Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Antibacterial Properties of Silver-Doped Titania

Cargado por

hesamalaTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Antibacterial Properties of Silver-Doped Titania

Cargado por

hesamalaCopyright:

Formatos disponibles

Antibacterial surfaces

DOI: 10.1002/smll.200600481

Antibacterial Properties of Silver-Doped

Titania**

J. Thiel, L. Pakstis, S. Buzby, M. Raffi, C. Ni,

D. J. Pochan, and S. Ismat Shah*

Silver has been known to exhibit strong cytotoxicity towards

a broad range of micro-organisms. Silver composites with a

tailored slow silver-release rate are currently being investi-

gated for various applications.

[1]

Silver has an oligodynamic

effect, that is, silver ions are capable of causing a bacterio-

static (growth inhibition) or even a bactericidal (antibacte-

rial) impact. Nanometer-sized inorganic particles and com-

posites display unique physical and chemical properties and

represent a unique class of materials in the development of

novel devices, which can be used in numerous physical, bio-

logical, biomedical, and pharmaceutical applications.

[2]

Silver composites have applications in many industries, such

as aerospace, surface coatings (e.g. , in refrigerators, food

processing, kitchen furniture), and for use in hospitals. Re-

search indicates that silver is also effective in purification

systems for disinfecting water or air.

[36]

However, in order

to make the use of silver economical, there is a need to find

cheaper ways of using silver in potential applications with-

out jeopardizing its functionalities.

The bactericidal behavior of silver nanoparticles is at-

tributed to the presence of electronic effects, which are a

result of the changes in the local electronic structure of the

surfaces of the smaller-sized particles. These effects are con-

sidered to be contributing towards an enhancement of the

reactivity of silver-nanoparticle surfaces. It has been report-

ed that ionic silver strongly interacts with thiol groups of

vital enzymes and inactivates them. It has been suggested

that DNA loses its replication ability once the bacteria have

been treated with silver ions.

[1]

Two-dimensional (2D) elec-

trophoresis and protein-identification analyses of the anti-

bacterial action of silver nanoparticles have revealed an ac-

cumulation of envelope-protein precursors. Silver nanoparti-

cles target the bacterial membrane, which leads to the de-

stabilization of the plasma-membrane potential and the de-

pletion of the levels of intracellular adenosine triphosphate

(ATP), resulting in bacterial cell death.

[7]

Bacteria cells grow by a process called binary fission in

which one cell doubles in size then splits in half to produce

two identical daughter cells.

[8]

If a bacterial population in an

environment is without any growth restrictions by nutrient

or metabolic products, the number of bacteria increases as

an exponential function of time.

[9]

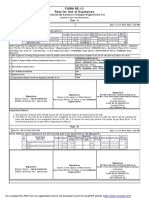

Bacterial growth can be

depicted generally by the growth curve shown in Figure 1.

There is always a lag phase, where bacteria adapt them-

selves to the growth media and conditions. During this

period, individual bacteria mature but they are not yet able

to divide themselves. At the log or exponential phase, indi-

vidual bacteria reproduce at their maximum rate; there is

no restriction by nutrient or metabolic products. During the

stationary phase, the growth rate declines and finally growth

ceases due to the depletion of nutrients. This phase is

reached as the bacteria begin to exhaust the resources that

are available to them. At the death phase, bacteria run out

of nutrients and begin to die.

[8]

The bacterial cell colonies on agar plates are detected

by viable cell counts, while in the solution the bacteria con-

centration affects the optical density of the solution, which

can be monitored by optical techniques. Viable cell counts

are the counted number of colonies that have developed

after a sample has been diluted and spread over the surface

of a nutrient medium solidified with agar and contained in a

petri dish. Biomass in a nutrient culture medium is usually

estimated from the turbidity. Liquid cultures are turbid be-

cause microbes have a higher refractive index than water

and, thus, they scatter light. The turbidity can be measured

by the attenuation of light as a result of scattering from a

liquid-culture sample.

[9]

Figure 1. Growth curve of E. coli bacteria.

