Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Safety and Handling of Organic Peroxides

Cargado por

Максим ХилоTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Safety and Handling of Organic Peroxides

Cargado por

Максим ХилоCopyright:

Formatos disponibles

SAFETY AND HANDLING OF ORGANIC PEROXIDES:

A Guide Prepared by the

ORGANIC PEROXIDE PRODUCERS SAFETY DIVISION

of

THE SOCIETY OF THE PLASTICS INDUSTRY, INC.

Publication # AS-109

The Society of the Plastics Industry, Inc., August, 1999

Acknowledgement

The Organic Peroxide Producers Safety Division of the Society of the Plastics Industry, Inc. gratefully acknowledges

Dr. Chester McCloskey

for his original paper Safe Handling of Organic Peroxides: An Overview, * on which this guide is based.

*Plant/Operations Progress, 1989, 8, 185-189

TABLE OF CONTENTS

INTRODUCTION CONFUSION OVER PROPERTIES CHARACTERISTIC PROPERTIES TYPES OF ORGANIC PEROXIDES RULES FOR SAFE HANDLING Temperature Control Contamination Control Confinement Control

PAGE

3 4 6 12 14 16 18 19 20 22 23 25

Quantity Control Disposal of Wastes Fire Protection

REFERENCES

SAFETY AND HANDLING OF ORGANIC PEROXIDES: A GUIDE INTRODUCTION When considering safe handling procedures, organic peroxides have a specific chemical structure which makes them useful but also requires their careful handling and storage. A great deal of mystique and partial or misinformation has surrounded organic peroxides, particularly as it applies to safety. Thus, there was and is a need for a better understanding of organic peroxides. However, because of the wide range of properties that organic peroxides possess and the number of compositions that have been developed for commercial use or increased safety, completely covering the safe handling practices of all organic peroxide formulations1 is beyond the scope of this Guide. As a result, this Guide will endeavor to provide a basis for understanding the basic nature of organic peroxides as related to their safe use, handling and storage by addressing the following questions:

1. Why has there been so much confusion and so many misconceptions about the properties of organic peroxides?

2. Why has it taken so long to develop tests to quantify the hazardous properties of organic peroxides and rational codes and regulations for their storage, transport, and safe handling?

a technically pure organic peroxide or a mixture with one or more materials, usually diluents.

3.

What are the characteristic properties of organic peroxides which are important in

their safe use and handling, and how are they manifest?

4.

Based on present knowledge, how are organic peroxides handled safely?

CONFUSION OVER PROPERTIES Organic peroxides are not a neat little family of compounds characterized by a single

physical or chemical property. An organic peroxide is, by definition, any organic chemical that contains an oxygen-oxygen (---0---0---) linkage or bond (peroxy group). That potentially includes a very large number of compounds with a wide range of properties. In practice however, manufacturers and users are concerned with commercial organic peroxide formulations, so the number of compounds, while large, is manageable. There are many commercial uses for organic peroxides. Some are used as the technically

pure compound, liquid or solid. Others are diluted as solutions, pastes, solid granules, etc., as the application or safe handling requires. With the wide range of properties possessed by organic peroxides and many physical forms and concentrations, commercial formulations have an extraordinarily large range of safety-related properties. Organic peroxide formulations vary in reactivity hazard from self-extinguishing to the potential for a violent deflagration. The broad range of safety-related properties among organic peroxide formulations was both confusing to the user and a major safety problem because all organic peroxide formulations tended to be grouped together. Thus the need for a classification system.

Given that commercial organic peroxide formulations must be shipped and handled

safely, the Bureau of Explosives of the American Association of Railroads started testing commercial organic peroxide formulations over 50 years ago to determine if such compositions met the Bureaus (and the Interstate Commerce Commissions) minimum standards for shipment. Major efforts were made by Factory Mutual [3] and the Organic Peroxide Producers Safety Division (OPPSD) of The Society of the Plastics Industry (SPI) [4] to classify organic peroxide formulations by hazard level, but these efforts received only limited U.S. or Worldwide acceptance. Until the adoption of The National Fire Protection Association (NFPA) 43B (currently NFPA 432), Code for the Storage of Organic Peroxide Formulations, there was no officially recognized U.S. code to group the commercial organic peroxides by hazard class.

Hazard Identification and Classification Problems The identification and rating of the hazardous properties of organic peroxides has been a

difficult task. Commercial organic peroxide formulations, while energetic substances, release so much less energy on decomposition than high explosives that most of the tests used for high explosives have little application. Unable to use the tests developed by the vast resources of the worlds defense establishments that focus on propellants and explosives, in the U.S., the burden fell on the relatively limited resources of the Organic Peroxide Producers Safety Division (OPPSD) aided by the Bureau of Explosives, and later, the Bureau of Mines (supported by the Department of Transportation). Internationally, besides manufacturers, Germany (BAM) [5], the Netherlands (TNO) [6], and the United Kingdom (Health and Safety Executive) [7] have been major contributors. Others that have contributed are Japan, France and Sweden. It has been

reassuring that, while different countries developed different test procedures, similar hazard classifications were derived for most organic peroxide formulations. The identification of the hazards, the development of the quantitative test methods, and

the comparison of the test results obtained with field experience, led to the formulation of classifications, codes and regulations. An excellent example of this is the adoption by the United Nations of many of the test methods and their use to develop the classification system for organic peroxides in the UNs Recommendations for the Transport of Dangerous Goods (UN Orange Book). CHARACTERISTIC PROPERTIES

While there are many types of organic peroxides, they all have at least one oxygenoxygen

(-0-0-) bond in their chemical structure (see page 14 for examples). For the organic peroxide to be useful, this bond must be broken, usually by heating to produce free radicals which can initiate polymerization or another desired end result. This decomposition produces heat and by-products. The rate of decomposition is different for each organic peroxide. For those where the rate is rapid at room temperature, this type of organic peroxide is stored and shipped under refrigerated conditions. Other organic peroxides can be stored and shipped safely at or above ambient temperatures.

