and strongly encourages suggestions for improvements

5S Kaizen Principles

Seiri means to straighten up

Seitonmeans putting things in order

Seisomeans to clean up

Seiketsumeans personal cleanliness

Shitsukemeans discipline.

Seiri means to straighten up /sort /clear out

Differentiate between the necessary and unnecessary and discard the unnecessary

It includes

Work in process

Unnecessary tools

Unused machinery

Defective products.

Papers and documents

Seitonmeans putting things in order/Set Things in Order

Keep the things in order so that they are ready to use when required.

This avoids waste of time due to searching for things like tools, parts, components.

everything should be at its place and there should be place for everything

Seisomeans to clean up /clean and shine

keep the work place clean

Every individual should clean the workplace every day before starting the days work

and also at the time of closing the work

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 45

Seiketsumeans personal cleanliness/Standardize

Having good housekeeping practices by personal attention to personal cleanliness

Shitsukemeans discipline.

Every worker and manager has to follow procedures in the work place with discipline.

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 46

Module 4

Business Process Re-engineering (BPR) Introduction, Need for BPR, Implementing BPR, Steps

in BPR, Re-engineering vs. TQM, BPR Vs. Kaizen, Re-engineering the structure, change

management and BPR, BPR and IT, Advantages and Limitations, Indian examples of BPR

OBJECTIVE

To understand the meaning of Business Process Re-engineering (BPR) & Introduction,

To realize the Need for BPR,

To explore the process of BPR Implementation & Steps in BPR,

To differentiate between Re-engineering vs. TQM,

To distinguish between BPR Vs. Kaizen,

To appreciate the need for Re-engineering the structure, change management and BPR,

To understand the relation among BPR and IT,

To recognize the advantages and Limitations of BPR,

To discuss Indian examples of BPR

INTRODUCTION TO BPR

Customer satisfaction has increasingly become the cardinal principle governing any successful

business

Despite emphasis on customer satisfaction, there has been complaints and disappointment , the

reasons for this lies in the process and systems

In many cases, present systems can no longer be fixed and improvements are not sufficient

Hence reengineering of the entire system is needed.

Michael Hammer of the US coined the term re-engineering .

the fundamental rethinking and radical design of business processes to achieve dramatic

improvements in critical contemporary measures of performance such as cost, quality, service and

speed

It is also known as process reengineering or business process re-engineering

It involves asking basic questions about business processes why do we do it? Why it is done in

this way?

Radical redesigning involves tossing out existing procedures and reinventing the process.

The goal is to achieve quantum leaps in performance

Principles of BPR

Rule 1: Organise around outcomes, not tasks

Rule 2: Have those who use the output of the process perform the process (work should be

carried where it is)

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 47

Rule 3: Merge information processing work into real work that produces the information

Rule 4: Treat geographically dispersed resources as though they work centralized

Rule 5: Link parallel activities instead of integrating their results

Rule 6: Put the decision point where the work is performed and build control into the process

Rule 7: Capture information once-at the source

NEED FOR BPR

Develop business vision and process objectives

Identify processes to be redesigned

Understand and measure existing processes

Identify information technology levels

Design and build a prototype of the process

THE IMPLEMENTATION OF BUSINESS PROCESS REENGINEERING

As more organizations undertake business process reengineering (BPR), issues in implementing

BPR projects become a major concern. This field research seeks empirically to explore the

problems of implementing reengineering projects and how the severity of these problems relates

to BPR project success. Based on past theories and research related to the implementation of

organizational change as well as field experience of reengineering experts, a comprehensive list

of sixty-four BPR implementation problems was identified. The severity of each problem was

then rated by those who have participated in reengineering in 105 organizations. Analysis of the

results clearly demonstrate the central importance of change management in BPR

implementation success. Resolutions of problems in other areas as technological competence and

project planning were also determined to be necessary, but not sufficient, conditions for

reengineering success. Further, problems that are more directly related to the conduct of a project

such as process delineation, project management, and tactical planning were perceived as less

difficult, yet highly related to project success. This situation was also true for human resource

problems such as training personnel for the redesigned process. These findings suggest that

reengineering project implementation is complex, involving many factors. To succeed, it is

essential that change are more contextual (e.g., management support and technological

competence) as well as factors that pertain directly to the conduct of the project (e.g., project

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 48

management and process delineation). As one of the first pieces of empirical evidence based on a

field study, this research emphasizes the importance of addressing BPR implementation within

the broader context of organizational change in a complex sociotechnical environment.

