Documentos de Académico

Documentos de Profesional

Documentos de Cultura

An Experimental Study On The Effect of MIG Welding Parameters On The Weld-Bead Shape Characteristics

Cargado por

tejap314Descripción original:

Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

An Experimental Study On The Effect of MIG Welding Parameters On The Weld-Bead Shape Characteristics

Cargado por

tejap314Copyright:

Formatos disponibles

Welding 3/6/14 parameters on the Weld-Bead Shape Characteristics

This is the html version of the file http://www.estij.org/papers/vol2no42012/12vol2no4.pdf. Google automatically generates html versions of documents as we crawl the web.

Page 1

IRACST Engineering Science and Technology: An International Journal (ESTIJ), ISSN: 2250-3498, Vol.2, No. 4, August 2012

An Experimental Study on the Effect of MIG Welding parameters on the Weld-Bead Shape Characteristics

K. Abbasi

ASET (Mechanical Engg. Deptt.), Amity University Utter Pradesh, Lucknow. Email:kabbasi@rediffmail.com

Abstract In this study the effect of MIG welding parameters on the weld bead and shape factor characteristic of bright drawn mild steel specimen of dimensions 144 31 10 mm has been investigated. T he welding current, arc voltage, welding speed, heat input rate are chosen as welding parameters. T he depth of penetration and weld width were measured for each specimen after the welding operation and effect of welding speed and heat input rate parameters on depth of penetration and weld width were investigated. T he present paper aims at the evaluation of depth of penetration and weld width by employing different MIG welding parameters. Ke y wards: welding current, Arc Voltage, Welding Speed, penetration depth, weld width, shape factor.

S. Alam and Dr. M.I. Khan

Department of Mechanical Engineering, Integral University, Lucknow sfzsa@rediffmail.com & mikyh_20@yahoo.com water tubing for cooling for the torch [11]. In the present work MIG process has been used. The metal inert gas welding process consists of heating, melting and solidification of parent metal and a filler material in localized fusion zone by a transient heat source to form a joint. MIG welding parameters are the most important factors affecting the quality, productivity and cost of welded joint [1]. Metal transfer in MIG welding refers to the process of transferring material of the welding wire in the form of molten liquid droplets to the work-piece [9]. Mild steel is most commonly used form of steel, because it is relatively low in cost, but it provides good material properties, which required for many engineering applications. The input variables directly affect the shape factor. The input variables consider for investigation are as follows: Welding current It is the most important variable for welding, because it controls the burn off rate of electrode, fusion depth and weld geometry. Welding voltage It determines the shape of fusion zone and weld reinforcement height. Welding speed It is defined as the rate of travel work piece under

1/5

1 INTRODUCTION Welding is a process of joining two materials. It is more economical and is much faster process compared to both casting and riveting [2]. Various welding methods are: Shielded Metal Arc Welding

w ebcache.googleusercontent.com/search?q=cache:http://w w w .estij.org/papers/vol2no42012/12vol2

Welding 3/6/14 parameters on the Weld-Bead Shape Characteristics

(SMAW), Tungsten GasGas (TIG) Welding, Plasma Arc Welding Inert (PAW), Metal Arc Welding (GMAW), Flux Cored Arc Welding (FCAW), Electro Slag Welding (ESW), Oxy-acetylene (OA) Welding and Friction Welding [3].Submerged Arc Welding (SAW)[5] .The two most commonly used types of Gas Metal Arc Welding (GMAW) processes are tungsten inert gas (TIG) and metal inert gas (MIG) [8]. TIG welding (Tungsten inert gas welding) is also called as gas Tungsten Arc Welding (GTAW) uses a non consumable electrode and a separate filler metal with an inert shielding gas. GTAW process welding set utilizes a suitable power source, A cylinder of Argon gas, torch with connections for current supply, tubing for shielding gas supply and

electrode [7]. Heat Input Speed of welding(s) = Travel of electrode/ arc time mm/min. Heat input rate = (VA60) /S joules per mm Where, V is arc voltage in volts, A is welding current in ampere, S is speed of welding in mm/min [12]. Shape Factor It is the ratio of Penetration Depth to Weld Width. Shape factor = Penetration Depth/Weld Width The above factor i.e. arc current, arc voltage and welding speed and their interactions play a significant