The oxygen-oxygen linkage or bond (peroxy group) (-0-0-), which characterizes organic

peroxides, is a thermally sensitive and energetic bond. It contributes the special properties that organic peroxides, to varying degrees, have in common. These are:

Sensitivity to heat. Release of heat on decomposition. Formation of free radicals on decomposition Sensitivity to contamination (selective). Formation of gases and mists on decomposition (selective). Limited oxidizing properties.

The properties listed above are manifested to varying degrees in all organic peroxide

formulations, as follows:

1.

Temperature induced decomposition: There is no specific temperature at which decomposition begins. The rate of decomposition, simplistically stated, is dependent on, or is a function of, the temperature. There is some decomposition occurring even at very low temperatures. The rate of decomposition of organic peroxides increases rapidly as the temperature increases, faster than most chemical reactions increase. As the temperature increases it will reach a temperature at which the rate becomes so rapid that large quantities of heat and reaction products (some often gaseous) are produced. If the heat generated is not dissipated or absorbed, the temperature of the organic peroxide increases, which increases the rate of decomposition. The decomposition may then autoaccelerate and, with very energetic formulations, become uncontrollable.

Confinement during a rapid or runaway decomposition may result in very high pressures and temperatures. Transition to a higher order of decomposition may result.

During thermal decomposition, most organic peroxides to some extent react with their decomposition products (including free radicals). This often increases the rate as the decomposition proceeds. Diluents, including other organic peroxides, may participate as well; some may reduce and others may increase the rate and type of decomposition.

The temperature at which an organic peroxide formulation visibly decomposes when heated rapidly (rapid heat decomposition temperature: RHDT) occurs at a much higher temperature than the self accelerating decomposition temperature (SADT). The SADT is the lowest temperature at which an organic peroxide formulation in a commercial package undergoes self-accelerating decomposition (temperature increase >6 oC over 7 days). With some energetic and low temperature formulations, the final decomposition may be uncontrollable. The SADT and RHDT may be quite different from, and should not be confused with, the -life numbers given for organic peroxides in a dilute solution. Determining the safe handling, storage and shipping temperatures is a significant part of the testing that must be done before an organic peroxide formulation is offered for sale.

2.

Increased burning rate: The burning rate is higher for an organic peroxide formulation than for a similar composition without the peroxy group. This is the result of the energy liberated when the peroxy group decomposes, supplying heat to the burning organic peroxide in addition to the heat flux from the flame.

3.

Burning with acceleration: This is a characteristic property of organic peroxide formulations that decompose rapidly at a temperature below their boiling points and that are not formulated to absorb the heat of decomposition during burning. When such organic peroxide formulations burn, the temperature of the material increases. As in No. 2 above, when the temperature range is reached at which rapid decomposition occurs, the heat of decomposition, which is liberated internally, increases the temperature of the material, the burning rate and, thus, the heat flux back to the burning surface. As the temperature further increases so does the rate of decomposition and heat release, further accelerating the burning rate.

4.

Increased flame temperature: If the temperature range at which rapid decomposition occurs is higher than the boiling point of the organic peroxide, then the decomposition and the major energy release takes place in the flame, increasing the flame temperature.

5.

Contamination initiated (Promoted) decomposition: In addition to thermal decomposition, organic peroxides can be induced to decompose by contaminates such as: promoters, amines, metal ions, strong acids and bases, strong reducing and oxidizing agents and contact with some metals. Susceptibility to decomposition due to contamination or contact varies greatly among different organic peroxide types and formulations. For example: organic peroxides that are particularly susceptible are those with the -O-O-H group. Decomposition can be by radical and by ionic pathways.

6.

Auto-ignition during decomposition: It is the ease of splitting the peroxy group to give

two free radicals that makes organic peroxides so useful. However, the presence of energetic free radicals during decomposition (particularly in hot gases or mists) can cause auto-ignition to occur at a lower temperature than would otherwise be normal for a similar structure without the peroxy group.

7.

Release of flammable gases and mists during decomposition: Some organic peroxide formulations release a considerable amount of gases and/or mists particularly when rapid decompositions occur. Not all gases released are flammable. In fact, these gases are rarely oxygen, with carbon dioxide being a common decomposition product. However, when flammable gases or mists are released there is always the potential danger of a fire or explosion.

8.

Oxidizing Properties: While most organic peroxides exhibit weak oxidizing properties toward reducing agents, contrary to wide-spread belief, most organic peroxide formulations are fuels, not oxidizers. Only one type, the peroxy acids, shows strong oxidizing properties. The oxygen-oxygen bond only rarely decomposes to give free oxygen. It is not surprising that there has been confusion since, at one time, the DOT labels for oxidizers and organic peroxides were the same and the latter still uses a yellow label, although different from that for oxidizers. It should be noted that organic peroxides and strong oxidizers are not compatible.