[*] J. Thiel

Department of Ceramic Materials and Components

University of Bremen

28195 Bremen (Germany)

Dr. L. Pakstis, S. Buzby, M. Raffi, Dr. C. Ni, Prof. D. J. Pochan,

Prof. S. I. Shah

Department of Materials Science and Engineering

University of Delaware

Newark, DE 19716 (USA)

M. Raffi

Department of Chemical and Materials Engineering

Pakistan Institute of Engineering and Applied Sciences

Islamabad, 45650 (Pakistan)

Prof. S. I. Shah

Department of Physics and Astronomy

University of Delaware

Newark, DE 19716 (USA)

Fax: (+1) 302-831-4545

E-mail : ismat@udel.edu

[**] The authors acknowledge NSF-NIRT Grant No. DMR-0210284 for

the funding of this project.

small 2007, 3, No. 5, 799 803 2007 Wiley-VCH Verlag GmbH&Co. KGaA, Weinheim 799

This study is aimed at the synthesis and characterization

of silver-doped titania nanoparticles by the solgel tech-

nique. Experimental results of synthesis and characteriza-

tion of silver-doped titania particles and their antibacterial

properties and kinetics of cytotoxicity are presented. The

solgel synthesis technique is a promising low-temperature

route that provides good homogeneity and control over the

concentration and distribution of dopants in the matrix for

the preparation of nanocomposites. Both the metallic

dopant and the oxide matrix develop simultaneously in this

process, which leads to a uniform dopant distribution

throughout the nanoparticles. Nanoparticle agglomeration is

inhibited in the network matrix, thus limiting the particle

size. Annealing of metal oxide composites is an important

step since the size, distribution, and number density of the

nanoparticles are dependent on the annealing temperature,

environment, and duration.

[10]

The antibacterial effect of our nanoparticles was tested

against Escherichia coli (E. coli) bacteria both in liquid-nu-

trient growth medium and on agar plates. The antibacterial

efficacy was determined by using pure titania nanoparticles

and silver-doped titania nanoparticles. The results were

compared against those of pure silver nanoparticles. Silver

atoms in silver-doped titania nanoparticles continuously in-

teract with the bacterial cells and thus they exhibit an excel-

lent toxicity against the E. coli bacteria.

Antibacterial studies were carried out on silver-doped ti-

tania samples that had been annealed in air at 6008C for

one hour. The X-ray diffraction (XRD) patterns of the sam-

ples annealed at 6008C are shown in Figure 2. For the sam-

ples with silver-dopant concentrations of 0.0, 0.39, and

0.72 atom% silver, titania was found to be in the purely

anatase phase. However, as can be seen in Figure 2, samples

doped with 1.01 atom% silver show the beginning of the

transformation from the anatase phase to the rutile phase,

which is the most stable phase in bulk titania. The recorded

XRD patterns were analyzed so as to determine the intensi-

ty, position, and width of the peaks. Full width at half-maxi-

mum (FWHM) data was used along with Scherrers formula

to determine the average particle size. Scherrers formula is

given by:

t

0:9l

b cos q

1

where l is the X-ray wavelength, b is the FWHM and q is

the Bragg diffraction angle.

[11]

Figure 3 shows the average

particle size for anatase titania, as determined by Scherrers

formula, as a function of doping concentration. Transmission

electron microscopy (TEM) images of each of the four sam-

ples (0.0, 0.39, 0.72, and 1.01 atom% silver) are shown in

Figure 4. Although the size distribution of each of the sam-

ples was large, the average particle sizes match with those

calculated from the XRD data.

The average particle size of the silver-doped titania

nanoparticles decreased as the dopant concentration was in-

creased from 0.0 to 0.72 atom% silver. However, as the

dopant concentration increased further to 1.01 atom%

silver, the average particle size started to increase. The

amorphous-to-anatase-to-rutile phase transformations of ti-

tania are known to be nucleation and growth processes

during which nuclei that are formed at the grain boundaries

grow in size with increasing temperature. The addition of

dopant ions causes grain-boundary pinning in which grain

growth is limited by the symmetry-breaking effects of the

dopant at the boundary, resulting in smaller particle sizes.

[10]

As the anatase-to-rutile transformation begins, as is ob-

served in the case of 1.01 atom% silver dopant, adjacent

anatase particles begin to coalesce by diffusion of atoms to

form larger anatase particles before converting to the rutile

phase.

[12, 13]

The optical density of the liquid-nutrient growth

medium as a function of time is shown in Figure 5. The in-

crease in the optical density reflects the amount of bacterial

cell growth in the sample. Neither the pure titania nor the

0.39 atom% silver-doped titania showed any inhibition

effect on the bacteria density at either of the test concentra-

Figure 2. XRD patterns of 0.0, 0.39, 0.72, and 1.01 atom% silver-

doped titania, annealed at 6008C.

Figure 3. Average particle size versus doping concentration for ana-

tase titania annealed at 6008C.