599

Page 2

IRACST Engineering Science and Technology: An International Journal (ESTIJ), ISSN: 2250-3498, Vol.2, No. 4, August 2012

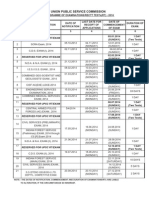

role in determining the weld bead shape characteristics [4,10]. 2 PLAN OF INVESTIGATION The research work was carried out in the following steps: (i) Identifying the important process variables; (ii) Conducting the experiments. (iii) Recording the response, viz. penetration depth and weld width. (iv) Presenting the effects the significant interactions between the different parameters in graphical form and; (v) Analyzing the results to draw specific conclusions. 3 EXPERIMENTAL DETAILS In this investigation, MIG welding has been used. Specimen of dimensions 144 31 10 mm were prepared. The shielding gases employed were mixture of Argon + 8%CO2 . The Welding Voltage and Welding current were 16 V and 165 amp. Table 1: MIG welding variables and their responses

7 1.32

1450 109. 14

2.62

1.875

1.4

8 1.24

1500 105. 6

2.17

1.61

1.35

1.2

1550 102. 19

1.90

1.43

1.32

10 1.16

1600

99

1.49

1.15

1.30

4 RESULTS AND DISCUSSION: Total 10 experiments were performed with constant welding current and arc voltage. Welding speed was varied. The results as a function of welding parameters and their response have been summarized in Table 1. (a) The effect of welding speed on penetration depth: After welding all the welded specimens

S N

Arc Time (Sec)

Weldin g Speed (mm/m in)

Heat input (J/m m)

Weld Width (mm)

Penetrat ion (mm)

Shape Factor

were cut perpendicular to the direction of welding to measure the penetration depth. It has been found that as the welding speed increases; penetration depth also increases up to speed of 1450 mm/min, which is the optimum value to obtain maximum

2/5

w ebcache.googleusercontent.com/search?q=cache:http://w w w .estij.org/papers/vol2no42012/12vol2

Welding parameters on the Weld-Bead Shape Characteristics

1 2.01

900

176. 00

1.27

1.01

1.25

penetration; which decreases as beyond shown in fig.1 the penetration

2 1.86

1000 158. 40

1.35

1.08

1.28

3 1.69

1100 144. 00

1.43

1.10

1.3

4 1.43

1300 121. 84

1.63

1.24

1.32

5 1.43

1350 117. 33

1.86

1.40

1.33

6 1.32

1400 113. 32

2.06

1.53

1.35 Fig.1 Penetration depth as a function of welding speed

600

Page 3

IRACST Engineering Science and Technology: An International Journal (ESTIJ), ISSN: 2250-3498, Vol.2, No. 4, August 2012

(b)The effect of heat input on penetration depth:

Penetration depth increases with increase in heat input. Maximum penetration occurs at heat input rate of 109.14 J/min., beyond which penetration depth starts decreasing. Therefore optimum results were obtained at a heat input of 109 J/min as shown in fig 2. Fig. 3 Shape factor as a function of welding speed

5 CONCLUSIONS From the above investigation on bright drawn mild steel of dimensions 144 31 10 mm, and using a current of 165 amp and arc voltage of 16 V the following conclusions have been drawn:

w ebcache.googleusercontent.com/search?q=cache:http://w w w .estij.org/papers/vol2no42012/12vol2