Properties Related to Structure and Additives (Diluents) The properties of an individual peroxide depend on the size and structure of the organic

groups attached to the oxygens. One of the groups can be hydrogen. The properties are

commonly further modified by the use of additives to phlegmatize (desensitize), stabilize or otherwise prepare the organic peroxide for commercial use. Commercial formulations are occasionally mixtures of organic peroxides. The peroxy group is the main source of commercial utility for organic peroxides.

However, the groups attached at either end of the -0-0- determine the relative thermal stability and chemical activity of the peroxide. Each peroxy group is considered to contain one active oxygen atom. The concept of active oxygen content is useful for comparing the relative concentration of peroxy groups in formulations, which is related to the energy content. In general, energy content increases with active oxygen content and thus, the higher the molecular weight of the organic groups, the lower the energy content and, usually, the lower the hazard. However, the active oxygen content at which a transition from a simple to a higher order decomposition can occur varies considerably between organic peroxide types (structures) and individuals within the types. For example, when benzoyl peroxide (98%) at 6.5% active oxygen is burned, it

undergoes transition from a low order to a high order decomposition with slight confinement, while the decomposition rate of cumyl hydroperoxide (85%) at 8.9% active oxygen is relatively unaffected by the confinement of a steel drum.

TYPES OF ORGANIC PEROXIDES The simplified formula for organic peroxides is R1OOR2 where R1 is an organic group and R2 is the same or different organic group or hydrogen. R1OOR2 R1 = organic group R2 = (same or different) group

Common types of commercially available organic peroxides are shown on the following page. Note that within each type, the exact structure of the various organic groups determines the thermal stability of any particular member. For some types, such as peroxydicarbonates, the nature of the organic groups has little effect on the thermal stability. For other types, like peroxyesters, the organic groups can have a dramatic effect on thermal stability. In some of the types, one or more of the organic groups must be tertiary-alkyl groups in order for the peroxides to be good radical initiators.

Common Types Typical Formula Temperature Activity Range (C)2 dialkyl peroxides R1-OO-R2 117 - 133 hydroperoxides R1-OO-H 133 - 172

2

Expressed as 10 hour half-life temperatures in a dilute solution

diacyl peroxides

O O || || R1 C-OO-C R2

20 - 75

O O || || peroxydicarbonates 49 - 51

R1 OC-OO-COR2 O || R2-OO-CR1

peroxyesters 49 - 107

R1 | ketone peroxides N/A H-OO-(C-OO-)nH |

2 R2 peroxyketals 92 115 |

alkylperoxy carbonates

(R1-OO-)2C | R3

R1 and R2 are generally alkyl groups, often tertiary-alkyl groups. If attached directly to the peroxy group, n is 1 - 3.

O || R1-OO -COR2

90 100

RULES FOR SAFETY AND HANDLING ORGANIC PEROXIDE FORMULATIONS

Know your product. Read the directions! With so many types of organic peroxide formulations it is absolutely essential that the characteristics and the particular conditions for the safe handling of each formulation are read and understood. The label, product bulletin and

material safety data sheet (MSDS) are good places to start. Consult the manufacturer, distributor or supplier for recommendations for safe use and storage. Know the NFPA 432 hazard class and the properties associated with that class. These standards define safe storage and fire fighting methods. The classification description given in NFPA 432, together with the fire hazard characteristics, are described below. Classes are only for organic peroxide formulations in their original DOT shipping container. Class I describes those formulations which are capable of deflagration, but not detonation. Fire hazard characteristics: Class I formulations present a deflagration hazard through easily initiated, rapid explosive decomposition. Class I includes some formulations that are relatively safe only under closely controlled temperatures. Either excessively high or low temperatures may increase the potential for severe explosive decomposition. Class II describes those formulations that burn very rapidly and that present a severe reactivity hazard. Fire hazard characteristics: Class II formulations present an NFPA fire hazard similar to Class I flammable liquids such as acetone or toluene. The decomposition is not as rapid, violent, or complete as that produced by Class I formulations. As with Class I formulations, this class includes some formulations that are relatively safe when used under controlled temperatures or when diluted. Class III describes those formulations that burn rapidly and that present a moderate reactivity hazard. Fire hazard characteristics: Class III formulations are characterized by rapid burning and high heat liberation, due to decomposition. They present a hazard similar to Class II combustible liquids such as #2 fuel oil.

Class IV describes those formulations that burn in the same manner as ordinary combustibles and that present a minimal reactivity hazard. Fire hazard characteristics: Class IV formulations present fire hazards that are easily controlled. Reactivity has little effect on fire intensity. Class V describes those formulations that burn with less intensity than ordinary combustibles or do not sustain combustion and that present no reactivity hazard. Fire hazard characteristics: Class V formulations do not present severe fire hazards. Those that do burn do so with less intensity than ordinary combustibles.