800 www.small-journal.com 2007 Wiley-VCH Verlag GmbH&Co. KGaA, Weinheim small 2007, 3, No. 5, 799 803

communications

tions of 1.5 g and 10 g per 130 mL of solution. Similarly, nei-

ther the 0.72 nor the 1.01 atom% silver-doped titania sam-

ples had an effect on the bacterial growth patterns when

1.5 g of these were added in

the flask. However, as the

amount of silver-doped tita-

nia particles added to the

bacterial culture solution was

increased to 10 g per 130 mL

of solution in each flask, the

inhibitory effect on the bac-

terial growth was apprecia-

ble. After an incubation

period of 45 min, bacterial

growth in the flasks contain-

ing 10 g of particles declined

sharply. It was observed that

in the flasks containing 10 g

of 1.01 atom% silver-doped

titania particles 30% of bac-

terial cells survived, whereas

for the flasks incubated with

10 g of 0.72 atom% silver-

doped titania, there was

complete bacterial inhibition.

No further changes in the

growth patterns were noticed

in the remaining observation

period.

The effect of 0.39, 0.72,

and 1.01 atom% silver-doped

titania particles and that of

pure silver on colony-form-

ing units (CFUs) of E. coli

observed on agar plates as a

function of particle concen-

tration is shown in Figure 6.

As expected, the number of

CFUs decreased as the silver-doped titania particle concen-

tration was increased from 0.00 to 50.95 mgcm

2

. At concen-

trations above 25.46 mgcm

2

there was no notable bacterial

growth on the agar plates spread with 0.72 and 1.01 atom%

Figure 4. TEM images of a) 0.0, b) 0.39, c) 0.72, and d) 1.01 atom% silver-doped titania.

Figure 5. Antibacterial effect of 0.0, 0.39, 0.72, and 1.01 atom%

silver-doped titania in solution.

Figure 6. Antibacterial effect of 0.0, 0.39, 0.72, and 1.01 atom%

silver-doped titania and pure silver on agar plates.

small 2007, 3, No. 5, 799 803 2007 Wiley-VCH Verlag GmbH&Co. KGaA, Weinheim www.small-journal.com 801

silver-doped titania and pure Ag samples. However, while

the amount of observed CFUs on the 0.39 atom% silver-

doped titania samples steadily decreased, even at sample

concentrations of 50.95 mgcm

2

, at least 10% of the bacteria

still survived. Therefore, it may be concluded that

0.39 atom% silver-doped titania inhibited bacterial growth

but did not have a complete toxic effect on the E coli bac-

teria. It is remarkable that pure silver has a lower effect on

the bacteria than the two titania samples with the higher

doping concentrations. In all the investigated cases, the

0.72 atom% silver-doped samples were more effective than

the 1.01 atom% silver-doped samples. The probable reason

for samples with a lower concentration of silver being more

effective is the difference in the particle sizes of the samples.

As can be seen from Figure 3, the 0.72 atom% silver-doped

titania sample has a much smaller average particle size

(25.7 nm) than the 1.01 atom%-doped sample (47.1 nm).

This can be translated into a larger surface-to-volume ratio

with less particle agglomeration (Figure 4c and d). This re-

sults in a more efficient bactericidal behavior as more silver

atoms are available at the surface of the particle, thus giving

a higher antibacterial efficacy against E. coli bacteria.

Bacteria have different membrane structures on which

their Gram-positive or Gram-negative classifications are

based. The membranes structural differences lie in the or-

ganization of a key component known as peptidoglycan.

Gram-negative bacteria including E. coli exhibit only a thin

peptidoglycan layer (ca. 23 nm) between the cytoplasmic

membrane and the outer membrane. We believe that when

the silver-doped titania particles were dispersed in the

growth media the silver atoms present in these particles in-

teracted with the bacterial cells and adhered to the bacterial

cell walls. The overall charge on the bacterial cell surface at

biological pH values is negative, which is due to the excess

number of carboxylic and other groups that upon dissocia-

tion make the cell surface negative.

[14]

The bacteria and the

silver atoms in the nanoparticles have opposite charges, and

these electrostatic forces may be the reason for their adhe-

sion and bioactivity.

Silver-doped titania particles have been demonstrated to

be useful and effective in bactericidal applications and pres-

ent a reasonable alternative for the development of new

bactericides. Silver-doped titania nanoparticles with silver-

doping concentrations from 0.0 to 1.01 atom% silver and

grain sizes ranging between 26 nm and 56 nm were synthe-

sized via a solgel technique and studied against E. coli in

order to gain an understanding of their antibacterial proper-

ties. Both solution and agar-plate studies concluded that

pure titania had no antibacterial effect and that the

0.72 atom% silver-doped samples were most effective, even

more effective than pure silver nanoparticles of similar size.