3/5

Welding 3/6/14 parameters on the Weld-Bead Shape Characteristics

1. When speed is taken as variable parameters, penetration depth increases with increase in speed upto an optimum Fig. 2 Penetration depth as a function of heat input value of 1450 mm/min, beyond that speed penetration starts decreasing. 2. When the heat input is taken into consideration the depth of penetration increases with increase in heat input (c)The effect of welding speed on shape factor: upto a rate 109 J/min, beyond which the penetration depth starts decreasing. 3. Shape factor increases with increase in Shape factor increases with increase in welding speed. Maximum shape factor was observed at a welding speed of 1450 mm/min., beyond that the shape factor starts decreasing. Thus the optimum shape factor was obtained at a welding speed of 1450 mm/min as shown in fig. 3. welding speed. An optimum shape factor was observed at a welding speed of 1450 mm/min., beyond which shape factor starts decreasing. Therefore optimum shape factor was observed at welding speed of 1450 mm/min.

It can, therefore, be concluded that at a given current of 165 amp and arc voltage of

601

Page 4

IRACST Engineering Science and Technology: An International Journal (ESTIJ), ISSN: 2250-3498, Vol.2, No. 4, August 2012

16 V as the welding speed increases the penetration depth increases until optimum value is reached, at which penetration depth and shape factor are optimum. Beyond that speed penetration depth and shape factor start decreasing. REFERENCES

[1] H.R. Ghazvinloo, A. Honarbakhsh-Raouf and N.Shadfar , Effect of arc voltage, welding current and welding speed on fatigue life, impact energy and bead penetration of AA6061 joints produced by robotic MIG welding, Indian Journal of Science and Technology, Vol. 3 No. 2 Feb 2010 pp 156-162. [2] S Kumanan, J Edwin, Raja Dhas, K Gowthaman, Determination of submerged arc welding process parameter using Taguchi method and regression analysis, Indian Journal of Engineering & Materials Sciences Vol 14, June 2007,pp 177-183. [3] P . Kumari, K. Archna and R.S. P armar, Effect of Welding P arameters on Weld Bead Geometry in MIG Welding of Low Carbon Steel, International Journal of Applied [12] [11] [10] [9]

Weld Bead Geometry in GMAW, World Academy of Science, Engineering and Technology 59 2009 pp 138-141. M.St. Wglowski, Y. Huang, Y.M. Zhang, Effect of welding current on metal transfer in GMAW Archives of Materials Science and Engineering, Volume 33 Issue 1 September 2008,pp 49-56. K. Abbasi, S. Alam and M.I. Khan, An Experimental Study on the Effect of Increased P ressure on MIG Welding Arc, International Journal Of Engineering Research, Dindigul, Volume 1, No 3,2010, pp 22-27. Ahmed Khalid Hussain, Abdul Lateef, Mohd Javed, P ramesh.T, Influence of Welding Speed on Tensile Strength of Welded Joint in TIG Welding P rocess, International Journal Of Applied Engineering Research, Dindigul, Volume 1, No 3,2010, pp 518-527. S. Alam and M.I.Khan, P rediction of Weld Bead Reinforcement Height for Steel using SAW P rocess P arameters, International Journal Of Applied Engineering Research, ISSN 0973-4562, Volume 6, No 15,2011, pp 1857-1871. AUTHORS PROFILE K.Abbasi , M.Tech. He is Assistant P rofessor ASET in Amity Applied

w ebcache.googleusercontent.com/search?q=cache:http://w w w .estij.org/papers/vol2no42012/12vol2