RIGOROUSLY CONTROL: Temperature Contamination Confinement Quantity

Whether shipping, handling or storing, these are the most important parameters to

control. The Department of Transportation has greatly assisted safe handling by regulating the

shipping temperature, the package size and the degree of confinement from the container. TEMPERATURE CONTROL

No single parameter is as important as the control of the temperature. Whether shipping,

handling or storing, if the temperature is maintained well below its self-accelerating decomposition temperature (SADT), most hazards are avoided. The SADT can be anywhere from - 10 to + 200C and depends on the particular organic peroxide formulation and package. For shipping purposes, the SADT (as previously defined) is the lowest temperature at which selfacceleratingdecomposition occurs within seven days for a peroxide formulation in its DOT shipping container when held at that temperature. At the SADT, the rate of evolution of heat from decomposition exceeds the rate of heat loss to the surroundings so that the peroxides temperature increases with time and the decomposition becomes increasingly more rapid or selfaccelerating. For storage over a longer period of time, the manufacturers recommended temperature

for storage should be rigorously followed. It should also be noted since decomposition temperatures are time dependent, temperatures higher than the shipping temperature can be tolerated for short periods during handling and use. To repeat, proper temperature control is important to prevent run-away decompositions, evolution of gases and mists (that may lead to vapor explosions), auto-ignition or loss of product quality.

The maximum possible transport temperature, also known as Control Temperature

(CT), is dependent on the SADT and is determined as follows: CT = SADT minus 20 C if SADT < 20 C

CT = SADT minus 15 C if SADT < 25 C, 30 C or 35 C CT = SADT minus 10 C if SADT < 40 C, 45 C or 50 C

Note: There is no CT, if the SADT is higher than 50 C. The CT is the temperature up to which the organic peroxide can be safely transported for

an extended period. It is also the alarm temperature. The CT is supplemented by an Emergency Temperature which is higher than the CT but still well below the SADT. The CT may be exceeded if maintenance is necessary or until alternative cooling (e.g. dry ice or wet ice) is available. However, if the Emergency Temperature is reached, immediate steps must be taken to remove personnel from the area and, if possible, to cool down and then dispose of the organic peroxides. Often, the recommended storage temperature is lower than the control temperature, not

for safety, but to minimize the unavoidable active oxygen loss due to gradual decomposition. On the other hand, some liquid or paste organic peroxides must not be stored below a certain minimum temperature as turbidity, phase separation, crystal deposits or solidification can occur. The recommended temperature range of temperature for storage can be found on each organic peroxide package and in the corresponding technical literature. In general, in addition to the temperature, the rate and type of thermal decomposition for

individual organic peroxides will depend, in part, on quantity, heating rate, time and confinement.

CONTAMINATION CONTROL

Contamination can lead to rapid decomposition and all of the problems associated with

lack of temperature control. Susceptibility of organic peroxides to induced decomposition from contamination varies greatly between the types of organic peroxides and the specific contaminants. Nevertheless, contamination has been a major source of accidents from run-away decompositions, particularly during handling and use. Especially sensitive are the ketone peroxides, hydroperoxides, peroxyketals, and some diacyl peroxides. The contaminants most often causing problems have been redox agents such as cobalt salts and other accelerators and promoters, as well as various metal ions and ionizing acids such as high concentrations of sulfuric acid. Strong oxidizing and reducing agents can also cause decompositions. Examples of decomposition initiated by contamination are: methyl ethyl ketone peroxide

(open chain) by cobalt salts, benzoyl peroxide by dimethylaniline and di(t-butylperoxy) cyclohexane by concentrated sulfuric acid. To avoid problems from contamination, never return unused organic peroxides to the

original container. Use only scrupulously clean equipment and make certain that all materials that the organic peroxide comes in contact with are compatible, especially if equipment such as pumps are used for multiple services. When a diluent is used, the selection of a diluent and its purity must be strictly controlled. Contact your supplier for recommendations. While it is a good practice in any situation where a reactive diluent is employed, a general blending rule is to add the organic peroxide to a resin or monomer, not the reverse. Never add organic peroxides to a hot diluent or process. When reactive materials, such as styrene, are employed as diluents (or solvents), strictly adhere to temperature controls and venting requirements because of potential heating due to polymerization.

The effectiveness of diluents, as a phlegmatizer (or desensitizer), is due in part to the

reduction in energy level by dilution or energy absorption, and may also act as a mild chain stopper since most decompositions proceed by a chain mechanism. For contamination problems from absorbents used during spills, see the section on spills.

CONFINEMENT CONTROL

Once rapid decomposition is initiated, confinement of an organic peroxide formulation

may greatly accelerate the rate of its decomposition. With the higher energy classes, transition from a manageable decomposition to a deflagration can occur, which ordinary venting will not control. When it is necessary to confine high-energy organic peroxides by more than the confinement provided by the DOT shipping container, dilution of the peroxide usually is required. See diluents under Contamination Control above. The selection of a diluent and its purity must be strictly controlled. Nevertheless, in many manufacturing operations it is necessary or desirable to use

containers, pumping systems and piping to deliver or handle the organic peroxide being used at processing areas or work stations. If the organic peroxide is not diluted and the system provides additional confinement, then the quantities must be kept to the very minimum and sufficient venting provided to prevent pressure build up. Shielding may be required. If this is not done, then the organic peroxide often must be handled as a higher hazard class material. t-Butyl peroxybenzoate is an example of an organic peroxide for which properties differ

markedly between confinement in a polyethylene container and in a steel drum.