It was observed that with concentrations as low as

25 mgcm

2

of silver-doped titania, surfaces that are com-

pletely antibacterial may be synthesized.

Experimental Section

A solgel technique was used to synthesize homogenous

silver-doped titania nanoparticles. To synthesize silver-doped ti-

tania particles, silver acetylacetonate was used as the silver pre-

cursor and Ti(IV) chloride as the titanium precursor. The silver

precursor was first dissolved in ethanol then Ti(IV) chloride was

added dropwise to this solution. During the addition of the tita-

nium precursor the temperature of the resultant solution in-

creased and gas evolution began. When the addition was com-

pleted the resulting yellow-colored solution was allowed to rest

in a fume hood until the solution returned to room temperature

and all gas evolution stopped. This solution was then placed

into a furnace and dried in air at 808C for 24 h. The concentra-

tion of the silver dopant in various samples was controlled stoi-

chiometrically by varying the amount of the silver precursor dis-

solved in ethanol. Composite samples with target compositions

of 0.0, 0.5, 1.0, and 1.5 atom% silver were prepared. After

drying, the samples were annealed in air for one hour at 6008C.

The silver concentrations of the doped titania samples were de-

termined by X-ray photoelectron spectroscopy (XPS) analysis em-

ploying Al Ka (hn=1486.6 eV) excitation radiation. The peak po-

sitions were internally referenced to the C 1s peak at 284.6 eV.

Figure 7 shows the XPS survey spectrum of the 0.72 atom%

silver-doped titania nanoparticles. As expected, only peaks asso-

ciated with Ti (3p, 3s, 2p, 2s), O (2p, 2s, 1s), Ag (3d), and C (1s)

were observed. The silver concentrations were determined from

the Ag 3d peak area from the survey scans and were found to be

0.0, 0.39, 0.72, and 1.01 atom% silver. The inset of Figure 7

shows the high-resolution XPS spectrum of the Ag 3d region of

the 0.72 atom% silver-doped titania sample. Both the positions

(367.81 and 373.82 eV) and the separation (6.01 eV) of the

peaks indicate that silver is present in metallic form (Ag

0

).

[15]

The antibacterial efficacy of silver-doped titania particles,

both in liquid-nutrient growth medium and on agar plates was

Figure 7. XPS survey spectrum of 0.72 atom% silver-doped titania.

Inset: high-resolution XPS spectrum of the Ag 3d region.

802 www.small-journal.com 2007 Wiley-VCH Verlag GmbH&Co. KGaA, Weinheim small 2007, 3, No. 5, 799 803

communications

studied. E. coli bacteria (BL 21), frozen in glycerol at 808C and

2xYT media (5 g NaCl, 2.5 g yeast extract, and 5 g tryptone, dis-

solved in 500 mL distilled water), were used for both studies.

Frozen bacteria cells were grown overnight in a nutrient medium

to prepare cultures for the solution studies. The prepared cell

culture (125 mL) was then added to a nutrient solution (5 mL)

containing ampicillin and chloramphenocol (5 ml). These bacteria

cultures were then incubated in the dark in the presence of

silver-doped titania nanoparticles of each of the dopant concen-

trations and using two different quantities (1.5 g and 10 g), inde-

pendently. The bacteria cultures were allowed to grow in a

shaker incubator at 378C and 200 rpm for 5.5 h. Shaking provid-

ed the bacteria aeration and homogeneity. The bacteria were

healthiest at mid log phase (Figure 1). The optical density of so-

lution was measured every 30 min by use of a UV/Vis spectro-

photometer at a wavelength of 600 nm. Control flasks were used

containing growth medium, bacterial culture, and titania nano-

particles only. Agar was added to the nutrient solution to make

plates. After autoclaving the solution, it was poured and solidi-

fied in petri dishes. The silver-doped titania samples at concen-

trations of 0.00, 1.27, 3.18, 6.37, 25.46, and 50.95 mgcm

2

were mixed with the bacterial solution and spread on the plates.

Samples of 0.0, 0.39, 0.72, and 1.01 atom% silver-doped tita-

nia, as well as pure silver nanoparticles with an average particle

size of 15 nm were used. After completion of spreading, all petri

dishes were incubated in the dark at 378C for 24 h and the

number of CFUs was counted. Experiments were performed in

triplicate and sterile conditions were maintained.