4/5

Welding 3/6/14 parameters on the Weld-Bead Shape Characteristics

Engineering Research, ISSN 0973-4562 Volume 6, No. 2 (2011) pp 249258. [4] G. Raghu Babu, K. G. K. Murti and G. Ranga Janardhana, An experimental study on the effect of welding parameters on mechanical and microstructural properties of AA 6082-T6 friction stir welded butt joints, ARP N Journal of Engineering and Applied Sciences, VOL. 3, No. 5, October 2008 pp 68-74. [5] Amar P atnaik, An evolutionary approach to parameter optimization of submerged arc welding in the hard facing process, Int. J. Manufacturing Research, Vol. 2, No. 4, 2007. [6] A.W. Stalker and G.R. Salter, A P reliminary study of The Effect of increased pressure on the welding Arc, WI report No. 3412/6/74 (RRISMT-R- 7505),1975. [7] S. P . Tewari , Ankur Gupta,Jyoti P rakash, Effect of welding parameters on the weldability of material, International Journal of Engineering Science and Technology, Vol. 2(4), 2010, pp512-516. [8] Farhad Kolahan, Mehdi Heidari, A New Approach for P redicting and Optimizing . University Uttar P radesh Lucknow. He has published numerous research papers in conferences and international Journals. He has more than 12 years of teaching experience. S. ALAM, M. Tech and pursuing P hD .He is Associate P rofessor (Jr.), Department of Mechanical Engineering at Integral University, Lucknow. He has published numerous research papers in national and international Journals. M. I. Khan, P hD , He is P rofessor in Department of Mechanical Engineering at Integral University, Lucknow. Earlier, he has been Reader both at MNNIT Allahabad and University of Basrah, Iraq and P rofessor at University of Garyounis,Benghazi,Libya. He has more than four decades of teaching and research Experience. Dr.Khan authoured four books, and also has published numerous research papers in reputed journals. He is a Fellow of the Institution of Engineers (India) and a Senior Member of the Society of Manufacturing Engineers (USA).He received the title of Man of the Year for 2009 for India from the American Bibliographical Institute, USA.He has also received the Bharat Vidya Ratan Award, Bharat Jyoti Award, Eminent Educationist Award and Jewel of India Award from India

602

w ebcache.googleusercontent.com/search?q=cache:http://w w w .estij.org/papers/vol2no42012/12vol2

5/5

También podría gustarte

- Math 3121 Abstract Algebra I: Sections 5-6: Subgroups and Cyclic GroupsDocumento29 páginasMath 3121 Abstract Algebra I: Sections 5-6: Subgroups and Cyclic GroupsvatouvinAún no hay calificaciones

- Cold cracking in steel welds explainedDocumento10 páginasCold cracking in steel welds explainedNormix FlowersAún no hay calificaciones

- MAT220-Algebra NotesDocumento56 páginasMAT220-Algebra NotesSofia Tirabassi100% (1)

- Abstract AlgebraDocumento78 páginasAbstract Algebracat100percentileAún no hay calificaciones

- Siri Krishana Math : Group Theory AssignmentDocumento6 páginasSiri Krishana Math : Group Theory AssignmentGeo JosAún no hay calificaciones

- Trig Substitution Area EllipseDocumento12 páginasTrig Substitution Area EllipseMahmoud Abdel-SalamAún no hay calificaciones

- Exam 9: Integral Calculus: Tan XDXDocumento5 páginasExam 9: Integral Calculus: Tan XDXElmarc CodenieraAún no hay calificaciones

- MATH 221 Final Exam Statistics For DecisionDocumento8 páginasMATH 221 Final Exam Statistics For DecisiongeorgettashipleyAún no hay calificaciones

- Group Theory: Lecture NotesDocumento102 páginasGroup Theory: Lecture NotesViral patelAún no hay calificaciones

- Course Syllabus in Modern Geometry: Concepcion Holy Cross College College of Education DepartmentDocumento7 páginasCourse Syllabus in Modern Geometry: Concepcion Holy Cross College College of Education DepartmentGrenica GamingAún no hay calificaciones

- Chapter 1 ProbabilityDocumento13 páginasChapter 1 ProbabilityVaibhavGuptaAún no hay calificaciones

- Laws of Exponents ReviewDocumento1 páginaLaws of Exponents ReviewJohn Philip ReyesAún no hay calificaciones

- DOST ScholarshipDocumento6 páginasDOST ScholarshipFoxRain08Aún no hay calificaciones