QUANTITY CONTROL Both quantity per container and the total quantity must be controlled in order to minimize

the loss from a fire or decomposition. These quantities are determined by the properties of the particular organic peroxide formulation being handled. For shipping, the Department of Transportation regulates the package size and number per outside container. The quantity in storage must be controlled in accordance with the limitations in NFPA 432. During use, the quantity in the process area should be maintained at the lowest practical level. If quantities are not strictly controlled, the potential exists during a fire or decomposition of a transition from a low order to a higher order event. The hazard to surrounding or adjacent structures is also increased as the stored quantity is increased.

Avoid Spills Spills can result in a host of problems. Potential hazards involved are: 1. Fire (most non-aqueous peroxide formulations contain flammable solids and/or highly combustible liquids) Decomposition (due to either increased temperature or contamination) Evaporation of a safety diluent (either because the diluent is volatile at ambient temperature, or because the spill involved a hot surface) Increased worker exposure (peroxide formulations, especially hydroperoxides and ketone peroxide, can be strong irritants) Incorrect choice of absorbent material and/or methods

2. 3.

4.

5.

Know what action is recommended for each specific formulation that is used. Cleaning

up a spilled organic peroxide formulation may not present a serious problem, or considerable time may elapse before a serious problem develops. On the other hand, rapid and proper action may be required; this is normally the best procedure in any case. With flammable liquids and solids the problem is immediate. Beware. Many organic peroxide formulations are difficult to ignite but burn vigorously once ignited. Depending on the peroxide and contaminant, it may take a long time for decomposition to occur, if at all. On the other hand, decomposition may occur within a short time period, so take precautions accordingly. In any case, it is most important to avoid decomposition or a fire. In many cases, dilution with a compatible inert solid absorbent followed by wetting with

water is very effective. Dilution with a compatible high boiling organic liquid prior to

absorption is often effective and desirable especially with the more energetic or flammable formulations. Caution: absorbents often have high surface areas which may catalyze decomposition as well as contain catalyzing impurities. Special care must be used when water wet solids are spilled. Avoid drying out by wetting down spilled material immediately. Use the MSDS provided with the organic peroxide formulation (and manufacturers=

technical brochures, if available) to prepare for proper action in the event of a spill. Have personnel protection equipment, fire fighting equipment, absorbents, diluents, clean-up tools (non-sparking), and other emergency supplies available in all areas where organic peroxides are handled or stored. Standard precautions should be taken when handling waste from an organic peroxide spill

(or container leakage). In addition, special precautions should be taken to prevent a subsequent decomposition due to contamination or heat. Waste after clean up should be removed from work and storage areas and isolated for further emergency treatment and prompt disposal. Do not store in tightly sealed closed containers. Permit venting of further decomposition products.

DISPOSAL OF WASTES

Disposal of wastes after the clean up of an organic peroxide spill or from container

leakage is always a problem. This material should not be reused. Because of the rapid changes in the Federal and State regulations concerning waste disposal, it is beyond the scope of this Guide to cover waste disposal. Consult the MSDS and available manufacturers literature for information regarding proper disposal. Workers involved in handling, dispensing and spill

clean-ups should be reminded of the potential hazards that some formulations may have from decomposition due to contamination or heat. FIRE PROTECTION

Fire not only can originate from within the organic peroxides due to decomposition

initiated by temperature or contamination, but it may spread to the organic peroxides from adjacent areas. Proper storage and use of mechanical devices can help prevent damage to surrounding areas from burning or decomposing organic peroxides. The recommendations in NFPA 432 should be followed. Keep organic peroxides well away from other combustible materials in their storage area, preferably isolating them by means of firewalls. If possible, store organic peroxides in a separate building at some distance from adjacent buildings. All areas of organic peroxide storage should be equipped with fire control systems, such as automatic sprinklers. Water is usually the agent of choice to fight fire. The effectiveness of water in the

control (by sprinklers or hoses) of fires in storage and work areas varies with the individual organic peroxide formulations. It is especially useful for those formulations that are heavier than water. Water is also useful in cooling areas not yet involved in a fire. When using hoses, spray or fog is most effective. For low boiling and low-density formulations, Aqueous Fire Fighting Foam (AFFF) may be more effective than water alone. In some very special cases, dry chemical formulations may be effective but may also be a problem with others. Water can aggravate control of fires or cause decomposition of low temperature organic peroxides due to the warming

of the organic peroxide by the water. With low temperature organic peroxides, specialized fire control methods are required. Manual fighting of fires should be undertaken only with lower energy organic peroxides - consult NFPA 432.

LITERATURE CITED

1. 2. 3. 4. 5. 6. 7.

NFPA 432 Storage of Organic Peroxide Formulations, 1997, National Fire Protection Association, Battery Park, Quincy, MA 02269. Recommendations on the Transport of Dangerous Goods, 10th rev.ed. United Nations, New York, 1997. Loss Prevention Bulletin 7-8, Factory Mutual Engineering Corp., August 1986. Bulletin 19A-1975, Suggested Relative Hazard Classification of Organic Peroxides, Society of the Plastics Industry, Inc., 1801 K Street, N.W., Suite 600K, Washington, DC 20006. Bundersanstalt fr Material-prfung (BAM), Unter den Eichen 87, 1000 Berlin 75, Federal Republic of Germany. Prins Maurits Laboratorium, Nederlandse Organisatie voor toegepast natuurwetenschappelijk onderzoek (TNO), Postbus 45, 2280 AA Rijswijk, Netherlands. Health and Safety Executive, Research and Laboratory Services Division, Harpur Hill, Buxton SK17 9JN, United Kingdom.