IMPLEMENTING BPR, STEPS IN BPR

Step 1: Formulate / Modify business visions, policies, objectives

Step 2: Formulate / Modify business strategies according to changing customer requirements,

technology changes and competition

Step 3: Analyze the existing business process cycles & workflows and determine how they may

be modified or refined

Step 4: Apply IT to setup an optimal Business Information Management Architecture (BIMA) to

support the reengineered business process

Step 5: Modify or redesign the existing processes according to the reengineering strategies and

develop refined Business Process Automation Systems (BPAS)

Step 6: Apply IT strategies to map BIMA onto an Enterprise Information Management System

(EIMS) that is integrated across the enterprise and that fits into and supports the reengineered

Business process cycles and workflows.

Step 7: Integrate the EIMS with the BPAS to build up the completed reengineered business

system

Understanding

the process

Stream-

lining

Measurement

& controls

Continuous

improvements

Understanding

the process

Understanding

the process

Understanding

the process

Understanding

the process

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 49

Step 8: Repeat steps 1-7 for continuous BPR due to changing customer demands, technology

changes and business strategies, which leads to business stability

Reengineering in a service industry

Make the customer the starting point for change

Design work processes in light of organizational goals

Restructure to support frontline performance

3 Rs of reengineering

Rethink: this phase requires examining the organizations current objectives and underlying

assumptions to determine how well they incorporate the renewed commitment to customer

satisfaction

Redesign: This phase requires an analysis of the way the organization produces the products

or services it sells-how jobs are structured, who accomplishes what tasks and the results of each

procedure. Which element to be redesigned is determined to make the customer satisfied.

Retool: This phase requires a thorough evaluation of the current use of advanced

technologies, especially electronic data processing systems, to identify opportunities for

change that can improve quality of services and customer satisfaction

RE-ENGINEERING VS. TQM

It is very important to understand that Reengineering is not a separate discipline. It is, in fact, a

subset of TQM. The essential difference between (Business Process) Reengineering and TQM is

that reengineering aims at quantum gains on the order of 30 to 50 percent or more, whereas Total

Quality Management programs stress incremental progress, striving for inch-by-inch gains again

and again.

The two approaches to improve performance are not mutually exclusive; it makes sense to use

them in tandem. Reengineering can be used to first produce good basic design that dramatically

improves a business process. Total quality programs can be used to work out bugs, perfect the

processes, and gradually improve both efficient and effectiveness.

Such two-pronged approach to implementing organizational and strategic change is like a

marathon race where you run fast four laps as fast as you can, then gradually pick up speed the

remainder of the way.

Both TQM and BPR are customer-oriented. They both aim on improving the customer

satisfaction. Also, they both suggest thinking outside in. On the other words, they both suggest to

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 50

think from the customer's viewpoint. Also, both TQM and BPR are process-oriented. They both

target to alter the processes, but not just on the product. Moreover, they both take team approach.

Nearly all BPR projects are initiated by top-down approach. Since BPR would results great

changes, staff resistance is obvious. Therefore, top management's support and commitment are

very important. For TQM, both top-down approach and bottom-up approach are possible.

The basic assumptions of TQM and BPR are different. TQM assumes that the existing practices

or systems are principally right and useful. The target of TQM is to improve on the basis of the

existing system. However, BPR takes an opposite assumption. BPR assumes the existing system

is useless and suggests starting it over. Unlike TQM that aims on smoothly and incremental

improvements, BPR aims on dramatic results.

TQM emphasis on total involvement, including all the stakeholders. The involvement even

extends to suppliers and customers. Also, TQM also suggests involving all the processes in the

company, including human resources management, order fulfilling, manufacturing, marketing

and customer management and others. However, for BPR, the project can be controlled to a

specified area only.

Standardization is one of the key points of TQM. TQM aims on standardize the practices, thus

achieving a consistent performance. It also makes that there is a certain degree of documentation

for TQM. However, BPR emphasis on flexibility and believes that standardization would

increase the complexity of the process. Therefore, standardization is rare in BPR and the level of

documentation is much lower.

TQM emphasis on the use of statistical process control. However, there is no similar concern for

BPR. On the other hand, BPR emphasis more on the enabling role of information technology.

TQM is a cultural issue. Once the culture is built, TQM is absorbed in the daily operation.

However, BPR is a project. It is with a clear target that should be achieved as soon as possible.