Keywords:

bacteria doping nanoparticles sol-gel processes

titania

[1] J. R. Morones, J. L. Elechiguerra, A. Camacho, Nanotechnology

2005, 16, 23462353.

[2] I. Sondi, B. S. Sondi, J. Colloid Interface Sci. 2004, 275, 177

182.

[3] C. Baker, A. Pradhan, L. Pakstis, D. J. Pochan, I. Shah, J. Nano-

sci. Nanotechnol. 2005, 5, 244249.

[4] The Silver Institute at http://www.silverinstitute.org

[5] S. Zhang, R. Fu, D. Wu, Carbon 2004, 42, 32093216.

[6] G. J. Chi, S. W. Yao, J. Fan, Surf. Coat. Technol. 2002, 157, 162

165.

[7] C. Lok, C. Ho, R. Chen, J. Proteome Res. 2006, 5, 916924.

[8] J. Lederberg, Encyclopedia of Microbiology, Academic Press, San

Diego, CA 2000.

[9] K. A. Farrell, Masters Thesis, Worcester Polytechnic Institute,

Worcester, UK 2001.

[10] A. Burns, G. Hayes, W. Li, J. Hirvonen, J. D. Demareed, S. I.

Shah, Mater. Sci. Eng. B 2004, 111, 150155.

[11] B. D. Cullity, Elements of X-ray Diffraction, Addison-Wesley Pub-

lishing Company, Reading, MA 1978.

[12] H. Zhang, J. F. Banfield, Chem. Mater. 2002, 14, 41454154.

[13] H. Zhang, J. F. Banfield, J. Mater. Chem. 1998, 8, 20732076.

[14] P. K. Stoimenov, R. L. Klinger, G. L. Marchin, Langmuir 2002, 18,

66796686.

[15] C. D. Wagner, W. M. Riggs, L. E. Davis, J. F. Moulder, G. E. Muilen-

berg (Ed), Handbook of X-ray Photoelectron Spectroscopy,

PerkinElmer, Eden Prairie, MN 1979.

Received: September 8, 2006

Revised: January 25, 2007

Published online on March 6, 2007

small 2007, 3, No. 5, 799 803 2007 Wiley-VCH Verlag GmbH&Co. KGaA, Weinheim www.small-journal.com 803

También podría gustarte

- Ni HardMaterialDataandApplications 11017 PDFDocumento28 páginasNi HardMaterialDataandApplications 11017 PDFhesamalaAún no hay calificaciones

- Ni HardMaterialDataandApplications 11017 PDFDocumento28 páginasNi HardMaterialDataandApplications 11017 PDFhesamalaAún no hay calificaciones

- True WestDocumento63 páginasTrue WestJared BoyceAún no hay calificaciones

- Synthesis and Photoluminescence of Well-Dispersible Anatase TiO2 NanoparticlesDocumento6 páginasSynthesis and Photoluminescence of Well-Dispersible Anatase TiO2 NanoparticleshesamalaAún no hay calificaciones

- Lam ParterDocumento23 páginasLam ParterhesamalaAún no hay calificaciones

- People Courses 5 PhysProcediaDocumento8 páginasPeople Courses 5 PhysProcediahesamalaAún no hay calificaciones

- What Is Sputtering PDFDocumento3 páginasWhat Is Sputtering PDFhesamalaAún no hay calificaciones

- Nano ZaratDocumento16 páginasNano ZarathesamalaAún no hay calificaciones

- People Courses 5 IEEE Nickel Dot ArraysDocumento6 páginasPeople Courses 5 IEEE Nickel Dot ArrayshesamalaAún no hay calificaciones

- J Membrane Science Paper 2009Documento10 páginasJ Membrane Science Paper 2009hesamalaAún no hay calificaciones

- Mechanical Properties of Nano Crystalline MaterialsDocumento130 páginasMechanical Properties of Nano Crystalline MaterialsSingh UmeshAún no hay calificaciones

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (119)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2099)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- Merchandising Calender: By: Harsha Siddham Sanghamitra Kalita Sayantani SahaDocumento29 páginasMerchandising Calender: By: Harsha Siddham Sanghamitra Kalita Sayantani SahaSanghamitra KalitaAún no hay calificaciones

- PESO Online Explosives-Returns SystemDocumento1 páginaPESO Online Explosives-Returns Systemgirinandini0% (1)