- UntitledDocumento10 páginasUntitledJoanaPaulaBaclayBiñasAún no hay calificaciones

- Integral CalculusDocumento1 páginaIntegral CalculusJustinnAún no hay calificaciones

- Graph Review GuideDocumento29 páginasGraph Review GuideVanessaAún no hay calificaciones

- Applications of DerivativesDocumento8 páginasApplications of DerivativesMarikannan GAún no hay calificaciones

- Practical Research 2.1Documento28 páginasPractical Research 2.1Edlyn MabutiAún no hay calificaciones

- Modern Geometry EssentialsDocumento14 páginasModern Geometry EssentialsJondel IhalasAún no hay calificaciones

- Probability Methods in Engineering Spring 2018Documento3 páginasProbability Methods in Engineering Spring 2018Chaudry Arshad MehmoodAún no hay calificaciones

- Electric Field and Electric Forces PDFDocumento69 páginasElectric Field and Electric Forces PDFRia Grace P AbdonAún no hay calificaciones

- Quiz - Electric ChargesDocumento3 páginasQuiz - Electric ChargesApril Joy LascuñaAún no hay calificaciones

- TOPIC 2 - Functions and Equivalence RelationDocumento87 páginasTOPIC 2 - Functions and Equivalence RelationDomz Sensei100% (1)

- Unit 1 Angle MeasureDocumento7 páginasUnit 1 Angle MeasureJoshua John JulioAún no hay calificaciones

- Research and Publication EthicsDocumento4 páginasResearch and Publication EthicsHemalatha SivakumarAún no hay calificaciones

- Integration ProblemsDocumento4 páginasIntegration ProblemsAneesh Amitesh ChandAún no hay calificaciones

- Lecture Notes (Chapter 2.3 Triple Integral)Documento5 páginasLecture Notes (Chapter 2.3 Triple Integral)shinee_jayasila2080100% (1)

- Sheet 2: A Sequence: ( ) ( 4 )Documento2 páginasSheet 2: A Sequence: ( ) ( 4 )abanoubNashaatAún no hay calificaciones

- LAS 5 Parts of A Capstone Research Paper ClassicalDocumento1 páginaLAS 5 Parts of A Capstone Research Paper ClassicalMiskAún no hay calificaciones

- Similar Triangles Notes 1226332385515355 9Documento17 páginasSimilar Triangles Notes 1226332385515355 9Cruz L AntonioAún no hay calificaciones

- Wiedemann Franz LawDocumento3 páginasWiedemann Franz LawAleš NagodeAún no hay calificaciones

- Rosenthal 1995 PsychBDocumento10 páginasRosenthal 1995 PsychBĐinh Đức TâmAún no hay calificaciones

- ch03-Q&A HW3Documento5 páginasch03-Q&A HW3Ingi Abdel Aziz Srag100% (1)

- 15.3 Double Integrals Over General Region: X Ax BDocumento4 páginas15.3 Double Integrals Over General Region: X Ax BNourAldin AbuSalehAún no hay calificaciones

- CHAPTER-3 - RevDocumento5 páginasCHAPTER-3 - RevJaymark SorianoAún no hay calificaciones

- Calculating pirate gold standard deviationDocumento9 páginasCalculating pirate gold standard deviationPresana VisionAún no hay calificaciones

- Lesson 2 Families of CurveDocumento16 páginasLesson 2 Families of CurveeulaAún no hay calificaciones

- Pre-Calc Trig IdentitiesDocumento1 páginaPre-Calc Trig Identitiessolikan45Aún no hay calificaciones

- 1 2 3 Literature Review 4 Experiment Objective 5 Methodology 6 Results 7 Discussions 8 Conclusion & Recommendations 9 References 10 AppendicesDocumento16 páginas1 2 3 Literature Review 4 Experiment Objective 5 Methodology 6 Results 7 Discussions 8 Conclusion & Recommendations 9 References 10 Appendicesmonkeystar12100% (3)