También podría gustarte

- The Storage and Handling of Organic Peroxides Guidance Note CS21Documento26 páginasThe Storage and Handling of Organic Peroxides Guidance Note CS21Максим ХилоAún no hay calificaciones

- High-Purity Oxygen Production Using Mixed Ionic-Electronic Conduc PDFDocumento108 páginasHigh-Purity Oxygen Production Using Mixed Ionic-Electronic Conduc PDFJason MandelaAún no hay calificaciones

- Industrial TrainingDocumento21 páginasIndustrial TrainingVinamra MittalAún no hay calificaciones

- Trimethylolpropane Msds enDocumento12 páginasTrimethylolpropane Msds enronnyprbAún no hay calificaciones

- PHOSGENE Incident Management v2Documento10 páginasPHOSGENE Incident Management v2djsp5009Aún no hay calificaciones

- Isononanol: Material Safety Data SheetDocumento10 páginasIsononanol: Material Safety Data SheetKayalvilli ShanmugamAún no hay calificaciones

- Vol. 3 Phosgene 435Documento13 páginasVol. 3 Phosgene 435ichsan hakimAún no hay calificaciones

- Chemical Engineer-Trevor Kletz PDFDocumento4 páginasChemical Engineer-Trevor Kletz PDFnewprocessAún no hay calificaciones

- N-Propanol - CAS # 71-23-8: Product Handling GuideDocumento2 páginasN-Propanol - CAS # 71-23-8: Product Handling Guidesharmi2011Aún no hay calificaciones

- Biomedical New Hire OrientationDocumento29 páginasBiomedical New Hire OrientationBEJOYAún no hay calificaciones

- Hazardous Substances and Human Health: Exposure, Impact and External Cost Assessment at the European ScaleDe EverandHazardous Substances and Human Health: Exposure, Impact and External Cost Assessment at the European ScaleAún no hay calificaciones

- EIGA 151 Prevention of Excessive Pressure During Filling of Cryogenic VesselsDocumento14 páginasEIGA 151 Prevention of Excessive Pressure During Filling of Cryogenic VesselsFilipAún no hay calificaciones

- Atul LTD Risk AssessmentDocumento108 páginasAtul LTD Risk AssessmentdevangAún no hay calificaciones

- OXYGEN PLANT SAFETY PRINCIPLES: THE ROLE OF AIR CONTAMINANTSDocumento10 páginasOXYGEN PLANT SAFETY PRINCIPLES: THE ROLE OF AIR CONTAMINANTShwang2Aún no hay calificaciones

- Thesis On CatalystDocumento36 páginasThesis On CatalystMahfuzur Rahman SiddikyAún no hay calificaciones

- Chemical Ammonia Report PDFDocumento72 páginasChemical Ammonia Report PDFAli J. Hojeij100% (1)

- Brochure PhosgeneDocumento15 páginasBrochure Phosgenephaniraj_cAún no hay calificaciones

- Phosgene PDFDocumento60 páginasPhosgene PDF8460272421Aún no hay calificaciones

- Safety of Chlorine ProductionDocumento12 páginasSafety of Chlorine ProductionAmin Heidary100% (1)

- TA Chemicals Guide en LRDocumento24 páginasTA Chemicals Guide en LRYehor HorbatkoAún no hay calificaciones

- Guidelines for Determining the Probability of Ignition of a Released Flammable MassDe EverandGuidelines for Determining the Probability of Ignition of a Released Flammable MassAún no hay calificaciones

- Ammonium Nitrate Brief (Official)Documento4 páginasAmmonium Nitrate Brief (Official)JuanpolicydebatesAún no hay calificaciones

- Activated Carbon VRS SYstemDocumento2 páginasActivated Carbon VRS SYstemThamilselvan VengatasalamAún no hay calificaciones

- Oxygen Plant Specification (50Nm3)Documento6 páginasOxygen Plant Specification (50Nm3)Win MinAún no hay calificaciones

- Williams Case Study 2016-10-19Documento74 páginasWilliams Case Study 2016-10-19Indermohan MehtaAún no hay calificaciones

- Peroxides PDFDocumento16 páginasPeroxides PDFxcvAún no hay calificaciones

- Msds - Auto I.T KeroseneDocumento6 páginasMsds - Auto I.T KeroseneCharith LiyanageAún no hay calificaciones

- SulfolaneAppendices A EDocumento158 páginasSulfolaneAppendices A Erkhandelwal9604Aún no hay calificaciones

- Msds For KeroseneDocumento6 páginasMsds For KeroseneMahadeva PrasadAún no hay calificaciones

- Chemical Safety & Security - Fire ProtectionDocumento33 páginasChemical Safety & Security - Fire Protectionsimbua72Aún no hay calificaciones

- BASF 100 Years Ammonia 1902-1924 - enDocumento4 páginasBASF 100 Years Ammonia 1902-1924 - enSyukri ShahAún no hay calificaciones

- HSE - Loss Prevention in The Petrochemical and Chemical-Process High-Tech Industries in TaiwanDocumento8 páginasHSE - Loss Prevention in The Petrochemical and Chemical-Process High-Tech Industries in TaiwanLandryAún no hay calificaciones

- Preventing ExplosionDocumento4 páginasPreventing ExplosionBtbayr BaatadAún no hay calificaciones