- Cushman Wakefield - PDS India Capability Profile.Documento37 páginasCushman Wakefield - PDS India Capability Profile.nafis haiderAún no hay calificaciones

- #3011 Luindor PDFDocumento38 páginas#3011 Luindor PDFcdouglasmartins100% (1)

- Honda Wave Parts Manual enDocumento61 páginasHonda Wave Parts Manual enMurat Kaykun86% (94)

- всё необходимое для изучения английского языкаDocumento9 páginasвсё необходимое для изучения английского языкаNikita Chernyak100% (1)

- Audit Acq Pay Cycle & InventoryDocumento39 páginasAudit Acq Pay Cycle & InventoryVianney Claire RabeAún no hay calificaciones

- Prenatal and Post Natal Growth of MandibleDocumento5 páginasPrenatal and Post Natal Growth of MandiblehabeebAún no hay calificaciones

- Portfolio by Harshit Dhameliya-1Documento85 páginasPortfolio by Harshit Dhameliya-1Aniket DhameliyaAún no hay calificaciones

- Neuropsychological Deficits in Disordered Screen Use Behaviours - A Systematic Review and Meta-AnalysisDocumento32 páginasNeuropsychological Deficits in Disordered Screen Use Behaviours - A Systematic Review and Meta-AnalysisBang Pedro HattrickmerchAún no hay calificaciones

- Experiences from OJT ImmersionDocumento3 páginasExperiences from OJT ImmersionTrisha Camille OrtegaAún no hay calificaciones

- Cold Rolled Steel Sections - Specification: Kenya StandardDocumento21 páginasCold Rolled Steel Sections - Specification: Kenya StandardPEng. Tech. Alvince KoreroAún no hay calificaciones

- MBO, Management by Objectives, Pooja Godiyal, Assistant ProfessorDocumento20 páginasMBO, Management by Objectives, Pooja Godiyal, Assistant ProfessorPooja GodiyalAún no hay calificaciones

- FS2004 - The Aircraft - CFG FileDocumento5 páginasFS2004 - The Aircraft - CFG FiletumbAún no hay calificaciones

- Energy AnalysisDocumento30 páginasEnergy Analysisca275000Aún no hay calificaciones

- Built - in BeamsDocumento23 páginasBuilt - in BeamsMalingha SamuelAún no hay calificaciones

- Ujian Madrasah Kelas VIDocumento6 páginasUjian Madrasah Kelas VIrahniez faurizkaAún no hay calificaciones

- India Today 11-02-2019 PDFDocumento85 páginasIndia Today 11-02-2019 PDFGAún no hay calificaciones

- Column Array Loudspeaker: Product HighlightsDocumento2 páginasColumn Array Loudspeaker: Product HighlightsTricolor GameplayAún no hay calificaciones

- Software Requirements Specification: Chaitanya Bharathi Institute of TechnologyDocumento20 páginasSoftware Requirements Specification: Chaitanya Bharathi Institute of TechnologyHima Bindhu BusireddyAún no hay calificaciones

- Music 7: Music of Lowlands of LuzonDocumento14 páginasMusic 7: Music of Lowlands of LuzonGhia Cressida HernandezAún no hay calificaciones

- QuickTransit SSLI Release Notes 1.1Documento12 páginasQuickTransit SSLI Release Notes 1.1subhrajitm47Aún no hay calificaciones

- Movement and Position: Question Paper 4Documento14 páginasMovement and Position: Question Paper 4SlaheddineAún no hay calificaciones

- Three-D Failure Criteria Based on Hoek-BrownDocumento5 páginasThree-D Failure Criteria Based on Hoek-BrownLuis Alonso SAAún no hay calificaciones

- Origins and Rise of the Elite Janissary CorpsDocumento11 páginasOrigins and Rise of the Elite Janissary CorpsScottie GreenAún no hay calificaciones

- Obstetrical Hemorrhage: Reynold John D. ValenciaDocumento82 páginasObstetrical Hemorrhage: Reynold John D. ValenciaReynold John ValenciaAún no hay calificaciones

- Android software download guideDocumento60 páginasAndroid software download guideRizky PradaniAún no hay calificaciones

- ISO 9001:2015 Explained, Fourth Edition GuideDocumento3 páginasISO 9001:2015 Explained, Fourth Edition GuideiresendizAún no hay calificaciones

- The Berkeley Review: MCAT Chemistry Atomic Theory PracticeDocumento37 páginasThe Berkeley Review: MCAT Chemistry Atomic Theory Practicerenjade1516Aún no hay calificaciones