- Chapter 1 Mathematical PreliminariesDocumento19 páginasChapter 1 Mathematical PreliminariesAyad SlabyAún no hay calificaciones

- Angles and Their MeasuresDocumento27 páginasAngles and Their MeasuresMaria Jemimah B. AgravanteAún no hay calificaciones

- 9.5 - Testing Convergence at EndpointsDocumento13 páginas9.5 - Testing Convergence at Endpointsasoni98Aún no hay calificaciones

- Chapter 3 InterpolationDocumento76 páginasChapter 3 InterpolationAkmal HanafiAún no hay calificaciones

- W4 Applications of First Order Differential Equations - ModuleDocumento6 páginasW4 Applications of First Order Differential Equations - ModuleRaison MichAún no hay calificaciones

- MATH23Documento8 páginasMATH23Lin Xian XingAún no hay calificaciones

- Lecture07 - Least Squares RegressionDocumento32 páginasLecture07 - Least Squares RegressionNa2ryAún no hay calificaciones

- Engineering Mechanics Vectors and ScalarsDocumento42 páginasEngineering Mechanics Vectors and ScalarssatwantAún no hay calificaciones

- Binomial Expansion & Pascal's TriangleDocumento27 páginasBinomial Expansion & Pascal's TriangleKingX_ChinAún no hay calificaciones

- Definite Integral: Area Under Curve From a to bDocumento10 páginasDefinite Integral: Area Under Curve From a to bWanda AdelineAún no hay calificaciones

- Numerical Analysis PDFDocumento15 páginasNumerical Analysis PDFaauppalAún no hay calificaciones

- Introduction To Numerical Methods For Variational Problems PDFDocumento216 páginasIntroduction To Numerical Methods For Variational Problems PDFmottenerAún no hay calificaciones

- Design and Development of Spur Gear by Using Three Dimensional PrintingDocumento3 páginasDesign and Development of Spur Gear by Using Three Dimensional PrintingEditor IJTSRD0% (1)

- MA8151 Engineering Mathematics SyllabusDocumento2 páginasMA8151 Engineering Mathematics SyllabusPAMANI1981Aún no hay calificaciones

- Estimation of Global and Diffuse Solar Radiation For Hyderabad Sindh PakistanDocumento5 páginasEstimation of Global and Diffuse Solar Radiation For Hyderabad Sindh PakistanLuis Martín PomaresAún no hay calificaciones

- Emtl Bit Bank Mid IDocumento38 páginasEmtl Bit Bank Mid IRadhika Mahankali100% (1)

- An Experimental Study On The Effect of MIGDocumento4 páginasAn Experimental Study On The Effect of MIGBhramandhikaNalendraGhuptaAún no hay calificaciones

- Nik Weld ParameterDocumento5 páginasNik Weld ParameterHarmish BhattAún no hay calificaciones

- A Review On Various Welding TechniquesDocumento7 páginasA Review On Various Welding TechniquesIJMER100% (1)

- The Effect of Gas Metal Arc Welding (GMAW) Processes On Different Welding Parameters - DoneDocumento5 páginasThe Effect of Gas Metal Arc Welding (GMAW) Processes On Different Welding Parameters - DoneAsim AliAún no hay calificaciones

- Recruitment Advertismnet India Goverment Kollkata For Various Posts.Documento14 páginasRecruitment Advertismnet India Goverment Kollkata For Various Posts.tejap314Aún no hay calificaciones

- Notification WaterDocumento25 páginasNotification WaterSurender NAún no hay calificaciones

- Sl. No Holiday Date Day of Week: Institute Holidays For The Year 2013Documento1 páginaSl. No Holiday Date Day of Week: Institute Holidays For The Year 2013tejap314Aún no hay calificaciones

- Cds English SolutionsDocumento7 páginasCds English SolutionsmanthmightyAún no hay calificaciones