- Syngas HazardsDocumento21 páginasSyngas HazardsMuhammad Sajid100% (2)

- The 1989 Phillips Disaster (Pasedena)Documento4 páginasThe 1989 Phillips Disaster (Pasedena)guruAún no hay calificaciones

- Bijlage 5 CEFIC Guidelines Storage H2O2Documento48 páginasBijlage 5 CEFIC Guidelines Storage H2O2Atul JainAún no hay calificaciones

- Diborane MSDSDocumento8 páginasDiborane MSDSankitrao31Aún no hay calificaciones

- 2015 5 Talarico Casale Reliable Design of Ammonia and Urea PlantsDocumento16 páginas2015 5 Talarico Casale Reliable Design of Ammonia and Urea PlantsMichael Taylor WarrenAún no hay calificaciones

- Methanol Catalyst Poisons - A Literature Study (CCS)Documento19 páginasMethanol Catalyst Poisons - A Literature Study (CCS)ahsan888Aún no hay calificaciones

- Case Study Human Factors - Alarm Failure - Risk ReductionDocumento8 páginasCase Study Human Factors - Alarm Failure - Risk ReductionMuhammad TaufikAún no hay calificaciones

- Catalyst MsdsDocumento3 páginasCatalyst MsdsJaime MendozaAún no hay calificaciones

- Design and Optimization of A Catalytic Membrane Reactor For The DirectDocumento8 páginasDesign and Optimization of A Catalytic Membrane Reactor For The DirectGerardOo Alexander SAún no hay calificaciones

- Review of Small Stationary Reformers For Hydrogen ProductionDocumento52 páginasReview of Small Stationary Reformers For Hydrogen ProductionSoineth GuzmánAún no hay calificaciones

- Compressed Gas Cylinder SafetyDocumento36 páginasCompressed Gas Cylinder Safetyelvis hidalgoAún no hay calificaciones

- Plant LayoutasdfDocumento5 páginasPlant LayoutasdfVishwanath KrAún no hay calificaciones

- Chlorination of EthaneDocumento7 páginasChlorination of EthaneMuqtadirul WarisAún no hay calificaciones

- Occupational Health and SafetyDocumento6 páginasOccupational Health and SafetyPennyHoward2012Aún no hay calificaciones

- Case Study: Barton SolventsDocumento14 páginasCase Study: Barton SolventsVan Sot100% (1)

- Hydrogen SafetyDocumento3 páginasHydrogen SafetyAnish181Aún no hay calificaciones

- (A) H&S LegislationDocumento4 páginas(A) H&S LegislationArran DaviesAún no hay calificaciones

- Waste and Biodiesel: Feedstocks and Precursors for CatalystsDe EverandWaste and Biodiesel: Feedstocks and Precursors for CatalystsAún no hay calificaciones

- Techno-Economic Assessment About Propylene OxideDocumento5 páginasTechno-Economic Assessment About Propylene OxideIntratec SolutionsAún no hay calificaciones

- Chapter 3Documento14 páginasChapter 3Larry Jampong100% (1)

- Fixed Gaseous SuppressionDocumento3 páginasFixed Gaseous SuppressionVijay Sharma100% (1)

- Pre-Sulfiding On-Line Sulfiding ProceduresDocumento8 páginasPre-Sulfiding On-Line Sulfiding ProceduresIrma Brennan0% (1)

- Review of H2S Sorbents at Low-Temperature Desulfurization of BiogasDocumento7 páginasReview of H2S Sorbents at Low-Temperature Desulfurization of BiogasHamed HpAún no hay calificaciones

- 005 PDFDocumento8 páginas005 PDFGrootAún no hay calificaciones

- BAT - For Emission of RefineriesDocumento185 páginasBAT - For Emission of Refineriesbiondimi66Aún no hay calificaciones

- Risk Management of Complex Inorganic Materials: A Practical GuideDe EverandRisk Management of Complex Inorganic Materials: A Practical GuideViolaine VerougstraeteAún no hay calificaciones

- Radiacid 0208Documento7 páginasRadiacid 0208Максим ХилоAún no hay calificaciones

- Sizing HX in Aspen PlusDocumento38 páginasSizing HX in Aspen PlusKarthik RajeshAún no hay calificaciones

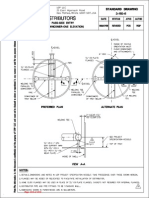

- 3-180-6 Distributors. Four Pass-Side Entry (Side Downcomers-One Elevation)Documento1 página3-180-6 Distributors. Four Pass-Side Entry (Side Downcomers-One Elevation)Максим ХилоAún no hay calificaciones

- VEFV3100Documento19 páginasVEFV3100adolfocienfuegosAún no hay calificaciones

- Thermal Decomposition of Aluminum Chloride HexahydrateDocumento8 páginasThermal Decomposition of Aluminum Chloride HexahydrateМаксим Хило0% (1)

- PIP STF05501 Fixed Ladders and CagesDocumento11 páginasPIP STF05501 Fixed Ladders and CagesHowo4Die86% (7)

- ISA-20.00.03-2001 Specification Forms. Part 3Documento30 páginasISA-20.00.03-2001 Specification Forms. Part 3Максим ХилоAún no hay calificaciones

- PNE00001Documento23 páginasPNE00001Максим ХилоAún no hay calificaciones

- HydrotreatingPoster PDFDocumento1 páginaHydrotreatingPoster PDFekosmind100% (2)