In fact, BPR is a risky project that is suitable for organizations in deep trouble or facing great

challenges. However, an organization cannot always be under BPR. TQM, on the other hand, can

be treated as a consolidation approach for the organizations to maintain continuously

improvements.

BPR VS. KAIZEN

BPR assumes lack of processes as the basis of change that might not be true in all cases.

Kaizen accepts current state of processes and works towards gradual improvement.

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 51

BPR starts the process of improvement from a clean slate, i.e. totally ignore current status

as opposed to kaizen.

BPR is hard to implement, technology oriented and requires and considerable change

management ,opposed to kaizen which is simpler, people oriented and long term oriented.

RE-ENGINEERING THE STRUCTURE

Restructuring the firm consists of altering its decision-making, operating divisions, and

management culture. Reengineering entails changing the procedures by which the work is

accomplished and products delivered.

Process restructuring, as championed by Michael Hammer and James Champy in their

Reengineering the Corporatio, can deliver costs reductions of 50 percent or more. Corporate

restructuring, as portrayed by John Womack and colleagues in The Machine that Changed the

World, also suggest a law of halves. Womack and his colleagues studied the Japanese

automobile industry, and their research revealed that Toyota and other makers by applying the

principles of teamwork, quality control, customer focus, minimal buffers and continuous

improvement had cut product defects by half, factory space by half, work-time by half, and

development time by half.

While diversification had been a hallmark of good management during the 1960s, shedding

unrelated business had become the measure during the 1980s and 1990s. De-diversification,

back to basics, and a return to core competencies emerged as restructuring drivers for good

reason. More focused firms, as Robert Hoskisson and Michael Hitt show in Downscoping,

display superior performance.

Restructuring actions taken in single areas tend to achieve few enduring gains. Downsizing the

workforce generates short-term cost savings, but in the absence of a broader reorganization, it

brings only temporary relief. Reengineering business process creates immediate gains, but the

gains are short-lived without changes in performance measures, compensation incentives,

information technologies, employee skills, and organizational structure. Restructuring and

reengineering, then, should be seen as a multi-faceted revamping of the corporation.

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 52

Company restructuring has both worsened and improved the lot of those who work there. Lean

redesigns, cost reductions, and repeated downsizings have terminated careers and decimated

communities. At the same time, reengineering, flexible work, and streamlined hierarchies have

improved employee productivity and product quality. The process of restructuring frequently

brings long work weeks and high stress levels, but the product of restructuring also often results

in greater autonomy and more challenging work. One study of restructuring experience revealed

heightened loads, diminished morale, and reduced employee commitment, but it also found

enhanced quality, customer service, risk taking, workforce competence, and productivity.

The dual impact of corporate restructuring on those who experience and manage it accounts for

some of the schizophrenia toward restructuring. Work environments can be filled with high

anxiety and low morale. At the same time, however, the quality of work life often improves,

with more variety, responsibility, and teamwork. Executives experience stress as they manage

the transformation, but in doing so they are also laying a framework for improved company

performance, richer compensation packages, and enhanced shareholder return.

CHANGE MANAGEMENT AND BPR

BPR is all about the process. Change Management is all about the people.

In a BPR context, unless you've completely automated the process then you won't get 100% of

your ROI until 100% of the people involved have internalized the new process! One of the key

reasons that many Hammer and Champy style BPR initiatives failed miserably was that their

total focus was on the Q component, to the exclusion of the A component. Alas, for most

business initiatives you don't get dollar one of ROI until somebody's behavior changes. I

won't repeat the most excellent rant extended polemic of the previous post, but there's more

discussion of the topic there if you're interested.

All of these three terms relate to change, but to different levels and types of change. The problem

with the fuzzy definitions is that it leads to people applying the wrong practice to their business

challenge. Its like someone saying, We need to dig a tunnel from England to France; let me get

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 53

my Black & Decker rechargeable drill. Or equally bad, We need to place a screw in the living

room wall to hang a mirror; hold on while I get the dynamite.

Change Management, Process Reengineering and Corporate Transformation are clearly diffent.

They are distinct processes, require special capabilities, and are applied in different ways.

Change Management is geared towards communications and training on some specific shift in

the use of an information system or process.

Business Process Reengineering (BPR) relates to taking an entire end-to-end business process,

like billing and collecation or sales as examples, breaking it down to component steps,

realignigng the steps to be more efficient and effective, and implmenting the new process. The

implementation of BPR projects typically entail major systems changes and significant changes

to the organization and how business is conducted.