- Bharat Sanchar Nigam Limited: Receipt DetailsDocumento1 páginaBharat Sanchar Nigam Limited: Receipt Detailstejap314Aún no hay calificaciones

- Cds 2, 2010 GK Answer For Series ADocumento1 páginaCds 2, 2010 GK Answer For Series Atejap314Aún no hay calificaciones

- FAQ Foro Post ApplyDocumento3 páginasFAQ Foro Post Applytejap314Aún no hay calificaciones

- Apgenco Ae Mechanical 2012 PaperDocumento13 páginasApgenco Ae Mechanical 2012 PaperRahul Kumar KAún no hay calificaciones

- MSC PsyDocumento14 páginasMSC Psysolomon_paulrajAún no hay calificaciones

- Manual For Asian CountriesDocumento12 páginasManual For Asian Countriestejap314Aún no hay calificaciones

- General Knowledge SET A 2012Documento2 páginasGeneral Knowledge SET A 2012tejap314Aún no hay calificaciones

- MSG 02730Documento4 páginasMSG 02730tejap314Aún no hay calificaciones

- Afcat 1Documento10 páginasAfcat 1ismav123Aún no hay calificaciones

- 2010 2 Engsentence ImprovementDocumento3 páginas2010 2 Engsentence Improvementtejap314Aún no hay calificaciones

- Final Book Price List - ColourDocumento2 páginasFinal Book Price List - ColourSumit SharmaAún no hay calificaciones

- Domestic Tariff Delhi CCDocumento16 páginasDomestic Tariff Delhi CCgsevenxtAún no hay calificaciones

- Jee Advanced 2014-1 Fiit JeeDocumento28 páginasJee Advanced 2014-1 Fiit JeeImranHashmiAún no hay calificaciones

- Marriages To Overseas Indians A Guidance BookletDocumento98 páginasMarriages To Overseas Indians A Guidance BookletRohit JainAún no hay calificaciones

- North American Stainless: Long Products Stainless Steel Grade SheetDocumento8 páginasNorth American Stainless: Long Products Stainless Steel Grade Sheettejap314Aún no hay calificaciones

- Approved Annual Programme 2015Documento1 páginaApproved Annual Programme 2015Sharath HegdeAún no hay calificaciones

- Design For Reliability and Quality: IIT, BombayDocumento13 páginasDesign For Reliability and Quality: IIT, Bombaytejap314Aún no hay calificaciones

- Design For Reliability and Quality: IIT, BombayDocumento30 páginasDesign For Reliability and Quality: IIT, Bombaytejap314Aún no hay calificaciones

- Module 4 Lecture 8 FinalDocumento17 páginasModule 4 Lecture 8 Finaltejap314Aún no hay calificaciones

- Design For Reliability and Quality: IIT, BombayDocumento27 páginasDesign For Reliability and Quality: IIT, Bombaytejap314Aún no hay calificaciones

- Design For Reliability and Quality: IIT, BombayDocumento12 páginasDesign For Reliability and Quality: IIT, Bombaytejap314Aún no hay calificaciones

- Module 4 Lecture 5 FinalDocumento12 páginasModule 4 Lecture 5 Finaltejap314Aún no hay calificaciones

- Design For Reliability and Quality: IIT, BombayDocumento14 páginasDesign For Reliability and Quality: IIT, Bombaytejap314Aún no hay calificaciones

- Design For Assembly: Iit BombayDocumento16 páginasDesign For Assembly: Iit Bombaytejap314Aún no hay calificaciones

- US Welding PPDocumento18 páginasUS Welding PPMihailescu AdrianAún no hay calificaciones

- Short and Open Circuit Test On TransformerDocumento1 páginaShort and Open Circuit Test On TransformerRyan DagsilAún no hay calificaciones

- Rpdir-L12 Shielding WebDocumento73 páginasRpdir-L12 Shielding WebWiie ArdiAún no hay calificaciones

- Marine Chock InstallationDocumento48 páginasMarine Chock InstallationSumeet SawantAún no hay calificaciones