- APV Evaporation HandbookDocumento68 páginasAPV Evaporation HandbookМаксим ХилоAún no hay calificaciones

- Organic Peroxides Their Safe Handling and UseDocumento16 páginasOrganic Peroxides Their Safe Handling and UseМаксим ХилоAún no hay calificaciones

- PGS8 ORGANIC PEROXIDES: STORAGE English June 2012Documento115 páginasPGS8 ORGANIC PEROXIDES: STORAGE English June 2012Максим Хило100% (1)

- CHEMISTRY MONTHLY TEST MAY 2021Documento2 páginasCHEMISTRY MONTHLY TEST MAY 2021Osmany MadrigalAún no hay calificaciones

- Huntsman Jeffamine T 403 SDSDocumento15 páginasHuntsman Jeffamine T 403 SDSJohn ZoidbergAún no hay calificaciones

- Chapter 5Documento14 páginasChapter 5skywalker100% (1)

- Performance comparison of phenol removal in pharmaceutical wastewaterDocumento10 páginasPerformance comparison of phenol removal in pharmaceutical wastewaterErickAún no hay calificaciones

- Acid and Base Number Testing: PetroleumDocumento2 páginasAcid and Base Number Testing: PetroleumRaden ArdyAún no hay calificaciones

- Bulk Emulsion Suspension 18BCH35S-U4Documento13 páginasBulk Emulsion Suspension 18BCH35S-U4Nadeem ShakeelAún no hay calificaciones

- BENEBiOL - PCD - Mitsubishi Chemical Corporation - Rev2Documento15 páginasBENEBiOL - PCD - Mitsubishi Chemical Corporation - Rev2Kishore Gowda A SAún no hay calificaciones

- Bio PolymersDocumento8 páginasBio PolymersSarfrazAún no hay calificaciones

- Why Is Foam CreatedDocumento5 páginasWhy Is Foam CreatedSumeet JainAún no hay calificaciones

- ANIMAL NUTRITION MCQSDocumento10 páginasANIMAL NUTRITION MCQSvishnu100% (2)

- The Composition: of Manila Elemi OilDocumento3 páginasThe Composition: of Manila Elemi OilРусланAún no hay calificaciones

- Semisolid Dosage Forms: Prepared By, Lalith Mukesh.A Ap, SnscphsDocumento36 páginasSemisolid Dosage Forms: Prepared By, Lalith Mukesh.A Ap, SnscphsShweta Singh ChauhanAún no hay calificaciones

- Gleitmo 800 EngDocumento5 páginasGleitmo 800 EngrenanevesAún no hay calificaciones

- Separation and Identification of Amino Acids by Paper ChromatographyDocumento4 páginasSeparation and Identification of Amino Acids by Paper Chromatographyroxannediana86% (14)

- Alkane, Alkenes, AlkynesDocumento9 páginasAlkane, Alkenes, AlkynesMark AquinoAún no hay calificaciones

- Gate Chemistry 2007Documento21 páginasGate Chemistry 2007uvir iitmAún no hay calificaciones

- Schadstoff-Liste-Englisch 2019 11 02 2020Documento10 páginasSchadstoff-Liste-Englisch 2019 11 02 2020JohnraphelAún no hay calificaciones

- 13 Miller Chap 4b LectureDocumento21 páginas13 Miller Chap 4b LectureGerone Tolentino AtienzaAún no hay calificaciones

- Frorensic Chemistry Group 4Documento21 páginasFrorensic Chemistry Group 4Princess Mae EstabilloAún no hay calificaciones

- Ash, Michael - Ash, Irene - Handbook of Rheology ModifiersDocumento6033 páginasAsh, Michael - Ash, Irene - Handbook of Rheology ModifiersJay SteeleAún no hay calificaciones

- C-3 Fats and OilsDocumento10 páginasC-3 Fats and OilsAesha TyagiAún no hay calificaciones

- Aqua12 Module.9Documento11 páginasAqua12 Module.9Rheinald BaldoAún no hay calificaciones

- Chelatin-Sa: Sarex ChemicalsDocumento2 páginasChelatin-Sa: Sarex Chemicalssivanesan seeranganAún no hay calificaciones

- Learning Plan Calendar: SUBJECT: Science Grade: 9 Quarter: 1Documento16 páginasLearning Plan Calendar: SUBJECT: Science Grade: 9 Quarter: 1richardsamranoAún no hay calificaciones

- Actual List of CDC Cargo: Back To Full List Click Here For Up Date CDCDocumento74 páginasActual List of CDC Cargo: Back To Full List Click Here For Up Date CDCBoris PopovicAún no hay calificaciones

- AminesDocumento12 páginasAminesMadhu SomavarapuAún no hay calificaciones

- Chapter 2 AlkanesDocumento37 páginasChapter 2 AlkanesLionel MessiAún no hay calificaciones

- Process Aids Booklet ENG Print A4 AB VickersDocumento8 páginasProcess Aids Booklet ENG Print A4 AB VickersFabioAún no hay calificaciones

- SewageDocumento34 páginasSewageMongolian MutuAún no hay calificaciones

- Model (1) Answer All The Following Questions: Department: Food Science & TechnologyDocumento2 páginasModel (1) Answer All The Following Questions: Department: Food Science & TechnologyIslam ImadAún no hay calificaciones