Corproate Transformation is more focused on changing the business overall. A transformation

effort is centered on clarifying the corporate strategy and putting a process and discipline in

place to drive strategy execution, alignment of the orgnaization and disciplined follow through

for performance.

The most common mistake we see in selecting the right tool for change is underestimating the

level of change that is being called up. What may seem to management as a minor tweak in

business process is often received by sales and operations as a major shift that is disruptive to the

daily operations and requires much more preparation and considerations to accomplish. My

ChangeThis artice titled, People Dont Hate Change, They Hate How Youre Trying to Change

Them became one of the fastest downloaded pieces on their site. The team at ChangeThis said

that they knew that trying to get corporate change right was one of the biggest frustrations people

have and so this was no surprise to them.

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 54

BPR AND IT

IT has penetrated the office and services environment since the 1978.The shift from mainframe

to PC based technology is breaking down communication barriers between employees and

customers. Now managers and employees from various departments are designing and

controlling complex business information systems. IT capabilities involve improving information

access and coordination across organizational units. It is so powerful that it can actually create

new process design options, rather than simply support it. In his book, Business the Speed of

Thought, Bill Gates argues that if the 1980s were about quality and the 1990s were about

reengineering, then the 2000s will be about velocity. Gates advocates complete digitalization of

all aspects of life. He argues that to be successful in the digital age, companies need to develop a

new digital infrastructure similar to the Human nervous system. This new digital system enables

companies to run smoothly and efficiently, makes them respond quickly to emergencies and

opportunities, provides a mean for quickly getting valuable information to the people in the

company who need it. This in turn empowers employees to make decisions and interact with

customers .What is the Relation between BPR & Information Technology? Hammer considers IT

as the key enabler of BPR . Davenport & Short argue that BPR requires taking a broader view of

both IT and business activity, and of the relationships between them. IT capabilities should

support business processes, and business processes should be in terms of the capabilities IT can

provide. They believe IT's promise and its ultimate impact is to be the most powerful tool for

reducing the costs of coordination .It has been argued that innovative uses of IT would inevitably

lead many firms to develop new, coordination -intensive structures, enabling them to coordinate

their activities in ways that were not possible before. Such coordination -intensive structures may

lead to strategic advantages.

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 55

IT Roles in Initiating and Sustaining Reengineering

Before the Process Design

During the Process Design

During the Implementation

Create infrastructures and

manage information that

support evolving organization

Bring vast amounts of

information into the process

Create a digital feedback

loop

Foster process thinking in

organizations

Bring complex

analytical

methods to bear on the process

Establish resources for

critical evaluation of the

reengineered process

Identify and select process for

redesign

Enhance employees ability to

make more informed decisions

with less reliance on formal

vertical information flows

Improve IT processes to

meet increasing needs of

those divisions that have gone

under reengineering

processes

Participate in predicting the

nature of change and

anticipate the information

needs to support that change

Identify enablers for process

design

Institute a program of

cleanup and damage

control in case of failure

Educate IT staff in non

- technical issues such as

marketing, customer

relationships, etc.

Capture the nature of proposed

change and match IT strategy to

that change

Communicate ongoing results

of the BPR effort

Participate in designing

measures of success/ failures

of reengineering

Capture and disseminate

knowledge and expertise to

improve the process

Help to build commitment to

BPR

Communicate ongoing results

of the BPR effort

Evaluate the potential

investment and return of

reengineering efforts

Transform unstructured

processes into reutilized

transactions

Reduce/replace labor in a

process

Define clear performance goals

TOTAL QUALITY MANAGEMENT 12MBA42

DEPT OF MBA,SJBIT Page 56

and objectives to drive the

implementation

Define the boundaries and

scope of the process

ADVANTAGES OF BPR

1. Organization can achieve radical changes in performance by cost , cycle time, service and quality

2. It boosts competitiveness in the operations through simpler, leaner and more productive processes

3. Encourages organization to problem solving thinking approach

4. It helps organizations to make noticeable changes in the pace& quality to respond to customer

needs

5. An organization can be transformed from rule driven organization to a marketing structured

organization to focus on customer

6. It helps to get better market share and profitability

7. Workers are encouraged to make suggestions and creates a TQM culture

8. It helps in creating challenging and more rewarding jobs with broader responsibilities

LIMITATIONS OF BPR

1. It is not a panacea, application of it matters a lot.