- 4 - ch01 - SQ - E: Solutions MarksDocumento37 páginas4 - ch01 - SQ - E: Solutions Marks5A35 YIP HOI PAKAún no hay calificaciones

- MCQ 140Documento14 páginasMCQ 140Aawez AkhterAún no hay calificaciones

- Fabric Expansion JointsDocumento28 páginasFabric Expansion Jointswarmachine269889Aún no hay calificaciones

- CZ-RTC4 - Service ManualDocumento68 páginasCZ-RTC4 - Service ManualAnonymous 31Airw50% (2)

- Enclosed Control Product Guide: April 2008Documento456 páginasEnclosed Control Product Guide: April 2008MED-ROBIN2000Aún no hay calificaciones

- More power in less space with SMA SUNNY CENTRAL UPDocumento4 páginasMore power in less space with SMA SUNNY CENTRAL UPBrahadeesh Perinkolam MuraliAún no hay calificaciones

- Waste Water-Sewage PumpDocumento111 páginasWaste Water-Sewage Pumpcharadeg100Aún no hay calificaciones

- 03 MAN D2Z2IM ACT350xx ENDocumento24 páginas03 MAN D2Z2IM ACT350xx ENAlfonso Lopez toroAún no hay calificaciones

- Method of Lighting CalculationsDocumento3 páginasMethod of Lighting CalculationsSpencer Josh RegedorAún no hay calificaciones

- CH 1Documento13 páginasCH 1badgujar_bandhuAún no hay calificaciones

- GH G ConversionDocumento146 páginasGH G ConversionjorgeAún no hay calificaciones

- Spe 21970 MSDocumento13 páginasSpe 21970 MSasu jaranAún no hay calificaciones

- Masterpact NT and NW: Maintenance GuideDocumento32 páginasMasterpact NT and NW: Maintenance GuideRoshin99Aún no hay calificaciones

- Galcon ProductDocumento69 páginasGalcon Productapi-36492444Aún no hay calificaciones

- SGMF Hose BunkeringDocumento15 páginasSGMF Hose BunkeringFilipAún no hay calificaciones

- Cwi QuestionsDocumento6 páginasCwi QuestionsGokul Thangam75% (4)

- Various Configurations of Co2 CaptureDocumento16 páginasVarious Configurations of Co2 CaptureMaythee SaisriyootAún no hay calificaciones

- Sany HBT8018C-5S (T3) Trailer Pump - 004118Documento2 páginasSany HBT8018C-5S (T3) Trailer Pump - 004118اهى عيشه وبن عشها just a lifeAún no hay calificaciones

- VS1-2 Manual PDFDocumento284 páginasVS1-2 Manual PDFJorge InostrozaAún no hay calificaciones

- Unidad de Potencia Hidraulica Hycon HPP13 FlexDocumento9 páginasUnidad de Potencia Hidraulica Hycon HPP13 FlexJorge Diaz Nestor MonsalveAún no hay calificaciones

- Factors Affecting Potential EnergyDocumento3 páginasFactors Affecting Potential EnergyArgyll PaguibitanAún no hay calificaciones

- LT AB Cable GTPsDocumento3 páginasLT AB Cable GTPsnishant sainiAún no hay calificaciones

- Volkswagen 2.0L TDI Common Rail Engine Service TrainingDocumento90 páginasVolkswagen 2.0L TDI Common Rail Engine Service TrainingАлла Харютина100% (1)

- Specification For Smoke Bomb Test PDFDocumento4 páginasSpecification For Smoke Bomb Test PDFARUNAún no hay calificaciones

- Three-Phase Induction MotorDocumento21 páginasThree-Phase Induction MotorRajeev ValunjkarAún no hay calificaciones

- Fallout 1 ManualDocumento124 páginasFallout 1 ManualDave100% (1)

- Valve RecessionDocumento26 páginasValve RecessionHamid HasanAún no hay calificaciones